1. Introduction

Doubly-fed induction generator based wind turbines (DFIG-WTs), due to their high efficiency, variable-speed constant-frequency (VSCF) operation, bidirectional power flow regulation capability, and small power electronic converter size, are widely installed, which takes over 50% of the total number of wind turbines all over the world [

1,

2,

3,

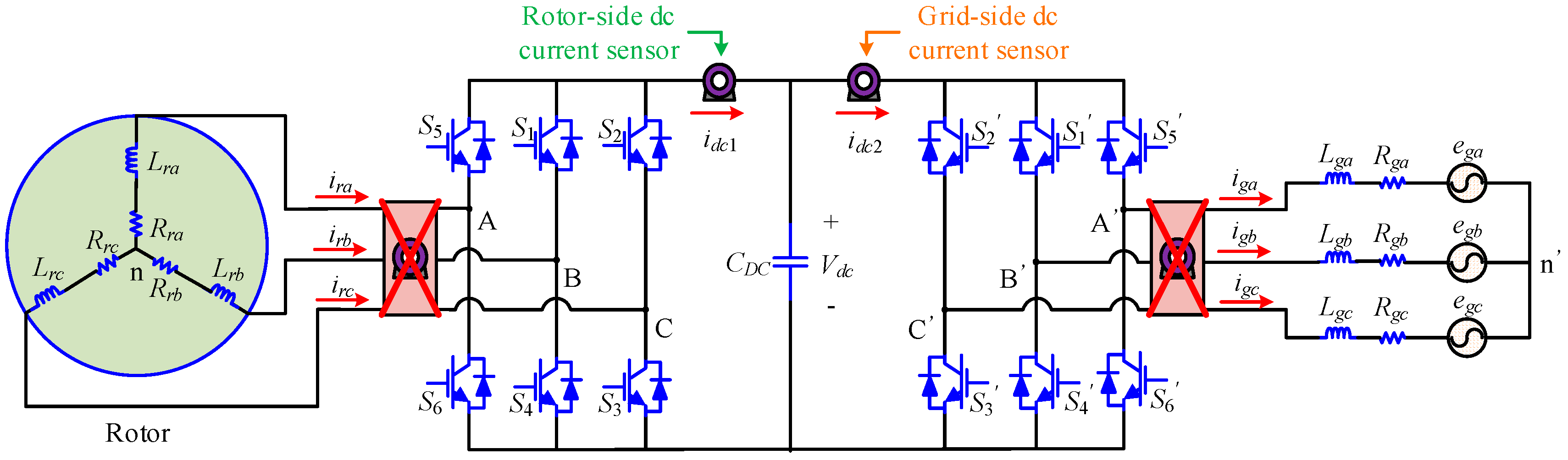

4]. Different from a fully rated wind energy conversion system (WECS), which is usually based on a permanent magnet synchronous generator (PMSG), the stator of DFIG-WT is directly connected to the grid, while the rotor is fed by a back-to-back (BTB) converter [

5]. By employing this topology, the overall volume and cost of the power electronic converters are greatly reduced since only the slip power is to be regulated. However, a more complex control system is introduced. The rotor-side converter (RSC) and grid-side converter (GSC) are independently controlled, and the three-phase currents in the stator and GSC are separately measured, which means that more current sensors are equipped, adding to the hardware complexity. In addition, the rotor speed and position information should be captured by using a speed/position sensor. Therefore, the reliability of these sensors in the control system of DFIG-WT is of paramount significance to the normal operation of doubly-fed induction generator (DFIG) WECS.

It was reported in [

6] that the failure rate of electrical control subsystem is around 40% for a wind turbine (WT) per year, which takes the second highest frequency of failure, and it is only lower than that of electrical system in WT. According to [

7], over 14% of failures of WTs are caused by the failure of sensors. At the late stage of DFIG-WTs, the failure rate of each device swiftly increases, and it is highly possible that different categories of sensors are out of service at the same time. For example, the phase current sensors and speed/position sensor fail simultaneously, which is a severe sensor failure scenario, and the information of phase currents, rotor speed and position is lost, leading to the fact that the DFIG-WT becomes uncontrollable and has to disconnect from the grid. Especially for an offshore WT, once there is a fault that impedes the normal operation, maintenance will not be taken immediately due to high maintenance cost and low accessibility [

8]. Therefore, a hybrid fault-tolerant strategy for dealing with the severe sensor failure scenario is proposed in this paper.

To obtain the rotor speed and position information, mechanical and optical sensors are usually installed in the control system of an electrical machine [

9]. In addition to the increased hardware complexity and system cost, the reliability of control system is reduced as these sensors are prone to fail [

10]. Therefore, different sensorless control schemes were proposed in response to the aforementioned disadvantages, which can be classified into the methods based on signal injection [

11,

12,

13] and mathematical modeling [

14,

15,

16,

17]. Usually, the latter one is chosen for controlling induction machines (IMs) in high speed scenarios, which is also applicable for DFIG-WTs.

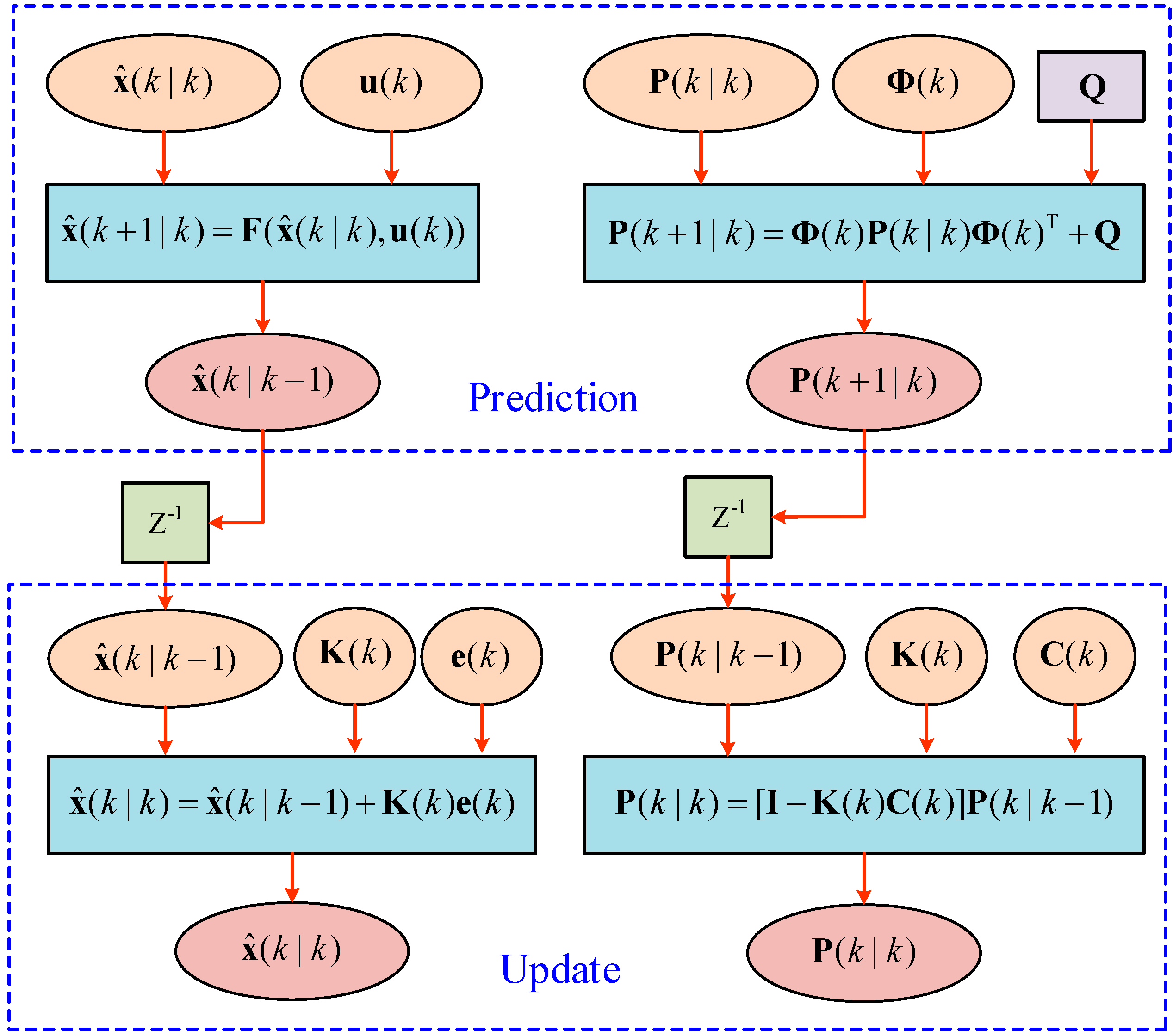

Apart from the deterministic sensorless control schemes, stochastic approaches can also be employed, where Kalman filter (KF) [

18] is a representative of this kind of method. By taking the system uncertainties and measurement errors into account, the KF continuously minimizes the difference between the real value and the estimated one. However, for a nonlinear system, proper linearization has to be performed, which can be accomplished by applying the extended Kalman filter (EKF) algorithm [

19,

20]. In [

21], position sensorless control of an interleaved current source inverter (CSI) fed permanent magnet synchronous motor (PMSM) drive was presented with EKF. In addition, the design and implementation of a field-programmable gate array (FPGA)-based sensorless PMSM speed control were performed with the employment of a reduced-order EKF (ROEKF) in [

22], where the iteration process was significantly simplified. Besides, several studies were published to investigate modified EKF algorithms for controlling IMs. A bi input-EKF was applied in [

23,

24] to overcome the simultaneous estimation problem caused by the variations in stator and rotor resistances. A robust ROEKF was researched in [

25] to demonstrate its superiority over an ordinary ROEKF. In [

26] an interfacing multiple-model EKF was applied in the speed-sensorless vector control for IM. On top of that, the research of a speed sensorless finite-state predictive torque control (FS-PTC) based on EKF was carried out for IM sensorless control in [

27]. However, there is rare literature focusing on the EKF algorithm for DFIG-WT. In [

28], a suitable model was proposed for estimating the mechanical variables of DFIG. In [

29], an EKF was proposed as the rotor position estimator and the observability of the DFIG was analyzed. Nevertheless, the methods proposed in these studies are only applicable when other devices are healthy, and complicated operating conditions are not considered.

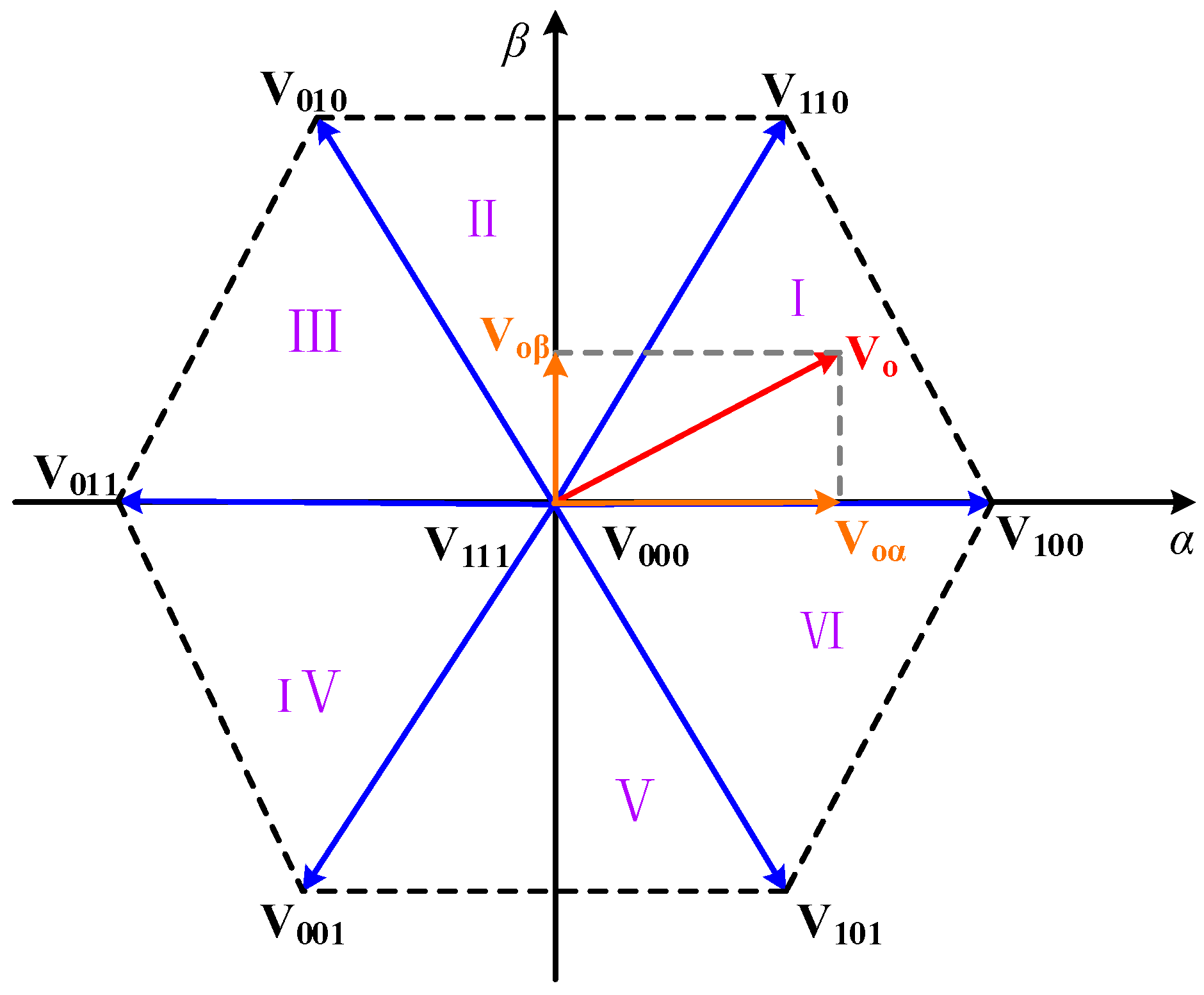

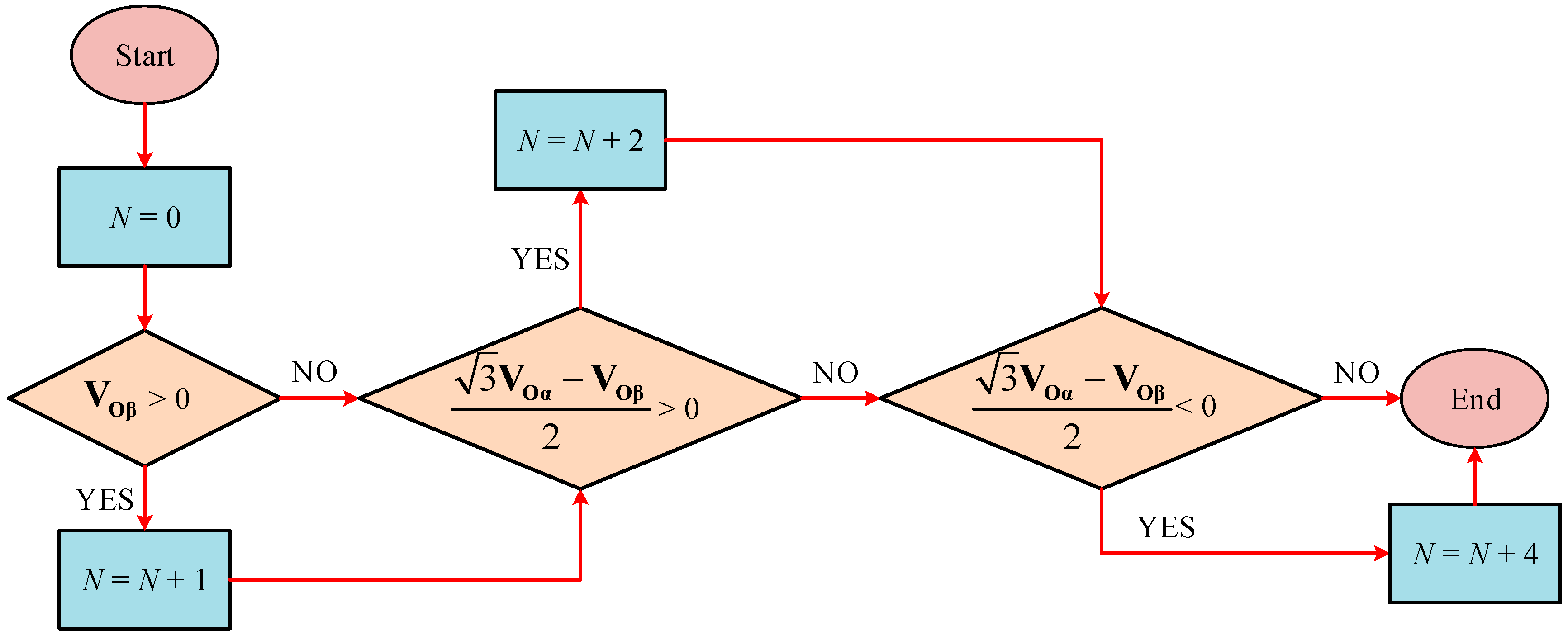

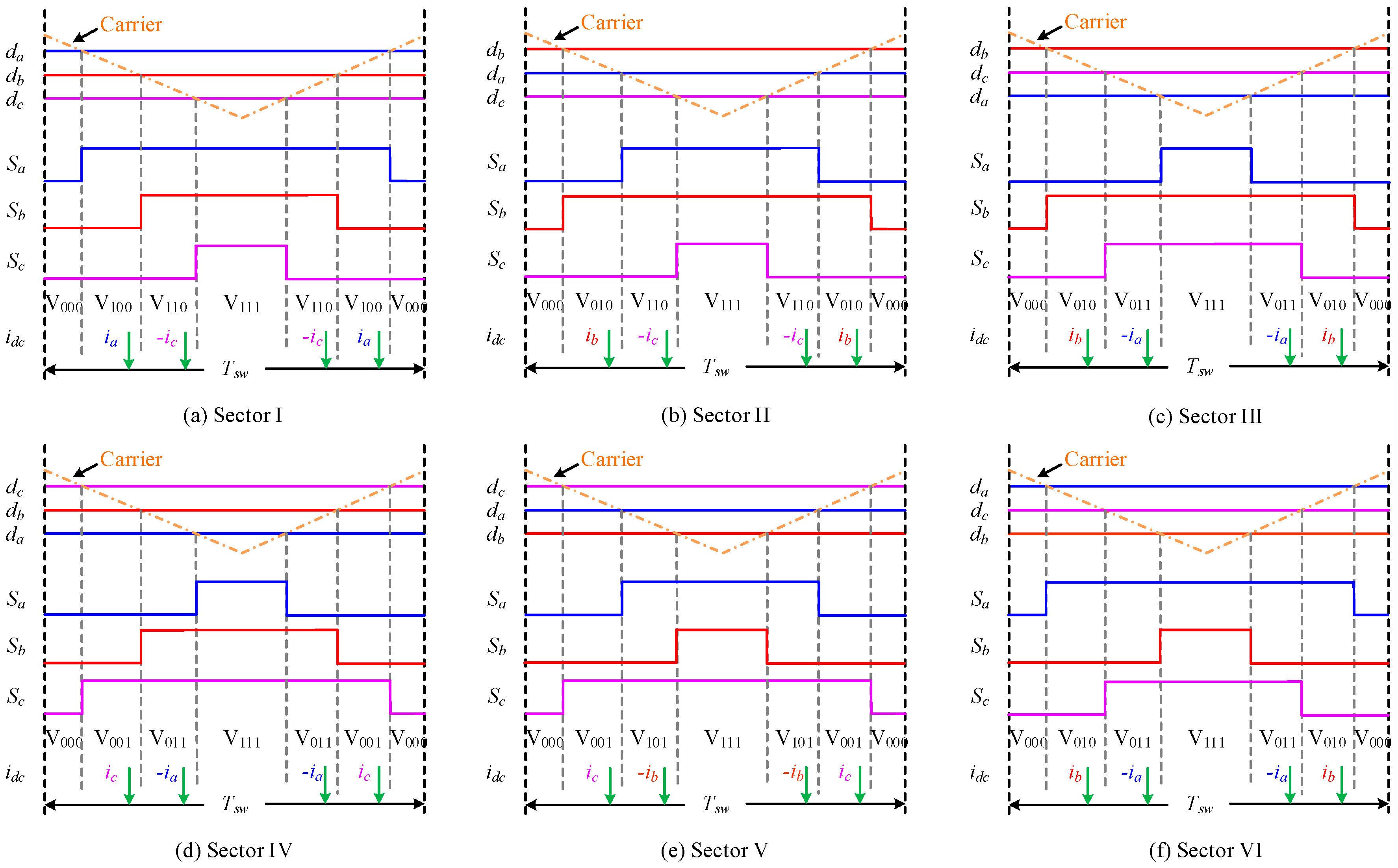

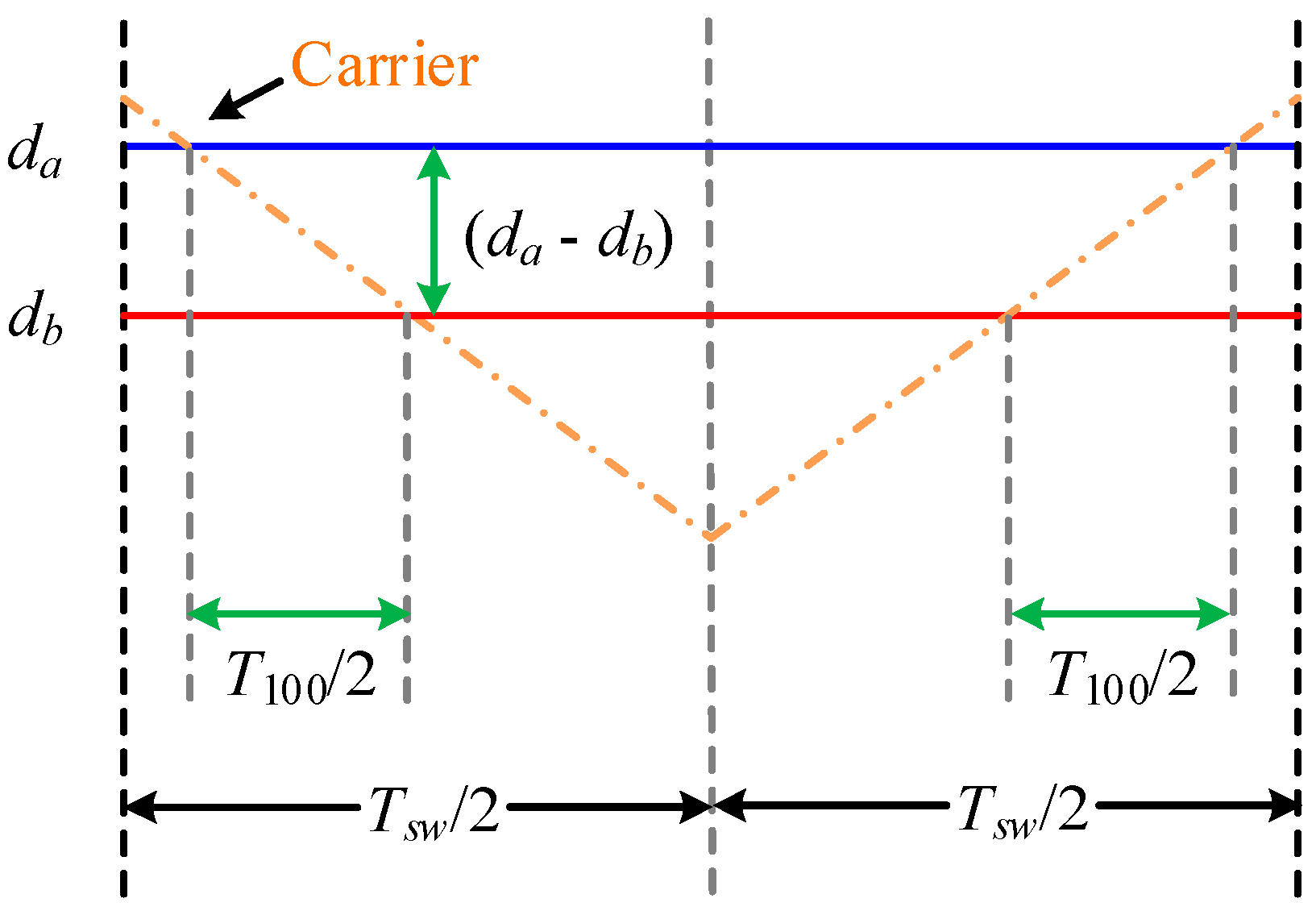

In a three-phase AC/DC or DC/AC converter, two phase current sensors and a DC-link current sensor are required for obtaining phase current information and preventing the DC bus from overcurrent. To reduce the cost and increase the system reliability, the phase currents can be reconstructed according to the current information derived from the DC-link current sensor and the switching states [

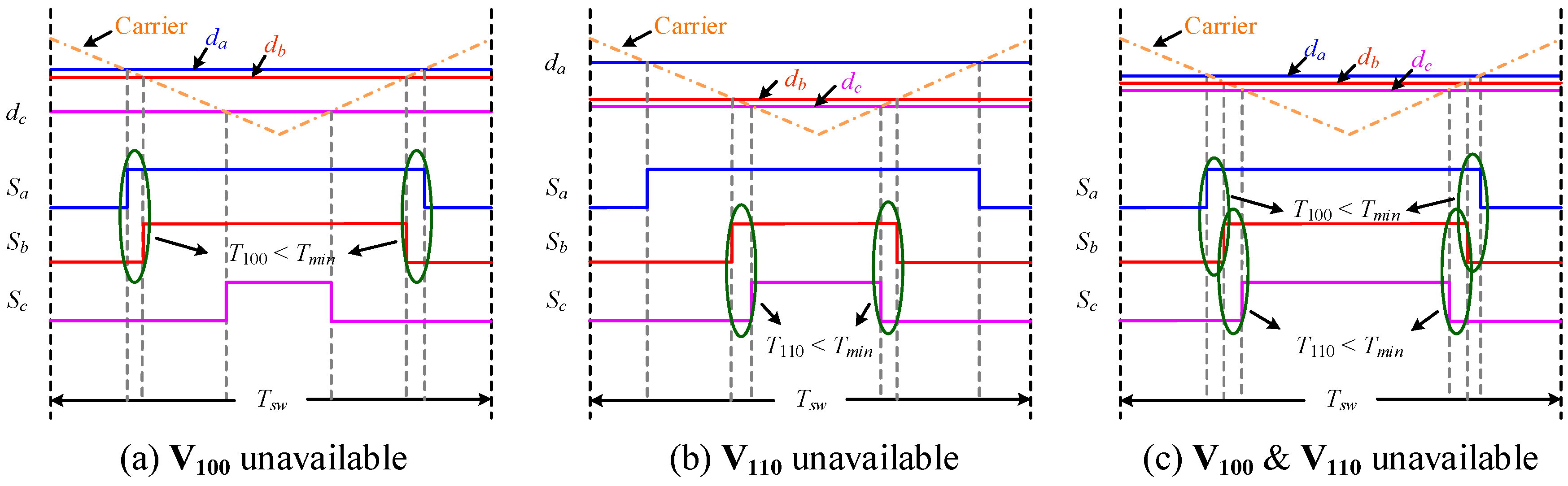

30]. Therefore, only one current sensor is required for providing current signals for the DFIG control system. However, immeasurable regions are created when the action time of a targeted switching state is shorter than the minimum required sampling time. A switching state phase shift method was proposed in [

31] to prolong the action time for the targeted nonzero switching state so that correct current information can be obtained. While unsymmetrical pulse width modulation (PWM) waveforms are induced, which results in poorer current quality. In addition, the phase currents can be reconstructed based on current prediction strategies [

32]. By combining the advantages of space vector pulse width modulation (SVPWM) technique and carrier-based PWM method, a hybrid PWM technique was proposed in [

33], while the computational complexity increases. An overmodulation method was proposed in [

34], which avoided voltage vector error and reduced the total harmonic distortion (THD). In [

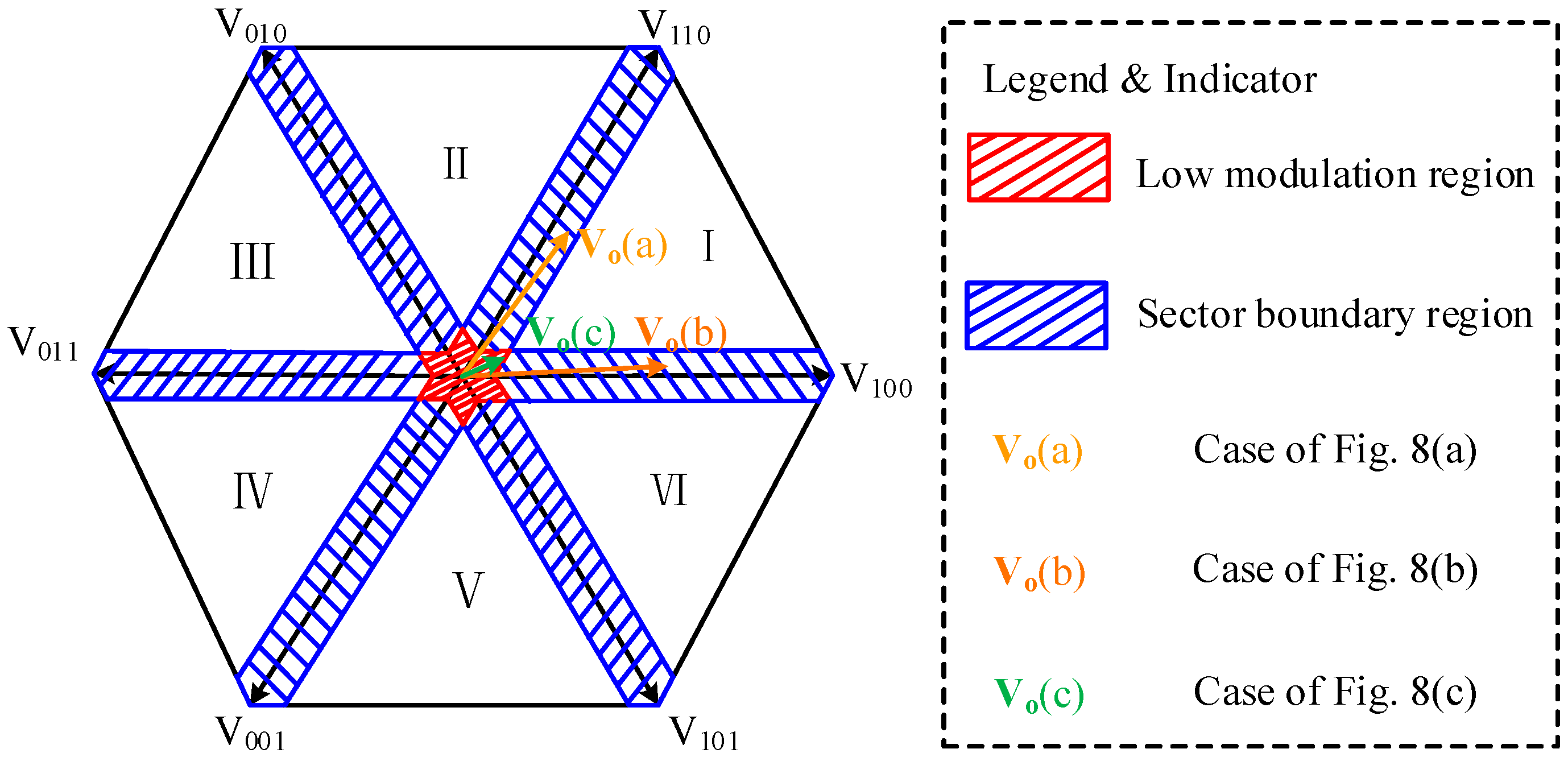

35], a tri-state PWM (TSPWM) strategy was proposed for obtaining the three-phase current information by using a single DC-link current sensor. Fixed sampling points are enabled in this method, and it is possible to enlarge the measurable area to almost the whole hexagon of SVPWM diagram, while high THD is induced in the low modulation region. Without modifying the PWM signal, a zero voltage vector sampling method (ZVVSM) [

36] was proposed for phase current reconstruction to move the immeasurable regions to the edge of the SVPWM hexagon. However, the practical issues of wiring and choosing the type of current sensor are encountered.

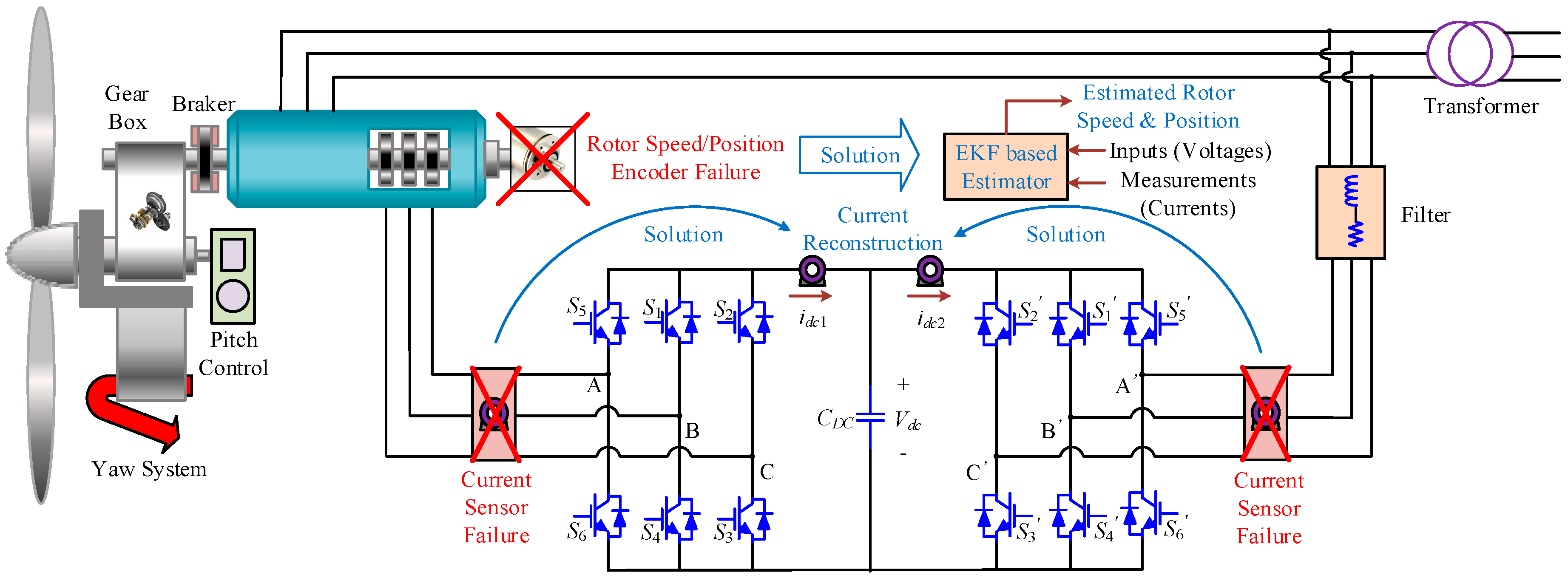

In this paper, a hybrid fault-tolerant strategy for simultaneous failures of the phase current sensors and speed/position sensor is proposed to strengthen the reliability of late-stage offshore DFIG-WTs. A duty ratio adjustment method is proposed to improve the quality of phase current reconstruction, and the corresponding compensation strategy is put forward to avoid the variations in the amplitude and orientation of the reference voltage vector. By employing this strategy, the implementation is easy to realize, and heavy computational burden is not required. Additionally, the 7th-order dynamic model of DFIG is deeply analyzed and the robustness of EKF to system uncertainties and measurement noises is demonstrated in the sensorless control process. The accuracy of rotor speed and position estimation is investigated when wind speed step change and noises are considered. The severe senor failure scenario considered in this paper is displayed in

Figure 1.

The paper is arranged in the following structure: In

Section 2, the DFIG-WT modeling is carried out in terms of the wind turbine model, DFIG dynamic model and state space model. Then, the sensorless control of DFIG-WT based on the EKF algorithm is explained in

Section 3. In

Section 4, the phase current reconstruction strategy in BTB converter of DFIG-WT is illustrated in detail, and the proposed duty ratio adjustment scheme is presented. In

Section 5, the simulation results are displayed with analysis and discussions of the proposed hybrid fault-tolerant sensorless control scheme. In

Section 6, the discussion and future work in an experimental rig are explained. Finally, the conclusion is derived in

Section 7.

5. Simulation Results

When the severe sensor failure scenario occurs in DFIG-WT, the EKF based position sensorless algorithm and the single DC-link current sensor based phase current reconstruction method are applied simultaneously to maintain continuous operation of the system. The control block diagram of the hybrid sensorless control strategy for post-fault operation of DFIG-WT is illustrated in

Figure 12, which is to be verified by simulation studies in Matlab/Simulink2017a (MathWorks, Natick, MA, USA).

The rotor speed and position are estimated by applying the EKF algorithm based on the 7th-order DFIG dynamic state space model. By measuring the DC-link currents

idc1 and

idc2, along with the duty ratios for the RSC and GSC, the rotor-side and grid-side three-phase AC currents are reconstructed. In the simulation process, the post-fault operation of a 1.5 MW DFIG-WT is investigated, with the initial slip set as −0.2, and the initial rotor position equals 0. The sampling time

Ts is set to 5 μs. The system parameters for the 1.5 MW DFIG-WT are shown in

Table 6.

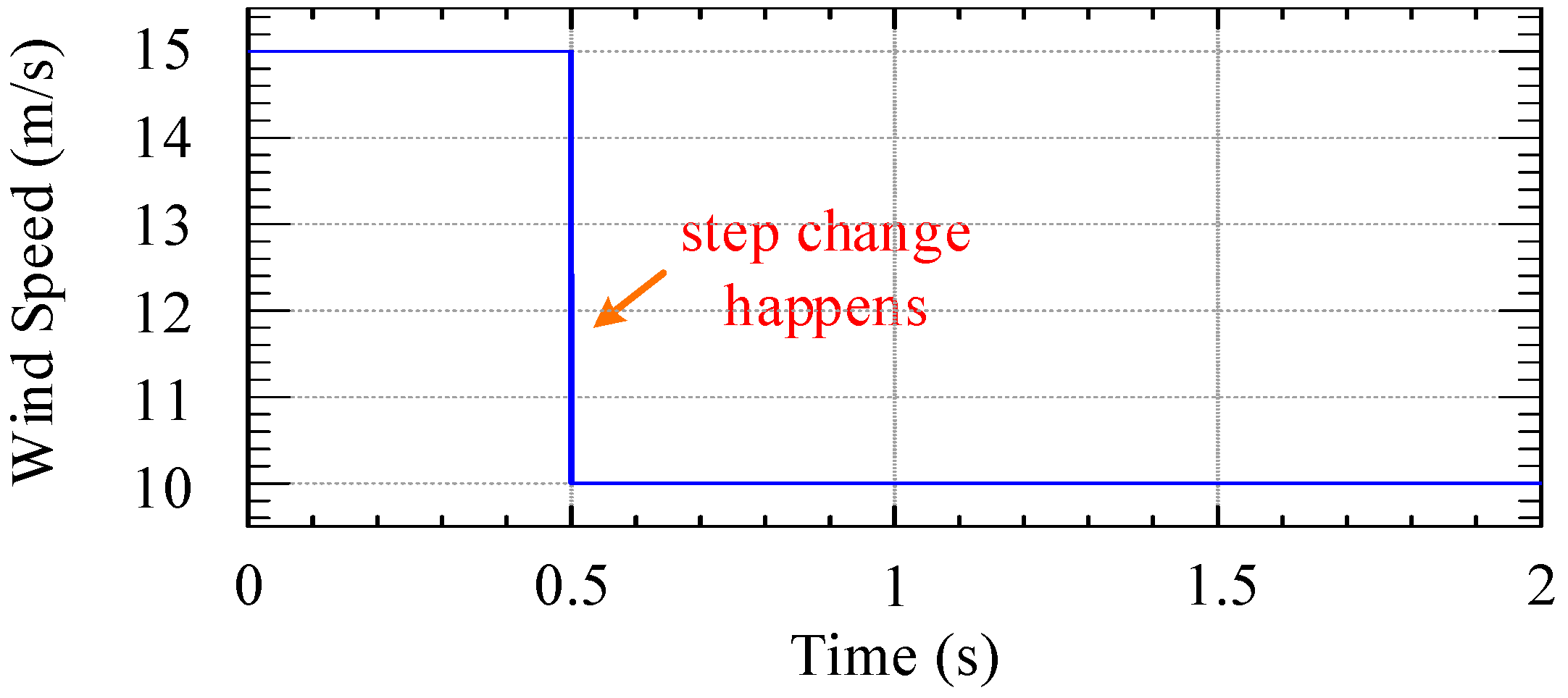

In the simulation study, the wind speed change from 15 m/s to 10 m/s at

t = 0.5 s is considered to verify if the estimated or reconstructed values track the real values well. The graph of wind speed is shown in

Figure 13. All the simulation results shown in this section are derived by considering wind speed step change from 15 m/s to 10 m/s at

t = 0.5 s.

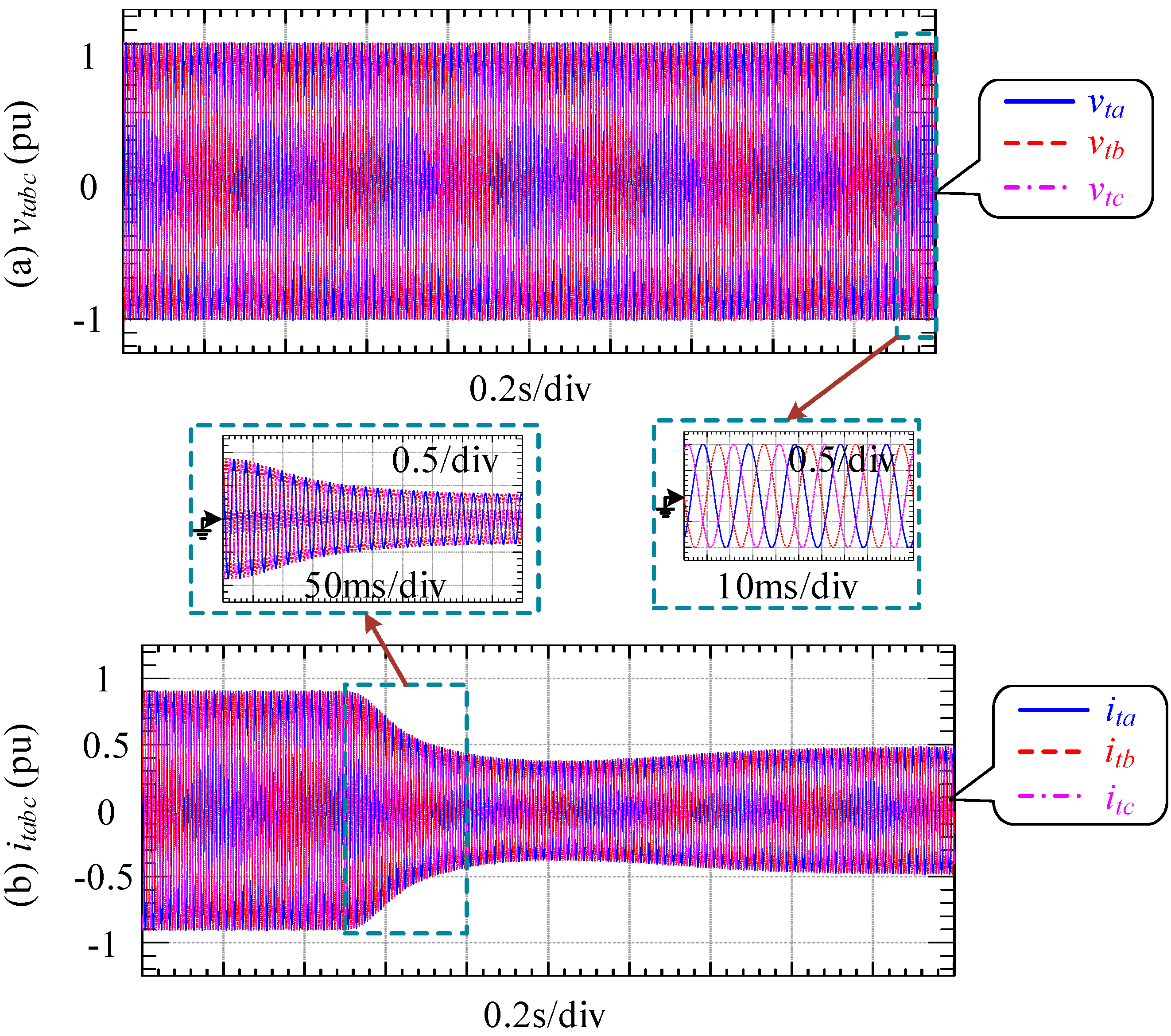

Therefore, the total output electrical power decreases at 0.5 s, and the three-phase total output voltages and currents to the AC grid are displayed in

Figure 14.

In

Figure 14, it can be seen that the amplitude of the phase current drops to around half the original value to maintain the balance between the input mechanical power and the output electrical power.

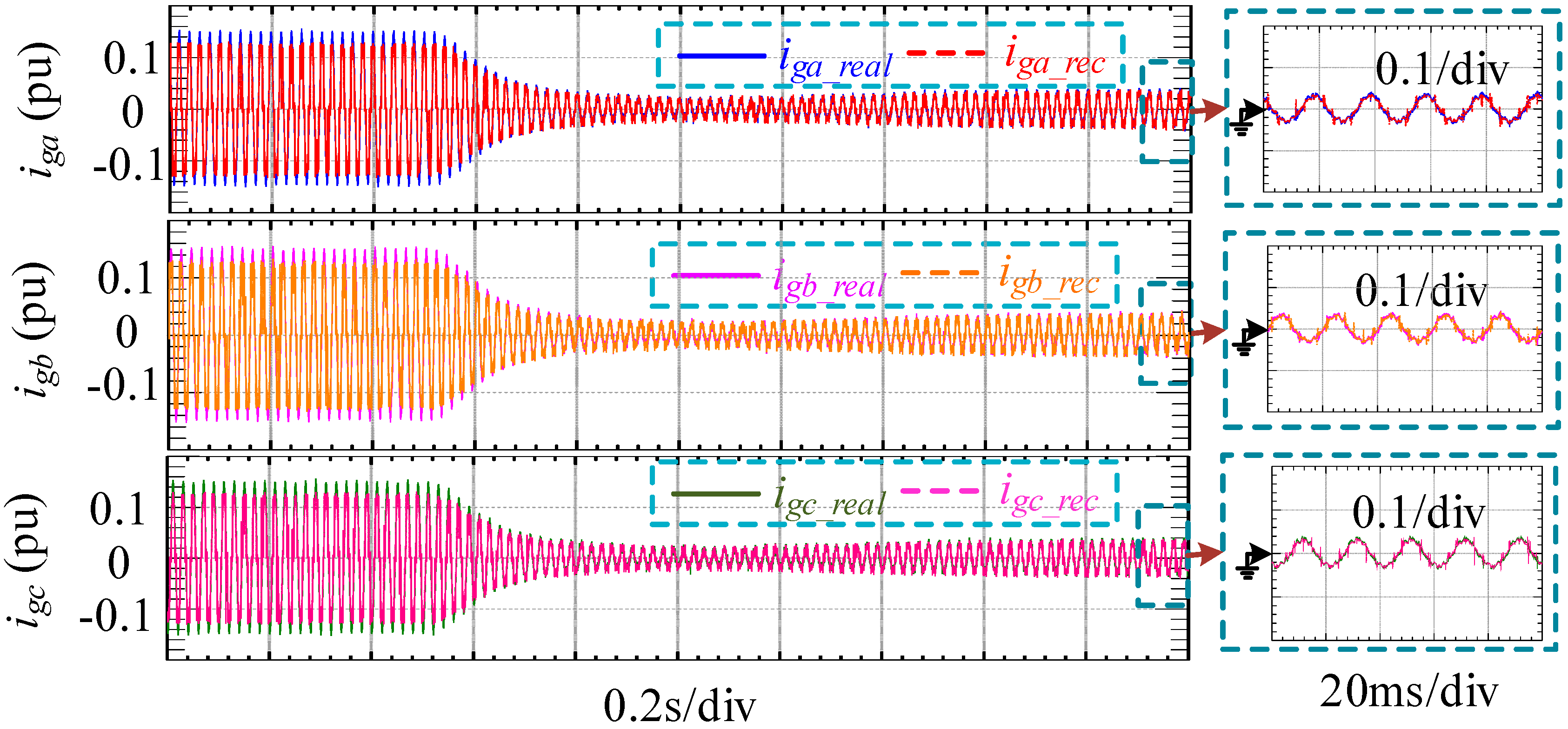

The three-phase currents are reconstructed to replace the functions of phase current sensors, and only a DC-link current sensor is required in this case, which saves the cost and improves the fault-tolerant ability of the control system. The real and reconstructed three-phase GSC AC currents are presented in

Figure 15.

It can be seen in

Figure 15 that the reconstructed current value tracks the real one accurately for each phase, which demonstrates the validity of the proposed current reconstruction strategy. With the purpose of observing the effects of the reconstructed currents on the system performance, the graphs of the total output active power (

Pt), reactive power (

Qt), and power factor (PF) derived when applying the measured currents and reconstructed currents, are depicted as shown in

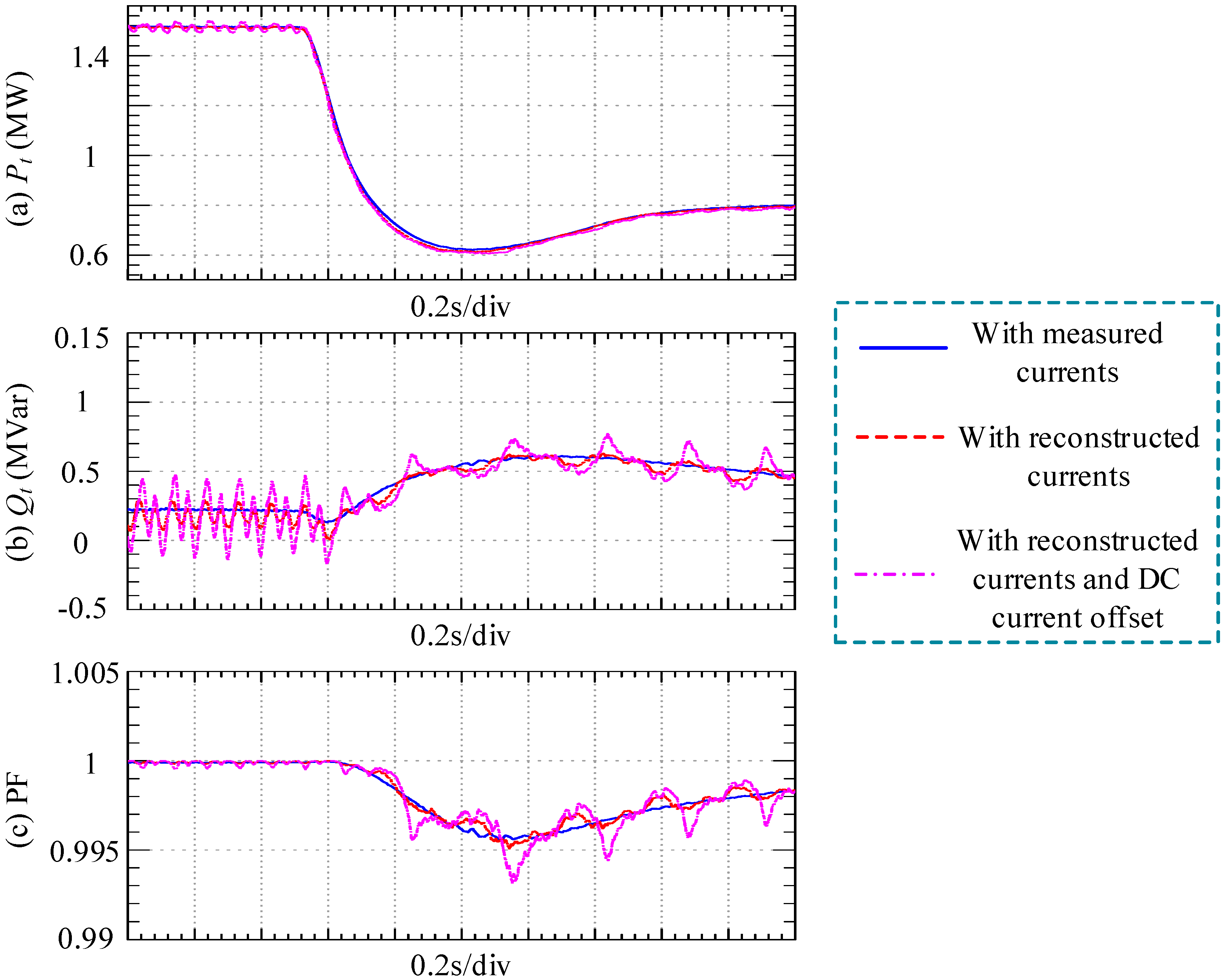

Figure 16. Moreover, when the DC current offset of 0.1 pu is taken into account in the DC-link current sensors, the corresponding graphs are also illustrated in

Figure 16.

In

Figure 16, it can be seen that when the measured three-phase grid-side and rotor-side currents are used, the total output active power drops from 1.5 MW to 0.8 MW after the wind speed step change, with a period of around 1 s to adjust the value to a stable one. There is also a slight increase in the reactive power output, which reaches around 0.06 MVar at 1.2 s. However, it moderately declines back to the desired value after that. In terms of the power factor, the minimum value is around 0.996 at 1.2 s, and then it returns back to unity steadily. When the reconstructed phase currents are applied as the inputs for the control system, the graphs of

Pt,

Qt and PF are shown as the red dashed lines in

Figure 16. Although some fluctuations are observed, the errors between the values derived by using the measured and reconstructed currents are relatively small. Therefore, the DFIG-WT with serious sensor fault scenario can still work properly. Furthermore, after taking the inaccuracy of the DC-link current sensors into account, the active power output can still be tracked precisely. Even though the quality of output power is deteriorated, the average value of the power factor is high enough for acceptable operation.

In addition, the rotor speed

ωm and position

θm are estimated by using the EKF algorithm based on a 7th-order DFIG state space model. By directly taking the uncertainties in the stochastic process into account, the Kalman gain matrix

K(

k) is calculated that minimizes the error between the real and estimated values. The algorithm is performed online so that the adjustment of the components in the Kalman gain matrix is carried out according to the variations in the errors. The white noises in the model and measurement processes are determined as shown below.

To simulate the scenario that inaccurate initial estimation of the variables is presented and make the EKF estimator minimize the errors over time, the primary error covariance between any two state variables is assumed to be relatively large, and the initial state covariance matrix

P0 is set as

With the stator and rotor voltages as inputs, and the stator and rotor currents as measurements, the estimation of the rotor speed and position can be completed based on the recursive algorithm. The real and estimated rotor speed and position are displayed in

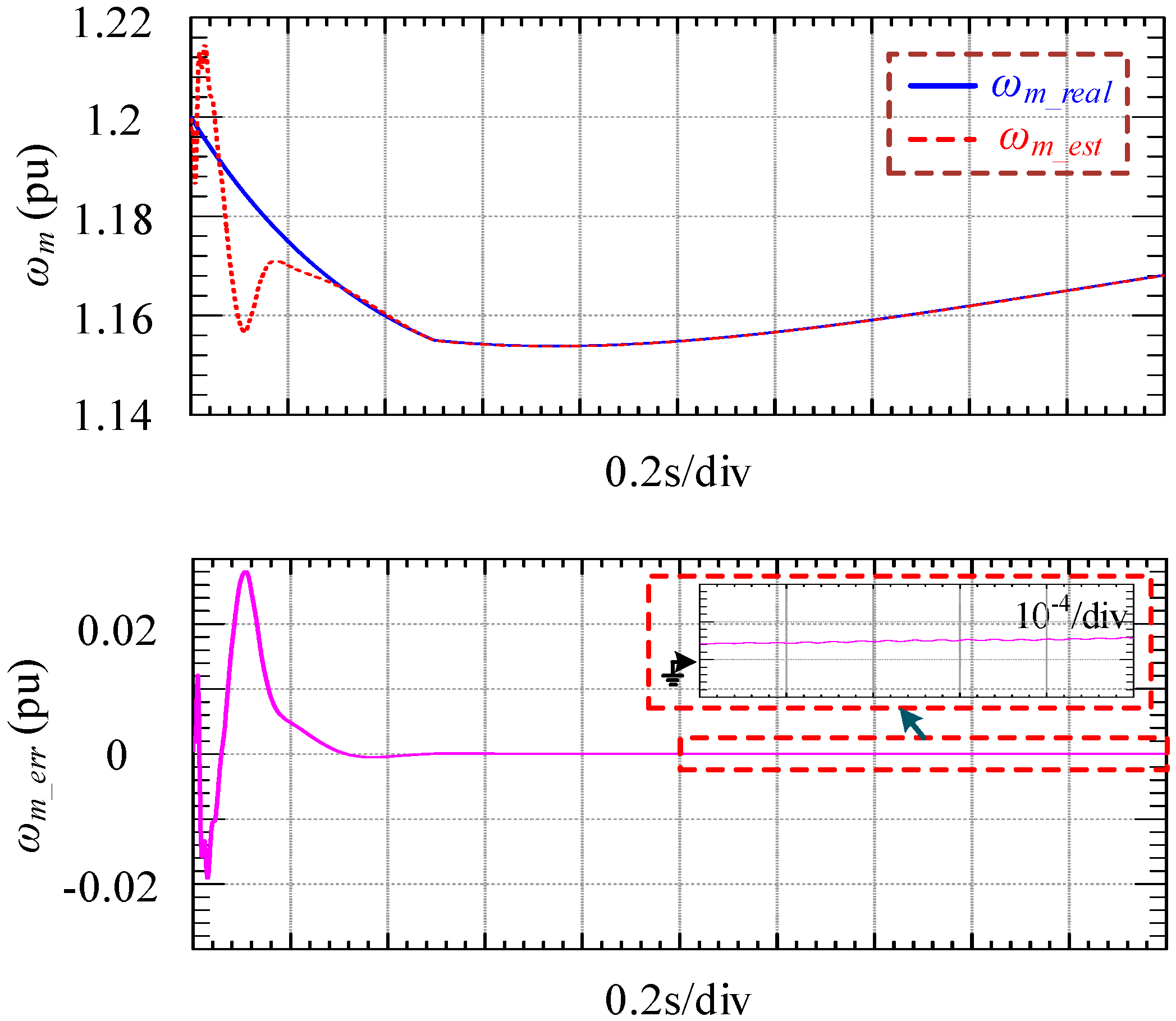

Figure 17 and

Figure 18, respectively, with the difference illustrated.

It can be seen in

Figure 17 that, at the beginning, the rotor speed estimation deviates from the real value by around 0.2 pu, which is large compared to the initial rotor speed of 1.2 pu. However, in around 0.3 s, the tracking performance is good enough for the estimated rotor speed to replace the real one since the difference between them is only about 4 × 10

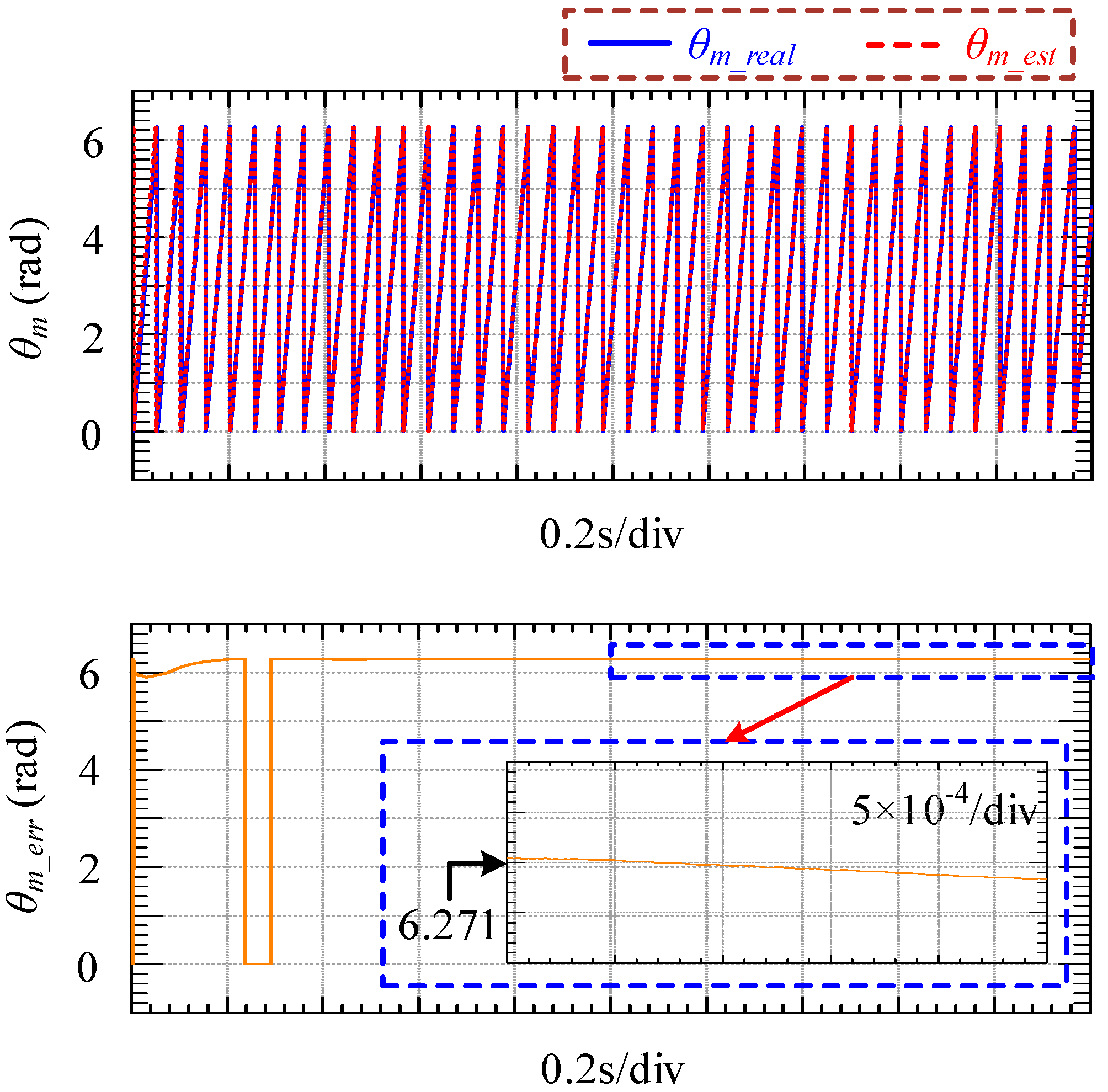

−5 pu, regardless of the wind speed step change. In addition, the estimated rotor position is almost equal to the real one, which can be observed in

Figure 18. It should be noted that the range of rotor angular position is [0, 2π]. Although the error displayed in

Figure 18 is approximately 6.271 rad, it can also be expressed as (6.271 − 2π) rad, whose absolute value is only 0.0122 rad, since the rotor position is a periodic function of time. Therefore, the estimated rotor position is accurate enough for sensorless control of DFIG-WT. To demonstrate the mechanical performance of DFIG-WT, the mechanical and electromagnetic torques are displayed in

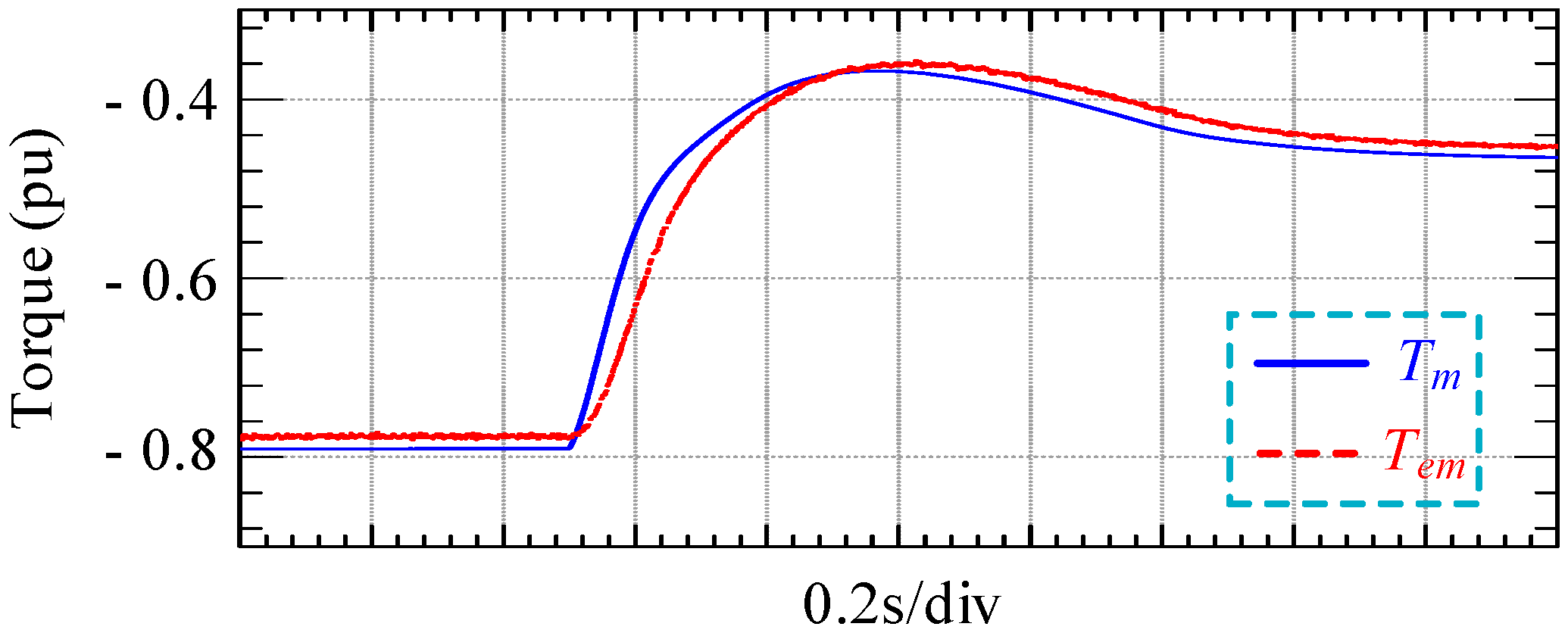

Figure 19.

Since the machine operates in generator mode, the torque values are negative, indicating that the electromagnetic torque Tem functions as the load torque. It can be seen that Tem is almost equal to the mechanical one Tm in the high wind speed period. Then, during a short time period after the wind speed step change, the absolute value of Tem is larger than that of Tm, and the rotor slows down in this case. After that, the distance becomes smaller as the rotor speed tends to be approximately a steady value.

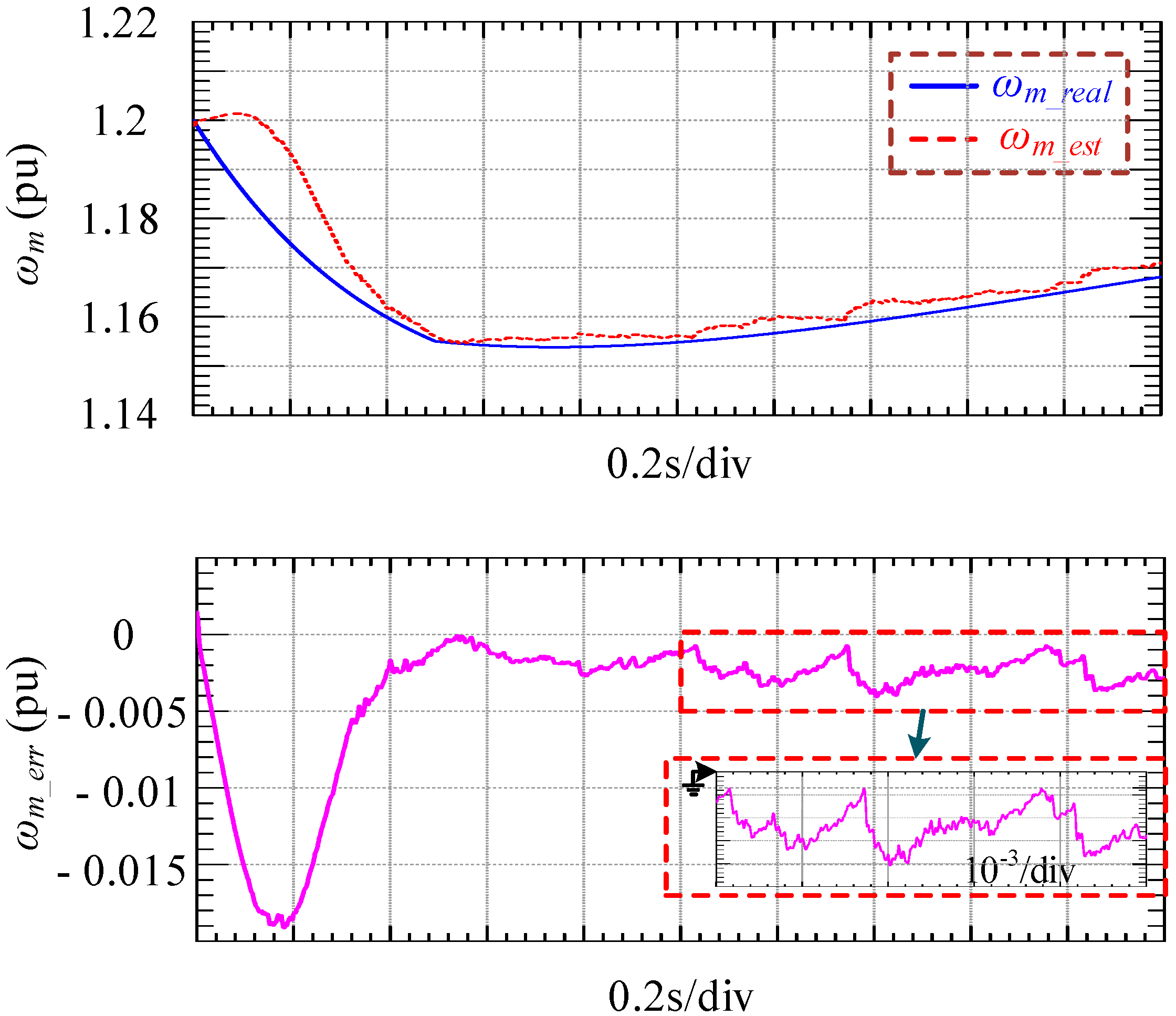

Good robustness to noises in a nonlinear dynamic system is a unique characteristic of EKF, which is also applicable for DFIG dynamic model. To further verify the validity of EFK based sensorless control algorithm for DFIG-WT, system model uncertainties and measurement disturbances are taken into account. After considering the noises in the system model and measurements, the estimations of rotor speed and position along with the differences are illustrated in

Figure 20 and

Figure 21, respectively.

In

Figure 20 and

Figure 21, although there are noises caused by system model uncertainties and measurement disturbances, the estimated rotor speed and position still track the real values well, whereas the estimation accuracy decreases. With the noises added, the EKF has to repeatedly calculate the optimal Kalman gain to minimize the error, which takes several time periods. As can be seen from

Figure 20, the error between the real and estimated rotor speeds is within 4 × 10

−3 pu, while it keeps fluctuating. In

Figure 21, there is approximately a difference of 6.26 rad (0.0232 rad) between the real and estimated rotor positions, with the fluctuation of ±0.02 rad. Nevertheless, the estimation precision is still good enough as divergence does not occur in this case, and the EKF based speed/position sensorless control algorithm is demonstrated to be robust to noises.

6. Discussion and Future Work with Experiments

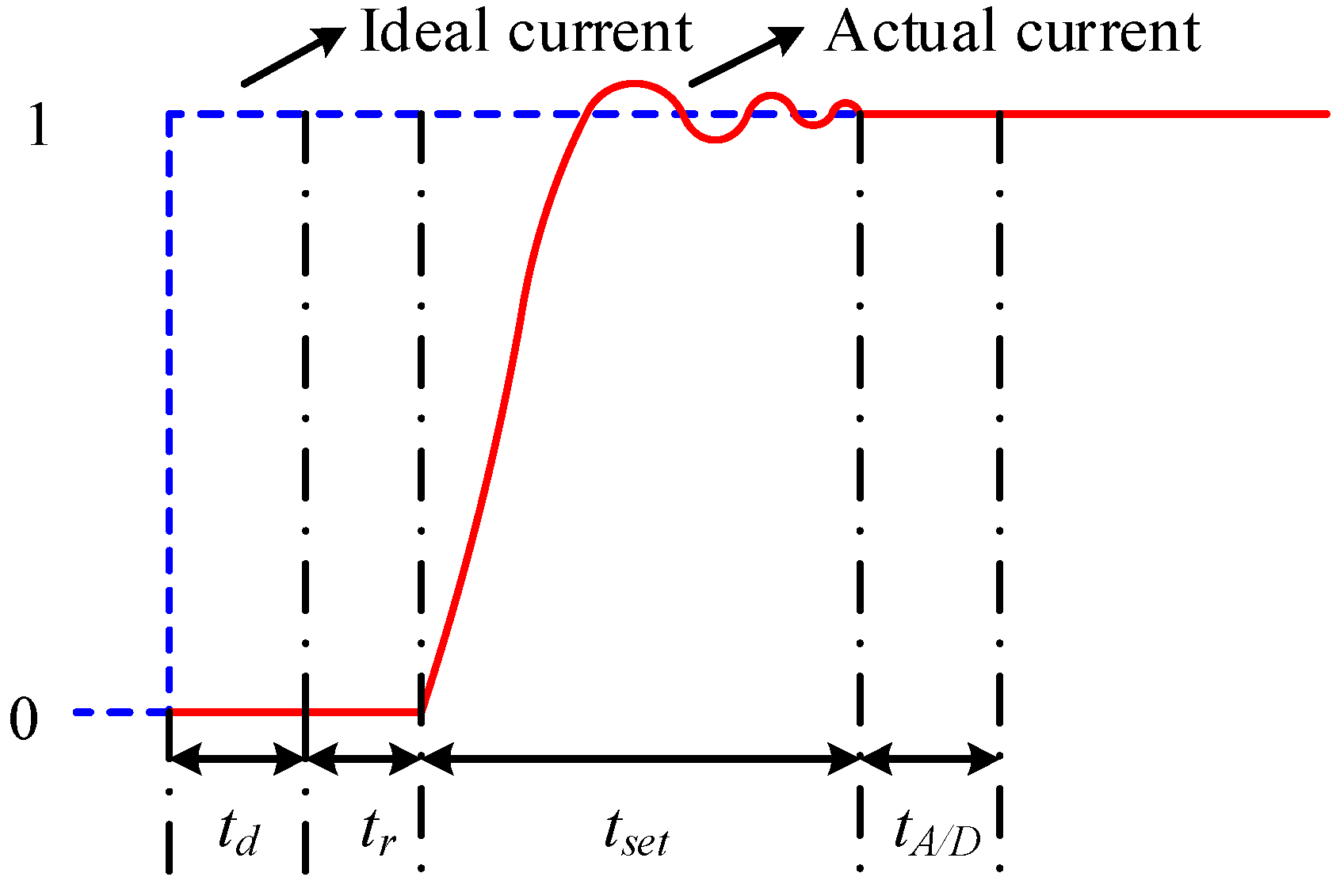

Although the proposed hybrid fault-tolerant strategy in a 1.5 MW DFIG-WT is verified by simulation results, experiments are going to be undertaken in the future by using a down-scaled DFIG experimental platform, including a 20 kW DFIG, a 23 kW permanent magnet synchronous motor (PMSM), back-to-back power electronic converters, and a DSpace controller. The parameters of the machines and converters should be cautiously selected according to the specific experimental conditions. In addition, tuning of PI parameters and the parameters in the initial state covariance matrix will be a time-consuming task. In the experiment, an HS01-C hall sensor (BEIJING CHUANG SI FANG ELECTRONICS LIMITED BY SHARE LTD, Beijing, China) will be chosen as the current sensor for DC-link current measurement, since it has good robustness, strong voltage isolation ability, and high reliability. The rated input and output currents of the HS01-C hall sensor are 50 A and 50 mA, respectively, with the measurement range from 0 A to 70 A, and the working temperature is between −20 °C and 75 °C.

In terms of the model behavior in the experimental rig, taking the external disturbances of uncertain grid power quality (current harmonics, grid unbalance, frequency oscillations) and the noises in analog-to-digital (A/D) process into account, deteriorated control performance will be observed. Specifically, obvious spikes will be presented in the voltage and current waveforms, and the output power quality will not be as high as that derived in the simulation results. In addition, due to the unpredictable aging process of the DC-link current sensor, the accuracy of current measurement may not be high enough, which is also detrimental to the performance of DFIG. To exclude the noises produced during the experiments, additional filters should be used.