Development of Automotive Permanent Magnet Alternator with Fully Controlled AC/DC Converter

Abstract

:1. Introduction

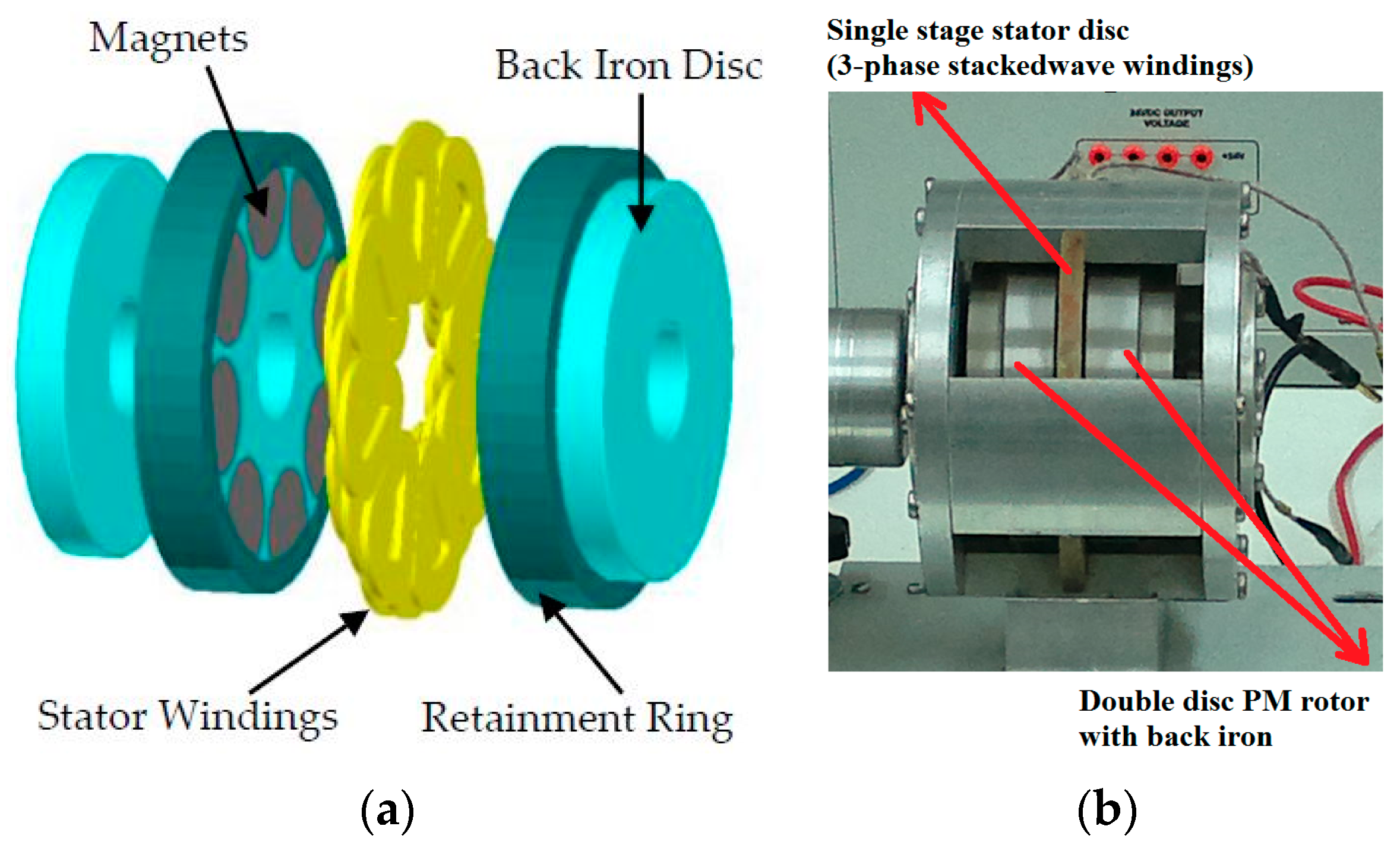

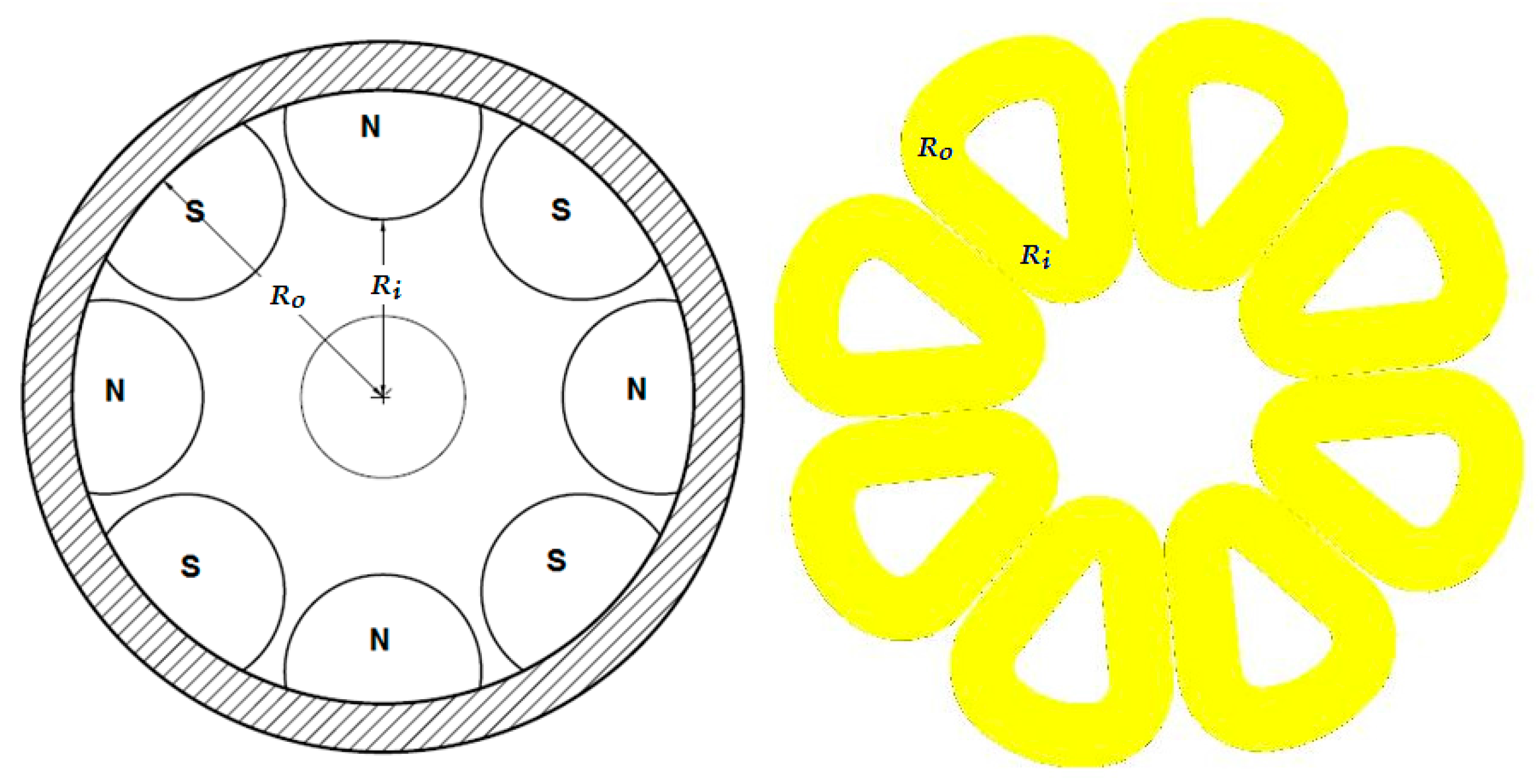

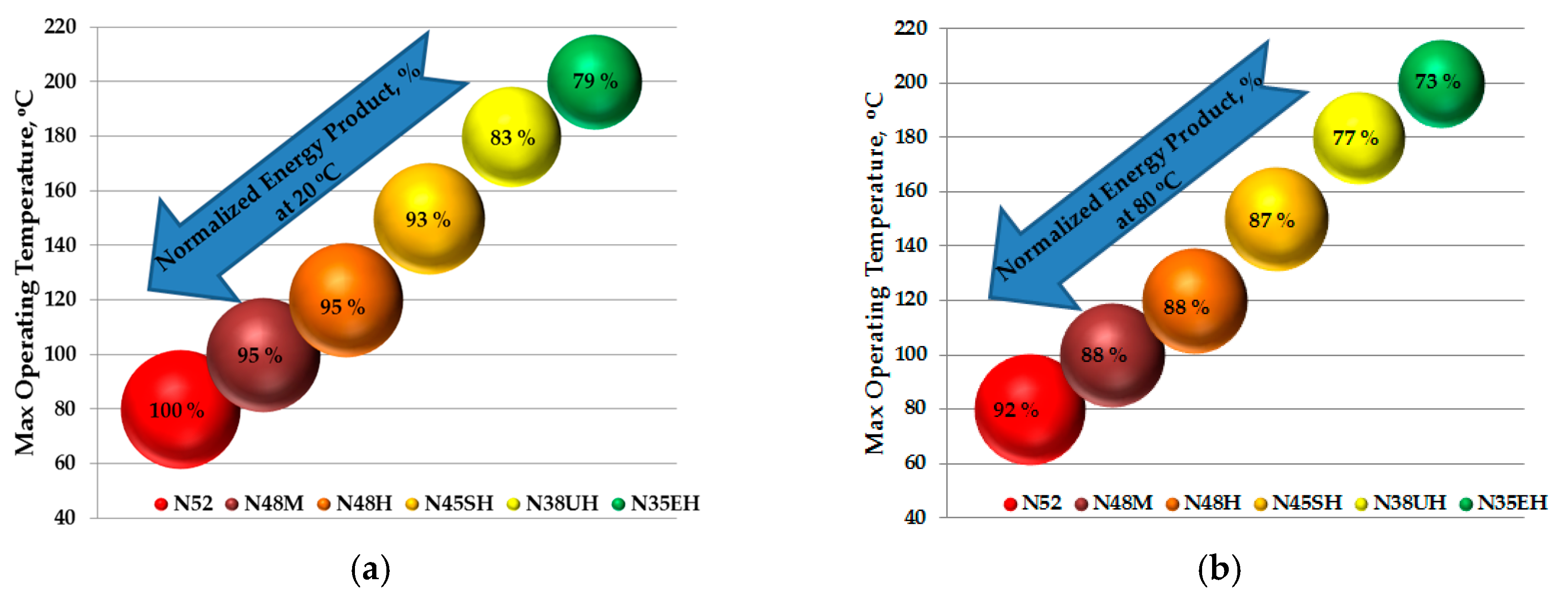

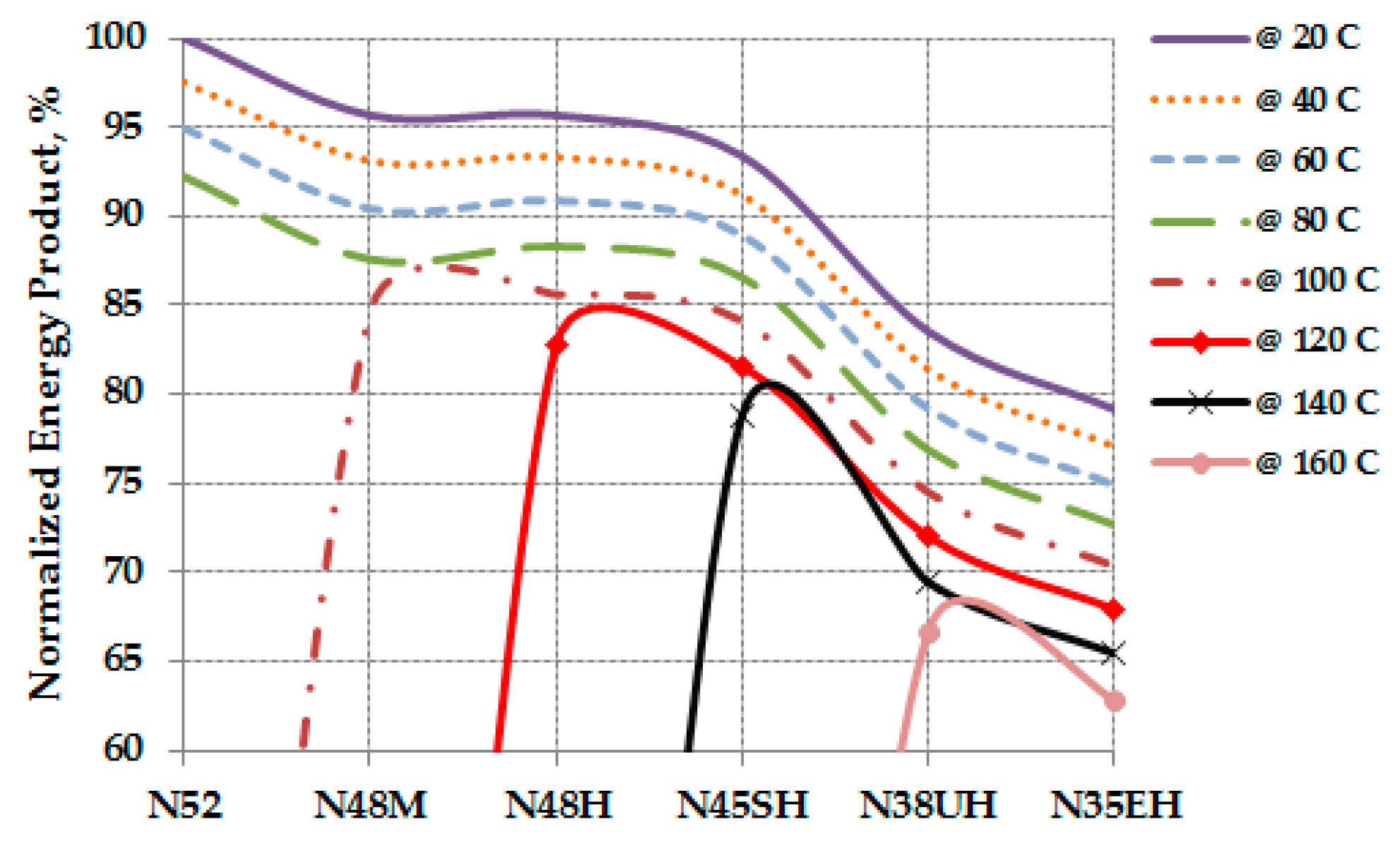

2. Description and Design Requirements of the AFPMA

3. Design Consideration and Sizing of the AFPMA

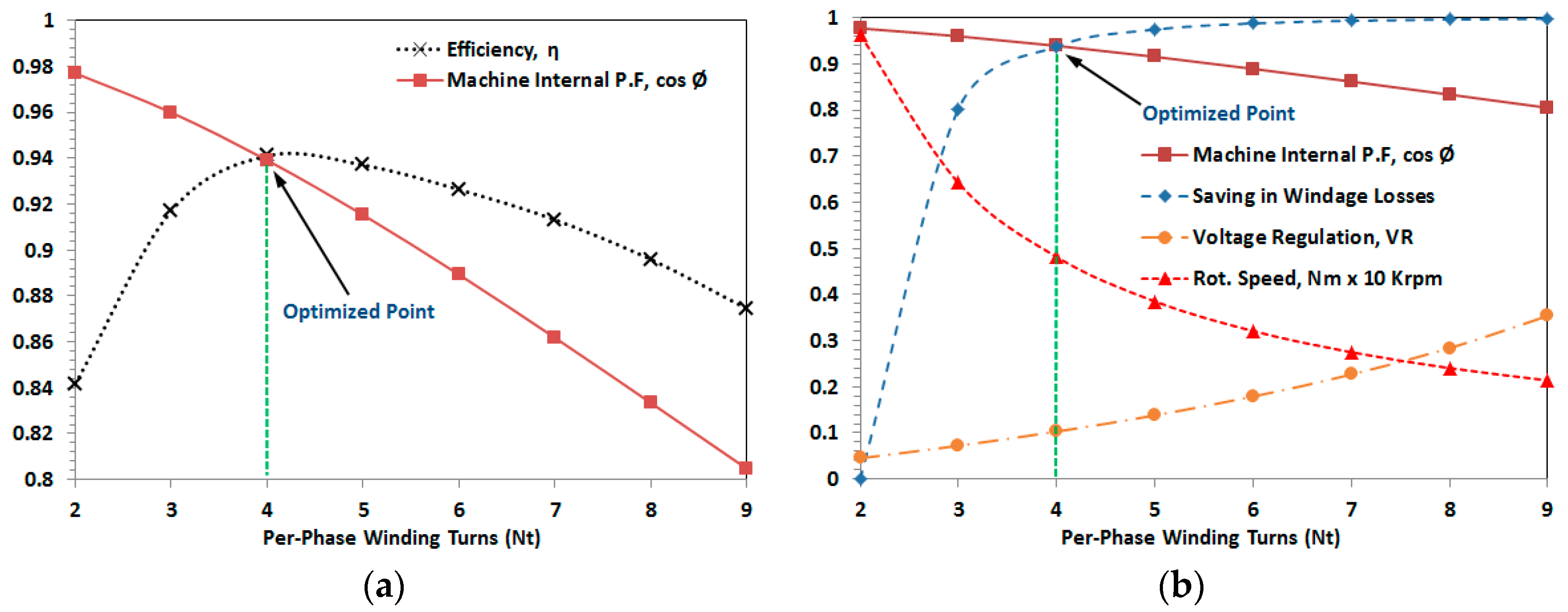

4. Optimization of the AFPMA

4.1. Machine Efficiency

4.2. Machine Internal Power Factor (cos φ)

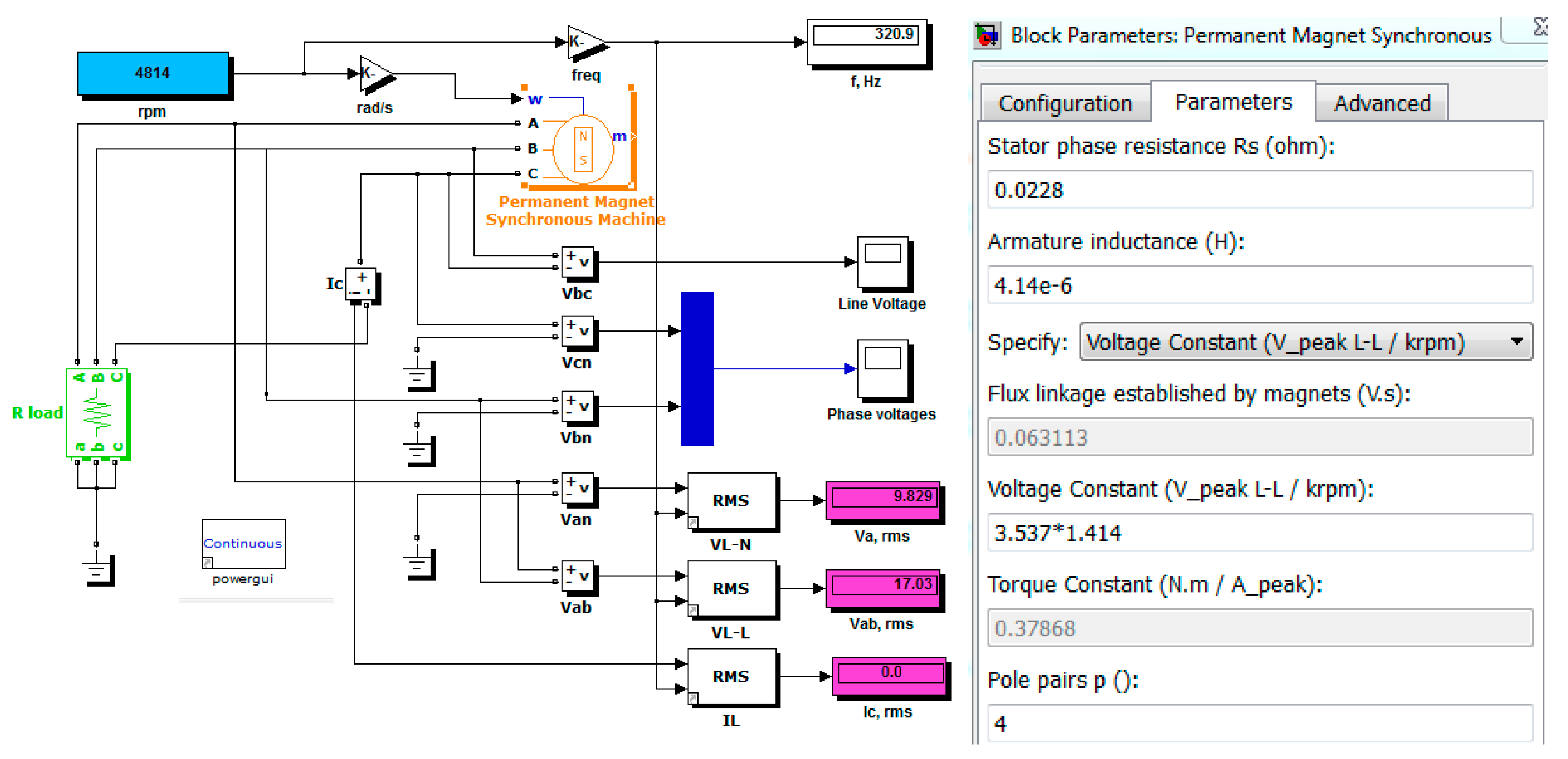

5. Modelling and Simulation of the AFPMA

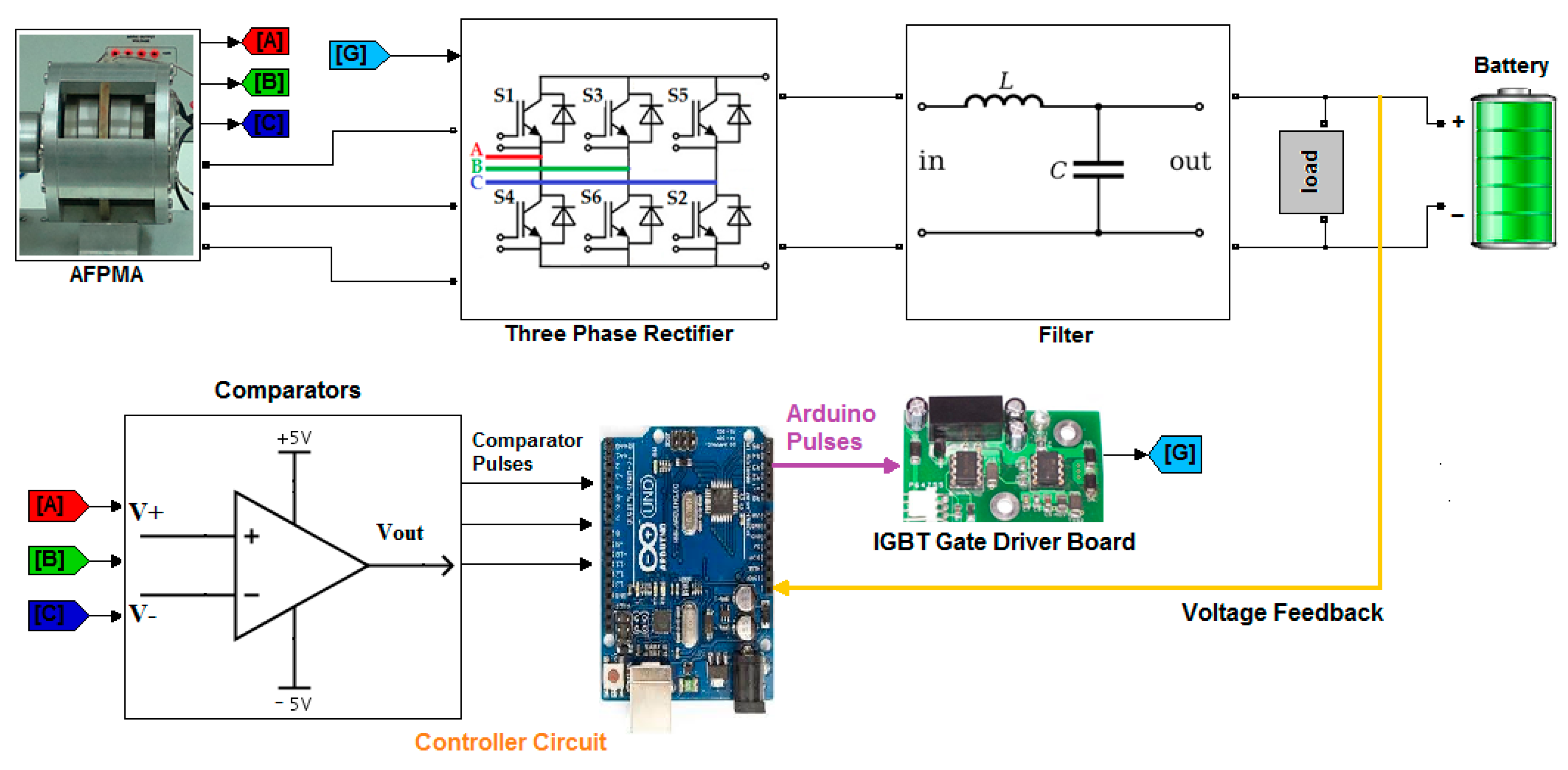

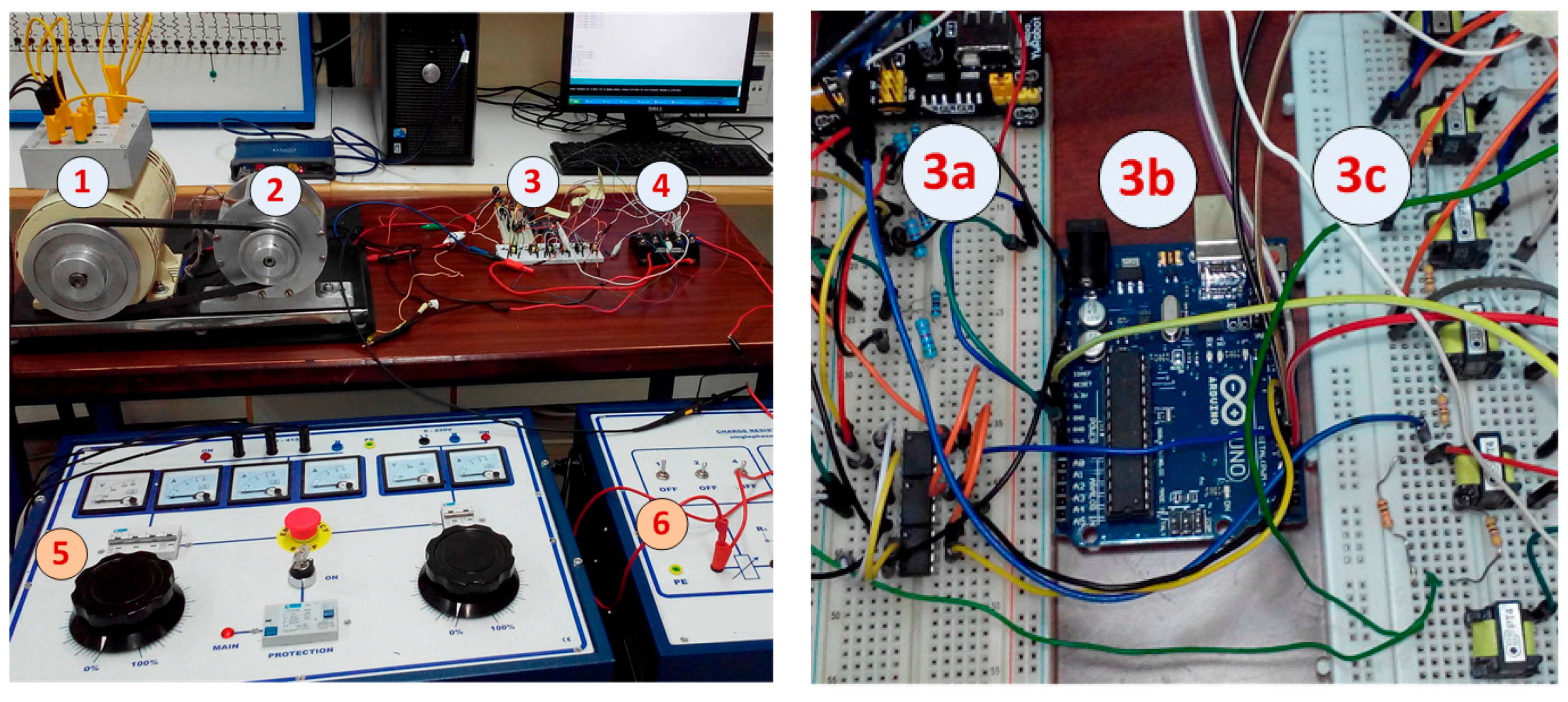

6. Development of the Controlled AC/DC Rectifier for the AFPMA

- IGBT six-pack module (CM100TF-12H)

- Microcontroller (Arduino Uno)

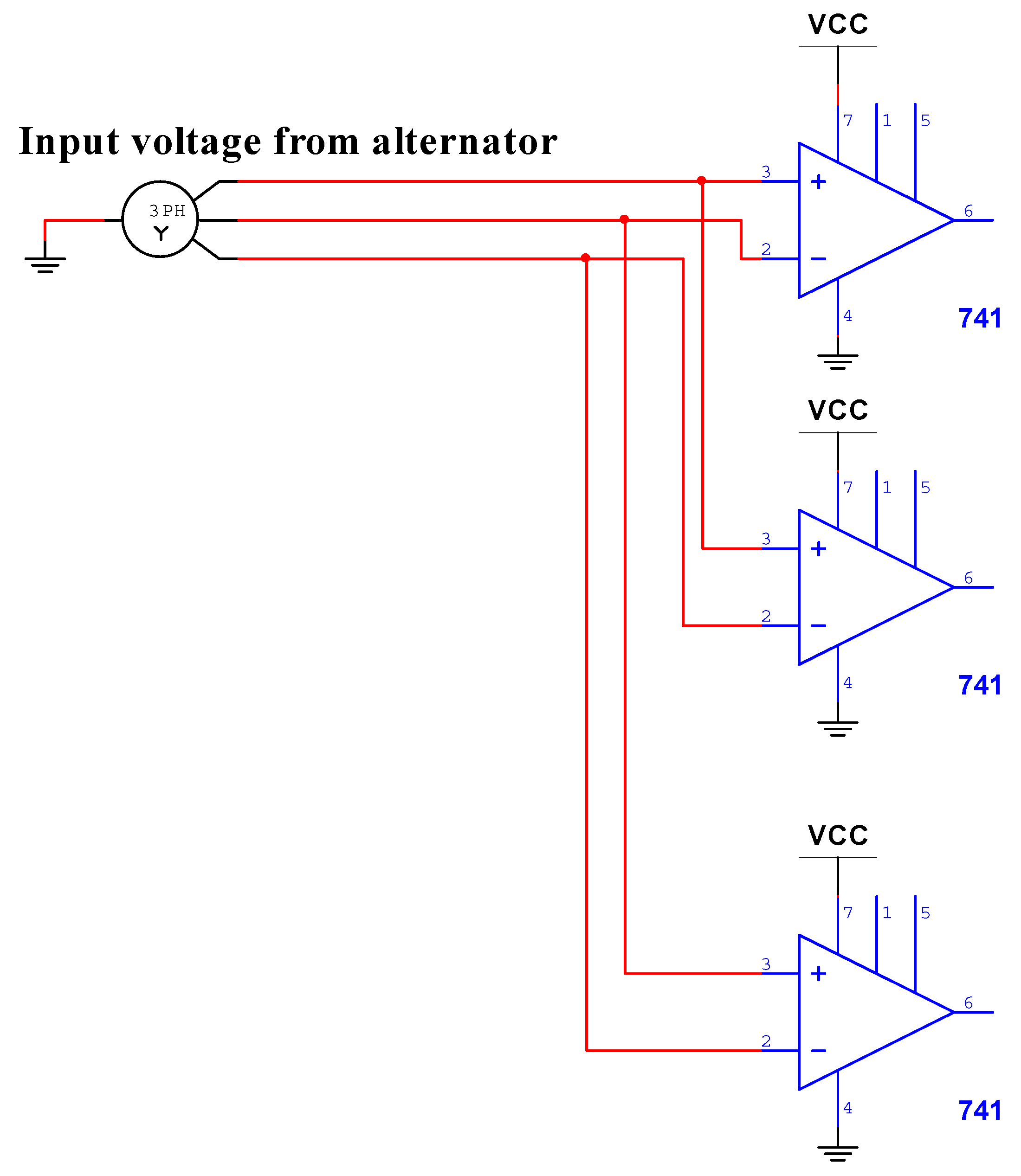

- Comparator circuit (voltage sensing).

- LC filter.

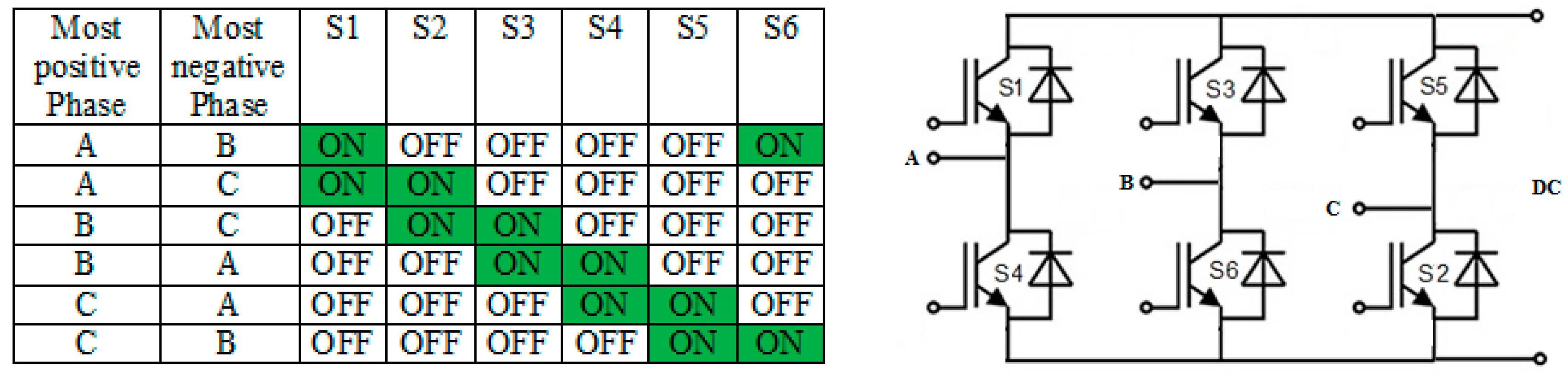

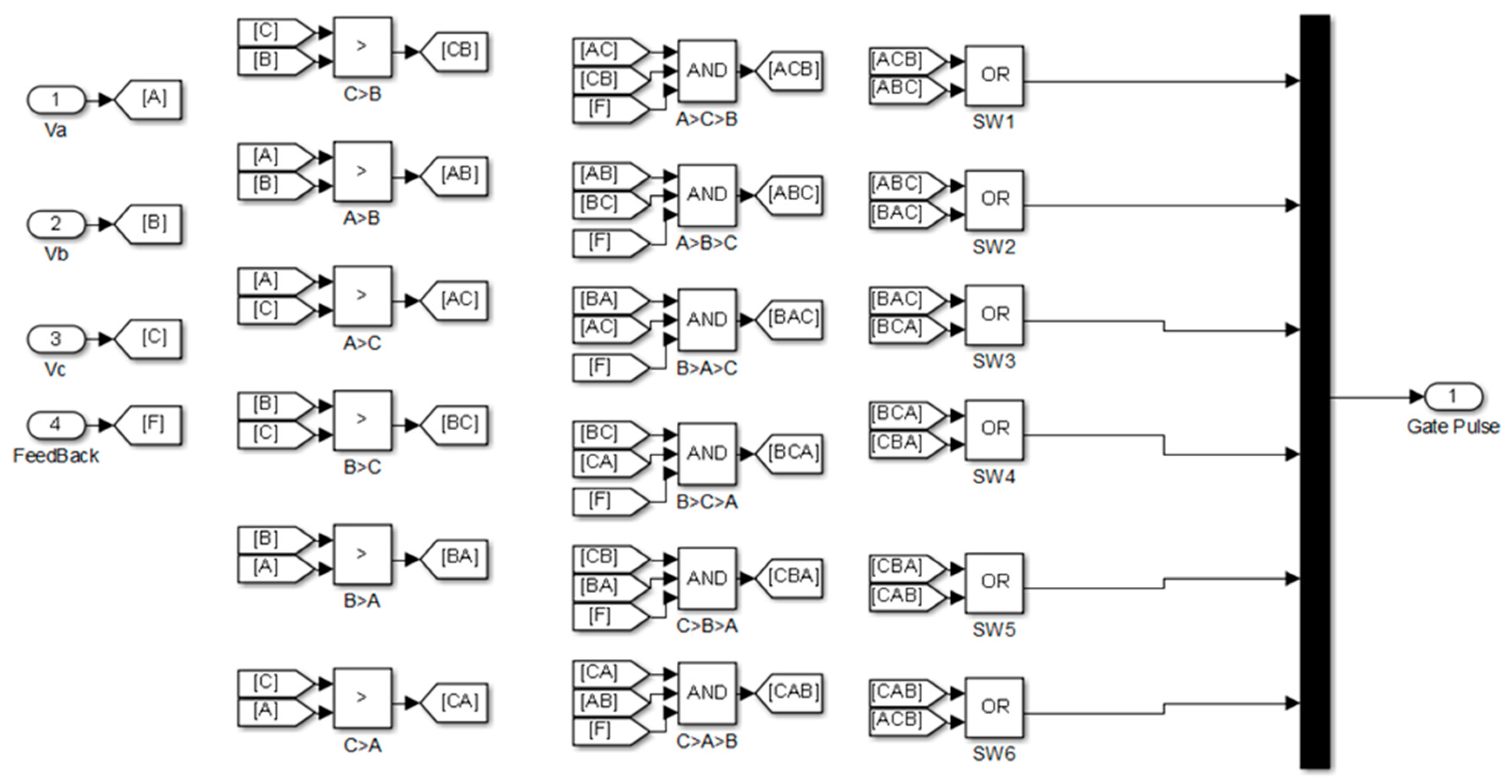

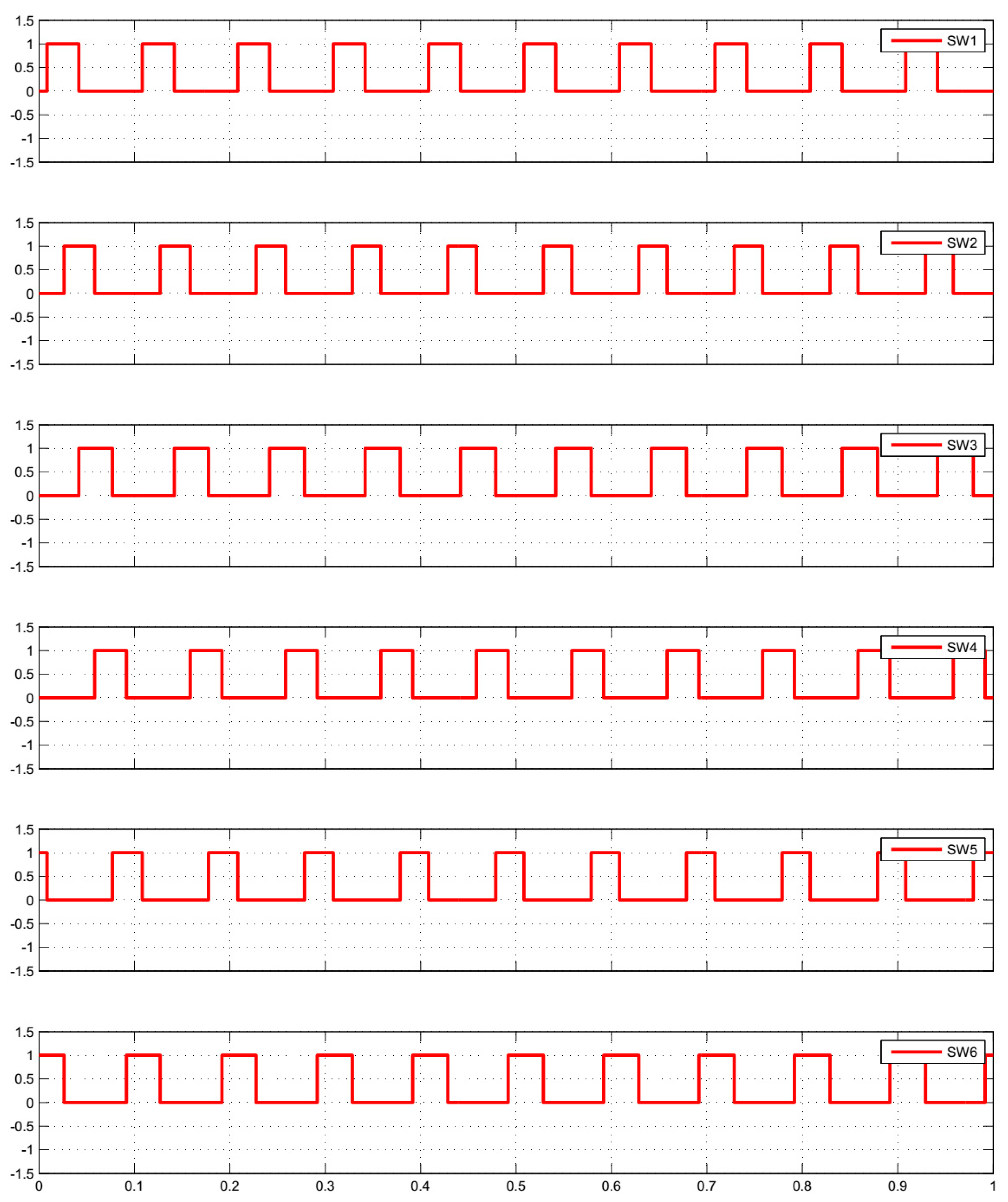

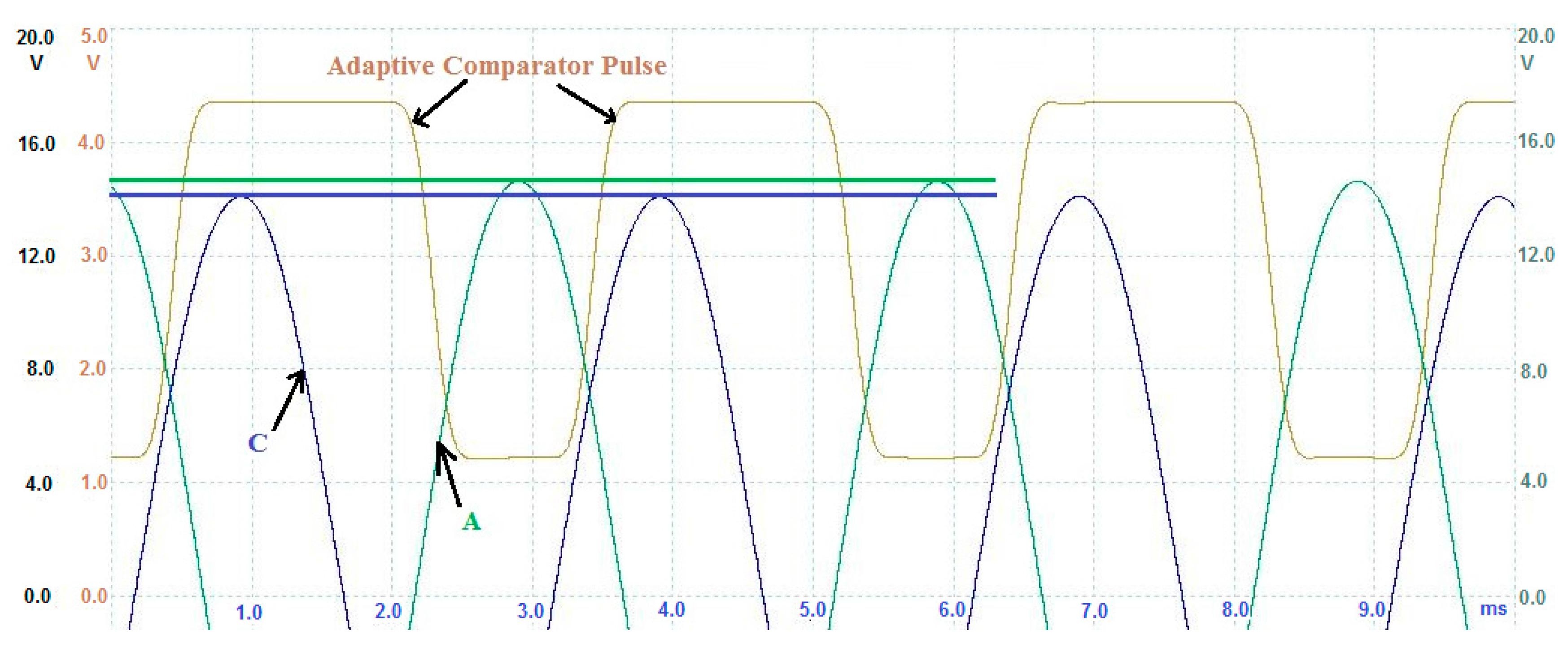

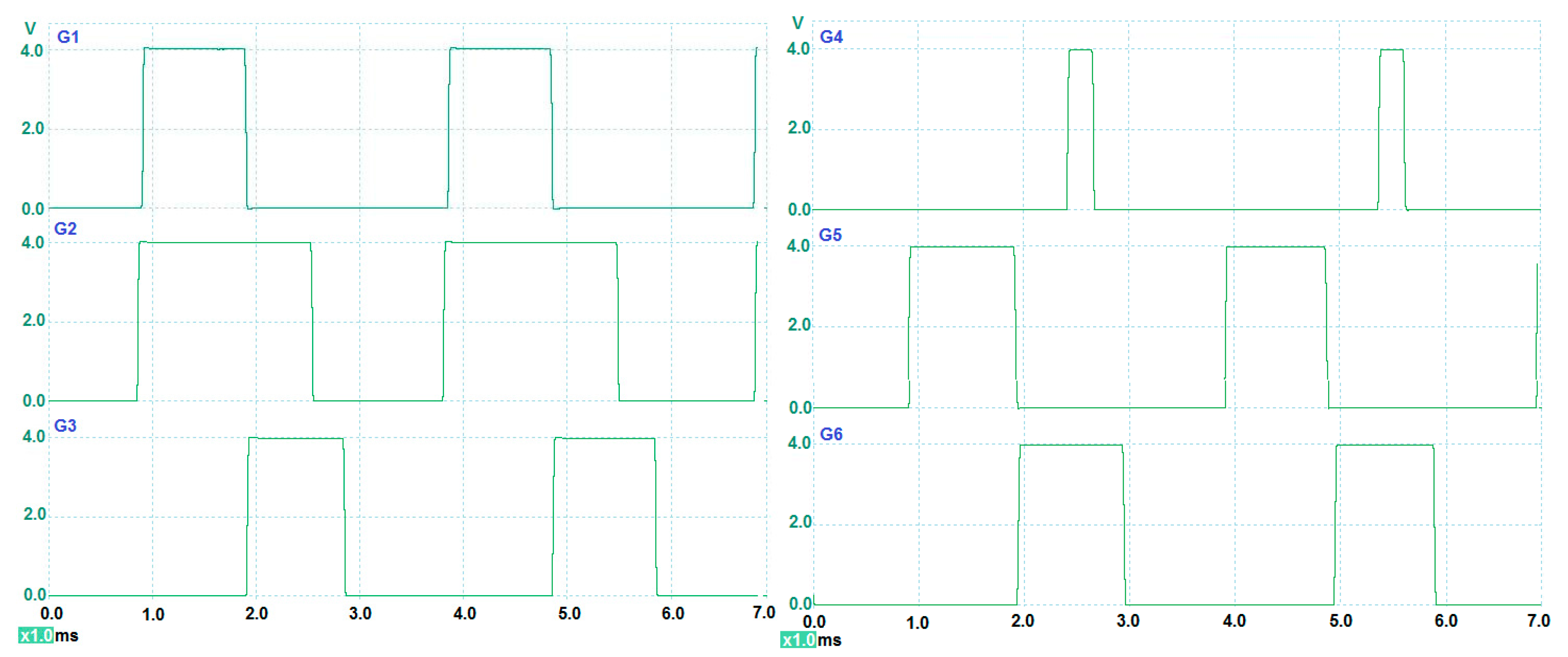

6.1. Control Scheme

6.2. Controlled Rectifier Design Calculations

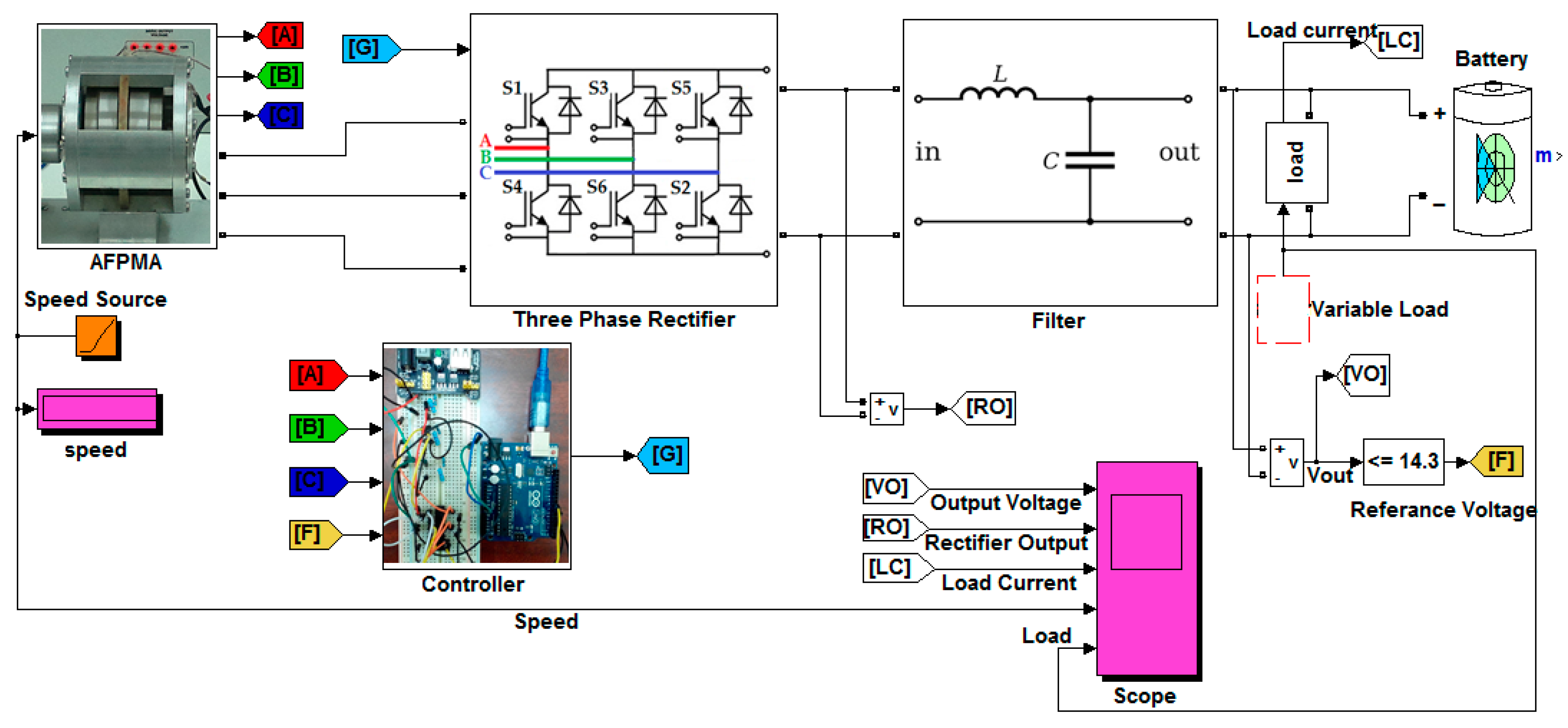

7. Overall System Simulation

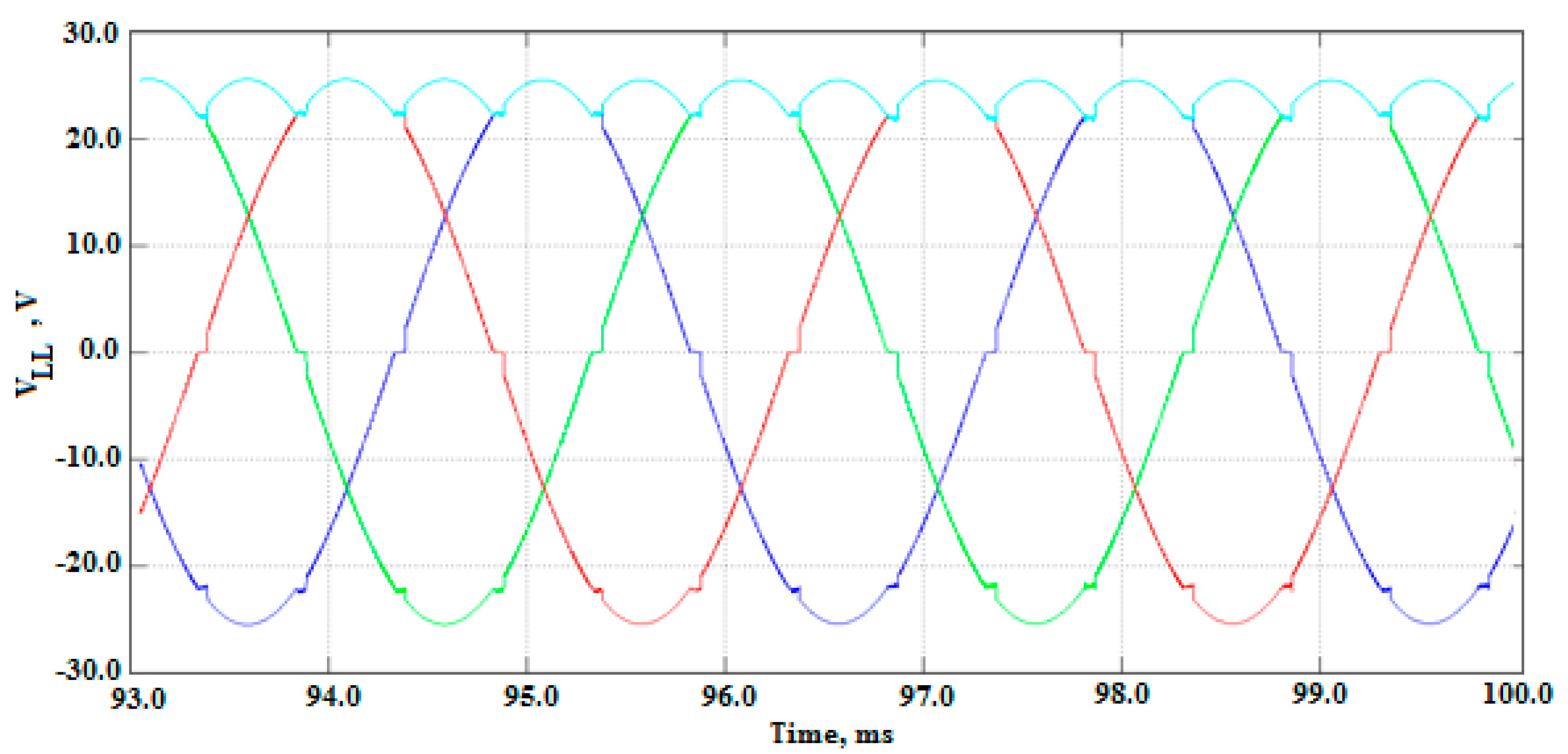

7.1. System Simulation with Open Circuit

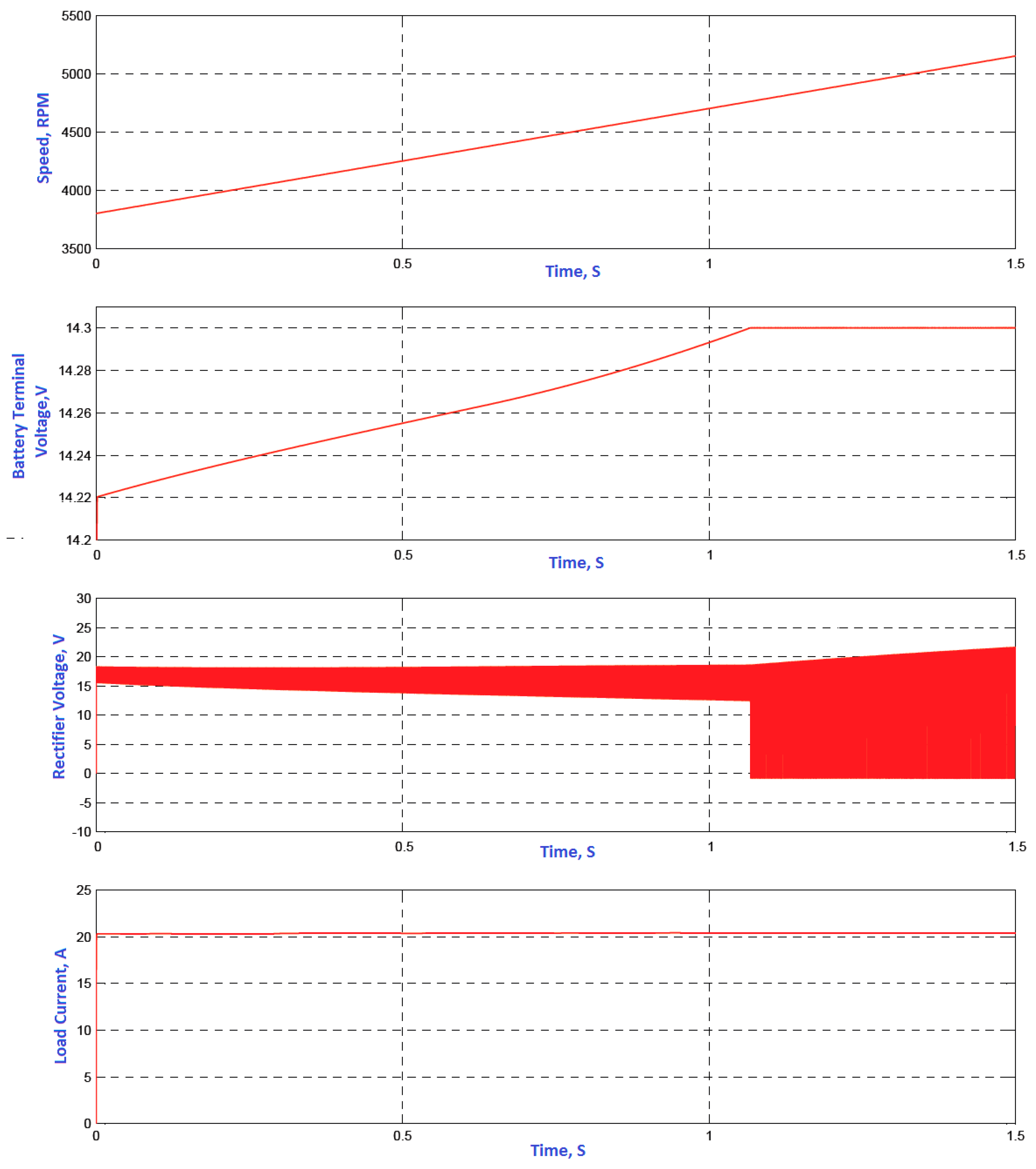

7.2. System Simulation with Constant Load and Variable Speed

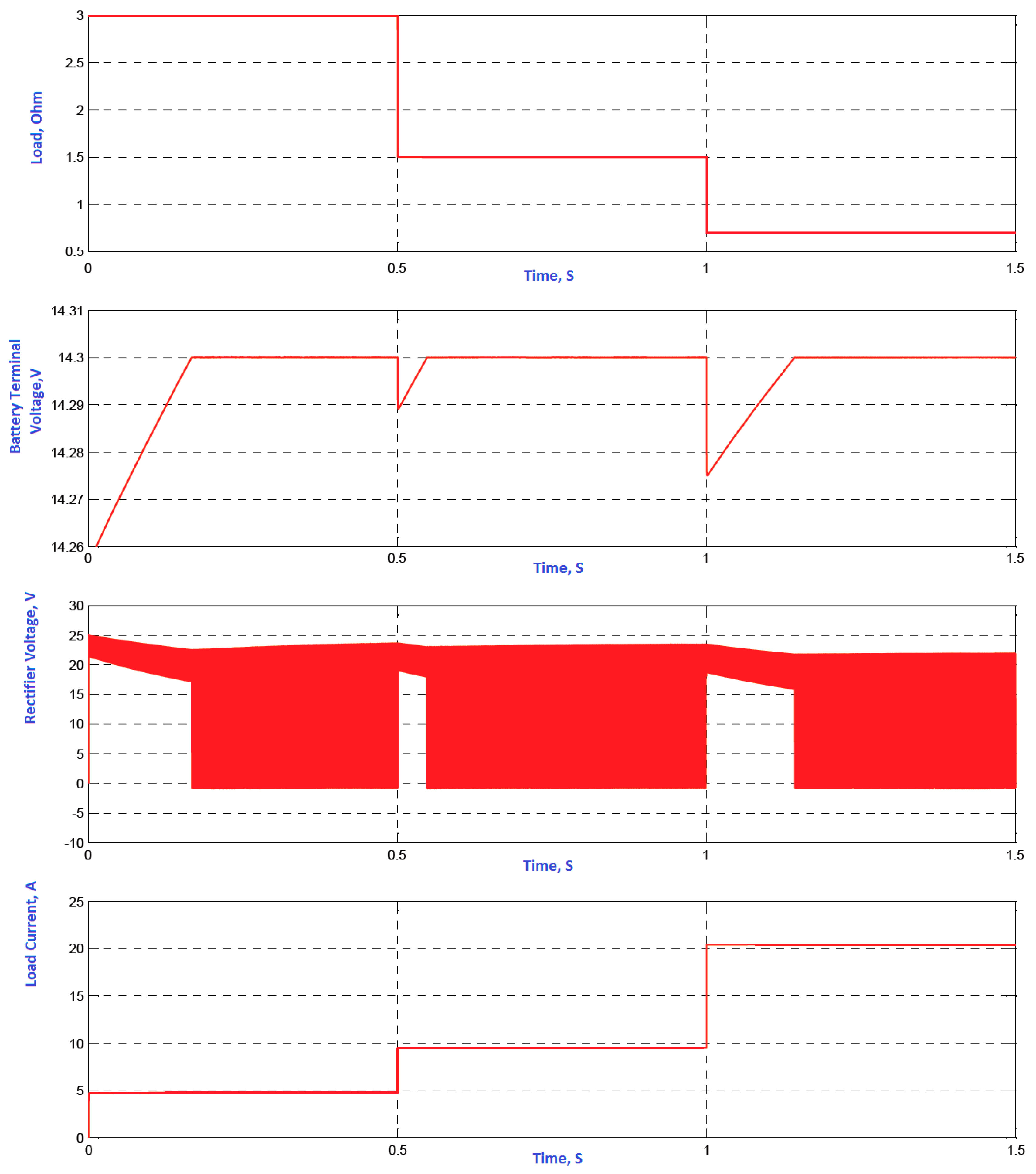

7.3. System Simulation with Constant Speed and Variable Load

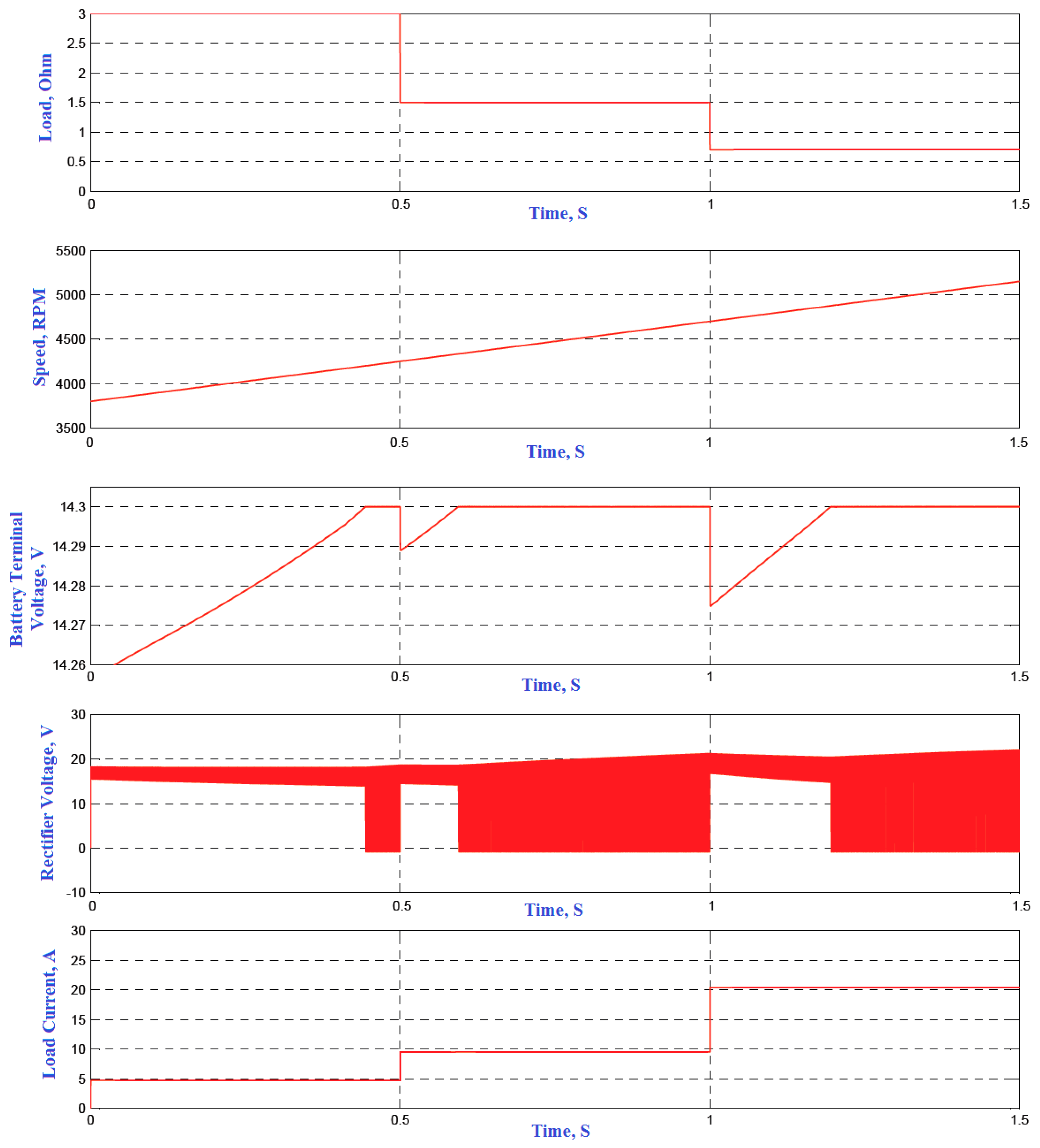

7.4. System Simulation with Variable Speed and Variable Load

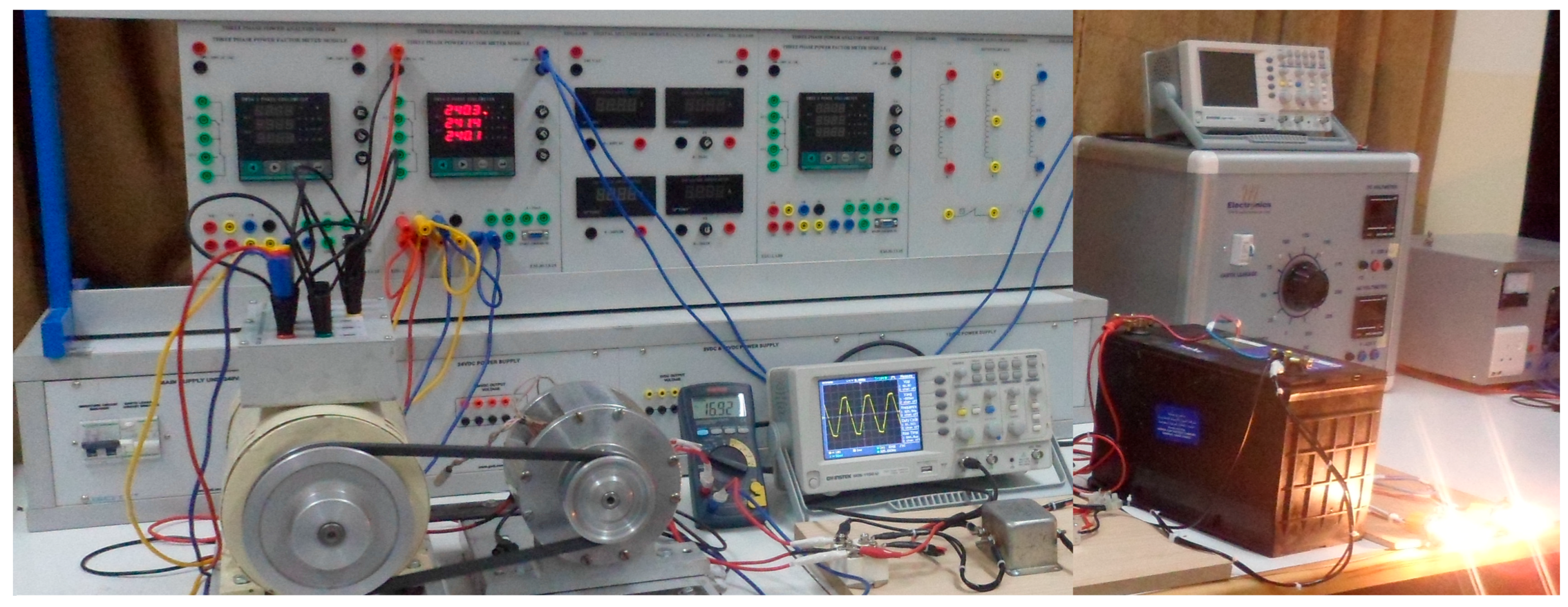

8. Testing and Experimentation of the AFPMA

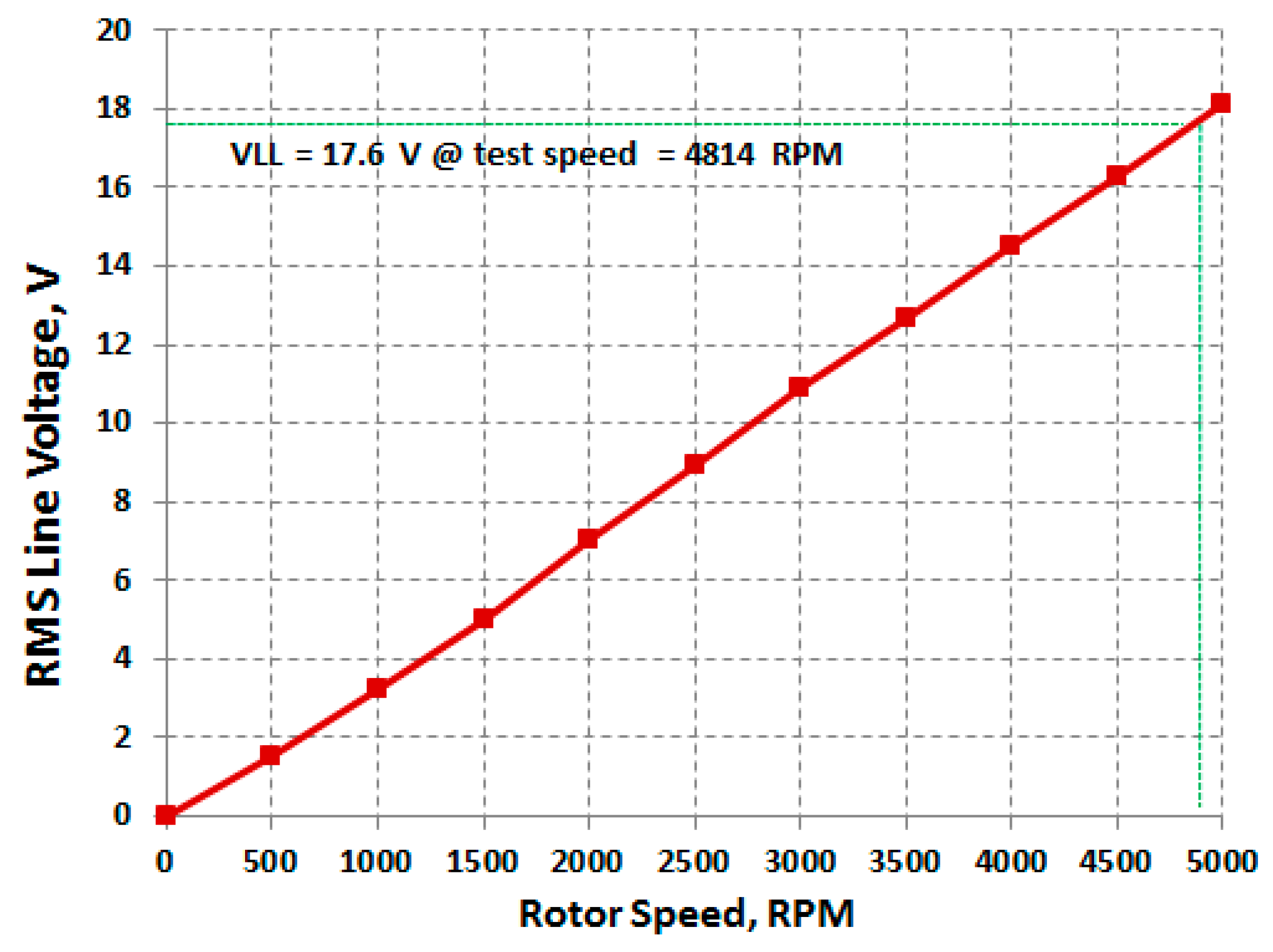

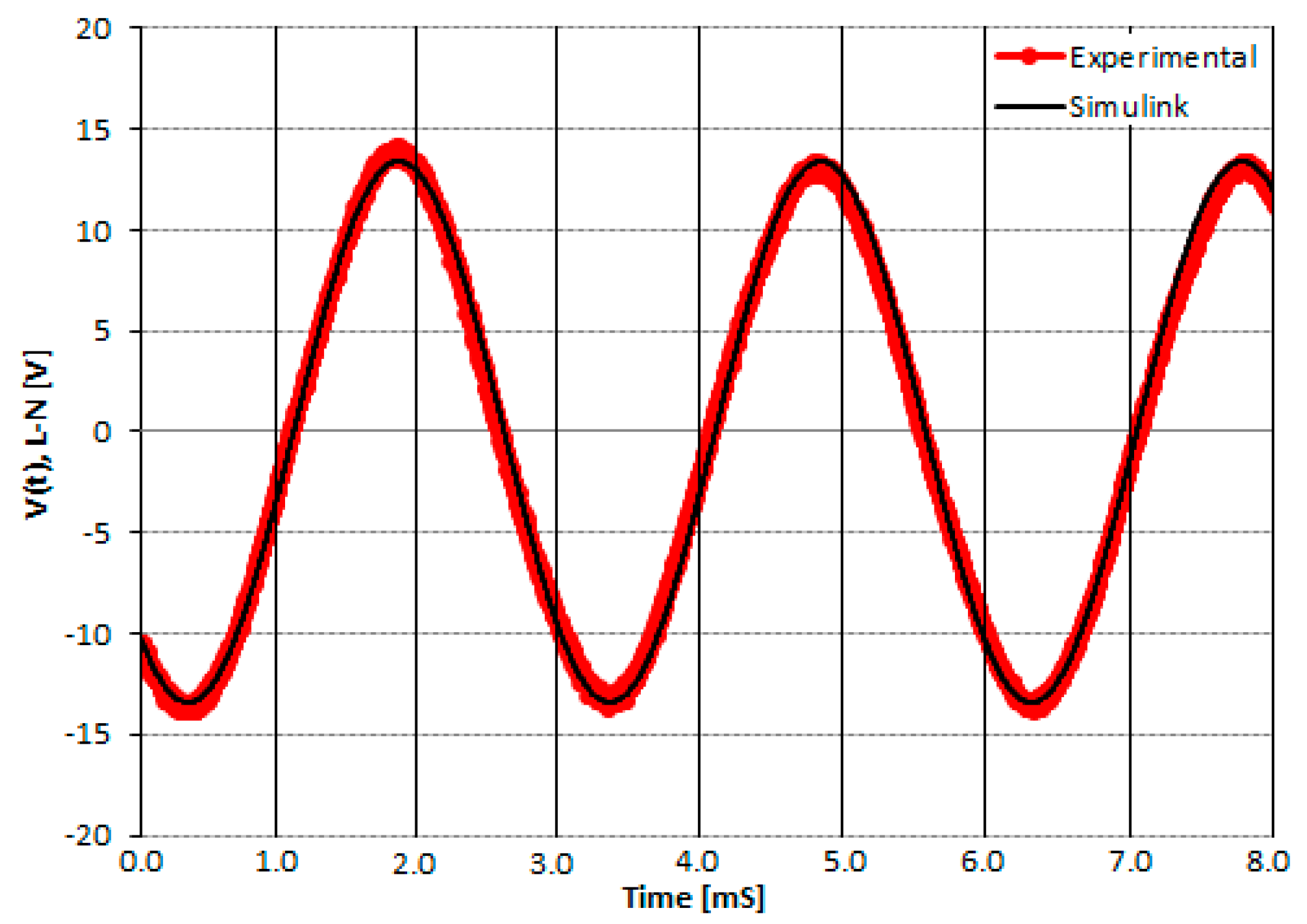

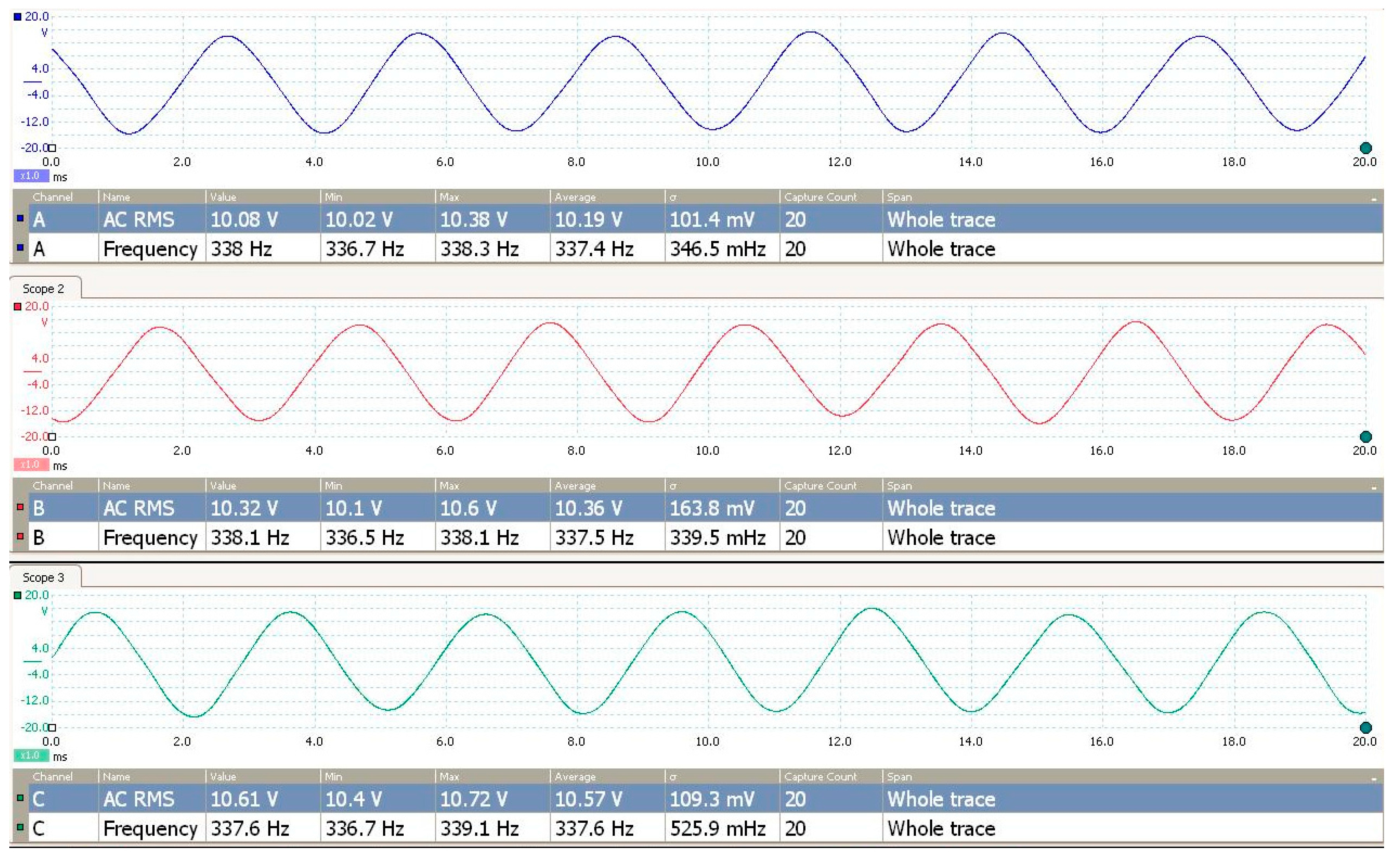

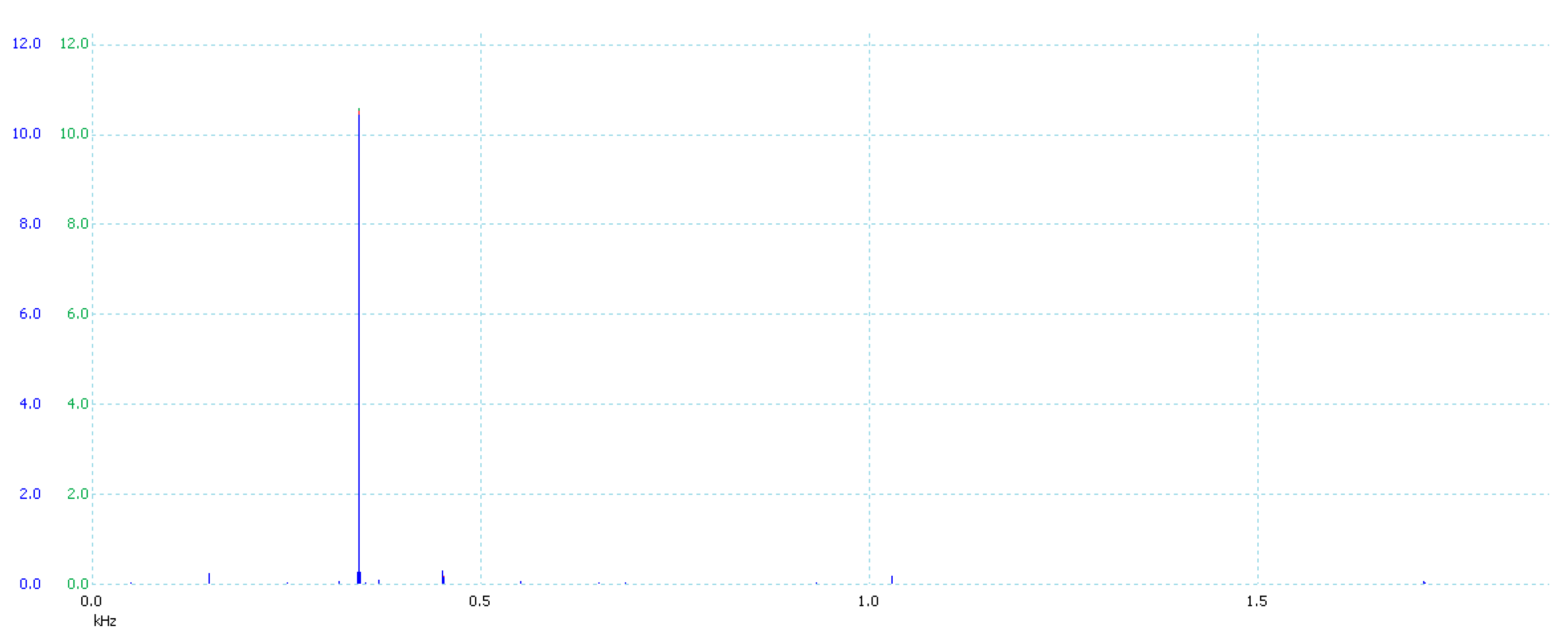

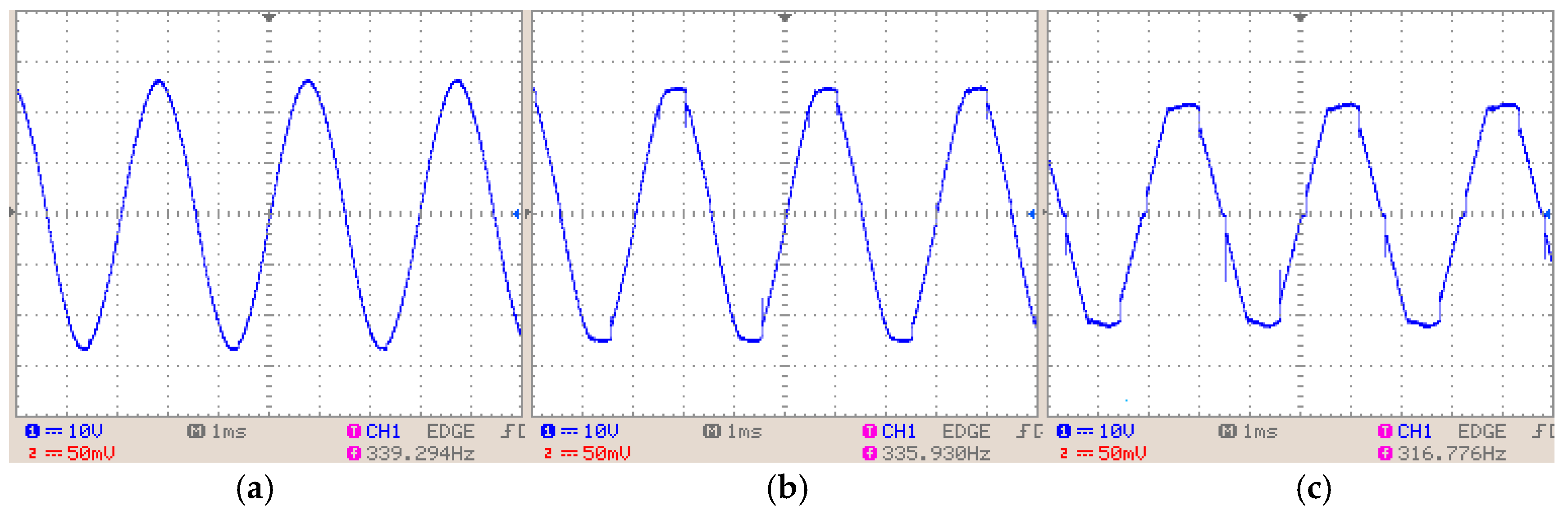

8.1. No Load Tests

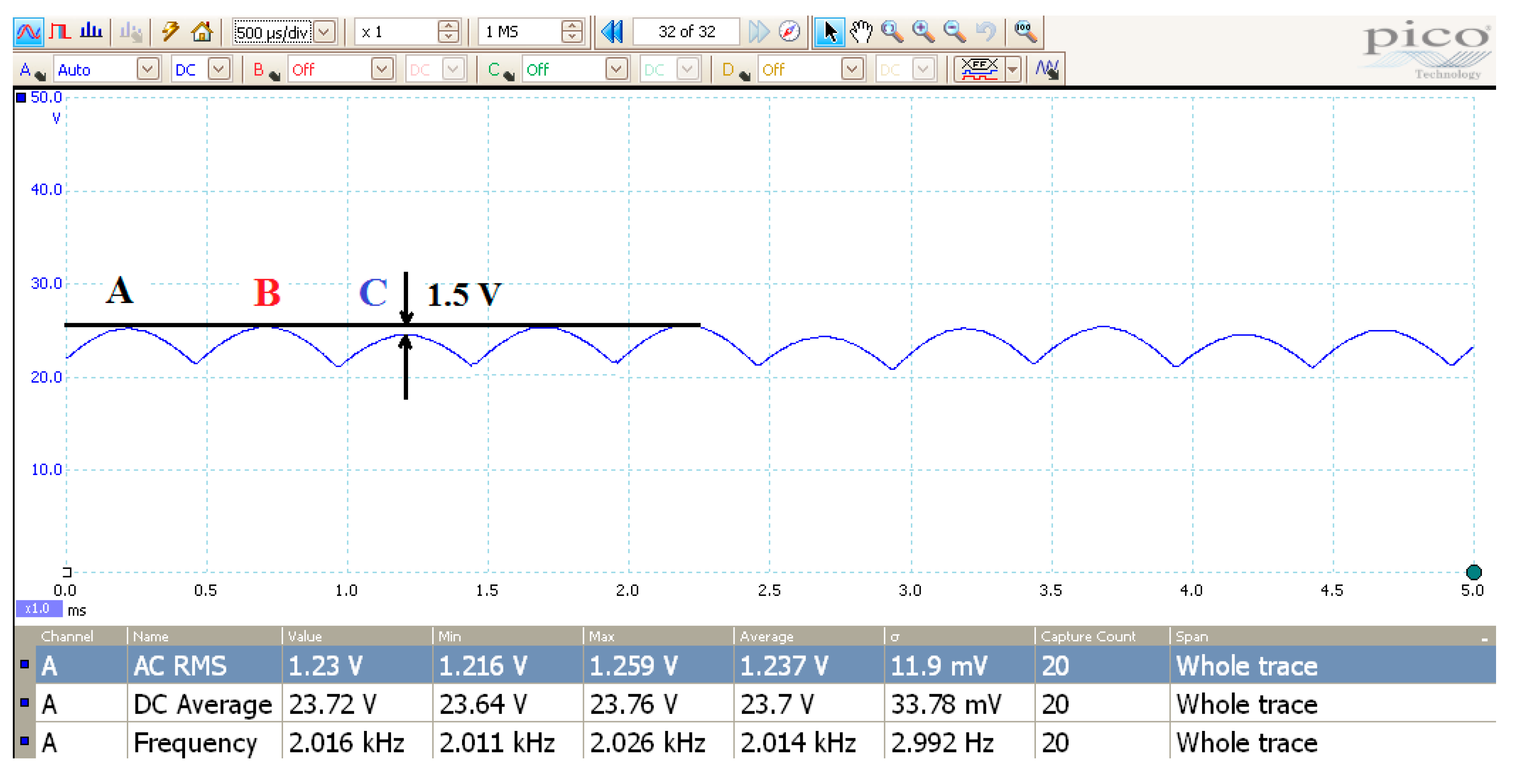

8.2. Load Tests

9. Conclusions and Future Recommendations

Acknowledgments

Conflicts of Interest

Nomenclature

| Air gap/magnet interface area | |

| Winding cross sectional area | |

| Air gap magnetic flux density | |

| Magnetic remanence | |

| Coefficient drag for turbulent flow | |

| Coil mean path length | |

| Wire diameter | |

| Induced voltage in a conductor | |

| Per phase internal generated voltage | |

| Electrical frequency of the voltage | |

| Magnetic coercive force | |

| Armature current | |

| d-axis current | |

| q-axis current | |

| Machine geometrical constant | |

| Machine magnetic constant | |

| Conductor length | |

| d-axis inductance | |

| Per phase leakage inductance | |

| Magnet axial length | |

| Total magnet air gap length | |

| q-axis inductance | |

| Winding Inductance | |

| Magnetization inductance | |

| Machine voltage/speed constant | |

| Mechanical speed | |

| Minim acceptable speed of the AFPMA | |

| Number of rotating discs | |

| Number of winding turns | |

| Rotor number of poles | |

| Copper losses | |

| Wire packing factor | |

| Internal power factor for the machine | |

| Machine output power | |

| Windage losses | |

| Maximum windage losses | |

| Saving in the windage losses | |

| Average radius of conductor | |

| Centre point of the PM disc | |

| Reynolds number | |

| Reluctance of the path of the magnetising flux | |

| Inner radius of the coil | |

| Outer radius of the coil | |

| Shaft radius | |

| Winding resistance | |

| Electromagnetic torque | |

| Linear velocity vector | |

| d-axis voltage | |

| Rectifier average output voltage | |

| RMS line voltage | |

| Minim line-line RMS voltage | |

| Voltage regulation of the machine | |

| q-axis voltage | |

| Full load phase voltage | |

| No load phase voltage | |

| Total winding length | |

| Air gap half-distance | |

| Winding reactance | |

| Rectifier firing angle | |

| Temperature coefficient for | |

| Temperature coefficient for | |

| Machine power angel | |

| Efficiency of the machine | |

| Peak flux reaching the stator windings | |

| Coefficient of viscosity of the air | |

| Specific density of the surrounding air | |

| Mechanical angular velocity |

Appendix A. Derivation of the Sizing Equations for the AFPMA

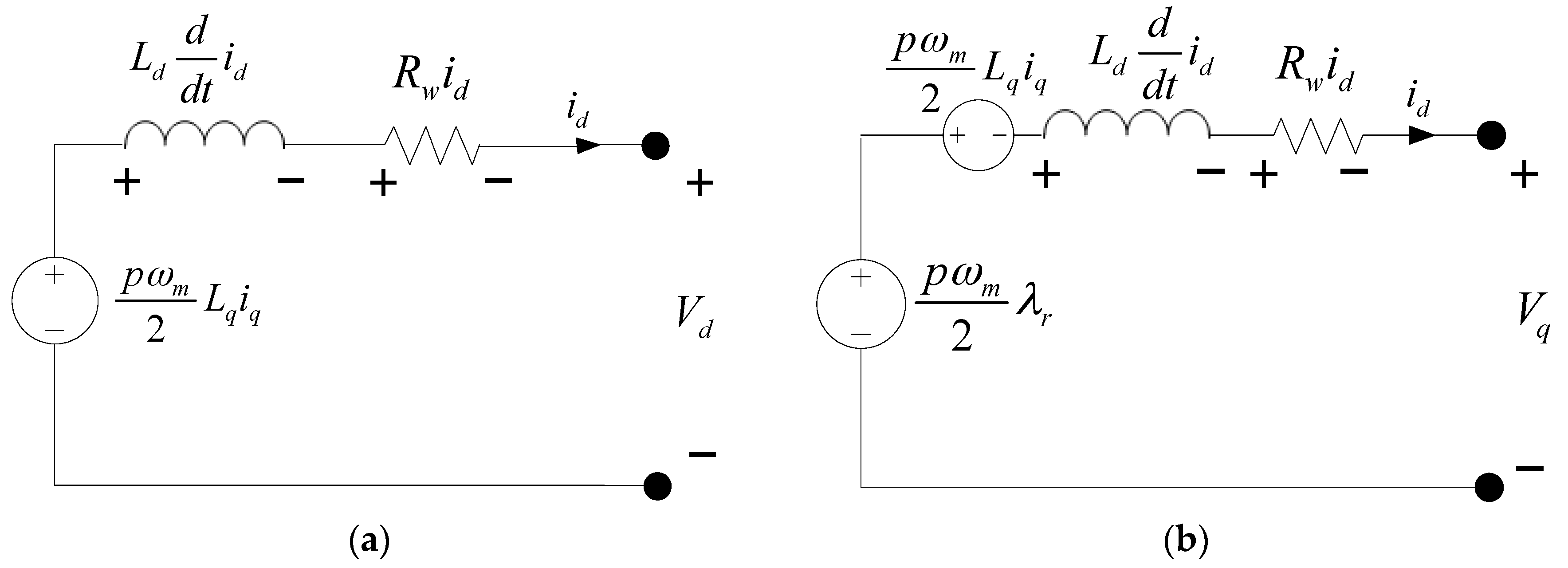

Appendix B. Simulink Mathematical Model of the AFPMA in Rotor Reference Frame (dq-Axis)

References

- Ivankovic, R.; Cros, J.; Kakhki, M.T.; Martins, C.A.; Viarouge, P. Power Electronic Solutions to Improve the Performance of Lundell Automotive Alternators. In New Advances in Vehicular Technology and Automotive Engineering; InTech: London, UK, 2012; Chapter 6. [Google Scholar] [CrossRef]

- Whaley, D.M.; Soong, W.L.; Ertugrul, N. Extracting More Power from the Lundell Car Alternator. In Proceedings of the Australasian Universities Power Engineering Conference (AUPEC 2004), Brisbane, Australia, 26–29 September 2004. [Google Scholar]

- Tang, S.C.; Otten, D.M.; Keim, T.A.; Perreault, D.J. Design and Evaluation of a 42-V Automotive Alternator with Integrated Switched-Mode Rectifier. IEEE Trans. Energy Convers. 2010, 25, 983–992. [Google Scholar] [CrossRef]

- Perreault, D.J.; Caliskan, V. Automotive Power Generation and Control. IEEE Trans. Power Electron. 2004, 19, 618–630. [Google Scholar] [CrossRef]

- Wang, Q.; Niu, S.; Yang, L. Design Optimization and Comparative Study of Novel Dual-PM Excited Machines. IEEE Trans. Ind. Electron. 2017, 64, 9924–9933. [Google Scholar] [CrossRef]

- Pop, A.C.; Gyselinck, J.J.; Pinto, D.E.; Vintiloiu, I. Optimization of Low-Power Brushless PM-Machines for Automotive Applications with Focus on High-Volume Mass Production. IEEE Trans. Ind. Electron. 2017, 64, 9767–9775. [Google Scholar] [CrossRef]

- Chen, A.; Nilssen, R.; Nysveen, A. Performance Comparisons among Radial-Flux, Multistage Axial-Flux, and Three-Phase Transverse-Flux PM Machines for Downhole Applications. IEEE Trans. Ind. Appl. 2010, 46, 779–789. [Google Scholar] [CrossRef]

- Cavagnino, A.; Lazzari, M.; Profumo, F.; Tenconi, A. A comparison between the axial flux and the radial flux structures for PM synchronous motors. IEEE Trans. Ind. Appl. 2002, 38, 1517–1524. [Google Scholar] [CrossRef]

- Ishikawa, T.; Amada, S.; Segawa, K.; Kurita, N. Proposal of a Radial- and Axial-Flux Permanent-Magnet Synchronous Generator. IEEE Trans. Magn. 2017, 53. [Google Scholar] [CrossRef]

- Pop, A.A.; Jurca, F.; Oprea, C.; Chirca, M.; Breban, S.; Radulescu, M.M. Axial-flux vs. radial-flux permanent-magnet synchronous generators for micro-wind turbine application. In Proceedings of the 15th Conference on Power Electronics and Applications (EPE’13 ECCE Europe), Lille, France, 3–5 September 2013. [Google Scholar]

- Kahourzade, S.; Mahmoudi, A.; Ping, H.W.; Uddin, M.N. A Comprehensive Review of Axial-Flux Permanent-Magnet Machines. Can. J. Electr. Comput. Eng. 2014, 37, 19–33. [Google Scholar] [CrossRef]

- Nguyen, T.D.; Tseng, K.J.; Zhang, S.; Nguyen, H.T. A Novel Axial Flux Permanent-Magnet Machine for Flywheel Energy Storage System: Design and Analysis. IEEE Trans. Ind. Electron. 2010, 58, 3784–3794. [Google Scholar] [CrossRef]

- Chan, T.F.; Lai, L.L. An axial-flux permanent-magnet synchronous generator for a direct-coupled wind-turbine system. IEEE Trans. Energy Convers. 2007, 22, 86–94. [Google Scholar] [CrossRef]

- El-Hasan, T.S.; Luk, P.C.; Bhinder, F.S.; Ebaid, M.S. Modular design of high-speed permanent-magnet axial-flux generators. IEEE Trans. Magn. 2000, 36 Pt 1, 3558–3561. [Google Scholar] [CrossRef]

- El-Hasan, T.S.; Luk, P.C. Magnet topology optimization to reduce harmonics in high-speed axial flux Generators. IEEE Trans. Magn. 2003, 39 Pt 2, 3340–3342. [Google Scholar] [CrossRef]

- Fei, W.; Luk, P.C.K.; El-Hasan, T.S. Rotor Integrity Design for a High-Speed Modular Air-Cored Axial-Flux Permanent-Magnet Generator. IEEE Trans. Ind. Electron. 2011, 58, 3848–3858. [Google Scholar] [CrossRef] [Green Version]

- Bumby, J.R.; Martin, R. Axial-Flux Permanent-Magnet Air-Cored Generator for Small-Scale Wind Turbines. IEE Proc. Electr. Power Appl. 2005, 152, 1065–1075. [Google Scholar] [CrossRef]

- Ferreira, Â.P.; Costa, A.F. Direct Driven Axial Flux Permanent Magnet Generator for Small-Scale Wind Power Applications. In Proceedings of the International Conference on Renewable Energies and Power Quality (ICREPQ’11), Las Palmas de Gran Canaria, Spain, 13–15 April 2010. [Google Scholar]

- El-Hasan, T.S. Development of axial flux permanent magnet generator for direct driven micro wind turbine. In Proceedings of the IEEE International Conference on Renewable Energy Research and Applications (ICRERA 2016), Birmingham, UK, 20–23 November 2016. [Google Scholar]

- Di Gerlando, A.; Foglia, G.M.; Iacchetti, M.F.; Perini, R. Sizing comparison of axial flux PM motors, for automotive application. In Proceedings of the 2014 International Conference on Electrical Machines (ICEM), Berlin, Germany, 2–5 September 2014. [Google Scholar]

- Bastiaens, K.; Jansen, J.W.; Jumayev, S.; Lomonova, E.A. Design of an axial-flux permanent magnet machine for an in-wheel direct drive application. In Proceedings of the 2017 IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017. [Google Scholar]

- Javadi, S.; Mirsalim, M. Design and Analysis of 42-V Coreless Axial-Flux Permanent-Magnet Generators for Automotive Applications. IEEE Trans. Magn. 2010, 46, 1015–1023. [Google Scholar] [CrossRef]

- Javadi, S.; Mirsalim, M. A Coreless Axial-Flux Permanent-Magnet Generator for Automotive Applications. IEEE Trans. Magn. 2008, 44, 4591–4598. [Google Scholar] [CrossRef]

- China YY Magnetics. Available online: http://www.smi-mag.com/Neodymiummagnets.html?gclid=EAIaIQobChMIhZ2C5qa32AIVJyjTCh0OUAYgEAAYASAAEgI7-_D_BwE (accessed on 6 January 2018).

- Deeb, R.; Janda, M.; Makki, Z. Design of Cooling System of Permanent Magnet Servo Motor. In Proceedings of the 14th International Scientific Conference Electric Power Engineering 2013; VSB—Technical University of Ostrava: Ostrava, Czech Republic, 2013; pp. 205–209. ISBN 978-80-248-2988-3. [Google Scholar]

- E-Magnets UK Company. Available online: http://e-magnetsuk.com/neodymium_magnets/temperature_ratings.aspx (accessed on 6 January 2018).

- MathWorks. Available online: https://www.mathworks.com/help/physmod/sps/powersys/ref/permanentmagnetsynchronousmachine.html (accessed on 5 March 2017).

- Krah, J.O.; Holtz, J. High-Performance Current Regulation and Efficient PWM Implementation for Low Inductance Servo Motors. IEEE Trans. Ind. Appl. 1999, 35, 1039–1049. [Google Scholar] [CrossRef]

- Krahenbuhl, D.; Zwyssig, C.; Kolar, J.W. Half-Controlled Boost Rectifier for Low-Power High-Speed Permanent-Magnet Generators. IEEE Trans. Ind. Electron. 2011, 58, 5066–5075. [Google Scholar] [CrossRef]

- Bai, H. Study of PWM Rectifier/Inverter for a High Speed Generator. In Proceedings of the Power and Energy Engineering Conference, Chengdu, China, 28–31 March 2010. [Google Scholar]

- El-Hasan, T.; Elnasser, E.M. Development of a Low Cost Sensored Control for High-Speed Axial Flux Permanent Magnet Machines. J. Innov. Syst. Des. Eng. 2014, 5, 7–16. [Google Scholar]

- Hart, D.W. Power Electronics, 1st ed.; McGraw-Hill Education: New York, NY, USA, 2010; ISBN 10 0073380679. [Google Scholar]

- El-Hasan, T.S. Modelling, Simulation and Experimentation of PM Spring. Int. Rev. Model. Simul. 2016, 9, 56–63. [Google Scholar] [CrossRef]

- El-Hasan, T.S. Application of Permanent Magnets in Suspension and Recoil Buffer Systems. J. Innov. Syst. Des. Eng. 2015, 6, 1–14. [Google Scholar]

- Camacho, J.M.; Sosa, V. Alternative method to calculate the magnetic field of permanent magnets with azimuthal symmetry. Rev. Mex. Fis. E 2013, 59, 8–17. [Google Scholar]

- Babic, S.I. Improvement in the Analytical Calculation of the Magnetic Field Produced by Permanent Magnets ring. Prog. Electromagn. Res. C 2008, 5, 71–82. [Google Scholar]

- El-Hasan, T.S. Inductance Determination for Air-Cored Permanent Magnet Axial Flux Machine. In Proceedings of the Global Summit on Electronics and Electrical Engineering, Valencia, Spain, 3–5 November 2015. [Google Scholar]

| AFPMA Set Parameters | Value | Unit |

|---|---|---|

| RMS line–line voltage | 17 | V |

| Rated current | 40 | A |

| Rated speed | 5000 | RPM |

| Rated power @ rated speed | 1.2 | kVA |

| AFPMA Set Parameters | Value | Unit |

|---|---|---|

| Desired line–line RMS output voltage | 17.6 | V |

| Number of phases (star connected) | 3 | - |

| Air gap half-distance, | 10 | mm |

| Number of poles, | 8 | - |

| Axial thickness of PM, | 17 | mm |

| Inner radius of PM, | 27 | mm |

| Outer radius of PM, | 48 | mm |

| Remanence for NdFeB Grade 52, | 1.45 | T |

| Wire diameter, | 2.2 | mm |

| AFPMA Calculated Parameters | Value | Unit |

|---|---|---|

| Number of winding turns per pole per phase, | 4 | - |

| Winding resistance per phase, | 22.8 | mΩ |

| Winding inductance per phase, | 4.14 | µH |

| Design speed, | 4814 | RPM |

| No load machine voltage/speed constant, | 3.537 × 10−3 | V/RPM |

| Generated frequency, | 320 | Hz |

| Air gap flux density, | 0.546 | T |

| Voltage regulation, % | 10.3 | - |

| Machine internal power factor (cos φ), | 0.94 | - |

| Machine power angle, δ | 2 | Deg |

| Efficiency, (%) | 94 | - |

| AFPMA Speed, (RPM) | (V) | (V) | (V) |

|---|---|---|---|

| Design speed = 4814 | 17.6 | 24.89 | 23.7 |

| Minimum speed = 2997 | 10.6 | 14.9 | 14.3 |

| Maximum speed 5000 | 18.29 | 25.8 | 24.7 |

| Test Condition | Speed | |||

|---|---|---|---|---|

| (RPM) | (V) | (V) | (A) | |

| No load (rectifier only) | 5032 | 18.41 | 24.15 | 0 |

| Battery only | 5020 | 18.01 | 14.53 | 2.85 |

| Battery and one head lamp | 4876 | 16.89 | 13.57 | 7.62 |

| Battery and two head lamps | 4740 | 16.05 | 13.21 | 11.04 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Hasan, T.S. Development of Automotive Permanent Magnet Alternator with Fully Controlled AC/DC Converter. Energies 2018, 11, 274. https://doi.org/10.3390/en11020274

El-Hasan TS. Development of Automotive Permanent Magnet Alternator with Fully Controlled AC/DC Converter. Energies. 2018; 11(2):274. https://doi.org/10.3390/en11020274

Chicago/Turabian StyleEl-Hasan, Tareq S. 2018. "Development of Automotive Permanent Magnet Alternator with Fully Controlled AC/DC Converter" Energies 11, no. 2: 274. https://doi.org/10.3390/en11020274