A New ZVS Tuning Method for Double-Sided LCC Compensated Wireless Power Transfer System

Abstract

:1. Introduction

2. Double-Sided LCC Compensation Network and Parameter Tuning for ZVS

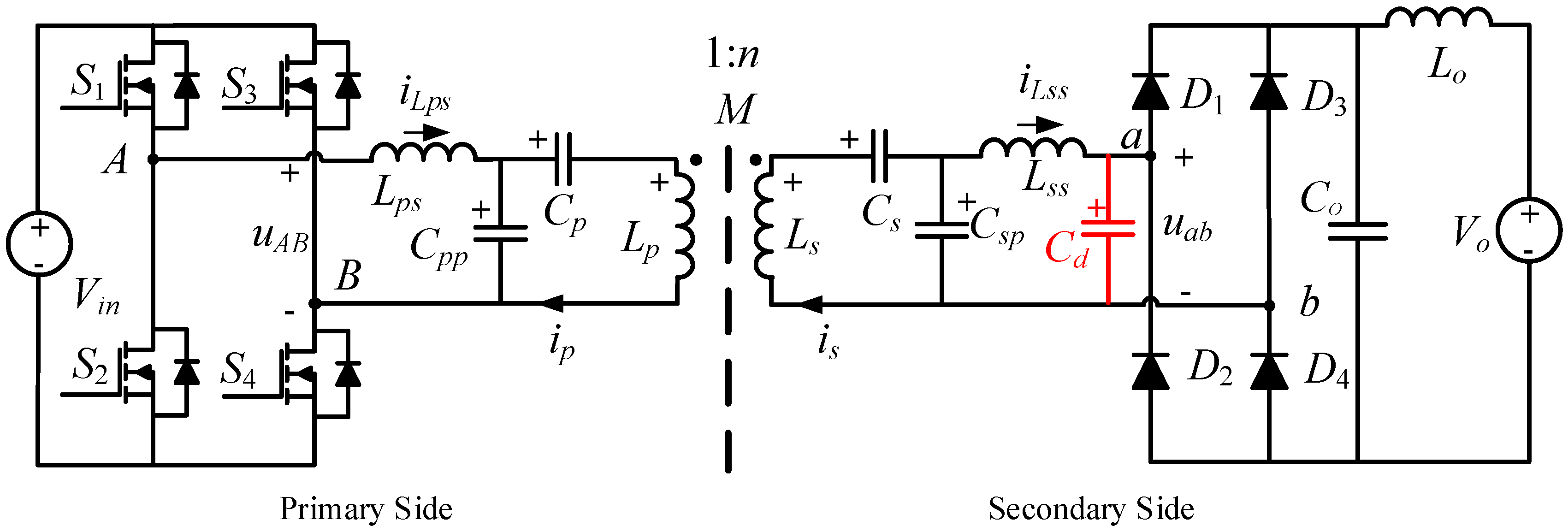

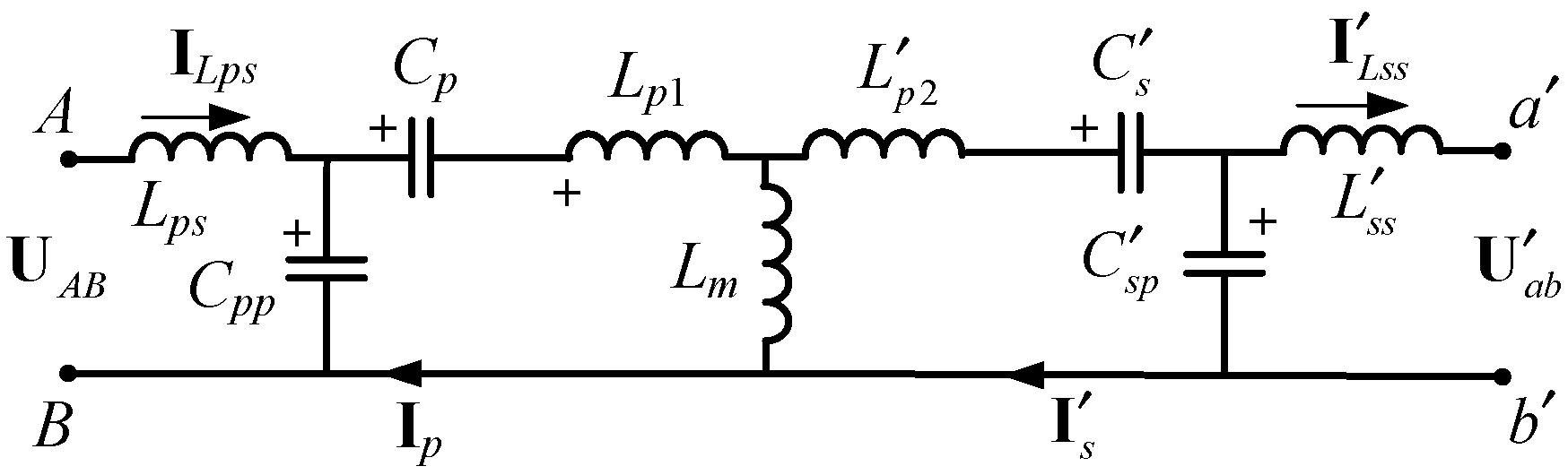

2.1. Double-Sided LCC Compensation Network

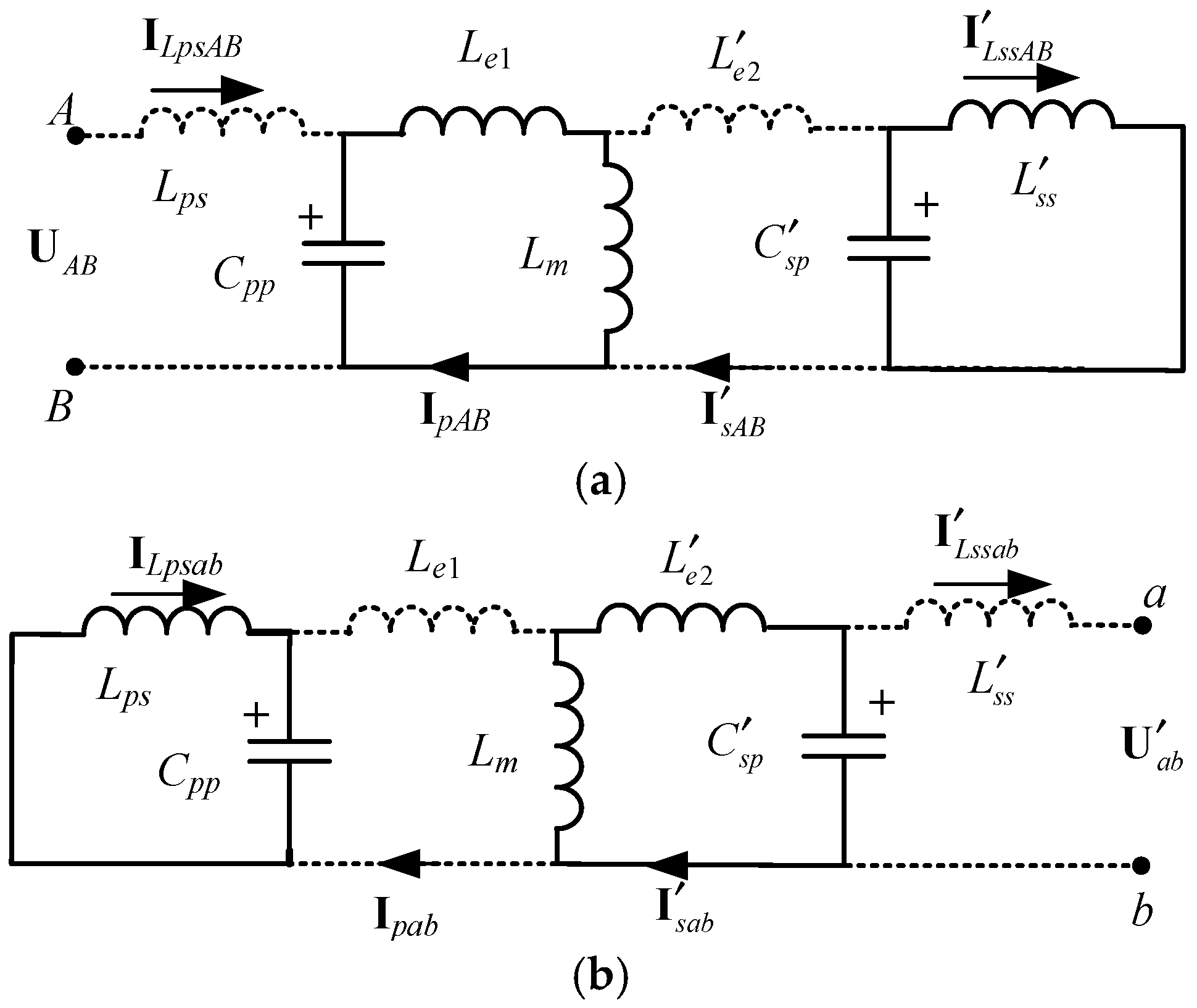

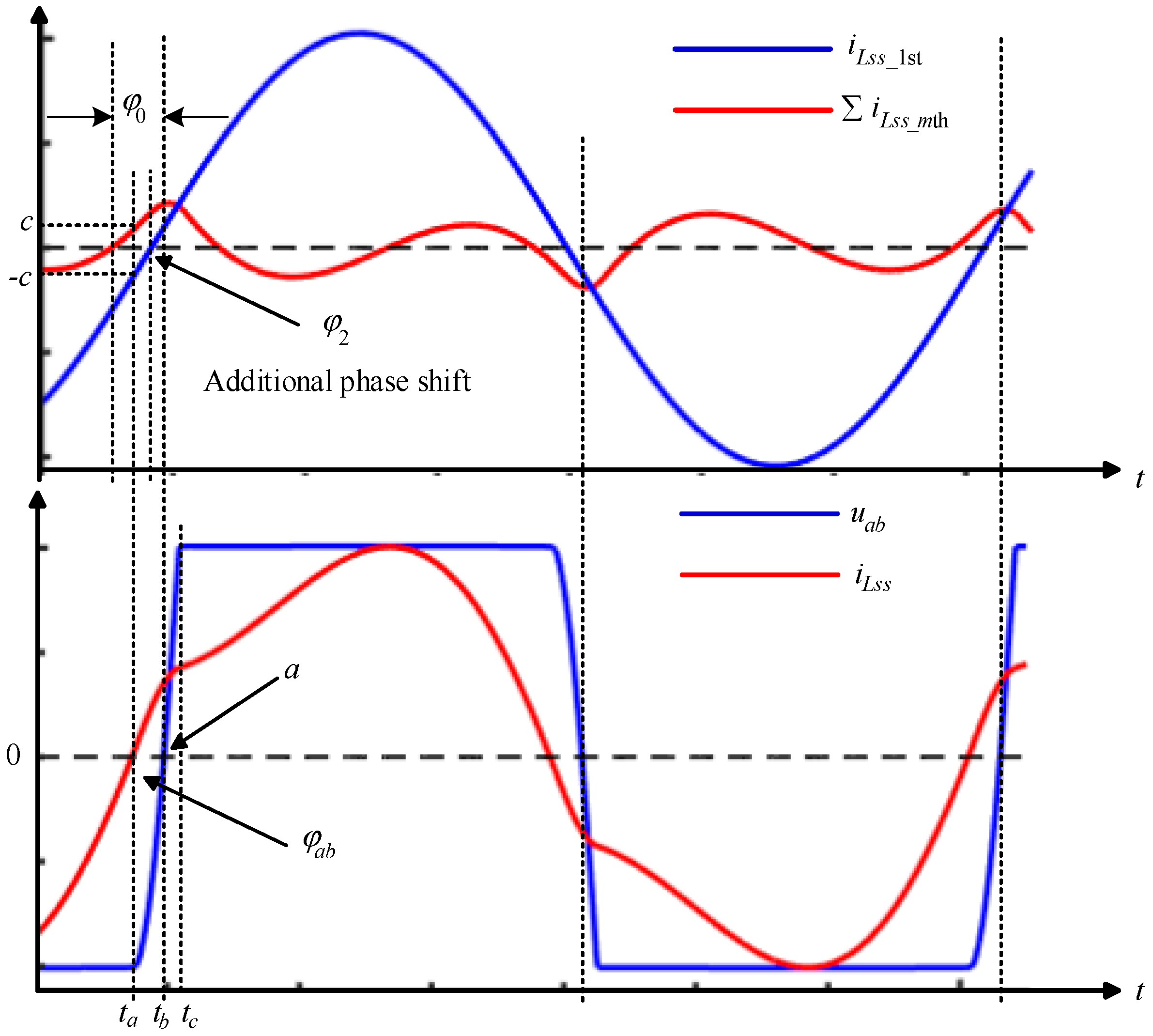

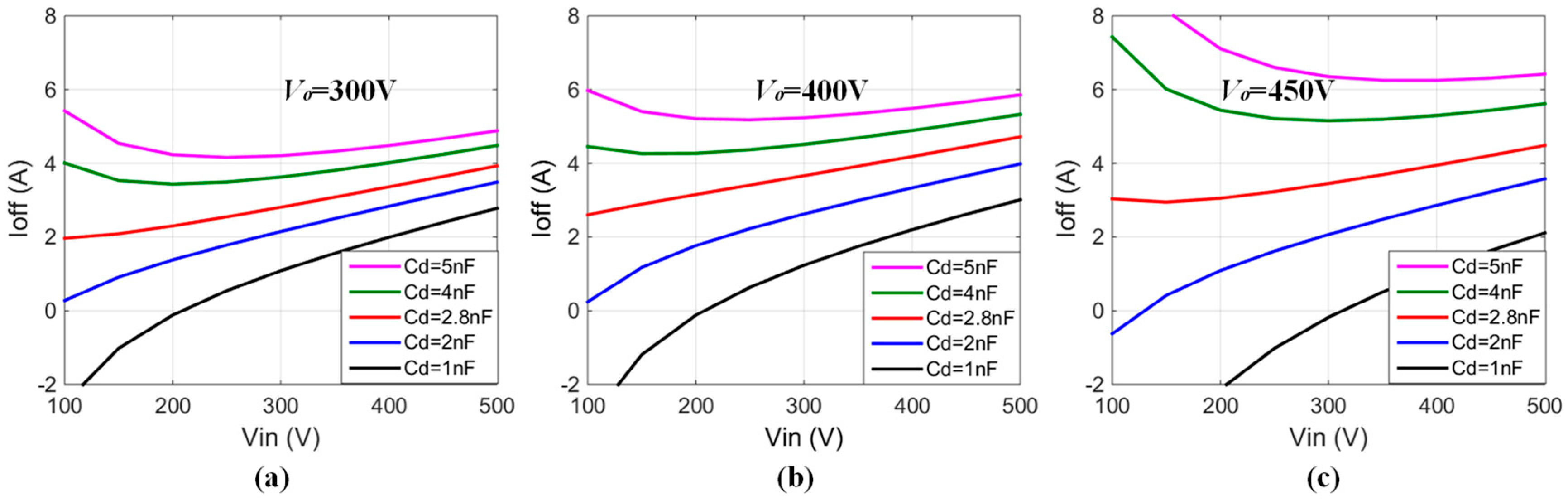

2.2. Parameter Tuning for ZVS

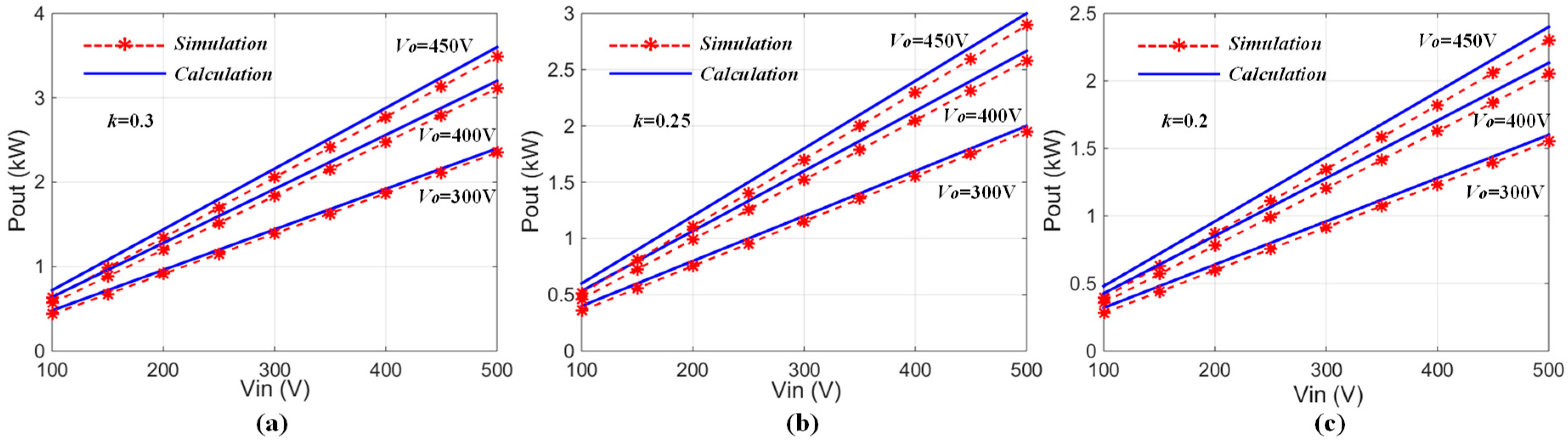

3. Parameter Design

4. Simulation and Experimental Results

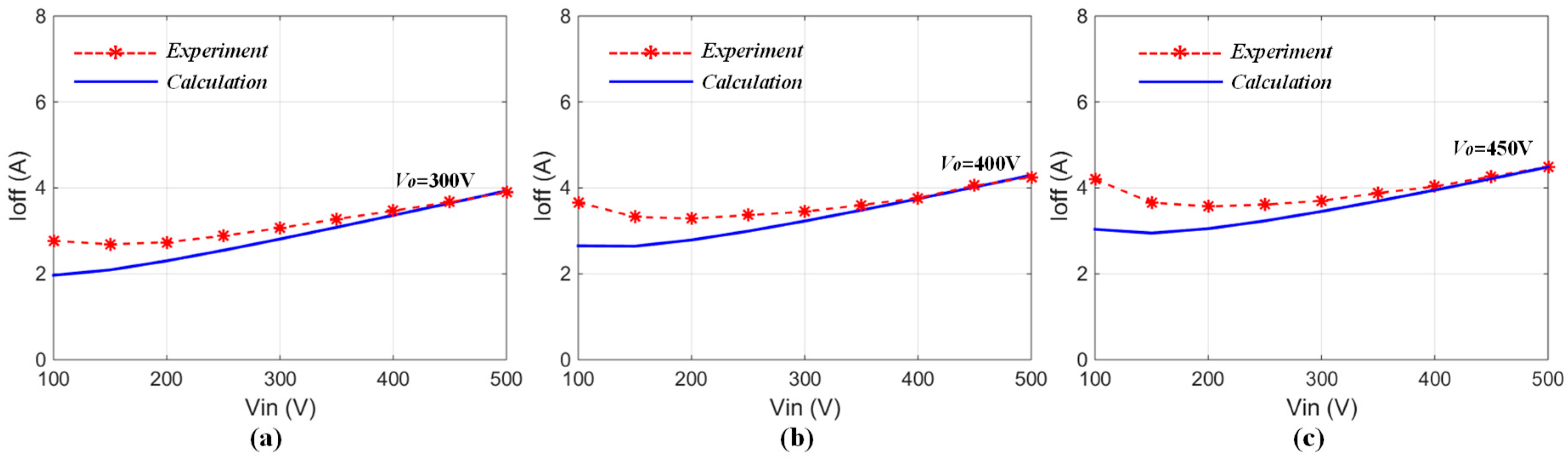

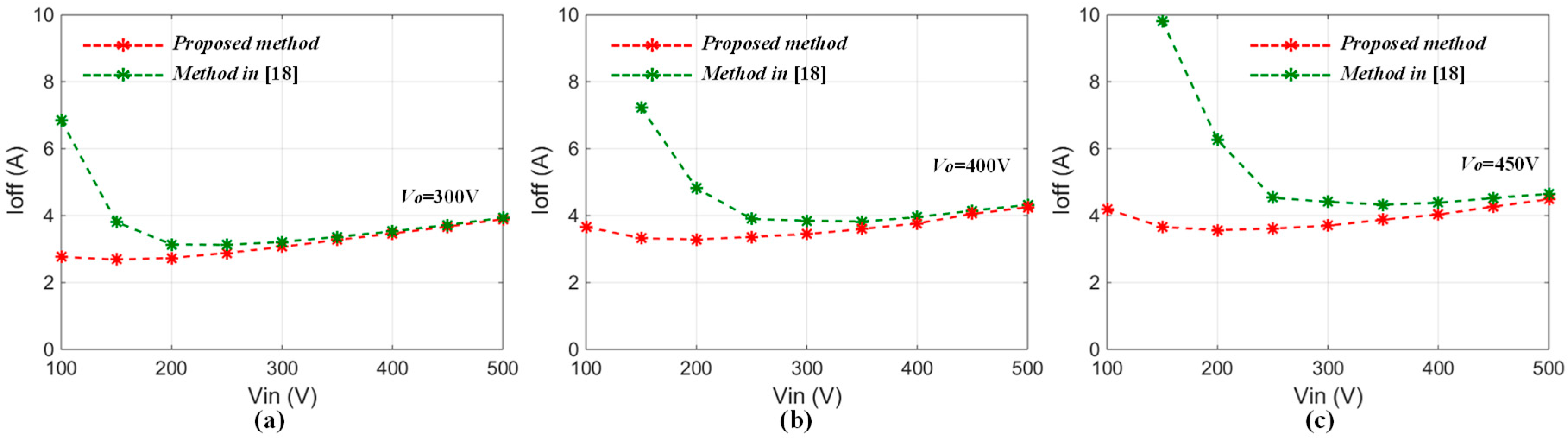

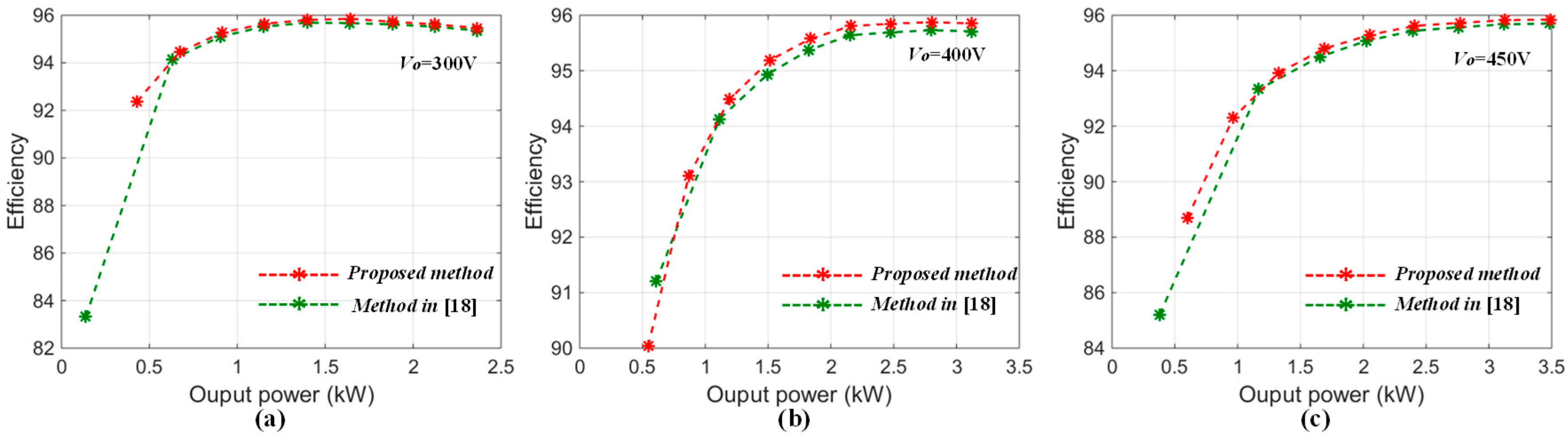

4.1. Simulated Results

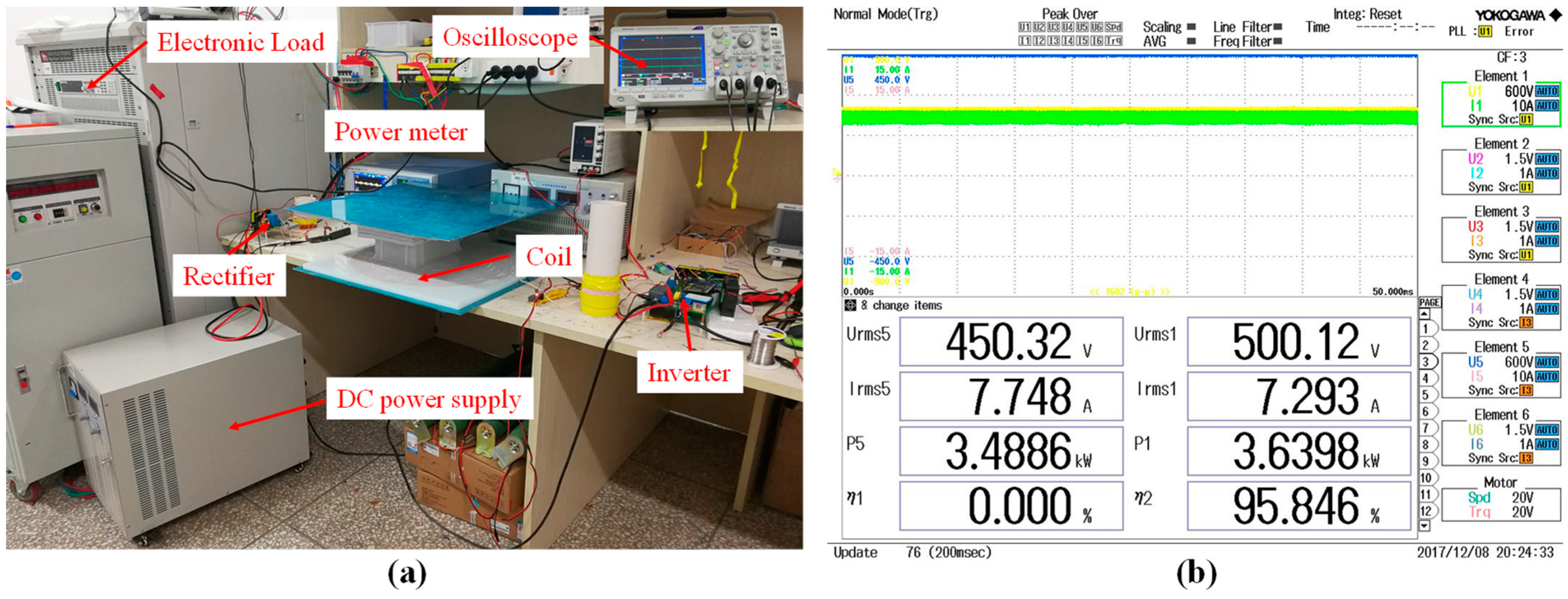

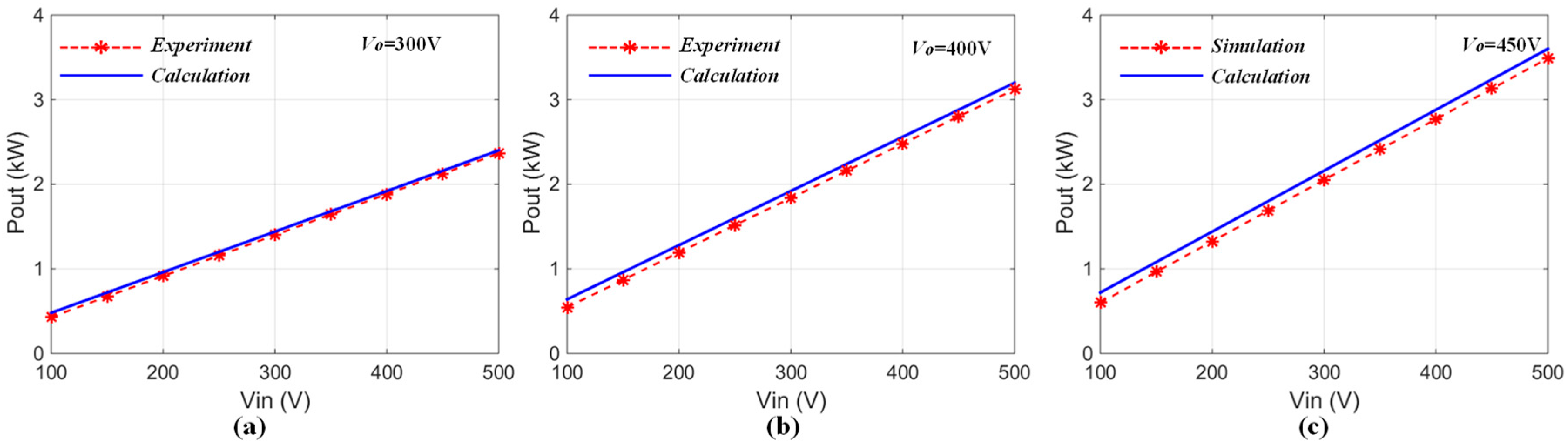

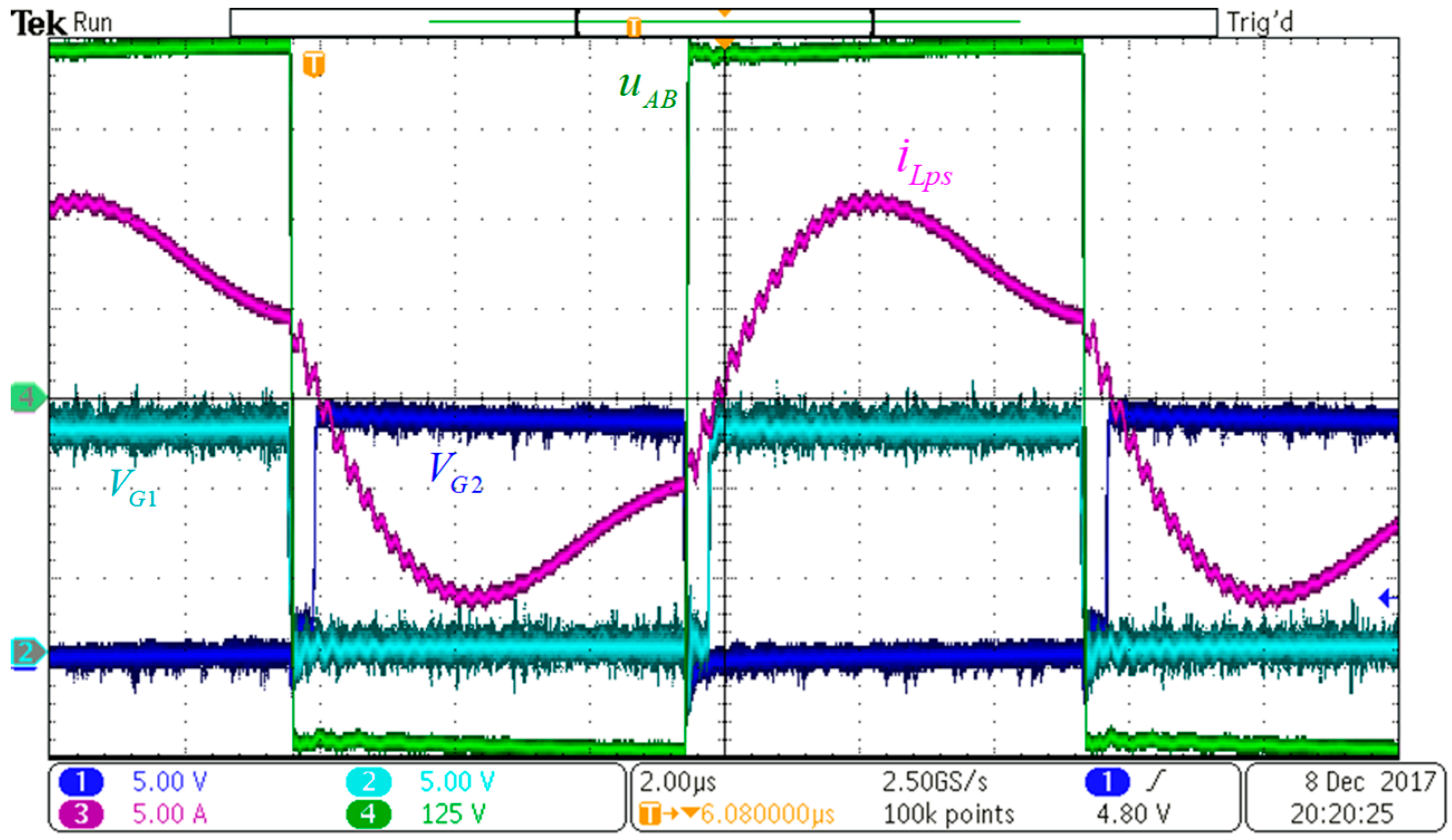

4.2. Experimental Results

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lu, F.; Zhang, H.; Mi, C. A Review on the Recent Development of Capacitive Wireless Power Transfer Technology. Energies 2017, 10, 1752. [Google Scholar] [CrossRef]

- Zhang, W.; Mi, C. Compensation Topologies of High-Power Wireless Power Transfer Systems. IEEE Trans. Veh. Technol. 2016, 65, 4768–4778. [Google Scholar] [CrossRef]

- Li, S.; Liu, Z.; Zhao, H.; Zhu, L.; Shuai, C. Wireless Power Transfer by Electric Field Resonance and Its Application in Dynamic Charging. IEEE Trans. Ind. Electron. 2016, 63, 6602–6612. [Google Scholar] [CrossRef]

- Li, S.; Mi, C. Wireless Power Transfer for Electric Vehicle Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 4–17. [Google Scholar]

- Vaka, R.; Keshri, R. Review on Contactless Power Transfer for Electric Vehicle Charging. Energies 2017, 10, 636. [Google Scholar] [CrossRef]

- Li, W.; Zhao, H.; Deng, J.; Li, S.; Mi, C. Comparison Study on SS and Double-Sided LCC Compensation Topologies for EV/PHEV Wireless Chargers. IEEE Trans. Veh. Technol. 2016, 65, 4429–4439. [Google Scholar] [CrossRef]

- Wang, C.; Stielau, O.; Covic, G. Design considerations for a contactless electric vehicle battery charger. IEEE Trans. Ind. Electron. 2005, 52, 1308–1314. [Google Scholar] [CrossRef]

- Khaligh, A.; Dusmez, S. Comprehensive Topological Analysis of Conductive and Inductive Charging Solutions for Plug-In Electric Vehicles. IEEE Trans. Veh. Technol. 2012, 61, 3475–3489. [Google Scholar] [CrossRef]

- Sohn, Y.; Choi, B.; Lee, E.; Lim, G.; Cho, G.; Rim, C. General Unified Analyses of Two-Capacitor Inductive Power Transfer Systems: Equivalence of Current-Source SS and SP Compensations. IEEE Trans. Power Electron. 2015, 30, 6030–6045. [Google Scholar] [CrossRef]

- Deng, J.; Li, W.; Nguyen, T.; Li, S.; Mi, C. Compact and Efficient Bipolar Coupler for Wireless Power Chargers: Design and Analysis. IEEE Trans. Power Electron. 2015, 30, 6130–6140. [Google Scholar] [CrossRef]

- Cho, S.; Lee, I.; Moon, S.; Moon, G.; Kim, B.; Kim, K. Series-Series Compensated Wireless Power Transfer at Two Different Resonant Frequencies. In Proceedings of the 5th IEEE Annual International Energy Conversion Congress and Exhibition (ECCE) Asia DownUnder Conference, Melbourne, Australia, 3–6 June 2013; pp. 1052–1058. [Google Scholar]

- Liu, X.; Clare, L.; Yuan, X.; Wang, C.; Liu, J. A Design Method for Making an LCC Compensation Two-Coil Wireless Power Transfer System More Energy Efficient Than an SS Counterpart. Energies 2017, 10, 1346. [Google Scholar] [CrossRef]

- Wang, C.; Covic, G.; Stielau, O. Investigating an LCL load resonant inverter for inductive power transfer applications. IEEE Trans. Power Electron. 2004, 19, 995–1002. [Google Scholar] [CrossRef]

- Madawala, U.; Thrimawithana, D. A Bidirectional Inductive Power Interface for Electric Vehicles in V2G Systems. IEEE Trans. Ind. Electron. 2011, 58, 4789–4796. [Google Scholar] [CrossRef]

- Borage, M.; Tiwari, S.; Kotaiah, S. Analysis and design of an LCL-T resonant converter as a constant-current power supply. IEEE Trans. Ind. Electron. 2005, 52, 1547–1554. [Google Scholar] [CrossRef]

- Pantic, Z.; Bai, S.; Lukic, S. ZCS LCC-Compensated Resonant Inverter for Inductive-Power-Transfer Application. IEEE Trans. Ind. Electron. 2011, 58, 3500–3510. [Google Scholar] [CrossRef]

- Keeling, N.; Covic, G.; Boys, J. A Unity-Power-Factor IPT Pickup for High-Power Applications. IEEE Trans. Ind. Electron. 2010, 57, 744–751. [Google Scholar] [CrossRef]

- Li, S.; Li, W.; Deng, J.; Nguyen, T.; Mi, C. A Double-Sided LCC Compensation Network and Its Tuning Method for Wireless Power Transfer. IEEE Trans. Veh. Technol. 2015, 64, 2261–2273. [Google Scholar] [CrossRef]

- Li, W.; Zhao, H.; Li, S.; Deng, J.; Kan, T.; Mi, C. Integrated LCC Compensation Topology for Wireless Charger in Electric and Plug-in Electric Vehicles. IEEE Trans. Ind. Electron. 2015, 62, 4215–4225. [Google Scholar] [CrossRef]

- Erickson, R.; Maksimovic, D. Fundamentals of Power Electronics, 2nd ed.; Academic: New York, NY, USA, 2001. [Google Scholar]

- Lu, B.; Liu, W.; Liang, Y.; Lee, F. Optimal Design Methodology for LLC Resonant Converter. In Proceedings of the Twenty-First Annual IEEE Applied Power Electronics Conference and Exposition, Dallas, TX, USA, 19–23 March 2006. [Google Scholar]

- Huh, J.; Lee, S.; Lee, W.; Cho, G.; Rim, C. Narrow-Width Inductive Power Transfer System for Online Electrical Vehicles. IEEE Trans. Power Electron. 2011, 26, 3666–3679. [Google Scholar] [CrossRef]

- Sharp, B.; Wu, H. Asymmetrical Voltage-Cancellation Control for LCL Resonant Converters in Inductive Power Transfer Systems. In Proceedings of the 27th IEEE Applied Power Electronics Conference and Exposition (APEC), Orlando, FL, USA, 5–9 February 2012; pp. 1052–1058. [Google Scholar]

- Luo, S.; Li, S.; Zhao, H. Reactive Power Comparison of Four-Coil, LCC and CLC Compensation Network for Wireless Power Transfer. In Proceedings of the IEEE PELS Workshop on Emerging Technologies-Wireless Power Transfer (WOW), Chongqing, China, 20–22 May 2017; pp. 268–271. [Google Scholar]

| Spec/Parameter | Values |

|---|---|

| Input DC voltage | <500 V |

| Output voltage | 300–450 V |

| Nominal gap | 120 mm |

| Coupling coefficient | 0.2–0.3 |

| Transmitting coil inductance | 300 μH |

| Transmitting coil AC resistance | ~500 mΩ |

| Receiving coil inductance | 202.7 μH |

| Receiving coil AC resistance | ~500 mΩ |

| Switching frequency | 85 kHz |

| Maximum power | ~3.6 kW |

| Parameter | Values |

|---|---|

| Lps | 97.4 μH |

| Lss | 72.05 μH |

| Cpp | 36 nF |

| Csp | 48.66 nF |

| Cps | 17.3 nF |

| Css | 26.83 nF |

| Cd | 2.8 nF |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, S.; Deng, X.; Shu, W.; Wei, X.; Li, S. A New ZVS Tuning Method for Double-Sided LCC Compensated Wireless Power Transfer System. Energies 2018, 11, 307. https://doi.org/10.3390/en11020307

Lu S, Deng X, Shu W, Wei X, Li S. A New ZVS Tuning Method for Double-Sided LCC Compensated Wireless Power Transfer System. Energies. 2018; 11(2):307. https://doi.org/10.3390/en11020307

Chicago/Turabian StyleLu, Sizhao, Xiaoting Deng, Wenbin Shu, Xiaochao Wei, and Siqi Li. 2018. "A New ZVS Tuning Method for Double-Sided LCC Compensated Wireless Power Transfer System" Energies 11, no. 2: 307. https://doi.org/10.3390/en11020307