A Comparative Study on Controllers for Improving Transient Stability of DFIG Wind Turbines During Large Disturbances

Abstract

:1. Introduction

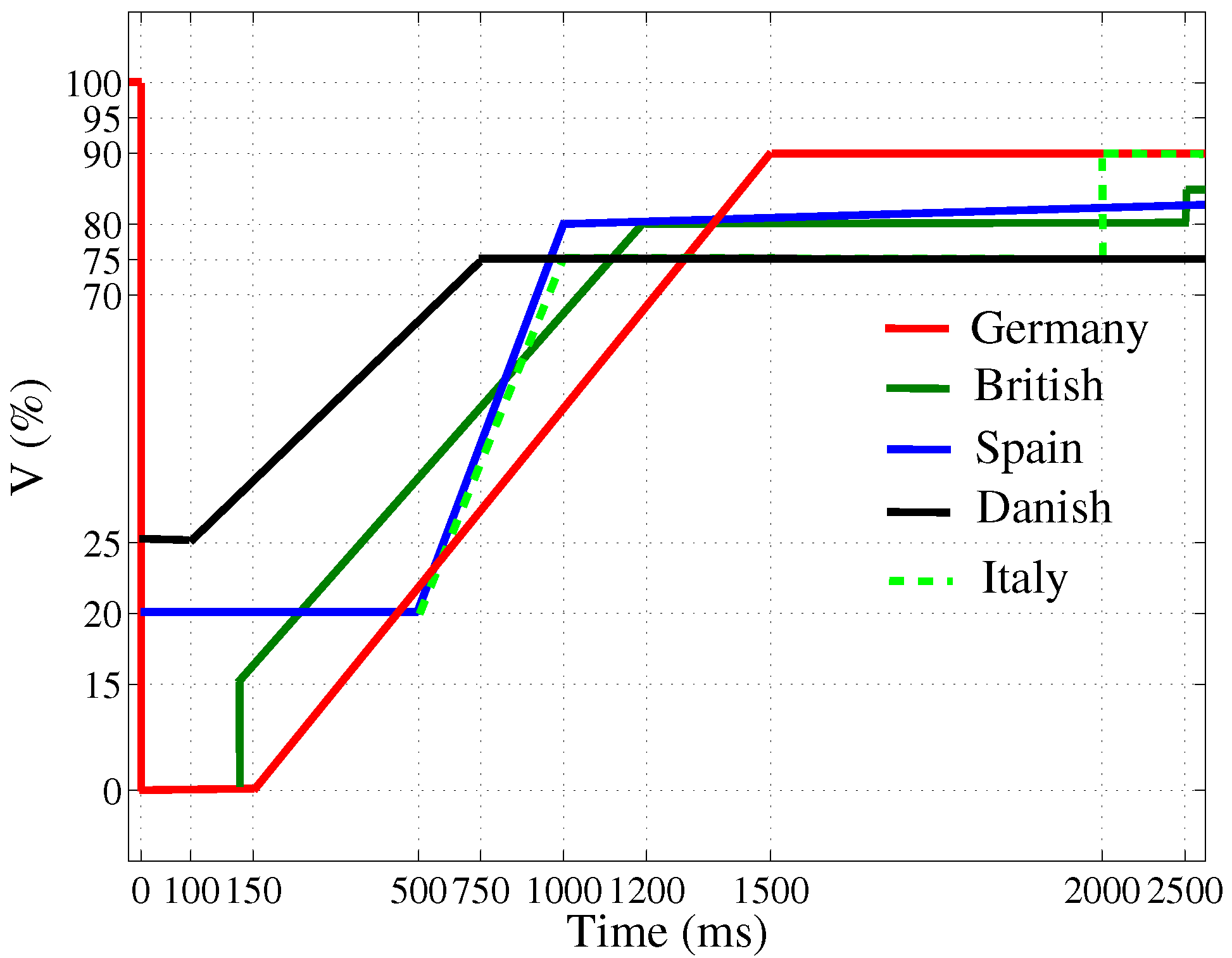

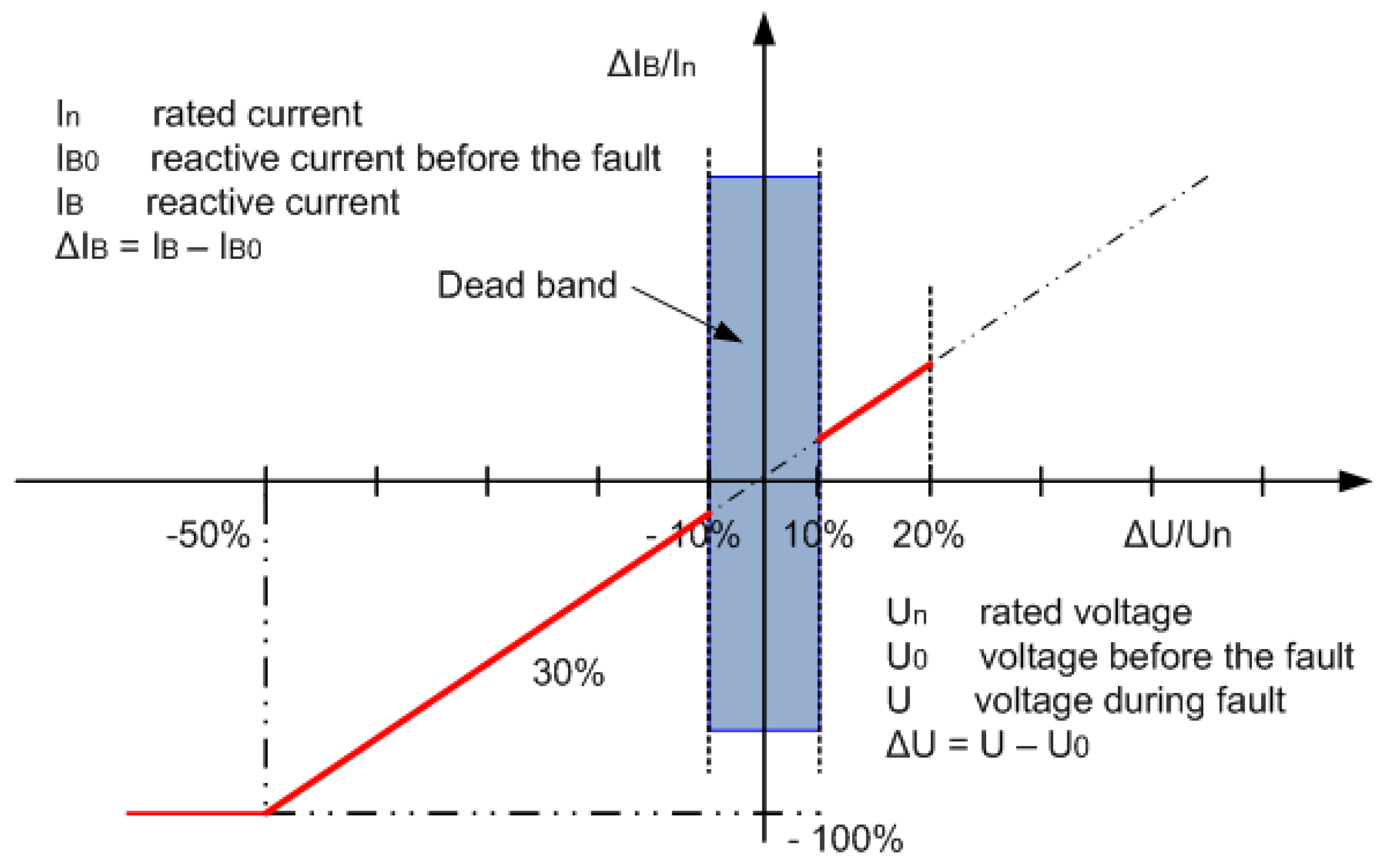

2. European Regulations for Wind Turbines Fault-Ride-Through Compliance

3. DFIG Behavior under Grid Disturbances and Crowbar Protection

3.1. DFIG under Disturbances

3.2. Crowbar Protection

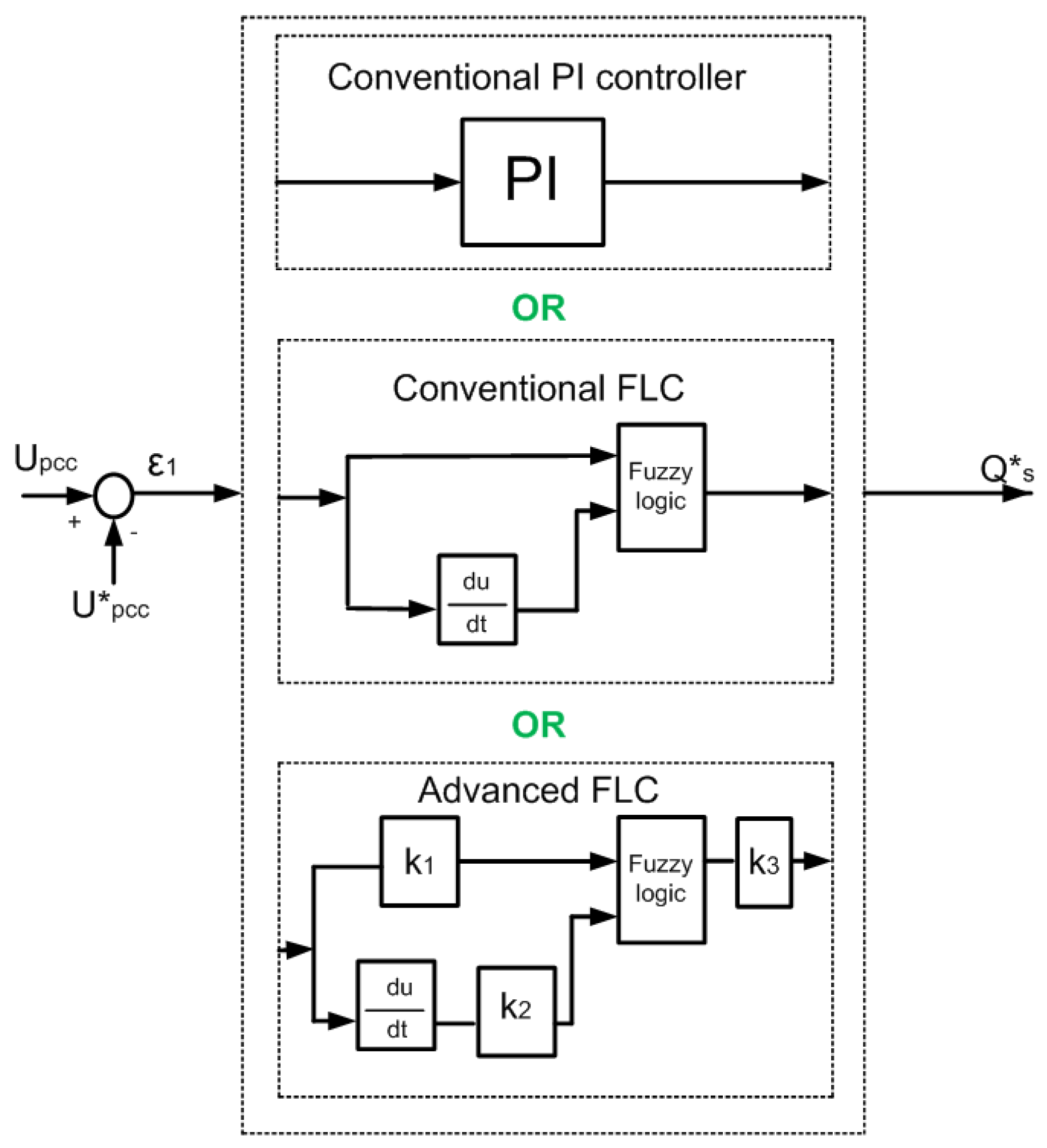

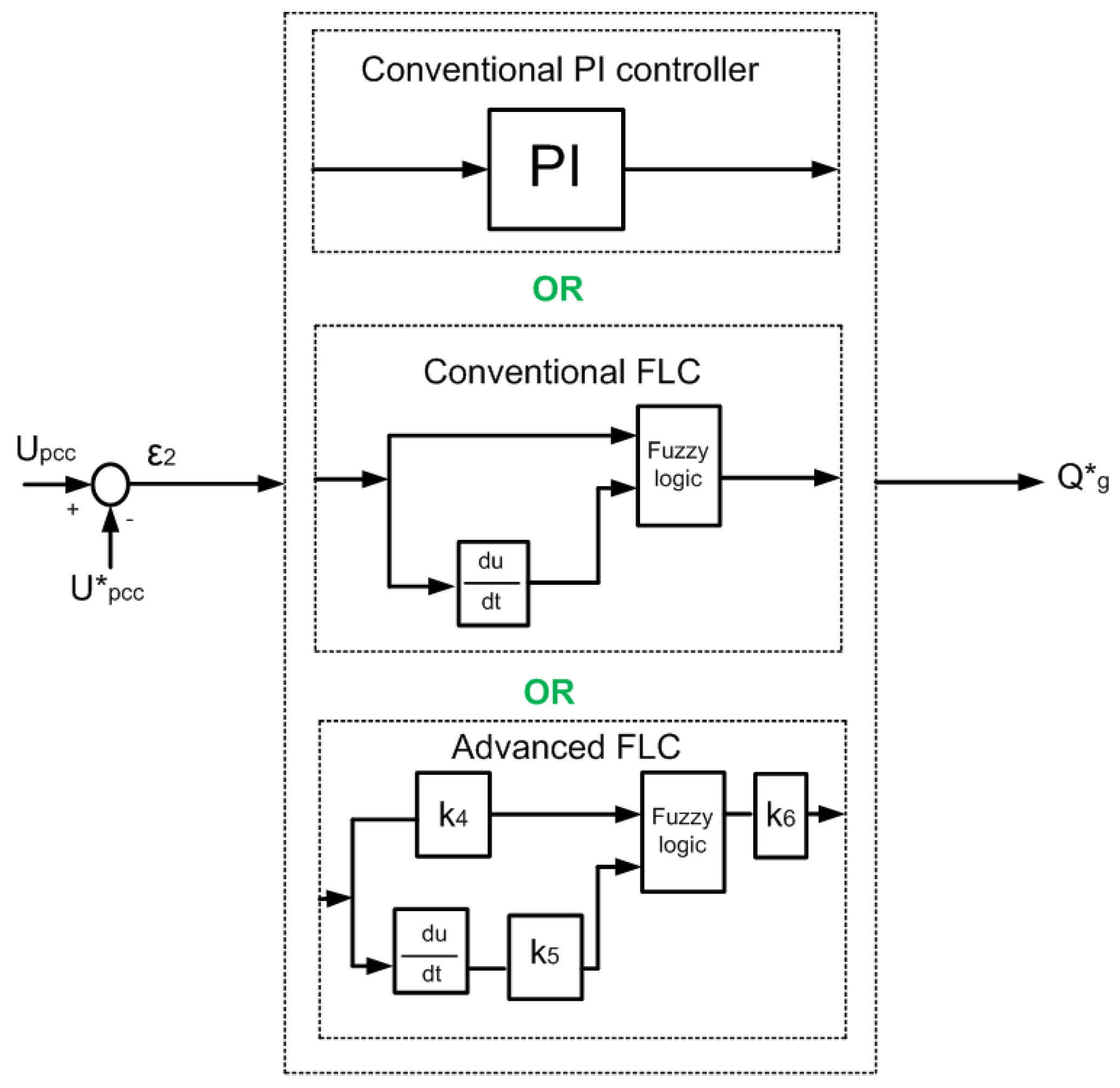

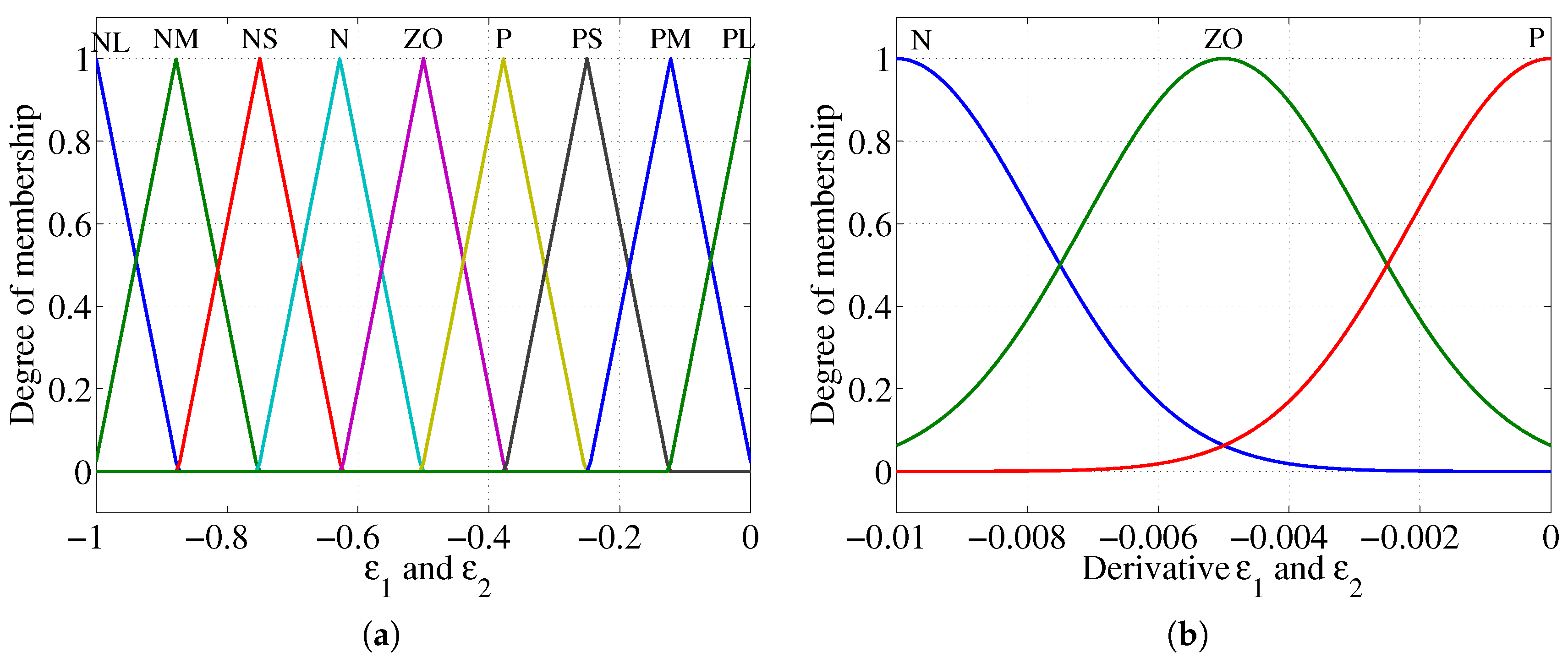

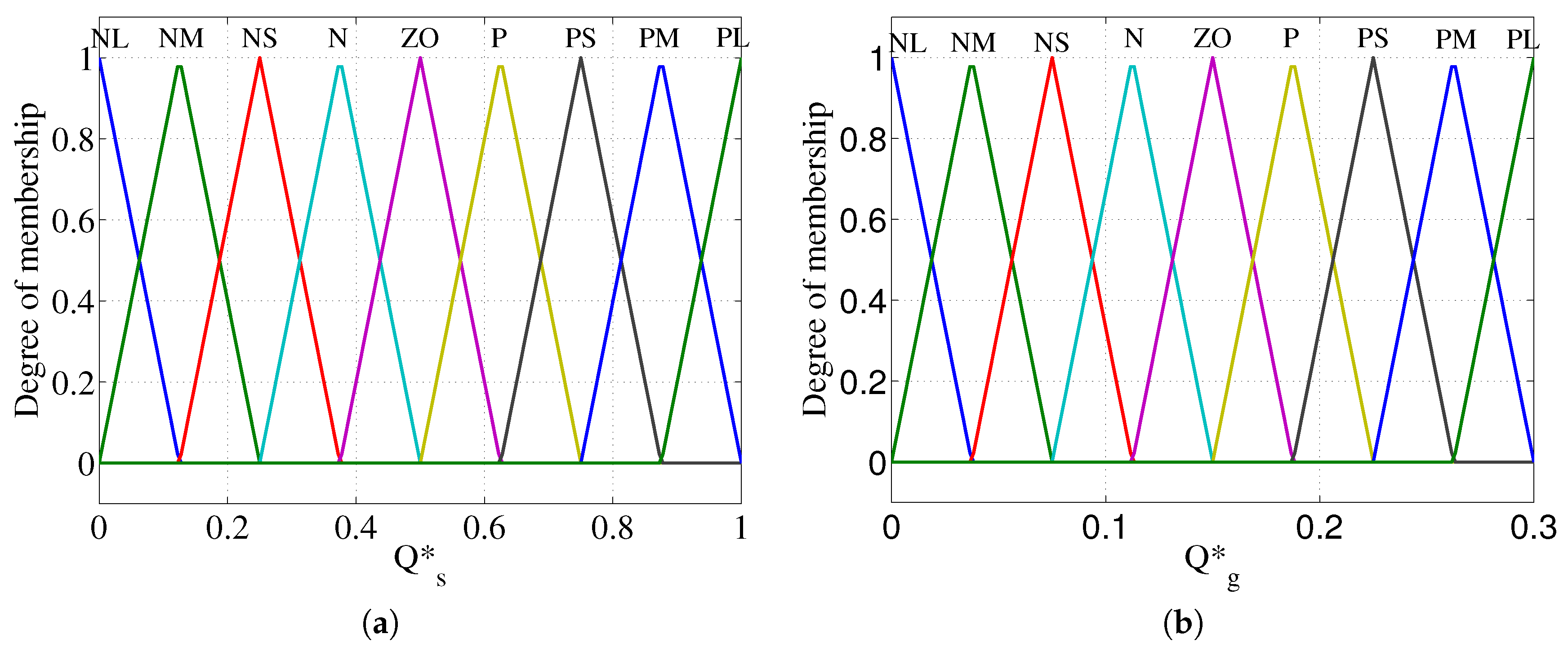

4. Proposed Control Strategy for DFIG FRT and Enhanced Voltage Grid Support

4.1. Conventional Scheme Using Crowbar Protection without Fault-Ride-Through

- the reference value of active power, , is determined by the maximum power point tracking logic, depending on the optimal generator speed ;

- the reference value of RSC reactive power is in general set to zero;

- the reference value of GSC reactive power can be set to a particular value, or even to zero.

4.2. Proposed Scheme Using Crowbar Protection with Fault-Ride-Through

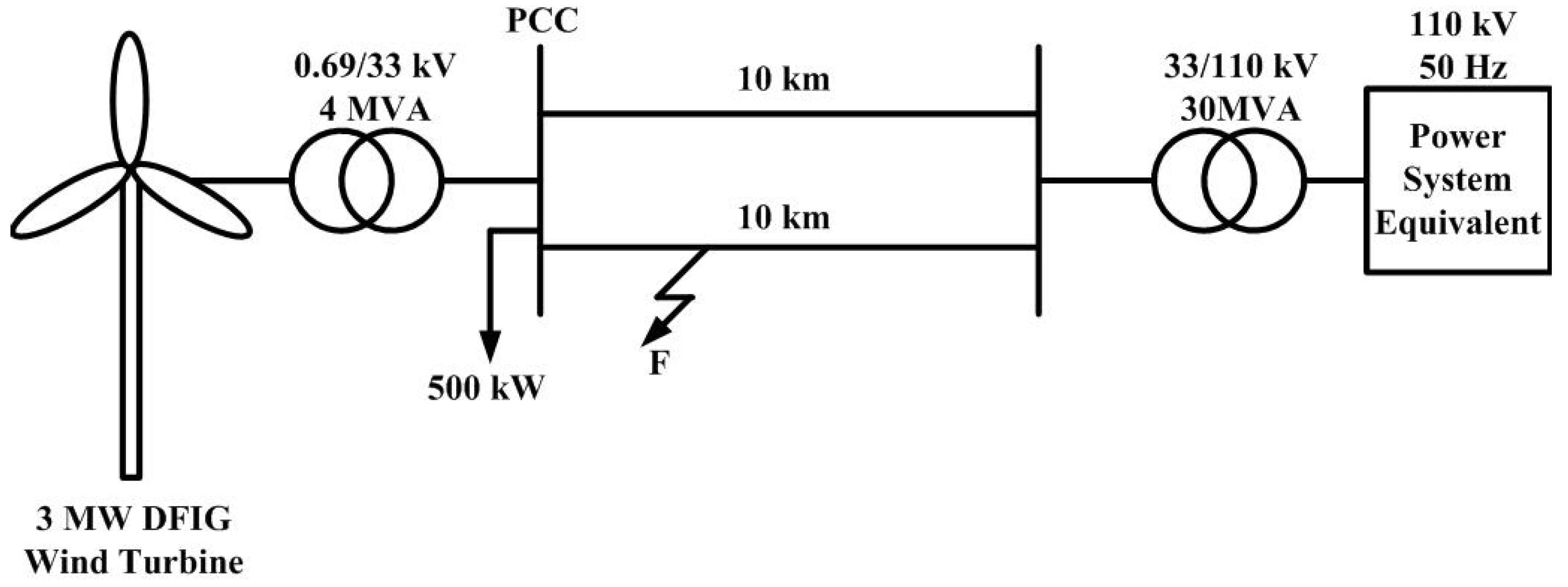

5. Results and Discussion

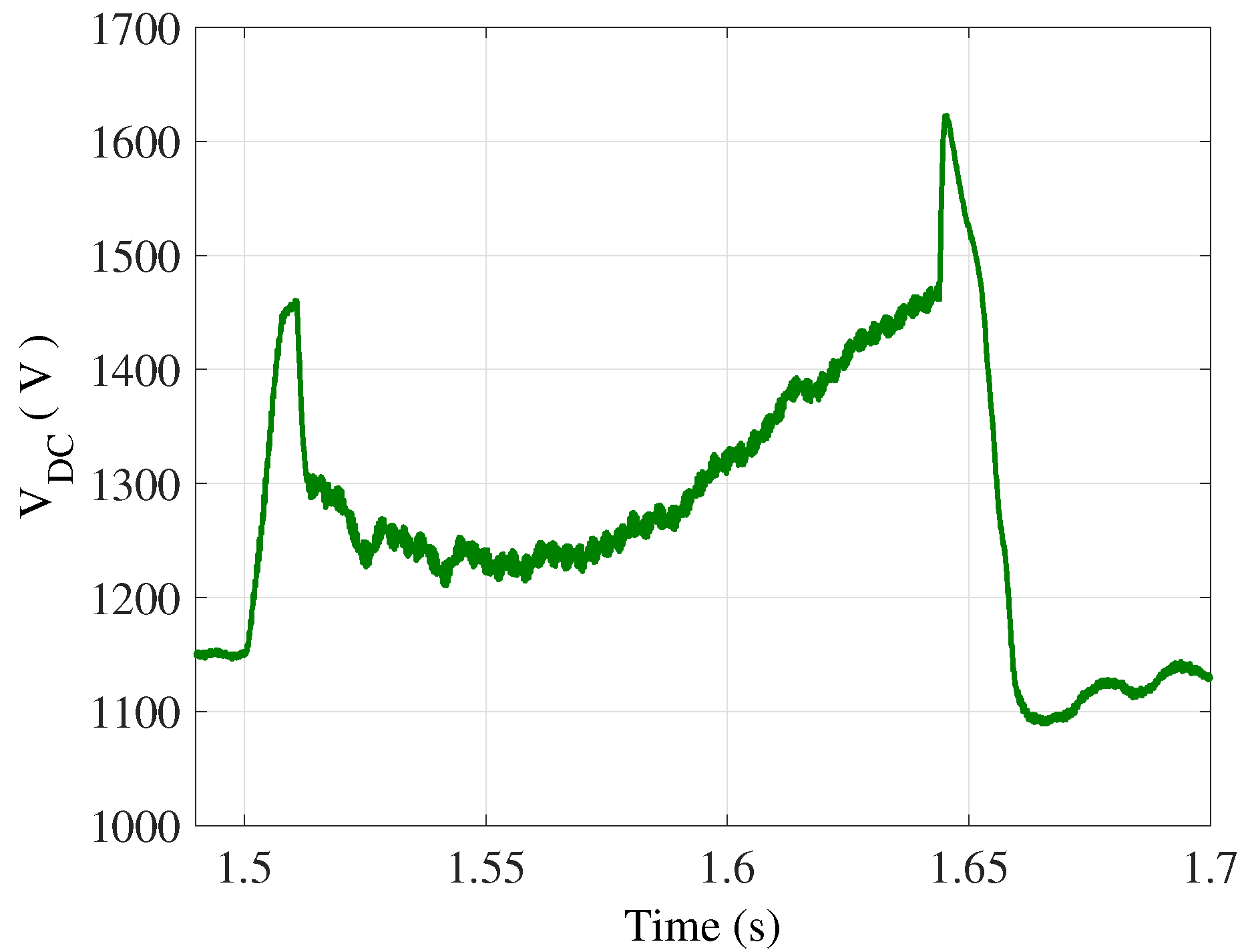

5.1. Crowbar with Hysteresis Controller Effect

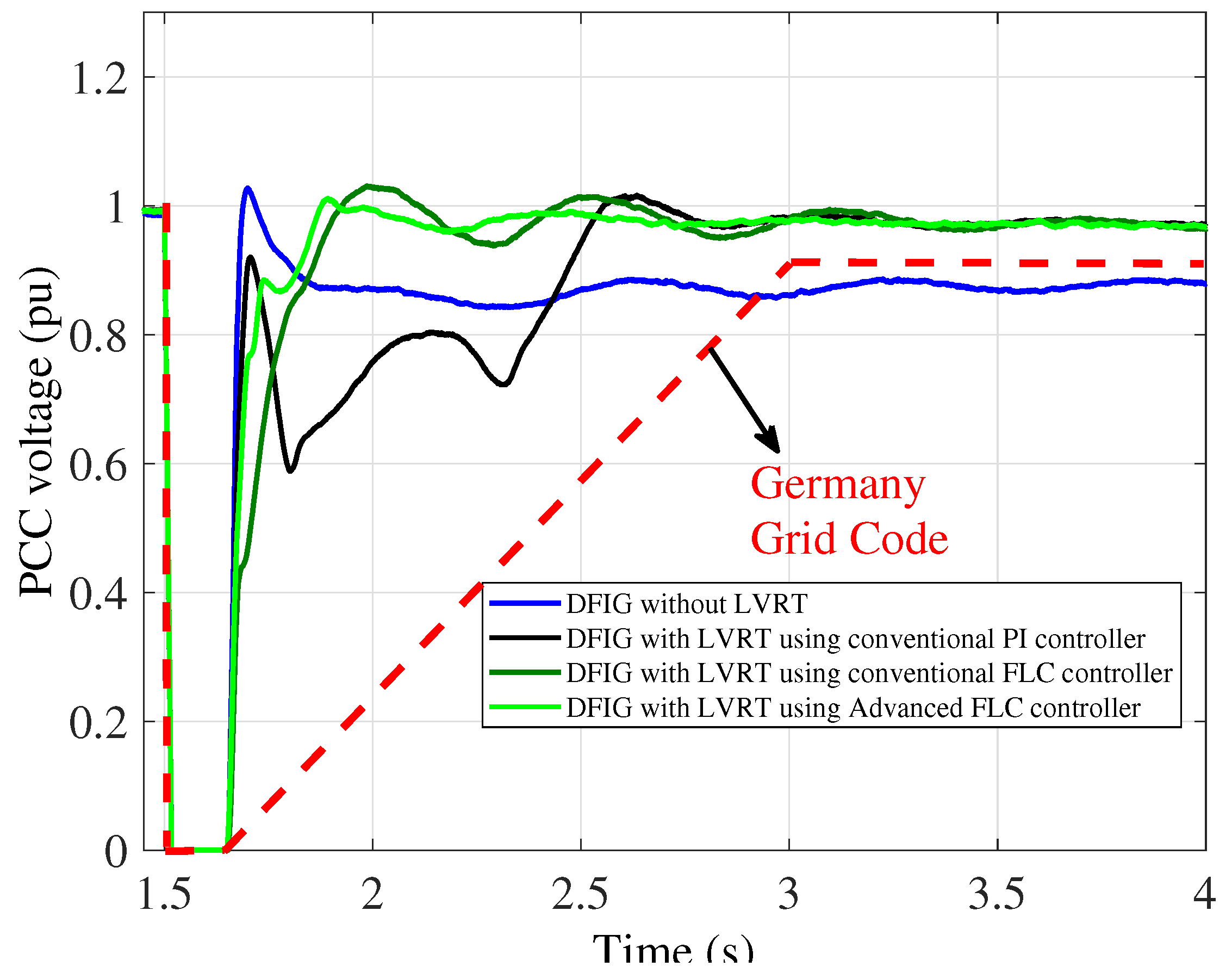

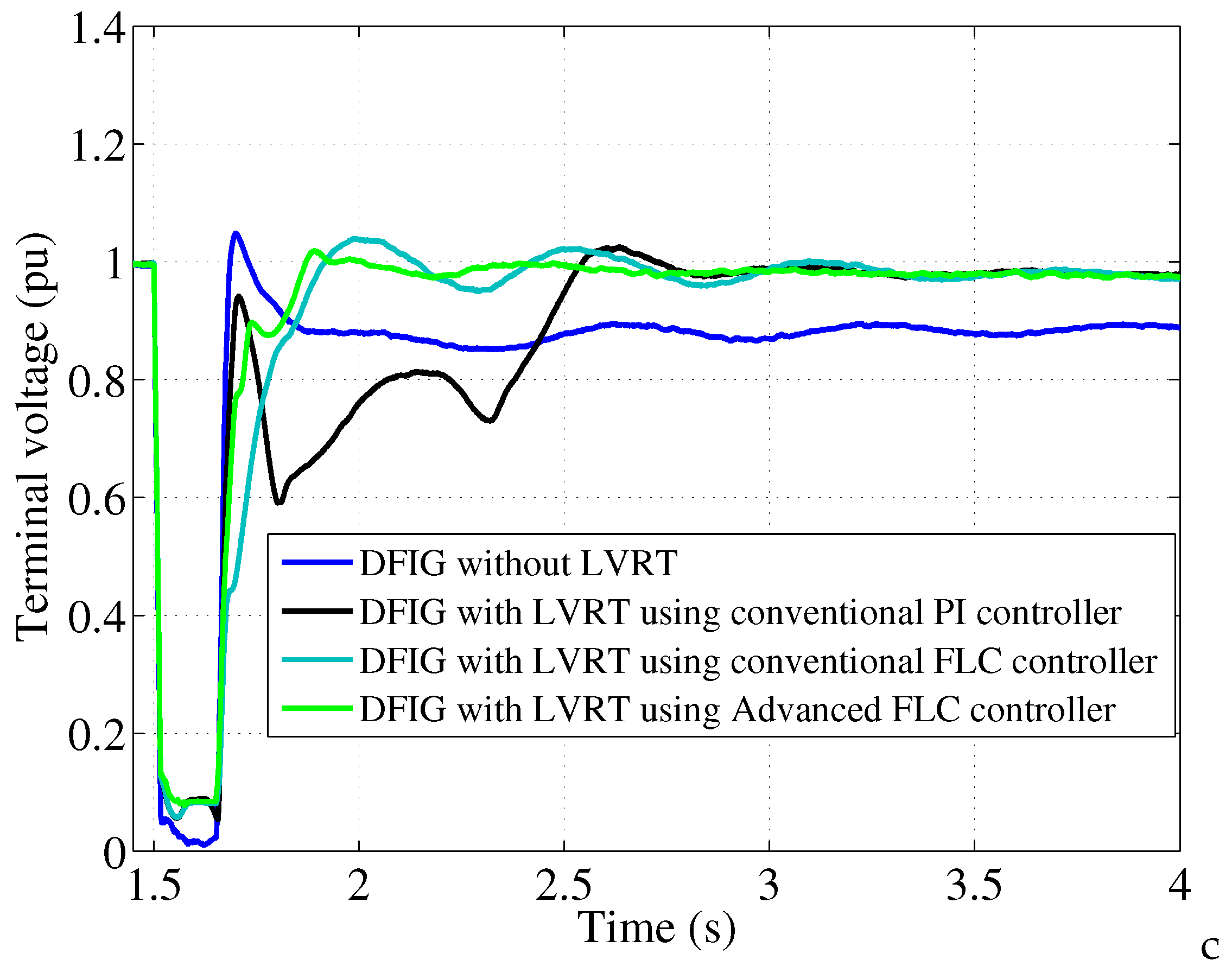

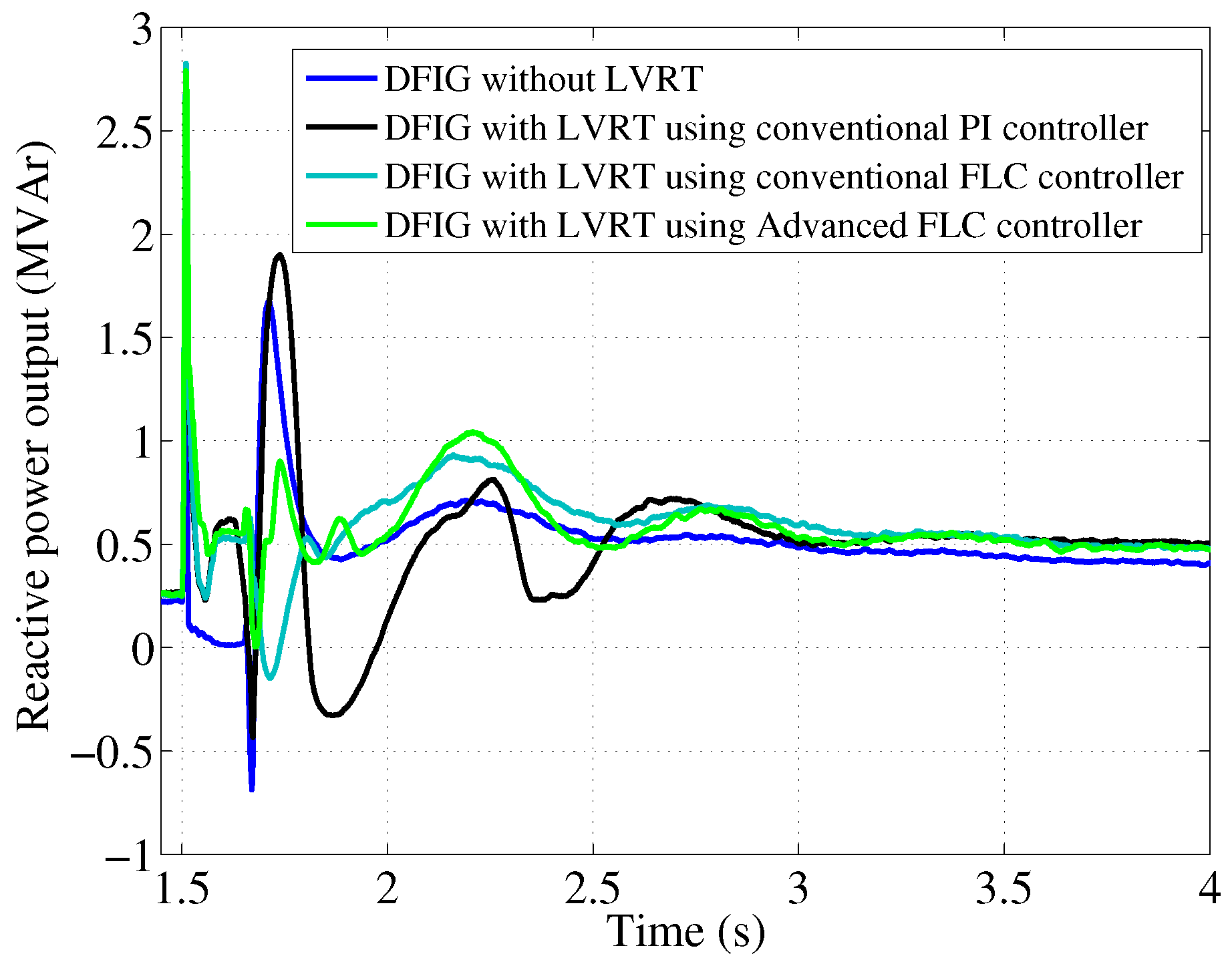

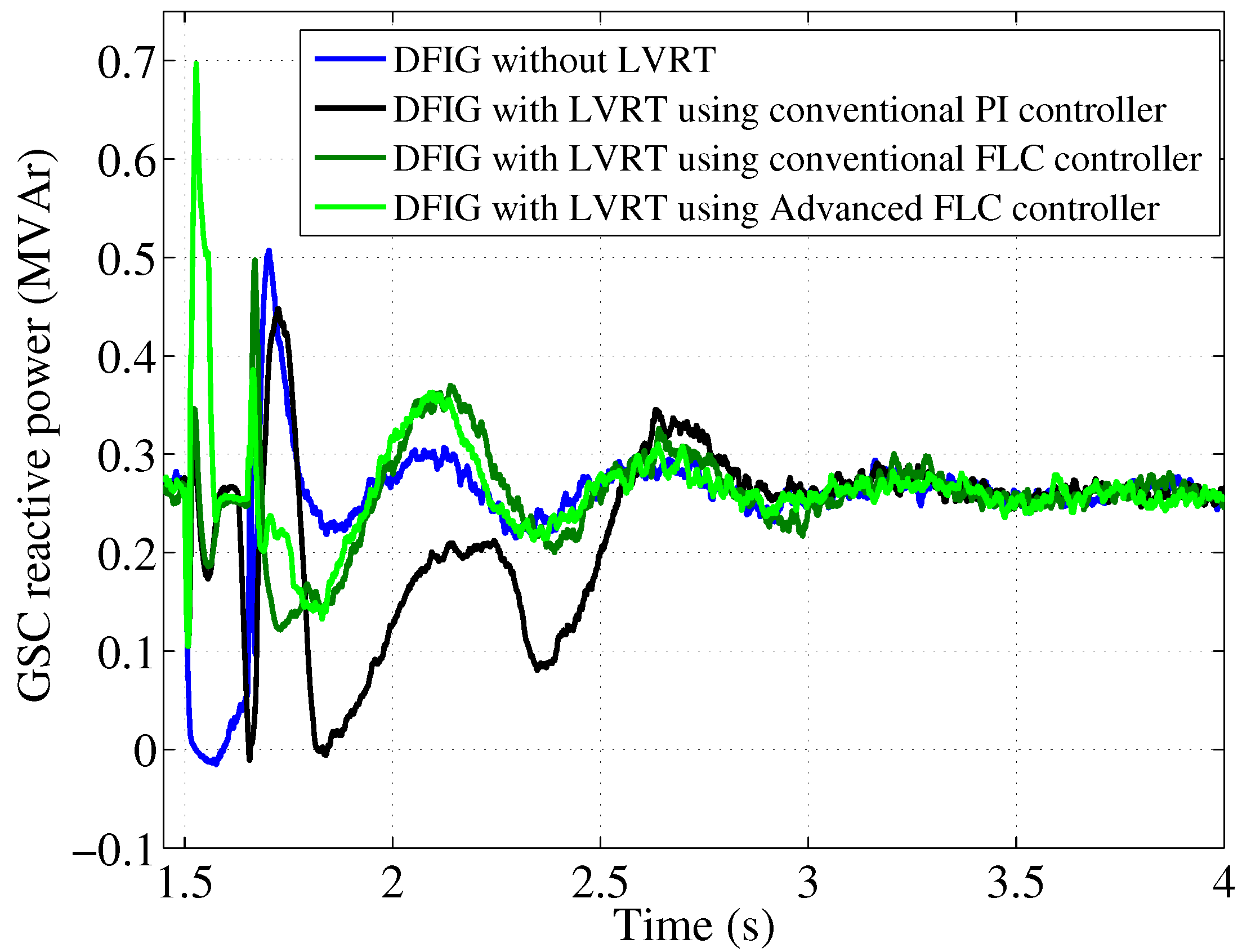

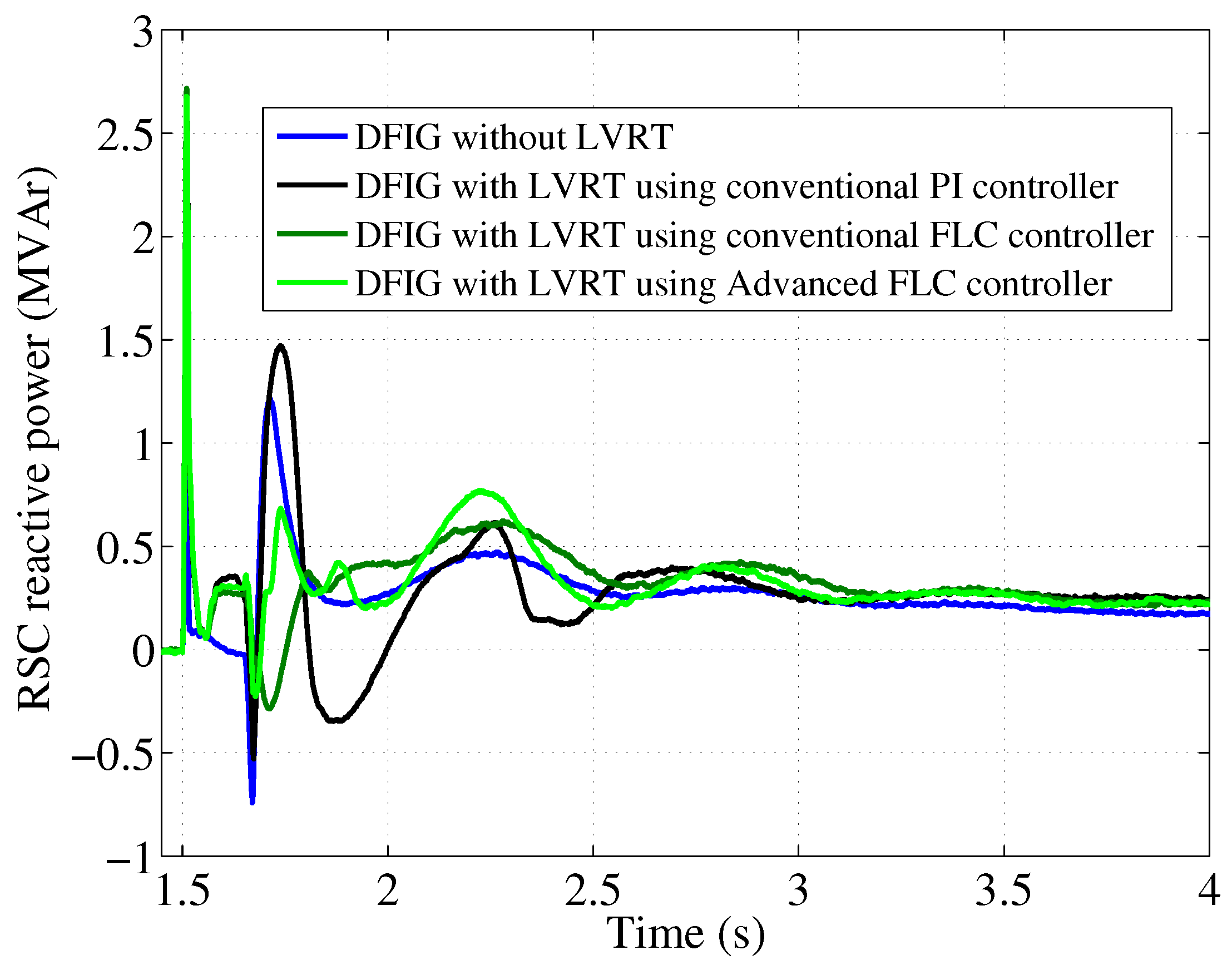

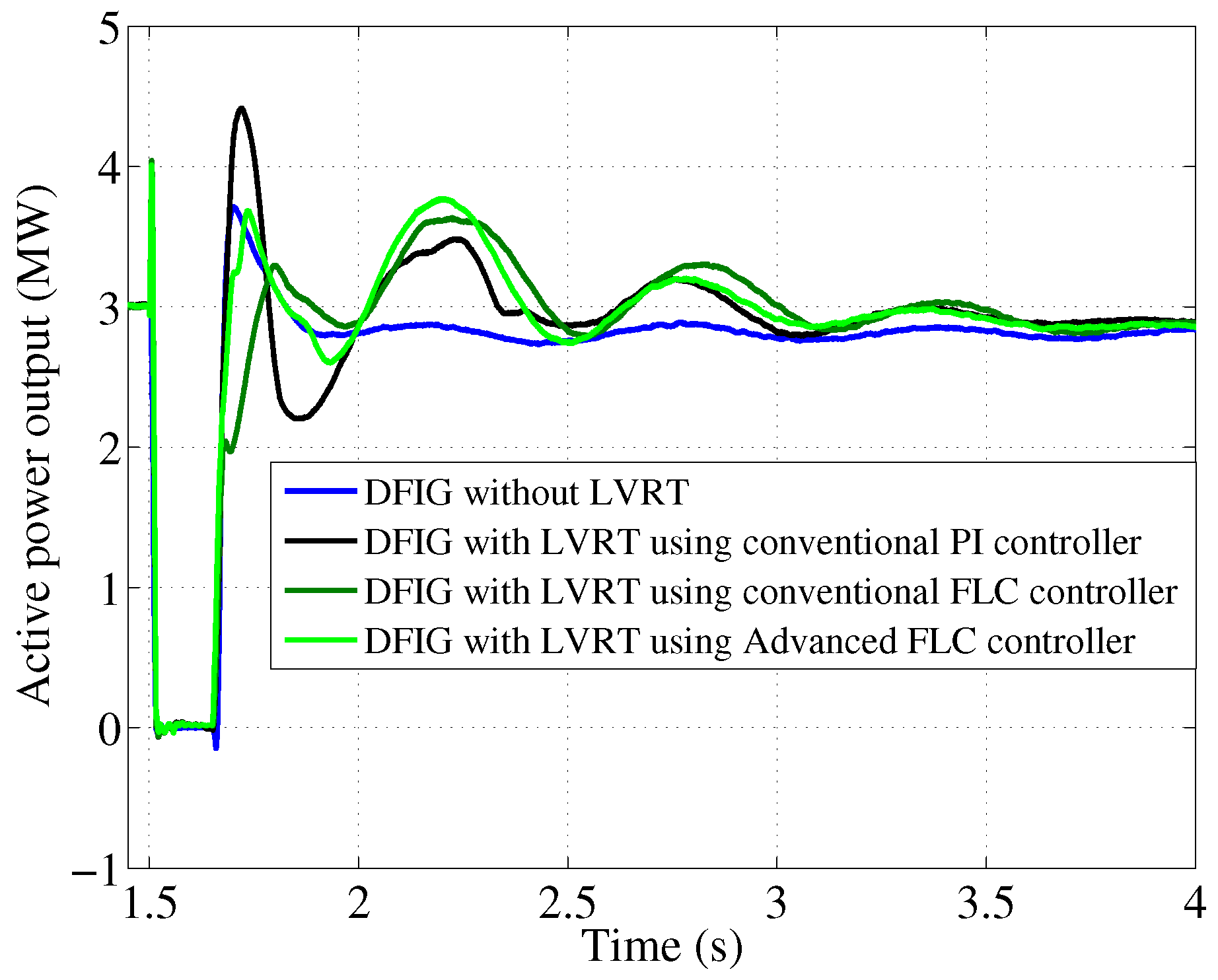

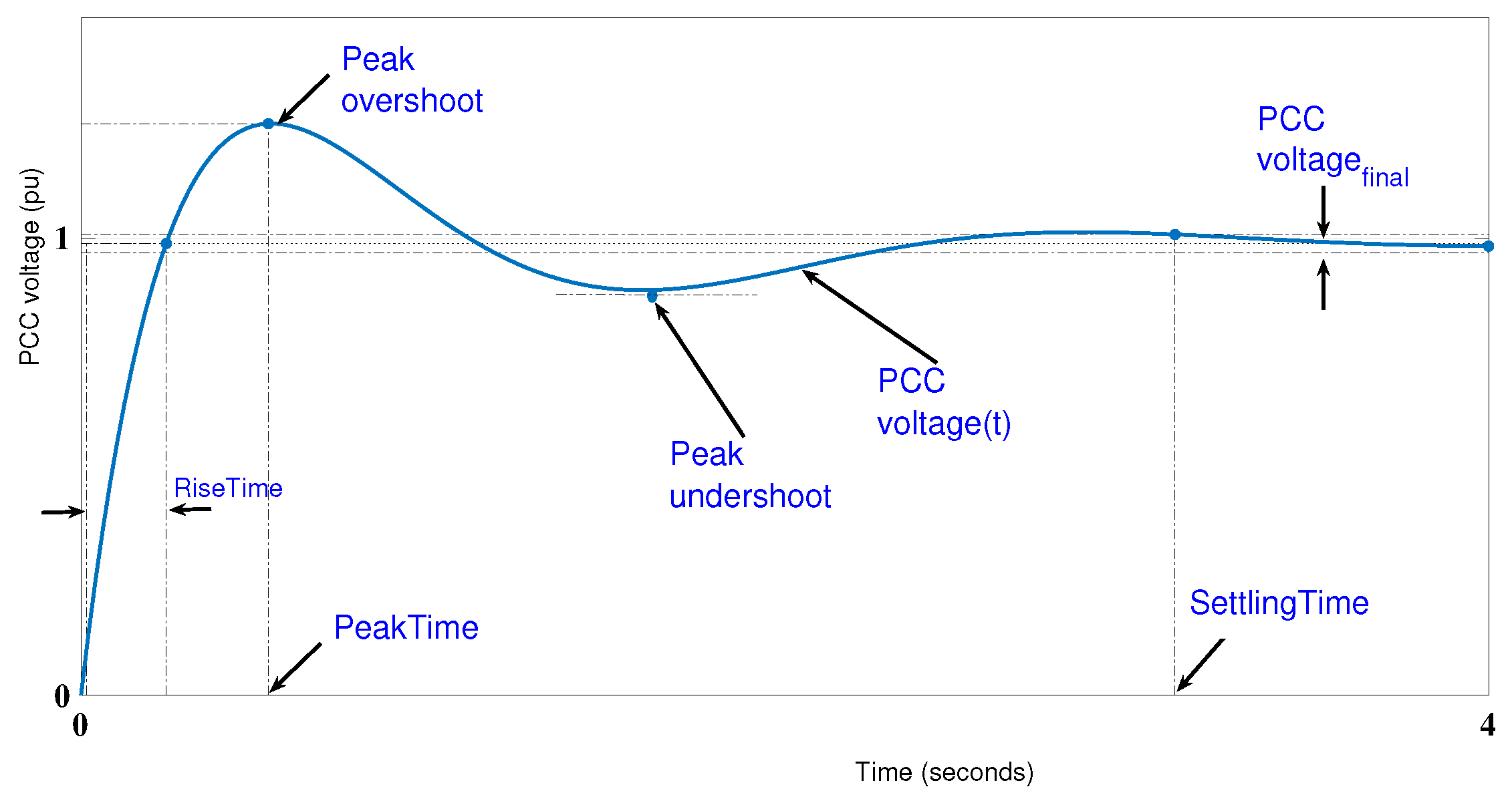

5.2. Performance Assessment of Voltage Grid Support Capability

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Global Wind Energy Council (GWEC). Global Wind Report—Annual Market Update; Global Wind Energy Council (GWEC): Brussels, Belgium, 2014. [Google Scholar]

- Golovanov, N.; Lazaroiu, G.; Roscia, M.; Zaninelli, D. Power Quality analysis in Renewable Energy Systems Supplying Distribution Grids. Measurements 2013, 7, 6–95. [Google Scholar] [CrossRef]

- Grimaccia, F.; Mussetta, M.; Zich, R. Neuro-fuzzy predictive model for PV energy production based on weather forecast. In Proceedings of the 2011 IEEE International Conference on Fuzzy Systems (FUZZ), Taipei, Taiwan, 27–30 June 2011; pp. 2454–2457. [Google Scholar]

- Shen, C.; Kaufmann, P.; Braun, M. Optimizing the generator start-up sequence after a power system blackout. In Proceedings of the 2014 IEEE PES General Meeting|Conference & Exposition, National Harbor, MD, USA, 27–31 July 2014; pp. 1–5. [Google Scholar]

- Duong, M.Q.; Ogliari, E.; Grimaccia, F.; Leva, S.; Mussetta, M. Hybrid model for hourly forecast of photovoltaic and wind power. In Proceedings of the 2013 IEEE International Conference on Fuzzy Systems (FUZZ), Hyderabad, India, 7–10 July 2013; pp. 1–6. [Google Scholar]

- Caputo, D.; Grimaccia, F.; Mussetta, M.; Zich, R. Photovoltaic plants predictive model by means of ANN trained by a hybrid evolutionary algorithm. In Proceedings of the 2010 International Joint Conference on Neural Networks (IJCNN), Barcelona, Spain, 18–23 July 2010; pp. 1–6. [Google Scholar]

- Duong, M.Q.; Grimaccia, F.; Leva, S.; Mussetta, M.; Ogliari, E. Pitch Angle Control Using Hybrid Controller for all Operating Regions of SCIG Wind Turbine System. Renew. Energy 2014, 70, 197–203. [Google Scholar] [CrossRef]

- Jafari, S.H.; Raoofat, M.; Samet, H. Improving transient stability of double fed induction generator using fuzzy controller. Int. Trans. Electr. Energy Syst. 2014, 24, 1065–1075. [Google Scholar] [CrossRef]

- Jazaeri, M.; Samadi, A.A. Self-tuning fuzzy PI-based controller of DFIG wind turbine for transient conditions enhancement. Int. Trans. Electr. Energy Syst. 2014, 25, 2657–2673. [Google Scholar] [CrossRef]

- Tsili, M.; Papathanassiou, S. A review of grid code technical requirements for wind farms. IET Renew. Power Gener. 2009, 3, 308–332. [Google Scholar] [CrossRef]

- Duong, M.Q.; Le, K.H.; Grimaccia, F.; Leva, S.; Mussetta, M.; Zich, R. Comparison of power quality in different grid-integrated wind turbines. In Proceedings of the 2014 16th International Conference on Harmonics and Quality of Power (ICHQP), Bucharest, Romania, 25–28 May 2014; pp. 448–452. [Google Scholar]

- Muller, S.; Deicke, M.; De Doncker, R.W. Doubly fed induction generator systems for wind turbines. IEEE Ind. Appl. Mag. 2002, 8, 26–33. [Google Scholar] [CrossRef]

- Cárdenas, R.; Peña, R.; Alepuz, S.; Asher, G. Overview of control systems for the operation of DFIGs in wind energy applications. IEEE Trans. Ind. Electron. 2013, 7, 2776–2798. [Google Scholar] [CrossRef]

- Sava, G.N.; Costinas, S.; Golovanov, N.; Leva, S.; Duong, M.Q. Comparison of active crowbar protection schemes for DFIGs wind turbines. In Proceedings of the 2014 16th International Conference on Harmonics and Quality of Power (ICHQP), Bucharest, Romania, 25–28 May 2014; pp. 669–673. [Google Scholar]

- Kasem, A.H.; El-Saadany, E.F.; El-Tamaly, H.; Wahab, M. An improved fault ride-through strategy for doubly fed induction generator-based wind turbines. IET Renew. Power Gener. 2008, 2, 201–214. [Google Scholar] [CrossRef]

- López, J.; Gubía, E.; Olea, E.; Ruiz, J.; Marroyo, L. Ride through of wind turbines with doubly fed induction generator under symmetrical voltage dips. IEEE Trans. Ind. Electron. 2009, 56, 4246–4254. [Google Scholar] [CrossRef]

- Kayikçi, M.; Milanović, J. Assessing transient response of DFIG-based wind plants—The influence of model simplifications and parameters. IEEE Trans. Power Syst. 2008, 23, 545–554. [Google Scholar] [CrossRef]

- Yang, J.; Fletcher, J.E.; O’Reilly, J. A series-dynamic-resistor-based converter protection scheme for doubly-fed induction generator during various fault conditions. IEEE Trans. Energy Convers. 2010, 25, 422–432. [Google Scholar] [CrossRef]

- Hansen, A.D.; Michalke, G. Fault ride-through capability of DFIG wind turbines. Renew. Energy 2007, 32, 1594–1610. [Google Scholar] [CrossRef]

- Hansen, A.D.; Michalke, G. Voltage grid support of DFIG wind turbines during grid faults. In Proceedings of the 2007 European Wind Energy Conference and Exhibition, Milan, Italy, 7–10 May 2007; pp. 93–97. [Google Scholar]

- Slootweg, J.; Kling, W. The impact of large scale wind power generation on power system oscillations. Electr. Power Syst. Res. 2003, 67, 9–20. [Google Scholar] [CrossRef]

- Gautam, D.; Vittal, V.; Harbour, T. Impact of increased penetration of DFIG-based wind turbine generators on transient and small signal stability of power systems. IEEE Trans. Power Syst. 2009, 24, 1426–1434. [Google Scholar] [CrossRef]

- Xiang, D.; Ran, L.; Tavner, P.J.; Yang, S. Control of a doubly fed induction generator in a wind turbine during grid fault ride-through. IEEE Trans. Energy Convers. 2006, 21, 652–662. [Google Scholar] [CrossRef]

- Abad, G.; Rodriguez, M.; Poza, J.; Canales, J. Direct torque control for doubly fed induction machine-based wind turbines under voltage dips and without crowbar protection. IEEE Trans. Energy Convers. 2010, 25, 586–588. [Google Scholar] [CrossRef]

- Yu, L.; Chen, G.C.; Cao, D.P.; Wu, G.X. Low voltage ride-through control of doubly fed induction generator during symmetric voltage sag. Electr. Mach. Control 2010, 14, 1–6. [Google Scholar]

- Pena, R.; Clare, J.; Asher, G. Doubly fed induction generator using back-to-back PWM converters and its application to variable-speed wind-energy generation. IEE Proc. Electr. Power Appl. 1996, 143, 231–241. [Google Scholar] [CrossRef]

- Duong, M.Q.; Grimaccia, F.; Leva, S.; Mussetta, M.; Sava, G.; Costinas, S. Performance analysis of grid-connected wind turbines. UPB Sci. Bull. C Electr. Eng. 2014, 76, 169–180. [Google Scholar]

- Duong, M.Q.; Grimaccia, F.; Leva, S.; Mussetta, M.; Le, K.H. A hybrid Fuzzy-PI cascade controller for transient stability improvement in DFIG wind generators. In Proceedings of the 2016 IEEE International Conference on Fuzzy Systems (FUZZ-IEEE), Vancouver, BC, Canada, 24–29 July 2016; pp. 1733–1739. [Google Scholar]

- Van, T.; Nguyen, T.; Lee, D. Advanced Pitch Angle Control Based on Fuzzy Logic for Variable-Speed Wind Turbine Systems. IEEE Trans. Energy Convers. 2015, PP, 1–10. [Google Scholar] [CrossRef]

- Boverie, S.; Demaya, B.; Ketata, R.; Titli, A. Performance evaluation of fuzzy controllers. IFAC Proc. Vol. 1992, 25, 69–74. [Google Scholar] [CrossRef]

- Godjevac, J. Comparison between PID and Fuzzy Control; Internal Report 93; Ecole Polytechnique Federale de Lausanne, Departement d’Informatique, Laboratoire de Microinformatique: Lausanne, Switzerland, 1993. [Google Scholar]

- Fortmann, J.; Pfeiffer, R.; Haesen, E.; van Hulle, F.; Martin, F.; Urdal, H.; Wachtel, S. Fault-ride-through requirements for wind power plants in the ENTSO-E network code on requirements for generators. IET Renew. Power Gener. 2014, 9, 18–24. [Google Scholar] [CrossRef]

- Netz, E. Grid Code High and Extra High Voltage; E. ON Netz GmbH: Bayreuth, Germany, 2006. [Google Scholar]

- ENTSO-E AISBL. ENTSO-E Network Code for Requirements for Grid Connection Applicable to All Generators; ENTSO-E AISBL: Brussels, Belgium, 2012. [Google Scholar]

- Schlabbach, J. Low voltage fault ride through criteria for grid connection of wind turbine generators. In Proceedings of the 2008 5th International Conference on European Electricity Market (EEM), Lisboa, Portugal, 28–30 May 2008; pp. 1–4. [Google Scholar]

- Peña, R.; Cárdenas, R.; Reyes, E.; Clare, J.; Wheeler, P. Control of a doubly fed induction generator via an indirect matrix converter with changing DC voltage. IEEE Trans. Ind. Electron. 2011, 58, 4664–4674. [Google Scholar] [CrossRef]

- Lopez, J.; Sanchis, P.; Roboam, X.; Marroyo, L. Dynamic behavior of the doubly fed induction generator during three-phase voltage dips. IEEE Trans. Energy Convers. 2007, 22, 709. [Google Scholar] [CrossRef]

- Abdel-Baqi, O.; Nasiri, A. Series voltage compensation for DFIG wind turbine low-voltage ride-through solution. IEEE Trans. Energy Convers. 2011, 26, 272–280. [Google Scholar] [CrossRef]

- Duong, M.Q.; Nguyen, H.H.; Le, K.H.; Phan, T.V.; Mussetta, M. Simulation and performance analysis of a new LVRT and damping control scheme for DFIG wind turbines. In Proceedings of the 2016 IEEE International Conference on Sustainable Energy Technologies (ICSET), Hanoi, Vietnam, 14–16 November 2016; pp. 288–293. [Google Scholar]

- Abad, G.; Lopez, J.; Rodríguez, M.; Marroyo, L.; Iwanski, G. Doubly Fed Induction Machine: Modeling and Control for Wind Energy Generation; John Wiley & Sons: New York, NY, USA, 2011; Volume 86. [Google Scholar]

- Peng, L.; Francois, B.; Li, Y. Improved crowbar control strategy of DFIG based wind turbines for grid fault ride-through. In Proceedings of the Twenty-Fourth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Washington, DC, USA, 15–19 February 2009; pp. 1932–1938. [Google Scholar]

- Qiao, W.; Harley, R.G.; Venayagamoorthy, G.K. Coordinated reactive power control of a large wind farm and a STATCOM using heuristic dynamic programming. IEEE Trans. Energy Convers. 2009, 24, 493–503. [Google Scholar] [CrossRef]

- Duong, M.Q.; Grimaccia, F.; Leva, S.; Mussetta, M.; Zich, R. Improving LVRT characteristics in variable-speed wind power generation by means of fuzzy logic. In Proceedings of the 2014 IEEE International Conference on Fuzzy Systems (FUZZ-IEEE), Beijing, China, 6–11 July 2014; pp. 332–337. [Google Scholar]

- Duong, M.Q.; Grimaccia, F.; Leva, S.; Mussetta, M.; Le, K.H. Improving Transient Stability in a Grid-Connected Squirrel-Cage Induction Generator Wind Turbine System Using a Fuzzy Logic Controller. Energies 2015, 8, 6328. [Google Scholar] [CrossRef] [Green Version]

- Abe, S. Fuzzy function approximators with ellipsoidal regions. IEEE Trans. Syst. Man Cybern. B Cybern. 1999, 29, 654–661. [Google Scholar] [CrossRef] [PubMed]

| du | Error | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| dt | NL | NM | NS | N | ZO | P | PS | PM | PL |

| N | N | NM | NS | N | N | ZO | P | PS | PM |

| ZO | NL | NM | NS | N | ZO | P | PS | PM | PL |

| P | NM | NS | N | ZO | P | P | PS | PM | PL |

| Parameters | Value | Unit |

|---|---|---|

| DFIG: | ||

| Rated power | 3 | MW |

| Rated speed | 12 | m/s |

| Cut in wind speed | 5 | m/s |

| Cut out wind speed | 19 | m/s |

| Rated Voltage | 690 | V |

| Frequency | 50 | Hz |

| 0.016 | pu | |

| 0.00549 | pu | |

| 0.18 | pu | |

| 0.16 | pu | |

| 2.9 | pu | |

| Grid power source: | ||

| Rated capacity | 12/110 | MVA/kV |

| Short-circuit ratio | 1 |

| Controller | ||||

|---|---|---|---|---|

| Advanced FLC: | 1 | 2 | 0.8 | 0.2 |

| FLC: | 3 | 5 | 1.5 | 0.3 |

| PI: | 3 | 40 | 1.5 | 1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duong, M.Q.; Leva, S.; Mussetta, M.; Le, K.H. A Comparative Study on Controllers for Improving Transient Stability of DFIG Wind Turbines During Large Disturbances. Energies 2018, 11, 480. https://doi.org/10.3390/en11030480

Duong MQ, Leva S, Mussetta M, Le KH. A Comparative Study on Controllers for Improving Transient Stability of DFIG Wind Turbines During Large Disturbances. Energies. 2018; 11(3):480. https://doi.org/10.3390/en11030480

Chicago/Turabian StyleDuong, Minh Quan, Sonia Leva, Marco Mussetta, and Kim Hung Le. 2018. "A Comparative Study on Controllers for Improving Transient Stability of DFIG Wind Turbines During Large Disturbances" Energies 11, no. 3: 480. https://doi.org/10.3390/en11030480