Identification and Quantification of Volatile Compounds Found in Vinasses from Two Different Processes of Tequila Production

Abstract

:1. Introduction

2. Results

2.1. Identification and Concentration of Volatile Compounds

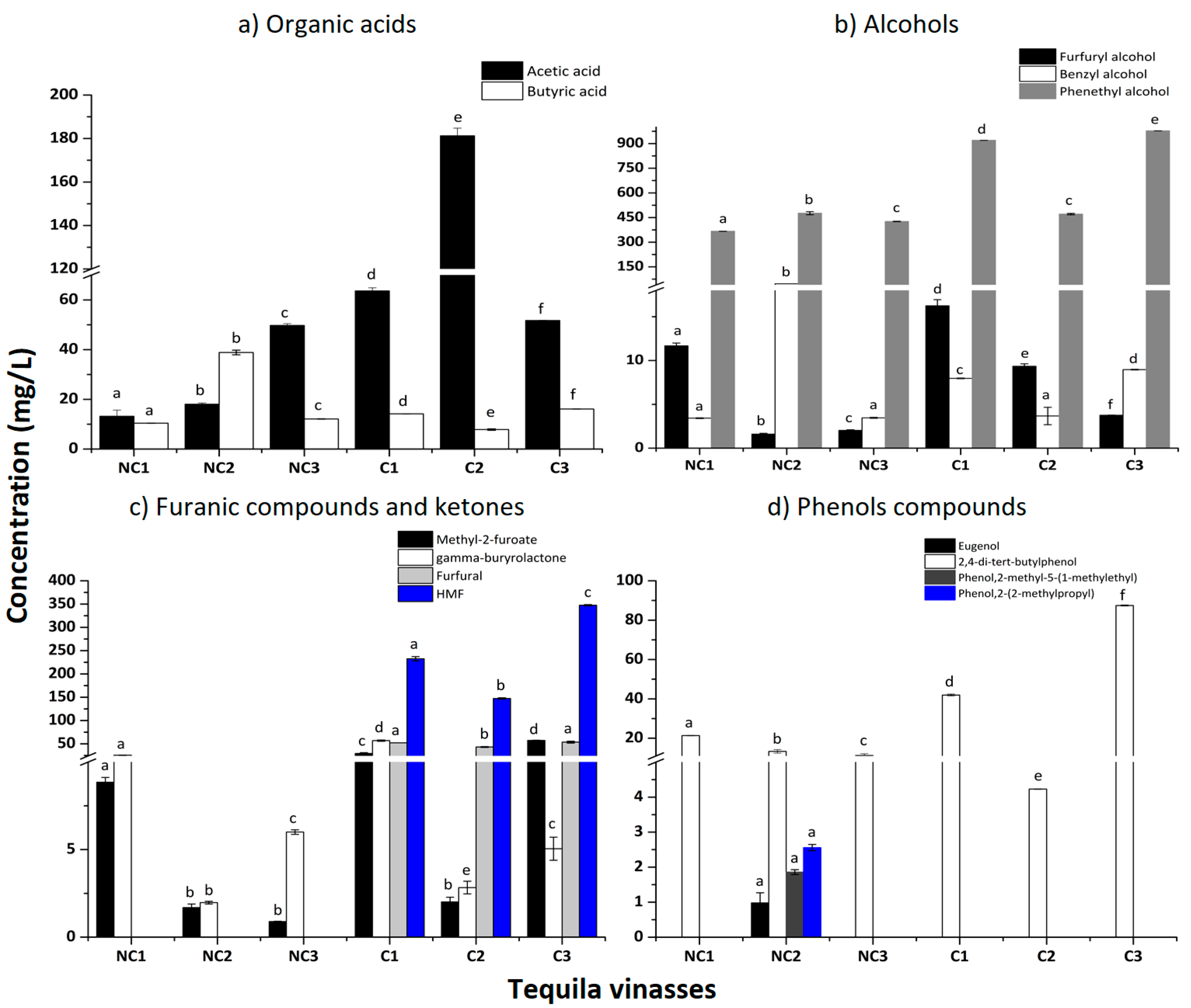

2.1.1. Organic Acids

2.1.2. Esters

2.1.3. Alcohols

2.1.4. Aldehydes

2.1.5. Alkanes

2.1.6. Furanic Compounds

2.1.7. Ketones

2.1.8. Phenols

2.1.9. Pyrans

2.2. Principal Component Analysis (PCA)

3. Discussion

3.1. Organic Acids

3.2. Esters

3.3. Alcohols

3.4. Aldehydes

3.5. Alkanes

3.6. Furanic Compounds

3.7. Ketones

3.8. Phenol Compounds

3.9. Pyrans

3.10. Relationship between PCA and Not-Cooking (NC) and Cooking (C) Processes

4. Materials and Methods

4.1. Chemicals and Standards Used

4.2. Samples

4.3. Volatile Compound Extractions

4.4. Separation and Identification of Volatile Compounds

4.5. Statistical Analysis

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Morin Couallier, E.; Salgado Ruiz, B.; Lameloise, M.-L.; Decloux, M. Usefulness of reverse osmosis in the treatment of condensates arising from the concentration of distillery vinasses. Desalination 2006, 196, 306–317. [Google Scholar] [CrossRef]

- Zhang, P.J.; Zhao, Z.G.; Yu, S.J.; Guan, Y.G.; Li, D.; He, X. Using strong acid-cation exchange resin to reduce potassium level in molasses vinasses. Desalination 2012, 286, 210–216. [Google Scholar] [CrossRef]

- Alves, P.R.L.; Natal-da-Luz, T.; Sousa, J.P.; Cardoso, E.J.B.N. Ecotoxicological characterization of sugarcane vinasses when applied to tropical soils. Sci. Total Environ. 2015, 526, 222–232. [Google Scholar] [CrossRef] [PubMed]

- Moran-Salazar, R.G.; Sanchez-Lizarraga, A.L.; Rodriguez-Campos, J.; Davila-Vazquez, G.; Marino-Marmolejo, E.N.; Dendooven, L.; Contreras-Ramos, S.M. Utilization of vinasses as soil amendment: Consequences and perspectives. SpringerPlus 2016, 5, 1007. [Google Scholar] [CrossRef] [PubMed]

- Díaz, B.; Gomes, A.; Freitas, M.; Fernandes, E.; Nogueira, D.R.; González, J.; Moure, A.; Levoso, A.; Vinardell, M.P.; Mitjans, M.; et al. Valuable Polyphenolic Antioxidants from Wine Vinasses. Food Bioprocess Technol. 2012, 5, 2708–2716. [Google Scholar] [CrossRef]

- Cedeño, M.C. Tequila Production. Crit. Rev. Biotechnol. 1995, 15, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Méndez-Acosta, H.O.; Snell-Castro, R.; Alcaraz-González, V.; González-Álvarez, V.; Pelayo-Ortiz, C. Anaerobic treatment of Tequila vinasses in a CSTR-type digester. Biodegradation 2010, 21, 357–363. [Google Scholar] [CrossRef] [PubMed]

- Robles-González, V.; Galíndez-Mayer, J.; Rinderknecht-Seijas, N.; Poggi-Varaldo, H.M. Treatment of mezcal vinasses: A review. J. Biotechnol. 2012, 157, 524–546. [Google Scholar] [CrossRef] [PubMed]

- Rajagopal, V.; Paramjit, S.M.; Suresh, K.P.; Yogeswar, S.; Nageshwar, R.D.V.K.; Avinash, N. Significance of vinasses waste management in agriculture and environmental quality-Review. Afr. J. Agric. Res. 2014, 9, 2862–2873. [Google Scholar] [CrossRef]

- López-López, A.; Davila-Vazquez, G.; León-Becerril, E.; Villegas-García, E.; Gallardo-Valdez, J. Tequila vinasses: Generation and full scale treatment processes. Rev. Environ. Sci. Bio/Technol. 2010, 9, 109–116. [Google Scholar] [CrossRef]

- Decloux, M.; Bories, A.; Lewandowski, R.; Fargues, C.; Mersad, A.; Lameloise, M.L.; Bonnet, F.; Dherbecourt, B.; Osuna, L.N. Interest of electrodialysis to reduce potassium level in vinasses. Preliminary experiments. Desalination 2002, 146, 393–398. [Google Scholar] [CrossRef]

- España-Gamboa, E.; Mijangos-Cortes, J.; Barahona-Perez, L.; Dominguez-Maldonado, J.; Hernández-Zarate, G.; Alzate-Gaviria, L. Vinasses: Characterization and treatments. Waste Manag. Res. 2011, 29, 1235–1250. [Google Scholar] [CrossRef] [PubMed]

- Cruz-Salomón, A.; Meza-Gordillo, R.; Rosales-Quintero, A.; Ventura-Canseco, C.; Lagunas-Rivera, S.; Carrasco-Cervantes, J. Biogas production from a native beverage vinasse using a modified UASB bioreactor. Fuel 2016, 198, 170–174. [Google Scholar] [CrossRef]

- Da Silva, M.A.; Griebeler, N.P.; Borges, L.C. Uso de vinhaça e impactos nas propriedades do solo e lençol freático (Use of stillage and its impact on soil properties and groundwater). Rev. Bras. Eng. Agríc. Ambient 2007, 11, 108–114. [Google Scholar] [CrossRef]

- Espinoza-Escalante, F.M.; Pelayo-Ortíz, C.; Navarro-Corona, J.; González-García, Y.; Bories, A.; Gutiérrez-Pulido, H. Anaerobic digestion of the vinasses from the fermentation of Agave tequilana Weber to tequila: The effect of pH, temperature and hydraulic retention time on the production of hydrogen and methane. Biomass Bioenergy 2009, 33, 14–20. [Google Scholar] [CrossRef]

- Waleckx, E.; Gschaedler, A.; Colonna-Ceccaldi, B.; Monsan, P. Hydrolysis of fructans from Agave tequilana Weber var. azul during the cooking step in a traditional tequila elaboration process. Food Chem. 2008, 108, 40–48. [Google Scholar] [CrossRef]

- Valenzuela, A.G. The Tequila Industry in Jalisco, Mexico; University of Arizona: Tucson, AZ, USA, 2016. [Google Scholar]

- Martínez, M.D.C.; Pérez, E.L. Análisis del Mercado Potencial del Tequila 100% Agave. PhD. Thesis, Instituto Politécnico Nacional, Mexico City, Mexico, 2008. [Google Scholar]

- Vazquez-Landaverde, P.A.; Rodriguez-Olvera, M.G. Tequila processing and flavor. Am. Chem. Soc. 2012, 1104, 237–276. [Google Scholar] [CrossRef]

- Salgado, O. Perspectivas Económicas de la Producción de Tequila vs. Tequila 100% Agave; Universidad Autónoma de Querétaro: Queretaro, Mexico, 2012. [Google Scholar]

- Cedeño Cruz, M.; Alvarez Jacobs, J. Production of tequila from agave: Historical influences and contemporary processes. In The Alcohol Textbook: A Reference for the Beverage, Fuel and Industrial Alcohol Industries; Nottingham University Press; Alltech Inc.: Nottingham, UK, 1999; pp. 225–241. [Google Scholar]

- Villanueva-Rodríguez, S.; Rodríguez-Garay, B.; Prado-Ramírez, R.; Gschaedler, A. Tequila: Tequila Raw Material, Classification, Process, and Quality Parameters. In Encyclopedia of Food and Health (FOHE); Academic Press: Waltham, MA, USA, 2015; pp. 1–7. [Google Scholar]

- Villanueva-Rodriguez, S.; Escalona-Buendia, H. Tequila and mezcal: Sensory Attributes and Sensory Evaluation; Woodhead Publishing Limited: Cambridge, UK, 2011; ISBN 9780857090515. [Google Scholar]

- Buitrón, G.; Carvajal, C. Biohydrogen production from Tequila vinasses in an anaerobic sequencing batch reactor: Effect of initial substrate concentration, temperature and hydraulic retention time. Bioresour. Technol. 2010, 101, 9071–9077. [Google Scholar] [CrossRef] [PubMed]

- González, C.; Durán, J.E. Producción de hidrógeno a partir del tratamiento anaerobio de vinazas en un reactor UASB. Tecnol. Marcha 2014, 27, 3–12. [Google Scholar] [CrossRef]

- Buitrón, G.; Prato-Garcia, D.; Zhang, A. Biohydrogen production from tequila vinasses using a fixed bed reactor. Water Sci. Technol. 2014, 70, 1919–1925. [Google Scholar] [CrossRef] [PubMed]

- Fagier, M.A.; Elmugdad, A.A.; Aziz, M.E.A.; Gabra, N.M. Identification of some Organic Compounds in Sugarcane vinasse by Gas Chromatography-Mass Spectrometry and Prediction of their Toxicity Using TEST Method. J. Chem. Pharm. Sci. 2015, 8, 899–905. [Google Scholar]

- Lima, A.V.A.; Barbosa, M.A.S.; Cunha, L.C.S.; De Morais, S.A.L.; De Aquino, F.J.T.; Chang, R.; Do Nascimento, E.A. Volatile compounds obtained by the hydrodistillation of sugarcane vinasse, a residue from ethanol production. Rev. Virtual Quim. 2017, 9, 764–773. [Google Scholar] [CrossRef]

- Mancilla-Margalli, N.A.; López, M.G. Generation of Maillard compounds from inulin during the thermal processing of Agave tequilana Weber var. azul. J. Agric. Food Chem. 2002, 50, 806–812. [Google Scholar] [CrossRef] [PubMed]

- Prado-Jaramillo, N.; Estarrón-Espinosa, M.; Escalona-Buendía, H.; Cosío-Ramírez, R.; Martín-del-Campo, S.T. Volatile compounds generation during different stages of the tequila production process: A preliminary study. LWT-Food Sci. Technol. 2015, 61, 471–483. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, J.J.; Creamer, K.S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. [Google Scholar] [CrossRef] [PubMed]

- Quéménur, M.; Hamelin, J.; Barakat, A.; Steyer, J.; Carrere, H.; Trably, E. Inhibition of fermentative hydrogen production by lignocellulose-derived compounds in mixed cultures. Int. J. Hydrogen Energy 2012, 7, 3150–3159. [Google Scholar] [CrossRef]

- De Sá, L.R.V.; De Oliveira Moutta, R.; Da Silva Bon, E.P.; Cammarota, M.C.; Ferreira-Leitão, V.S. Fermentative biohydrogen production using hemicellulose fractions: Analytical validation for C5 and C6-sugars, acids and inhibitors by HPLC. Int. J. Hydrogen Energy 2015, 40, 13888–13900. [Google Scholar] [CrossRef]

- Bundhoo, M.A.Z.; Mohee, R. Inhibition of dark fermentative bio-hydrogen production: A review. Int. J. Hydrogen Energy 2016, 41, 6713–6733. [Google Scholar] [CrossRef]

- Jolliffe, I.T. Principal Component Analysis. J. Technometrics 1988, 30, 487. [Google Scholar] [CrossRef]

- Siqueira, M.R.; Reginatto, V. Inhibition of fermentative H2 production by hydrolysis byproducts oflignocellulosic substrates. Renew. Energy 2015, 80, 109–116. [Google Scholar] [CrossRef]

- Wang, B.; Wan, W.; Wang, J. Inhibitory effect of ethanol, acetic acid, propionic acid and butyric acid on fermentative hydrogen production. Int. J. Hydrog. Energy 2008, 33, 7013–7019. [Google Scholar] [CrossRef]

- Franden, M.A.; Pilath, H.M.; Mohagheghi, A.; Pienkos, P.T.; Zhang, M. Inhibition of growth of Zymomonas mobilis by model compounds found in lignocellulosic hydrolysates. Biotechnol. Biofuels 2013, 6, 99. [Google Scholar] [CrossRef] [PubMed]

- Ciranna, A.; Ferrari, R.; Santala, V.; Karp, M. Inhibitory effects of substrate and soluble end products on biohydrogen production of the alkalithermophile Caloramator celer: Kinetic, metabolic and transcription analyses. Int. J. Hydrogen Energy 2014, 39, 6391–6401. [Google Scholar] [CrossRef]

- Mills, T.Y.; Sandoval, N.R.; Gill, R.T. Cellulosic hydrolysate toxicity and tolerance mechanisms in Escherichia coli. Biotechnol. Biofuels 2009, 2, 26. [Google Scholar] [CrossRef] [PubMed]

- Zaldivar, J.; Martinez, A.; Ingram, L.O. Effect of selected aldehydes on the growth and fermentation of ethanologenic Escherichia coli. Biotechnol. Bioeng. 1999, 65, 24–33. [Google Scholar] [CrossRef]

- Banerjee, N.; Bhatnagar, R.; Viswanathan, L. Inhibition of glycolysis by furfural in Saccharomyces cerevisiae. Eur. J. Appl. Microbiol. Biotechnol. 1981, 11, 226–228. [Google Scholar] [CrossRef]

- Palmqvist, E.; Hahn-Hagerald, B. Fermentation of lignocellulosic hydrolysates. II: Inhibitors and mechanisms of inhibition mechanisms of inhibition. Bioresour. Technol. 2000, 74, 25–33. [Google Scholar] [CrossRef]

- Abha, S.; Singh, C.S. Hydrocarbon Pollution: Effects on Living Organisms, Remediation of Contaminated Environments, and Effects of Heavy Metals Co-Contamination on Bioremediation. In Introduction to Enhanced Oil Recovery (EOR) Processes and Bioremediation of Oil-Contaminated Sites; INTECH: Rijeka, Croatia, 2012; pp. 185–206. [Google Scholar]

- Alrumman, S.A.; Standing, D.B.; Paton, G.I. Effects of hydrocarbon contamination on soil microbial community and enzyme activity. J. King Saud Univ. Sci. 2015, 27, 31–41. [Google Scholar] [CrossRef] [Green Version]

- Hamamura, N.; Ward, D.M.; Inskeep, W.P. Effects of petroleum mixture types on soil bacterial population dynamics associated with the biodegradation of hydrocarbons in soil environments. FEMS Microbiol. Ecol. 2013, 85, 168–178. [Google Scholar] [CrossRef] [PubMed]

- Haroun, B.M.; Nakhla, G.; Hafez, H.; Nasr, F.A. Impact of furfural on biohydrogen production from glucose and xylose in continuous-flow systems. Renew. Energy 2016, 93, 302–311. [Google Scholar] [CrossRef]

- Modig, T.; Lidén, G.; Taherzadeh, M.J. Inhibition effects of furfural on alcohol dehydrogenase, aldehyde dehydrogenase and pyruvate dehydrogenase. Biochem. J. 2002, 363, 769–776. [Google Scholar] [CrossRef] [PubMed]

- Monlau, F.; Sambusiti, C.; Barakat, A.; Quéméneur, M.; Trably, E.; Steyer, J.P.; Carrère, H. Do furanic and phenolic compounds of lignocellulosic and algae biomass hydrolyzate inhibit anaerobic mixed cultures? A comprehensive review. Biotechnol. Adv. 2014, 32, 934–951. [Google Scholar] [CrossRef] [PubMed]

- Lin, R.; Cheng, J.; Ding, L.; Song, W.; Zhou, J.; Cen, K. Inhibitory effects of furan derivatives and phenolic compounds on dark hydrogen fermentation. Bioresour. Technol. 2015, 196, 250–255. [Google Scholar] [CrossRef] [PubMed]

- Tejirian, A.; Xu, F. Inhibition of enzymatic cellulolysis by phenolic compounds. Enzyme Microb. Technol. 2011, 48, 239–247. [Google Scholar] [CrossRef] [PubMed]

- Qin, L.; Li, W.-C.; Liu, L.; Zhu, J.-Q.; Li, X.; Li, B.-Z.; Yuan, Y.-J. Inhibition of lignin-derived phenolic compounds to cellulase. Biotechnol. Biofuels 2016, 9, 70. [Google Scholar] [CrossRef] [PubMed]

- Min, K.; Freeman, C.; Kang, H.; Choi, S.-U.; Min, K.; Freeman, C.; Kang, H.; Choi, S.-U. The Regulation by Phenolic Compounds of Soil Organic Matter Dynamics under a Changing Environment. Biomed Res. Int. 2015, 2015, 825098. [Google Scholar] [CrossRef] [PubMed]

- Wacker, T.L.; Safir, G.R.; Stephens, C.T. Effects of ferulic acid on Glomus fasciculatum and associated effects on phosphorus uptake and growth of asparagus (Asparagus officinalis L.). J. Chem. Ecol. 1990, 16, 901–909. [Google Scholar] [CrossRef] [PubMed]

- Fries, L.L.M.; Pacovsky, R.S.; Safir, G.R.; Siqueira, J.O. Plant growth and arbuscular mycorrhizal fungal colonization affected by exogenously applied phenolic compounds. J. Chem. Ecol. 1997, 23, 1755–1767. [Google Scholar] [CrossRef]

- Lattanzio, V.; Lattanzio, V.M.T.; Cardinali, A.; Amendola, V. Role of phenolics in the resistance mechanisms of plants against fungal pathogens and insects. Phytochem. Adv. Res. 2006, 661, 23–67. [Google Scholar]

- Li, H.H.; Inoue, M.; Nishimura, H. Interactions oftrans-cinnamic acid, its related phenolic allelochemicals, and abscisic acid in seedling growth and seed germination of lettuce. J. Chem. Ecol. 1993, 19, 1775–1787. [Google Scholar] [CrossRef] [PubMed]

- Heipieper, H.J.; Keweloh, H.; Rehm, H.J. Influence of phenols on growth and membrane permeability of free and immobilized Escherichia coli. Appl. Environ. Microbiol. 1991, 57, 1213–1217. [Google Scholar] [PubMed]

- Alves, M.J.; Ferreira, I.C.F.R.; Froufe, H.J.C.; Abreu, R.M.V.; Martins, A.; Pintado, M. Antimicrobial activity of phenolic compounds identified in wild mushrooms, SAR analysis and docking studies. J. Appl. Microbiol. 2013, 115, 346–357. [Google Scholar] [CrossRef] [PubMed]

- Campos, F.M.; Couto, J.A.; Hogg, T.A. Influence of phenolic acid on growth and inactivation of Oenococcus oeni and Lactobacillus hilgardii. J. Appl. Microbiol. 2003, 94, 167–174. [Google Scholar] [CrossRef] [PubMed]

- Priou, S.; Aley, P.; Chujoy, E.; Lemaga, B.; French, E. Control Integrado de la Marchitez Bacteriana de la Papa; Food and Agriculture Orgnization of the United Nations: Rome, Italy, 1999. [Google Scholar]

- Gallego, A.; Giordano, W.; Rosero, E.; Echeverri, F. Effect of furans and a Pyran on Several Quorum Sensing Factors in Ralstonia solanacearum. J. Microb. Biochem. Technol. 2016, 8, 1–5. [Google Scholar] [CrossRef]

- Salazar-Leyva, J.A.; Osuna-Ruiz, I.; Rodríguez-Tirado, V.A.; Zazueta-Patrón, I.E.; Brito-Rojas, H.D. Optimization study of fructans extraction from Agave tequilana Weber azul variety. Food Sci. Technol. 2016, 36, 631–637. [Google Scholar] [CrossRef]

- Rong, C.; Ding, X.; Zhu, Y.; Li, Y.; Wang, L.; Qu, Y.; Ma, X.; Wang, Z. Production of furfural from xylose at atmospheric pressure by dilute sulfuric acid and inorganic salts. Carbohydr. Res. 2012, 350, 77–80. [Google Scholar] [CrossRef] [PubMed]

- Gomes, F.N.D.C.; Pereira, L.R.; Ribeiro, N.F.P.; Souza, M.M.V.M. Production of 5-hydroxymethylfurfural (HMF) via fructose dehydration: Effect of solvent and salting-out. Braz. J. Chem. Eng. 2015, 32, 119–126. [Google Scholar] [CrossRef]

- Iñiguez-Covarrubias, G.; Díaz-Teres, R.; Sanjuan-Dueñas, R.; Anzaldo-Hernández, J.; Rowell, R. Utilization of by-products from the tequila industry. Part 2: Potential value of Agave tequilana Weber azul leaves. Bioresour. Technol. 2001, 77, 101–108. [Google Scholar] [CrossRef]

- Jönsson, L.J.; Martín, C. Pretreatment of lignocellulose: Formation of inhibitory by-products and strategies for minimizing their effects. Bioresour. Technol. 2016, 199, 103–112. [Google Scholar] [CrossRef] [PubMed]

- Verardi, A.; De Bari, I.; Ricca, E.; Calabrò, V. Hydrolysis of Lignocellulosic Biomass: Current Status of Processes and Technologies and Future Perspectives. In Bioethanol; INTECH: Rijeka, Croatia, 2012; p. 290. [Google Scholar]

- Rodriguez-Campos, J.; Escalona-Buendía, H.B.; Contreras-Ramos, S.M.; Orozco-Avila, I.; Jaramillo-Flores, E.; Lugo-Cervantes, E. Effect of fermentation time and drying temperature on volatile compounds in cocoa. Food Chem. 2012, 132, 277–288. [Google Scholar] [CrossRef] [PubMed]

| Number | Compound | Retention Time (min) | Odor Quality a | Kovats Retention Index b | Sample Found | Identification c | Reference |

|---|---|---|---|---|---|---|---|

| Acids | |||||||

| 1 | Acetic acid | 11.89 | sour, astringent, viniegra | 1680 b | All samples | MS, IK, STD | Wanakhachornkrai & Lertsiri (2003) |

| 2 | Isobutyric acid | 14.48 | rancid, butter, cheese, hammy | ˃1500 b | NC1, NC2, NC3, C1, C3 | MS, IK | Chuenchomrat et al. (2008) |

| 3 | Butyric acid | 16.06 | - | 1720 b | All samples | MS, IK, STD | Wanakhachornkrai & Lertsiri (2003) |

| 4 | Isovaleric acid | 16.43 | sweat, acid, rancid | 1864 b | All samples | MS, IK, STD | Jerković et al. (2012) |

| 5 | Valeric acid | 19.4 | sweet | - | NC2 | MS, IK, STD | Chung et al. (1993) |

| 6 | Caproic acid | 22.5 | cheese, oil, pungent, sour, rancid, sickening | - | All samples | MS, IK | Wanakhachornkrai & Lertsiri (2003) |

| 7 | Oenanthic acid | 25.82 | rancid, sour, sweat | - | NC2 | MS | - |

| 8 | Caprylic acid | 29.09 | cheese, fat, grass, oil | - | NC1, NC2, NC3, C1, C3 | - | - |

| 9 | Benzoic acid, hexahydro- | 29.79 | fruit | - | NC2 | MS | - |

| 10 | 9-Decenoic acid | 37.15 | - | - | NC2 | MS | - |

| 11 | Hendecanoic acid | 41.25 | oil | - | NC1, NC3 | MS | - |

| 12 | Lauric acid | 41.5 | metal | - | NC2 | MS | - |

| 13 | 3-Methyl-benzoic acid | 42.56 | - | - | All samples | MS | - |

| 14 | Benzenepropanoic acid | 44.48 | - | - | NC2, C2 | MS | - |

| 15 | Palmitic acid | 51.775 | - | - | All samples | MS | - |

| 16 | Myristic acid | 57.6 | - | - | All samples | MS | - |

| Esters | |||||||

| 17 | Ethyl orthoformate | 7.07 | - | 1465 b | NC2, C2 | MS | - |

| 18 | Ethyl butanoate | 8.88 | - | ˃1493 b | C2 | MS, IK | Wanakhachornkrai & Lertsiri (2003) |

| 19 | 1,1-Dimethylpropyl ester, pentanoic acid | 9.38 | sweet | ˃1500 b | NC1, NC3 | MS | - |

| 20 | Ethyl lactate | 9.88 | pungent, rancid, soy | - | NC2, C1, C2, C3 | MS, IK | Wanakhachornkrai & Lertsiri (2003) |

| 21 | Methylthiohexanoate | 17.11 | - | ˃1500 b | NC2 | MS | - |

| 22 | Diethyl succinate | 17.4 | - | - | NC2 | MS | - |

| 23 | Ethyl acetate | 19.37 | aromatic, brandy, grape | - | C2 | MS, IK | - |

| 24 | Methyl salicylate | 20.43 | - | - | NC2 | MS | - |

| 25 | Allyl phenylacetate | 21.62 | floral | - | C2 | MS | - |

| 26 | Ethyl palmitate | 34.65 | - | - | NC1, NC2, NC3, C1, C3 | MS | - |

| 27 | 2-Phenylethyl acetate | 35.4 | flower, honey, rose | - | NC1, NC3 | MS | - |

| 28 | Monoethyl succinate | 38.62 | - | - | NC1, NC2, NC3, C1, C3 | MS | - |

| Alcohols | |||||||

| 29 | 2-Methyl-1-propanol | 6.36 | apple, bitter, cocoa, wine | 1107 b | NC1, NC3 | MS, IK | Chuenchomrat et al. (2008) |

| 30 | 3,7-Dimethyl-1-octanol | 6.57 | - | - | NC1, NC3 | MS | - |

| 31 | 1-Butanol | 7.21 | fruit | 1156 b | NC2 | MS, IK | Chuenchomrat et al. (2008) |

| 32 | 3-Penten-2-ol | 7.56 | - | - | All samples | MS | - |

| 33 | 2-Butyl-1-Octanol | 9.26 | - | - | NC1, NC3, C1, C2, C3 | MS | - |

| 34 | 3-Ethoxy-1-propanol | 10.37 | - | - | C2 | MS | - |

| 35 | 2-Ethyl-1-hexanol | 12.52 | - | ˃1361 b | C2 | MS, IK | Chung et al. (1993) |

| 36 | 1-Decanol, 2-hexyl- | 13.50 | - | - | NC2 | MS | - |

| 37 | 2,3-Butanediol | 14.69 | - | ˃1493 b | All samples | MS, IK | Chuenchomrat et al. (2008) |

| 38 | 1,2-Propanediol | 15.1 | - | - | NC2, C1, C2 | MS | - |

| 39 | Furfuryl alcohol | 17.13 | burnt, caramel, cooked | ˃1493 b | All samples | MS, IK, STD | Chuenchomrat et al. (2008) |

| 40 | 3-(Methylthio)-1-propanol | 18.65 | - | - | C1, C2 | MS | - |

| 41 | 1,3-Propanediol | 20.67 | - | - | C2 | MS | - |

| 42 | Benzyl alcohol | 23.54 | sweet, flowery, boiled cherries, moss, roasted bread, rose | 1943 b | All samples | MS, IK | Chuenchomrat et al. (2008) |

| 43 | Phenylethyl Alcohol | 24.58 | honey, spice, rose, flowery, caramel | 1997 b | All samples | MS, IK | Jerković et al. (2012) |

| 44 | Benzene propanol | 28.66 | - | - | All samples | MS | - |

| 45 | p-Menthane-1,8-diol | 30.17 | - | - | NC1, NC3 | MS | - |

| 46 | 1-(2-Furanyl)-1,2-ethanediol | 44.03 | - | - | All samples | MS | - |

| 47 | 1-Phenyl-1-decanol | 58.78 | - | - | NC1, NC3 | MS | - |

| 48 | 3-(p-Hydroxyphenyl)-1-propanol | 58.99 | - | - | NC2 | MS | - |

| Aldehydes | |||||||

| 49 | Benzaldehyde | 13.63 | bitter almond, burnt sugar, cherry, malt, roasted pepper | ˃1500 b | C1, C3 | MS, IK | Wanakhachornkrai & Lertsiri (2003) |

| 50 | 4-Methyl-benzaldehyde | 16.8 | - | ˃1500 b | NC1, NC2, NC3 | MS, IK | Wanakhachornkrai & Lertsiri (2003) |

| 51 | 3-Methyl-benzaldehyde | 37.35 | - | ˃1500 b | NC1, NC3, C2 | MS, IK | Wanakhachornkrai & Lertsiri (2003) |

| Alkanes | |||||||

| 52 | Dodecane | 7.823 | - | - | All samples | MS | - |

| 53 | 4,6-Dimethyl-dodecane | 7.90 | - | 1200 b | C1, C3, NC1, NC3 | MS, IK | Chung et al. (1993) |

| 54 | 2,3,6,7-Tetramethyl-octane | 8.064 | - | 1300 b | C1, C3 | MS, IK | Chung et al. (1993) |

| 55 | 5-Methyl-tridecane | 9.67 | - | - | NC1, NC3, C1, C3 | MS | - |

| 56 | Tetradecane | 10.54 | - | 1400 b | All samples | MS, IK | Jerković et al. (2012) |

| 57 | 3,3-Dimethyl-heptane | 10.61 | - | - | NC1, NC3 | MS | - |

| 58 | Farnesan | 11.13 | - | - | NC1, NC3, C2 | MS | - |

| 59 | 3-Ethyl-3-methylheptane | 15.30 | - | - | All samples | MS | - |

| 60 | Nonadecane | 17.80 | - | 1900 b | All samples | MS, IK | Jerković et al. (2012) |

| 61 | Eicosane | 12.48 | - | 2000 b | All samples | MS, IK | Chung et al. (1993) |

| Furanic | |||||||

| 62 | 2,2,3,3,4,4-Hexamethyltetrahydrofuran | 8.905 | - | - | C1, C3 | MS | - |

| 63 | Furfural | 12.30 | almond, baked potatoes, bread, burnt, spice | 1493 b | C1, C2, C3 | MS, IK, STD | Chuenchomrat et al. (2008) |

| 64 | 5-Methylfurfural | 12.38 | - | ˃1493 b | C1, C2, C3 | MS, IK | Chuenchomrat et al. (2008) |

| 65 | Acetylfuran | 13.20 | balsamic, cocoa, coffee | - | C1, C3 | MS | - |

| 66 | 2-Furoate-methyl | 14.88 | fruit | - | All samples | MS, STD | - |

| 67 | Furan, 2-(1,2-diethoxyethyl)- | 21.07 | - | - | All samples | MS, IK | - |

| 68 | 2-(Hydroxyacetyl)furan | 27.83 | - | - | NC1, NC3 | MS | - |

| 69 | 2,5-Dimethyl-2-(2-tetrahydrofuryl) tetrahydrofuran | 30.37 | - | - | All samples | MS | - |

| 70 | HMF | 41.99 | almond, baked potatoes, bread, burnt, spice | ˃1493 b | C1, C2, C3 | MS, IK, STD | Chuenchomrat et al. (2008) |

| 71 | Furan, 2-(1,2-dimethoxyethyl)- | 32.16 | - | - | NC2 | MS | - |

| 72 | Furan, 2-ethoxy-4-ethyl-2,3-dihydro | 36.04 | - | - | C1, C3 | MS | - |

| Ketones | |||||||

| 73 | 3(2H)-Furanone, dihydro-2-methyl | 8.8 | nuts | 1207 b | C1, C2, C3 | MS, IK | Wanakhachornkrai & Lertsiri (2003) |

| 74 | Acetoin | 9.057 | butter, creamy, green pepper | 1306 b | NC1, NC2, C1, C2, C3 | MS, IK | Chuenchomrat et al. (2008) |

| 75 | 2-Cyclopenten-1-one | 10.26 | - | - | C1, C3 | MS | - |

| 76 | 2-Butanone, 3,4-epoxy-3-ethyl | 13.18 | - | - | NC2 | MS | - |

| 77 | 2(3H)-Furanone, dihydro-5-methyl- | 15.87 | - | ˃1500 b | NC2, C1, C2, C3 | MS, IK | Wanakhachornkrai & Lertsiri (2003) |

| 78 | γ-Butyrolactone | 16.394 | caramel, cheese, roasted nut | 1610 b | NC1, NC2, NC3, C1, C2,C3 | MS, IK | Márquez et al. (2010) |

| 79 | 2-Cyclopenten-1-one, 2-hydroxy-3-methyl | 22.04 | - | - | C1, C2, C3 | MS | - |

| 80 | α, β-Angelica lactone | 17.75 | floral | - | C1, C2 | MS, IK | - |

| 81 | 2,5-Dimethyl-4-hydroxy-3(2H)-furanone | 22.96 | burnt, caramel, cotton candy, honey | 2024 b | C1, C3 | MS, IK | Fuhrmann & Grosch (2002) |

| 82 | Furyl hydroxymethyl ketone | 27.51 | - | - | NC3, C1, C2, C3 | MS | - |

| 83 | 2(3H)-Furanone, dihydro-3-hydroxy-4,4-dimethyl | 28.34 | - | - | C1, C3 | MS | - |

| 84 | Ethanone, 1-(2,6-dihydroxy-4-methoxyphenyl) | 39.39 | - | - | NC2 | MS | - |

| 85 | Ethanone, 1-(4-hydroxy-3,5-dimethoxyphenyl) | 54.24 | - | - | NC2 | MS | - |

| Phenols | |||||||

| 86 | p-Guaiacol | 23.06 | burnt, phenol, wood | ˃1500 b | NC2 | MS, IK | Wanakhachornkrai & Lertsiri (2003) |

| 87 | p-Methylguaiacol | 26.06 | phenol | ˃1500 b | NC2 | MS, IK | Wanakhachornkrai & Lertsiri (2003) |

| 88 | 3-Methyl phenol | 29.93 | - | - | NC2 | MS | - |

| 89 | Phenol, 2-methyl-5-(1-methylethyl) | 32.31 | caraway, spice, thyme | 2189 b | NC2 | MS, IK | Jerković et al. (2012) |

| 90 | 2,4-Di-tert-butylphenol | 36.67 | - | - | All samples | MS | - |

| 91 | Phenol, 2-(5-isoxazolyl) | 45.90 | - | - | NC2 | MS | - |

| 92 | Eugenol | 45.31 | burnt, clove, spice | - | NC2 | MS, STD | - |

| 93 | Phenol, 2-(2-methylpropyl) | 51.53 | - | - | NC2 | MS | - |

| 94 | 4-(2-Hydroxyethyl) phenol | 54.59 | - | - | C1, C3 | MS | - |

| Pyrans | |||||||

| 95 | 2H-Pyran-2,6(3H)-dione | 27.26 | - | - | NC1, NC3 | MS | - |

| 96 | 2-Pentoxy-tetrahydropyran | 28.10 | - | - | NC1, NC3 | MS | - |

| 97 | 4H-Pyran-4-one, 2,3-dihydro-3,5-dihydroxy-6-methyl | 35.27 | - | - | NC1, NC2, NC3 | MS | - |

| 98 | Pyrrolo[1,2-a] pyrazine-1,4-dione, hexahydro-3-(2-methylpropyl) | 60.62 | - | - | C1, C2, C3 | MS | - |

| Others | |||||||

| 99 | m-Dioxane, 2-methyl | 5.96 | - | - | C2 | MS | - |

| 100 | p-Dichlorobenzene | 11.78 | - | - | NC1, NC3 | - | |

| 101 | m-Di-tert-butylbenzene | 11.28 | - | - | C1, C2, C3 | MS | - |

| 102 | 6,7-Dihydro-7-hydroxylinalool | 26.69 | - | - | NC1, NC3 | MS | - |

| 103 | 4-Acetoxy-3-methoxystyrene | 33.29 | - | - | NC1, NC3 | MS | - |

| 104 | Ethyl linoleate | 60.85 | - | - | All samples | MS | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Félix, E.; Contreras-Ramos, S.M.; Davila-Vazquez, G.; Rodríguez-Campos, J.; Marino-Marmolejo, E.N. Identification and Quantification of Volatile Compounds Found in Vinasses from Two Different Processes of Tequila Production. Energies 2018, 11, 490. https://doi.org/10.3390/en11030490

Rodríguez-Félix E, Contreras-Ramos SM, Davila-Vazquez G, Rodríguez-Campos J, Marino-Marmolejo EN. Identification and Quantification of Volatile Compounds Found in Vinasses from Two Different Processes of Tequila Production. Energies. 2018; 11(3):490. https://doi.org/10.3390/en11030490

Chicago/Turabian StyleRodríguez-Félix, Elizabeth, Silvia Maribel Contreras-Ramos, Gustavo Davila-Vazquez, Jacobo Rodríguez-Campos, and Erika Nahomy Marino-Marmolejo. 2018. "Identification and Quantification of Volatile Compounds Found in Vinasses from Two Different Processes of Tequila Production" Energies 11, no. 3: 490. https://doi.org/10.3390/en11030490