Predictive tools for screening viscous oil reservoirs for a certain production technology can be valuable instruments when assessing technical feasibility and the potential performance of the process in a candidate reservoir. Two quick predictive models were developed here to estimate RF and CSOR in NFCRs that undergo steamflooding for heavy oil recovery. It is important to note that the steamflooding operation is generally ended when the cumulative steam oil ratio (CSOR) reaches the value of 60. Thus, the performance of steamflooding process is evaluated at this cut-off point.

7.1. Regression Analysis

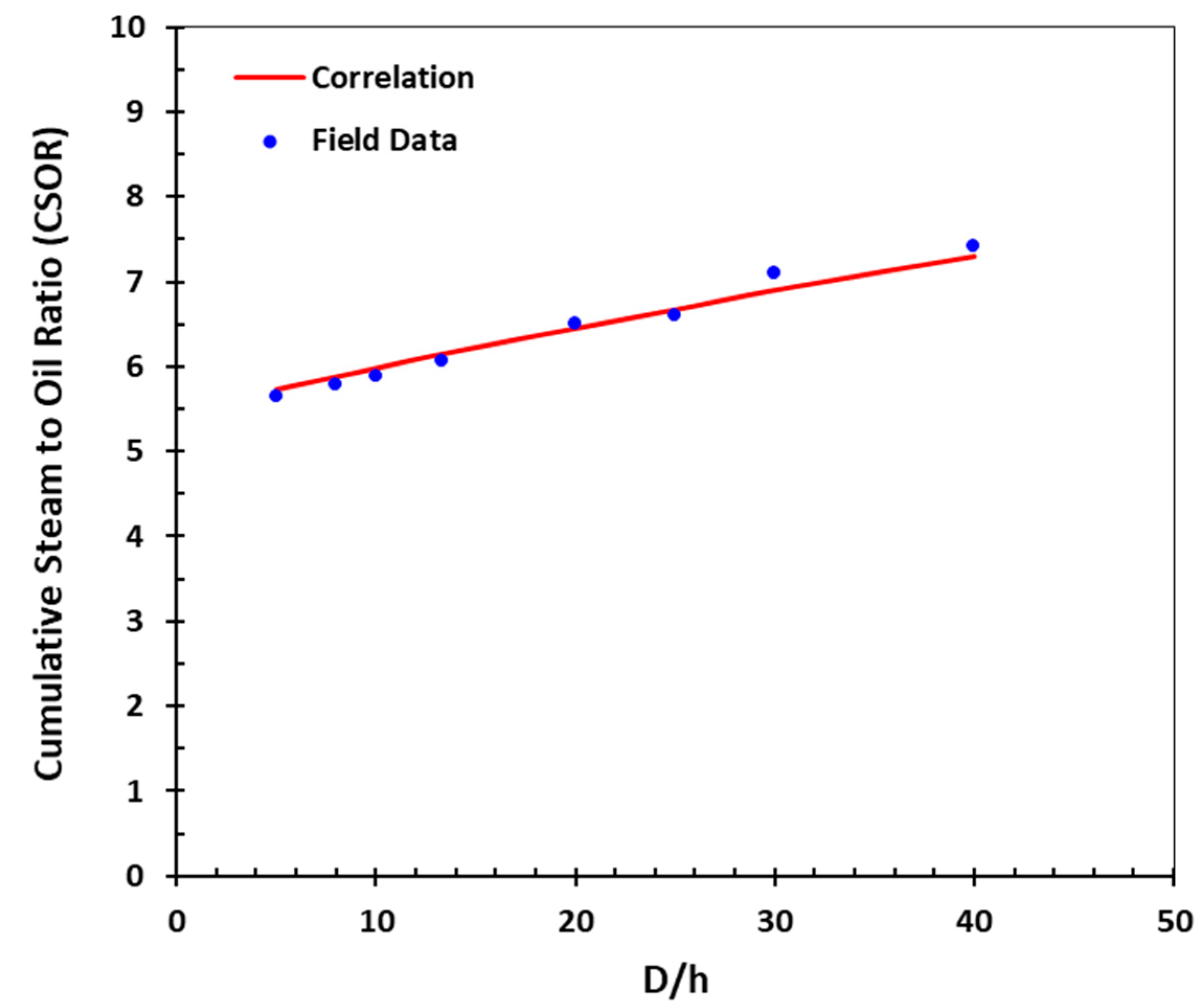

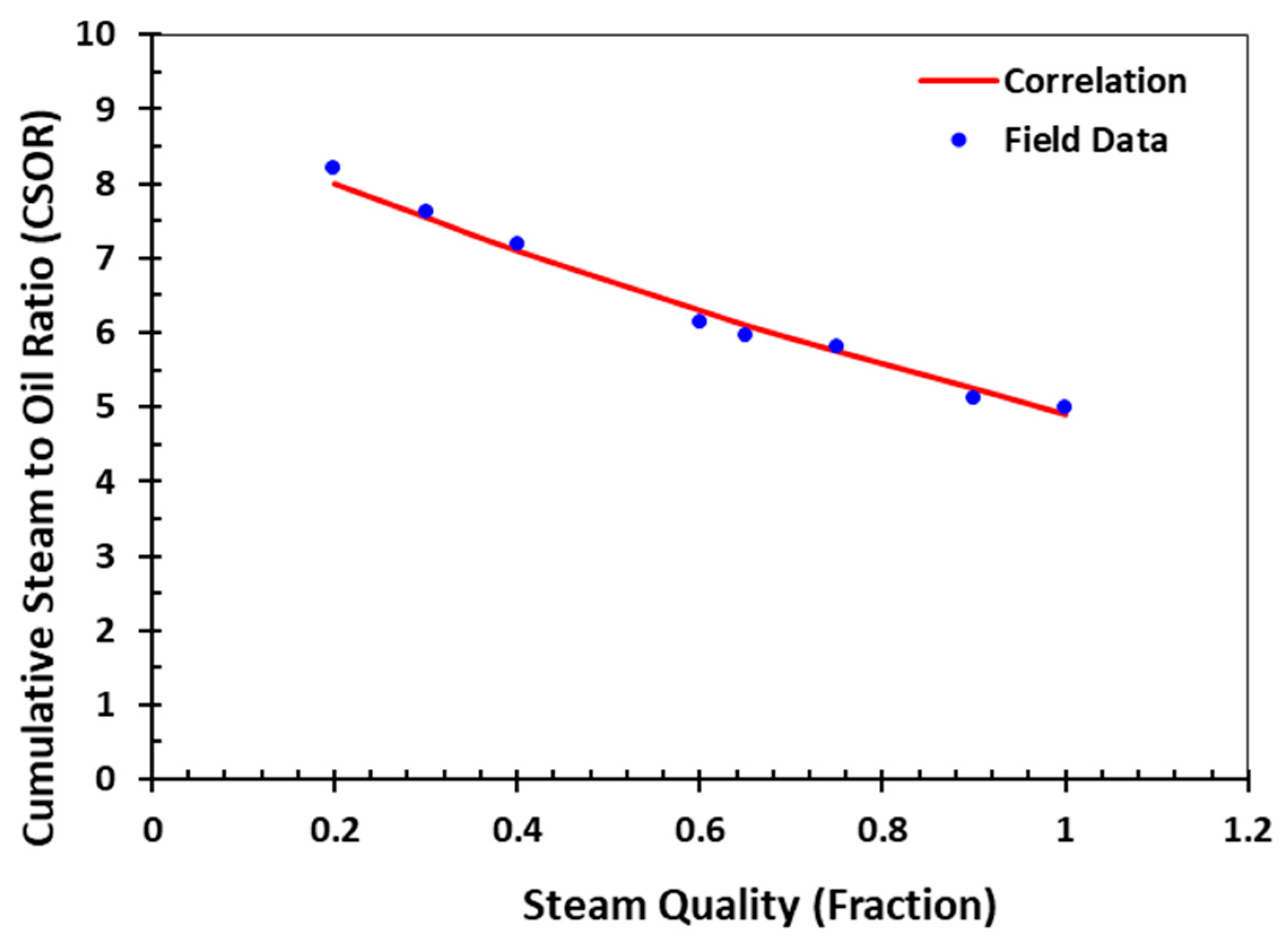

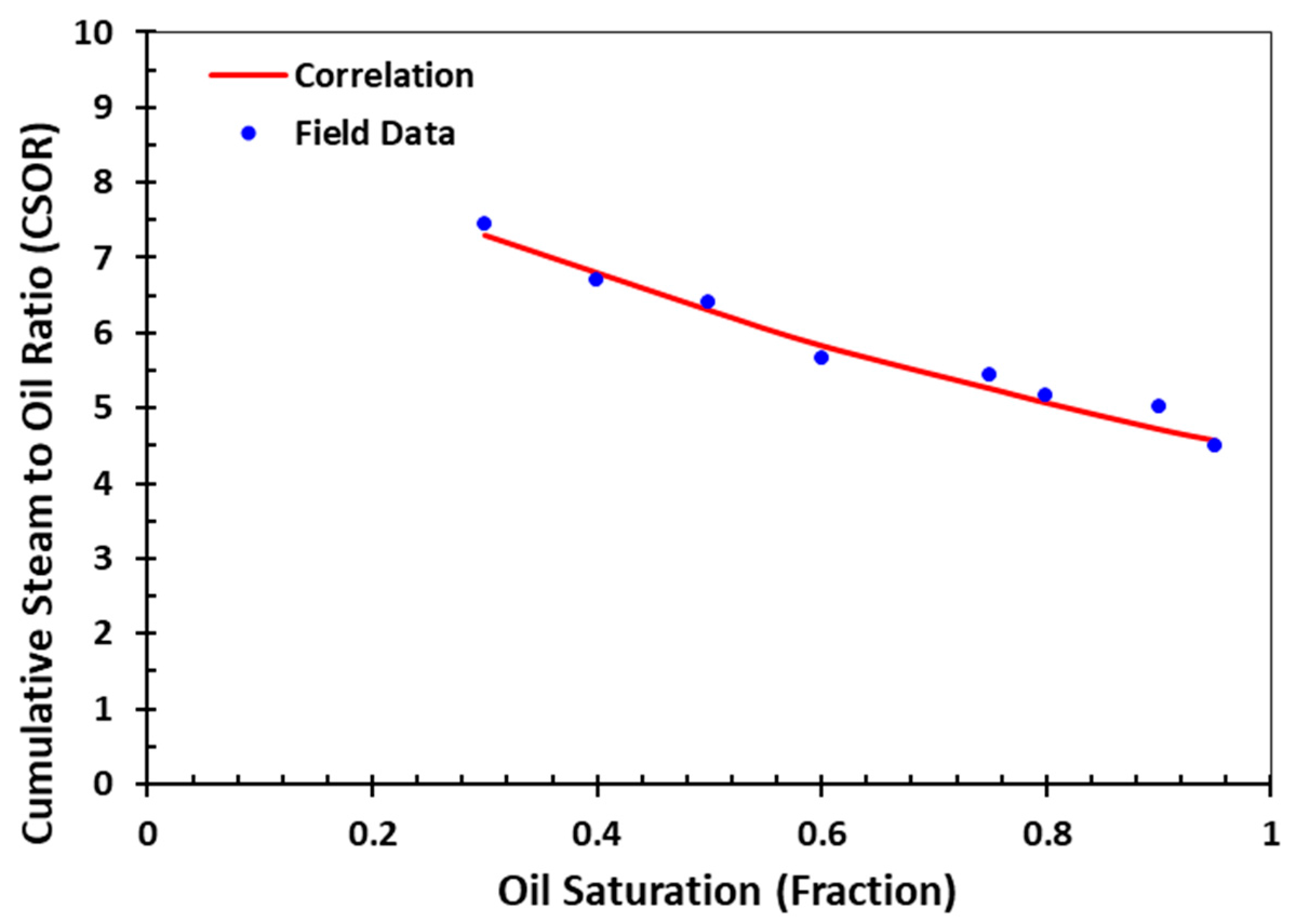

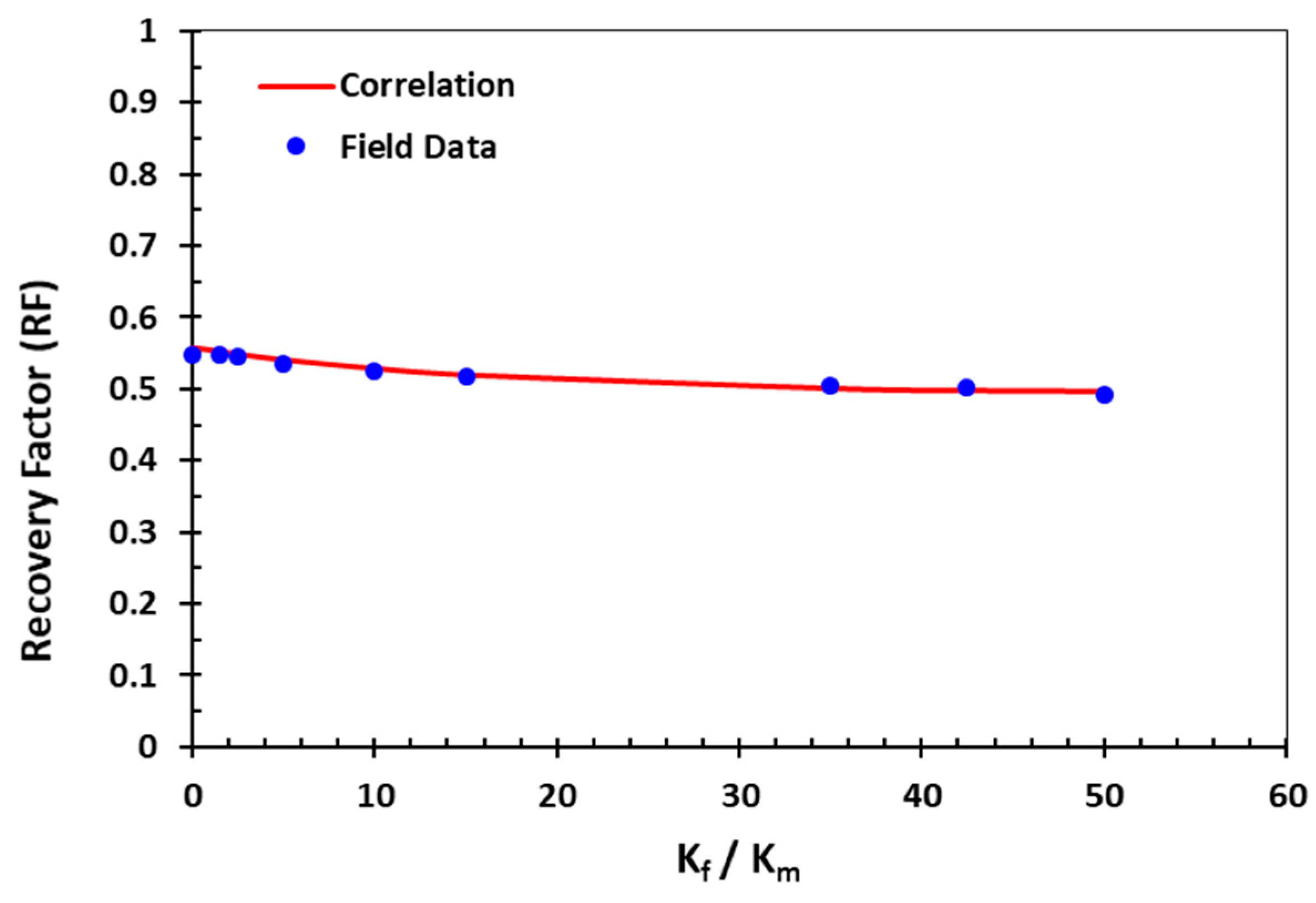

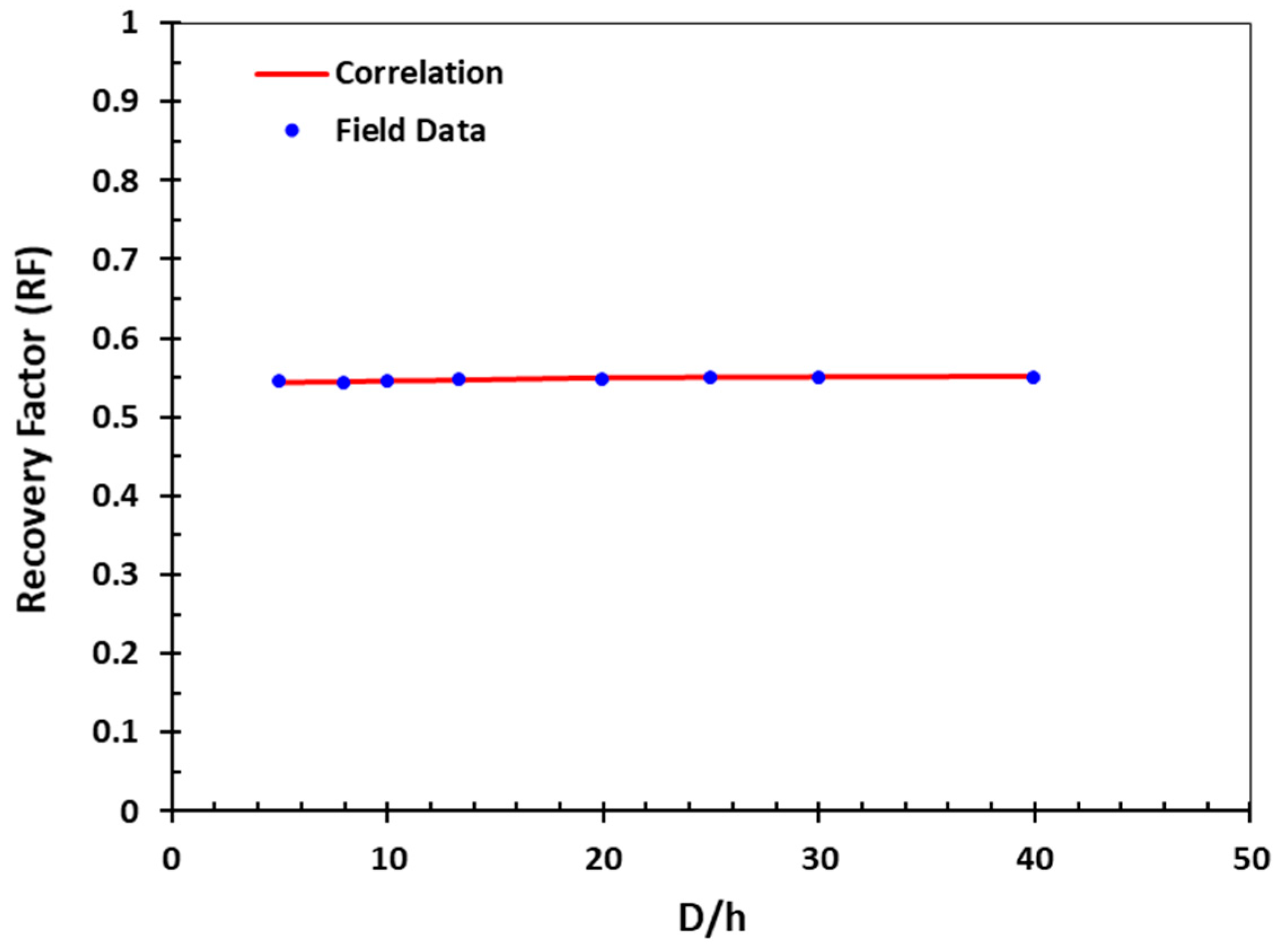

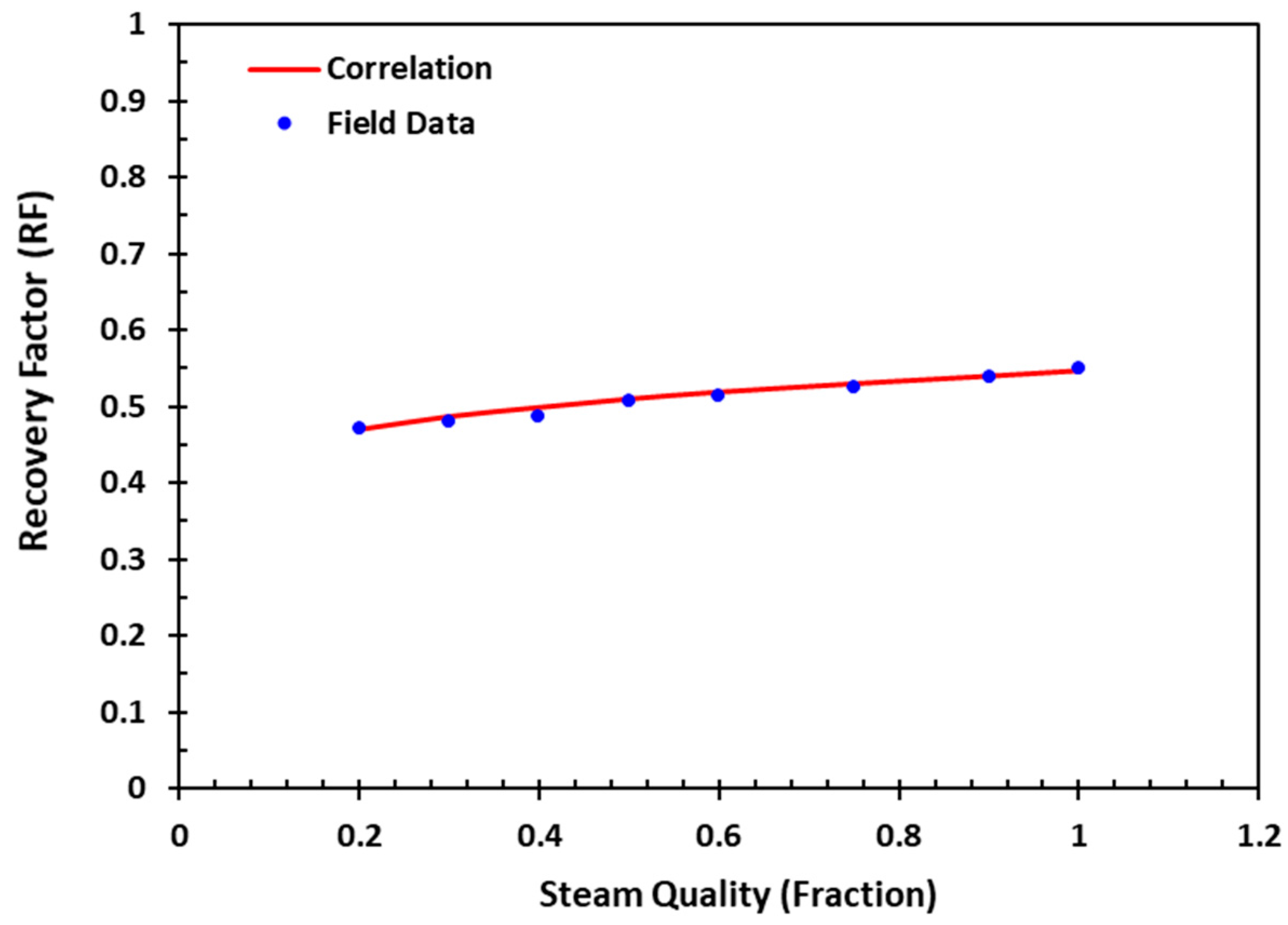

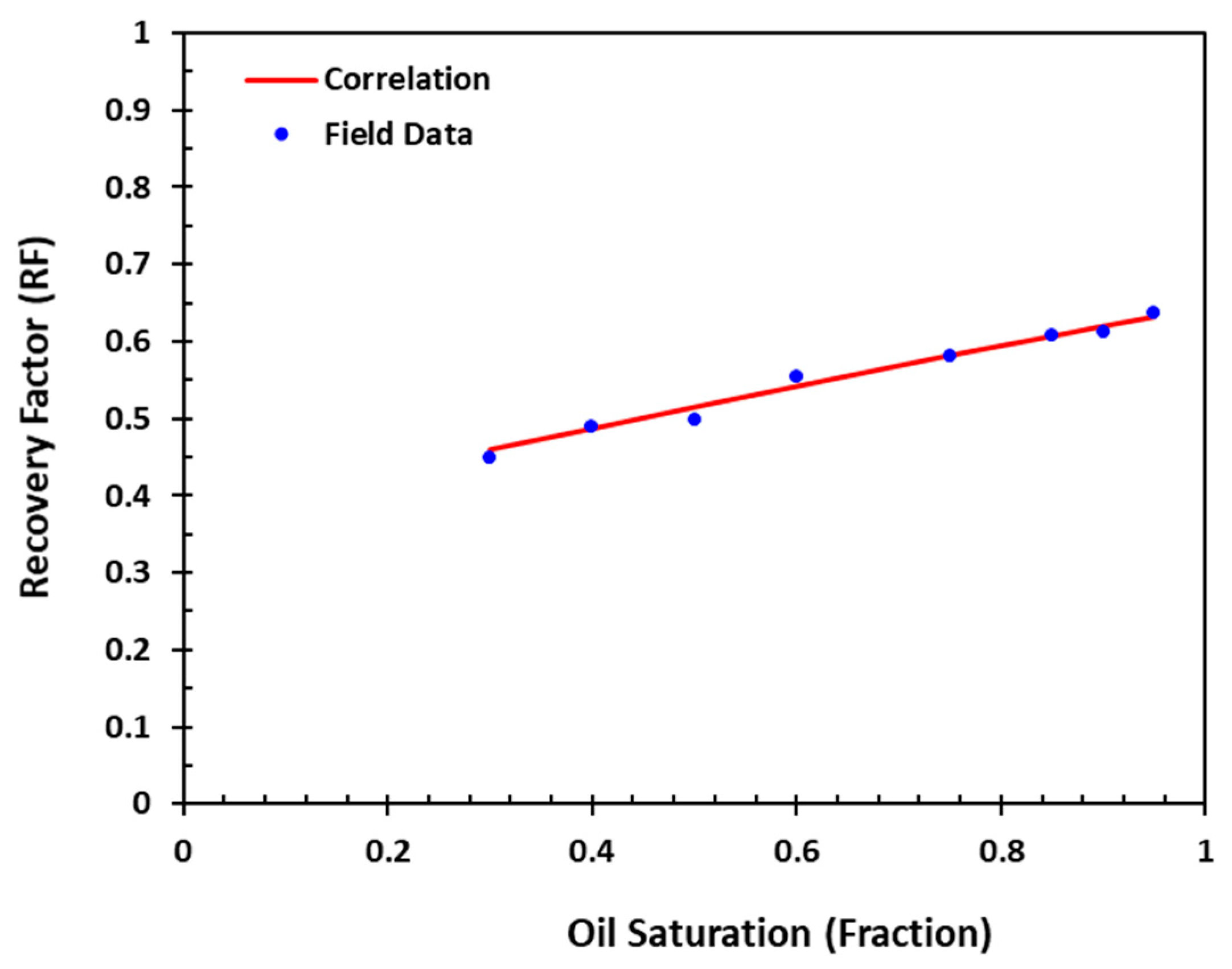

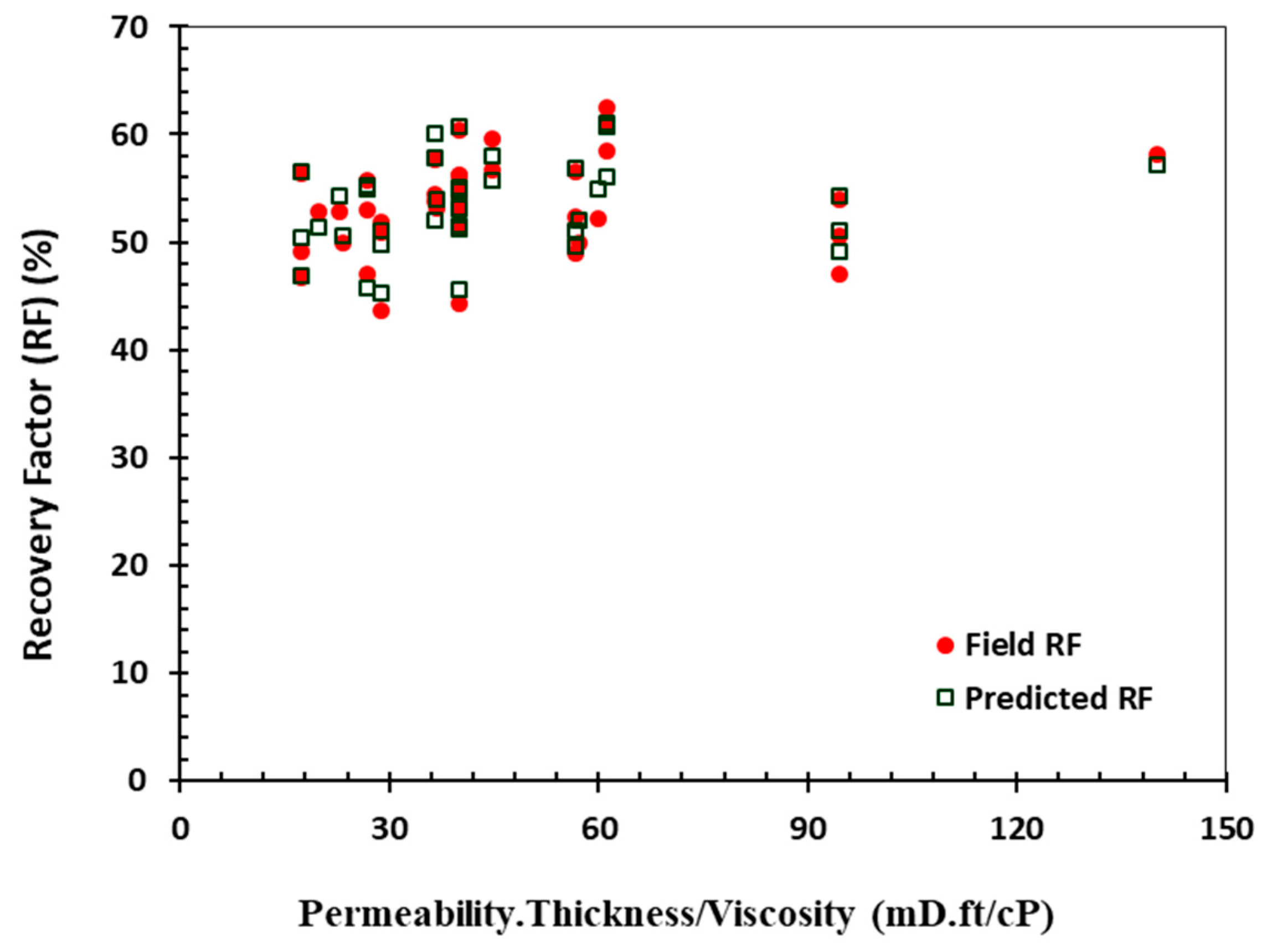

Scatter plots (

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10 and

Figure 11 for CSOR and

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16,

Figure 17,

Figure 18,

Figure 19,

Figure 20 and

Figure 21 for RF) show the dependency of a special response variable on a special fluid or/and reservoir property.

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6 and

Figure 7 and

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16 and

Figure 17 are obtained for the physical models with the same pattern (in shape and number of fractures) and the same dimensions in most cases. In addition, it is clear that all properties for steamflooding processes demonstrated on each figure except those on

x and

y-axes are the same when investigating effect of an independent variable on target functions. This conveys the message that these figures just present a limited volume of data used in this study to point out the important trends in performance of reservoirs during steamflooding according to a comprehensive parametric sensitivity analysis. Based on

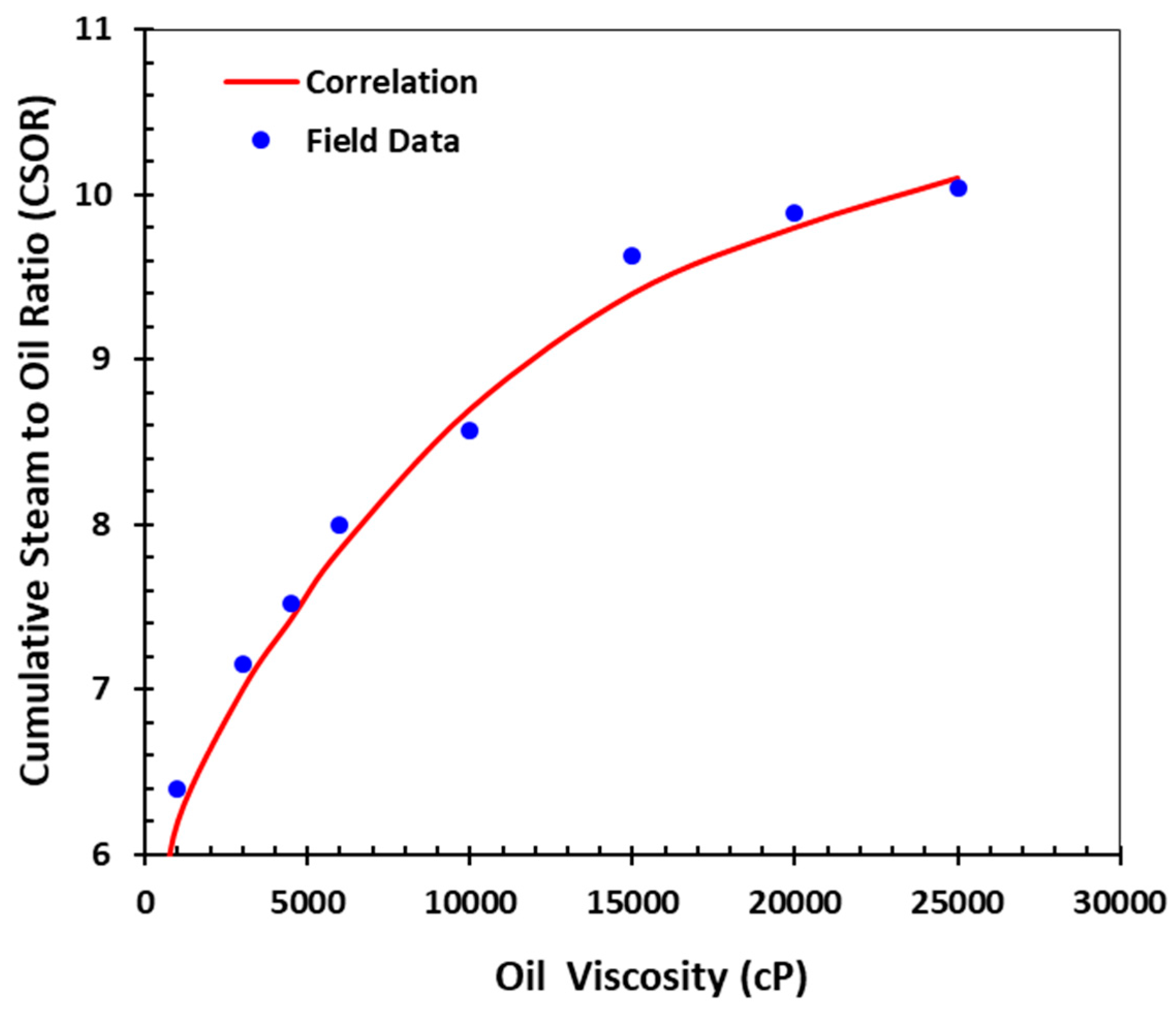

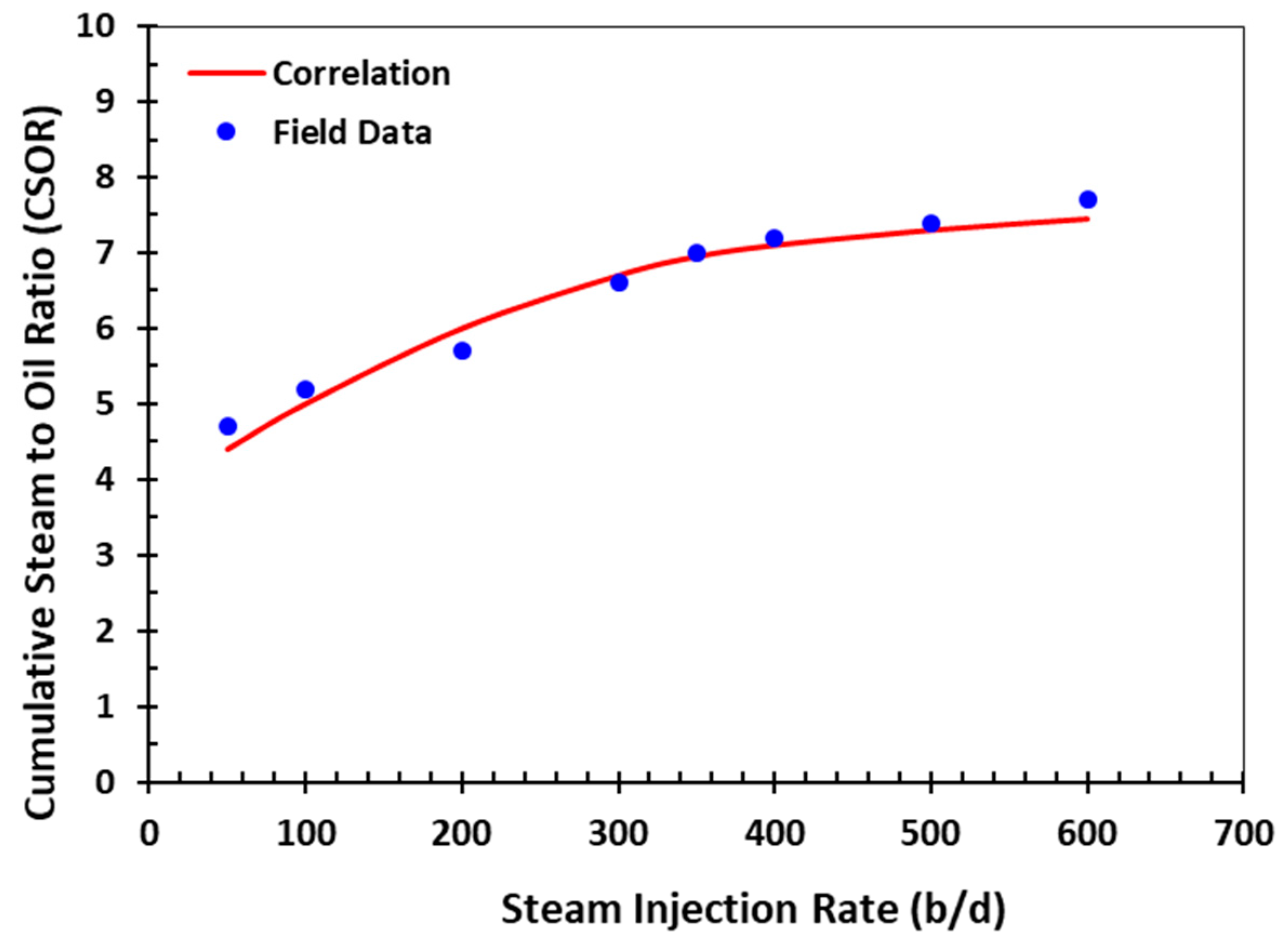

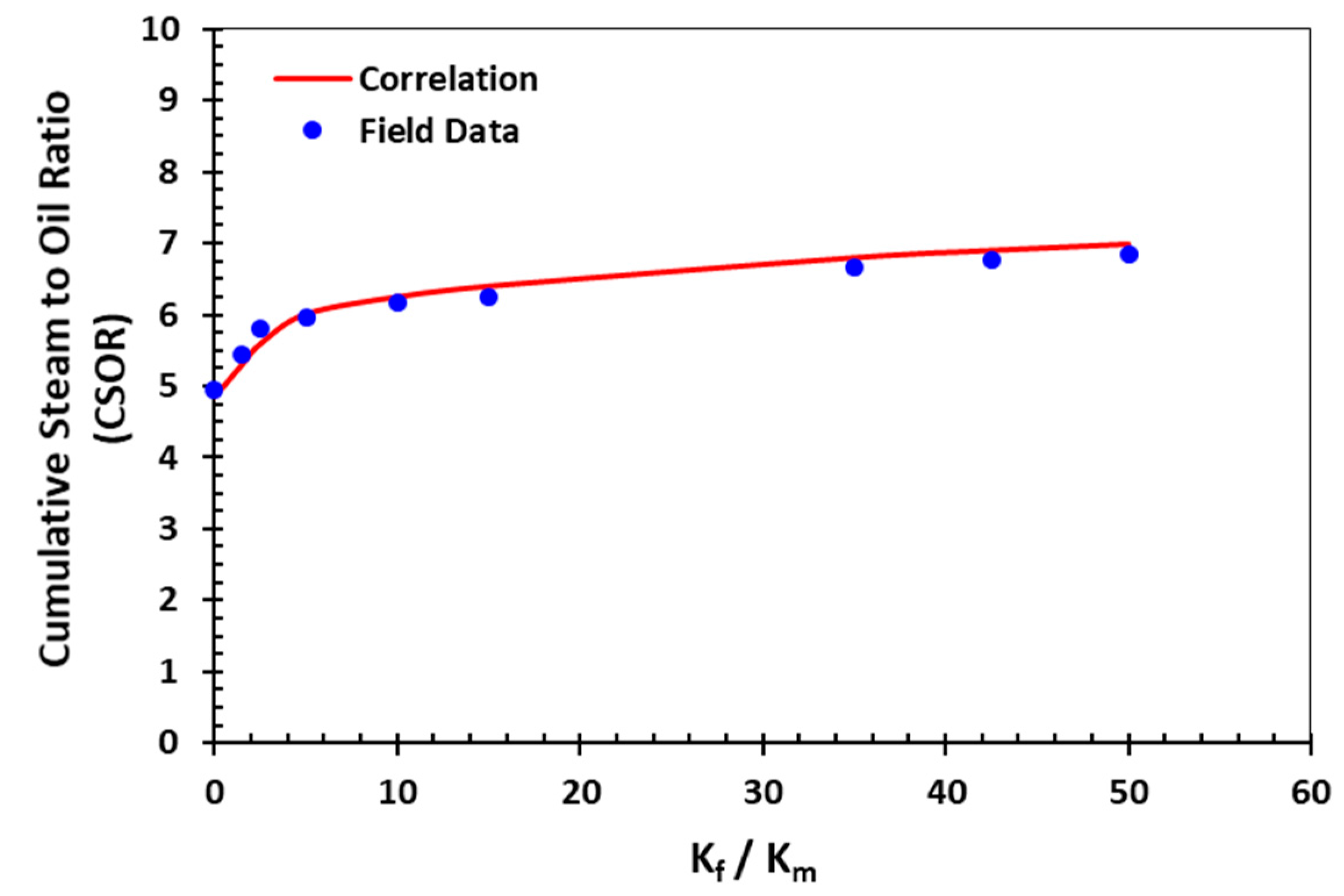

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6 and

Figure 7, CSOR increases with an increase in oil viscosity, steam injection rate, fracture to matrix permeability, and gross to net reservoir thickness. However, high steam quality and high initial oil saturation lead to reductions in CSOR, indicating better response to steam injection. In addition,

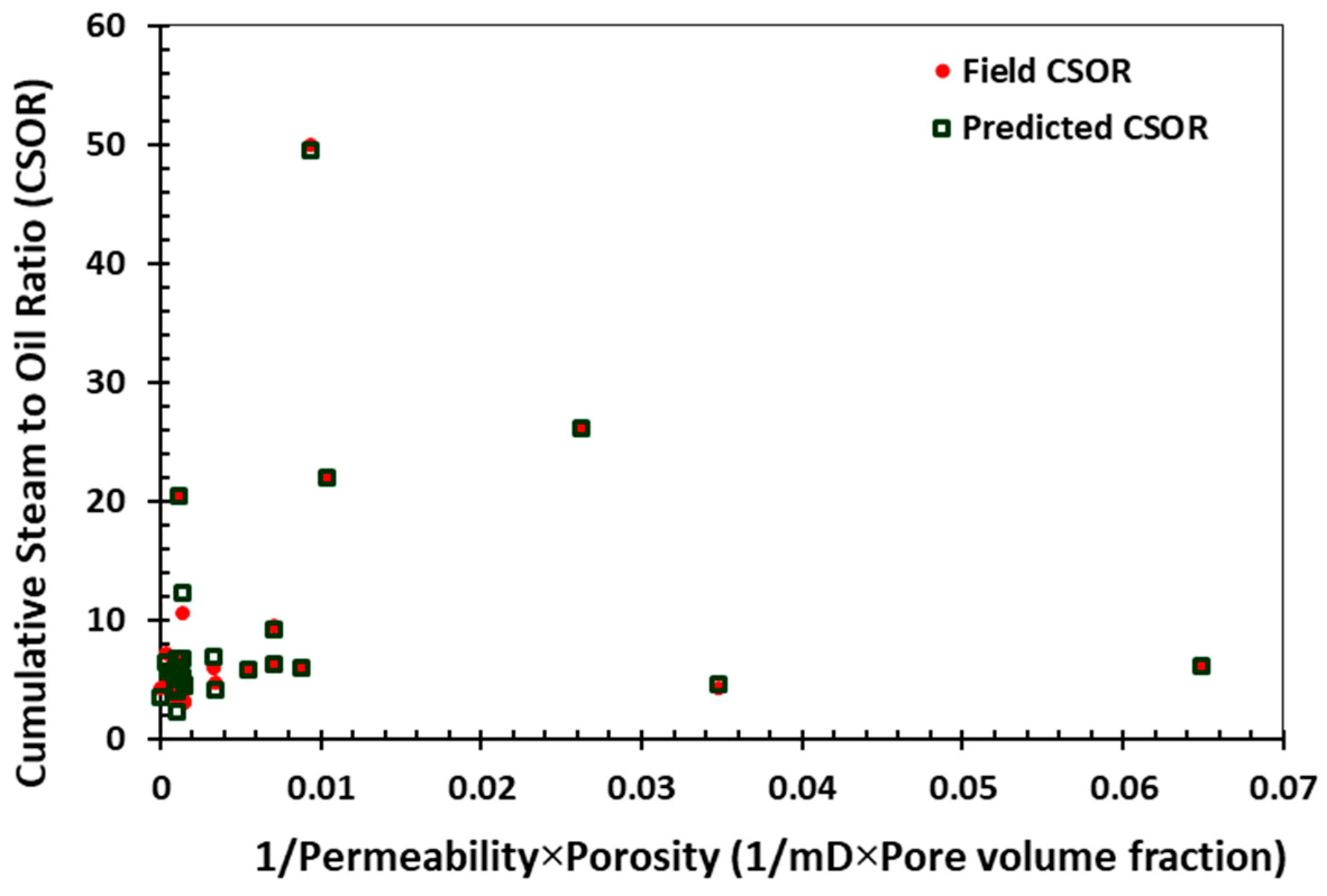

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10 and

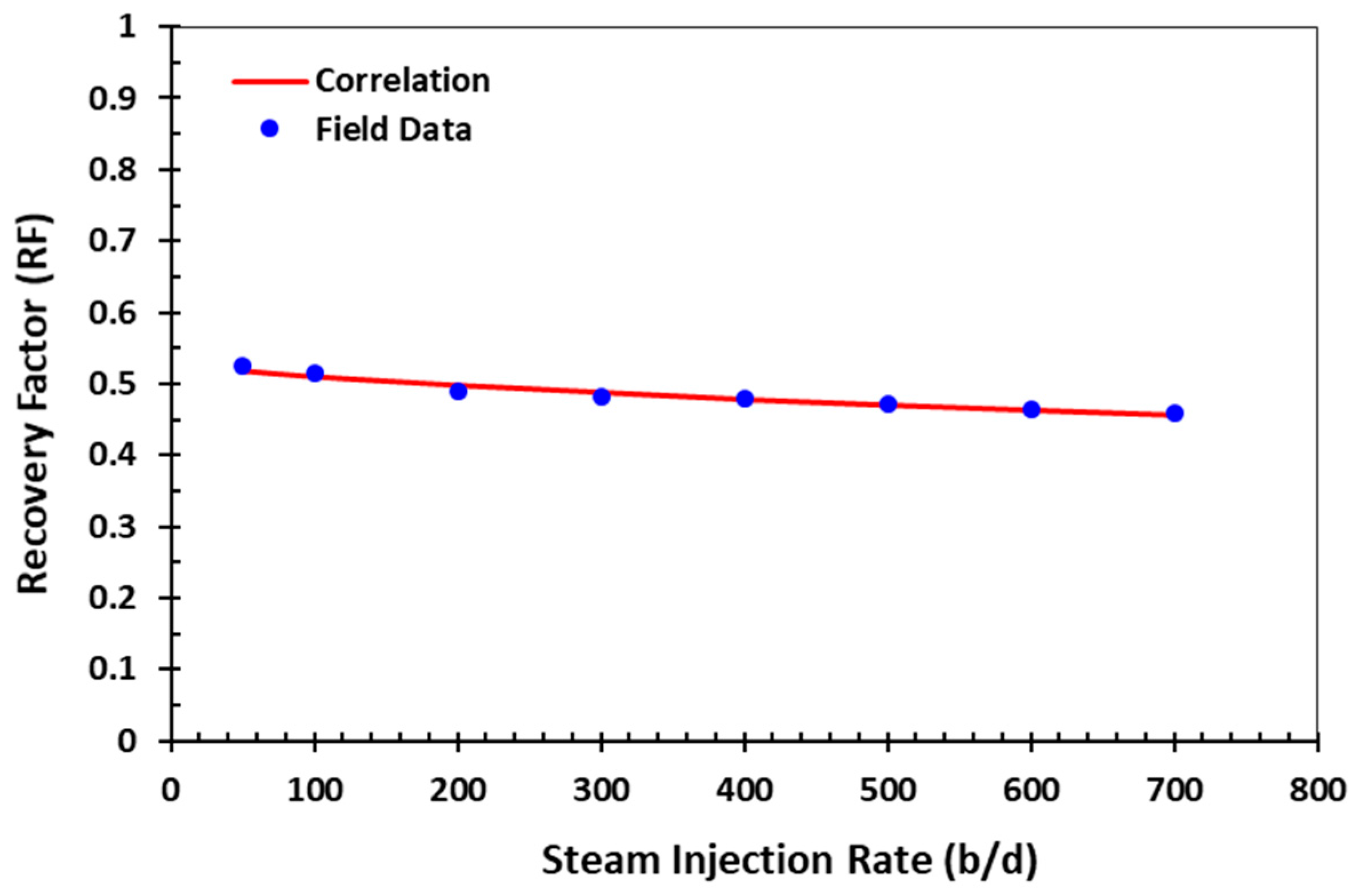

Figure 11 for CSOR indicate acceptable agreement between the field data and the predictions. It is clear that increase in steam injection rate improves the recovery rate but lowers the RF before steam breakthrough in fractured media (particularly highly fractured ones), as presented in

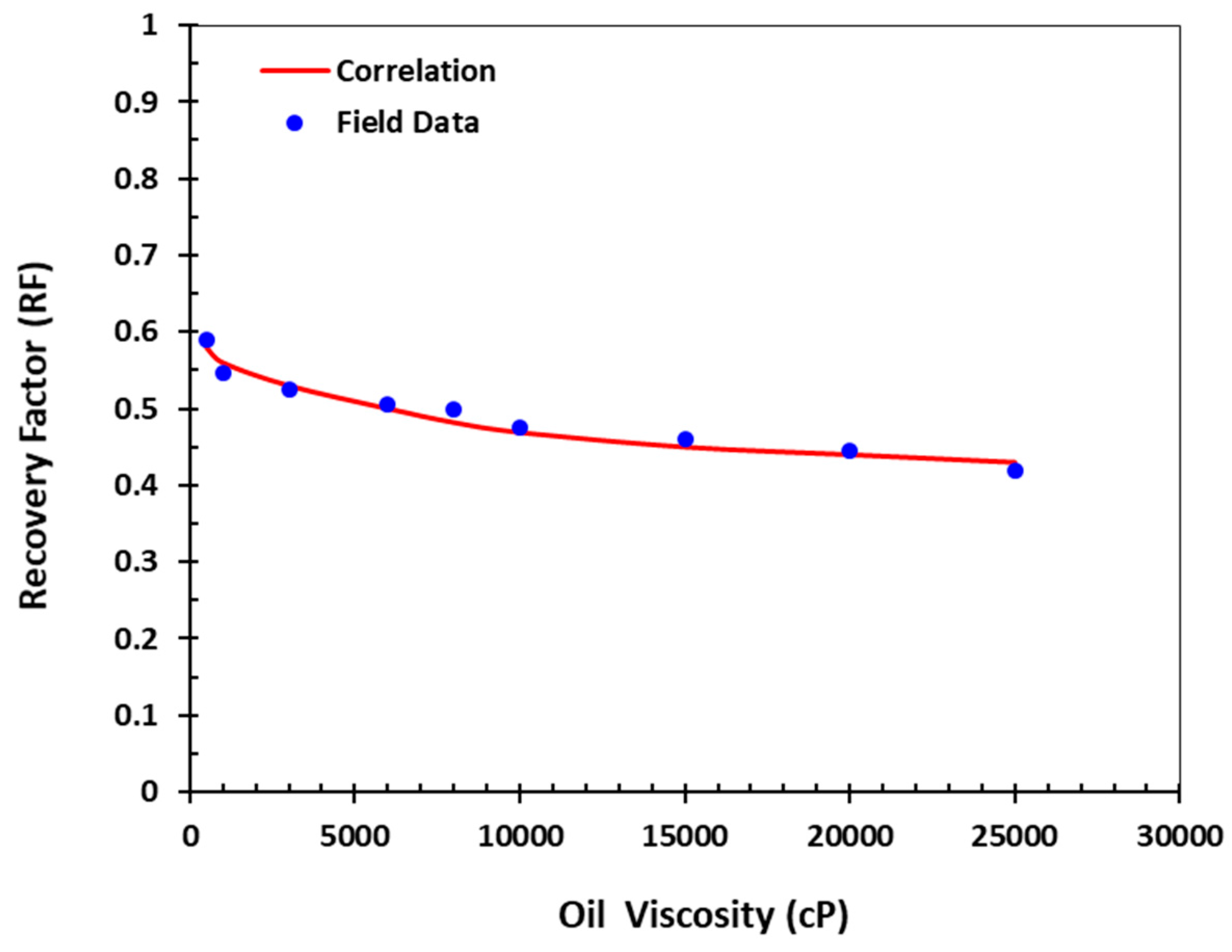

Figure 12. Furthermore, if the reservoir contains oil with high viscosity, some areas can be bypassed during steamflooding, resulting in early breakthrough and consequently lower RF, as demonstrated in

Figure 13. The same effect may occur when there are many fractures with high permeability in the reservoir (see

Figure 14). Although the presence of fractures can cause an increase in the rate of oil production, a high density of fractures may have undesired effects on the overall performance of steamflooding, as depicted in

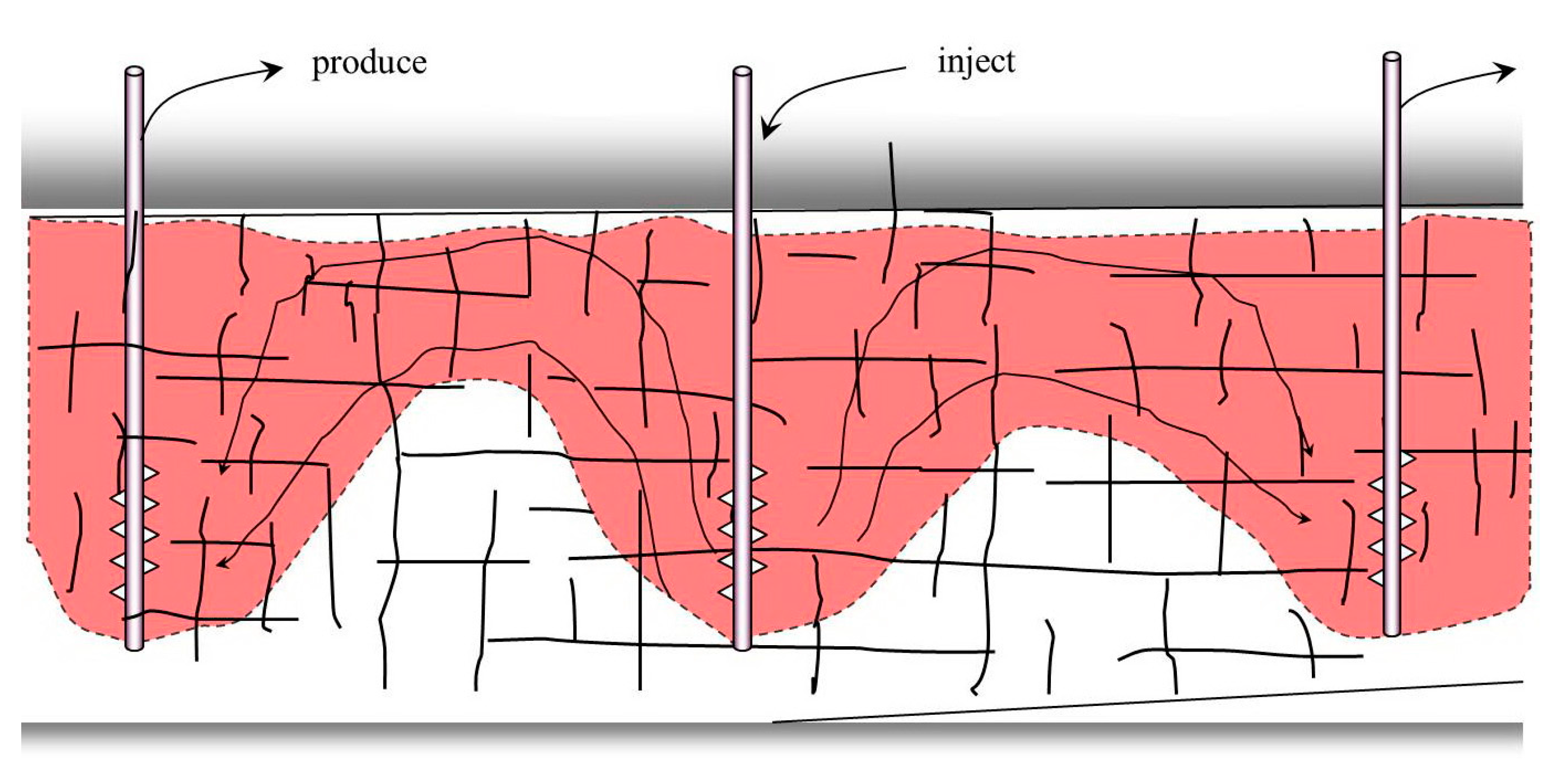

Figure 14.

Figure 15 shows that the ratio of the reservoir depth to the reservoir thickness does not have a noticeable impact on RF during steamflooding. As expected, steam quality and initial oil saturation have direct impacts on magnitude of RF. Increase in these two parameters can improve the performance of the steamflood (see

Figure 16 and

Figure 17). Clearly, steam injection with higher quality steam enters more heat into the reservoir leading to an increase in temperature. Hence, it causes viscosity reduction that enhances the oil recovery. The figures related to RF again confirm the effectiveness of the statistical approach adopted in this study as a good match was observed between the field data and the results obtained from the correlations.

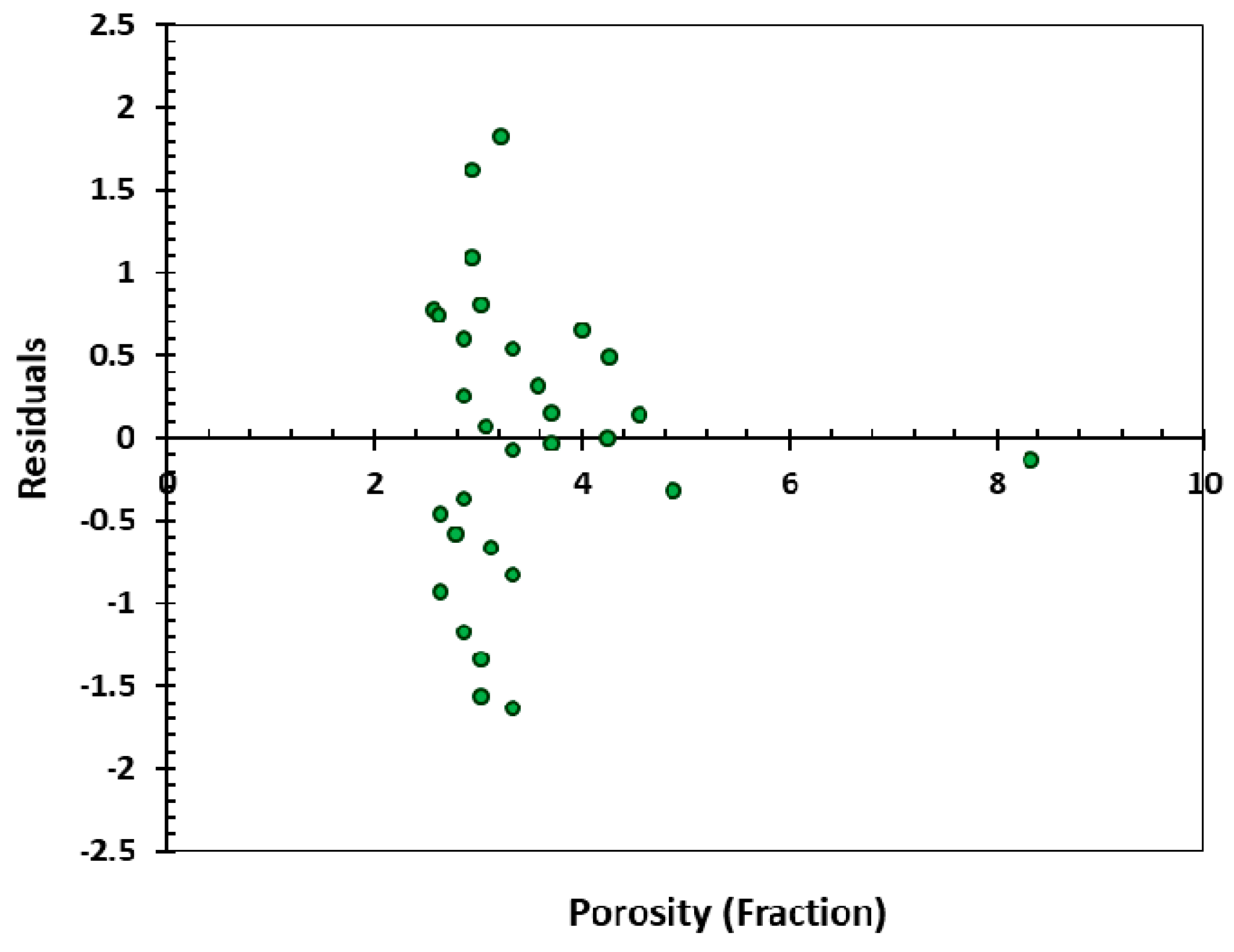

Figure 10 and

Figure 11 are the residual plots for the CSOR with respect to porosity and a combined interaction component (including formation depth and thickness), respectively. In addition, residual plots for RF versus porosity and “steam quality multiplied by steam injection rate” are presented in

Figure 20 and

Figure 21, respectively, as two samples of the analysis of the residuals. For these four residual plots, the residual data shows random distribution all along the horizontal axis. In other words, the proposed linear regressions are valid for CSOR and RF in terms of the particular dependent variables shown on

x-axis.

These results show that CSOR values for viscous oil extraction from NFCRs and some highly naturally fractured sandstone reservoirs can be correlated with reservoir and oil characteristics such as permeability, porosity, thickness, viscosity, and oil saturation. The following empirical relationship predictive function was developed in this study to estimate the CSOR during vertical well steamflooding in a NFCRs:

Table 3 presents the values for the correlation coefficients, standard errors, and the ranges for the coefficients involved in the equation for the CSOR. Needless to mention that definitions of all parameters introduced in

Table 3,

Table 4 and

Table 5 are presented in

Section 4 of this paper. Since the variables such as

Km (mD),

Kf (mD), (

φ) porosity (%),

So (%) have high magnitudes, their coefficients must be 4 to 6 digits significant while using regression correlations.

Recovery Factor (RF) is also an important asset assessment parameter, and a reliable tool to predict RF, even if only in a statistical manner, it would be valuable for first-order screening. Estimation of production performance is possible with initial and residual oil saturation data. The irreducible oil saturation is normally not known until the end of the thermal operation. Nevertheless, a correlation was established for RF prediction in terms of formation, steam, and oil properties considering the production history of some field pilots and laboratory tests data. To derive the following equation, a similar method as that for CSOR was implemented using statistical regression analysis:

The product of fracture permeability and matrix permeability and the interaction of all contributing parameters affect the RF in the form of “combinatory effects”.

Table 4 contains data on the statistical correlation coefficients.

The corresponding ANOVA for CSOR is presented in

Table 5. The

F observed for CSOR (196.645) exceeds the critical value (2.31). Hence, all of the parameters considered in multivariable linear regression analysis of CSOR and their attributed effects are significant and cannot be ignored to simplify the statistical model.

There is a vigorous dependence between the objective function (RF) and the process variables implemented in the statistical analysis. This is evident considering the high values of the observed “

F” compared with the tabulated critical value (

Table 6). It is also evident from

Table 6 that the regression analysis for RF has an acceptable accuracy.

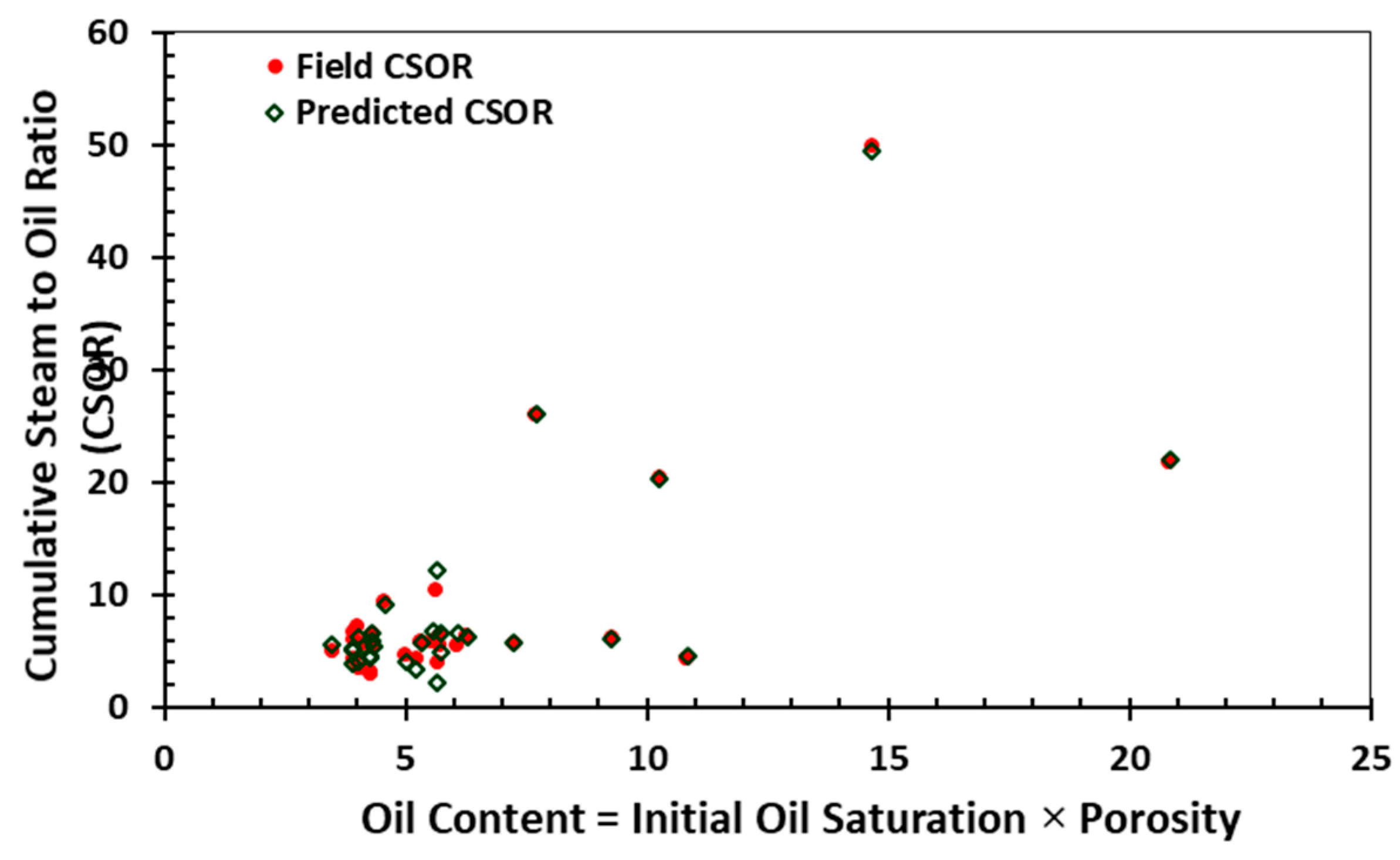

The magnitudes of the squared residuals (

Table 7) can be used to check the accuracy of a linear regression. The results obtained in this research suggest a reasonable compatibility between the measured (field pilots and experimental data) and the forecasts (regression analysis). The proposed model and the associated curves can be implemented to forecast CSOR and RF in any given VO NFCRs given the limitations of the database.

Based on this study, the in situ oil viscosity and the initial oil saturation are the most significant factors influencing CSOR and RF. This was expected because of the nature of the steam processes.

According to the statistical information provided in

Table 7 and

Table 8, there is an admissible match between the predicted and measured RF and CSOR. As shown in

Table 8, the statistical parameters (e.g.,

R2, minimum percentage error (MIPE), maximum percentage error (MAPE), and mean squared error (MSE)) for the new models obtained in this study and the relationships developed by other researchers such as Chu [

20], Vogel [

75], Boberg [

66], and Butler [

67] were obtained and compared. The statistical models developed, presented, and examined in this paper are more accurate in estimation of RF and CSOR as they appreciate from higher

R2 and lower MIPE, MAPE, and MSE.

The viscosity of cases analyzed ranges from 6 to 936 cP, thus the reservoirs are heavy oil reservoirs except for one medium heavy and one light oil reservoir in a NFR. The reservoir depth for the studied cases varies from 134 to 1350 m. This range covers the lower and upper limits of applicability of steamflooding. Matrix porosity and permeability vary from 0.12 to 0.35 and 1–4 D. In addition, the fracture “permeability” is between 1 and 1,000 D. These ranges represent an acceptable coverage for variation in parameters expected in such heterogeneous reservoirs despite small number of field pilots of steamflooding in NFCRs.

7.2. Screening of a Heavy Oil Field for Steamflooding

The Kuh-e-Mond heavy oil field, the largest on-shore heavy oil field in Iran, is a giant anticline located in the southwest of the country with a NW-SE trend. The field is 90 km long and 16 km wide with an estimated minimum heavy oil resource base of 10 × 10

9 barrels OOIP. The heavy oil is found in three separate layers with depths ranging from 400 to 1,200 m and oil viscosities of 550 to 1120 cP in situ [

78,

79,

80]. The trap structure formed during the main phase of Zagros folding in the late Miocene and Pliocene, as shown by the relatively constant thickness of the lower Miocene succession [

78,

79,

80]. According to petrophysical evaluations, the Jahrum Formation limestone is a poor reservoir. Only part of it has a good porosity (

φ) in the range of 0.24 to 0.31 and water saturation (S

w) around 0.20. This formation contains immobile heavy oil. The OOIP has been estimated at about 3 × 10

9 barrels [

78,

79,

80]. The Sarvak Formation, Cenomanian in geological age, is predominantly composed of intensely fractured marly limestone with some shale interbeds. The formation is divided into three main units in the study area: upper, middle, and lower units. The upper unit is composed of limestone with some weakly argillaceous impurities. Shale and marls are main rocks types in the middle Sarvak. Finally, the lower Sarvak predominantly consists of marly limestone with shale. Considering the intensely fractured nature of the Sarvak formation, heavy mud losses were reported during the drilling. The heavy oil resource in the Sarvak reservoir (OOIP) is estimated at 3.6 × 10

9 barrels [

78].

Lithostratigraphic information and fluid properties for the heavy oil reservoirs at the study area were collected, assessed, and summarized as presented in

Table 9. In assembling this database, data from various sources such as drilling logs, geophysical logs, and field and laboratory test data were used. The average magnitudes of reservoir and fluid properties were determined for each reservoir using the available data. Single values reported for some properties of the reservoirs here are the average values of the reservoirs’ parameters; while, the properties may change with respect to the location within the field.

Based on the predictive regression models, if 200 to 250 b/d of steam with 80% to 90% quality is injected into the formation then CSOR and RF will be in the ranges of 6 to 7.2 and 41% to 49%, respectively, for the Jahrum HO reservoir. These ranges will be 6.3 to 8 and 37% to 44% for CSOR and RF in Sarvak HO reservoir. The screening results imply that Jahrum reservoir is technically recoverable by using steamflooding despite an average rock matrix porosity of 19%. This is mainly because of other commendatory factors such as depth, thick net pay, and relatively high oil saturation. The Sarvak reservoir met the technical screening criteria but the Jahrum reservoir is considered a moderately better candidate. Very low matrix permeability and low oil saturation (<50% PV) lead to lower RF and higher CSOR in the Sarvak reservoir. However, under current economic conditions, HO exploitation from these reservoirs remains economically unattractive.

We examined the developed correlations for estimation of CSOR and RF in oil sands and unconsolidated heavy oil sandstone reservoirs and compared the results with the CSOR estimations predicted by a correlation proposed by Chu [

20]. The results suggest that the new correlations also can be used reliably to estimate CSOR and RF in oil sands and unconsolidated heavy oil sandstone reservoirs. The developed correlations can be considered a general from of correlations to be utilized for wide ranges of reservoir properties from NFCRs to oil sands and unconsolidated heavy oil sandstone reservoirs.

During utilization of steam injection in any given heavy oil reservoir, laboratory experiments and field interposition can serve the operator to avoid or rectify high CSOR by selecting an appropriate production rate and/or steam injection rate. The recovery and injection rates affect thermodynamic conditions, steam/oil ratio, and composition of the liquid phase, which is mobilized and moving to the production well. Hence, utilizing experiments and statistical modeling (i.e., using different flow rates as various dynamic conditions) which is much inexpensive and yet faster compared with field trials will be definitely beneficial in systematic assessment of the performance of steamflooding in any given HO NFCR. Estimation of vital process performance indicators such as CSOR and RF can provide invaluable directions for optimum design of a recovery technology in terms of flow rate and thermodynamic status of the fluids. Furthermore, accurate prediction of RF and CSOR for a given HO NFCR can enable process engineers with reasonable rules of thumb to minimize heat loss, which can lead to notable steam condensation in the reservoir.

7.3. Limitations and Assumptions for the Correlations of CSOR and RF

Table 10 presents the range of variables contributed in the correlations developed to forecast of RF and CSOR in NFCRs.

We have identified and acknowledged the following sets of limitations for the proposed statistical models. However, in practice they remain as appropriate and accurate predictive tools:

- (1)

Porous medium is non-deformable (constant porosity assumption).

- (2)

For mass, there is no source term except for the steam.

- (3)

A majority of the experimental data used in this research study have been obtained from the experiments in two-dimensional (2-D) porous systems.

- (4)

The correlations are only valid in the range of parameters used in the current study. Ranges of fluid and porous media properties in oil fields are almost the same as in the experimental studies considered in this statistical investigation.

- (5)

The Darcy law is valid throughout the EOR process. Flow in porous media is mostly laminar (i.e., Re < 1) during steamflooding.

- (6)

RF and CSOR forecasts are not affected greatly by the geometry of the physical models (experimental data taken from the literature) used in the experimental works (taken from the literature). It only influences the residual oil saturation, moderately. This is because the geometry dominates the shape of the corners and the end points in a porous system. In addition, in these experiments no changes was observed for a high capillary threshold and permeability with regard to geometry variations in the porous system.

- (7)

There were a certain number of porous media with specific fracture patterns selected for this statistical study. The proposed statistical models are very accurate for these fracture configurations. Thus, the only major limitation here is the type of fracture configuration. Nevertheless, if the effective fracture permeability is known for a porous system with unknown fracture configuration then the developed statistical models can be used to forecast the RF and CSOR with an acceptable accuracy.

Steamflooding and its variants utilizing either vertical, inclined, or horizontal wells can be used for any type of reservoirs regardless of the reservoir rock type if the oil viscosity is less than 5000 cP. This also includes conventional reservoirs containing light oil. In this case, steam and the resultant heat in the reservoir serve as stimulant rather than sweeping the oil or lowering down the oil viscosity (the well-known piston model). The only exception would be highly porous rocks such as diatomite and chalk which are also structurally very weak when exposed to heat [

81,

82]. In addition, the correlations introduced in this paper can be used to assess the performance of steamflooding in non-fractured reservoirs, as well. In fact, both fractured and non-fractured media are considered in the correlations and in the case of non-fractured media where there is no natural fractures, those parameters will be cancelled from the equations and the remaining terms can be used to evaluate the performance of the process in non-fractured systems (single porosity systems). The proposed correlations can be used as a proxy to assess the feasibility of the process in the candidate reservoirs. However, CSOR is a strong indicator of economic feasibility of any thermal operations under the current economic climate. For example, in Canada any thermal operations with CSORs below 3 are considered economic. Considering decades of experience in thermal operations in Canada especially for well-known and commercialised technologies such as SAGD and HCS, wealth of available field data, and advanced process optimization practices, the CSOR is now down to less than 2. Considering the case study presented here, this heavy oil field is a poor candidate for steamflooding. However, utilizing long horizontal wells will increase the oil recovery and will reduce the CSOR in the case studied. In addition, adopting cyclic steam stimulation processes can reduce the steam requirements, lower down the CSOR, and increase the RF and oil production rate. Nevertheless, the correlations developed and presented here can only be used for estimation of RF and CSOR in thermal heavy oil operations utilizing vertical wells. Clearly, new sets of correlations or models will be needed to predict performance of steam processes utilizing horizontal wells. Such projects still do not exist (therefore no filed data is available at the moment) when it comes to carbonate reservoirs. Some steam injection variants such as HCS process are being tried in bitumen saturated Devonian carbonates in Alberta, Canada.