1. Introduction

Current trends in automotive applications are characterized by a common rule—green energy, or blue energy. More and more non-conventional energy systems and powered electronic systems are used within the internal infrastructure of vehicles, whose energy storage and conversion systems are still transforming and being optimized as electric vehicles are being considered. The main reasons are efficiency, reliability and power density. Worth mentioning are energy storage systems, drive systems, fuel cells, solar panels, electronic devices for energy conversion etc. Most of the green energy systems are of low output voltage. If practical use of such devices is required or requested, then a proper conversion system must be used, i.e., low voltage energy source must be boosted to the values that are necessary for other electronic devices (power inverter and electric machine for example). For application within a power train of electric vehicles it is required to boost 80 VDC/120 VDC to the values that are required for electric driving, i.e., 400 VDC. Therefore, a boost converter must be used.

Conventional boost converters have limits that are related to voltage gain, power capability and efficiency. In other words, when high voltage gain is required, the converter may operate at an unacceptable duty cycle, which results in a very high voltage stress of devices, and conversion loss of the circuit will ensue. For that reason, perspective topological modification has been made. Most of the proposals are focused on the optimization of the voltage gain ratio in the pursuit of duty cycle improvement [

1,

2,

3,

4,

5]. Many single-stage high voltage gain converters have been developed [

6,

7,

8,

9,

10] with switched capacitors [

11,

12,

13,

14,

15,

16]. Interleaved topologies with coupled inductors [

17,

18,

19,

20,

21,

22] or with voltage lift techniques have been proposed [

23,

24,

25]. However, there still exist several disadvantages that might be further optimized in order to improve the electrical behavior at the power stage, which deal with power limit when interleaved topology is considered, while voltage gain is limited at high powers because of the conduction losses of the circuit, which increase by an extreme amount at high power levels together with losses of magnetic material, which are also a limiting factor when saturation or DC biasing comes into account [

26,

27,

28,

29,

30]. Almost magnetic components are very important parameters, and attention must be paid for perspective proposals when interleaved boost topology is considered. The inductors of interleaved boost converters, which are magnetically coupled, are continuously saturated by DC current components. The variable that is the most negatively affected in this case is efficiency.

This paper proposes a double interleaved boost converter with high voltage gain and with magnetically coupled inductors, while a third coupled winding is used for magnetic flux reset of the core during the converter operation as well as for the voltage gain adjustment. The topology of the proposal is simple, it does not require many additional components compared to standard interleaved topologies [

31,

32,

33,

34,

35] and it improves the transfer characteristics, as well as system efficiency even for high power levels [

36]. With its superior behavior related to the output voltage stiffness in dependency on load change, it might be a proper solution for applications where constant DC-bus voltage is required (DC-DC converter for inverters). The main focus within this paper is given to the steady state analysis, voltage transfer characteristic derivation, magnetic component stress reduction and system efficiency identification.

2. Dual Interleaved Boost Converter with Magnetically Coupled Inductors and with Demagnetizing Circuit

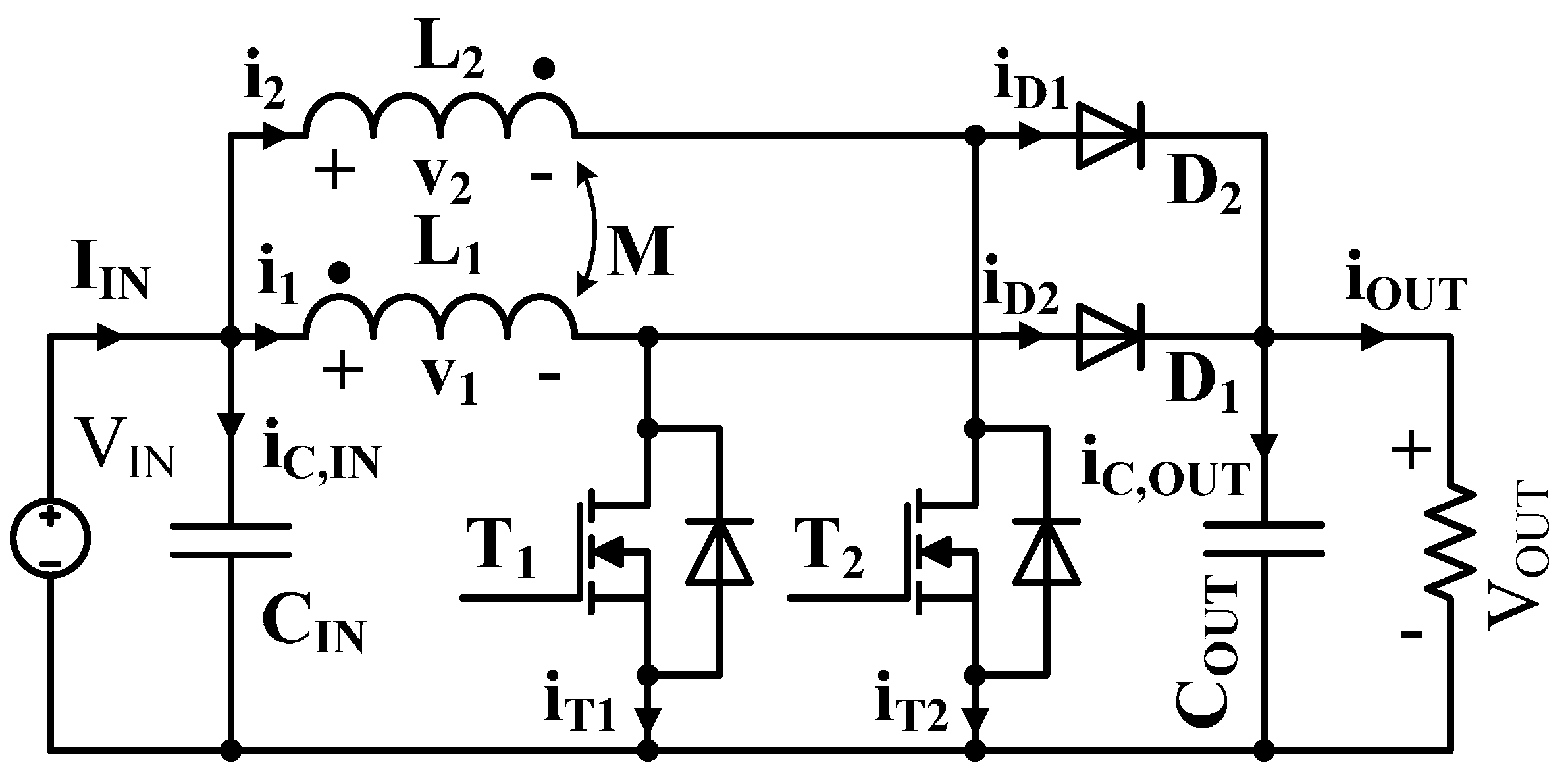

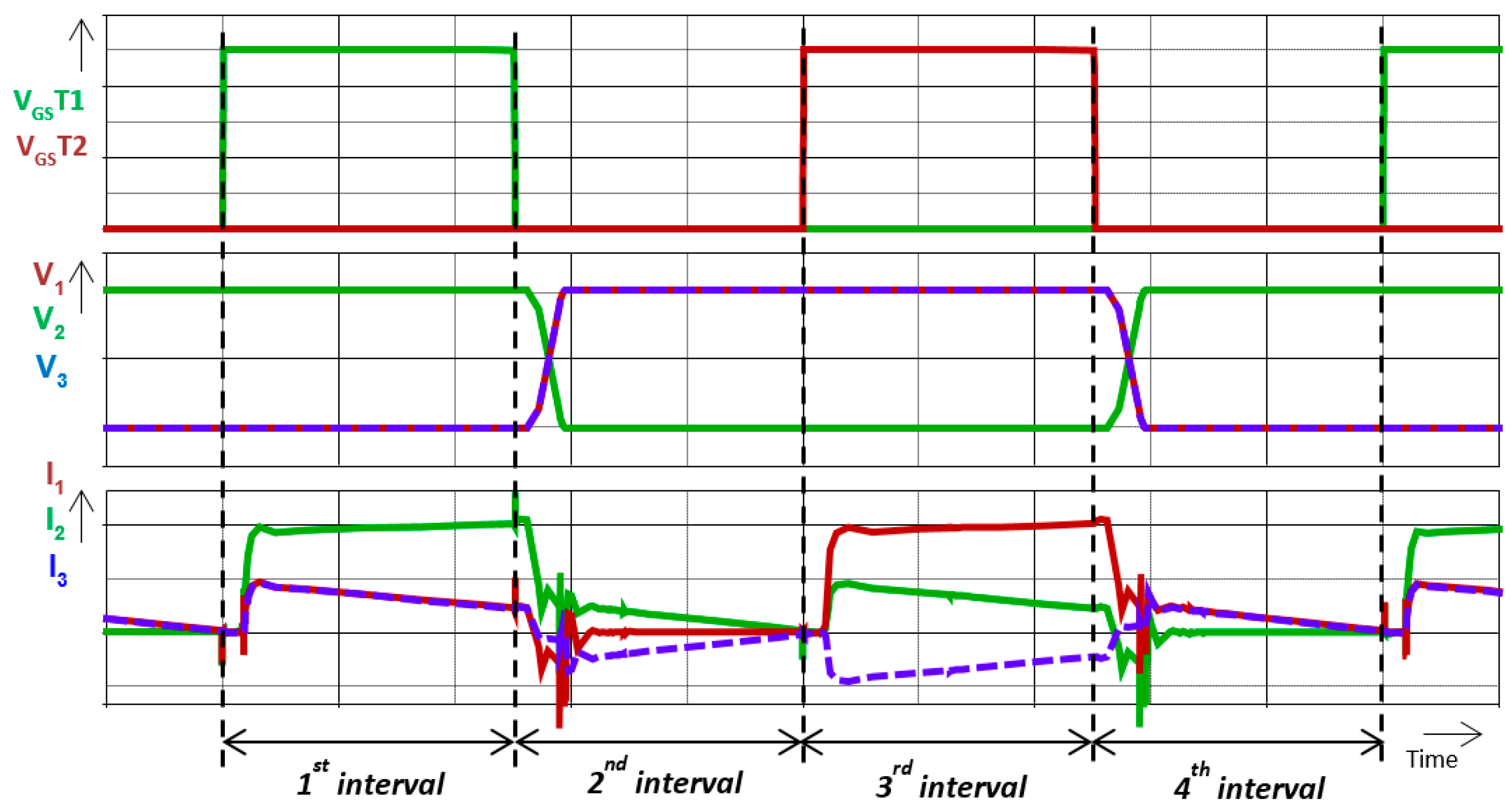

Figure 1 shows the dual interleaved DC-DC boost converter with magnetically coupled inductors. Analysis of the DC-DC converter (

Figure 1) is primarily done under operation in the CCM mode, so that the currents

i1 and

i2 are always positive. The advantages of CCM operation against DCM operation include the minimization of circuit ringing, inductor and input ripple current reduction, and voltage ripple effects elimination as well as elimination of their associated mitigation. Waveforms from steady state operation of dual interleaved boost converters for CCM operation with a duty ratio greater than 0.5 (while duty cycle of

T1 and

T2 is equal), are shown in

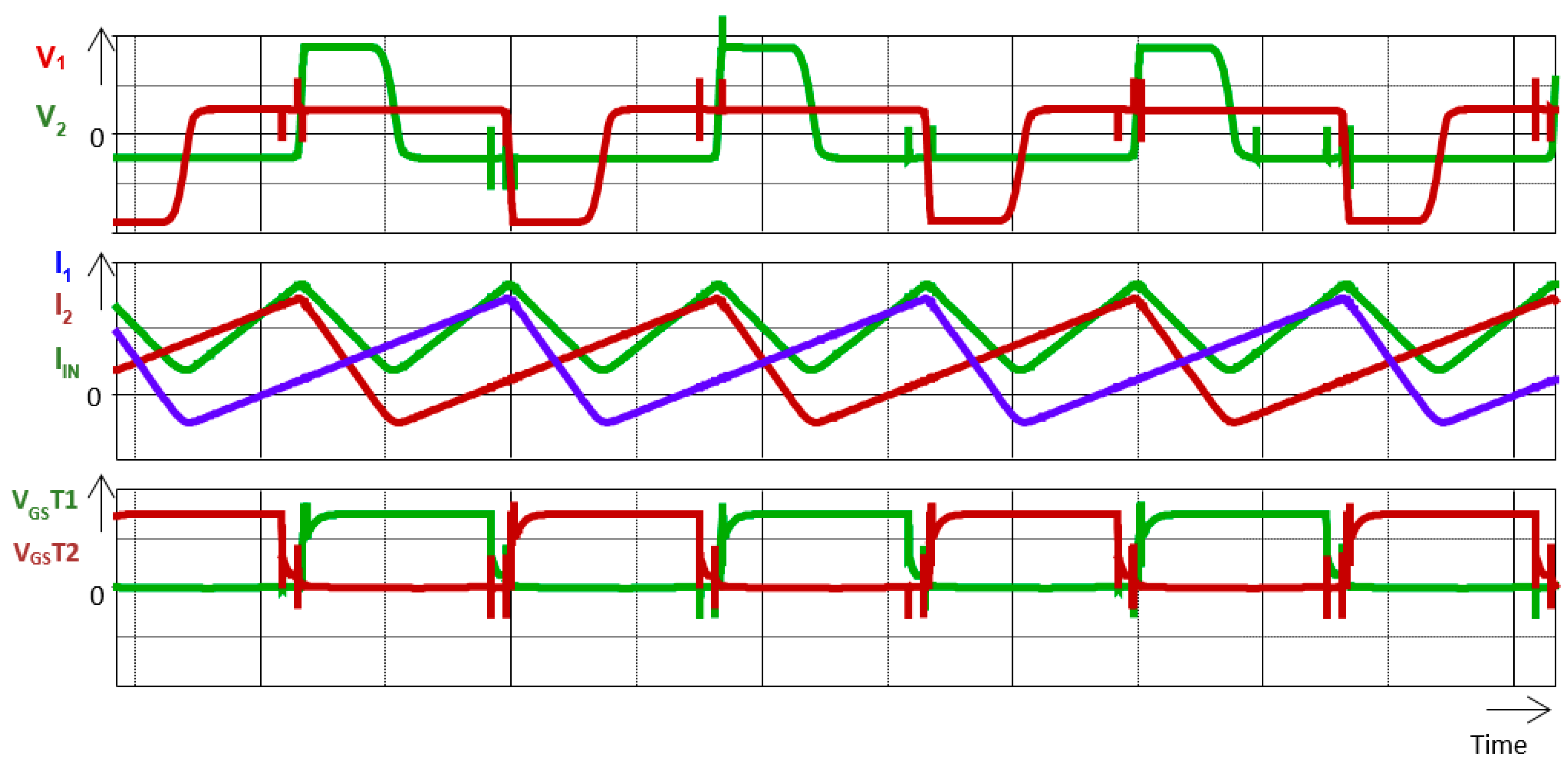

Figure 2. It shows input current (

iIN), inductor voltages (

V1,

V2), inductor currents (

i1,

i2), and

T1 and

T2 gate drives. For CCM operation, the voltage gain is the same as that given for a simple boost converter described by (1).

where

VOUT is output voltage of the converter,

VIN is input supply voltage and

D is the duty cycle.

It is observed that the voltage gain is primarily dependent on the duty cycle of the converter operation.

The standard solution to dual interleaved boost converters with magnetically coupled inductors has its advantages compared to the classic boost converter. They apply even when higher power demands are given on the power stage. Instead of that, reduction of voltage and current ripple enable a reduction in passive components, even when a high switching operation is considered. However, on the other side, some disadvantages arise and are related to the voltage gain and magnetic design and operation of coupled inductors. During each operating cycle, the DC component of the current of each winding (L1 and L2) exists. This limits the magnetic component to be used for higher power, and bulky magnetic core or special geometry modifications must be used in order to prevent saturation of the magnetic core. In the same way, the efficiency is affected and can be decreased when wrong magnetic design is performed.

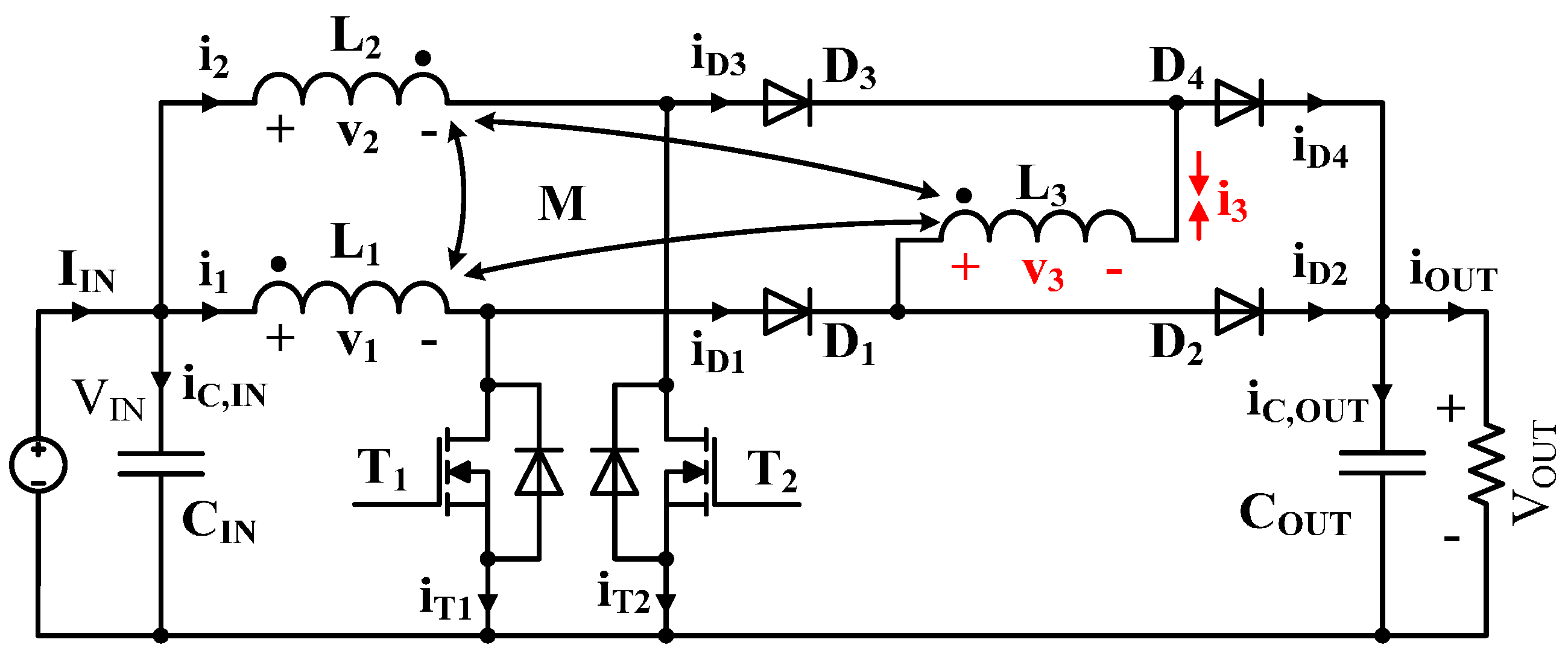

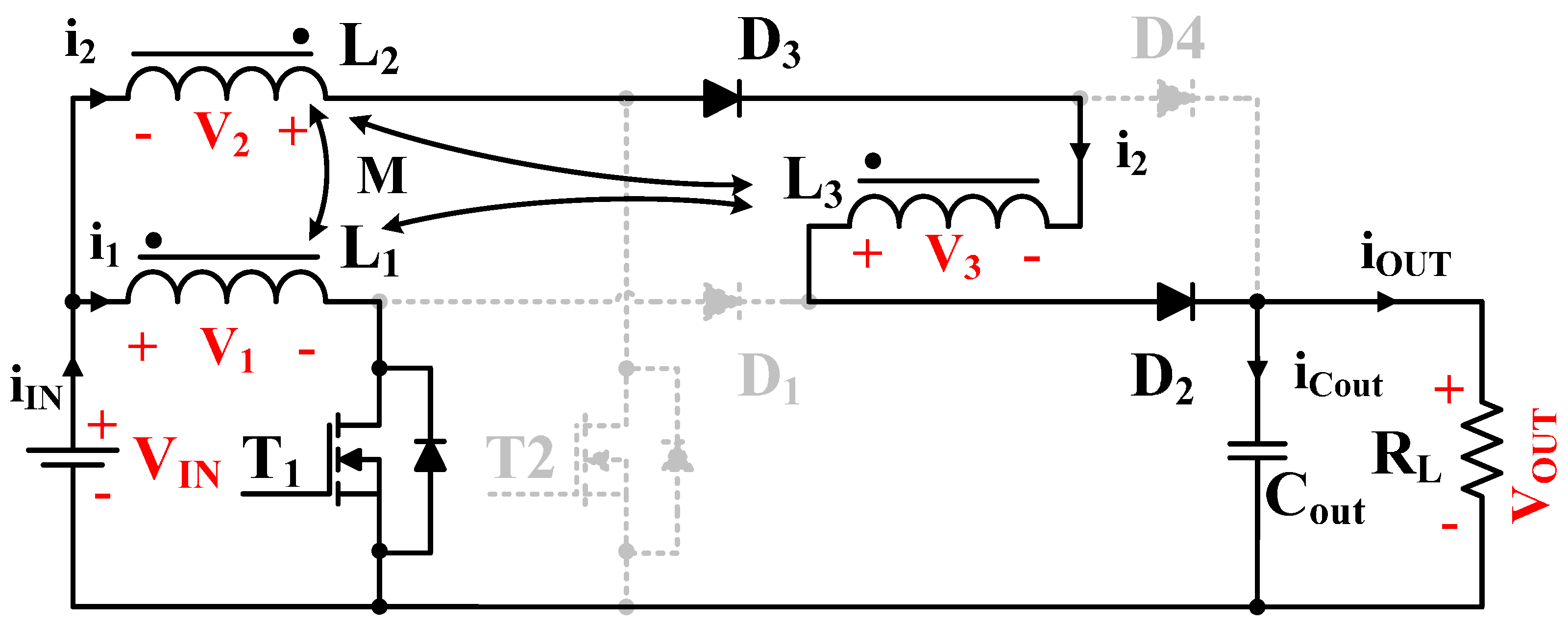

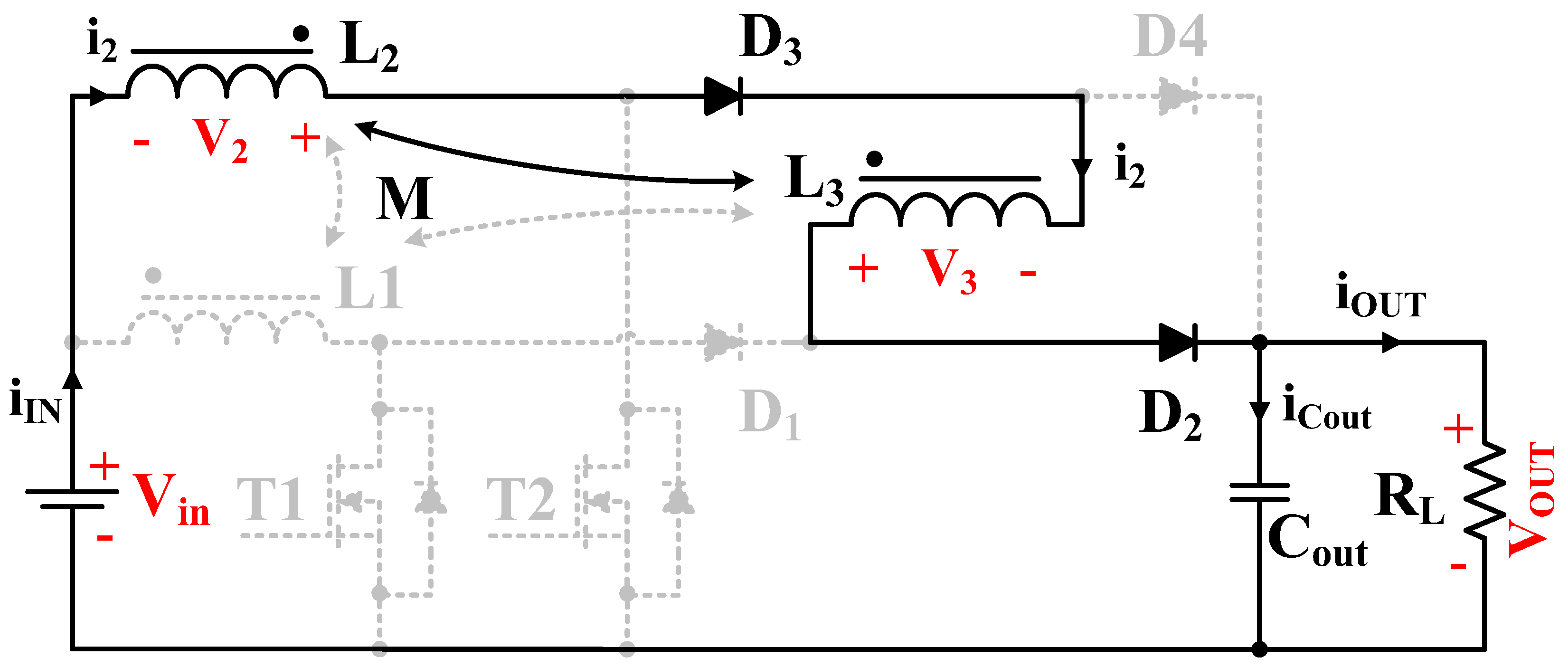

The proposed interleaved boost converter with magnetically coupled inductors and with demagnetizing circuit is shown in

Figure 3. It is composed of a standard double interleaved boost converter (

Figure 1), where a demagnetizing circuit, which consists of

L3-

D4-

D2 is added to the output part of the proposed converter. This demagnetizing circuit also creates an additional pseudo transformer within the proposed converter circuit, and as will be seen later, the ratio between boost inductances (

L1,

L2) and demagnetizing inductance (

L3) influences the voltage gain. The proposed converter is voltage gain independent on the duty cycle operation in wide operational range, and thus constant output voltage within wide range of output load can be achieved.

The switching operation is similar to the standard interleaved converter, i.e., transistors T1 and T2 are switching in an interleaved manner with given dead time. Inductor L3 is magnetically coupled altogether with L1 and L2 and serves as a demagnetizing snubber whose effect applies during each switching action of each transistor. In this configuration, it servers as an AC magnetic flux reset inductor. The current flow I3 during each operation cycle is opposed to the current of inductors L1 and L2. This enables a reduction in the magnetic core saturation, thus the DC component of the inductor currents can be eliminated.

3. Operational Analysis of Proposed Converter

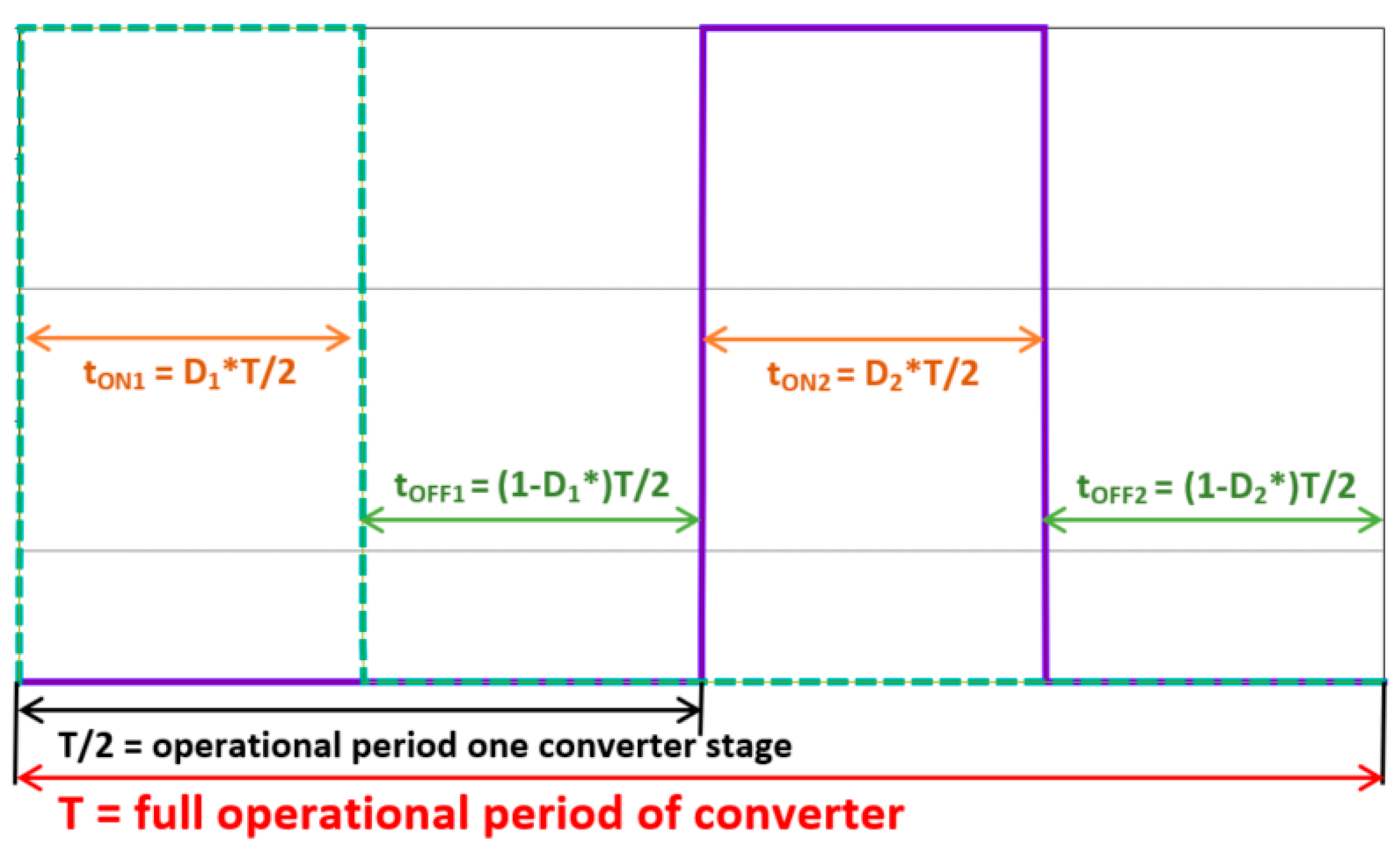

The operation of the dual interleaved boost converter with magnetically coupled inductors and with demagnetizing circuits can be divided into four operational intervals. One switching cycle can be then understood as in an ON and OFF state after consequent switching of transistors

T1 and

T2. Thus, 2 active and 2 passive intervals exist. For initial investigation of converter operation it can be assumed that the duration of active interval will be equal to the duration of the passive interval. The switching driving signals for this situation are shown in

Figure 4. It is also considered that the turns ratio between individual coils is equal to 1:1:1, so all inductors have the same value. The operational waveforms for analyzed steady state are shown on

Figure 5.

3.1. Working Intervals of Proposed Converter

The operation of the converter can be divided into four consecutive intervals, which periodically repeat. The initial analysis of the operation is done for the conditions where L1 = L2 = L3 = L, and M1 = M2 = M3 = M. The operation of the converter shall be considered within steady-state operation.

3.1.1. Interval (Active—T1—ON, T2—OFF)

Initial conditions:

- -

T1—ON,

- -

T2—OFF (the transistor T2 was before this interval in conduction state, thus L2 is accumulated with the energy),

- -

D2, D3—conducting,

- -

L1 is accumulating the energy,

- -

L2 and L3 are transferring energy into output capacitor COUT and to the load RL.

This interval (

Figure 6) starts after turn-on of

T1, while its ON-period is equal to the half of the half period cycle, i.e.,

tON1 =

D1 ×

T/2, whereby

D1 = 0.25. The current in the inductor

L1 linearly rises, while the current in the inductors

L2 and

L3 is linearly decreasing and is half the value of current

i1. The voltage on the coil

L1 is the opposite polarity to the voltages on inductors

L2 and

L3. Using Kirchhoff’s second law, it is possible to derive dependency of the output voltage on the inductor voltages. For the first-time interval of the converter’s operation, the following equations are valid:

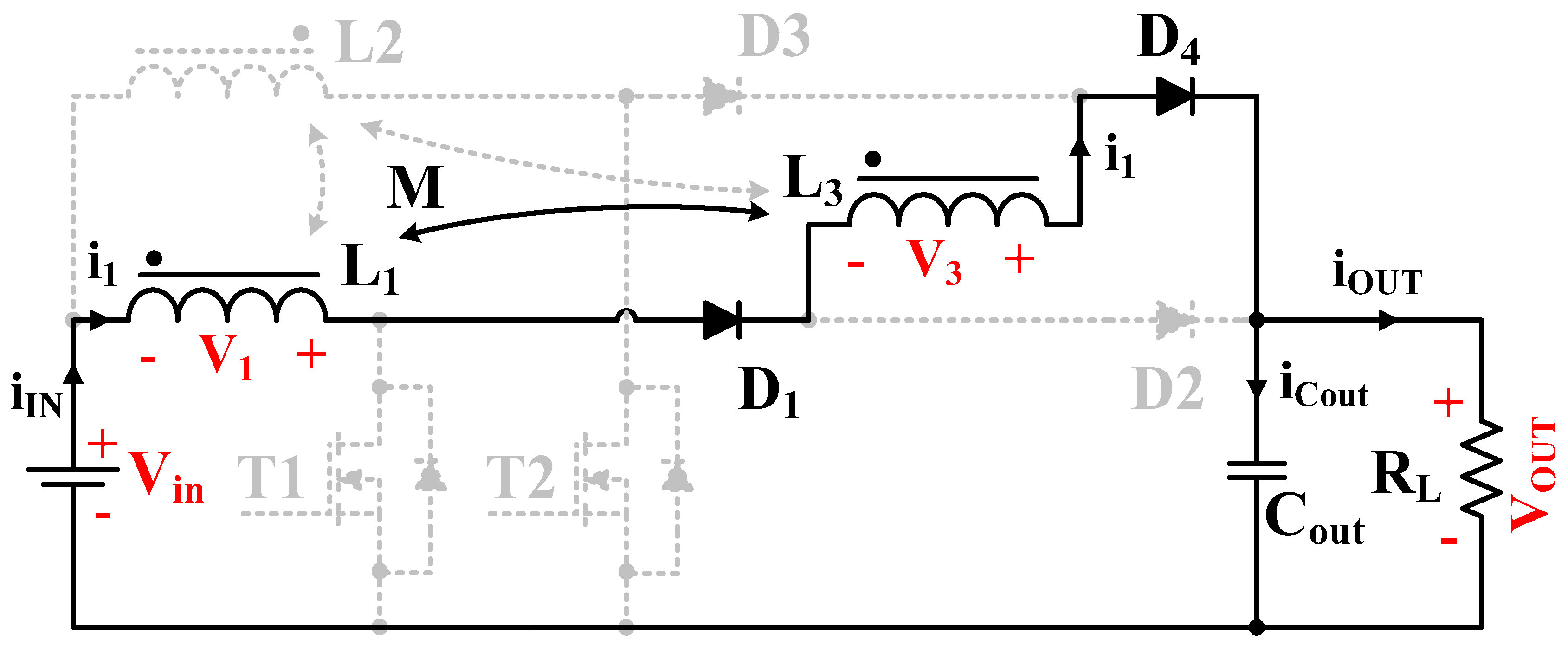

3.1.2. Interval (Passive—T1—OFF, T2—OFF)

Initial conditions:

- -

T1—OFF,

- -

T2—OFF,

- -

D1, D4—conducting,

- -

L1 and L3 are transferring energy into output capacitor COUT and to the load RL.

This interval (

Figure 7) begins after the transistor

T1 turns off. Duration of this interval is

tOFF1 = (1 −

D1) ×

T/2. This causes the polarity of the voltages on each inductor to change its polarity to the opposite value compared to the first interval. During this time interval, the current of inductor

L2 is equal to zero, because it is not connected to the main circuit. The current of the inductor

L1 flows also through the inductor

L3, while inductor

L1 acts as the source, thus its

i1 is linearly decreasing, whereby

i3 is linearly increasing. This interval can be characterized by the demagnetizing action of the common magnetic core, because inductor

L3 is acting in the opposite direction to the inductor

L1. It might be seen that within 1st and 2nd interval of the operation, the AC current is flowing through the

L3. The equation of the loop voltages within the main circuit during this time interval is given by (10), while the output voltage is defined by (11).

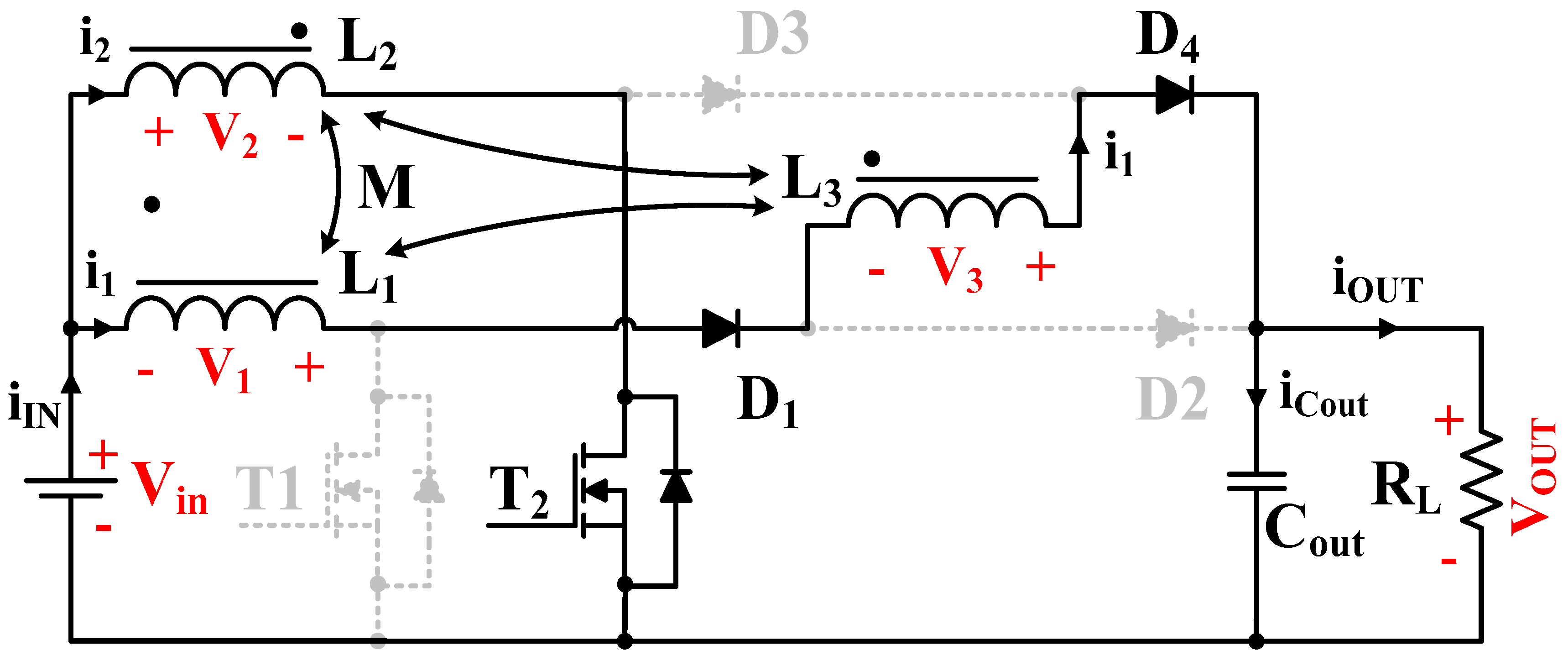

3.1.3. Interval (Active—T1—OFF, T2—ON)

Initial conditions:

- -

T2—ON,

- -

T1—OFF,

- -

D1, D4—conducting,

- -

L2 is accumulating the energy,

- -

L1 and L3 are transferring energy into output capacitor COUT and to the load RL.

The third (

Figure 8) interval is again the active interval, and its initialization is characterized by the turn on of the transistor

T2, while transistor

T1 is still turned off. This interval has the same ON period as the first one, i.e.,

tON2 =

D2 ×

T/2, where

D2 = 0.25. The polarity of the inductor voltages is unchanged compared to 2nd interval. Because direction of the current flow in

L3 is unchanged, and its current is linearly increasing from negative values, inductor

L1 is continuously acting as the voltage source, thus its current is linearly decreasing with the same slope as current

i3 rises. Inductor

L2 is being charged as in the case of standard boost converter. It is seen that the 3rd operational interval is similar to the 1st interval, while the only difference is the polarity and behavior of current

i3. Therefore based on the loop voltages, the equation for this time interval is given by (14), and consequently dependency of the output voltage is given by (18).

3.1.4. Interval (Passive—T1—OFF, T2—OFF)

Initial conditions:

- -

T1—OFF,

- -

T2—OFF,

- -

D2, D3—conducting,

- -

L2 and L3 are transferring energy into output capacitor COUT and to the load RL.

The 4th interval (

Figure 9) is a passive interval and from the operational point of view it is again comparable to the 2nd interval of the converter’s operation, thus duration is

tOFF2 = (1 −

D2) ×

T/2. Start of the interval is characterized by the turn-off action of transistor

T2; transistor

T1 is still in non-conductive state. The voltages on each inductor change their polarity compared to previous operational interval, thus inductors

L2 and

L3 are now acting as sources so their currents are linearly decreasing with the same ratio. Inductor

L2 is disconnected from the main circuit during this time interval, thus its current is equal to zero. The equation for final operational interval with steady state operation is given by (22). Dependency of the output voltage is given by (23).

Based on the previous analysis, it is seen that the proposed converter has advantages related to the voltage gain, which is dependent on the duty cycle of the converter. Instead of that, the converter is able to operate in a wide range of load, while output voltage is not affected and the only voltage decrease of

VOUT is caused by the voltage drop on the individual parasitic components. Voltage ratio between

VIN and

VOUT can also be adjusted by the ratio between number of turns of the boost inductances (

N1 =

N2), and number of turns of AC demagnetizing inductance. The process of the determination of the turns ratio between individual inductances (

L1–

L3) is determined by the requirements of the converter operation, i.e., CCM, DCM, BCM mode. Therefore the inductances

L1 and

L2 are selected based on the standard procedure for interleaved converter [

19,

20,

22]. The value of the

L3 inductance is then determined by the requirements on the voltage gain of the converter.

Table 1 shows voltage gain of the proposed converter for pre-defined multiples of the turns of inductances. It is the voltage gain related to the change of inductance ratio, while duty cycle is considered to be within the previous analysis, i.e.,

D1 =

D2 = 0.5.

3.2. Loss Distribution Analysis

Energy losses in elements of the boost converter can be divided into inductor losses, power switch losses and diode losses [

37,

38,

39,

40]. Total energy losses

PTOT is expressed as:

3.2.1. Inductor Losses

The estimation of the inductor losses is basically the same as that of the transformers. The conduction losses

PLCON are:

where

RL is serial resistance and

IL is current of

L.

The core losses (Steinmetz equation)

PLMAG are:

where

VCORE is the volume of the magnetic core, Δ

BL is the flux swing,

fSW is switching frequency,

k,

αCORE,

βCORE are the Steinmetz coefficients, which are provided by the manufacturer.

Then the losses of inductor are attained as:

3.2.2. Power Switch Losses

The losses of power switches mainly comprise the switching loss, conduction loss free-wheeling diode loss and the drive loss. The switching losses

PTSW are:

where

ETON,

ETOFF are MOSFET turn-on and switch-off energy.

The conduction losses

PTCON are:

where

RDSON is on-state resistance and

IT is current of power switch.

The free-wheeling diode losses

PTFWD are:

where

vD0 is diode on-state zero-current voltage,

IFAV is average diode current,

RD is diode on-state resistance,

IFRMS is RMS value of the diode current,

EDON is diode energy during MOSFET switch-on transient.

The drive losses

PTDRI are:

where

QGD is storage charge between the gate and drain,

VG is gate voltage.

Then the losses of power switch are attained as:

3.2.3. Diode Losses

The diode losses only contain the switching loss and conduction loss. The switching losses PDSW are:

where

VR is diode applied voltage,

IR is diode reverse current,

T is switching period,

tOFF is diode off-time,

ERR is switching energy loss due to reverse recovery.

The conduction losses

PDCON are:

where

VF is diode forward voltage,

IF is diode forward current,

tON is diode on-time.

Then the diode losses are attained as:

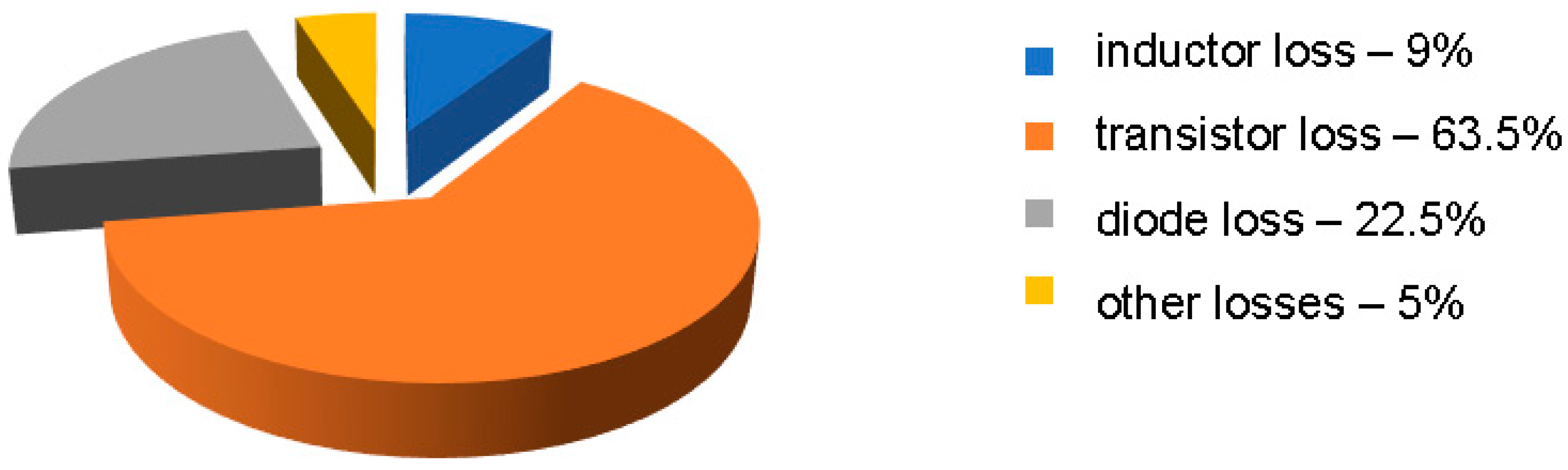

Based on the circuit parameters and circuit components, the determination of individual losses can be realized (

Table 2). These losses are valid for 1 kW output power of the proposed converter, supplied from 100 V

DC, voltage gain equal to 3.6, with operating frequency 100 kHz.

4. Simulation and Experimental Analysis of the Steady-State Operation

Initial investigation the analysis of the steady state operation is provided, in order to validate operational characteristics of the converter. In this study, these are related to the output characteristic (dependency of output voltage on the output power at constant duty cycle), efficiency characteristic (dependency of system efficiency on the output power at constant duty cycle), and voltage gain characteristic, i.e., dependency of the output voltage on the duty cycle at various output powers. Finally, the analysis of the voltage gain characteristic on the inductance ratio was performed, while the duty cycle is constant. The input-output condition of the simulation as well as of the experimental measurement are defined as follows, whereby OrCAD–Pspice was used for simulation analysis:

- -

VIN = 100 V

- -

Switching frequency (fSW) = 100 kHz

- -

VOUT = expected based on voltage gain = 400 V

- -

POUT = 1 kW (2.5 A)

- -

Duty cycle = D1 = D2 = range 0.1–0.45

- -

Voltage gain = 3.6 (N1 = N2 = 6, N3 =10 ≥ TR = 1:1.7)

- -

Inductor core = feroxcube EI43/3F3 planar

- -

Power transistors = Cree C3M0065100K

- -

Power diodes = STPSC1206D

- -

Input capacitors = 3 × 390 µF/160 V SAMWHA

- -

Output capacitors = 4 × 22 µF/450 V Wurth Electronic

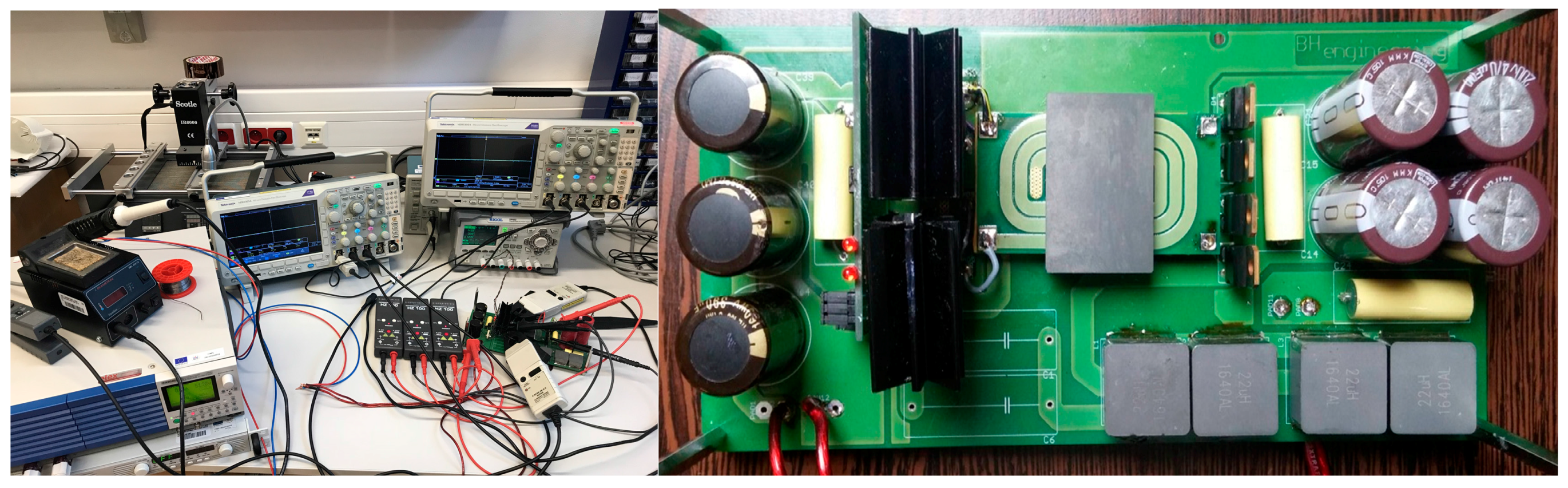

The experimental prototype of the proposed converter is shown on

Figure 10. The four-layer PCB was used for power stage. Control stage is realized with the universal board equipped by MCU, in order to provide various experiments related to the investigation of the steady-state performance. The integrated interleaved magnetics is equipped within planar technology, whereby EI E43 3F3 planar core was used.

4.1. Steady State Operation—Principal Waveforms

Initial experiments were performed in order to investigate the operational waveforms on the individual main components of the proposed converter within steady-state operation. Comparisons between simulation and measurements are given.

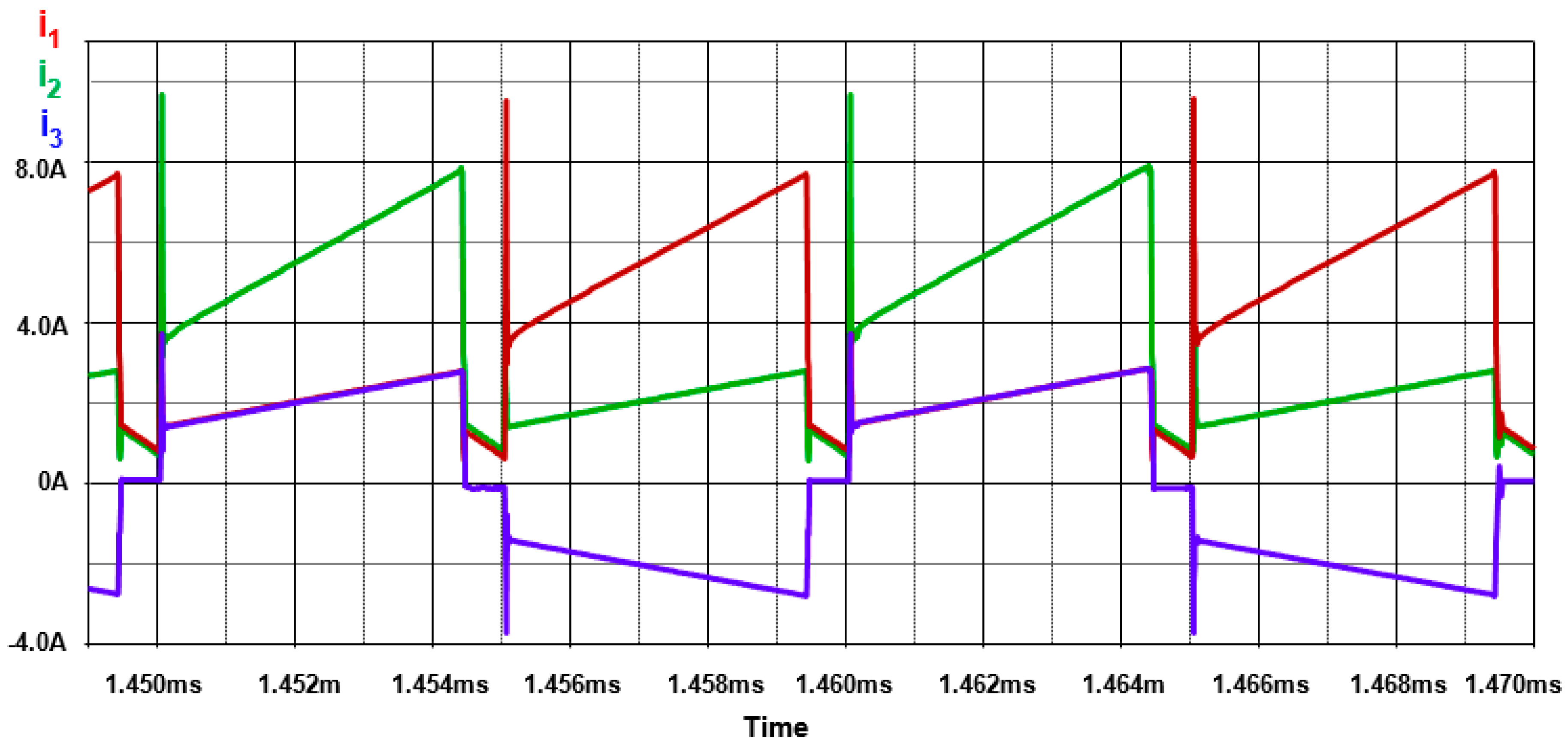

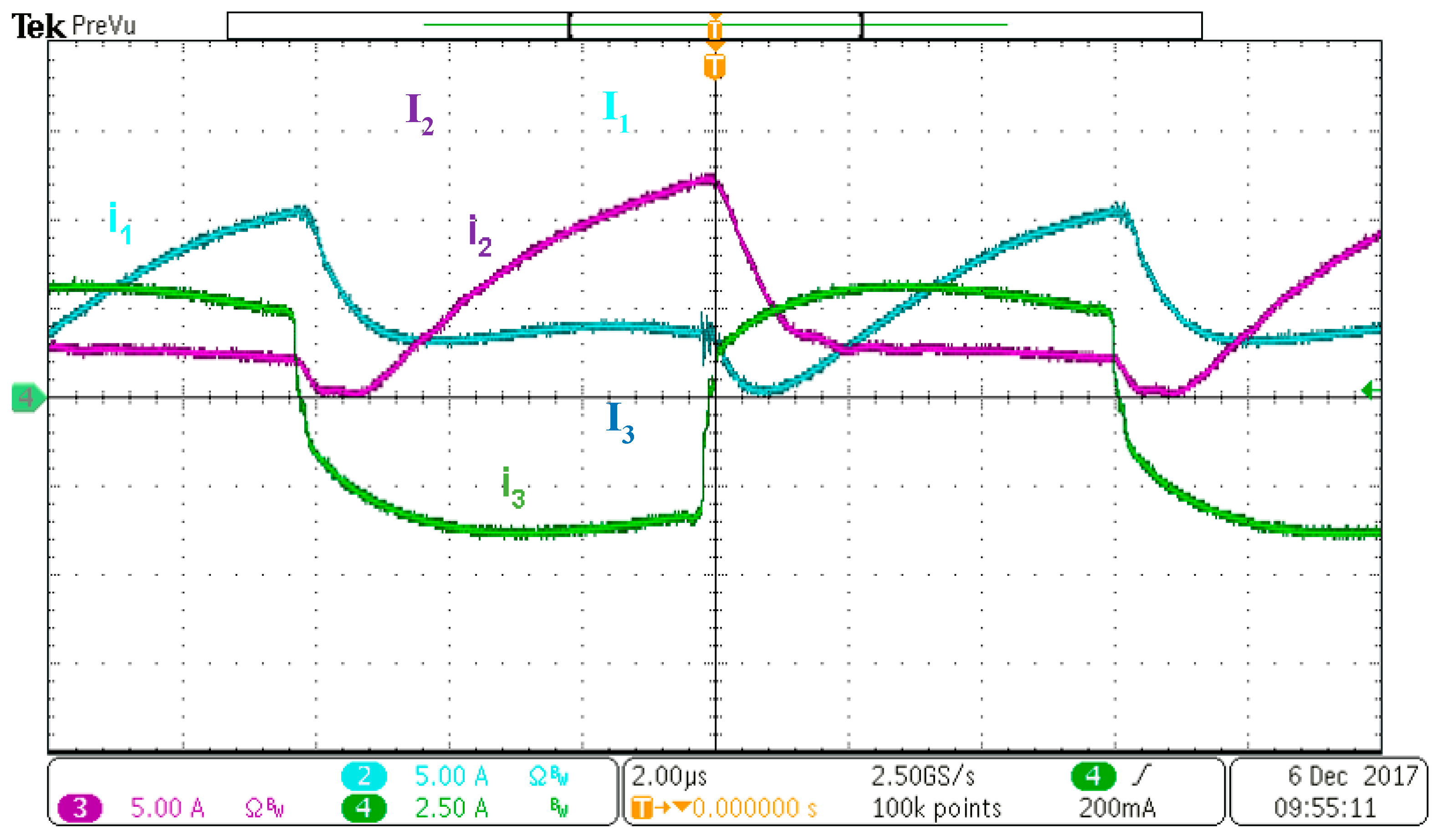

Figure 11 and

Figure 12 show current waveforms of individual inductors. It is seen that the current of the boost inductors

L1 and

L2 has DC offset and is of DC character. This fact may saturate the core of the inductor because of the existence of the DC component, but as can be seen, current through the reset inductor

L3 is a product of the current

i2 and

i1 and has AC character. Therefore the core of the proposed converter will not be saturated by the DC component, which is beneficial because a lower volume of the inductive component can be used, or higher power at the same size can be delivered considering an alternate interleaved converter.

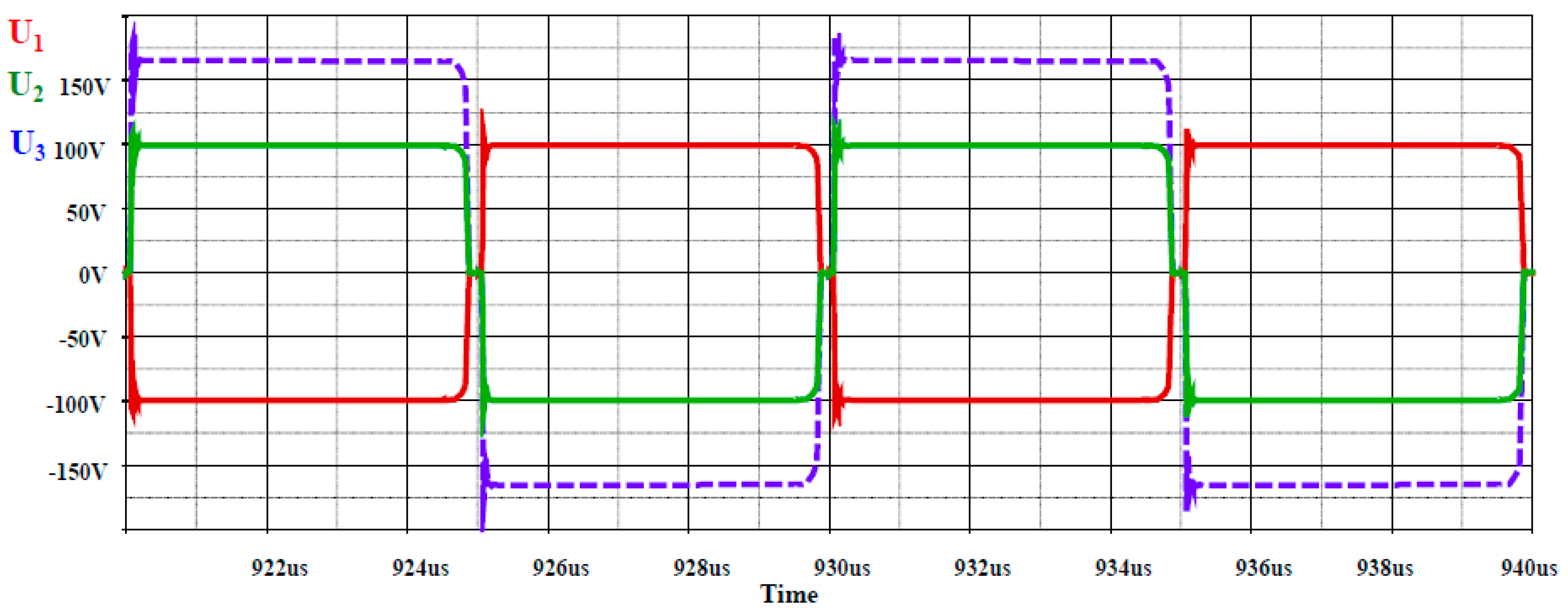

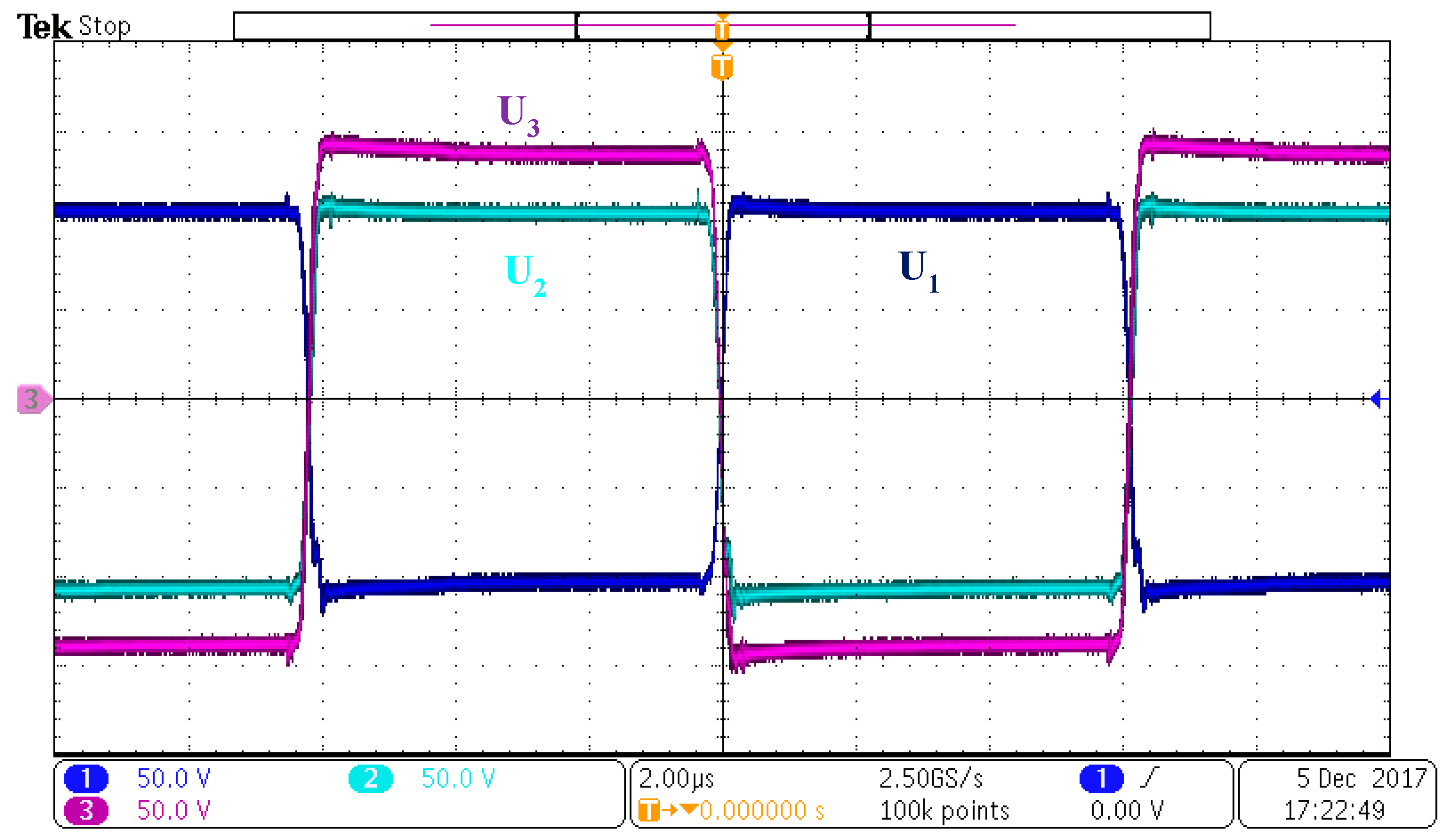

Figure 13 and

Figure 14 show the voltage waveforms on the individual inductances. It is seen again that the voltage on the

L3 is of different amplitude compared to the both voltage waveforms on the

L1 and

L2. This is relevant to the voltage gain modification through the turn ratio. In this case, it was set to 10:6, thus the voltage on the inductance

L3 shall be 1.6 times higher the voltages on the inductances

L1 and

L2, whose amplitude is equal to the amplitude of the supply voltage. This is confirmed both by the simulation and by the measurement.

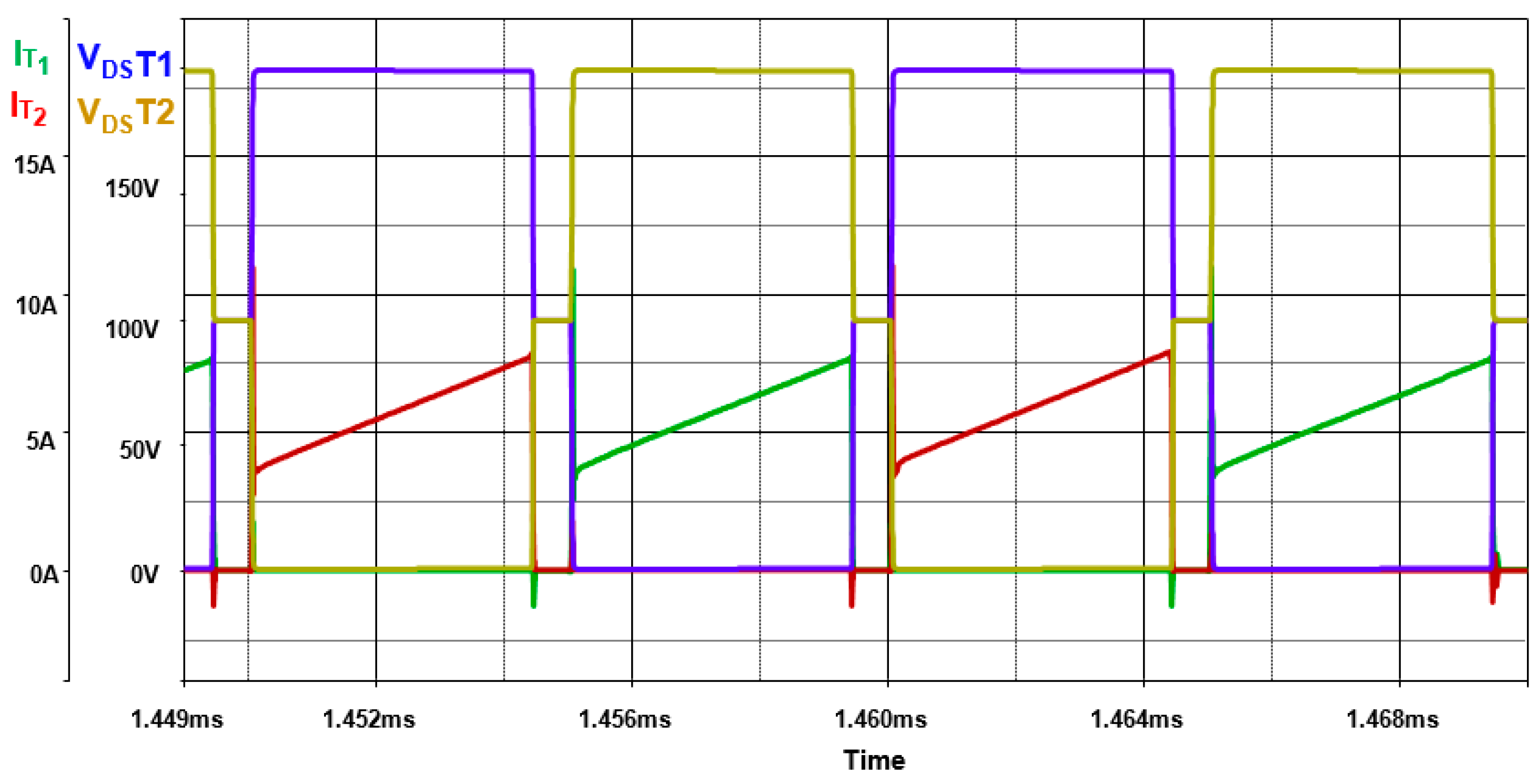

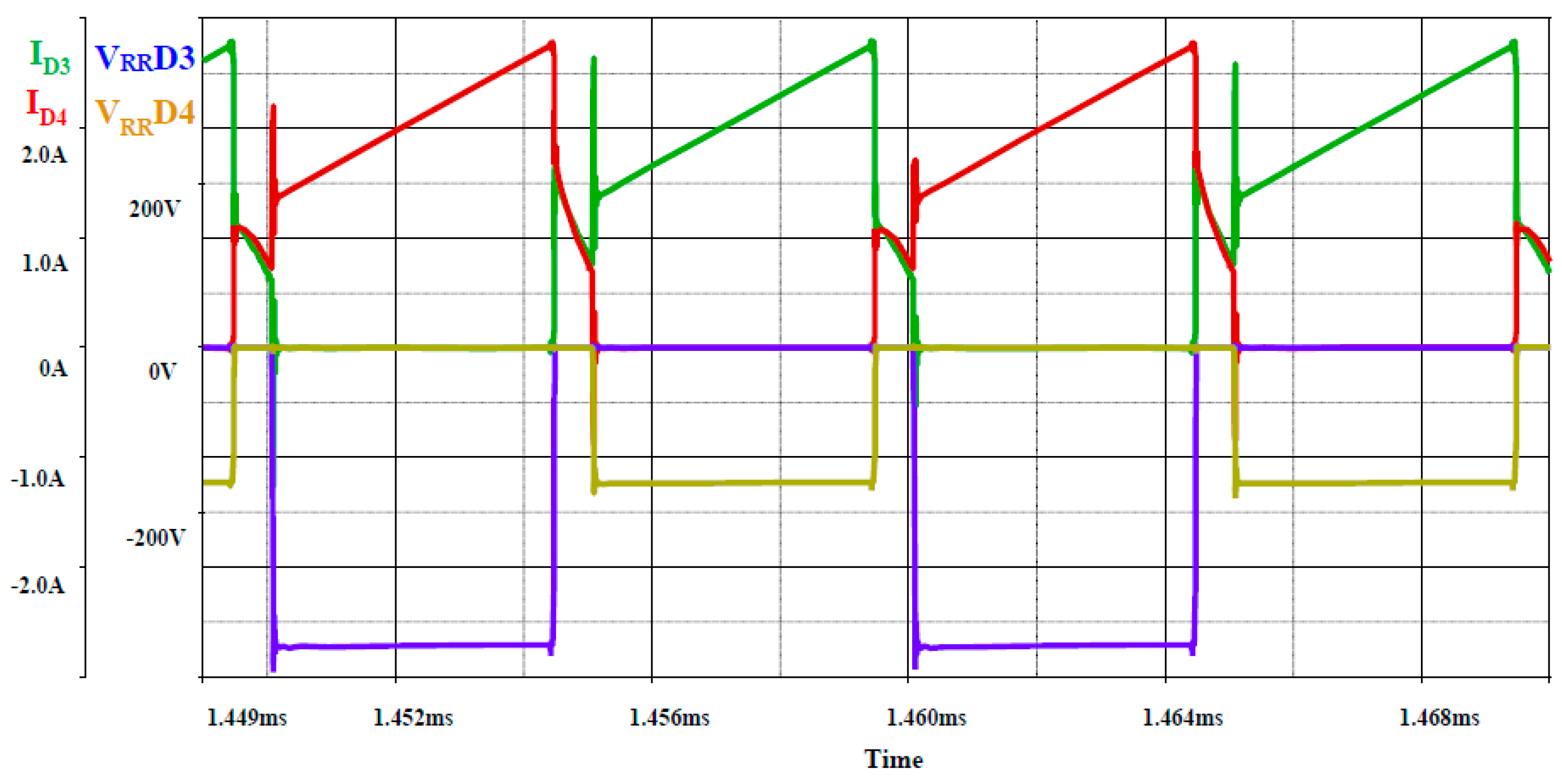

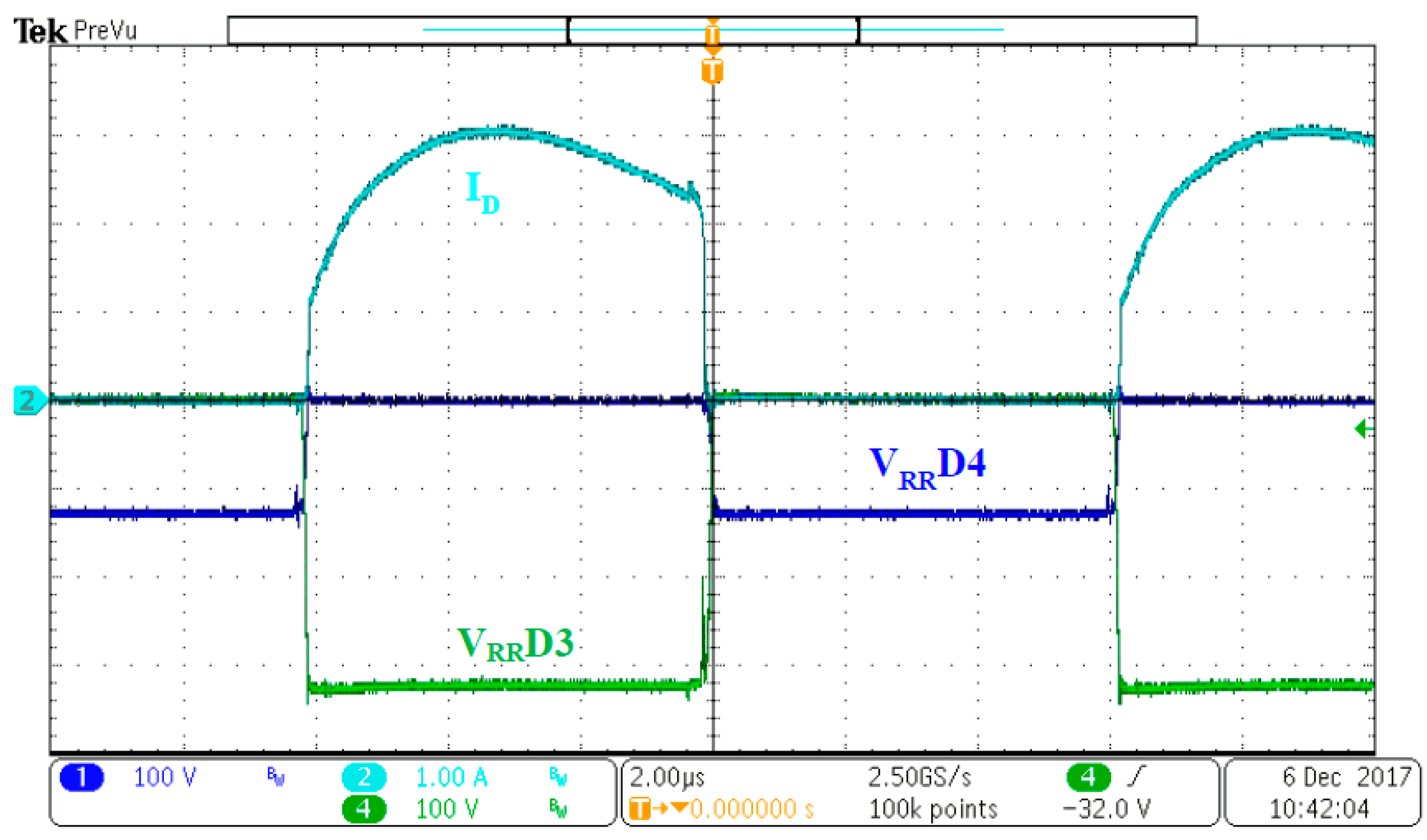

Figure 15,

Figure 16,

Figure 17 and

Figure 18 show current and voltage waveforms of the semiconductor devices. The converter is operating in the hard-switching mode, while waveforms are relevant to the basic operational characteristics of the boost converter. Thus, switching losses will be the most important part of the losses affecting the system efficiency. For that purpose, the proper selection of semiconductor devices will be important, or implementation of the soft switching technique shall also be considered.

Further investigation of the proposed converter is focused on the efficiency behavior within whole operational range, i.e., at various power levels and consequently the identification of the voltage transfer characteristic is done in dependency on the duty cycle, as well as on the value of turn’s ratio.

4.2. Operational Characteristics

4.2.1. Efficiency, Output Voltage = f (Output Power), Duty Cycle = Constant

Within this part of investigation several measurements were taken in relation to the efficiency performance, and output characteristic of the proposed converter was investigated. The measurements were taken for the variable power at constant duty cycle, i.e., at

D1 =

D2 = 0.45. Change of load was in the range of 10–100%.

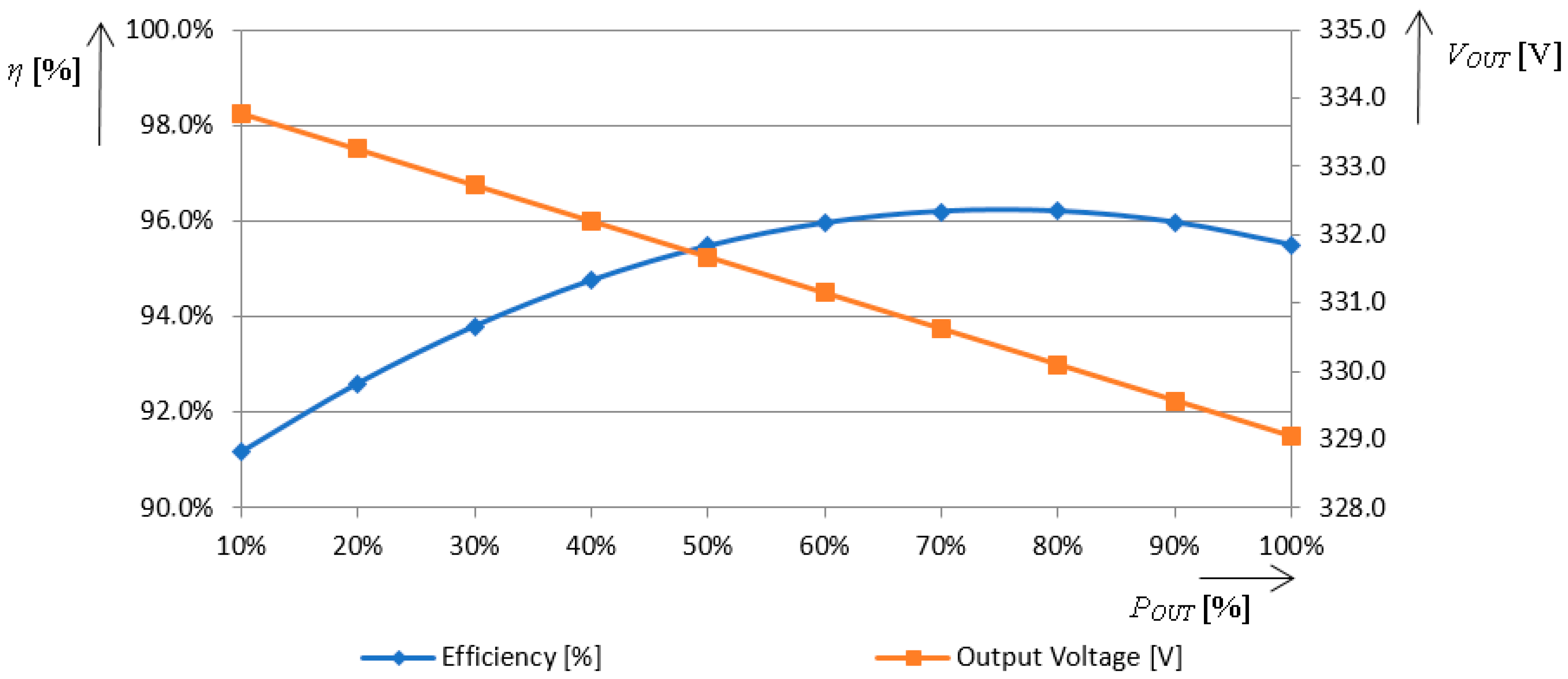

Table 3 shows individual values of the efficiency and the value of the output power in dependency on the output power. This is graphically interpreted in

Figure 19.

It is seen (

Figure 19) that the efficiency curve is flat when considering whole operating range, and system efficiency is not below 90%. This is a beneficial behavior for low-load conditions, whereby maximum efficiency is achieved at around the point of the maximal power, i.e., at 900 W, where efficiency is above 96%. It can be seen that the value of output voltage is not affected when considering the change of the output power. The converter has stiff behavior when the voltage drop from low load to the full load is 4 V. This behavior is highly valuable in applications where stiff DC voltage is required, i.e., for a DC bus for inverter stage.

Figure 20 shows power loss analysis based on Equations (26)–(37). The total calculated power loss is 40.53 W (

Table 3) within the peak efficiency of the converter (96.2%). At nominal output power, the efficiency of the converter is 95.5%, which is related to the power losses at the value of 47.15 W. Because the proposed converter operates at hard-switching commutation mode, the highest portion of the losses belongs to semiconductor devices (more than 85% of total losses belong to switching losses). Therefore, proper selection of transistors and diodes are critical for efficiency performance of the proposed converter.

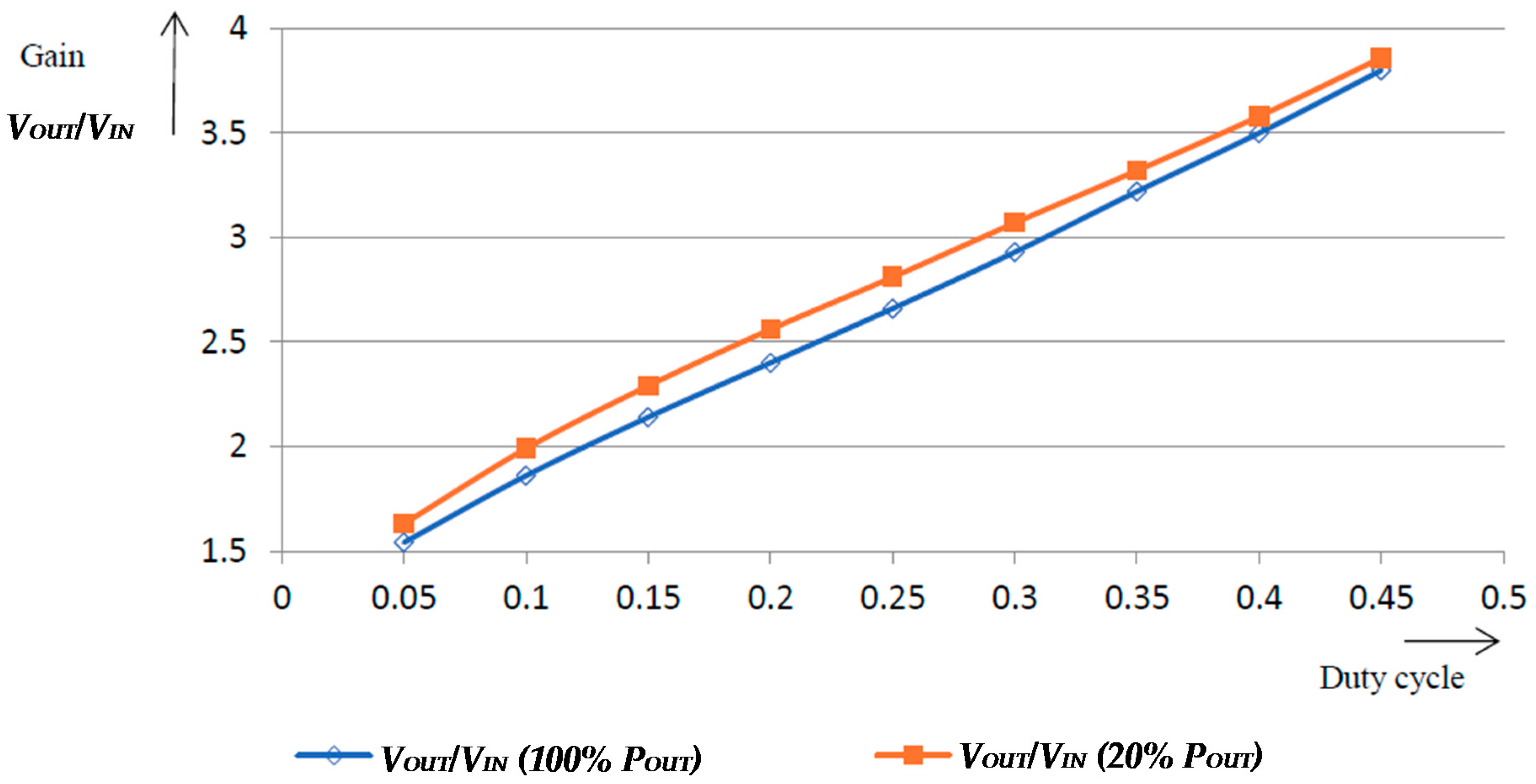

4.2.2. Voltage Gain = f (Duty Cycle), Output Power = 100%, 20%

Consequently, the investigation of the voltage gain in dependency on the duty cycle was performed. The results are listed in

Table 4, wherein two situations have been considered. The power load of 20% and 100% was defined within measurements. From the table it can be seen that the change of the load has very low effect on the change of the value of voltage gain. The voltage gain characteristic in dependency on duty cycle is shown on

Figure 21. At a given turns ratio, the voltage gain can be adjusted through the duty cycle modification in the range of 1.5–3.8.

4.2.3. Voltage Gain = f (Inductance Ratio), Duty Cycle = Constant

The last investigation within the steady-state performance of the converter related to the voltage gain characteristic was realized by way of the turn’s ratio modification. Within this experiment the number of turns on the boost inductors

L1 and

L2 was left constant, while the change of the turns on the reset inductance

L3 was provided. The duty cycle within this experiment was constant and equal to

D1 =

D2 = 0.45. The range of the turn’s ratio was done within 1–8. The following

Table 5 and

Table 6 show the dependency of the voltage gain on the turn’s ratio. It can be seen (

Figure 22) that this dependency is in linear relationship, thus with the increase of the turns on the reset inductance, the higher voltage gain can be achieved. It is a beneficial property of this proposed converter’s topology, because the range of the output voltage can be considerably increased.

4.3. Comparisons of Proposed Converter Performance to Other Circuit Alternatives

The given properties of the proposed converter are compared to the standard dual-interleaved boost type converter and to the classic boost converter. The input–output parameters are considered to be similar to those specified at the beginning of chapter 4, thus 1 kW output power supplied from input voltage source 100 V

DC, switching frequency is 100 kHz. The voltage gain of all converters was set to

VOUT/

VIN = 3.6. The results from the analysis related to the operational parameters/characteristics are listed in

Table 7.

From

Table 7 it is seen that the proposed converter has advantages related to the overall efficiency rated at full output power; even the number of components is higher. This is related to the fact that much a lower magnetic core can be used, while its performance is improved also by the fact that the AC component is continuously flowing through its circuit. In this way, core losses and hysteresis losses are much lower, because DC magnetization is eliminated. The value of bulky output electrolytic capacitor can be more than 10 times lower compared to the standard solution, and through this it is possible to eliminate losses related to parasitic ESR of electrolytic capacitor. Even when the value of capacitor of the proposed converter is very low, the output voltage ripple is more than 10 times lower compared to the interleaved boost converter and more than 25 times lower compared to the standard boost converter. The advantages are also related to the input current ripple, while due to the existence of an AC component in the circuit, the current ripple can be minimized compared to standard topologies. On the other hand, it is seen that the voltage gain of the proposed converter has limitations compared to other topologies, which is related to optimal selection of turns ratio between inductances

L1,

L2 and

L3.

5. Conclusions

Within this paper a new perspective topology was introduced. It is an interleaved boost converter with the core reset additional inductance. The existence of this inductance enables within each operational period of the converter a reset of the magnetic core, where all inductors are implemented. The AC waveform of the current flows through this inductance, thus the saturation of the core by the DC component is not critical, as opposed to the other standard interleaved boost topologies.

The steady state operation is described in more detail, while the main focus was placed on the efficiency, and voltage gain performance. It is seen that efficiency is competitive in the whole operational range, with the best-in-class topologies of power converters. Further improvements can be done with the implementation of a soft-switching technique, which will be the task for the future work. Voltage gain can be modified two ways, i.e., with the change of the duty cycle, or with the selection of the turns ratio between boost inductances and reset inductance. This feature will be valuable in applications where very high voltage gain is required. On the other hand, special focus must be given to the integrated magnetics design; this will also be a topic of the future research. Meanwhile, the highly advantageous characteristic of the proposed converter is its very tight output voltage character in the whole power range. This feature is highly appreciated in applications, such as the DC bus circuit, where requirements for stable voltage are given.

As mentioned, future work should focus further on efficiency improvements, and also on the dynamic and control analysis.