Comparative Modeling of a Parabolic Trough Collectors Solar Power Plant with MARS Models

Abstract

:1. Introduction

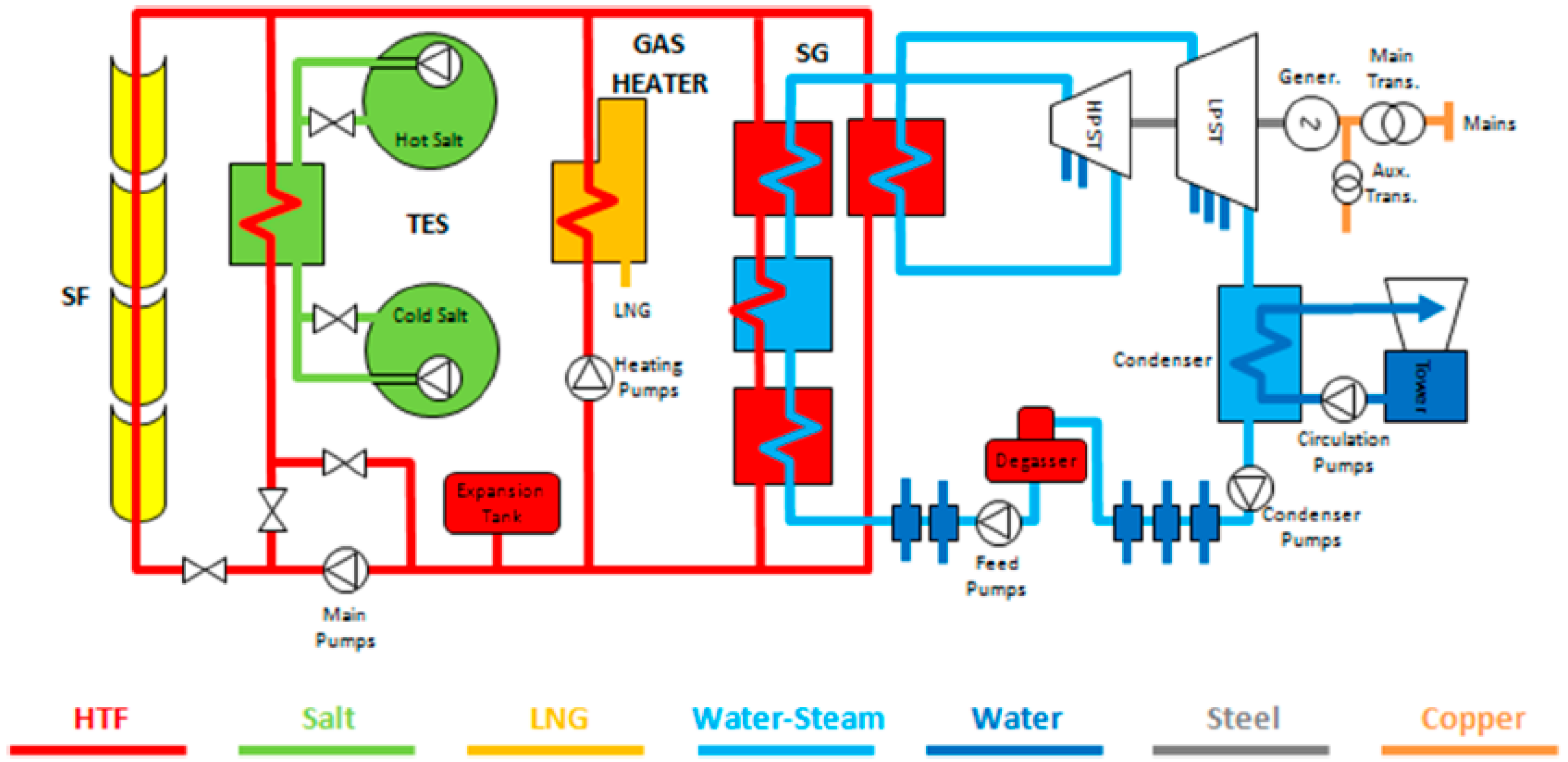

- SF (solar field): Formed by the needed elements to collect solar radiation and transform it into thermal energy. The modeling [2] of diffuse solar radiation at different planes, as well as at ground level, already represents an exclusive field of study in modeling efficient power plants.

- TES (thermal energy storage): It contains all of the elements in charge of storing the thermal energy, which is provided when the Sun is not enough. Even when other materials were tested, molten salts present more advantages in terms of security and cost. In any case, some others are being researched. The development of ternary and even quaternary mixtures of different types of salts has been studied [3]. These mixtures give a HTF (heat transfer fluid) with better operational characteristics. The lower melting points of these mixtures reduce the cost of the process by not needing an external energy supply to keep the mixtures melted at night.The study [4] of new mixtures other than the usual molten salts used as TES, provide satisfactory results in regard to stability, fluidity, and thermal inertia. These investigations could lead, in the near future, to the replacement of the salts in the TES by these types of mixtures, and even the use of the same as HTFs.

- Gas Heater: It provides energy for either maintaining the HTF above its melting point at night or on a cloudy day, or helping the SF to increment the power that heats the fluid by using natural gas. This block is used when the molten salt block does not have enough energy to keep the fluid at an adequate temperature. In these cases, some additional energy must be spent in order to maintain the fluid in the liquid state until a new daily period of insolation begins.

- SG (Steam Generator). It is formed by a steam generator train which, thanks to the contribution of thermal energy, converts liquid water into steam. This steam drives a turbine connected to an electric generator that produces electricity.

2. Methods and Data

2.1. Multivariate Adaptive Regression Splines Method (MARS)

- existing terms (called parent terms in this context),

- all of the variables (to select one of the new basis functions),

- all of the values of each variable (for the knot of the new hinge function).

- MARS models are more flexible than linear regression models [10].

- MARS models are easy to understand and interpret [15].

- MARS models can handle continuous and categorical data. MARS tends to be better than recurring division for numeric data, because the hinge functions are more appropriate for numeric variables than the constant segmentation used by recurring division.

- MARS models often require little or no data preparation. The hinge functions automatically divide input data, so the effect of outliers is contained. In this sense, MARS is similar to the recurring division that also divides data into distinct regions, although using a different method.

- MARS, as well as the recurrent division, automatically select variables, which means that it includes important variables in the model and excludes those of minor importance. We should bear in mind, however, that the selection of variables is not a solved problem yet, and there is usually some arbitrariness in the selection, especially in the presence of collinearity and concurvity.

- MARS models tend to have a good bias–variance trade-off, and are suitable for handling large data banks [22].

- The models of MARS, as with any other non-parametric regression, cannot directly calculate parameter confidence intervals and other controls in the model (unlike linear regression models). Cross-validation and similar techniques should be used to validate the model instead.

- Sometimes, MARS models do not give as good results as other model types, but can be built much more quickly and are more interpretable. An interpretable model is one that makes the effect of each predictor clear.

- MARS models can make predictions more quickly. The prediction function simply has to evaluate the MARS model formula. This is a fast prediction if we make a comparison to making a prediction about a support vector machine (SVM) model for example, where every variable must be multiplied by the corresponding element of every support vector. This can be a slow process if there are many variables and many support vectors.

2.2. Set of Experimental Data

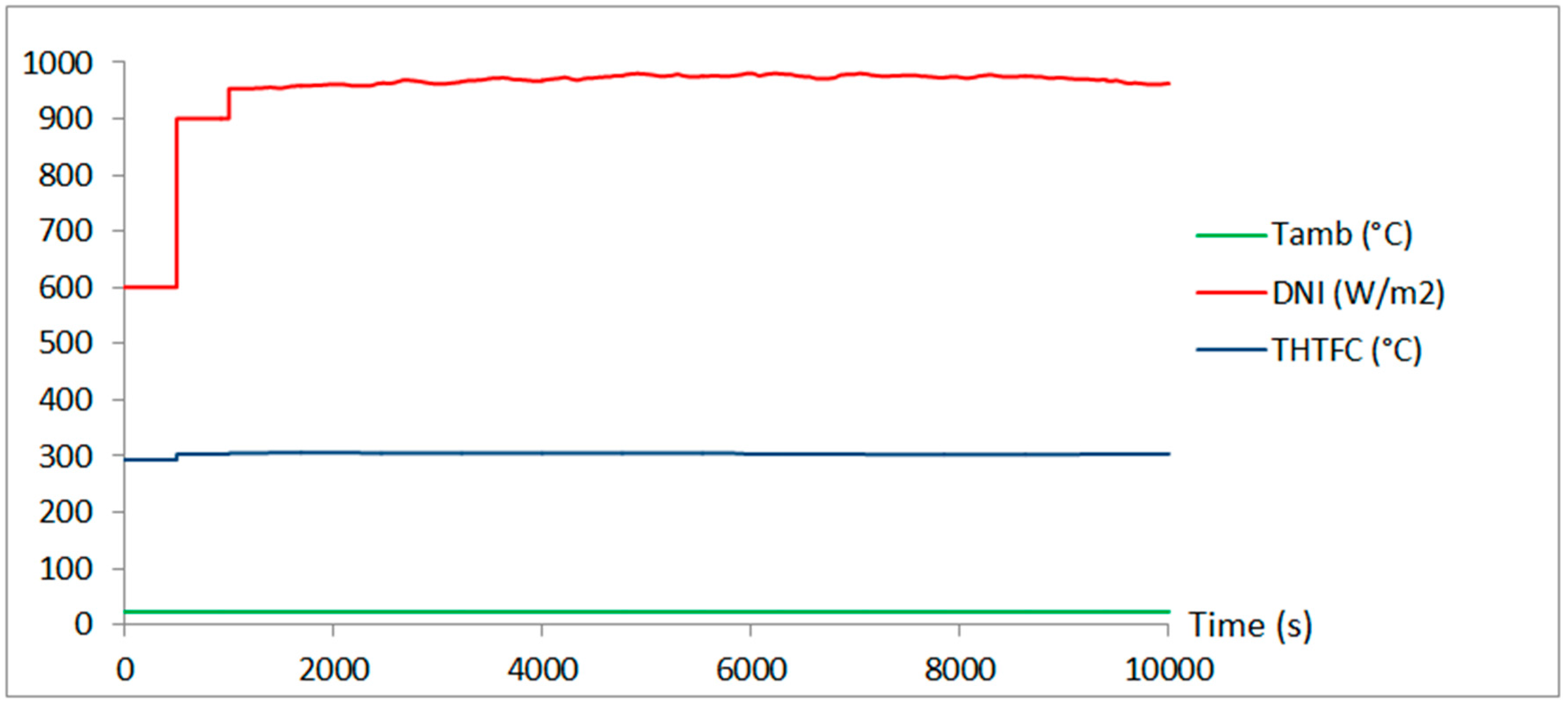

- Input values set definition. The input data set was obtained by combining artificially generated signals of sinusoidal, steps, and pulse type, with real measurements of the solar field. Figure 2 shows an example of how sinusoidal signals were generated.

- b.

- Training data set generation (DS_1). The input data set generated in step 1 was processed with the previously published tool [5], and the response of a feedforward PID controller to the above inputs was obtained: THTFC.

- c.

- Alternative training data set generation (DS_2). A second data set was defined from that obtained in step 2 by selecting only those inputs that generate outputs in the range of 390–396 °C, which is the ideal operating range of the plant.

- d.

- Training of the MARS model with the input data, obtained in the previous steps.

3. Results and Discussion

3.1. First Responses

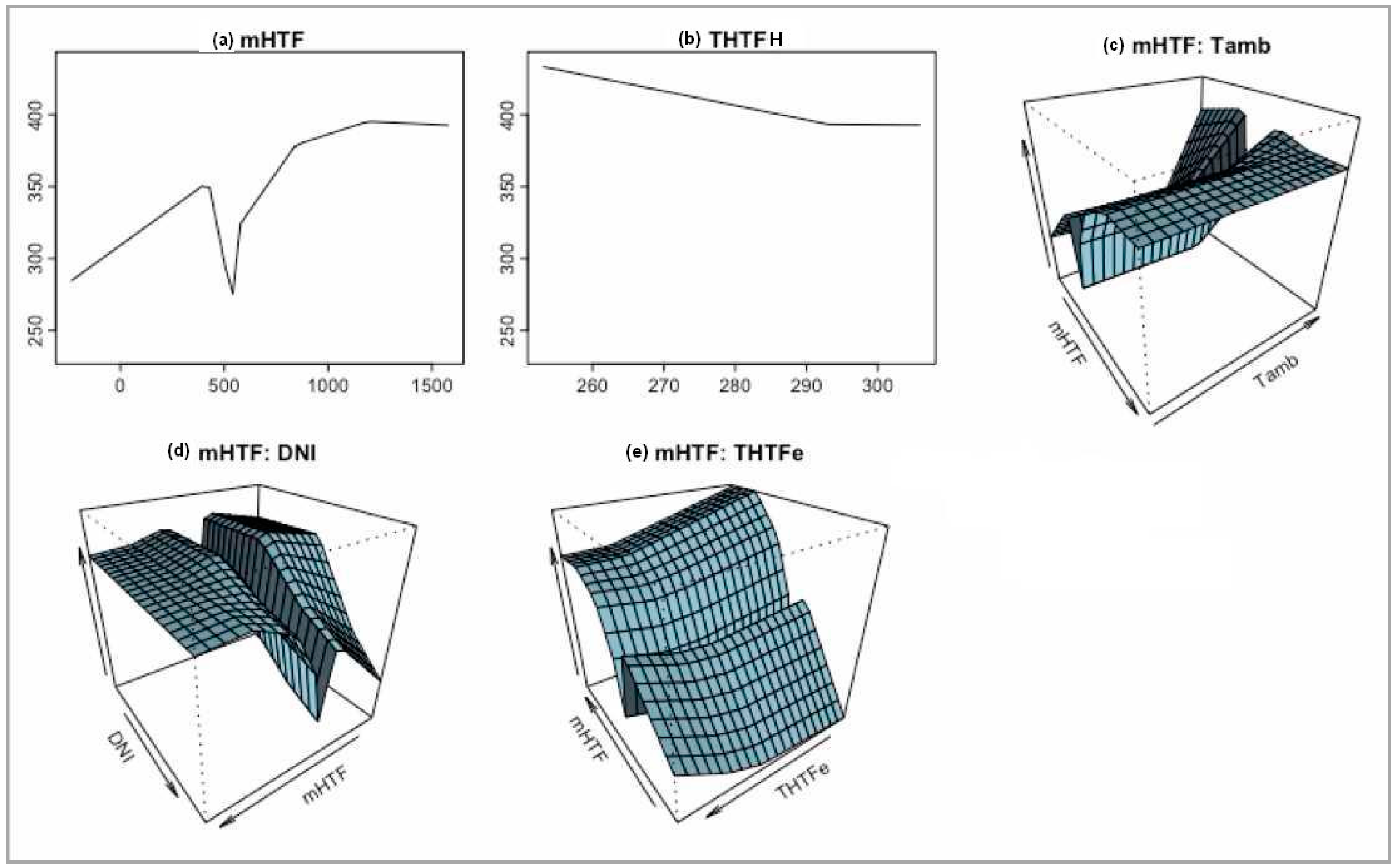

- THTFpk: maximum temperature reached by the HTF of the SF when the DNI increases.

- Setting time: time elapsed from the beginning of the increase in the DNI to the moment when the temperature of the HTF of the SF reaches steady state.

- Error (%): percentage of error between the temperature of the HTF of the SF in steady state and the set point (established at 393 °C).

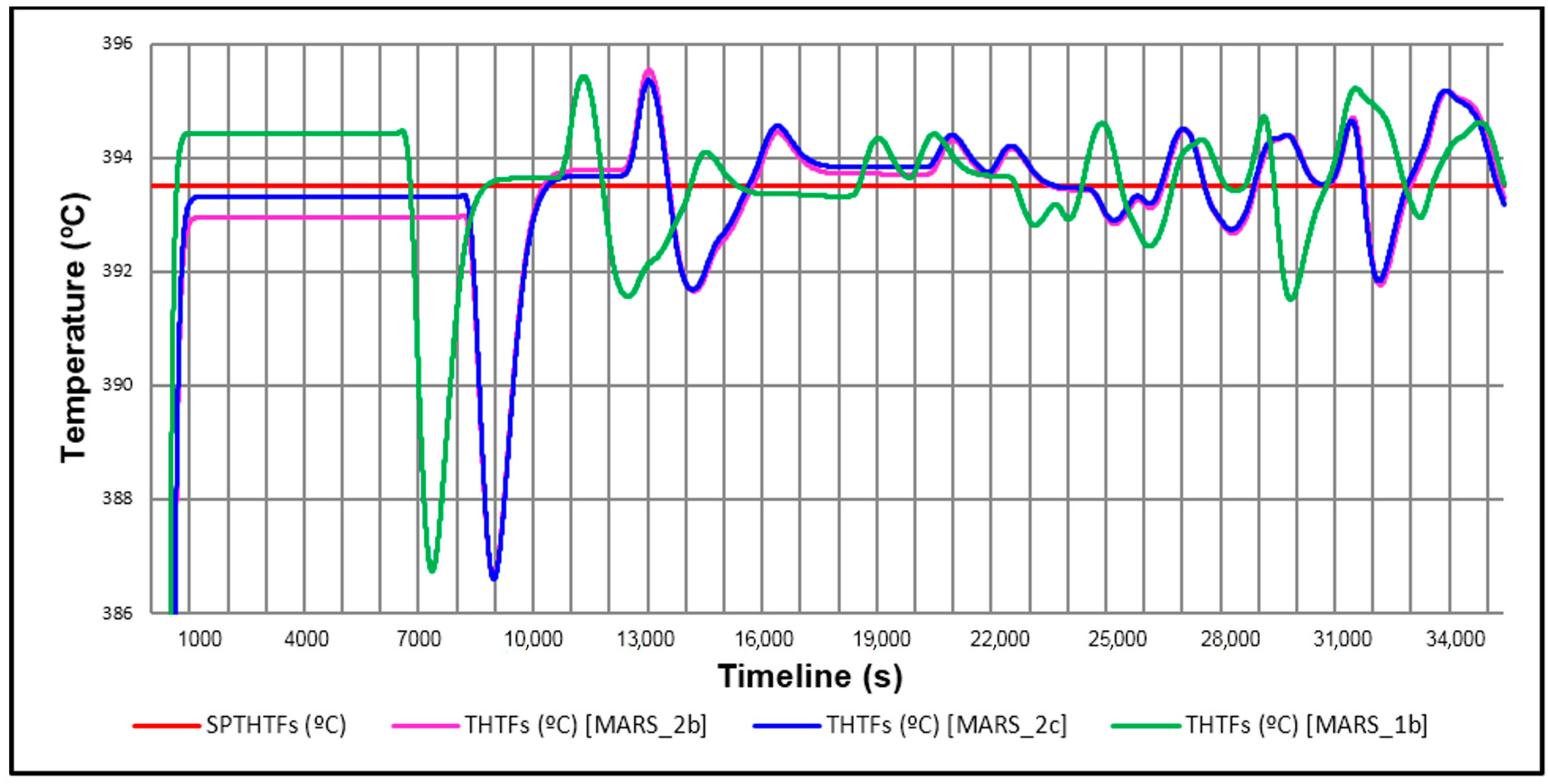

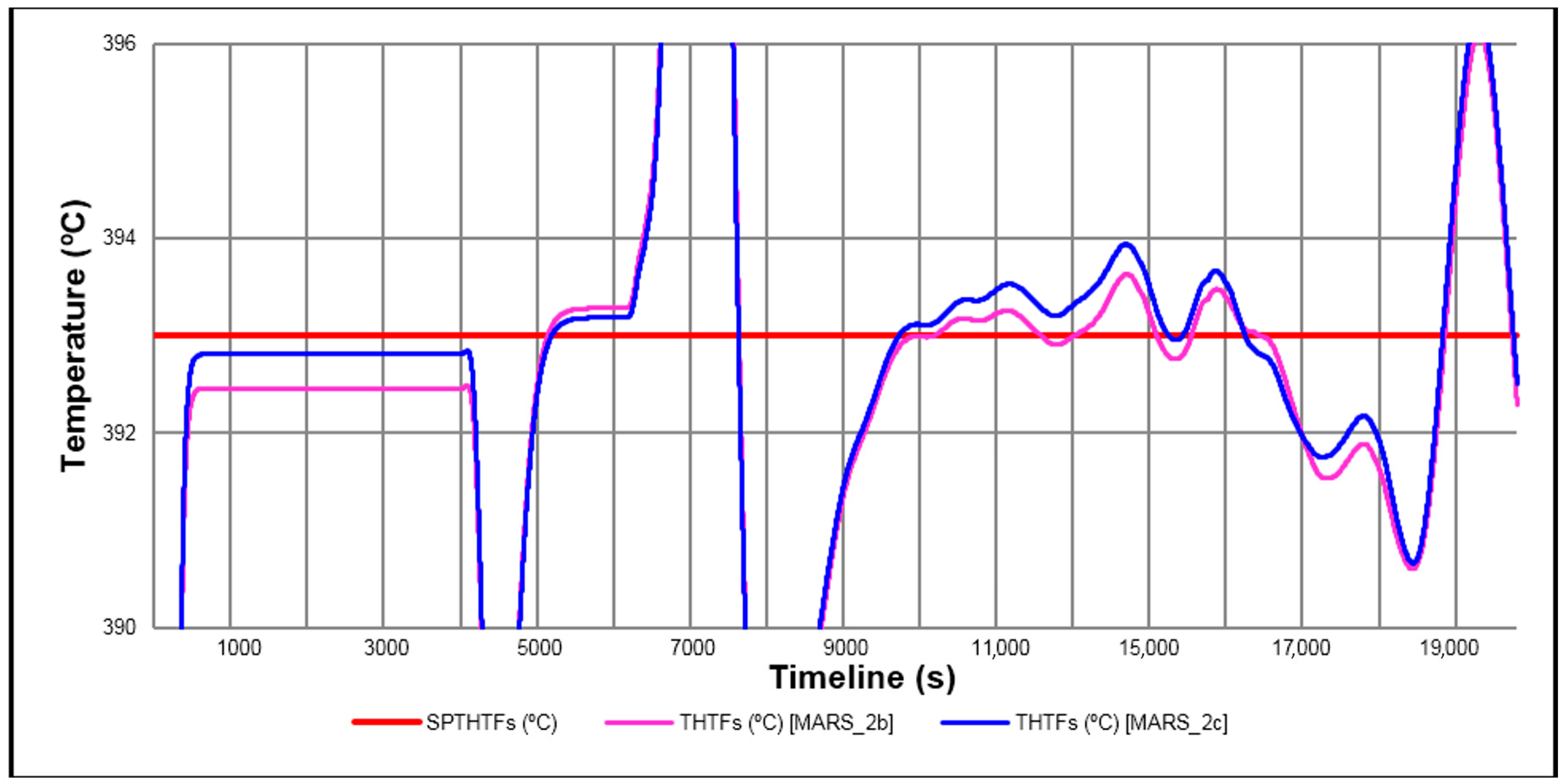

3.2. MARS Response to Real Input Data

4. Conclusions

- Validation of the developed models has been conducted by using real data extracted from the SF, of La Africana, located in Cordoba. The fact that the MARS models respond appropriately to real data confirms the feasibility of this type of model in applications such as the one described.

- When suitably trained, MARS models’ initialization times are around 80% shorter than those obtained with conventional control strategies, which is because MARS control systems are operating in real time and through an open loop, without feedback.

- The settling time after variations in an input is up to 94% shorter than the one achieved with the PID control, and 73% shorter than that obtained with the PIDFF.

- Suitably trained MARS models present a response to variations of the DNI with smaller oscillations than those obtained with PID, and similar to those obtained with the PIDFF.

- It is necessary to take into account in the actual process the inclusion of oil thermal inertia effect through the solar field and the headers when the MARS models are being trained. Any future modeling for direct application must be based on actual data from each thermosolar plant exclusively.

- Input data collection for future modeling shall be expanded with data that follow all the points of the process in real time. We can consider that the input data are not representative of the direct training of a MARS model. We have made use of feedback and training already obtained from the actual PID control of the plant, as a complement to the proposed MARS models.

Acknowledgments

Author Contributions

Conflicts of Interest

Glossary

| PTC | Parabolic Trough Collector |

| TES | Thermal Energy Storage |

| HTF | Heat Transfer Fluid |

| SF | Solar Field |

| SG | Steam Generator |

| PDI | Proportional Integral Derivative |

| PIDFF | PDI with Feedforward |

| MARS | Multivariate Adaptive Regression Splines |

| GCV | Generalized Cross Validation |

| SVM | Support Vector Machine |

| THTFC | HTF Cold Temperature in the solar field |

| THTFH | HTF Hot Temperature in the solar field |

| THTFpk | Maximum HTF Hot Temperature in the solar field |

| mHTF | HTF Mass Flow |

| WS | Wind Speed |

| DNI | Direct Normal Irradiance |

| Tamb | Ambient Temperature |

| ϕ | DNI incident angle |

| ηopt | Optical performance of the collectors |

References

- Thomas, A. Solar Steam Generating Systems Using Parabolic Trough Concentrators. Energy Convers. 1995, 37, 215–245. [Google Scholar] [CrossRef]

- Paulescu, E.; Blaga, R. Regression models for hourly diffuse solar radiation. Sol. Energy 2016, 125, 111–124. [Google Scholar] [CrossRef]

- Nunes, V.M.B.; Queirós, C.S.; Lourenço, M.J.V.; Santos, F.J.V.; de Castro, C.N. Molten salts as engineering fluids—A review Part I. Molten alkali nitrates. Appl. Energy 2016, 183, 603–611. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, H.; Yang, M.; Sun, W.; Yin, G.; Zhang, Q.; Ren, Z. Thermal reliability of Al-Si eutectic alloy for thermal energy storage. Mater. Res. Bull. 2017, 95, 300–306. [Google Scholar] [CrossRef]

- Barcia, L.A.; Peón Menéndez, R.; Martínez Esteban, J.Á.; José Prieto, M.A.; Martín Ramos, J.A.; de Cos Juez, F.J.; Nevado Reviriego, A. Dynamic Modeling of the Solar Field in Parabolic Trough Solar Power Plants. Energies 2015, 8, 13361–13377. [Google Scholar] [CrossRef]

- Alvarez, J.; Guzmán, J.; Yebra, L.; Berenguel, M. Hybrid modeling of central receiver solar power plants. Simul. Model. Pract. Theory 2008, 17, 664–679. [Google Scholar] [CrossRef]

- Fernández, J.A.; Muñiz, C.D.; Nieto, P.G.; de Cos Juez, F.J.; Lasheras, F.S.; Roqueñí, M.N. Forecasting the cyanotoxins presence in fresh waters: A new model based on genetic algorithms combined with the MARS technique. Ecol. Eng. 2013, 53, 68–78. [Google Scholar] [CrossRef]

- De Andrés, J.; Sánchez-Lasheras, F.; Lorca, P.; Juez, F.J.D.C. A hybrid device of self organizing maps (SOM) and multivariate adaptative regression splines (MARS) for the forecasting of firms’ bankruptcy. Account. Manag. Inf. Syst. 2011, 10, 351–371. [Google Scholar]

- De Cos Juez, F.J.; Lasheras, F.S.; Nieto, P.G.; Álvarez-Arenal, A. Non-linear numerical analysis of a double-threaded titanium alloy dental implant by FEM. Appl. Math. Comput. 2008, 206, 952–967. [Google Scholar] [CrossRef]

- Turrado, C.C.; López, M.D.C.M.; Lasheras, F.S.; Gómez, B.A.R.; Rollé, J.L.C.; Juez, F.J.D.C. Missing data imputation of solar radiation data under different atmospheric conditions. Sensors 2014, 14, 20382–20399. [Google Scholar] [CrossRef] [PubMed]

- Salazar, G.A.; Fraidenraich, N.; de Oliveira, C.A.A.; de Castro Vilela, O.; Hongn, M.; Gordon, J.M. Analytic modeling of parabolic trough solar thermal power plants. Energy 2017, 138, 1148–1156. [Google Scholar] [CrossRef]

- Barcia, L.A.; Peon, R.; Díaz, J.; Pernía, A.M.; Martínez, J.Á. Heat Transfer Fluid Temperature Control in a Thermoelectric Solar Power Plant. Energies 2017, 10, 1078. [Google Scholar] [CrossRef]

- Baccioli, A.; Antonelli, M. Control variables and strategies for the optimization of a WHR ORC system. In Proceedings of the IV International Seminar on ORC Power Systems (ORC 2017), Milano, Italy, 13–15 September 2017. [Google Scholar]

- Friedman, J.H.; Roosen, C.B. An introduction to multivariate adaptive regression splines. Stat. Methods Med. Res. 1995, 4, 197–217. [Google Scholar] [CrossRef] [PubMed]

- Friedman, J.H. Multivariate Adaptive Regression Splines. Ann. Stat. 1991, 19, 1–67. [Google Scholar] [CrossRef]

- De Cos Juez, F.J.; Sanchez Lasheras, F.; Roqueñi, M.N.; Osborn, J. An ANN-based smart tomographic reconstructor in a dynamic environment. Sensors 2010, 12, 8895–8911. [Google Scholar] [CrossRef] [PubMed]

- Suarez Sanchez, A.; Iglesias-Rodriguez, F.J.; Riesgo Fernandez, P.; De Cos Juez, F.J. Applying the K-nearest neighbor technique to the classification of workers according to their risk of suffering musculoskeletal disorders. Int. J. Ind. Ergon. 2016, 52, 92–99. [Google Scholar] [CrossRef]

- Suárez Sánchez, A.; Krzemień, A.; Riesgo Fernández, P.; Iglesias Rodríguez, F.J.; Sánchez Lasheras, F.; de Cos Juez, F.J. Investment in new tungsten mining projects. Resour. Policy 2015, 46, 177–190. [Google Scholar] [CrossRef]

- Casteleiro-Roca, J.L.; Calvo-Rolle, J.L.; Méndez Pérez, J.A.; Roqueñí Gutiérrez, M.N.; de Cos Juez, F.J. Hybrid Intelligent System to Perform Fault Detection on BIS Sensor during Surgeries. Sensors 2017, 17, 179. [Google Scholar] [CrossRef] [PubMed]

- De Cos Juez, F.J.; Lasheras, F.S.; García Nieto, P.J.; Suárez, M.S. A new data mining methodology applied to the modelling of the influence of diet and lifestyle on the value of bone mineral density in post-menopausal women. Int. J. Comput. Math. 2009, 86, 1878–1887. [Google Scholar] [CrossRef]

- Vapnik, V. Statistical Learning Theory; Wiley-Interscience: New York, NY, USA, 1998. [Google Scholar]

- Galán, C.O.; Lasheras, F.S.; de Cos Juez, F.J.; Sánchez, A.B. Missing data imputation of questionnaires by means of genetic algorithms with different fitness functions. J. Comput. Appl. Math. 2017, 311, 704–717. [Google Scholar] [CrossRef]

| Process Inputs | Process Output | Disturbances |

|---|---|---|

| THTFC—Cold HTF Temperature mHTF—HTF Mass Flow | THTFH—Hot HTF Temperature | DNI—Solar Irradiation Tamb—Ambient Temperature Ws—Wind Speed ϕ—Incidence Angle |

| Model | Main Features | Training Data |

|---|---|---|

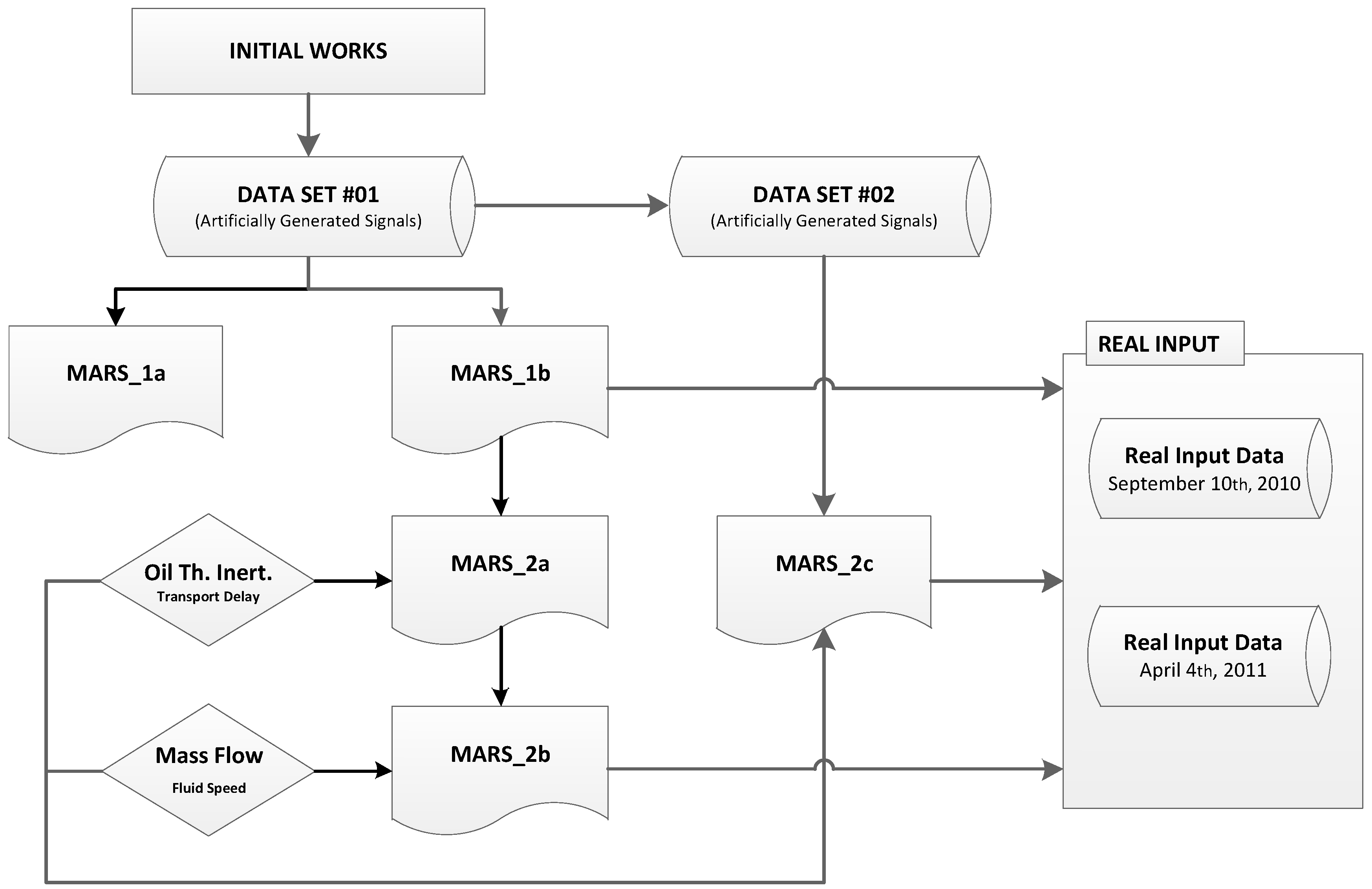

| MARS_1a | Standard Initial Model (SIM) | Artificial signals (sinusoidal, pulses) |

| MARS_1b | Standard Initial Model (SIM) | Artificial signals (sinusoidal, pulses, sharp step in DNI and knowledge from MARS_1A) |

| MARS_2a | SIM plus thermal inertia effect | Artificial signals (sinusoidal, pulses) and optimized knowledge from MARS_1B |

| MARS_2b | SIM plus mass flow effect | Artificial signals (sinusoidal, pulses, sharp step in DNI and optimized knowledge from MARS_2A) |

| MARS_2c | SIM plus thermal inertia and mass flow effects | Artificial signals (sinusoidal, pulses, sharp step in DNI and optimized knowledge from MARS_2B) |

| Response | THTFmin (°C) | THTFmax (°C) | Delay Time (s) 1 | Time to THTFmax 2 | Settling Time (s) 3 |

|---|---|---|---|---|---|

| MARS_1a | 387.50 | 395.20 | 20 | 1500 | 1100 |

| MARS_1b | 366.00 | 392.97 | 17 | 1100 | 1100 |

| MARS_2a | 392.25 | 395.34 | 2 | 1980 | 1980 |

| MARS_2b | 393.09 | 393.71 | 0 | 402 | 2083 |

| MARS_2c | 391.97 | 392.92 | 0 | 566 | 1935 |

| Model | THTFmax (°C) | THTFmin (°C) | Settling Time (s) | Error (%) |

|---|---|---|---|---|

| PID | 488.00 | 393.01 | 33,000 | 0.0025 |

| PIDFF | 393.70 | 393.01 | 7250 | 0.0025 |

| MARS_2b | 393.71 | 393.33 | 2083 | 0.0840 |

| MARS_2c | 393.07 | 392.97 | 1935 | 0.0178 |

| THTFH i | Definition | Ci |

|---|---|---|

| THTFH 1 | 1 | 433.8601 |

| THTFH 2 | h (mHTF-424) | −0.8421 |

| THTFH 3 | h (mHTF-538) | 2.6682 |

| THTFH 4 | h (mHTF-565) | −1.7243 |

| THTFH 5 | h(mHTF-843) | −0.1587 |

| THTFH 6 | h (1190-mHTF) | −0.0615 |

| THTFH 7 | h (mHTF-1190) | 0.0500 |

| THTFH 8 | h (293-THTFe) | 1.0003 |

| THTFH 9 | h (THTFe-293) | −0.0371 |

| THTFH 10 | h (1190-mHTF) × h (Tamb-30) | 0.0082 |

| THTFH 11 | h (1190-mHTF) × h (30-Tamb) | 0.0004 |

| THTFH 12 | h (1190-mHTF) × h (DNI-484) | −0.0002 |

| THTFH 13 | h (1190-mHTF) × h (484-DNI) | 0.0000 |

| THTFH 14 | h (1190-mHTF) × h (DNI-778) | 0.0001 |

| THTFH 15 | h (1190-mHTF) × h (THTFe-283) | 0.0018 |

| THTFH 16 | h (1190-mHTF) × h (283-THTFe) | −0.0009 |

| Model | THTFmax (°C) | THTFmin (°C) | Errormax (%) | Errormin (%) | Total Error (%) |

|---|---|---|---|---|---|

| PID | 401.85 | 367.81 | 2.25 | −6.41 | 8.66 |

| PIDFF | 395.90 | 390.40 | 0.74 | −0.66 | 1.40 |

| MARS_2b | 395.89 | 390.20 | 0.74 | −0.71 | 1.45 |

| MARS_2c | 396.09 | 390.60 | 0.79 | −0.61 | 1.40 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rogada, J.R.; Barcia, L.A.; Martinez, J.A.; Menendez, M.; De Cos Juez, F.J. Comparative Modeling of a Parabolic Trough Collectors Solar Power Plant with MARS Models. Energies 2018, 11, 37. https://doi.org/10.3390/en11010037

Rogada JR, Barcia LA, Martinez JA, Menendez M, De Cos Juez FJ. Comparative Modeling of a Parabolic Trough Collectors Solar Power Plant with MARS Models. Energies. 2018; 11(1):37. https://doi.org/10.3390/en11010037

Chicago/Turabian StyleRogada, Jose Ramón, Lourdes A. Barcia, Juan Angel Martinez, Mario Menendez, and Francisco Javier De Cos Juez. 2018. "Comparative Modeling of a Parabolic Trough Collectors Solar Power Plant with MARS Models" Energies 11, no. 1: 37. https://doi.org/10.3390/en11010037