1. Introduction

The permanent magnet synchronous motor (PMSM), which integrates the advantages of high-power density, high efficiency, light weight, easy maintenance, and good reliability, has been widely used in commerce, industry, transportation, and so on [

1,

2], thus it attracts the interest of many researchers from the international electrotechnical field [

3,

4,

5].

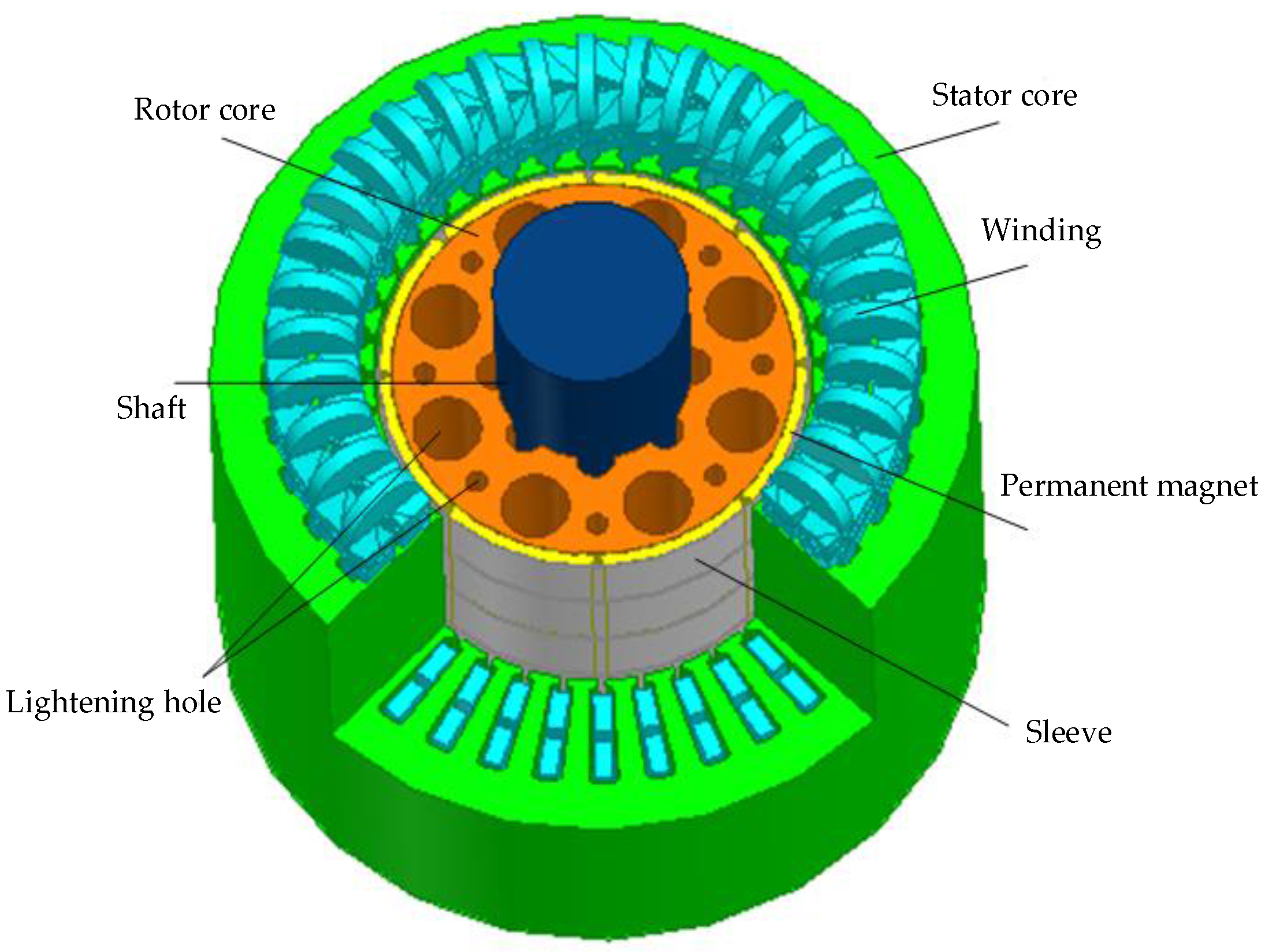

Generally, because the tensile capability of permanent magnets is poor, they can be destroyed by a large centrifugal force. A rotor sleeve could provide a suitable pre-pressure and reduce the influence of the centrifugal force on the permanent magnets. Therefore, a rotor sleeve often has been coated on the rotor outer surface to fix the magnets. However, eddy-current losses, caused by harmonic magnetic field, will appear in the rotor sleeve. This may increase the temperature of the PMSM and even cause the magnets to be demagnetized, which could not only decrease the PMSM performance, but also shorten the working life of the machine [

6,

7,

8]. Thus, it is very significant to seek measures for reducing the eddy-current losses in the rotor sleeve and permanent magnets.

There are many possible measures for reducing the eddy-current losses in the rotor. It is well known that carbon fiber has advantages of high strength, low conductivity, good performance, and simple processing. A machine with a carbon fiber sleeve has been researched [

9,

10,

11], and the influence of carbon fiber on the electromagnetic and temperature fields of the machine was calculated. Kirtley, and Lovelace, and Zhu et al, have tested prototypes with an alloy rotor sleeve [

12,

13]. Copper plating, has high conductivity, and the advantages of copper sleeves in reducing eddy-current losses was presented [

14,

15], and the influence of copper layer thickness on rotor eddy-current losses and temperature distribution was analyzed. In [

16], the electromagnetic and temperature fields of machine with different sleeve materials were researched.

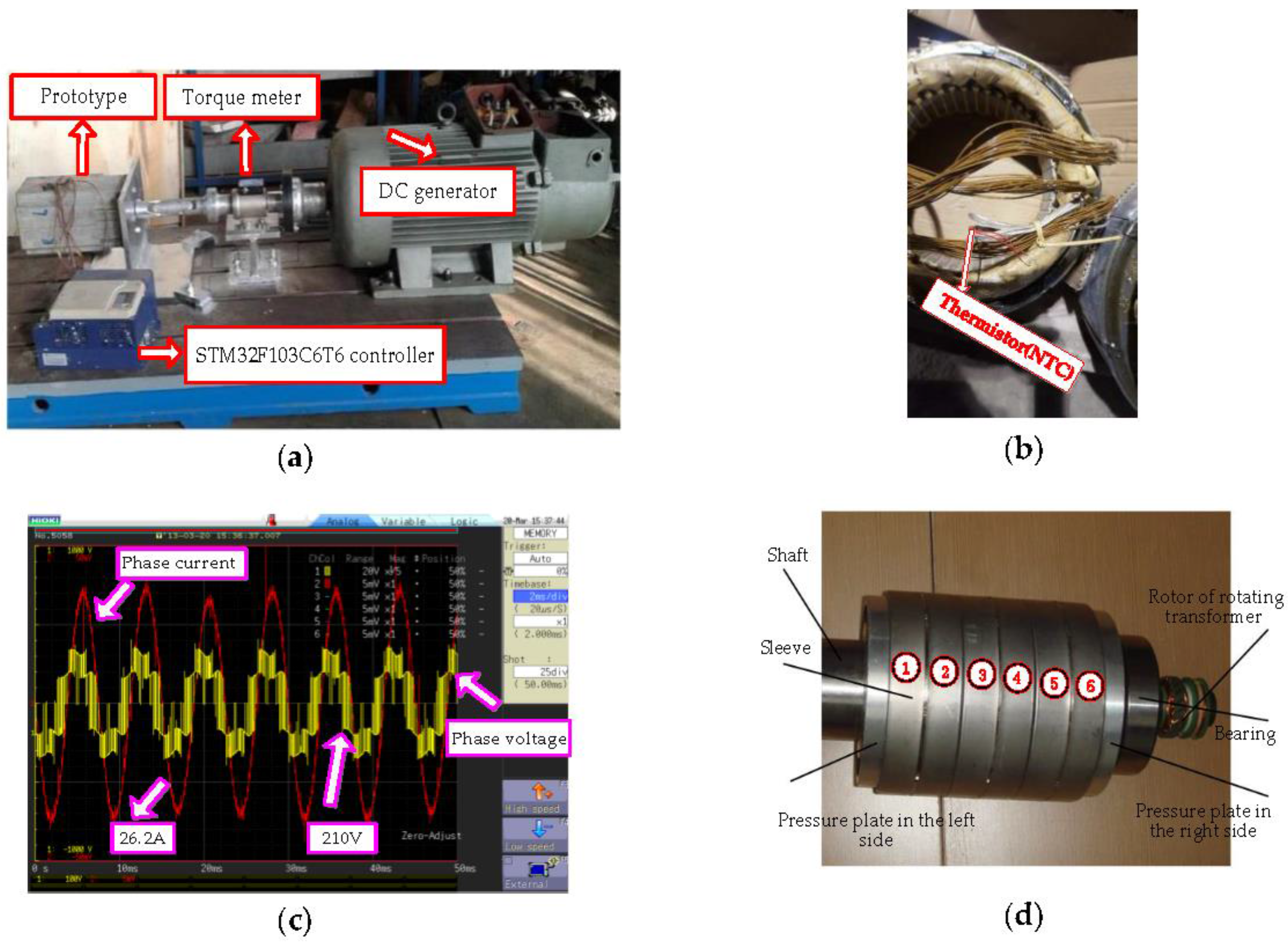

In this paper, taking a 12.5 kW, 2000 r/min PMSM with a 0.2 mm stainless steel sleeve as the study object, a method suppressing the local temperature peak of permanent magnets to solve the problem of the high temperature in the rotor is presented. Firstly, 3-D transient electromagnetic field mathematical and physical models are established, and then the electromagnetic field in the PMSM is calculated under rated-load conditions by using the time-stepping finite element method. Next, the losses in different part of PMSM are applied to the thermal field as heat sources, combined with the 3-D temperature field model, and the influence of the presented method on temperature distribution is studied. The calculated results show the effectiveness of the presented method in reducing the eddy-current losses and temperature in the rotor. In this process, it can be found that the position and zone of permanent magnet maximum temperature can change. Thus, in order to obtain the change rule of the maximum temperature position and zone, three designs are presented based on Multi- Physical Field. The obtained conclusions may provide a theoretical basis for the design and optimization of PMSMs, and in addition, they can also provide a useful reference for thermal studies on permanent magnet motors.

3. Research Suppressing Permanent Magnet Local Maximum Temperature

Through the above analysis, it can be known that the maximum temperature of the PMSM appears at the position of the permanent magnets. A high temperature could cause thermal demagnetization of permanent magnets and even endanger the safe operation of the PMSM. Therefore, it is necessary to devise a strategy to decrease the temperature of permanent magnets.

There are two main reasons which can affect the temperature distribution: the one is heat source distribution, the other one is the cooling mode. Through calculation and analysis, it can be known that the temperature of permanent magnets is low at the two ends and high in the middle. Thus, in this paper, from the point of view of improving the heat source distribution, a method for suppressing the permanent magnet local maximum temperature is presented. Although stainless steel has high temperature resistance and small coefficient of expansion, its high conductivity can cause a large eddy current loss in the rotor. It is well known that carbon fiber has the advantages of high temperature resistance and large tensile strength. This material if used as a sleeve could benefit the thermal conductivity and the reduction of eddy-current losses.

Table 4 gives the parameters of the material. Therefore, in this paper, the sleeves, which are coated on the outer surface of permanent magnet local maximum temperature, adopt carbon fiber material, and the other sleeves adopt stainless steel material. The proposed method (stainless steel and carbon fiber sleeves were used at the same model) integrates the inherent advantages of the two materials, so it can not only reduce the rotor eddy-current losses and decrease the temperature of permanent magnets, but also well fix the permanent magnets and protect them from being destroyed by the large centrifugal force.

By using the finite-element method, the electromagnetic field are calculated and the losses in different parts of PMSM are given in

Table 5.

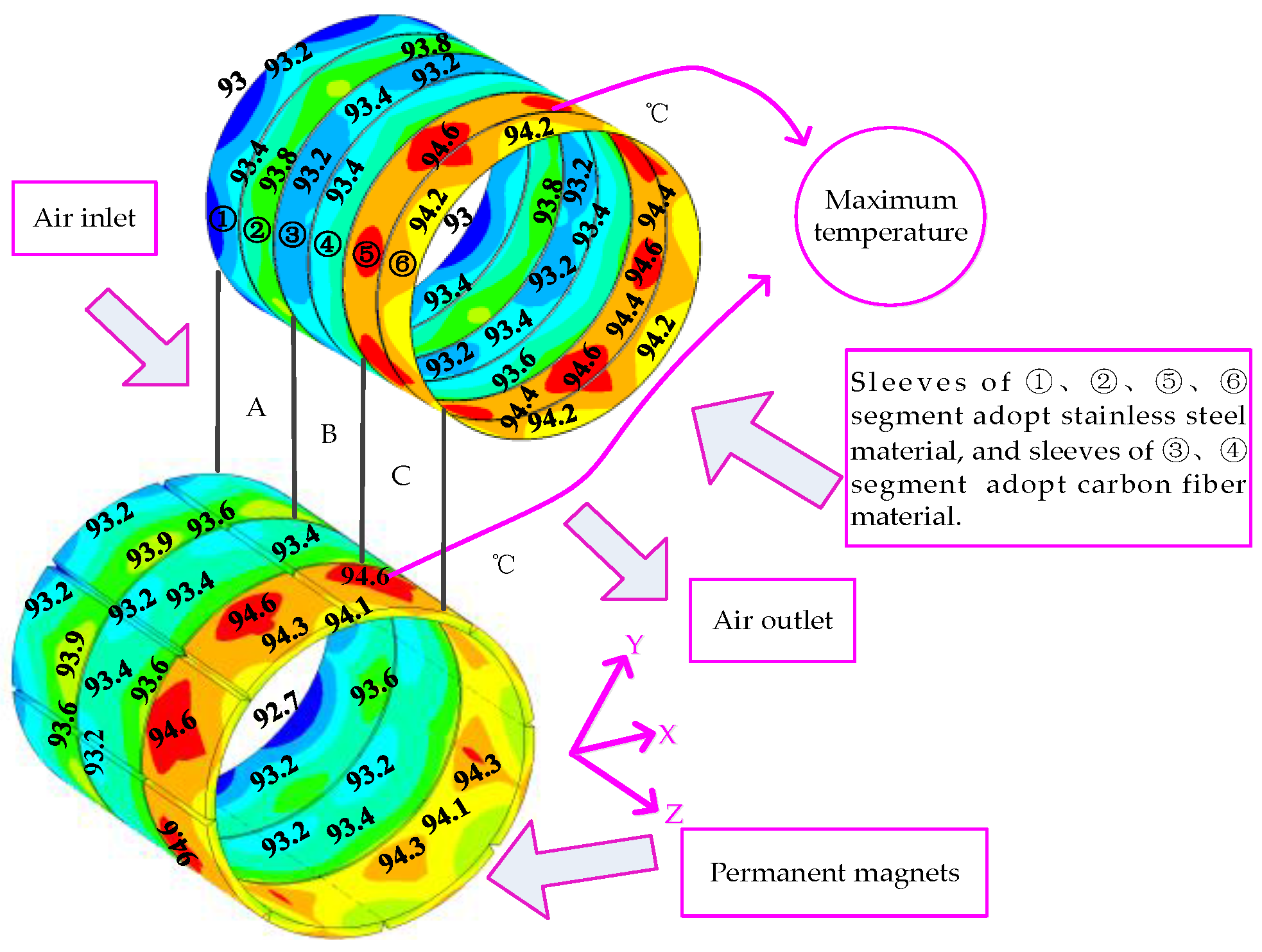

As shown in

Table 5, when ①, ②, ⑤, ⑥ segment sleeves adopt stainless steel and ③, ④segment sleeves adopt carbon fiber material, the eddy-current losses in ③, ④ segment sleeves are obviously much lower than those in ①, ②, ⑤, ⑥ segment sleeves. The eddy-current losses in permanent magnets are decreased correspondingly, thus, the total rotor eddy-current losses can also be decreased. From a 3-D temperature field, the temperature distributions in different parts of PMSM can be obtained. As shown in

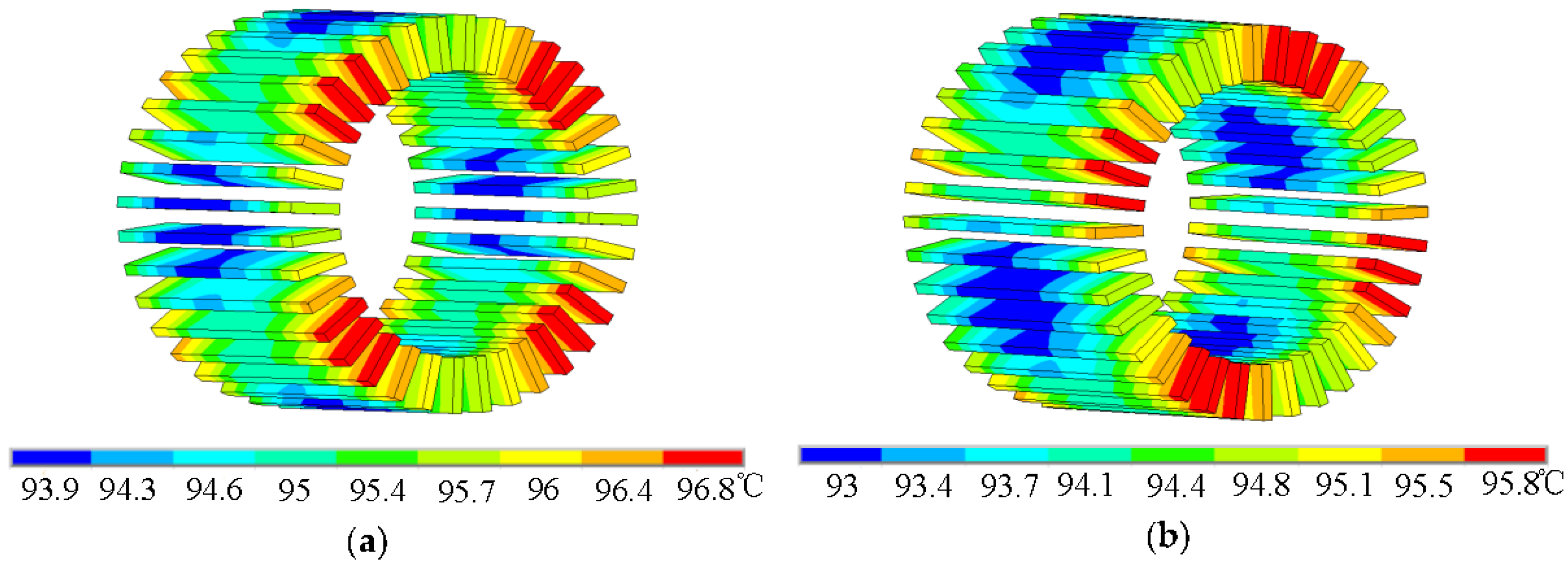

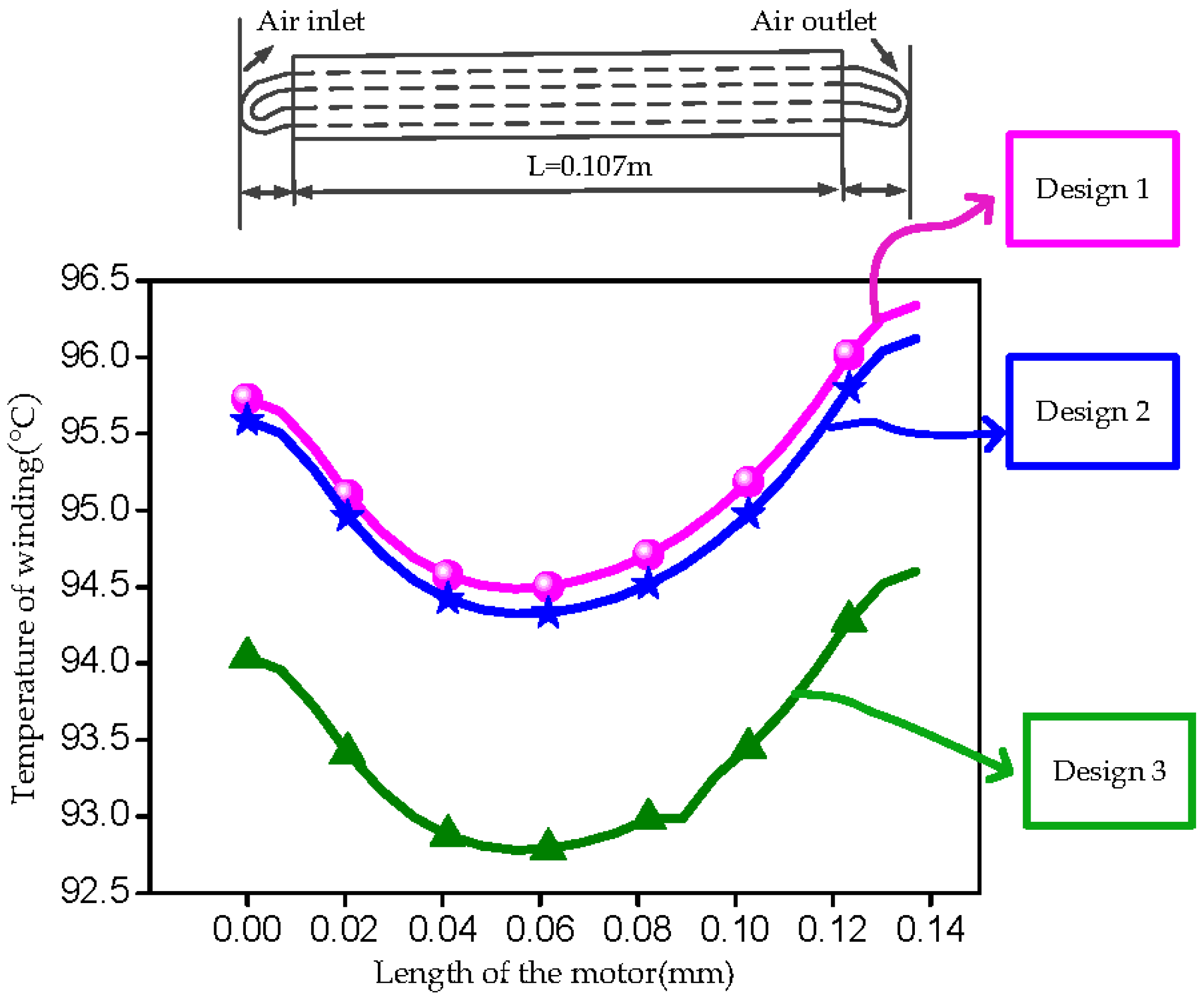

Figure 5, the temperature of the stator winding decreases with the carbon fiber, but the reduction is not obvious. One point to take notice of is that the temperature distributions of the stator winding are the same compared with the prototype PMSM, namely, a similar “saddle” with high points at the two ends and low in the middle. The reason is that the two end windings conduct heat by air and the straight segment of the winding conducts heat via the stator silicon steel sheet, moreover, the thermal conductivity of the silicon steel sleeve is larger than that of air. In addition, cooling wind flows through from air inlet (close to the fan) to the air outlet, thus, the temperature in the one end winding which is closer to the fan is lower than that at the back end.

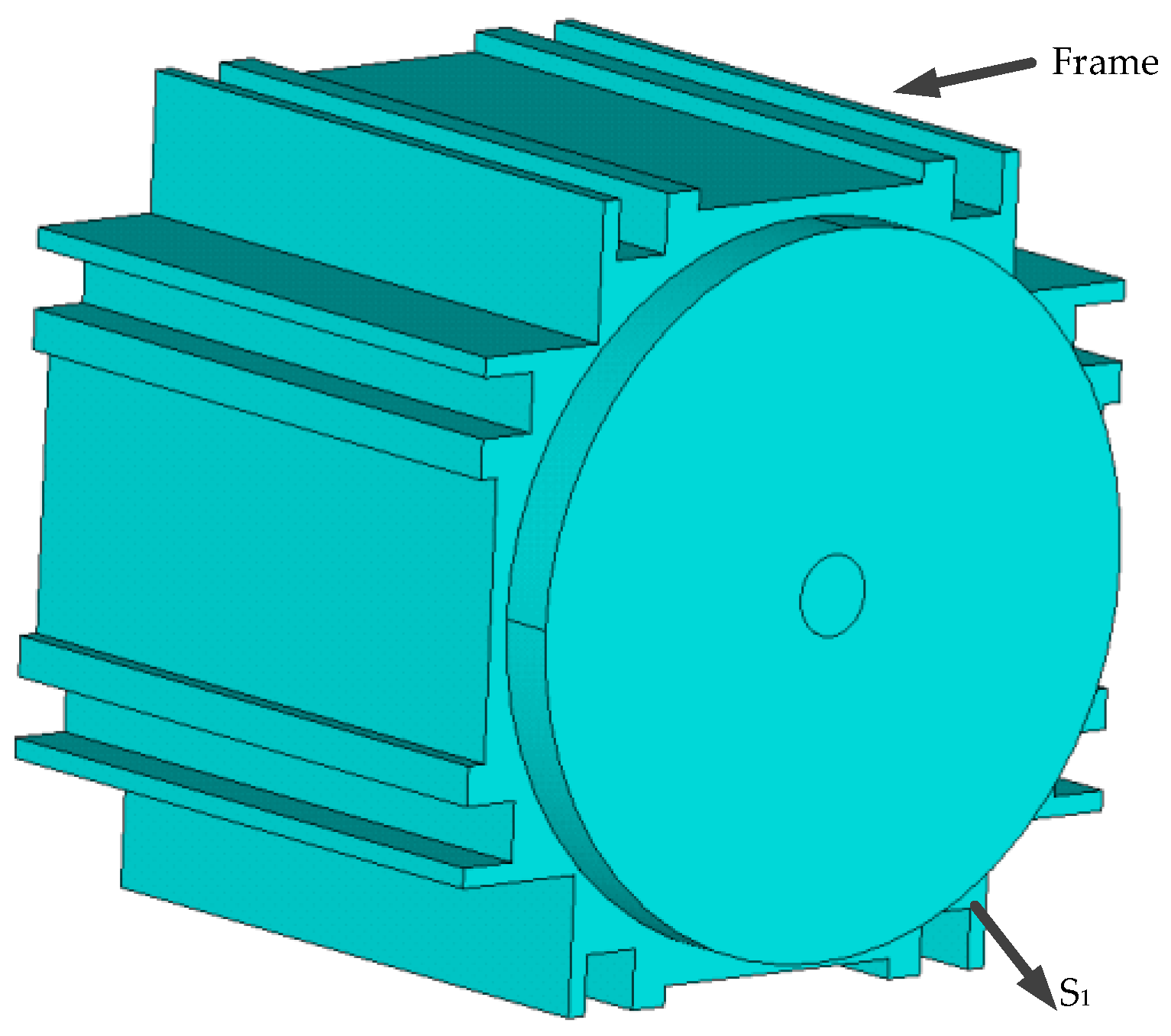

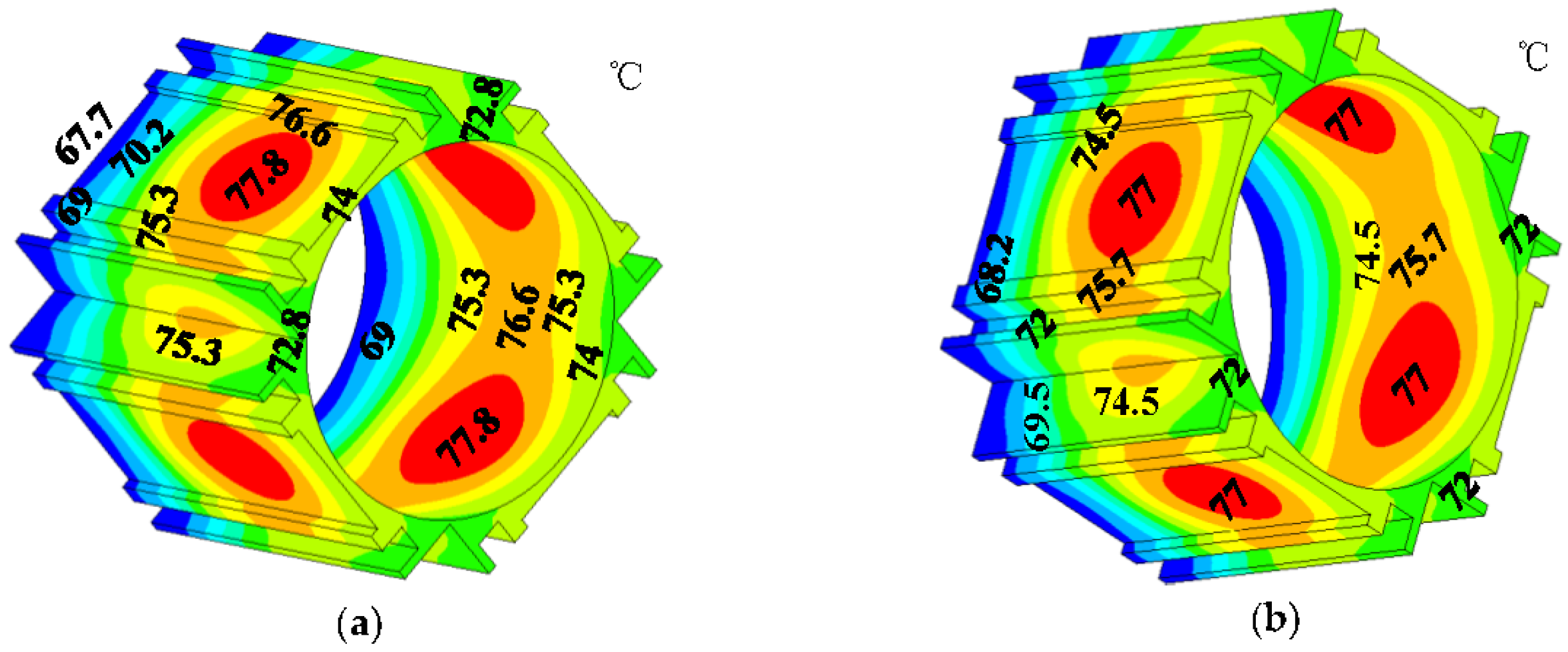

In the same way, after using carbon fiber, the temperature distribution of the frame can also decrease, but the reduction is not also obvious. The temperature distribution rule of the frame is low at the two ends and high in the middle, as shown in

Figure 6. The reason is that the heat in the middle is mainly from the stator core and winding losses, meanwhile, because of the fan at the frame back-end, the temperature of the frame back-end is lower compared with the frame front-end. In addition, the heat dissipation effect of the frame with a bare radiator is better.

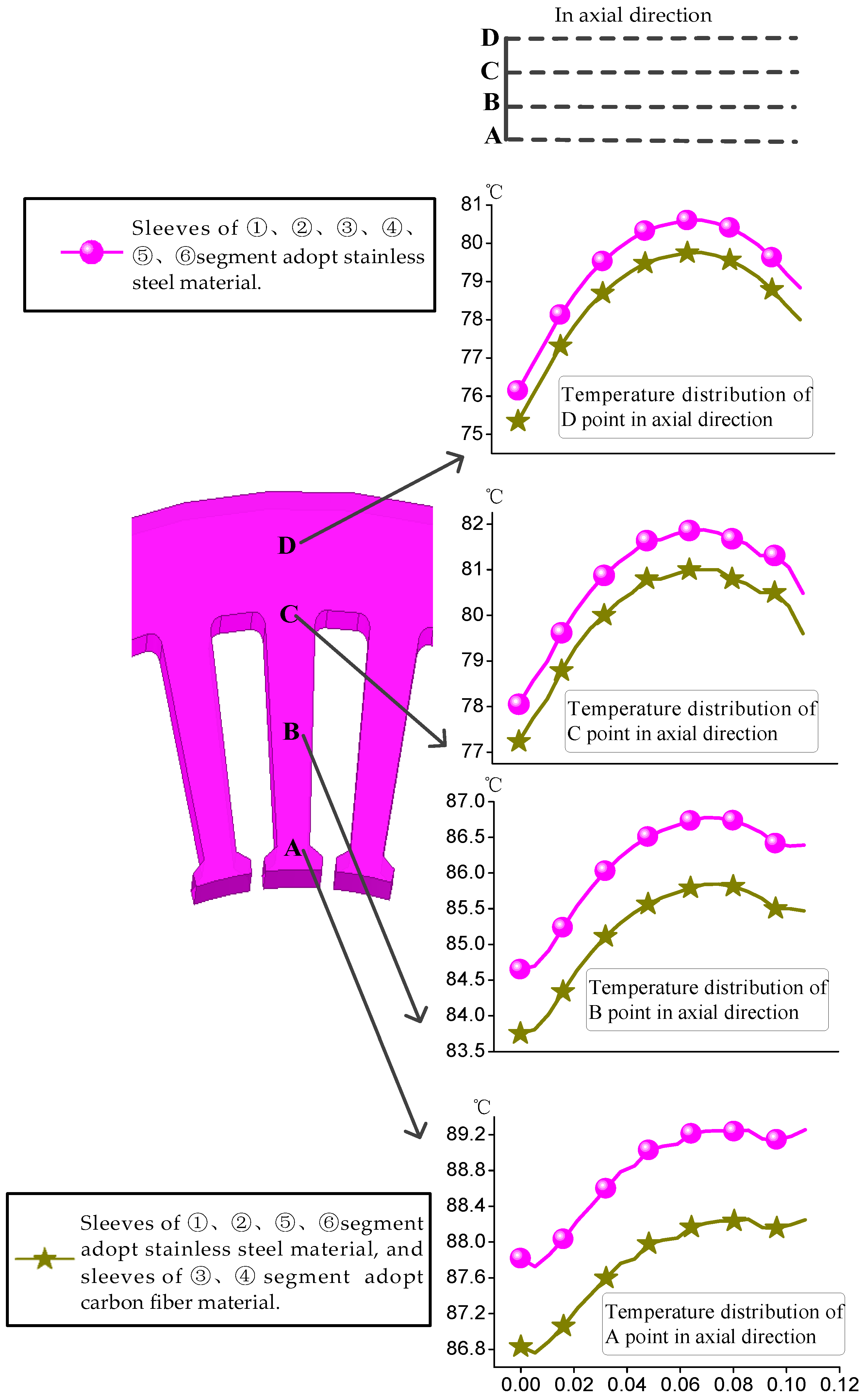

To study the temperature distribution of the stator core, uniformly taking A, B, C, D four points from tooth tip to yoke, when ①, ②, ⑤, ⑥ segment sleeves adopt stainless steel and ③, ④ segment sleeves adopt carbon fiber material, the temperatures of the tooth center line in the axial and radial direction both decrease, which is shown in

Figure 7.

From

Figure 7, it can also be found that the temperature from the stator tooth to the stator yoke gradually decreases in radius before and after the proposed method for suppressing the permanent magnet local maximum temperature is applied. The reason is that, A point is close to the air gap, resulting in difficulty in cooling the coil, and the stator yoke is close to the frame, so accordingly, the heat dissipation condition is better. In the axial direction, due to the eddy-current loss distribution and cooling effect, the temperature first increases and then decreases.

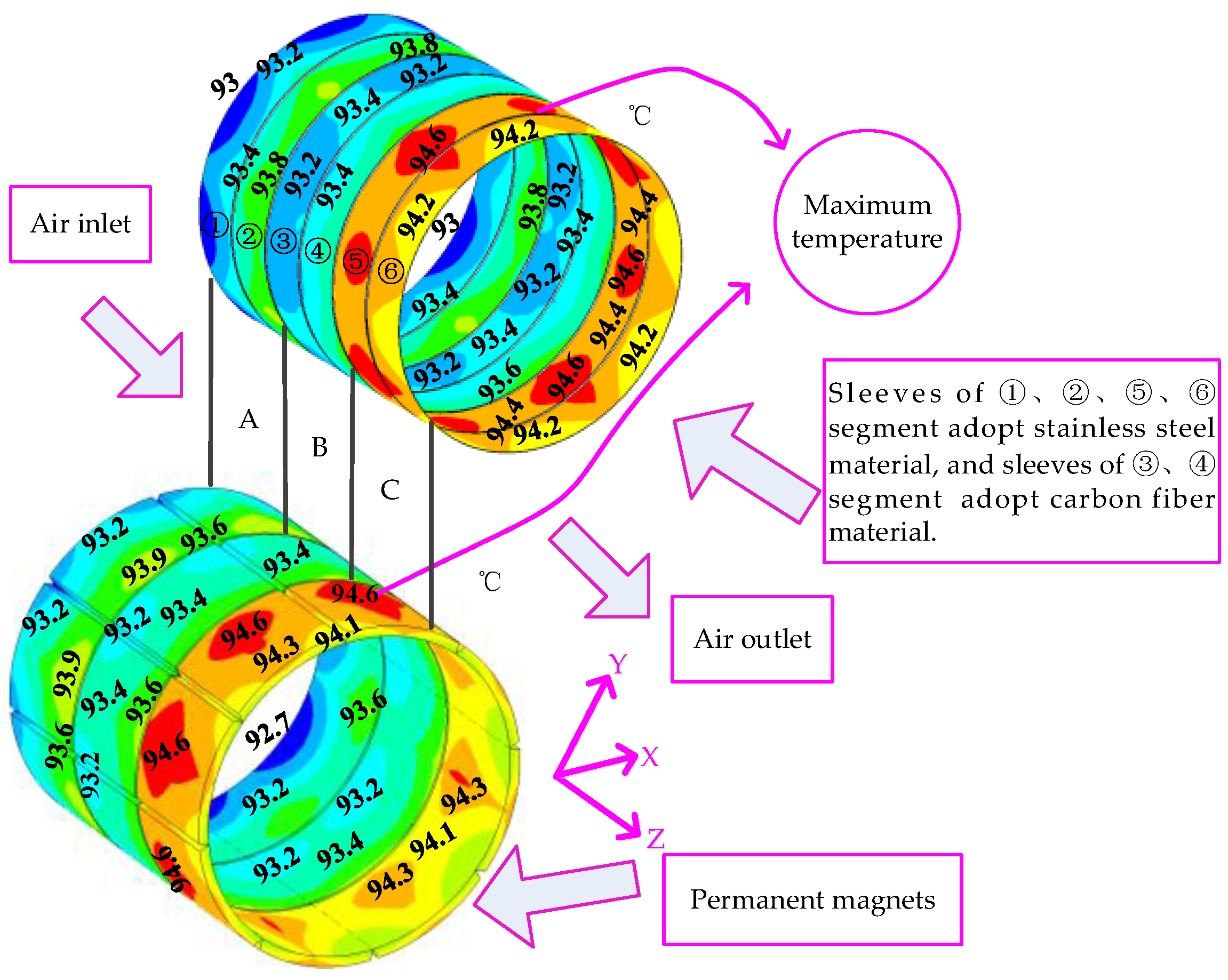

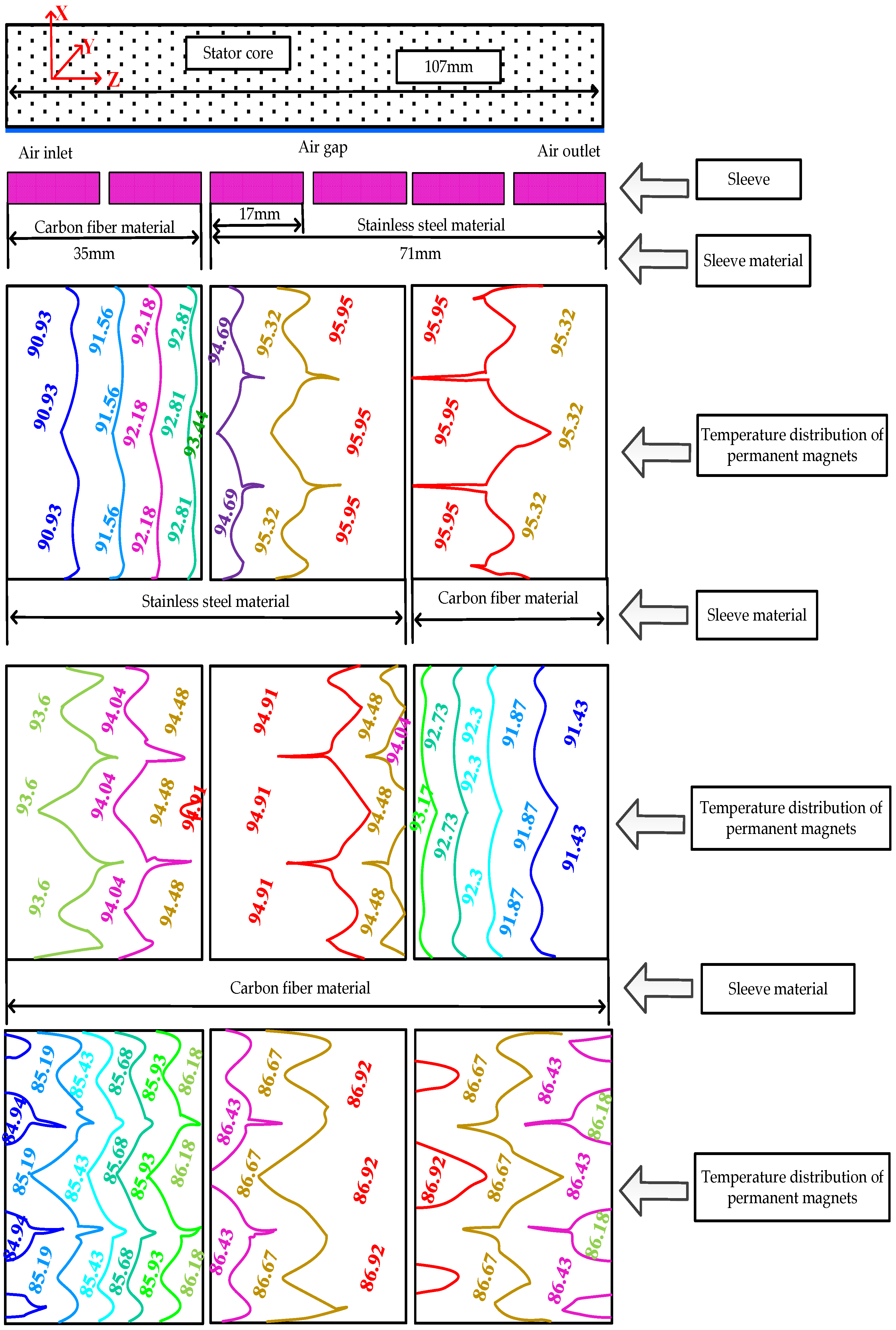

At the same time, this will have a significant effect on the rotor temperature, as shown in

Figure 8. Firstly, the maximum temperature of the permanent magnets decreases by 4.4 °C compared with the temperature of the prototype PMSM, which is below the N33SH magnets’ limiting working temperature (150 °C), moreover, the effect on decreasing the rotor temperature is larger than that decreasing the stator temperature. Next, the maximum temperature zone of the permanent magnets is greatly reduced. In addition, the position of the maximum temperature shows a fluttering phenomenon, whereby the maximum temperature position changes from the B segment to the C segment of the permanent magnet. Compared with the maximum temperature position of the prototype PMSM, this fluttering value is 16.1 mm. This can be explained as follows: on the one hand, because the conductivity of carbon fiber is relatively low, the total rotor eddy-current losses decrease. On the other hand, because the end of PMSM is close to a fan, its temperature is lower than that of the end far away a fan, and because the thermal conductivity of stainless steel is much larger than that of carbon fiber and the distribution of sleeves material is uneven in the axial direction, it can cause a heat transfer in the axial direction. Thus, the position of the maximum temperature of the permanent magnet is finally close to the air outlet, and the maximum temperature zone is reduced.

From the analysis results, it can be known that whether the motor power in different machines is large or small, the proposed method will have a relatively positive effect in decreasing the rotor eddy-current losses and the temperature of permanent magnets, which can suppress well permanent magnet demagnetization and protect the properties of permanent magnets. In order to find the variation law of the maximum temperature position and zone, in this paper, three rotor composite structures in the axial direction are presented, as follows:

- Design 1:

③, ④, ⑤, ⑥ segment sleeves adopt stainless steel material, and ①, ② segment sleeves adopt carbon fiber material.

- Design 2:

①, ②, ③, ④ segment sleeves adopt stainless steel material, and ⑤, ⑥ segment sleeves adopt carbon fiber material.

- Design 3:

①, ②, ③, ④, ⑤, ⑥ segment sleeves adopt carbon fiber material.

By time stepped finite element analysis, the losses in different parts of the PMSM can be obtained under the three designs, as shown in

Table 6,

Table 7 and

Table 8. From the loss calculation results, it can be seen that the eddy-current losses in the sleeve that adopted carbon fiber material are much lower than in those that adopted stainless steel, and the eddy-current losses in the sleeve that adopted carbon fiber material are almost 0 W, since the conductivity of carbon fiber is very low (1.5 × 10

5 S/m). Simultaneously, the three designs can reduce the total rotor losses, with the reduction degree of Design 2 being slightly better than that of Design 1. The reduction of Design 3 is most obvious, compared with the eddy-current losses of the prototype PMSM, the eddy-current losses in the sleeve and permanent magnet decrease by 14.36 W, 3.53 W, respectively. In addition, when ①, ②, ⑤, ⑥ segment sleeves adopt stainless steel material and ③, ④ segment sleeves adopt carbon fiber material, the influence on reducing the eddy-current loss is the same as with Design 1 and Design 2.

By a 3-D steady thermal finite element model, the whole region 3-D heat flow density distribution in different parts of the PMSM operating at rated speed (2000 r/min) and rated load (R = 0.32 Ω and cos φ = 0.79) can be obtained under the three designs, which has an ambient temperature of 10 °C.

As shown in

Figure 9, the three designs can decrease the temperature of the stator winding, Design 3 is the best compared with the prototype PMSM, and the maximum temperature of the stator winding decreases by 2.5 °C. In addition, Design 2 is better than Design 1. However, the temperature distribution rule of the stator winding is not changed under the three designs.

From

Figure 10, it can be known that the maximum temperature of the permanent magnets decreases by 3.05 °C under Design 1 compared with the temperature of the prototype PMSM. Moreover, the maximum temperature position is located on the permanent magnets which are coated on the inner surface of ④, ⑤ segment sleeves. However, the maximum temperature zone of the permanent magnets can increase. For Design 2, the maximum temperature position is located on the permanent magnets which are coated on the inner surface of ③, ④ segment sleeves, and the maximum temperature zone of the permanent magnets can increase. At the same time, the minimum temperature position is coated on the inner surface of ⑥ segment sleeve and decreases by 5.07 °C. This is because the conductivity of the carbon fiber is much lower and it can reduce the eddy current loss in the rotor, although the fan is close to segment sleeves ①, ②.

Design 1 and Design 2 can decrease the rotor temperature. However, their degree of decreasing is not better than with the strategy that ①, ②, ⑤, ⑥ segment sleeves adopt stainless steel and ③, ④ segment sleeves adopt carbon fiber. One point to be noticed is that, whether Design 1 or Design 2 is used, the maximum temperature zone can increase compared with the prototype PMSM. The reason is that the thermal conductivity of stainless steel (59 W/(m·K)) is much larger than that of carbon fiber (1.7 W/(m·K)), and because the distribution of sleeves material is uneven in the axial direction, it can cause a thermal transfer in the axial direction.

For Design 3, compared with the prototype PMSM, the maximum temperature of permanent magnets decreases by 12.08 °C, but the maximum temperature position and zone are not changed. The position is located on the permanent magnets which are coated on the inner surface of ④, ⑤segment sleeves. The reason is that sleeves adopt the same material, which cannot cause thermal transfer in the axial direction, and the fan only plays an air cooling effect. Therefore, it can be known that is all sleeves adopt the same material, the maximum temperature position and zone of the permanent magnets will not change.

From the above analysis, it can be known that the three designs can decrease rotor losses and temperature compared with the prototype PMSM. Thus, adopting a sleeve composition structure of carbon fiber and stainless steel could improve the cooling efficiency of the system. Simultaneously, compared with the method for suppressing permanent magnet local maximum temperature, the three designs revealed the change rule of the position and zone of the rotor maximum temperature. The obtained conclusions may provide useful references for the design and research of PMSMs.