Time Traveling Regularization for Inverse Heat Transfer Problems

Abstract

:1. Introduction

2. Methodology

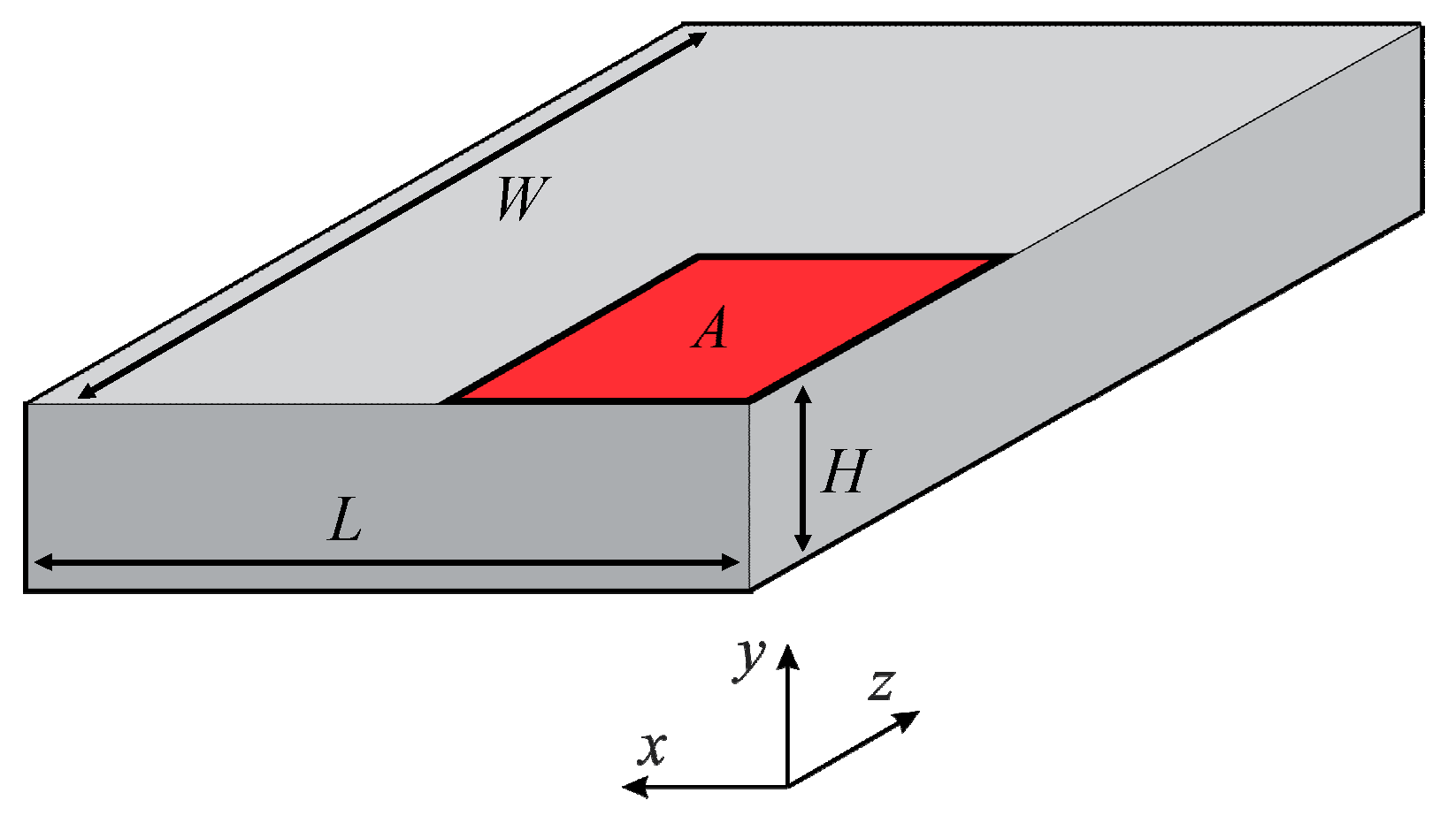

Heat Transfer Model

3. The Inverse Heat Conduction Problem (IHCP)

3.1. Time Traveling Regularization (TTR)

| Algorithm 1: The Golden Section Algorithm with Time Travelling Regularization | ||

| 1: | Start | |

| 2: | Given the input variables | |

| 3: | Define the tolerance for the objective function ε | |

| 4: | T = Define the initial condition | |

| 5: | Define the number of future times r | |

| 6: | for i = 1; i ≥ imax; i = i + 1 | |

| 7: | T* = T | |

| 8: | Xl = qmin | |

| 9: | Xu = qmax | |

| 10: | X1 = (1 − τ) Xl + τ Xu | |

| 11: | qi = X1 | |

| 12: | F1 = 0 | |

| 13: | for j = i; j ≤ i + r; j = j + 1 | TTR |

| 14: | A = Evaluate the coefficients for the step j | |

| 15: | B = Evaluate the source term for the step j | |

| 16: | T = A−1 B (Solve the direct model) | |

| 17: | F1 = F1 + (Yj − Tj)2 | |

| 18: | end for | |

| 19: | T = T* | |

| 20: | X2 = τ Xl + (1 − τ) Xu | |

| 21: | qi = X2 | |

| 22: | F2 = 0 | |

| 23: | for j = i; j ≤ i+r; j = j + 1 | TTR |

| 24: | A = Evaluate the coefficients for the step j | |

| 25: | B = Evaluate the source term for the step j | |

| 26: | T = A−1 B (Solve the direct model) | |

| 27: | F2 = F2 + (Yj − Tj)2 | |

| 28: | end for | |

| 29: | do | |

| 30: | T = T* | |

| 31: | if F1 > F2 | |

| 32: | Xl = X1 | |

| 33: | Fl = F1 | |

| 34: | X1 = X2 | |

| 35: | F1 = F2 | |

| 36: | Re-evaluate lines 20-28 | |

| 37: | Fobj = F1 | |

| 38: | Endif | |

| 39: | Else | |

| 40: | Xu = X2 | |

| 41: | Fu = F2 | |

| 42: | X2 = X1 | |

| 43: | F2 = F1 | |

| 44: | Re-evaluate lines 10-18 | |

| 45: | Fobj = F2 | |

| 46: | endif | |

| 47: | while (Fobj > ε) | |

| 48: | T = T* | |

| 49: | A = Evaluate the coefficients for the step i | |

| 50: | B = Evaluate the source term for the step i | |

| 51: | T = A−1B (Solve the direct model for qopt) | |

| 52: | end for | |

| 53: | End | |

3.2. The TTR Objective Function

3.3. Settling Time

3.4. Sequential Function Specification Method (SFSM)

3.5. Tikhonov Regularization

4. Experimental and Numerical Procedure

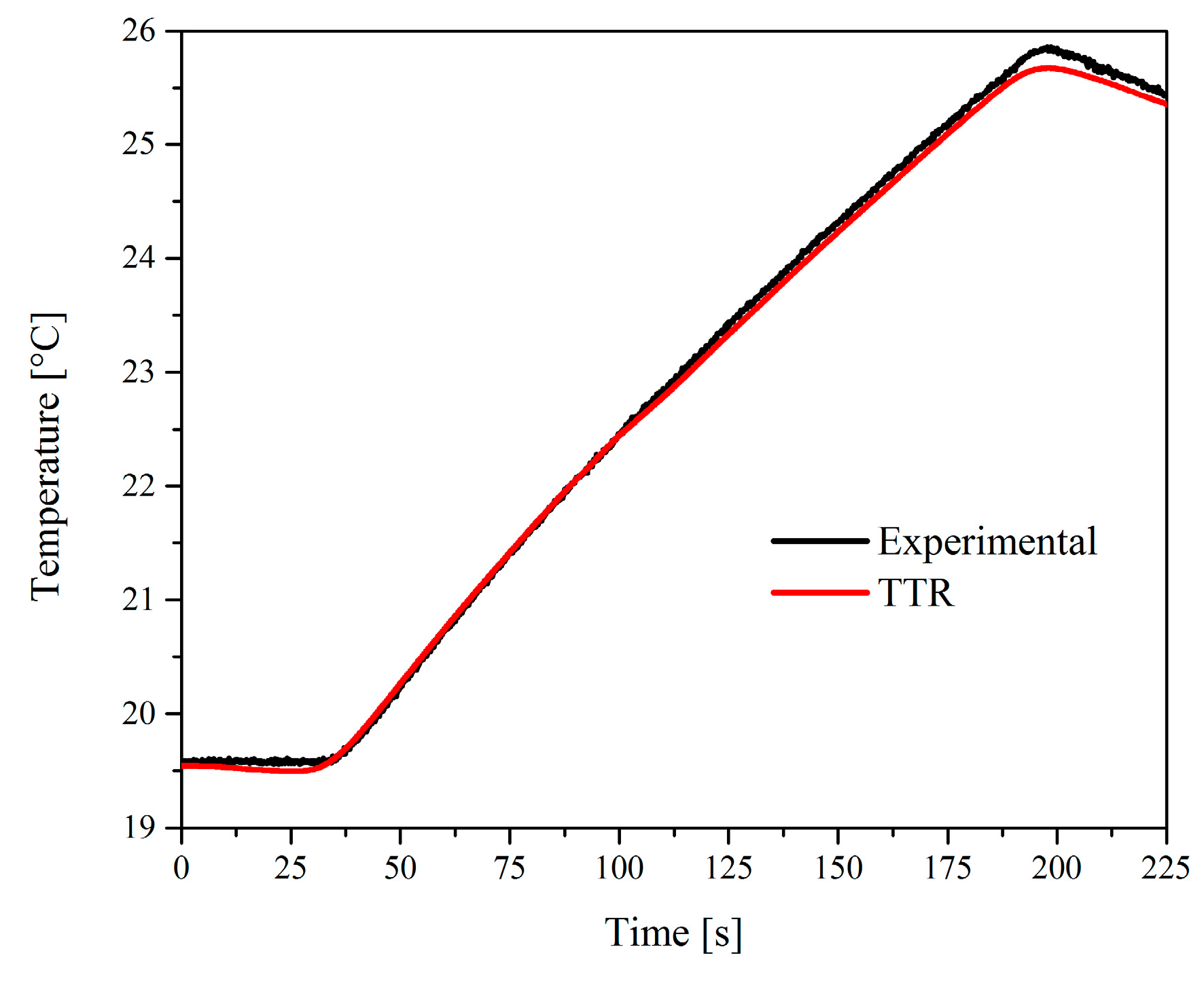

4.1. One-Dimensional Experiment Using Aluminum 5052

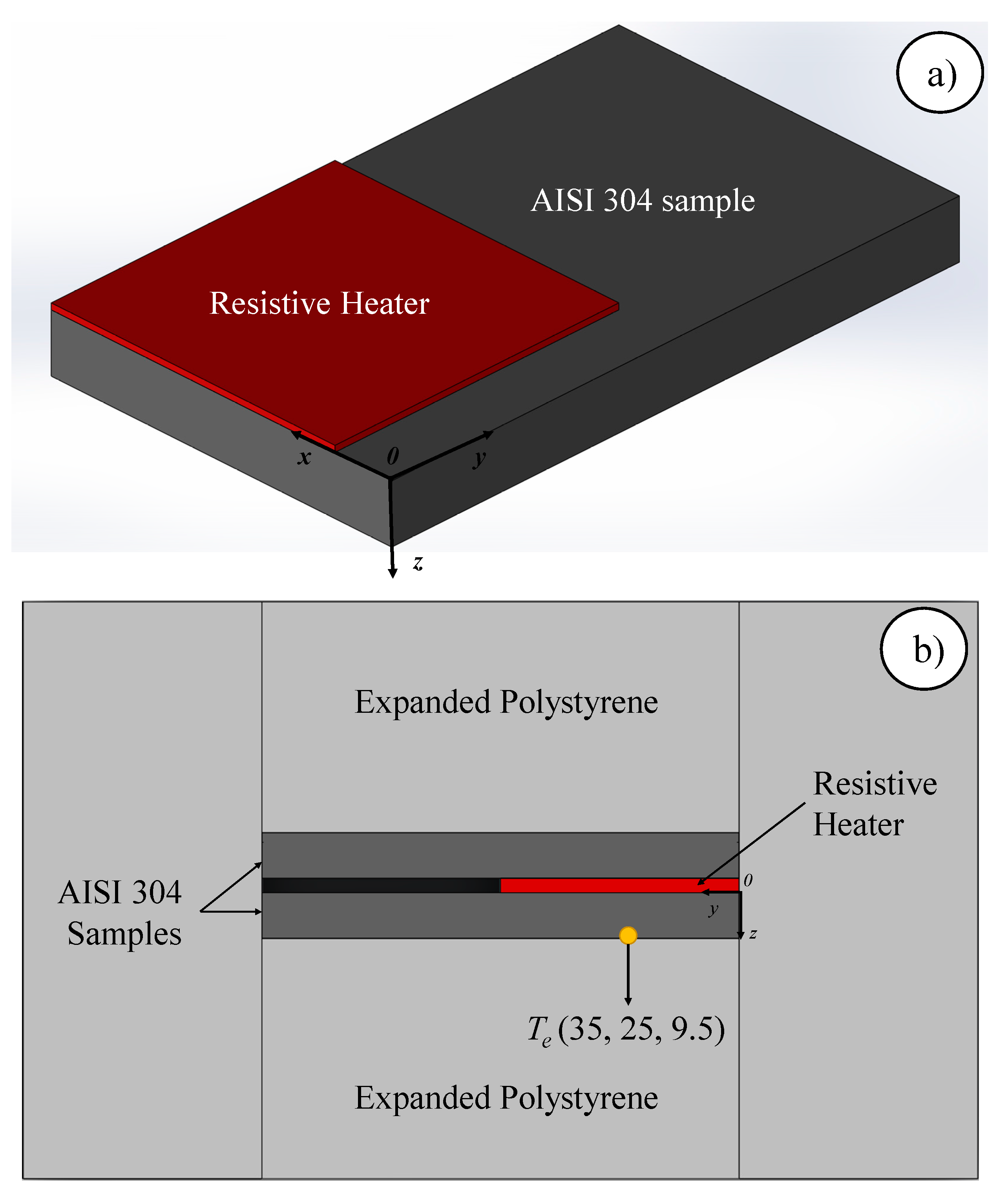

4.2. Three-Dimensional Experiment Using AISI 304

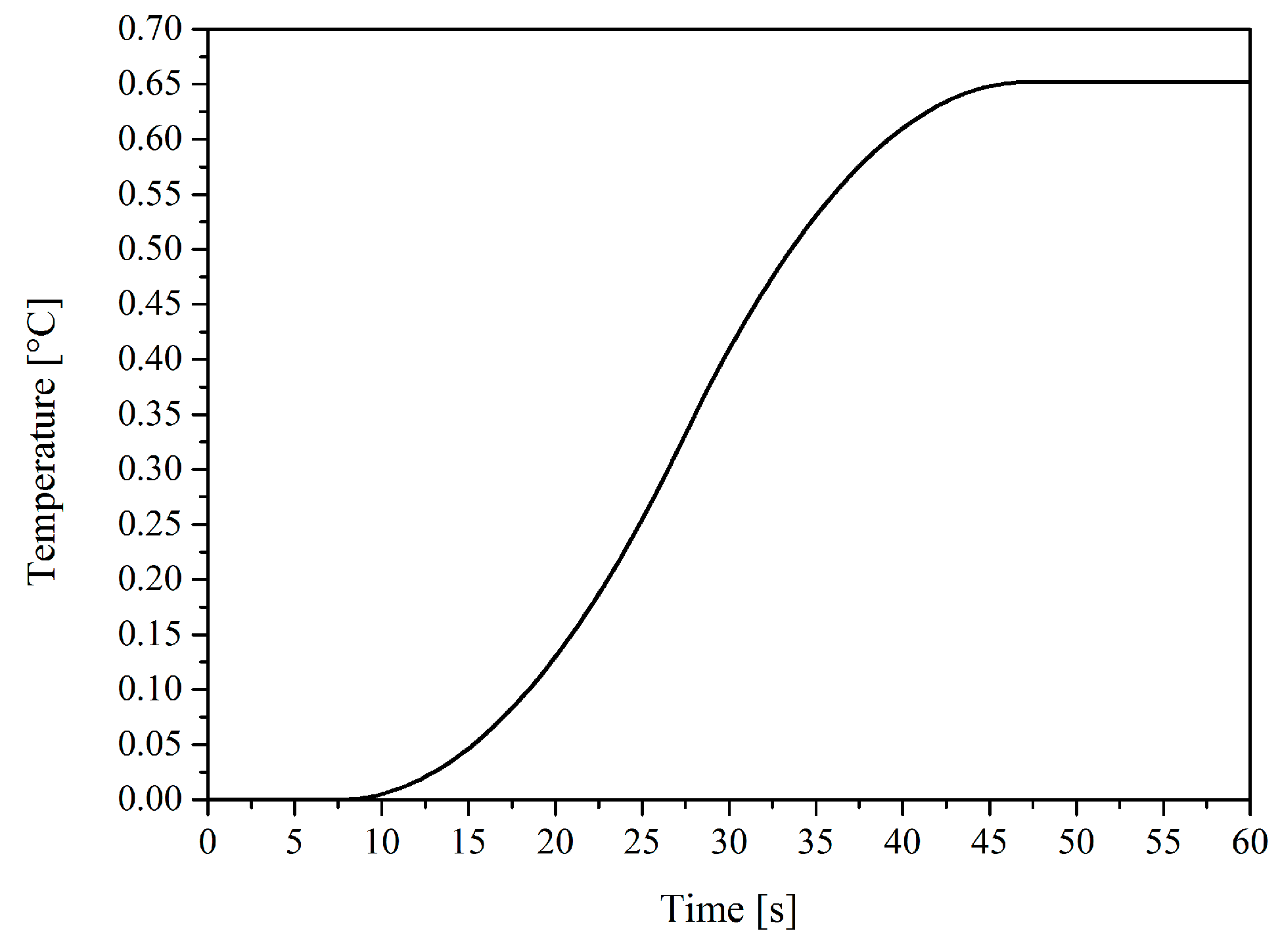

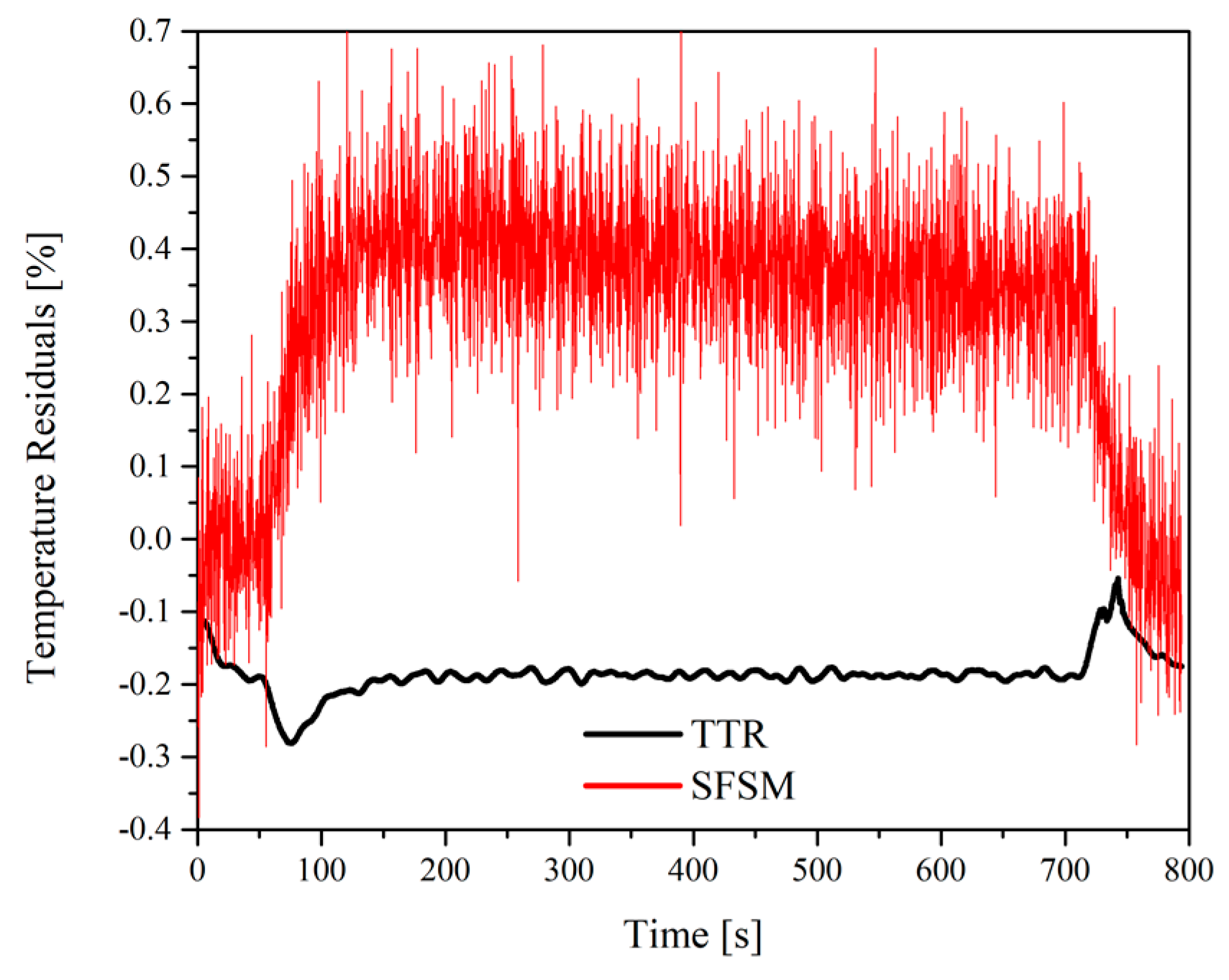

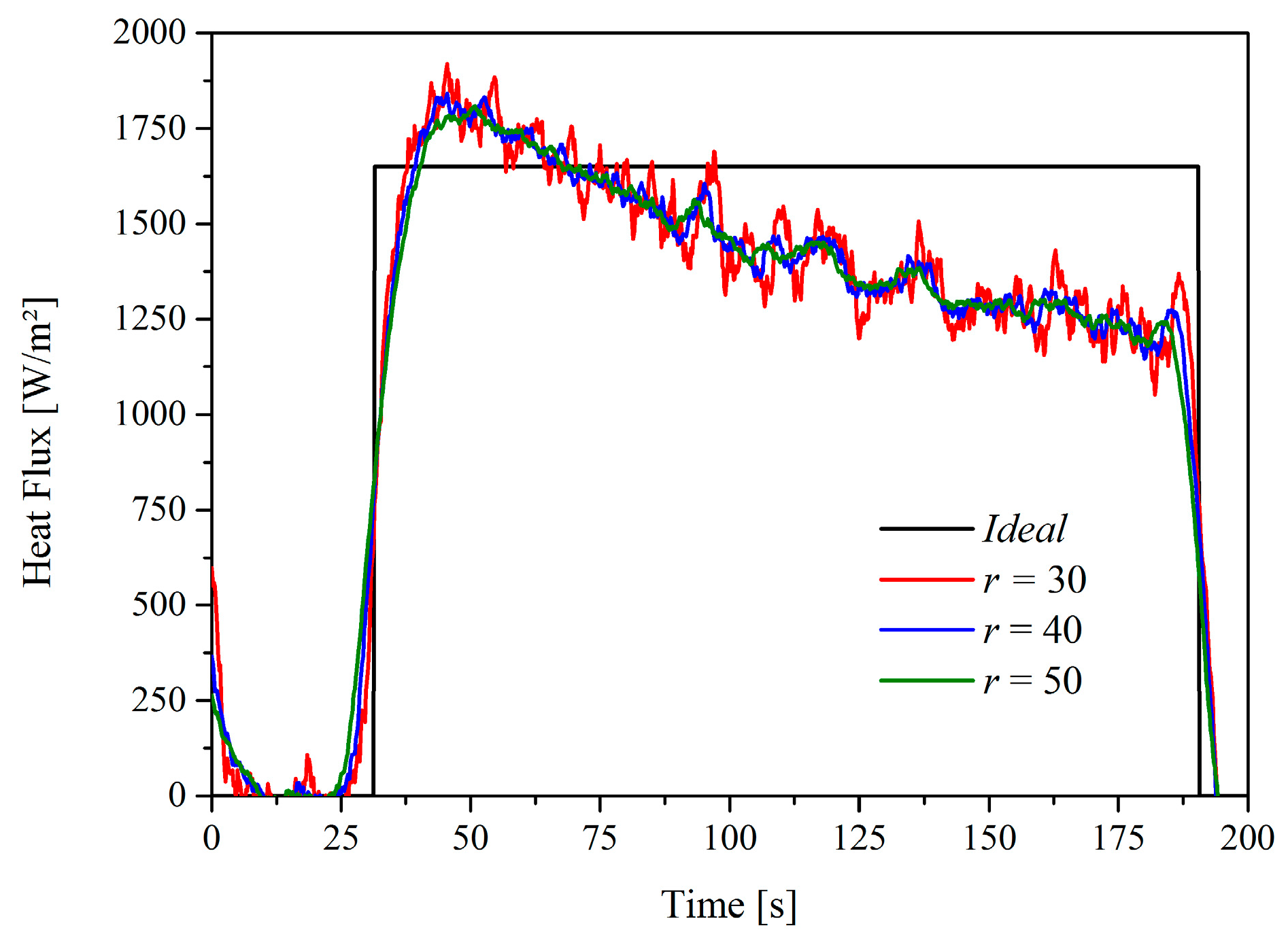

5. Random Error Analysis

6. Result Analysis

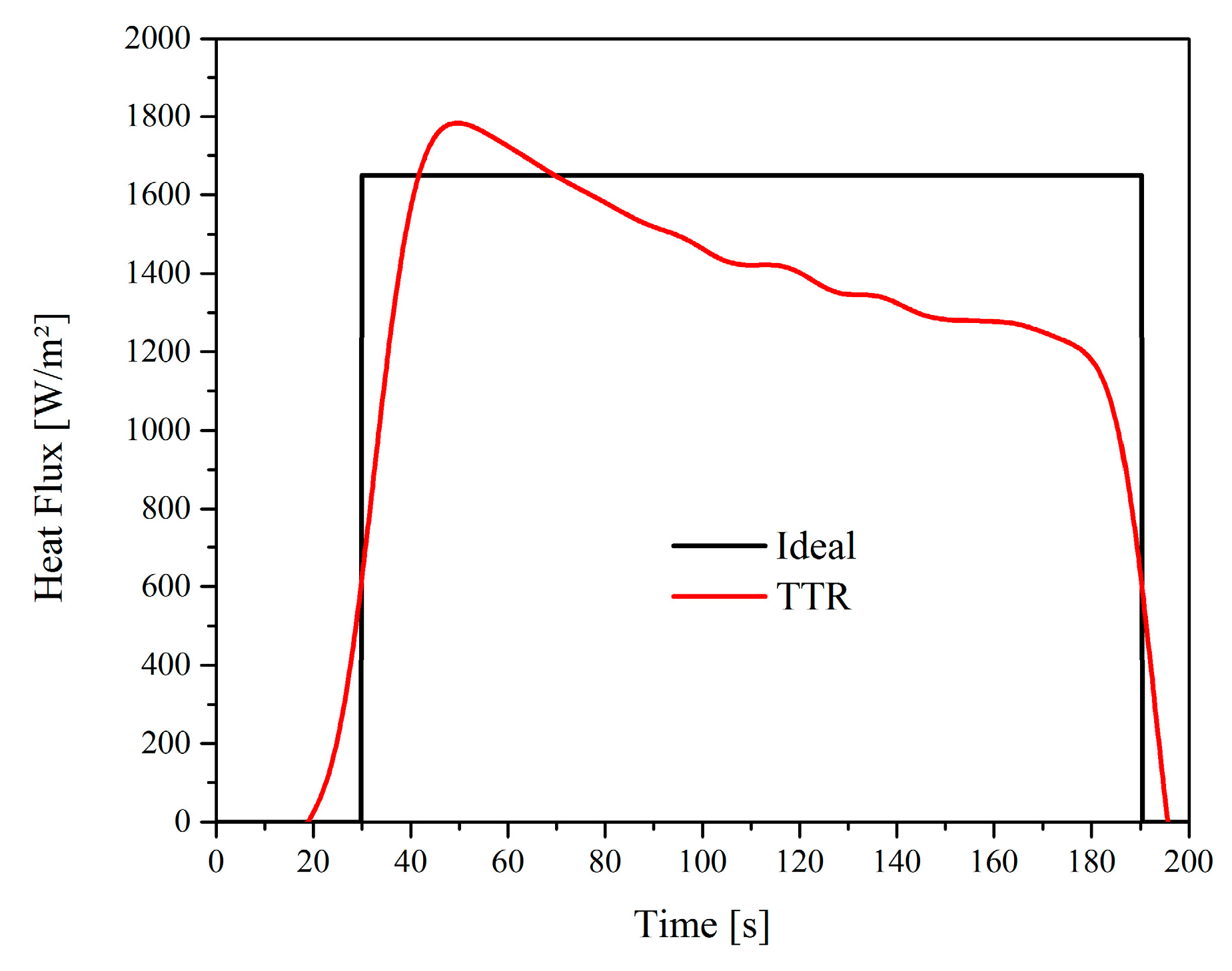

6.1. Aluminum 5052

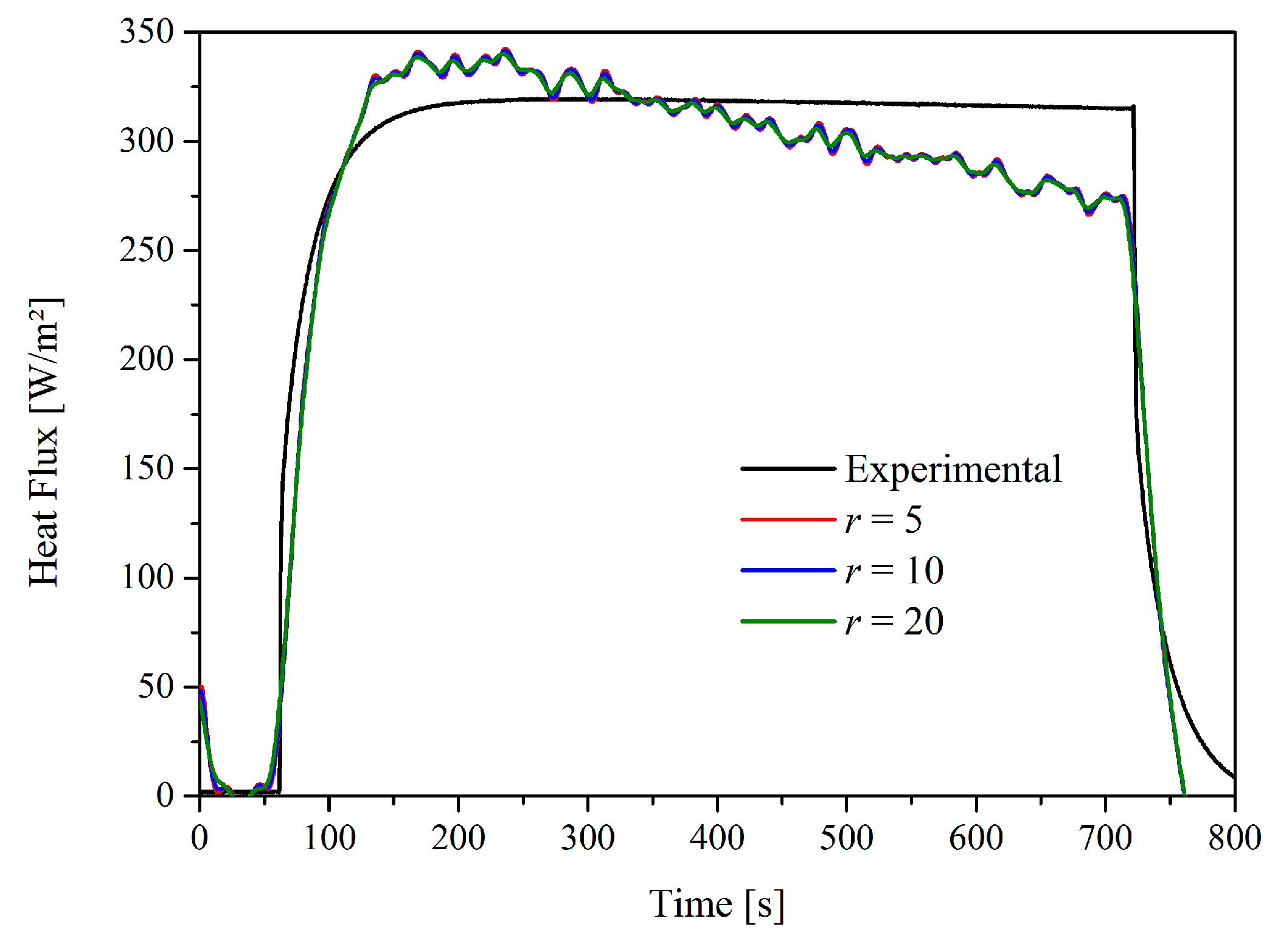

6.2. AISI 304 Stainless Steel

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kabanikhin, S.I. Definitions and examples of inverse and ill-posed problems. J. Inverse Ill-Posed Probl. 2008, 16, 317–357. [Google Scholar] [CrossRef]

- Tikhonov, A.N.; Arsenin, V.Y. Solutions of Ill-Posed Problems. Math. Comput. 1978, 32, 1320–1322. [Google Scholar] [CrossRef]

- Grasmair, M.; Haltmeier, M.; Scherzer, O. The residual method for regularizing ill-posed problems. Appl. Math. Comput. 2011, 218, 2693–2710. [Google Scholar] [CrossRef] [PubMed]

- Solodky, S.G.; Volynets, E.A. Adaptive scheme of discretization for one semiiterative method in solving ill-posed problems. J. Mat. Sci. 2011, 175, 477–489. [Google Scholar] [CrossRef]

- Zhang, J.; Mammadov, M. A new method for solving linear ill-posed problems. Appl. Math. Comput. 2012, 218, 10180–10187. [Google Scholar] [CrossRef]

- Cheng, J.; Hofmann, B.; Lu, S. The index function and Tikhonov regularization for ill-posed problems. J. Comput. Appl. Math. 2013, 265, 110–119. [Google Scholar] [CrossRef]

- Warner, J.E.; Aquino, W.; Grigoriu, M.D. Stochastic reduced order models for inverse problems under uncertainty. Comput. Methods Appl. Mech. Eng. 2015, 285, 488–514. [Google Scholar] [CrossRef] [PubMed]

- Beck, J.; Blackwell, B.; Clair, C. Inverse Heat Conduction: Ill-Posed Problems; Wiley: New York, NY, USA, 1985; ISBN 0471083194. [Google Scholar]

- Zhou, Z.; Chen, B.; Wang, R.; Bai, F.; Wang, G. Coupling effect of hypobaric pressure and spray distance on heat transfer dynamics of R134a pulsed flashing spray cooling. Exp. Therm. Fluid Sci. 2016, 70, 96–104. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, B.; Wang, Y.; Guo, L.; Wang, G. An experimental study on pulsed spray cooling with refrigerant R-404a in laser surgery. Appl. Therm. Eng. 2012, 39, 29–36. [Google Scholar] [CrossRef]

- Somasundaram, S.; Tay, A.A.O. A study of intermittent spray cooling process through application of a sequential function specification method. Inverse Probl. Sci. Eng. 2012, 20, 553–569. [Google Scholar] [CrossRef]

- Mohammadiun, M.; Molavi, H.; Bahrami, H.R.T.; Mohammadiun, H. Application of Sequential Function Specification Method in Heat Flux Monitoring of Receding Solid Surfaces. Heat Transf. Eng. 2014, 35, 933–941. [Google Scholar] [CrossRef]

- Beck, J.V.; Woodbury, K.A. Inverse heat conduction problem: Sensitivity coefficient insights, filter coefficients, and intrinsic verification. Int. J. Heat Mass Transf. 2016, 97, 578–588. [Google Scholar] [CrossRef]

- Kaipio, J.P.; Fox, C. The Bayesian Framework For Inverse Problems In Heat Transfer. Heat Transf. Eng. 2011, 32, 83. [Google Scholar] [CrossRef]

- Franck, I.M.; Koutsourelakis, P.S. Sparse Variational Bayesian approximations for nonlinear inverse problems: Applications in nonlinear elastography. Comput. Methods Appl. Mech. Eng. 2016, 299, 215–244. [Google Scholar] [CrossRef]

- Zhou, Z.F.; Xu, T.Y.; Chen, B. Algorithms for the estimation of transient surface heat flux during ultra-fast surface cooling. Int. J. Heat Mass Transf. 2016, 100, 1–10. [Google Scholar] [CrossRef]

- Tian, J.; Chen, B.; Zhou, Z. Methodology of surface heat flux estimation for 2D multi-layer mediums. Int. J. Heat Mass Transf. 2017, 114, 675–687. [Google Scholar] [CrossRef]

- Grysa, K.; MacIag, A.; Pawinska, A. Solving nonlinear direct and inverse problems of stationary heat transfer by using Trefftz functions. Int. J. Heat Mass Transf. 2012, 55, 7336–7340. [Google Scholar] [CrossRef]

- Duda, P. A general method for solving transient multidimensional inverse heat transfer problems. Int. J. Heat Mass Transf. 2016, 93, 665–673. [Google Scholar] [CrossRef]

- Park, H.M.; Chung, O.Y. Reduction of modes for the solution of inverse natural convection problems. Comput. Methods Appl. Mech. Eng. 2000, 190, 919–940. [Google Scholar] [CrossRef]

- Magalhães, E.D.S.; de Carvalho, S.R.; de Lima E Silva, A.L.F.; Lima E Silva, S.M.M. The use of non-linear inverse problem and enthalpy method in GTAW process of aluminum. Int. Commun. Heat Mass Transf. 2015, 66, 114–121. [Google Scholar] [CrossRef]

- Hosseini, M.M.; Basirat Tabrizi, H.; Jalili, N. Thermal optimization of friction stir welding with simultaneous cooling using inverse approach. Appl. Therm. Eng. 2016, 108, 751–763. [Google Scholar] [CrossRef]

- Vanderplaats, G.N. Numerical Optimization Techniques for Engineering Design, 4th ed.; Vanderplaats Research and Development: Colorado Springs, CO, USA, 2005. [Google Scholar]

- Schneider, G.E.; Zedan, M. A Modified Strongly Implicit Procedure for the Numerical Solution of Field problems. Numer. Heat Transf. Part B Fundam. 1981, 4, 1–19. [Google Scholar] [CrossRef]

- Shirtliffe, C.J. Establishing Steady-State Thermal Conditions in Flat Slab Specimens. Heat Transm. Meas. Therm. Insul. Am. Soc. Test. Mater. 1974, ASTM STP 5, 13–33. [Google Scholar]

- Calvetti, D.; Morigi, S.; Reichel, L.; Sgallari, F. Tikhonov regularization and the L-curve for large discrete ill-posed problems. J. Comput. Appl. Math. 2000, 123, 423–446. [Google Scholar] [CrossRef]

- Lima e Silva, S.M.M.; Guimarães, G.; Silva Neto, A.J. Uma Técnica para Determinação da Capacidade de Calor Volumétrica do Alumínio 5052. Proc. Congr. Iberoam. Ing. Mech. Mérida Venezuela 2001. (In Portuguese) [Google Scholar]

- Carollo, L.F.S.; Lima e Silva, A.L.F.; Lima e Silva, S.M.M. Applying different heat flux intensities to simultaneously estimate the thermal properties of metallic materials. Meas. Sci. Technol. 2012, 23, 65601. [Google Scholar] [CrossRef]

- Woodbury, K.A. Inverse Engineering Handbook; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magalhães, E.D.S.; Anselmo, B.D.C.S.; Lima e Silva, A.L.F.d.; Lima e Silva, S.M.M. Time Traveling Regularization for Inverse Heat Transfer Problems. Energies 2018, 11, 507. https://doi.org/10.3390/en11030507

Magalhães EDS, Anselmo BDCS, Lima e Silva ALFd, Lima e Silva SMM. Time Traveling Regularization for Inverse Heat Transfer Problems. Energies. 2018; 11(3):507. https://doi.org/10.3390/en11030507

Chicago/Turabian StyleMagalhães, Elisan Dos Santos, Bruno De Campos Salles Anselmo, Ana Lúcia Fernandes de Lima e Silva, and Sandro Metrevelle Marcondes Lima e Silva. 2018. "Time Traveling Regularization for Inverse Heat Transfer Problems" Energies 11, no. 3: 507. https://doi.org/10.3390/en11030507