Climate change is the most vital environmental issue in today’s world, and several nations are adopting different methods to promote sustainability. The transportation industry is the biggest contributor to greenhouse gases and global warming, as it contributed up to 27% of the greenhouse gas (GHG) emissions in the U.S. in 2015 [

1]. As a result, there is pressure on the automotive industry from governments around the world to decrease GHG emissions by producing more energy efficient cars. Therefore, transportation electrification, which is the most innovative change in the transport industry, was born. Hybrid electric vehicles (HEV) and electric vehicles (EV) are considered environmental-friendly and sustainable options. Recently, there has been a significant increase in the market share of these vehicles, driven largely by Tesla Motors, and is expected to increase further in the years to come. Reports suggest that HEVs and EVs reduce GHG emissions by almost 20%, which can be further reduced by 40% if the electricity used by these vehicles is obtained from renewable sources [

2].

Like any other new technology, there are some difficulties with the advancement of EVs. One of the major hurdles is the development of high power and energy density battery cells. Currently, the market holds several potential candidate batteries for EVs, such as nickel metal hydride (NiMH), lithium-ion (Li-ion), and lithium-ion polymer (LiPo) batteries. However, Li-ion batteries have attracted all the attention due to their high capacity, high efficiency, long-life and slow self-discharge rate [

2]. Li-ion batteries are most effective when they work within certain temperature and thermal specifications. For the batteries to perform without rapid degeneration, the ideal range of working temperatures is between 0 °C and 40 °C [

3]. A poorly designed thermal management system (TMS) of a battery pack can result in heat accumulation, which may overheat the battery pack. This can become a serious safety issue, and in some extreme cases may lead to the explosion of the battery pack. In addition to that, once the temperature of the cells exceeds the ideal range of operating temperature, the degradation of the cells accelerates, which results in reduced efficiency of the battery pack, a reduction of the life of the batteries, and thermal runaway in extreme cases [

4].

Moreover, the temperature uniformity within the battery pack affects its charging and discharging power. At low temperatures, the cell with the lowest temperature limits the power capability, but at high temperatures the cell with the highest temperature defines the rate of power limiting [

5]. A high temperature uniformity within the battery pack causes different charging/discharging of the individual cells, resulting in the electrical imbalance of the cells, thereby reducing the performance of the battery pack. A temperature variation of about 10 to 15 °C in the battery pack can lead to a 30% to 50% degradation [

6]. Therefore, uniformity in the temperature of the battery pack is required for optimum performance.

The TMS of a battery pack is divided into three separate categories, namely, air cooling, liquid cooling, and cooling by phase change materials. Air cooling is further divided into two categories, natural air cooling and forced air cooling. Li et al. [

3] conducted both numerical and experimental studies to investigate and compare natural air cooling and forced air cooling using the LiMn

2O

4 cylindrical cells. The results concluded that by using forced air cooling, the maximum temperature of the cell reduced by 3.5 °C when compared to natural air convection. Therefore, forced air cooling is considered more effective. Zhao et al. [

7] conducted a parametric study numerically, using the LiFePO

4 cylindrical cells to investigate the effects of different ventilation types and the optimum forced air velocities. The authors also investigated the effects of environmental and inlet air temperatures, and the optimum spacing between the adjacent cells. It was concluded from their results that by increasing the velocity of the air flow, the local temperatures decreased. In addition, the authors conducted simulations to investigate the effects of the cooling of the battery pack by introducing a counter-flow of air between the adjacent rows of the cells. It was concluded that this method of counter-flow of air is not an effective cooling method. Wang et al. [

8] conducted numerical and experimental studies to examine different types of arrangements of LiNiMnCoO

2 cylindrical cells. The results concluded that the optimum thermal performance was exhibited by the 5 × 5 cubic cell structure, in which the inlet fan was placed at the top of the battery pack and the exhaust placed at the bottom. Developing on this research and using the same 5 × 5 cubic cell structure, Wang et al. [

9] numerically explored the effects of inlet air temperature on the cooling of the cells. It was reported by the authors that the temperature of the inlet air should lie within the range of 20 °C and 35 °C in order to effectively cool the cells. However, the velocity of the air should be increased if the ambient temperatures are higher than the range provided, in order to achieve effective cooling. Cho et al. [

10] numerically studied the effects of ambient temperature on the temperature uniformity of the battery pack and the cells, and the results of their study concluded that at low ambient temperatures the temperature uniformity between the cells decreased, and at high ambient temperatures the temperature uniformity between the cells increased. It was also reported by the authors that irrespective of the ambient temperature, the maximum temperatures of the cells near the inlet exhibited lower temperatures compared to the cells near the outlet. Moreover, aligned and staggered cell configurations were numerically studied by Yang et al. [

11] using the LiFePO

4 cylindrical cells. The cell spacing between the adjacent cells in the longitudinal and transverse directions was investigated, and it was concluded that the optimum spacing distances should be 34 mm and 32 mm in the longitudinal and transverse directions, respectively. The results also concluded that the aligned configuration is better when compared to a staggered configuration in terms of the uniform cooling of the cells. Saw et al. [

6] conducted numerical and experimental studies to investigate the effects of the flow circuit by developing a battery pack based on the concept of air entering from the top and exhausting from the bottom of the battery pack. In their study, cylindrical Lithium Iron Phosphate (LFP) cells were used. Based on their results, the authors concluded that the highest temperatures were exhibited by the cells at the center of the battery pack due to the accumulation of the heat. Additionally, because of the lack of air flow, the cells at the front end of the battery pack also exhibited the highest temperatures. In another study, the reciprocating air flow inside the battery pack was investigated numerically by Mahamud and Park [

12] using the LiMn

2O

4 cylindrical cells. The results of their study showed that the temperature uniformity within the battery pack greatly improves using this technique, as the temperature difference between the cells was reduced by about 4 °C. Furthermore, based on the reciprocating period of 120 s, the maximum cell temperature was also reduced by 1.5 °C. Liu et al. [

13] also numerically investigated the reciprocating air flow system by conducting a parametric optimization study using Sony US-18650 cylindrical cells. Based on the range of values of the maximum temperature, minimum temperature, and the temperature difference, it was concluded that 6 m/s of air velocity, 283.15 K inlet temperature, and a reciprocation period of 67.5 s were the most optimal factors. However, reciprocating air flow systems are considered active systems, as they require timing valves to change the direction and the flow of the air, thereby increasing the power requirement and complexity of the system. Therefore, a forced air cooling system is required that is simple, eliminates the power requirement of reciprocating valves, and simultaneously reduces the non-uniformity of temperature within the battery pack. There have been very limited reported studies on the Li-ion 18650 cells examining temperature uniformity in the battery packs, especially for non-active systems. There is a need to examine the temperatures at different locations of a battery pack and cell surfaces in order to develop techniques to improve temperature uniformity at the pack and cell levels.

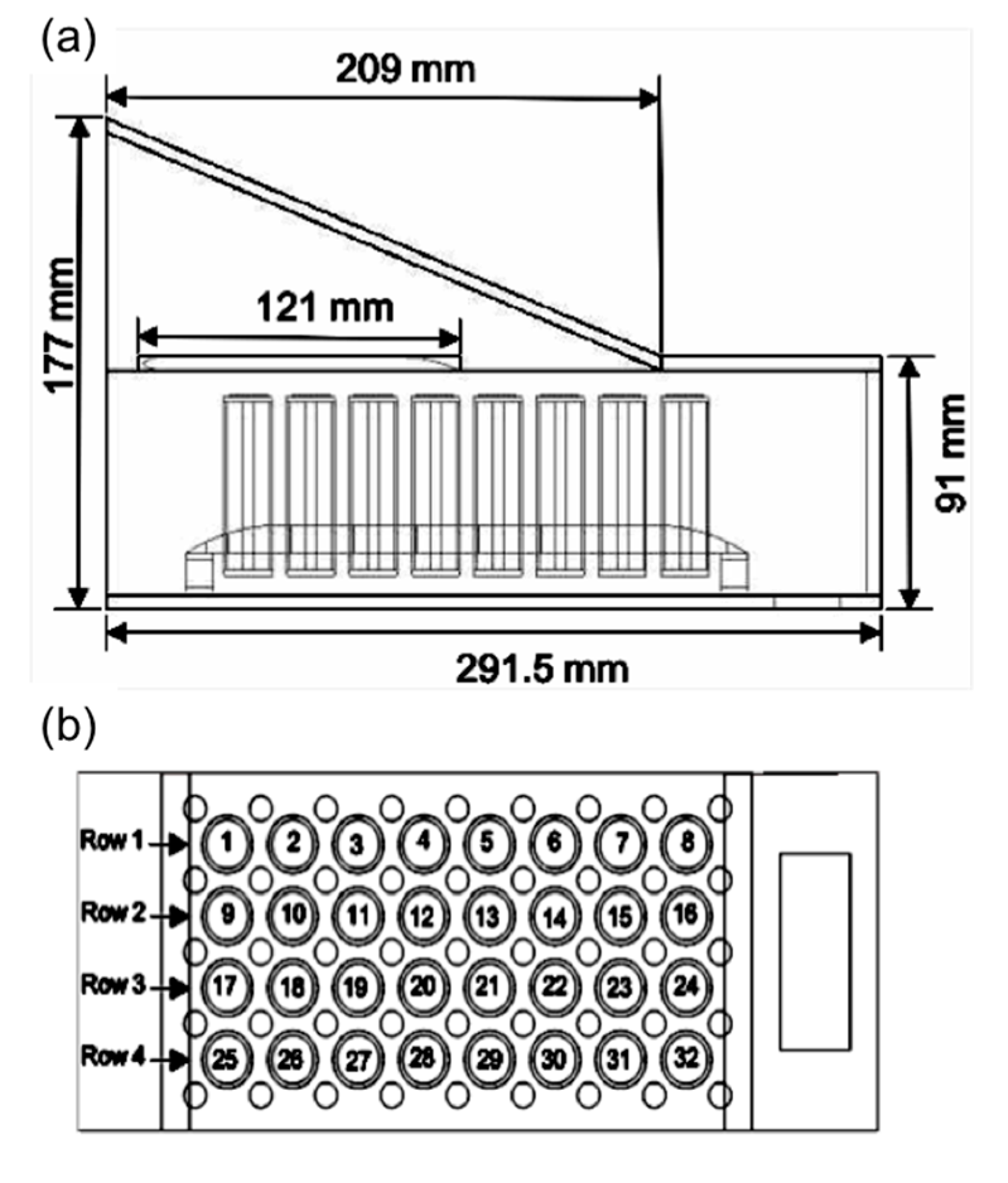

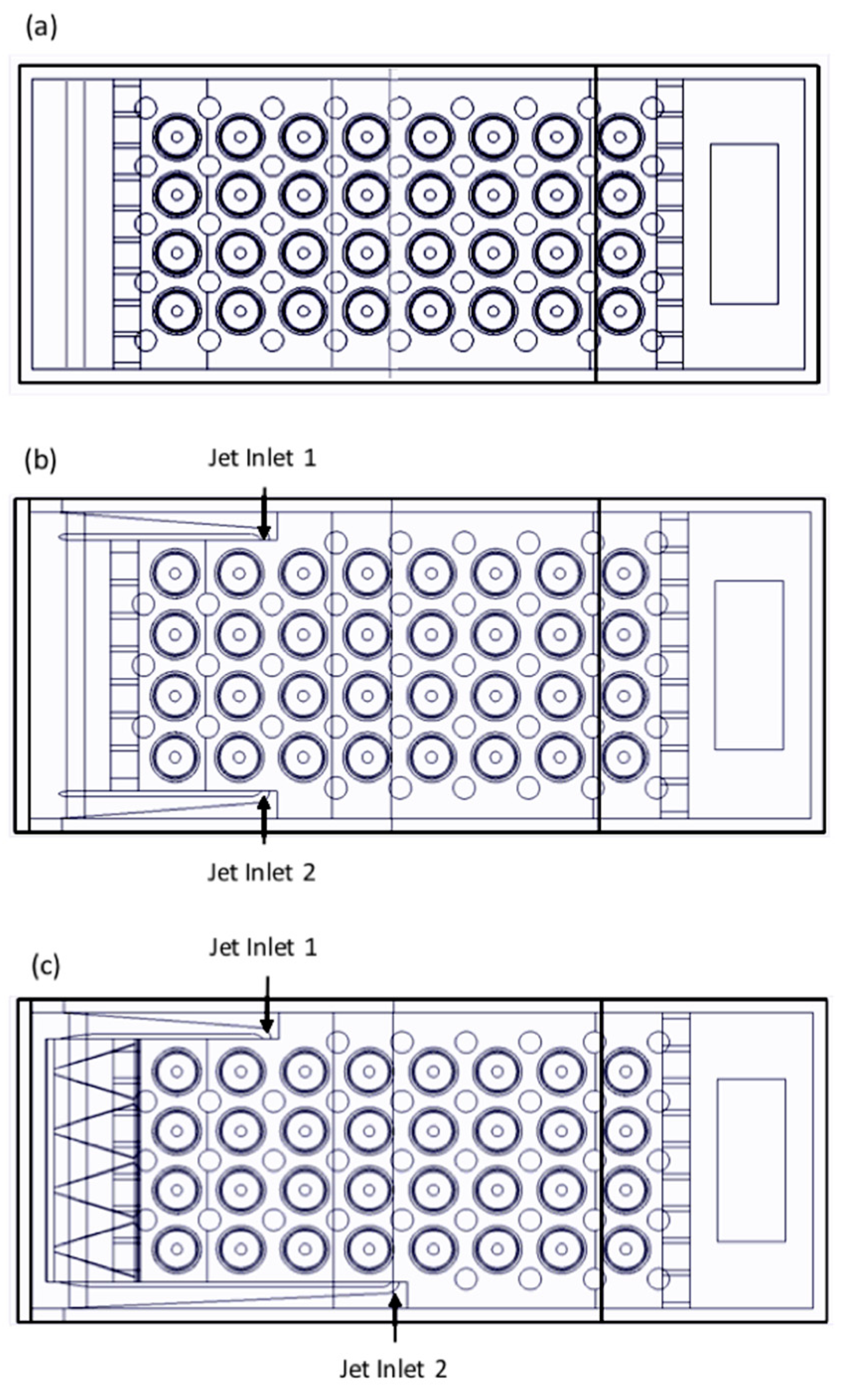

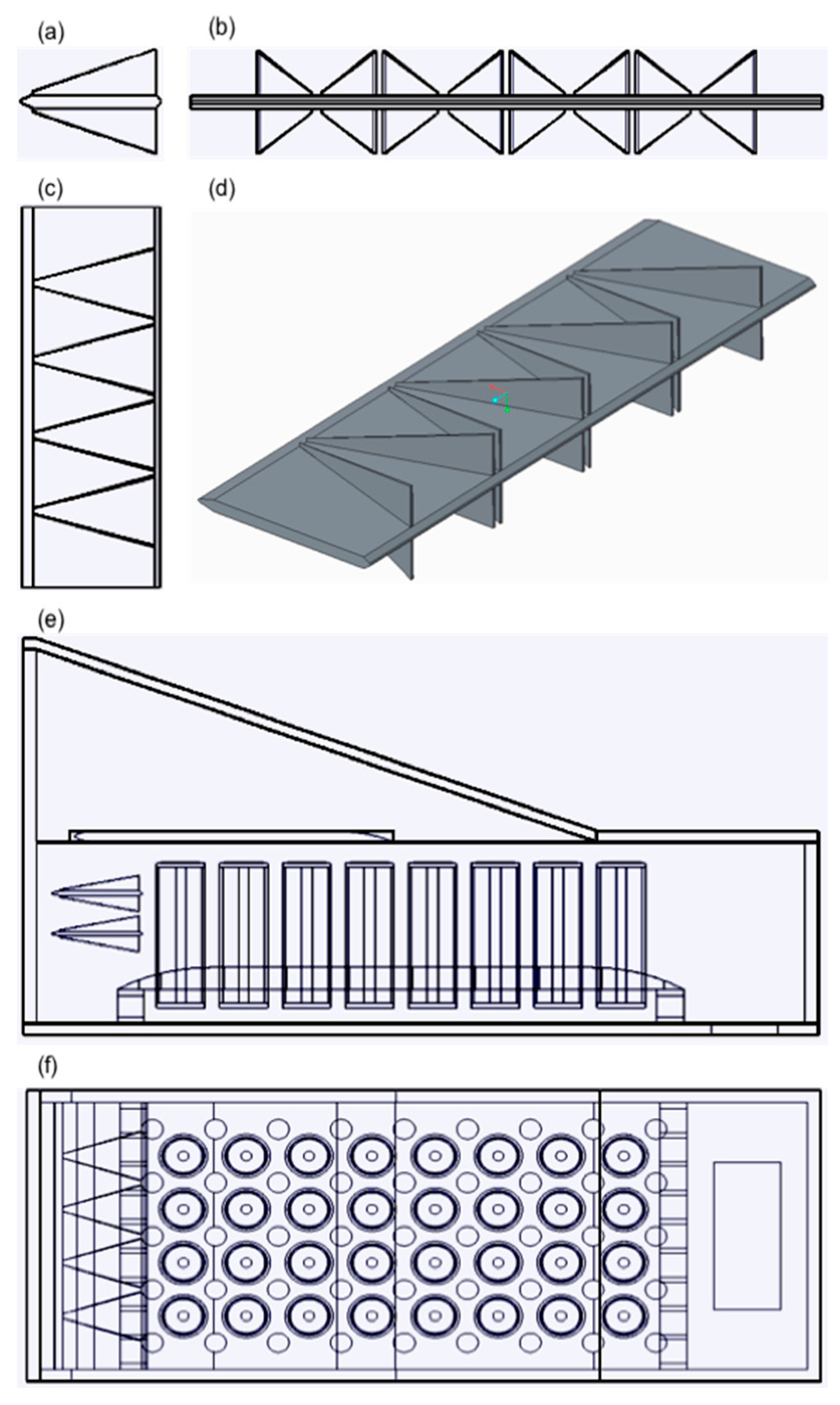

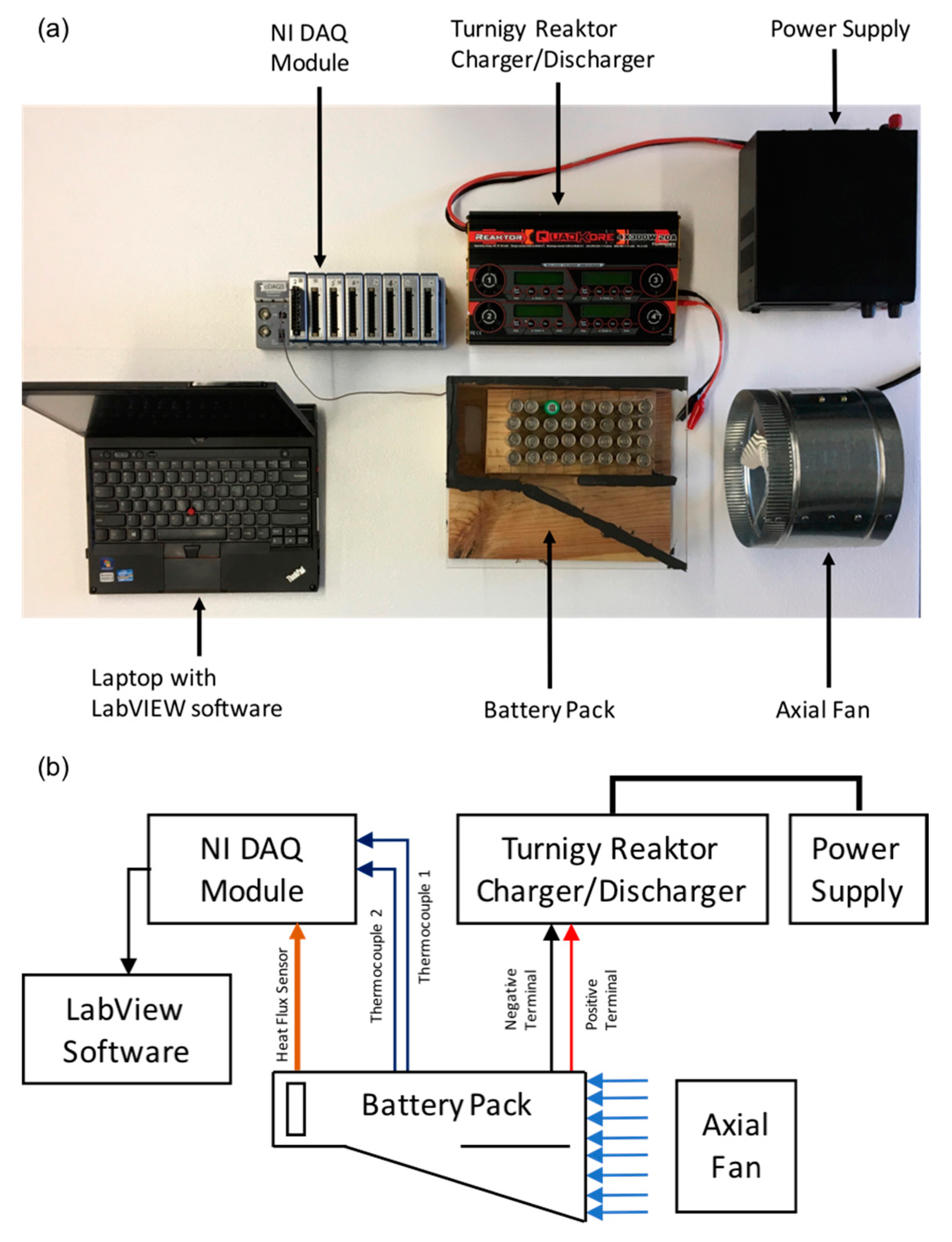

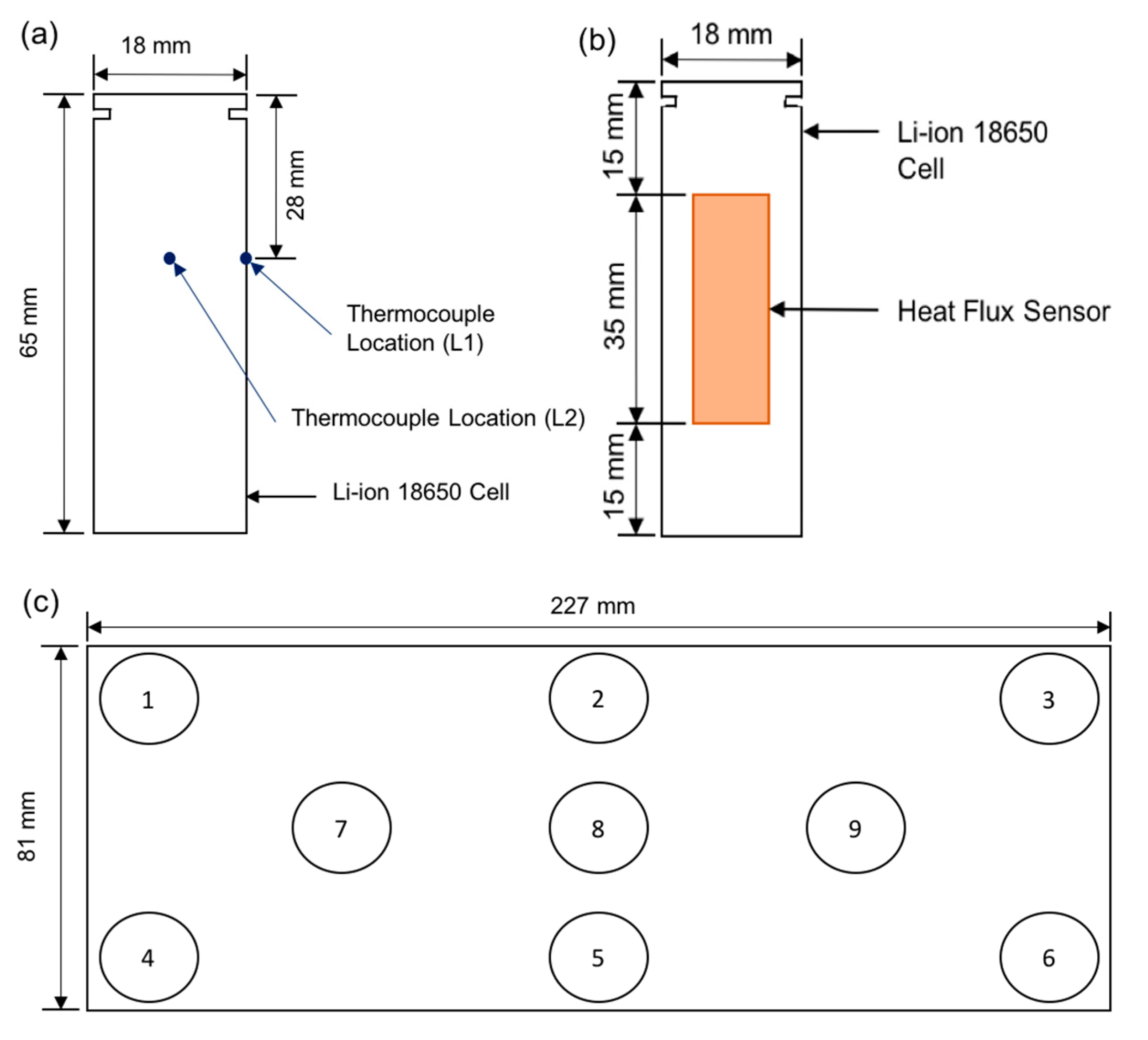

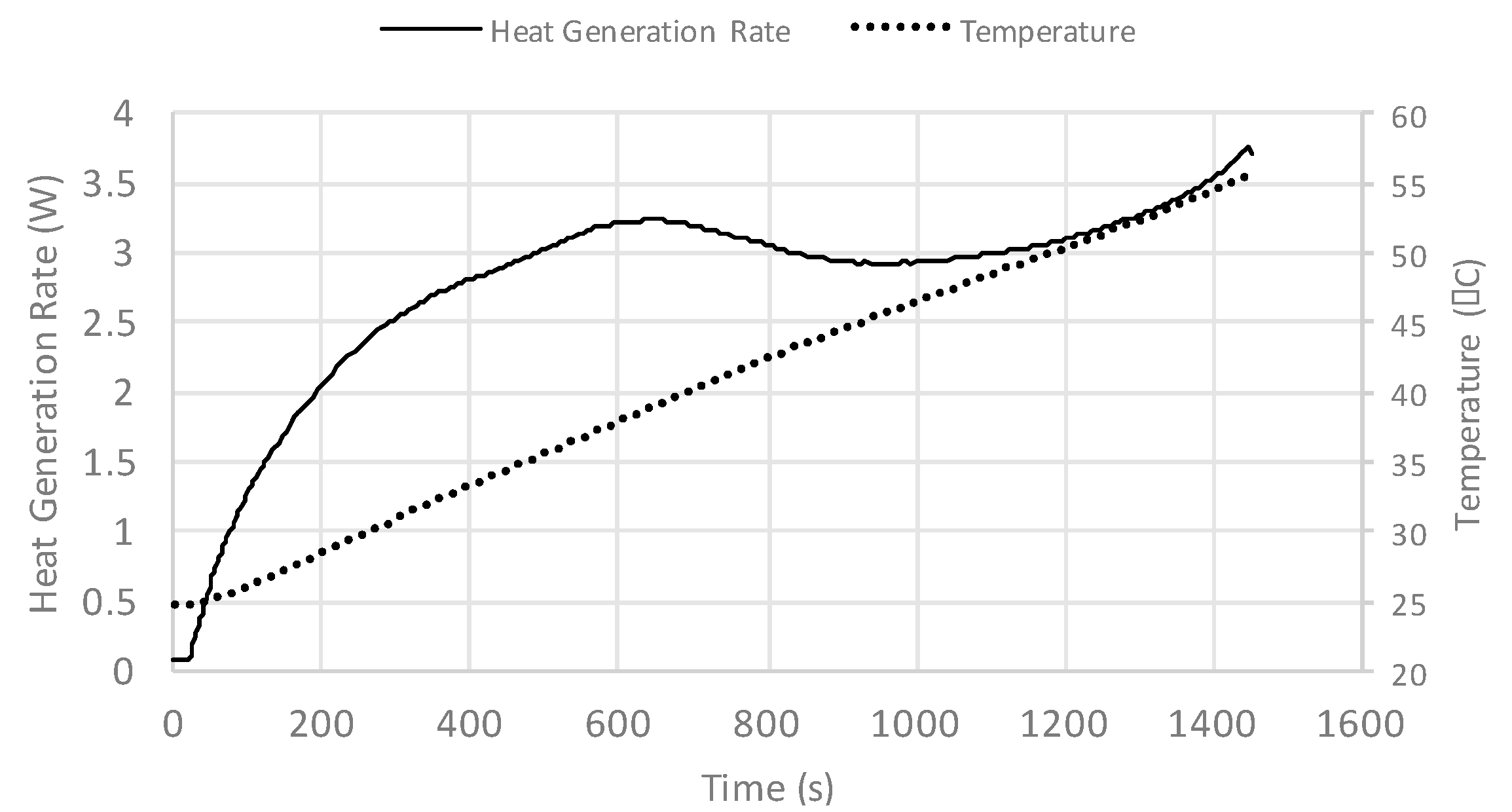

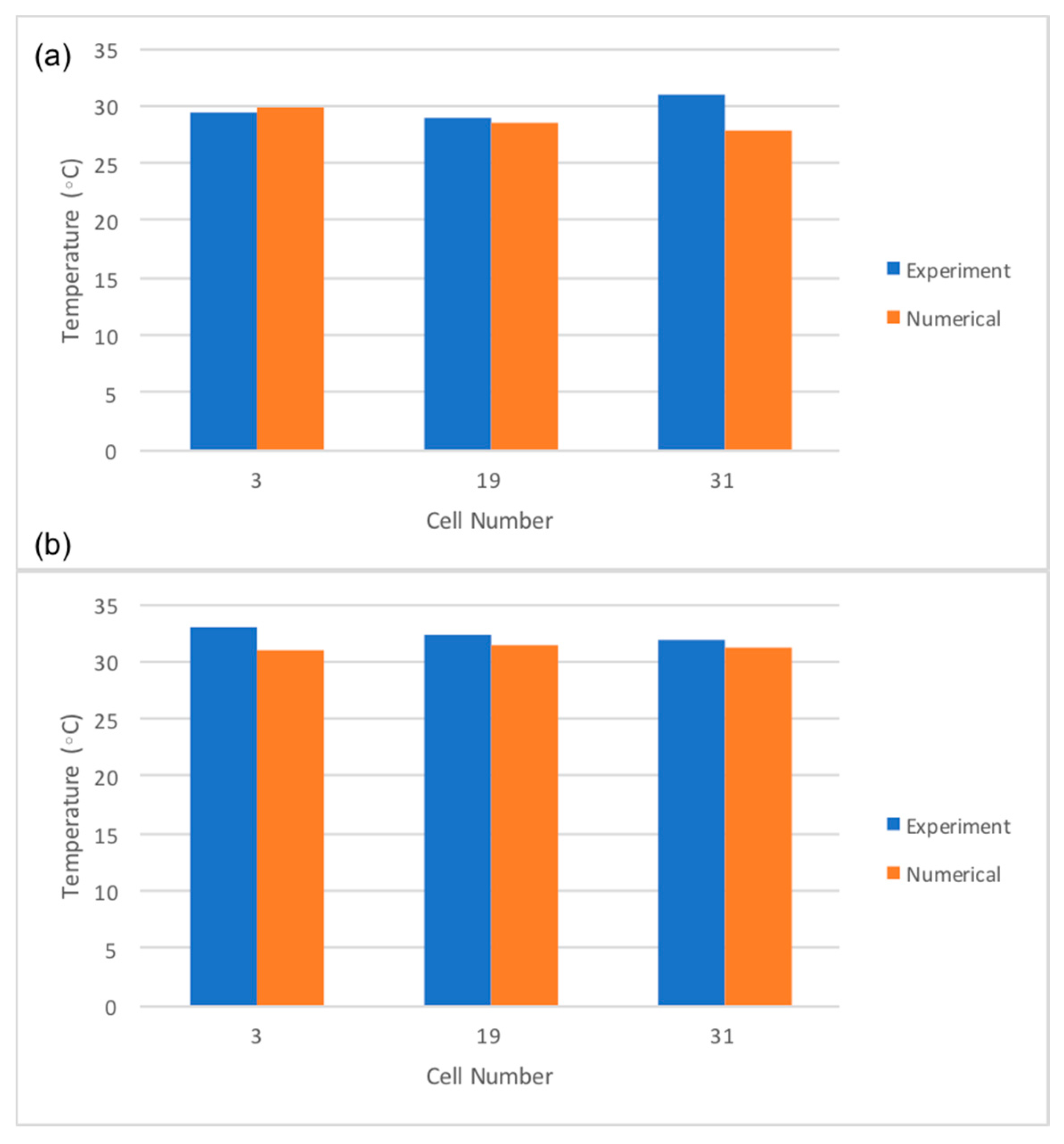

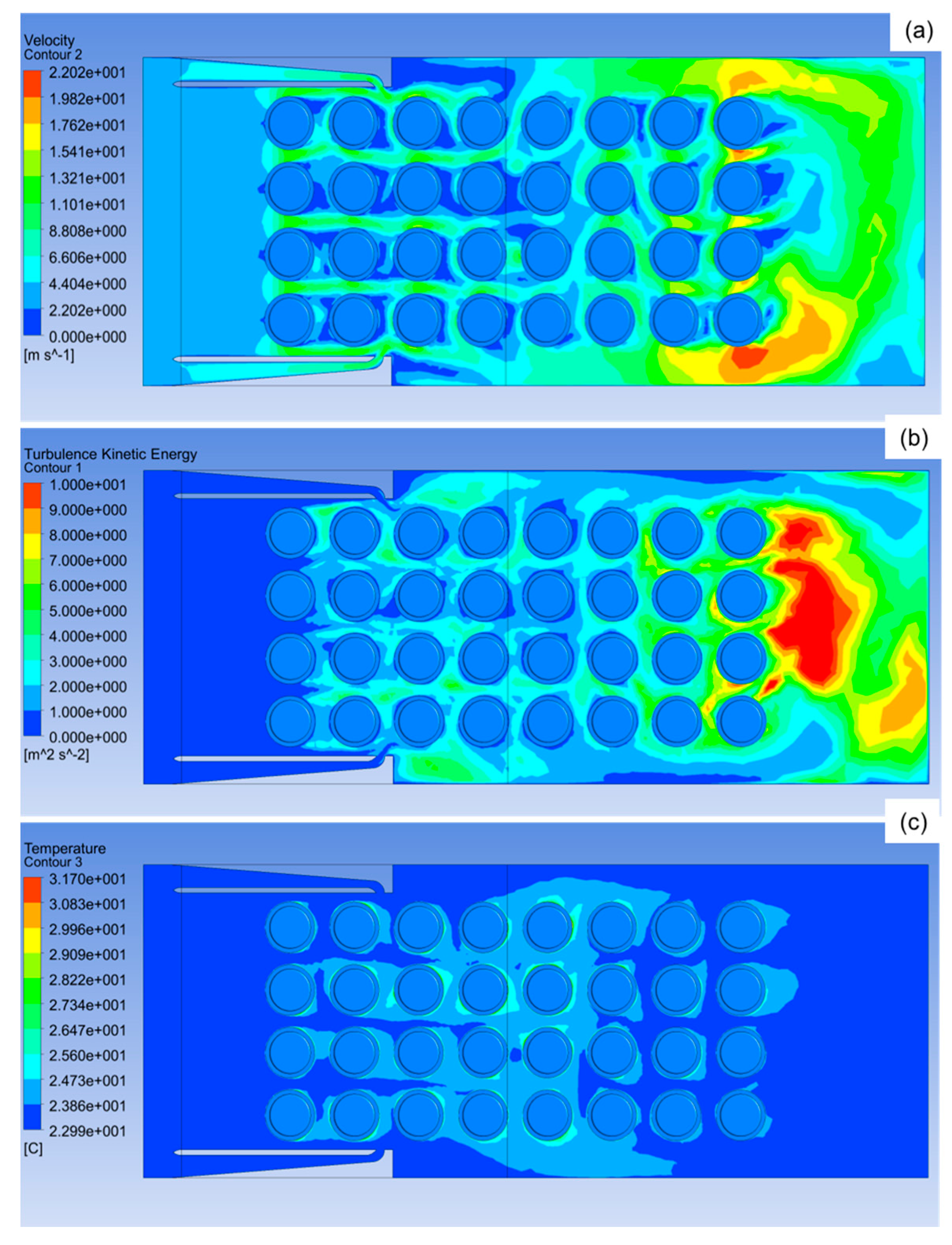

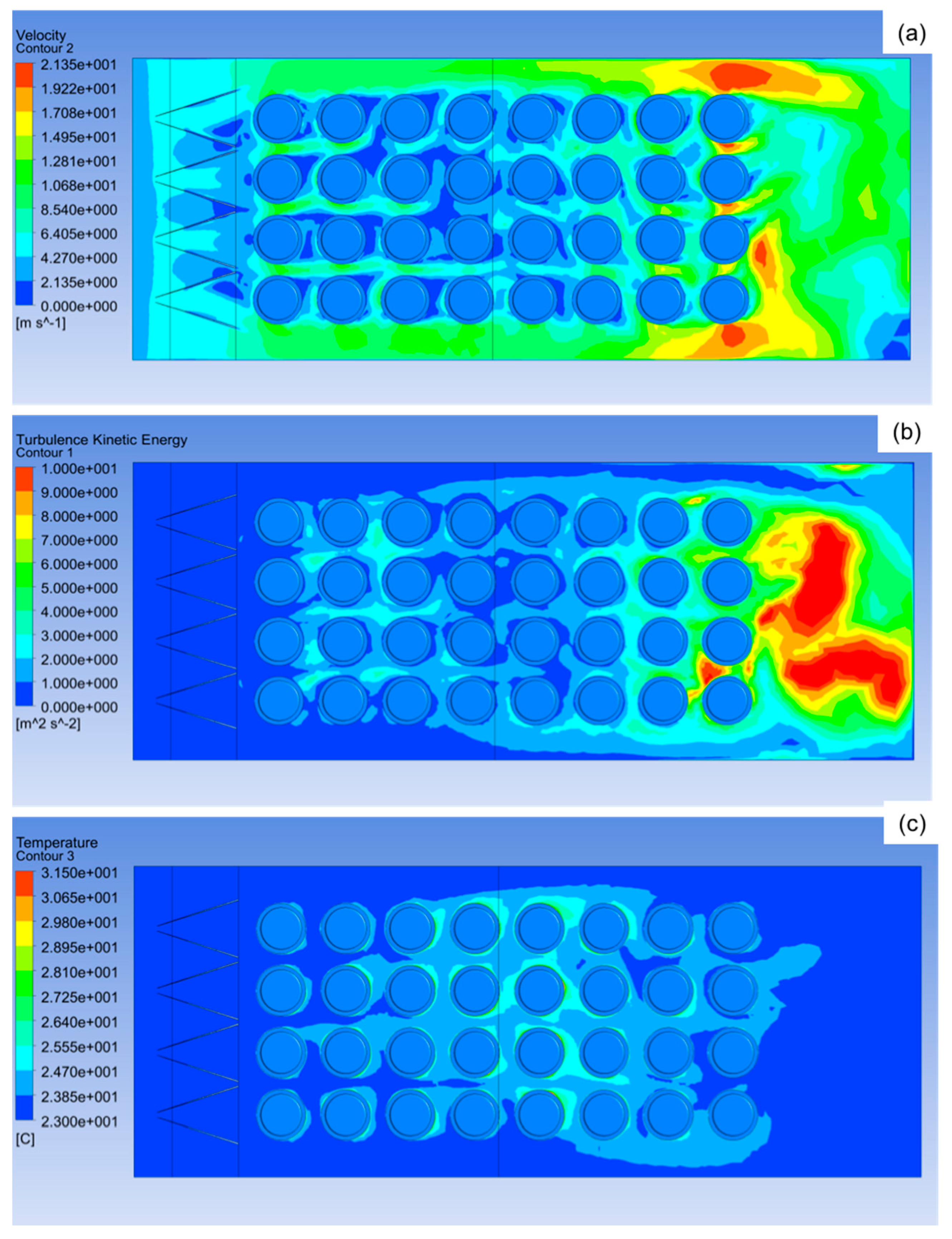

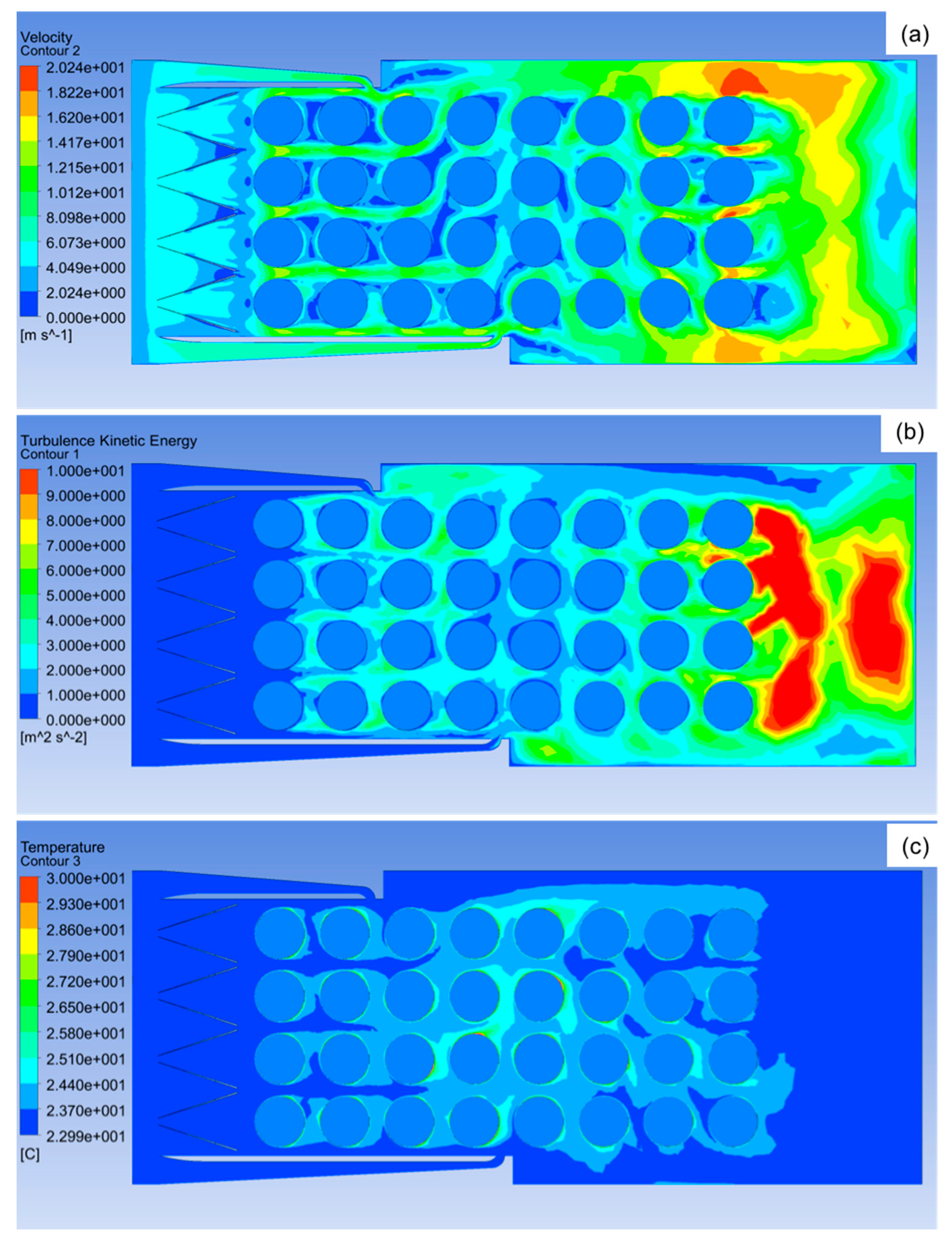

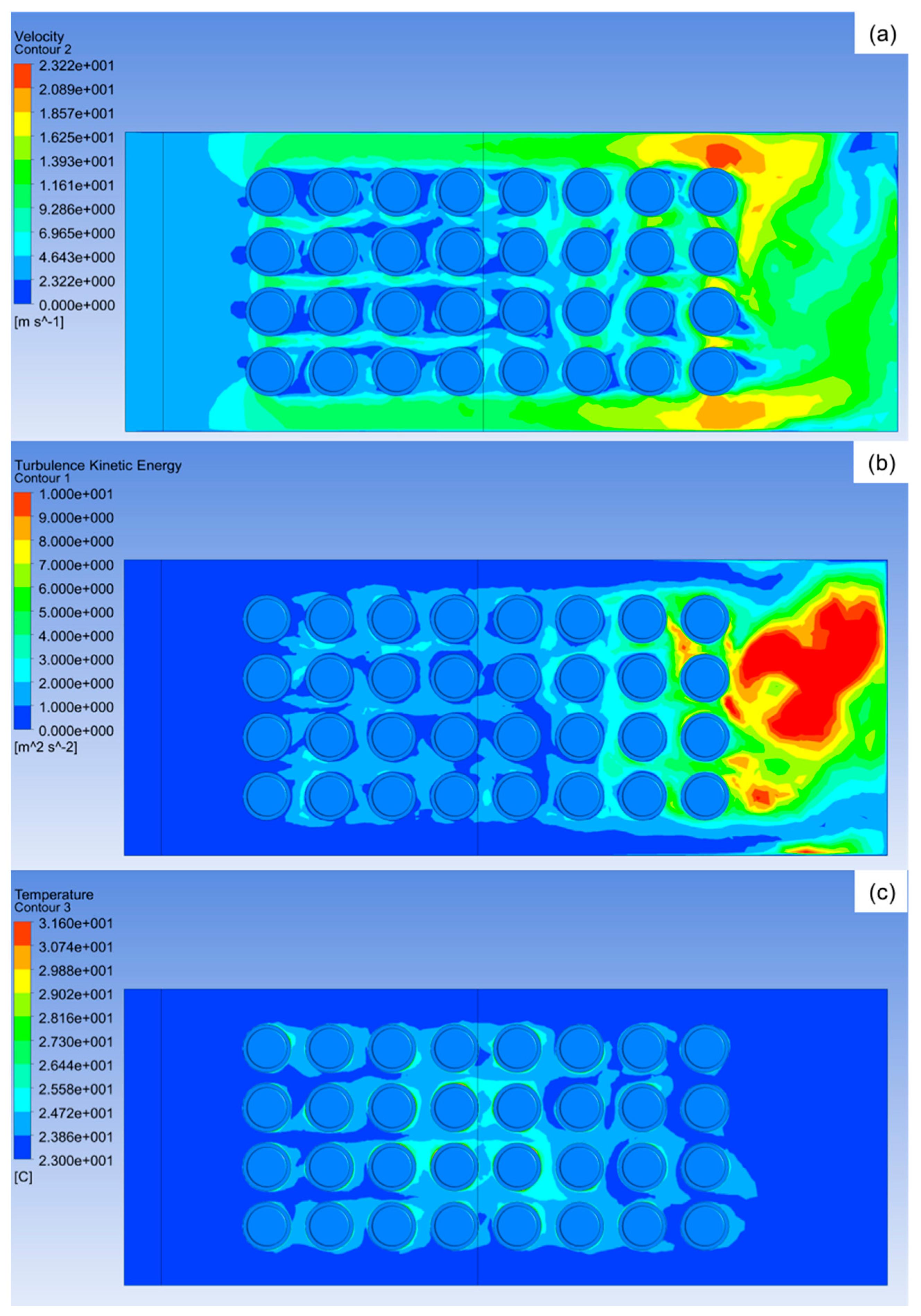

In this paper, an attempt is made to reduce the maximum temperature of the battery pack and to increase the temperature uniformity across the cell and the battery pack. This is implemented by incorporating new techniques in the battery pack without changing its dimensions. The objective of the study is to achieve an effective cooling without increasing the power requirement, and to obtain a desired temperature uniformity within the entire battery pack (not greater than 5 °C).