Energy Hub’s Structural and Operational Optimization for Minimal Energy Usage Costs in Energy Systems

Abstract

:1. Introduction

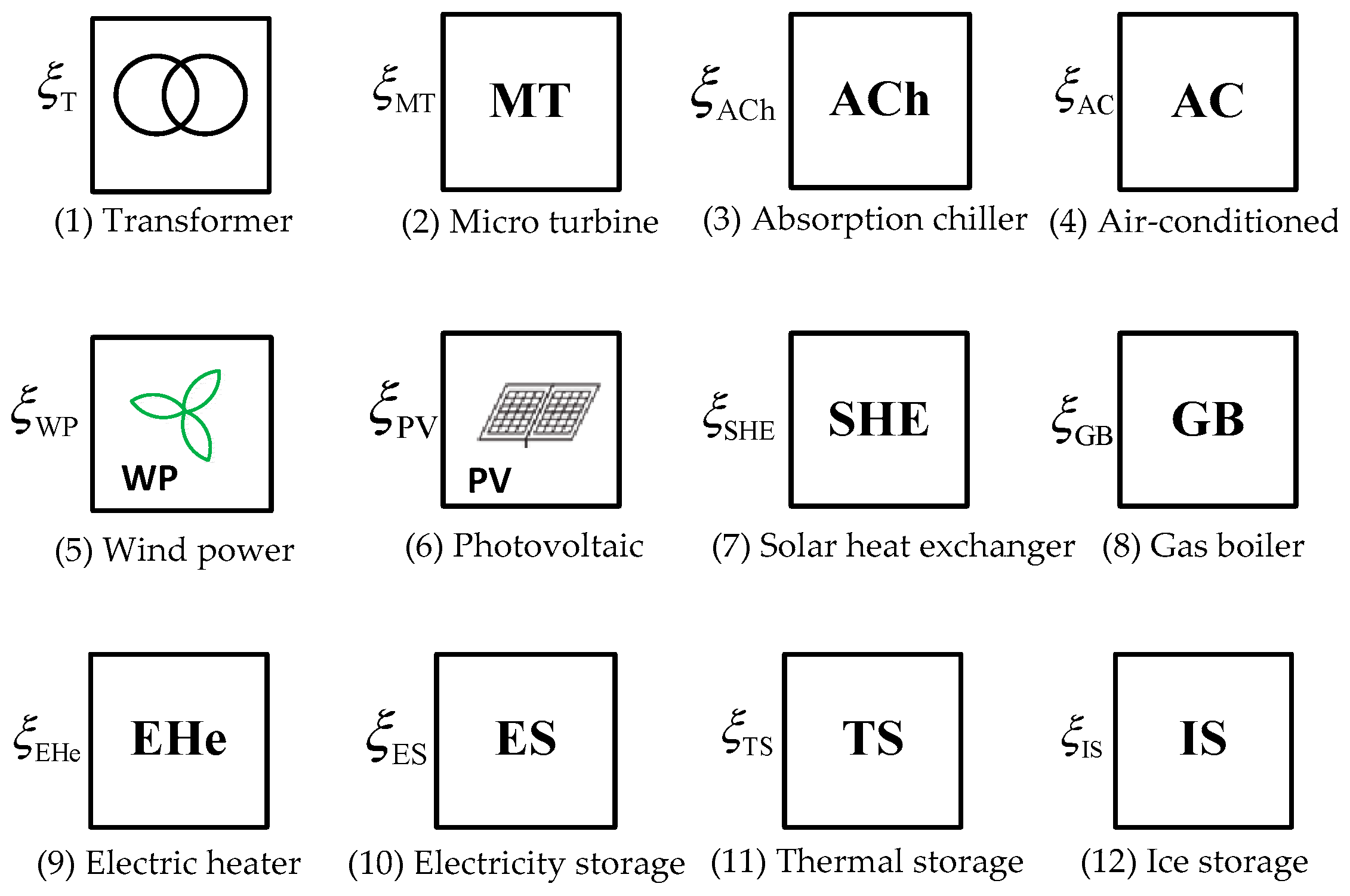

2. Design of the Model

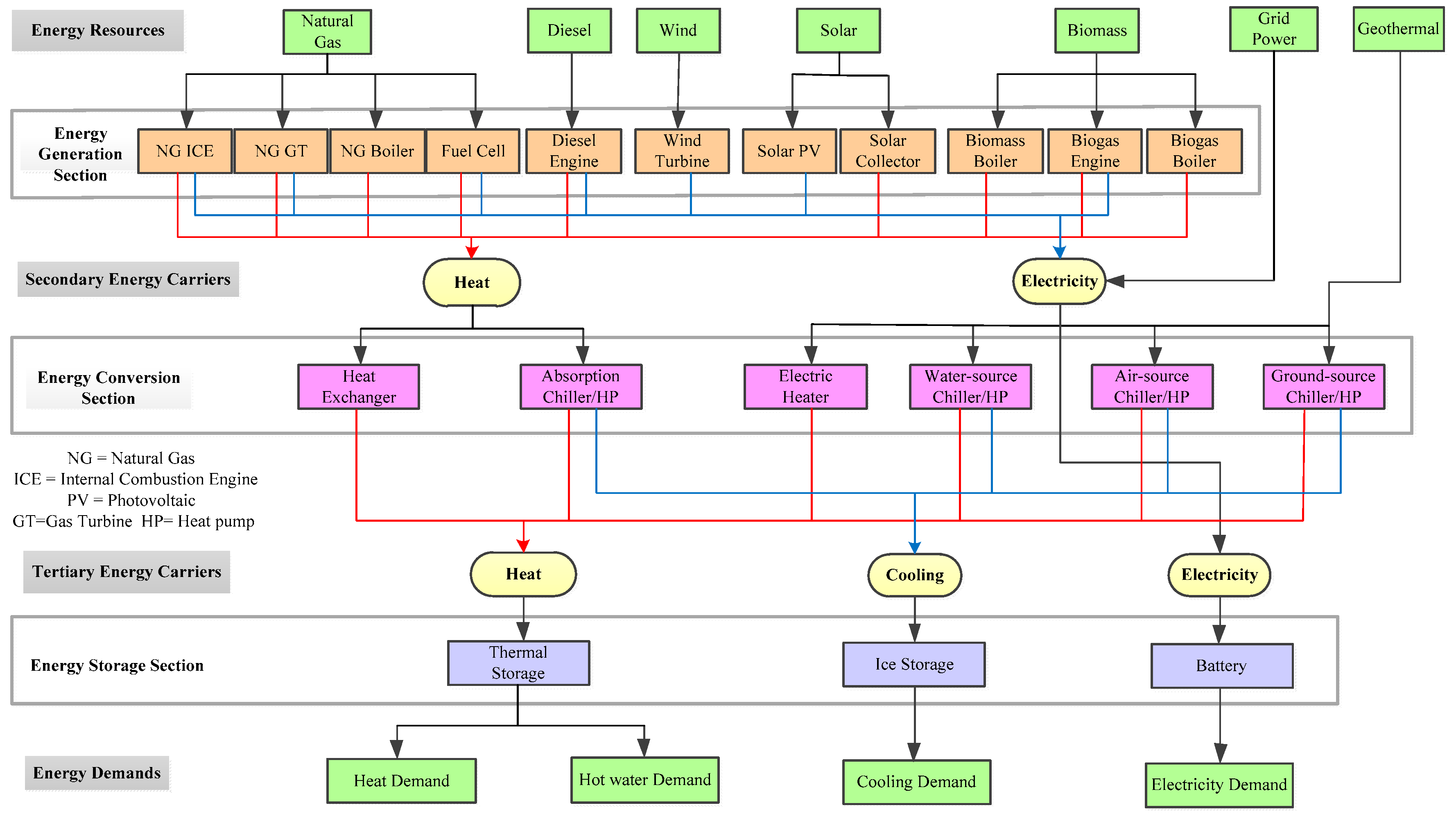

2.1. The Energy System’s Structure

2.2. The Structural Optimization of Hub Modeling

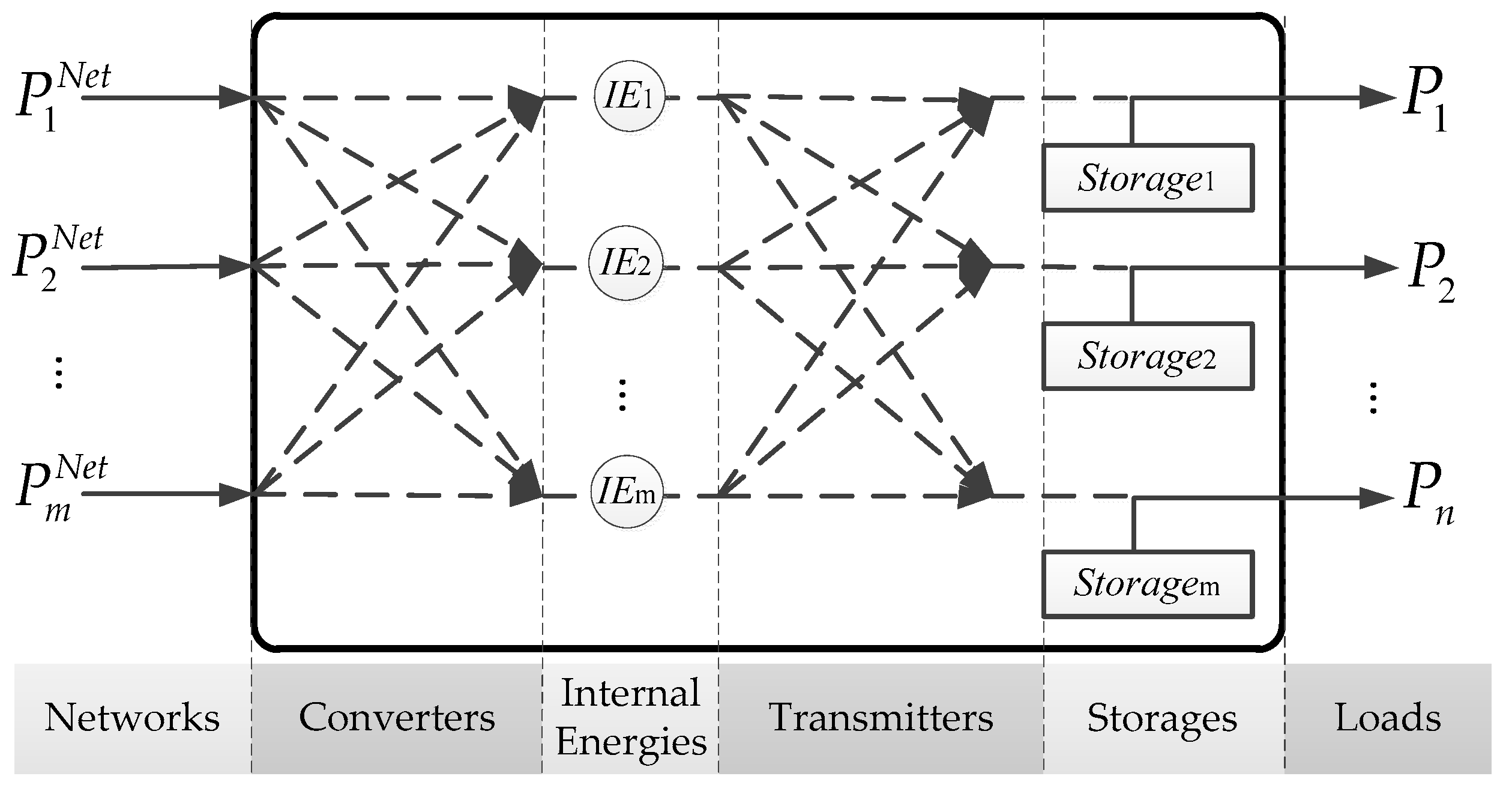

2.2.1. Energy Hub Concept

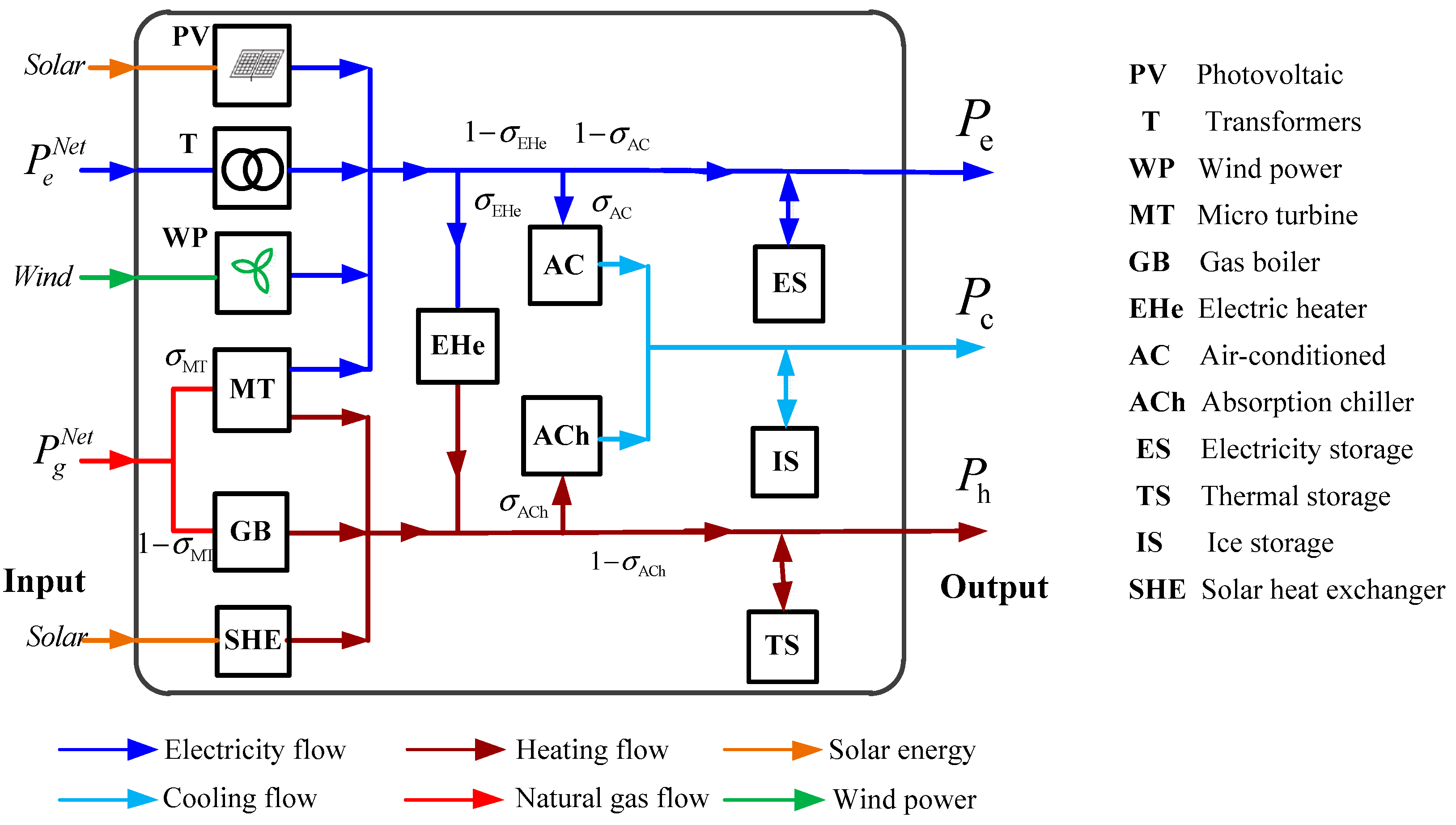

2.2.2. Proposed Energy Hub Model

2.2.3. The Optimization Problem of EH Structure

3. Mathematical Model

3.1. The Objective Function

3.2. Constraints

3.2.1. Energy Balance

- -

- Electricity power balance:

- -

- Heating balance:

- -

- Cooling balance:

3.2.2. Network Constraints

3.2.3. Conversion Limitations

3.2.4. Storage Constraints

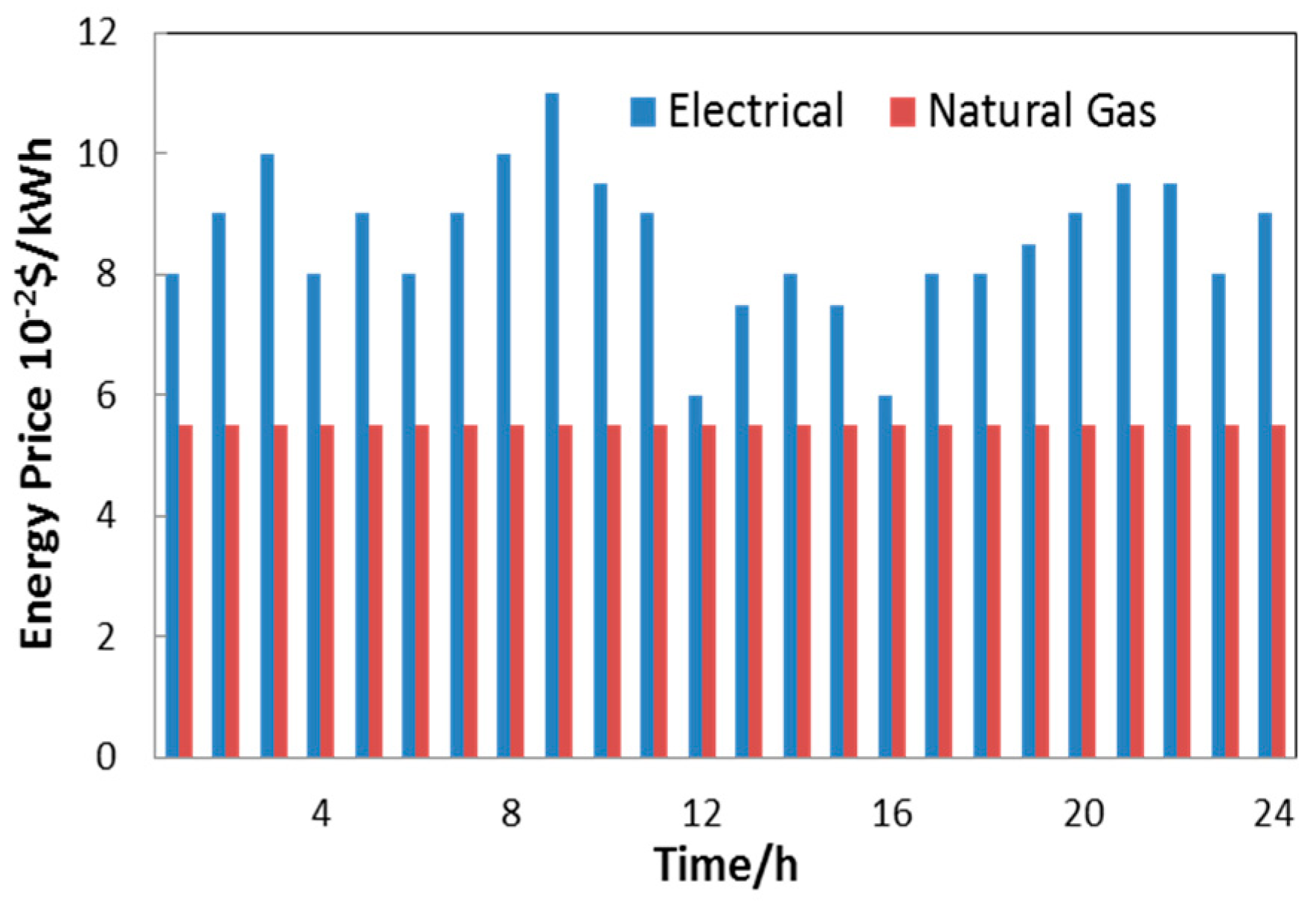

3.2.5. Energy Prices

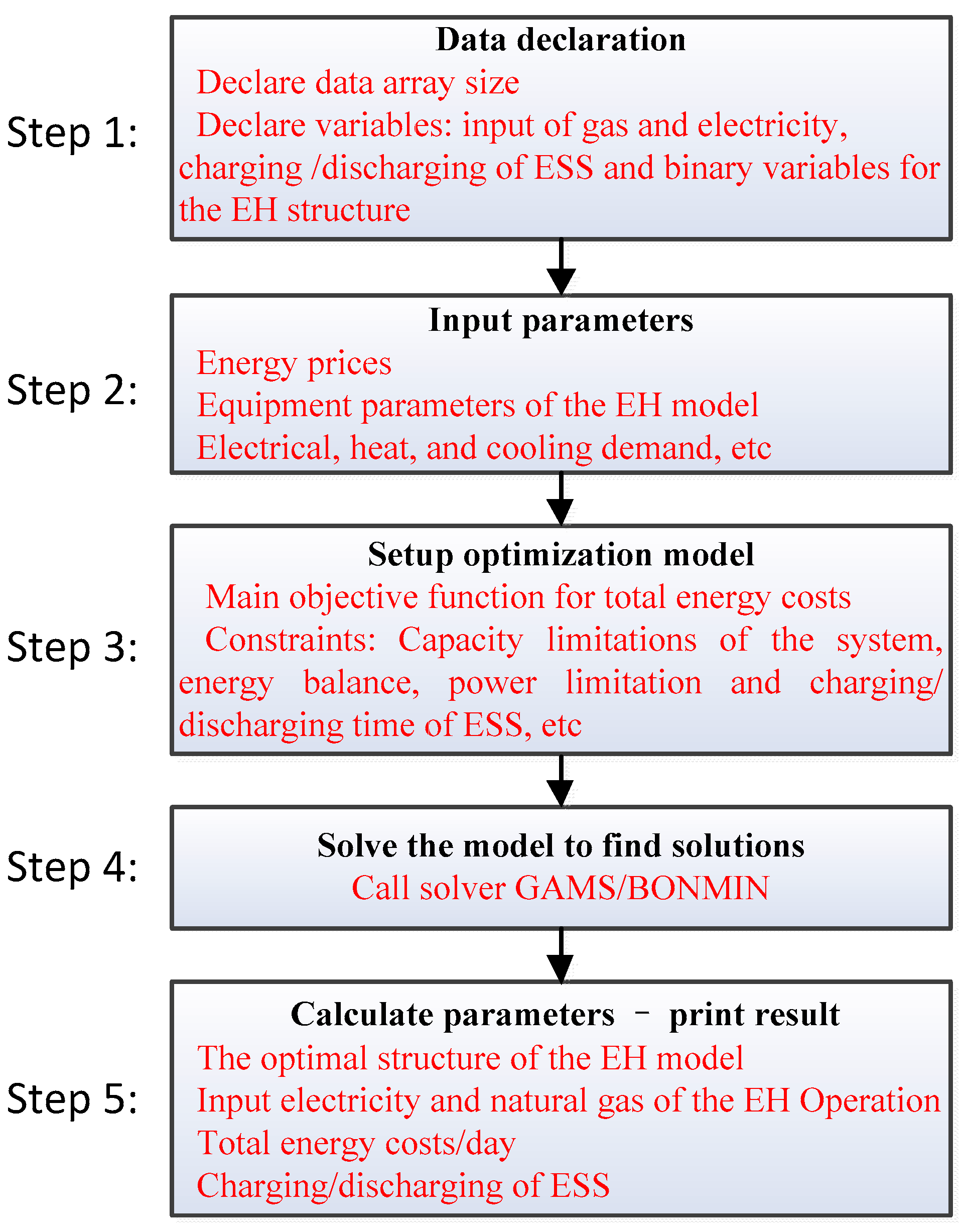

4. Simulation Result

4.1. Hub Data Description

4.1.1. Electricity, Heat, and Cooling Demand

4.1.2. Energy Price

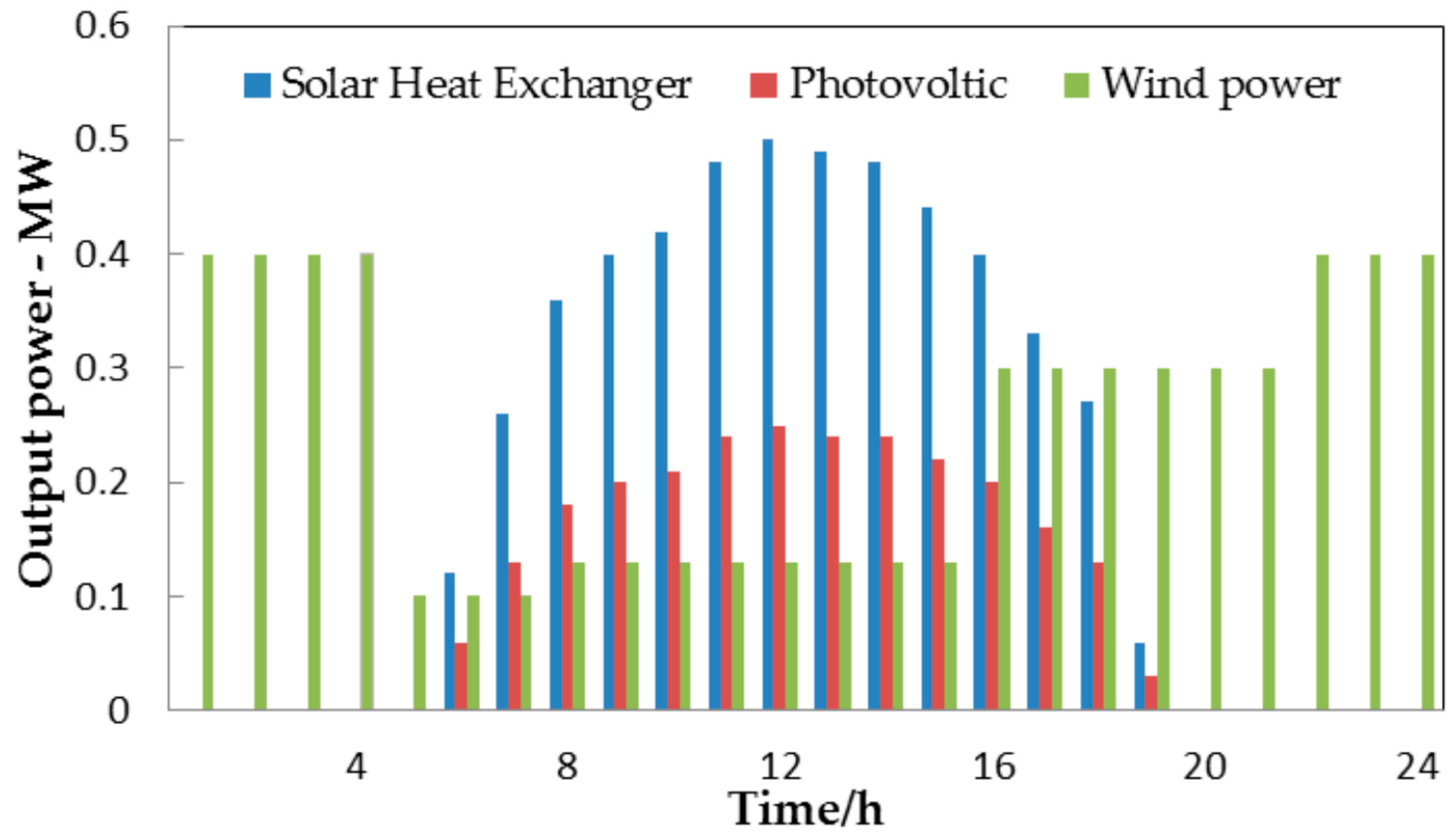

4.1.3. Solar and Wind Power

4.1.4. Device Parameters and System Capacity Limitations

4.2. Calculation Result

4.3. Result Discussions

- (1)

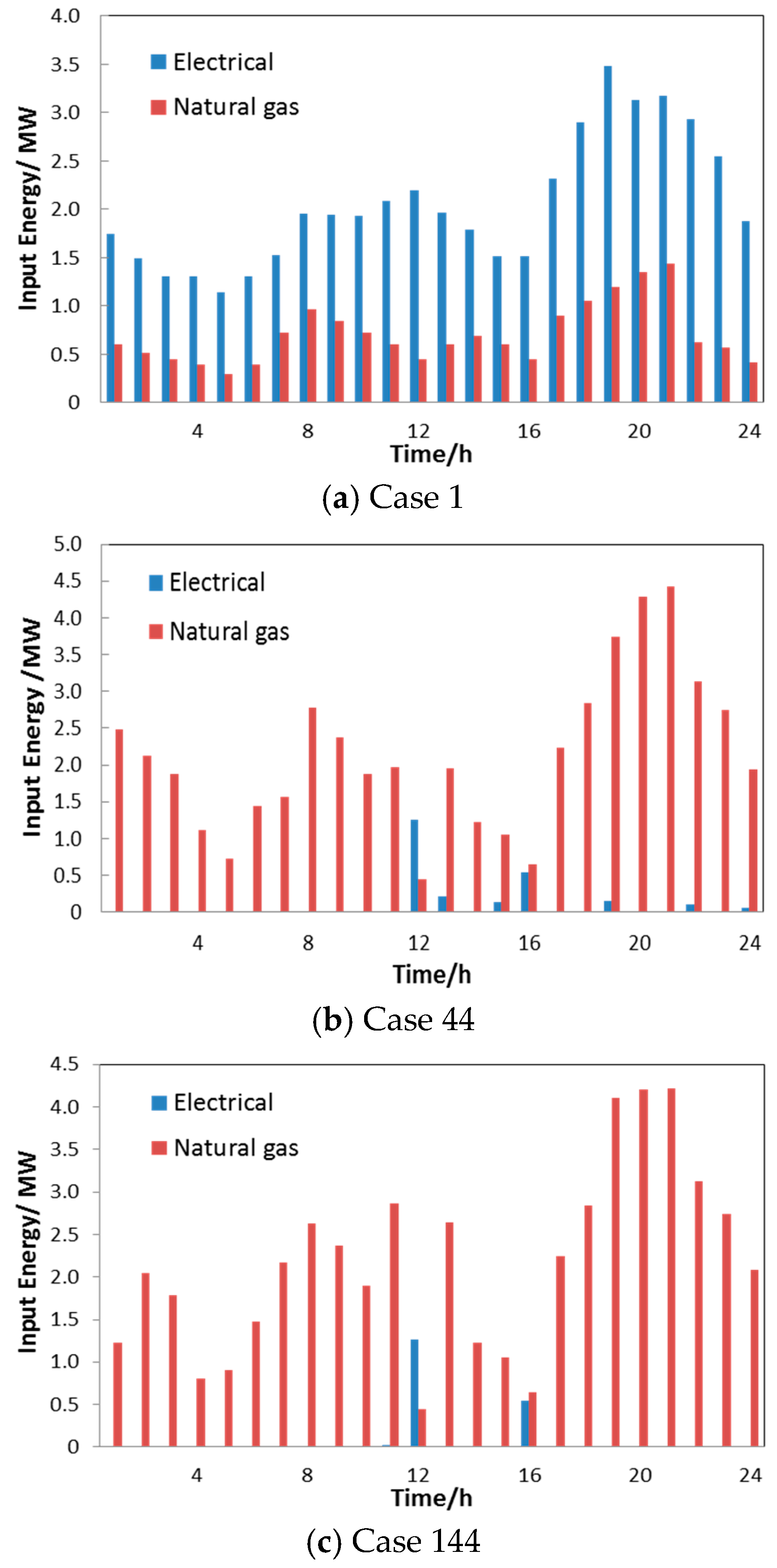

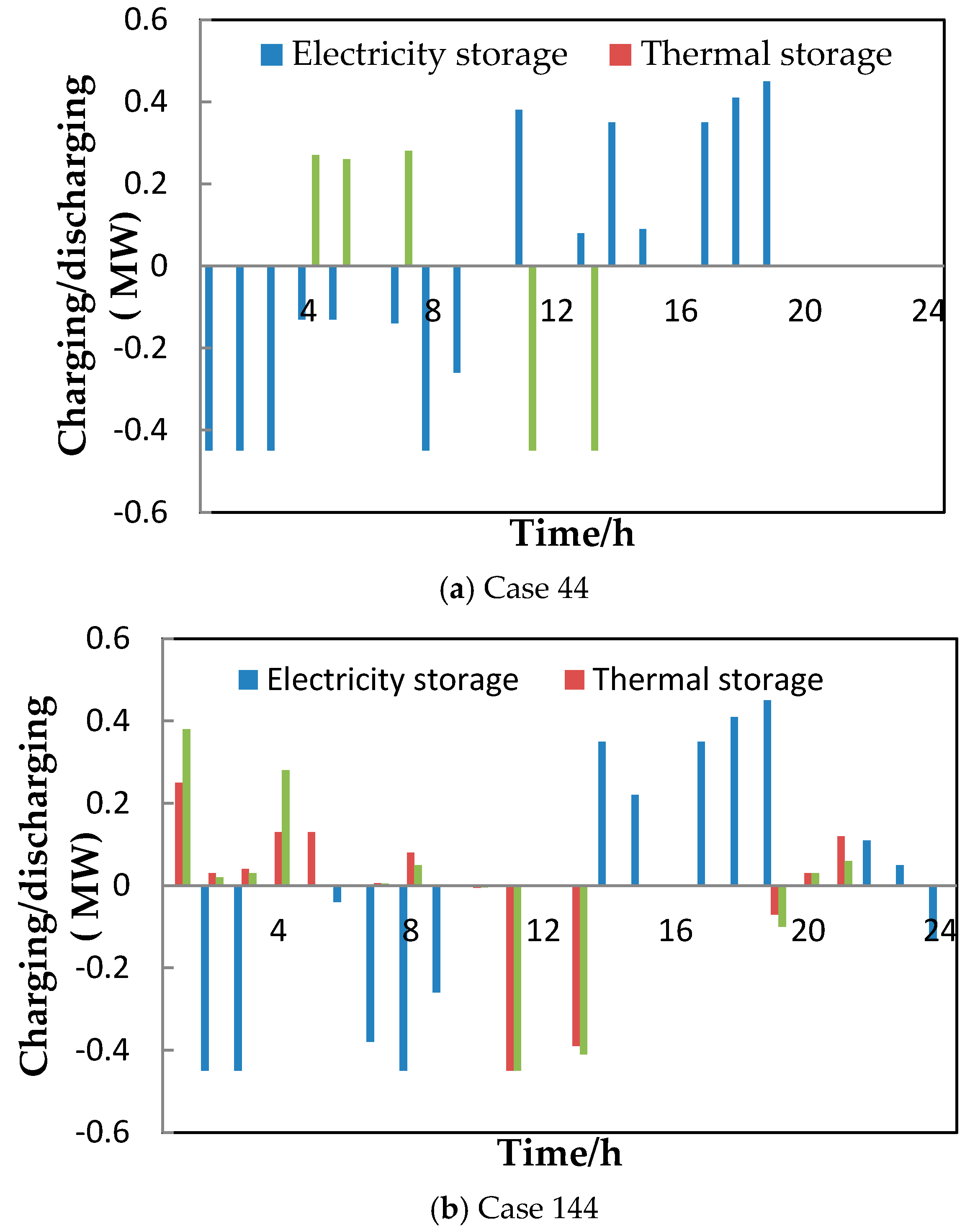

- The solution of the optimization problem for both optimums in hub structure and operation, associated with binary variables which indicate whether or not devices are involved in the various structured operating scenarios, has given accurate results. The optimal operating model and Case 44 have the same structure and total cost purchased from the system.

- (2)

- The computational results of 144 different structured comparisons in the operating scenarios have highlighted the model structure’s role and impact on the optimal operation efficiency problem characterized in the form of an economic indicator: total energy cost per day (Table A1). Case 44 has critically the lowest daily energy cost ($2968) in contrast to Case 1, which owns the highest energy cost of up to $5136. The difference of the total energy costs between the two scenarios is shown in Table 4.

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Case- i | T | MT | GB | EHe | AC | ACh | DER | ESS | Total Energy Cost ($/day) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| PV/ PW/ SHE | ES | TS | IS | ||||||||

| Output | Electricity | Electricity & Heat | Heat | Heat | Cooling | Cooling | Electricity & Heat | Electricity | Heat | Cooling | |

| Case 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 5136 |

| Case 2 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 4239 |

| Case 3 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 5081 |

| Case 4 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 4188 |

| Case 5 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 5100 |

| Case 6 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 4192 |

| Case 7 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 5058 |

| Case 8 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 0 | 4135 |

| Case 9 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 5101 |

| Case 10 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 4177 |

| Case 11 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 5029 |

| Case 12 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 4173 |

| Case 13 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 4973 |

| Case 14 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 4124 |

| Case 15 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 4979 |

| Case 16 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 4066 |

| Case 17 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 3912 |

| Case 18 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 3039 |

| Case 19 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 3849 |

| Case 20 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 2978 |

| Case 21 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 3870 |

| Case 22 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 2986 |

| Case 23 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 3834 |

| Case 24 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 2956 |

| Case 25 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 3856 |

| Case 26 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 2987 |

| Case 27 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 3606 |

| Case 28 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 2965 |

| Case 29 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 3855 |

| Case 30 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 2980 |

| Case 31 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 3842 |

| Case 32 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 2962 |

| Case 33 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 3906 |

| Case 34 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 3025 |

| Case 35 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 3855 |

| Case 36 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 2975 |

| Case 37 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 3867 |

| Case 38 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 2986 |

| Case 39 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 3836 |

| Case 40 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 2957 |

| Case 41 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 3230 |

| Case 42 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 2977 |

| Case 43 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 3597 |

| Case 44 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 2968 |

| Case 45 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 3858 |

| Case 46 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 2982 |

| Case 47 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 3854 |

| Case 48 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 2958 |

| Case 49 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 5136 |

| Case 50 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 4239 |

| Case 51 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 5105 |

| Case 52 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 4207 |

| Case 53 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 5090 |

| Case 54 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 4090 |

| Case 55 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 5042 |

| Case 56 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 4136 |

| Case 57 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 5073 |

| Case 58 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 4177 |

| Case 59 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 5018 |

| Case 60 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 4125 |

| Case 61 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 5033 |

| Case 62 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 4121 |

| Case 63 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 4996 |

| Case 64 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 4080 |

| Case 65 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 3910 |

| Case 66 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 3035 |

| Case 67 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 3848 |

| Case 68 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 2978 |

| Case 69 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 3884 |

| Case 70 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 2993 |

| Case 71 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 3833 |

| Case 72 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 2974 |

| Case 73 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 3875 |

| Case 74 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 3006 |

| Case 75 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 3840 |

| Case 76 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 2988 |

| Case 77 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 1 | 3846 |

| Case 78 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 2992 |

| Case 79 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 3383 |

| Case 80 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 2978 |

| Case 81 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 3906 |

| Case 82 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 3025 |

| Case 83 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 3855 |

| Case 84 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 2979 |

| Case 85 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 3862 |

| Case 86 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 2989 |

| Case 87 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 3838 |

| Case 88 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 2996 |

| Case 89 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 3878 |

| Case 90 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 3016 |

| Case 91 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 3835 |

| Case 92 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 3835 |

| Case 93 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 2974 |

| Case 94 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 3848 |

| Case 95 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 3818 |

| Case 96 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2976 |

| Case 97 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 5130 |

| Case 98 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 4239 |

| Case 99 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 5081 |

| Case 100 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 4186 |

| Case 101 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 5090 |

| Case 102 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 4222 |

| Case 103 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 5035 |

| Case 104 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 4140 |

| Case 105 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 5073 |

| Case 106 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 4177 |

| Case 107 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 5020 |

| Case 108 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 4123 |

| Case 109 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 5027 |

| Case 110 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 4149 |

| Case 111 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 4973 |

| Case 112 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 4088 |

| Case 113 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 3910 |

| Case 114 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 3035 |

| Case 115 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 3859 |

| Case 116 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 2976 |

| Case 117 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 3888 |

| Case 118 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 2993 |

| Case 119 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 3836 |

| Case 120 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 2980 |

| Case 121 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 3854 |

| Case 122 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 2985 |

| Case 123 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 3836 |

| Case 124 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 2966 |

| Case 125 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 1 | 3832 |

| Case 126 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 2969 |

| Case 127 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 2981 |

| Case 128 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 2967 |

| Case 129 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 5010 |

| Case 130 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 3025 |

| Case 131 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 3854 |

| Case 132 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 2989 |

| Case 133 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 3861 |

| Case 134 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 3003 |

| Case 135 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 3831 |

| Case 136 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 2982 |

| Case 137 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 3852 |

| Case 138 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 2982 |

| Case 139 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 3840 |

| Case 140 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 2997 |

| Case 141 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 3856 |

| Case 142 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 2996 |

| Case 143 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 3841 |

| Case 144 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2975 |

References

- Paudyal, S.; Cañizares, C.A.; Bhattacharya, K. Optimal Operation of Industrial Energy Hubs in Smart Grids. IEEE Trans. Smart Grid 2015, 6, 684–694. [Google Scholar] [CrossRef]

- Erdener, B.C.; Pambour, K.A.; Lavin, R.B.; Dengyz, B. An integrated simulation model for analysing electricity and gas systems. Electr. Power Energy Syst. 2014, 61, 410–420. [Google Scholar] [CrossRef]

- Barmayoon, M.H.; Fotuhi-Firuzabad, M.; Rajabi-Ghahnavieh, A.; Moeini-Aghtaie, M. Energy storage in renewable-based residential energy hubs. IET Gener. Transm. Distrib. 2016, 10, 3127–3134. [Google Scholar] [CrossRef]

- Chen, S.; Wei, Z.; Sun, G.; Cheung, K.W. Multi-Linear Probabilistic Energy Flow Analysis of Integrated Electrical and Natural-Gas Systems. IEEE Trans. Power Syst. 2017, 32, 1970–1979. [Google Scholar] [CrossRef]

- Shahmohammadi, A.; Moradi-Dalvand, M.; Ghasemi, H.; Ghazizadeh, M.S. Optimal Design of Multicarrier Energy Systems Considering Reliability Constraints. IEEE Trans. Power Deliv. 2015, 30, 878–886. [Google Scholar] [CrossRef]

- Moeini-Aghtaie, M.; Abbaspour, A.; Fotuhi-Firuzabad, M.; Hajipour, E. A decomposed solution to multiple-energy carriers optimal power flow. IEEE Trans. Power Syst. 2014, 29, 707–716. [Google Scholar] [CrossRef]

- Brahman, F.; Honarmand, M.; Jadid, S. Optimal electrical and thermal energy management of a residential energy hub, integrating demand response and energy storage system. Energy Buil. 2015, 90, 65–75. [Google Scholar] [CrossRef]

- Bozchalui, M.C.; Hashmi, S.A.; Hassen, H.; Canizares, C.A.; Bhattacharya, K. Optimal operation of residential energy hubs in smart grids. IEEE Trans. Smart Grid 2012, 3, 1755–1766. [Google Scholar] [CrossRef]

- Rastegar, M.; Fotuhi-Firuzabad, M.; Lehtonen, M. Home load management in a residential energy hub. Electr. Power Syst. Res. 2015, 119, 322–328. [Google Scholar] [CrossRef]

- Bozchalui, M.C.; Canizares, C.A.; Bhattacharya, K. Optimal energy management of greenhouses in smart grids. IEEE Trans. Smart Grid 2014, 6, 827–835. [Google Scholar] [CrossRef]

- Ha, T.T.; Zhang, Y.J.; Huang, J.A.; Thang, V.V. Energy hub modeling for minimal energy usage cost in residential areas. In Proceedings of the 2016 IEEE International Conference on Power and Renewable Energy (ICPRE), Shanghai, China, 21–23 October 2016; pp. 659–663. [Google Scholar]

- Parisio, A.; Del, V.C.; Vaccaro, A. A robust optimization approach to energy hub management. Int. J. Electr. Power Energy Syst. 2012, 42, 98–104. [Google Scholar] [CrossRef]

- Rastegar, M.; Fotuhi-Firuzabad, M.; Zareipour, H.; Moeini-Aghtaieh, M. A probabilistic energy management scheme for renewable-based residential energy hubs. IEEE Trans. Smart Grid 2017, 8, 2217–2227. [Google Scholar] [CrossRef]

- Ha, T.T.; Zhang, Y.J.; Thang, V.V.; Huang, J.A. Energy hub modeling to minimize residential energy costs considering solar energy and BESS. J. Mod. Power Syst. Clean Energy 2017, 5, 389–399. [Google Scholar] [CrossRef]

- Pazouki, S.; Mahmoud-Reza, H.; Javad, O. Effect of Wind Turbine, Solar Cells and Storages in Short Term Operation of Coupled Electricity and Gas Infrastructures in Different Climates. Int. J. Smart Electr. Eng. 2013, 2, 159–165. [Google Scholar]

- Shahmohammadi, A.; Dalvand, M.M.; Ghazizadeh, M.S. Energy hubs’ structural and operational linear optimization with energy storage elements. In Proceedings of the 2011 2nd International Conference on Electric Power and Energy Conversion Systems (EPECS), Sharjah, UAE, 15–17 November 2011; pp. 1–6. [Google Scholar]

- Ha, T.T.; Zhang, Y.J.; Hao, J.B.; Pham, T.H.A. Optimal Operation of Energy Hub with Different Structures for Minimal Energy Usage Cost. In Proceedings of the 2017 2nd International Conference on Power and Renewable Energy, Chengdu, China, 20–23 September 2017; pp. 31–36. [Google Scholar]

- Fan, H.; Chen, Q.; Liu, W.; Li, J.; Chen, Y. Optimal scheduling for energy hub in power markets. In Proceedings of the 2016 IEEE Innovative Smart Grid Technologies-Asia, Melbourne, VIC, Australia, 28 November–1 December 2016; pp. 127–131. [Google Scholar]

- Mohammadi, M.; Noorollahi, Y.; Mohammadiivatloo, B.; Yousefi, H. Energy hub: From a model to a concept–A review. Renew. Sustain. Energy Rev. 2017, 80, 1512–1527. [Google Scholar] [CrossRef]

- Pazouki, S.; Haghifam, M.R.; Moser, A. Uncertainty modeling in optimal operation of energy hub in presence of wind, storage and demand response. Int. J. Electr. Power Energy Syst. 2014, 61, 335–345. [Google Scholar] [CrossRef]

- Gas Commodity Fact Sheet for Maryland Public Service Commission. 2014. Available online: http://www.psc.state.md.us/gas/ (accessed on 20 Otcober 2017).

- A Guide to Electricity Charges Market Participants. Available online: http://www.ieso.caimoweb/role/wholesaleCharges.asp (accessed on 10 October 2017).

- Pazouki, S.; Haghifam, M.R. Scheduling of energy hubs including CCHP, solar and energy storages in different climates. In Proceedings of the 2015 20th Conference on Electrical Power Distribution Networks Conference (EPDC), Zahedan, Iran, 28–29 April 2015; pp. 101–106. [Google Scholar]

- Geidl, M.; Andersson, G. Optimal Coupling of Energy Infrastructures. In Proceedings of the 2007 IEEE Lausanne Power Tech, Lausanne, Switzerland, 1–5 July 2007; pp. 1398–1403. [Google Scholar]

- Houwing, M.; Negenborn, R.R.; De Schutter, B. Demand Response with Micro-CHP Systems. Proc. IEEE 2011, 99, 200–213. [Google Scholar] [CrossRef]

- Li, J.H.; Wang, S.; Liu, Y.; Fang, J.K. A coordinated dispatch method with pumped-storage and battery-storage for compensating the variation of wind power. Prot. Control Mod. Power Syst. 2018, 3, 2. [Google Scholar] [CrossRef]

- Brooke, A.; Kendrick, D.; Meeraus, A. GAMS. A User’s Guide; AMS Development Corp: Washington, DC, USA, 2003. [Google Scholar]

| 0.45 (MW) | 0.45 (MW) | 0.05 (MW) | 4.2 MWh | 0.02 | 0.93 |

| 0.45 (MW) | 0.45 (MW) | 0.05 (MW) | 4.2 MWh | 0.05 MW | 0.96 |

| 0.45 (MW) | 0.45 (MW) | 0.05 (MW) | 4.2 MWh | 0.9 | 0.95 |

| 0.95 | 0.4 | 0.9 | 0.5 |

| 0.9 | 0.88 | 5 MW | 5 MW |

| Binary Variables | The Optimal Operating Structure (Case 44) | The Highest Operating Cost Scenario (Case 1) | The Full Structure Scenario (Case 144) |

|---|---|---|---|

| 1 | 1 | 1 | |

| 1 | 1 | 1 | |

| 1 | 1 | 1 | |

| 0 | 0 | 1 | |

| 1 | 1 | 1 | |

| 1 | 0 | 1 | |

| 1 | 0 | 1 | |

| 1 | 0 | 1 | |

| 1 | 0 | 1 | |

| 1 | 0 | 1 | |

| 0 | 0 | 1 | |

| 1 | 0 | 1 | |

| Total cost ($/day) | 2968 | 5136 | 2975 |

| Calculation Results | CASE 1 | CASE 44 | ΔC |

|---|---|---|---|

| Total energy costs ($/day) | 5136 | 2968 | 2168 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ha, T.T.; Zhang, Y.; Hao, J.; Thang, V.V.; Li, C.; Cai, Z. Energy Hub’s Structural and Operational Optimization for Minimal Energy Usage Costs in Energy Systems. Energies 2018, 11, 707. https://doi.org/10.3390/en11040707

Ha TT, Zhang Y, Hao J, Thang VV, Li C, Cai Z. Energy Hub’s Structural and Operational Optimization for Minimal Energy Usage Costs in Energy Systems. Energies. 2018; 11(4):707. https://doi.org/10.3390/en11040707

Chicago/Turabian StyleHa, Thanh Tung, Yongjun Zhang, Jinbao Hao, V. V. Thang, Canbing Li, and Zexiang Cai. 2018. "Energy Hub’s Structural and Operational Optimization for Minimal Energy Usage Costs in Energy Systems" Energies 11, no. 4: 707. https://doi.org/10.3390/en11040707