1. Introduction

Wheel loaders are indispensable machines for the construction of infrastructure such as highways and in coal mining. The wheel loader operation is pretty repetitive and the vehicle is frequently exposed to large loads, leading to high fuel consumption [

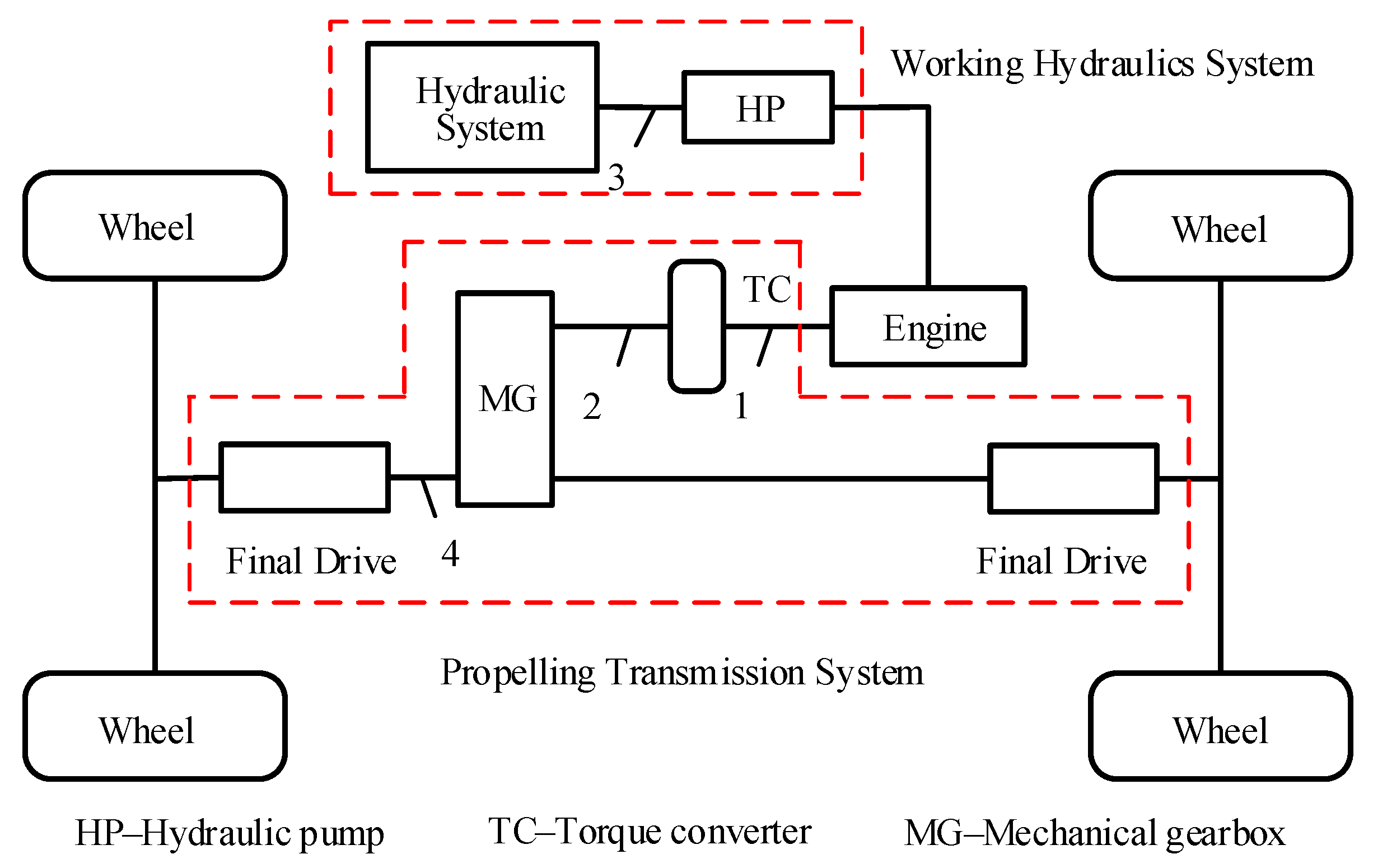

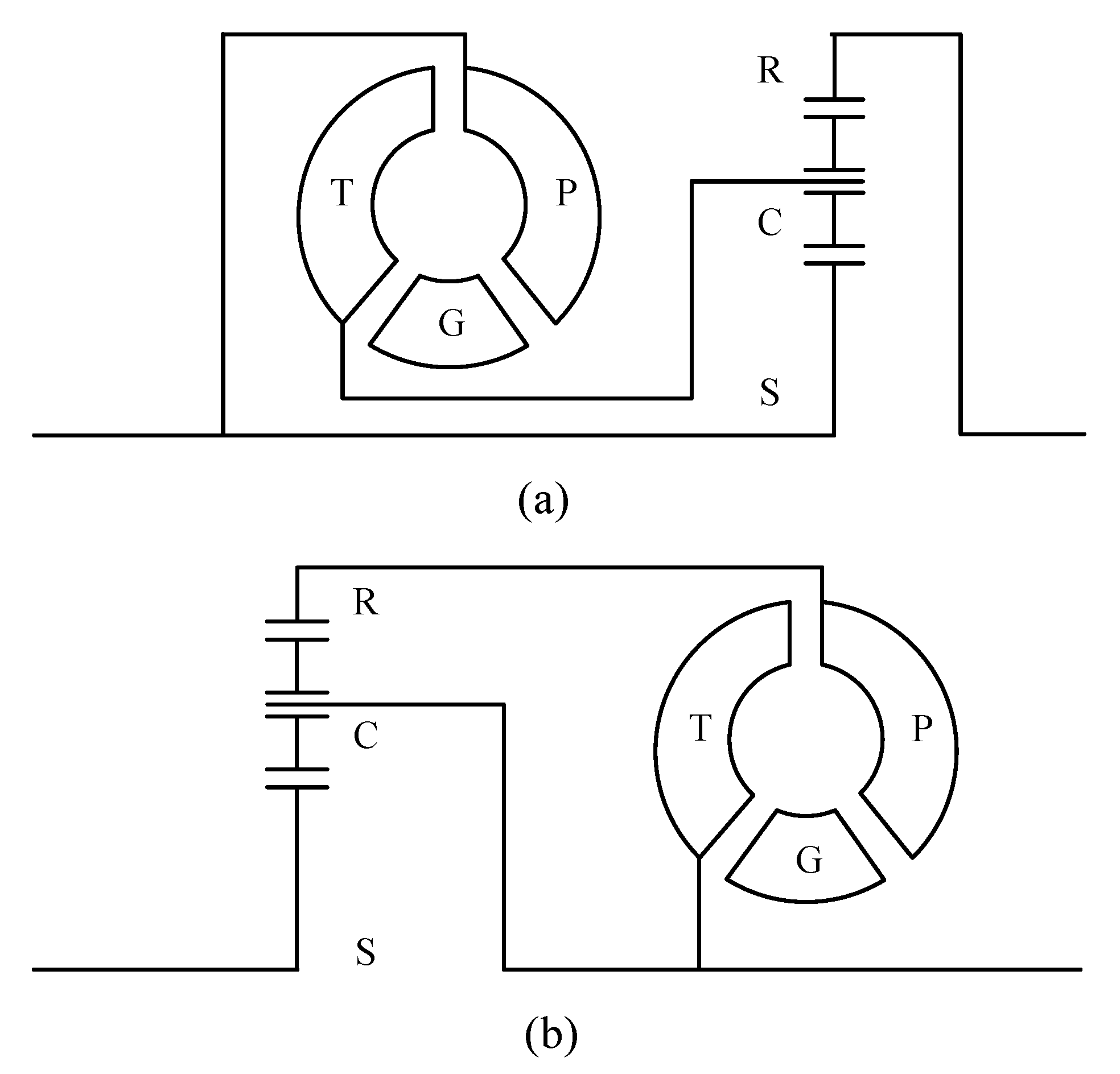

1]. Taking a five-ton class application as an example, the total fuel consumption each year can be as much as 25.6 tons (assuming the working times per day and per year are 8 hours and 200 days, respectively). Today the most common wheel loader powertrain arrangement is as displayed in

Figure 1 [

2]. The engine is required to supply energy to both the working hydraulics system and propelling transmission system, which allow the bucket to be manipulated and thrust the vehicle forward or backward, respectively.

In this architecture, the torque converter (TC) is a key element since it has the excellent vibration-damping and thoroughly self-adaptive performance which enable the engine to work robustly even though the vehicle is frequently subjected to variable loads. However, owing to the double energy conversion in the TC and high slip between two terminals that performance inevitably, results in high losses. The low efficiency of the TC is the main reason for the excessive fuel losses of wheel loaders [

3]. With the increasing emphasis on fuel savings and emission reduction worldwide, these devices may hardly meet the future development trends [

4]. Therefore, a substitute for the TC that improves the fuel economy of wheel loaders is essential.

The hydrodynamic mechanical power split transmission (HMPST) can be a desirable choice, since in it a part of the power is transferred by the mechanical branch and the rest is transferred through the TC [

5,

6]. With this special architecture, the HMPST simultaneously has a higher efficiency and retains most of the advantages of a TC. Furthermore, there is a possibility that the HMPST can enable the engine to work in the economical areas due to a wide variety of configurations available for HMPSTs. Therefore, in this paper, the HMPST is selected as the research subject.

HMPSTs comprise a TC and a planetary gear train (PGT). Many references have examined the basic characteristics of HMPSTs, providing comparative analyses for different configurations, as well as the design methods for HMPSTs. Wang et al. elaborated the operational principle of a new HMPST in a roadheader’s cutting unit. A dynamic model for such a transmission was constructed. The simulation results showed that both the vibration of the drive motor and the dynamic engagement force of the gears are substantially lessened compared to those of the prototype transmission when encountering pulse loads [

7]. Jo et al. suggested a new input torque coupled HMPST concept, where the hydraulic elements were placed at both the mechanical and hydraulic branches. To evaluate the usefulness of the designed mechanism relative to a prototype TC (TC), the torque ratio and efficiency for all six schemes were analyzed using the performance locus diagram [

8]. Linares et al. proposed a thorough methodology for designing a continuously variable power split transmission with several types of power flow suitable for an agricultural tractor. The objective of this study is to determine the design parameters for a general type of this transmission such as the transmission ratios of PGT, and the lockup point, which is the transition point between the hydromechanical transmission and the purely mechanical transmission [

9]. Achtenova et al. developed a software for designing highly efficient HMPSTs with several mechanical speeds, which aimed at obtaining continuously variable transmissions with wide speed ratio ranges. Each speed was the combinations of a few PGTs, and its mechanical efficiency was calculated by the matrix method. The advantages of this code are the high integration and computational efficiency [

10].

Other studies have concentrated on improving the performance of construction machinery using some types of HMPSTs. Zhao et al. implemented the design optimization for the crawler bulldozer equipped with a pure power split type of HMPST for increasing both the dynamic performance and fuel economy of the vehicle under a typical operating mode. These two objectives are achieved by the smaller TC diameter and less vehicle quality. However, the TC adopted in the HMPST is not based on the prototype TC. That is, the improvement of performance is not necessarily caused by the power split structure [

11]. Wang et al. proposed a power reflux hydrodynamic transmissions (PRHTS) applied to the wheel loader. For constructing the optimal matching between the diesel engine and the PRHTS, the design optimization for the PRHTS was conducted, which was based on the radar chart and genetic algorithm. However, a simulation model for the wheel loader powertrain system was not constructed, so whether the performance of the vehicle is increased needs to be justified. Moreover, such a transmission is only one type of HMPST and its rationality relative to other schemes requires to be verified as well [

12].

The objective of this paper is to improve the fuel economy of a wheel loader by applying the HMPST concept, which is rarely researched in previous works. In view of this, a design methodology for such a transmission is necessary. Moreover, considering the relatively complex construction of HMPSTs, the simplest form, which consists of a TC with three components and a single PGT, is adopted here.

In this paper, there are two critical issues to be dealt with. One is the preliminary selection of the the HMPST options. Since HMPSTs have a number of different schemes, if a design optimization for all the schemes is conducted, it is bound to cause a high calculation cost. The subsequent comparison analysis between each scheme can be hardly justified. This issue will be solved in

Section 3. Furthermore, the TC in the HMPSTs has to be based on the prototype, i.e., only the effective diameter of the TC can be altered. Only in this way a comparison between HMPSTs and a prototype TC can make sense.

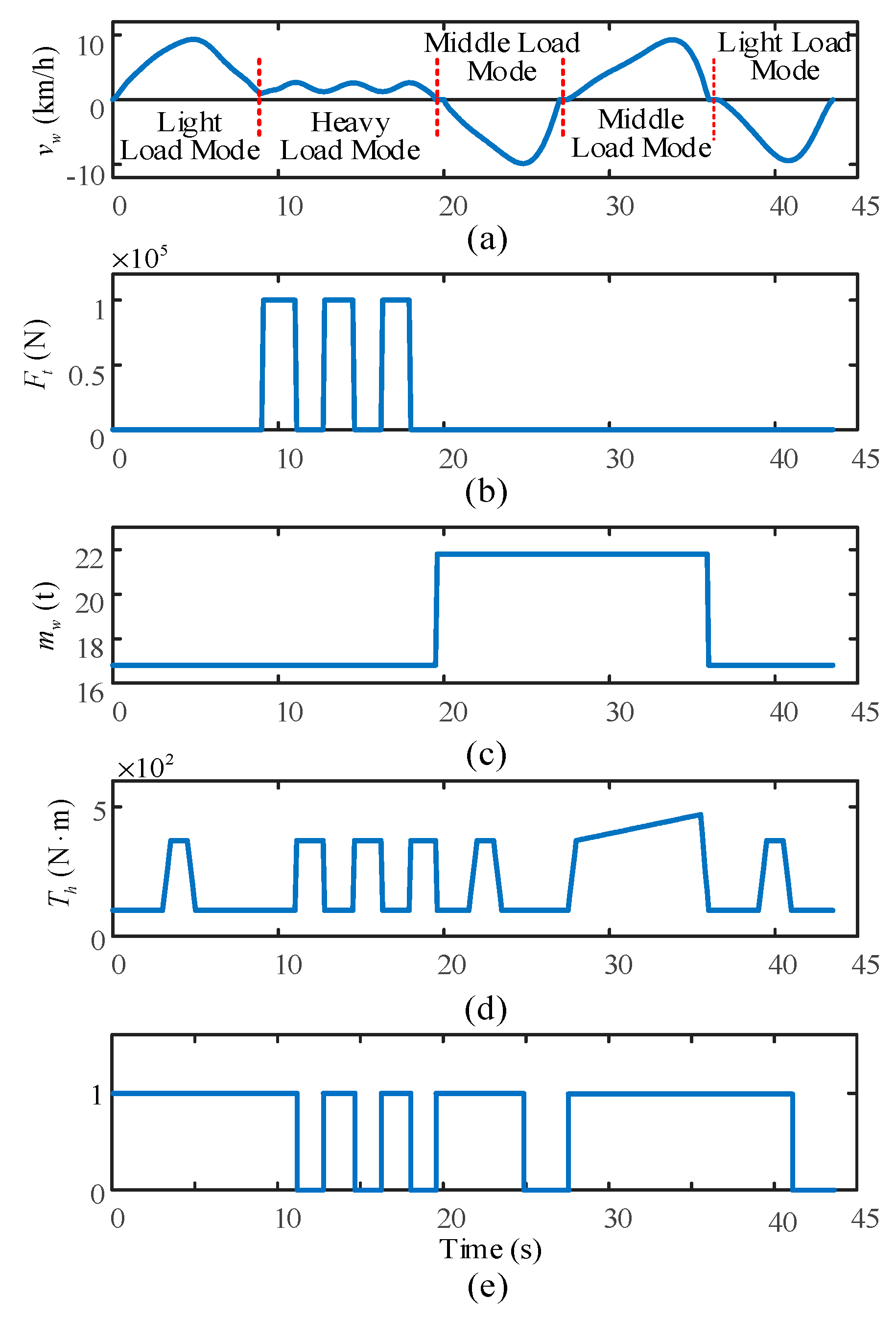

The other is the construction of an optimization model. Although the HMPST efficiency is the key factor influencing the fuel consumption of a wheel loader, it is not the only one. The engine efficiency is also an option. The ideal fuel saving solution provided by HMPSTs is that they have a higher efficiency and can enable the engine to work in the most economical area. However, the HMPST is a self-adaptive mechanism and thus it cannot actively control the engine to work in a specified areas. On the other hand, the wheel loader operation is highly repetitive, that means the general operating mode of wheel loaders can be predicted and modeled [

3,

13]. Considering these two aspects, this paper optimizes HMPSTs using some features of the typical operating mode, in order to find the optimal fuel saving potential solution for HMPSTs.

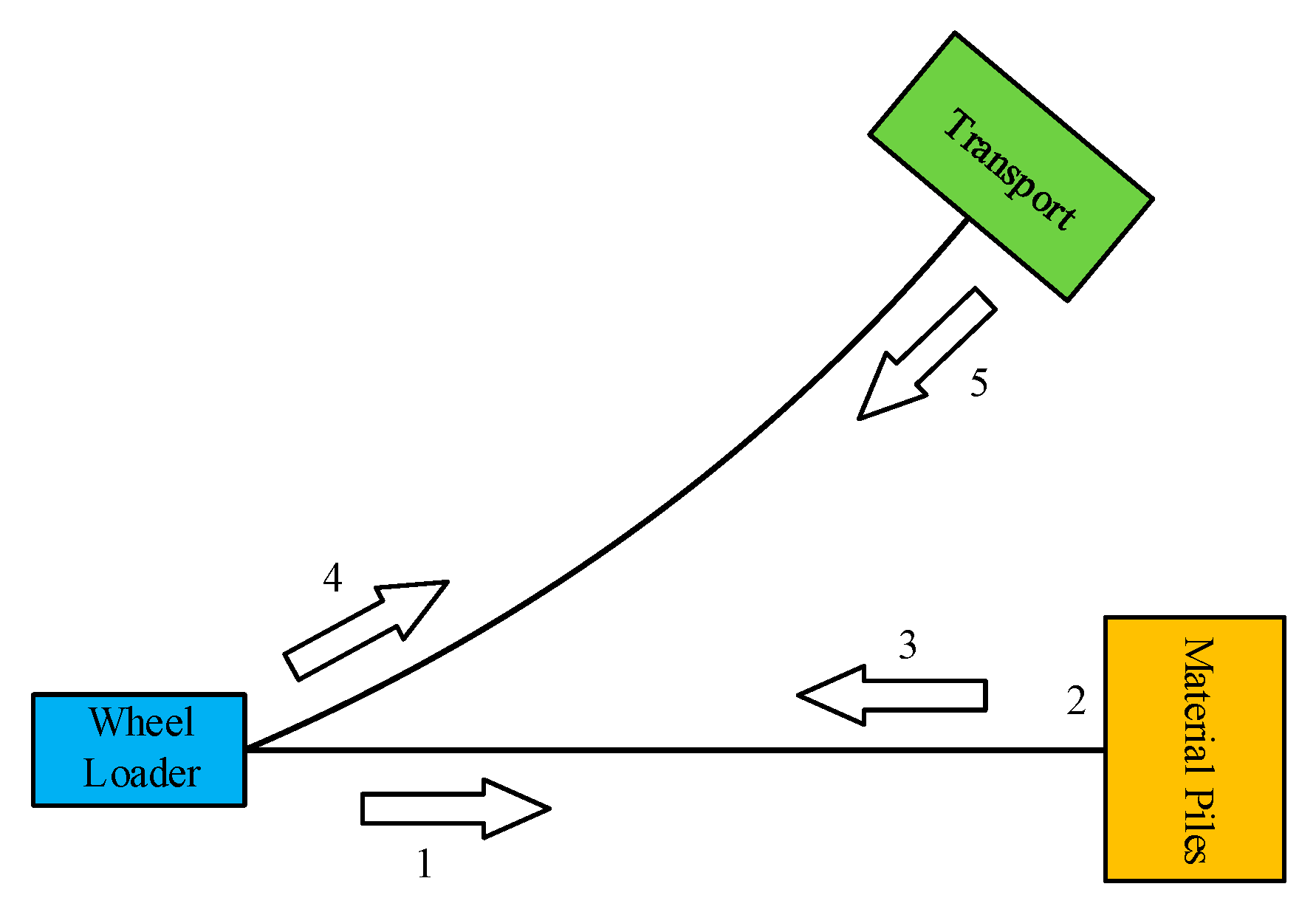

The rest of paper is arranged as follows: an operating mode for a wheel loader is constructed in

Section 2.

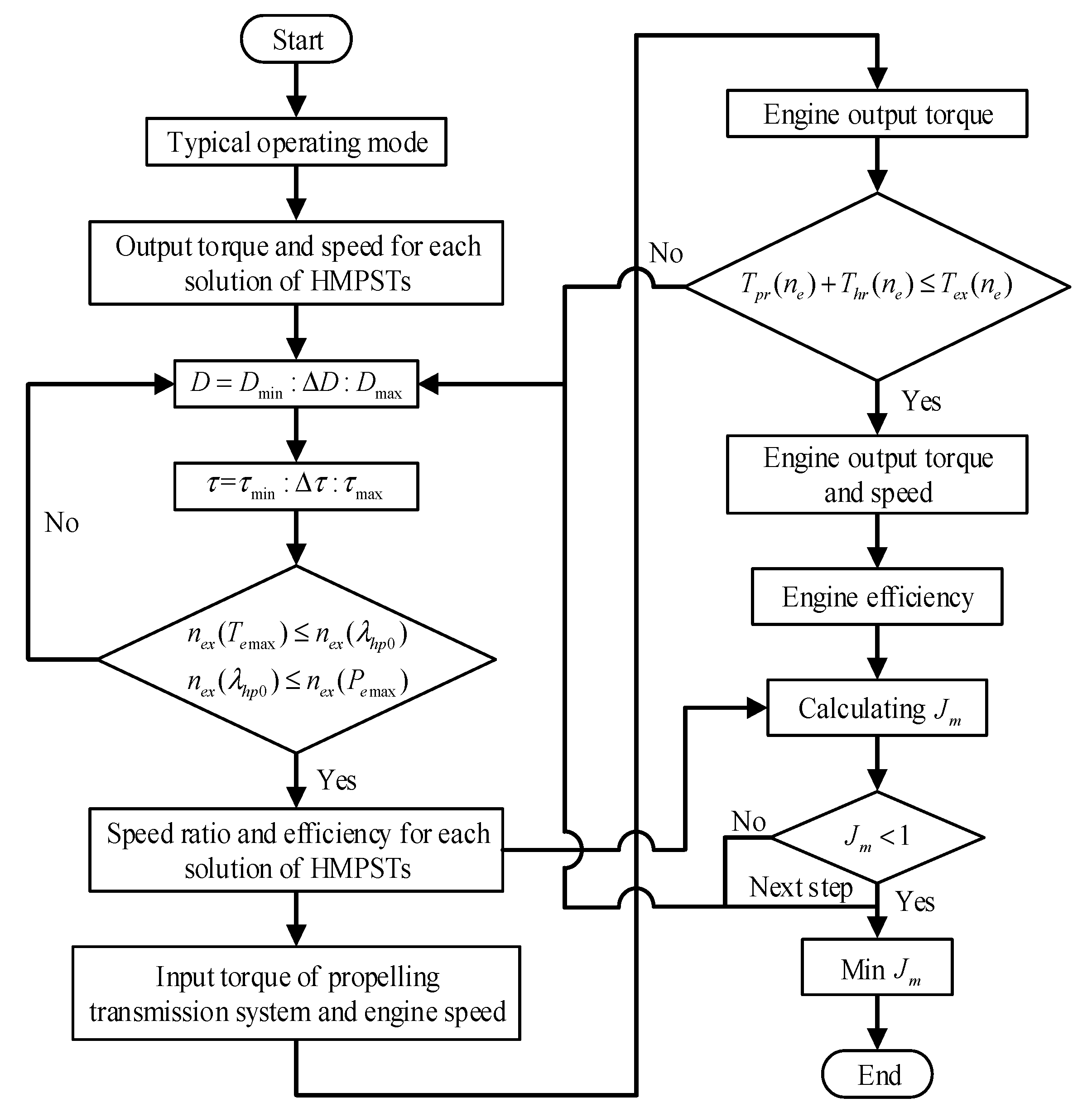

Section 4 implements the design optimization for the selected HMPSTs, where the objective function is the fuel saving potential relative to the prototype TC. After the results are obtained, a simulation to determine the optimal solution is conducted in the Matlab/Simulink environment, in order to verify the effectiveness of the constructed optimization model.

3. Initial Selection and Analysis for the HMPSTs

Since a lot of different HMPST configurations exist, the analysis and design for all these configurations would be a cumbersome task for an industrial designer. To avoid such a problem, this section firstly selects the most reasonable schemes from within the possible HMPSTs which can be initially applied to a wheel loader. Then the comparisons between the basic characteristics of each solution and that of the prototype TC are carried out, in order to get a clear understanding of these solutions.

3.1. Initial Selection

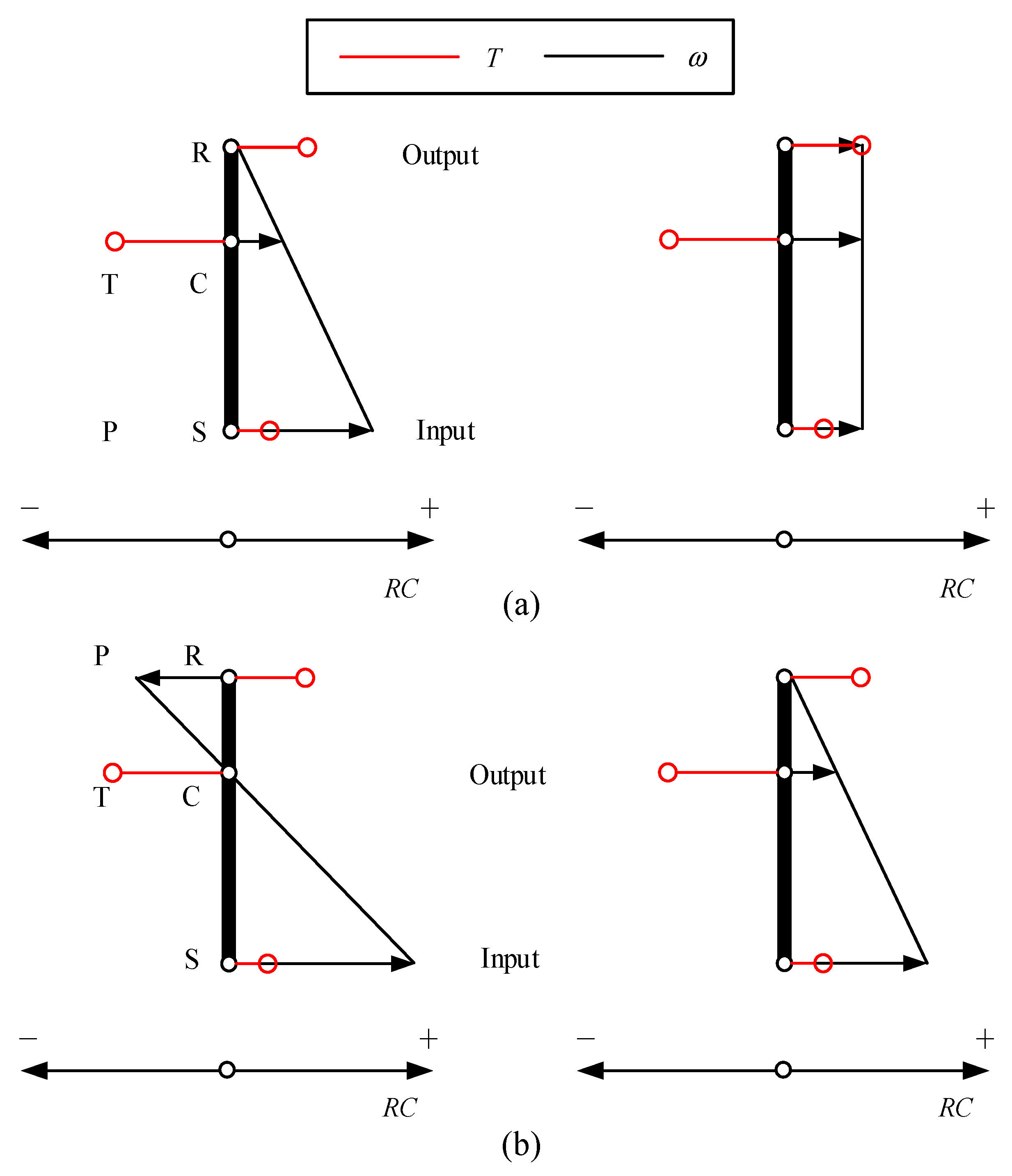

The HMPST mainly consists of a TC and a single PGT. According to the different features for the torque transferred by the two terminals of a HMPST, the HMPST can be divided into two types: the input torque coupled architecture and output torque coupled architecture, as shown in

Figure 6. The R, C and S denote the ring gear, the planet carrier and sun gear, respectively. The P, T and G denote the pump, the turbine and stator, respectively. In the input torque coupled HMPSTs, there are six basic schemes based on the connections of the input shaft of HMPST and the turbine to the three components of the PGT. Considering the TC can be inversely placed at the hydraulic branch, six additional schemes are possible for this architecture. Similarly, the output torque coupled HMPSTs also have 12 schemes, so there are 24 HMPST schemes in total.

Whether the HMPSTs can be applied to the wheel loader or not depends on both the working form of the TC and the power flows in the system. Since the TC can only work well in the first quadrant, the schemes that cannot meet this condition will deteriorate the working performance of wheel loader and have to be eliminated. Furthermore, the schemes that exist following two types of power flows have to be eliminated as well. One is that the power is transmitted from turbine to pump, the other is that the input power of TC is higher than that of system. The efficiencies of these two types are always lower than that of the prototype TC, which results in them lacking any practical value.

The reasonable HMPST schemes are selected by the lever diagram, since it can visualize both the power transfer path of the mechanism and the kinematic relationships between each link based on the torque equilibrium of all terminals and conservation of energy [

23,

24]. The lever diagram for

Figure 6a is shown in

Figure 7a, where the

RC is the reference coordinate system, and the circle and arrow indicate the direction of the torque

T and speed

, respectively. It can be observed that as the speed of the ring gear increases from the stall state, and the three components of the PGT rotate simultaneously in the same direction, which means that the TC always works in the first quadrant. However, the power transferred by planet carrier is the sum of that transferred by the ring gear and sun gear, which indicates that the sum of HMPST input power and the recirculating power passes through the TC with low efficiency. Consequently, this scheme should be rejected. The discriminant method for the scheme in

Figure 6b is presented in

Figure 7b.

The ring gear rotates in the opposite direction relative to the planet carrier while the planet carrier speed increases from zero to a certain value, which means that the pump and turbine rotate in opposite directions, and the TC works in the second quadrant. As a result, this scheme has to be rejected as well. Similarly, the remaining 22 schemes are judged by this method.

Figure 8 shows the four ultimately reasonable solutions for HMPSTs.

3.2. Basic Characteristics Analysis

As the TC is embedded in the HMPST, each of above four solutions is equivalent to a certain type of TC. The basic characteristics of the HMPSTs comprise efficiency

and loading characteristics

. The derivation for these basic characteristics are based on the steady state and the PGT efficiency treats as the constant [

25,

26]. According to the torque equilibrium of PGT, energy conservation and known power flow of each solution, the basic characteristics of each solution can be derived as:

where

m (

m =

a,b,c,d) denotes the four solutions in

Figure 8,

is the structural parameter of the PGT, which is the ratio of the numbers of ring gear teeth to that of sun gear teeth,

i is the HMPST speed ratio and equal to the ratio of output speed to input speed.

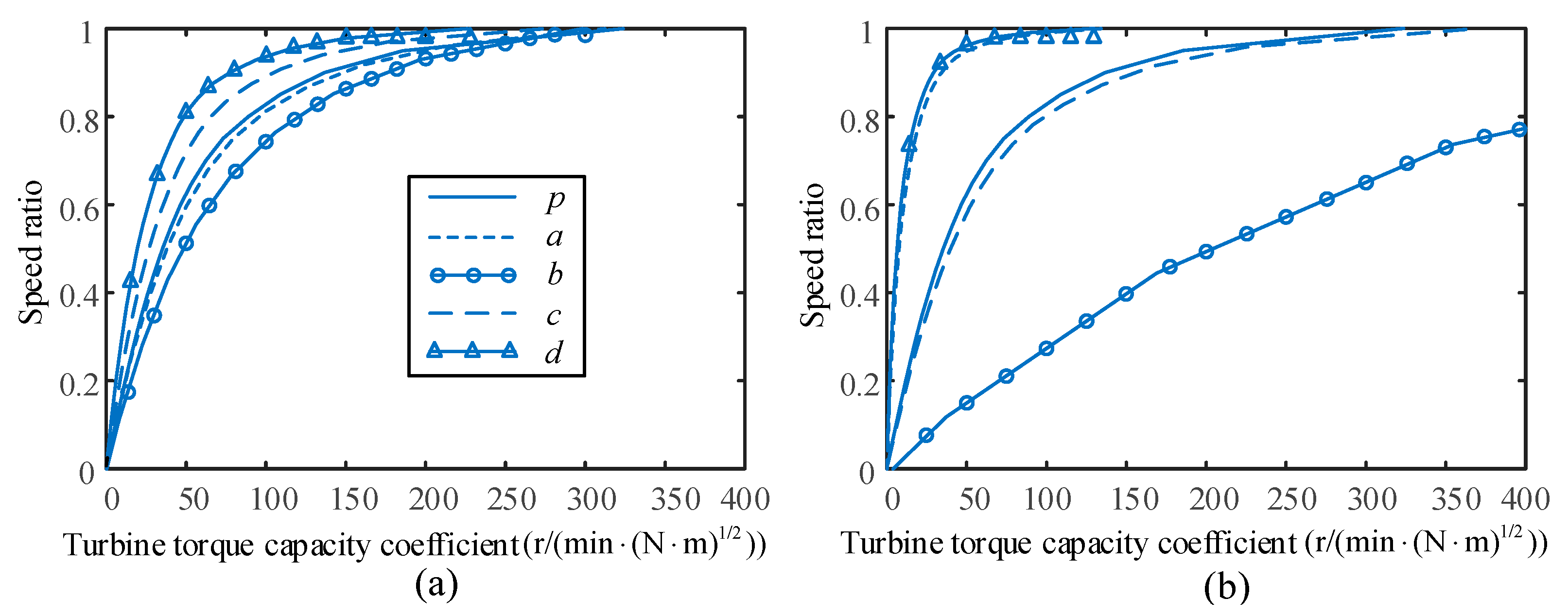

Equation (8) shows that the variable factors influencing the basic characteristics of each solution are the structural parameter of the PGT and the effective diameter of the TC circuit D. By further analysis, it is found that the efficiency varies strictly monotonically with and D. Therefore, the two boundary values for the and a specific value for the D are adopted to examine the basic characteristics of each solution.

Figure 9 shows the efficiency of each solution. The term

p denotes the prototype TC. For solution

a, its efficiency can gain a significant advantage over the prototype when the speed ratio is greater than about 0.65.

Figure 4 and

Figure 5 show that the engine works in the light load mode in this range. However, in the low speed ratio range, the engine outputs higher power. That means the proportion of fuel consumption for low speed ratio range are greater than that for high speed ratio range among the total fuel consumption. Due to the oversized

, the deficiency of efficiency in the low speed ratio range can hardly be made up by advantage of efficiency in the high speed ratio range. For solution

b, its efficiency is much less than that of prototype in the entire range of

. For solution

c, the efficiency integral area of such a solution is slightly greater than that of the prototype. The

decreases with the increase of

, which facilitates the improvement of fuel economy of vehicle in the low speed ratio range. As for the solution

d, it displays a similar situation to solution

a.

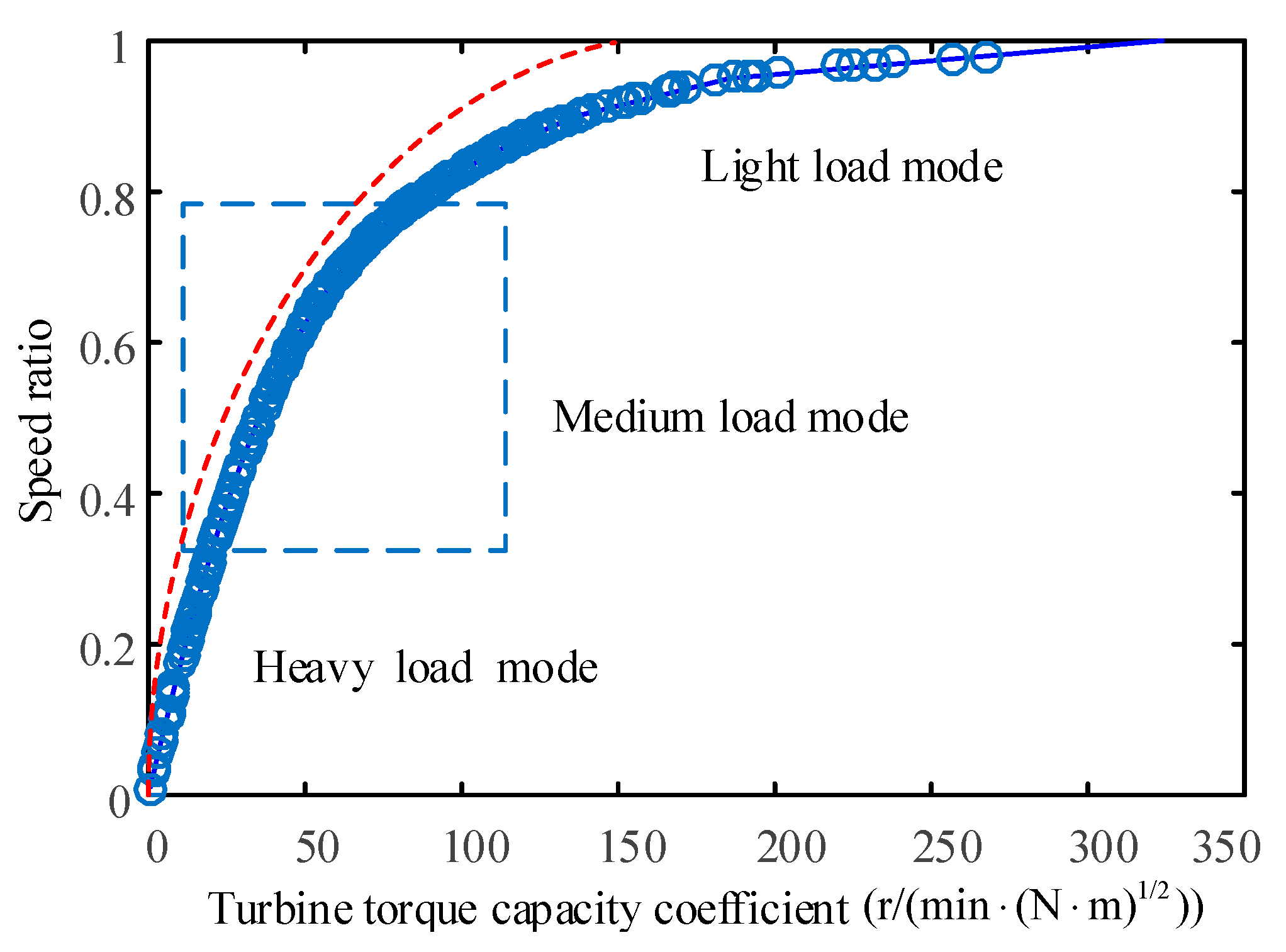

Figure 10 shows the loading characteristics of each solution. For the solution with characteristic curve above the prototype TC, it can achieve larger speed ratio at the same abscissa values. That means the engine can work at a smaller speed, and consequently the engine efficiency is increased. However, the change rate of speed ratio for this solution is greater than for the prototype. As a result, the working points of the engine will fluctuate in a larger range with the variation of external loads. Excessive transient conditions of engine are not conducive to improving the engine efficiency. Moreover, the solutions

a and

d cannot be applied to the wheel loader as the

τ increases nearly to 5, since they cannot match well with the external loads. In a word, the ideal curve of each solution should approach that of the prototype and make the engine work in the economical areas simultaneously.

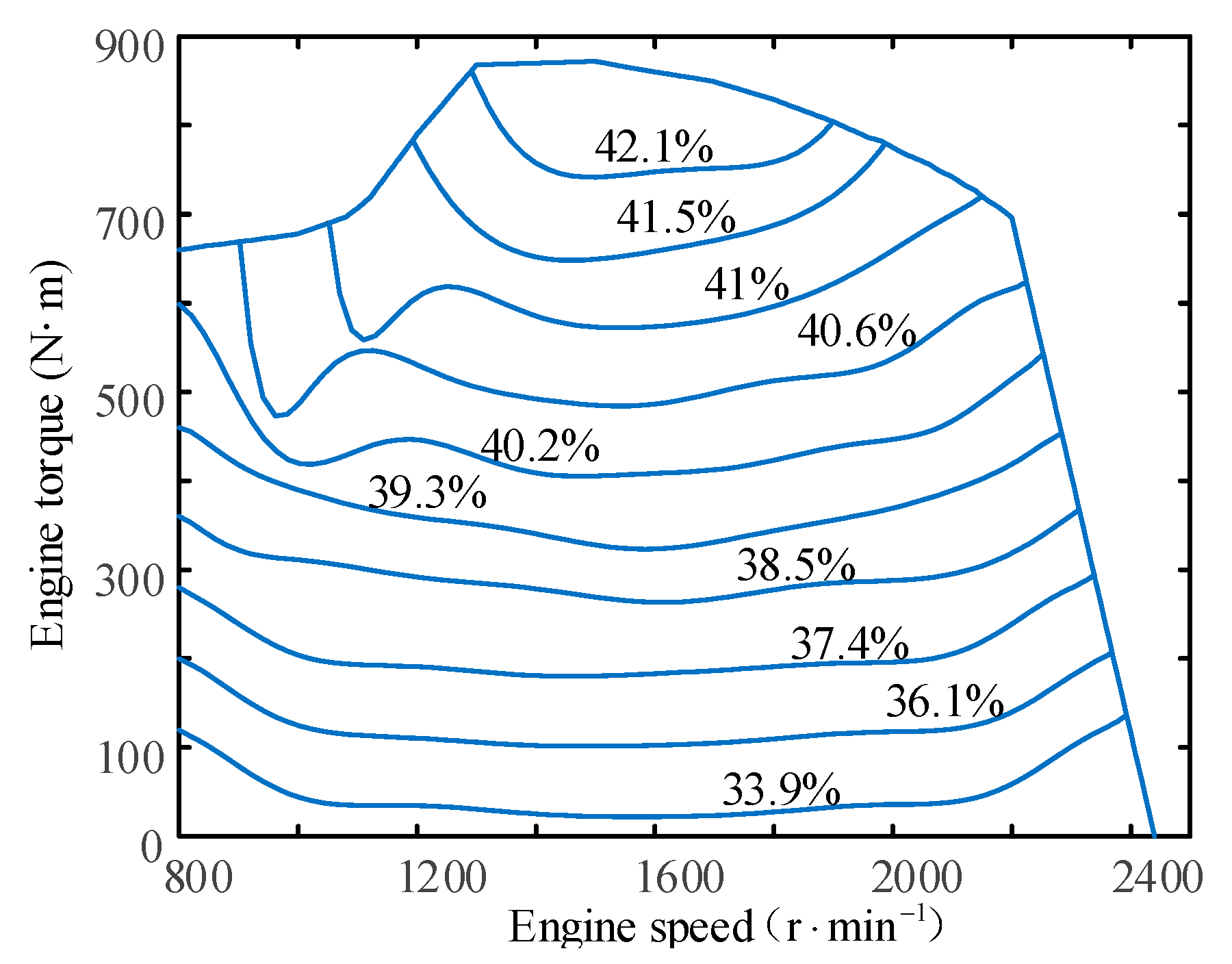

Figure 11 presents the engine efficiency map for this study.

6. Conclusions

In this paper, a HMPST was used to replace the existing TC for improving the fuel economy of wheel loaders. The initial selection for the HMPSTs was conducted based on the lever diagram. It was found that only four solutions can be applied to a wheel loader. Furthermore, the basic characteristics of these four solution were analyzed, and the results show all four solutions cannot show efficiency advantages over the prototype TC at all speed ratio points, which makes a design optimization of each solution necessary.

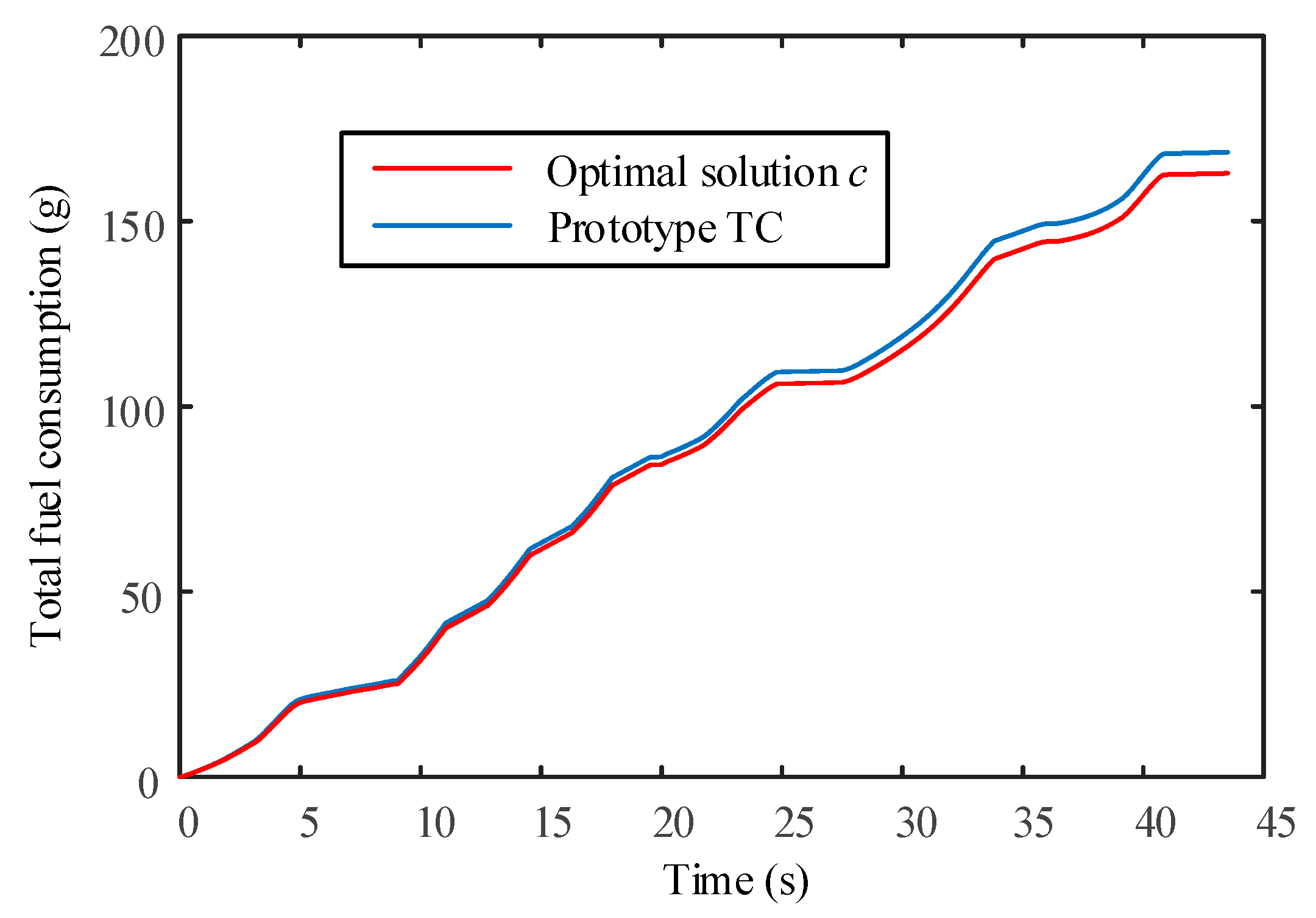

The optimized results show that only solution c can display a fuel savings benefit compared with the prototype TC. Despite the large numbers of possible configurations for the HMPSTs, the feasible solution replacing the TC is considerably less than expected. This situation may be due to the form of the prototype TC. If the basic characteristics of the prototype TC could be altered, more feasible solutions could applied to wheel loader. The effectiveness of solution c with the optimal structural parameters is validated in the Matlab/Simulation environment. The simulation results show that the solution c presents a fuel savings rate with 3.38% compared to the prototype TC. It is expected that the optimized HMPST solution c can be an ideal alternative to the existing TCs.