1. Introduction

With the increasing interest in energy conservation and the efficient use of energy around the world, the need for the development and use of new and renewable energy sources has increased rapidly, and related research and applications have been actively conducted. Among the new and renewable energy sources, systems using geothermal sources are attracting considerable attention. This is because while there is a lack of continuity of heat sources for systems using other heat sources, a stable supply of heat and efficient operation throughout the year are possible if geothermal energy is used as a heat source. Although geothermal energy shows excellent efficiency as a heat source for cooling and heating, geothermal heat pump systems have mainly been installed in public buildings, and systems with low capacity have mostly been installed because of the high initial investment costs and difficulty in construction. On the other hand, since regulations on new and renewable energy installation institutions for public buildings were implemented in Korea in 2004, installations in non-public buildings and public institutions have also increased.

While the installation of geothermal heat pump systems is increasing, the systems are not being operated efficiently. This results in a waste of energy due to the inefficient utilization after the installation of systems with more than the necessary capacity in conformity with the standards set forth in the relevant laws and regulations regarding the mandatory supply and installation. The geothermal heat pump system is generally responsible for a number of indoor units and is operated mostly under partial load conditions. On the other hand, most of the geothermal circulation pumps in geothermal heat pump systems are operated at a constant rate and a constant flow rate is supplied continuously, regardless of the load. As a result, the performance of the geothermal heat pump system is decreased. This paper proposes a variable water flow rate control method for a geothermal circulation pump to improve the efficiency of the geothermal heat pump system.

As the interest in geothermal heat pump systems has increased, various studies have been conducted on these systems [

1,

2,

3,

4,

5,

6,

7,

8]. Moreover, there have been several studies related to the cooling and heating performance evaluation of geothermal heat pump systems. Sohn [

9] and Kwon [

10] assumed that a geothermal heat pump system was installed in an actual commercial office building instead of a conventional heating and cooling system, and analyzed the cooling and heating performance of the geothermal system according to the time of the year through a simulation. They compared the actual energy consumption of the existing system and the estimated energy consumption of the geothermal system [

9]. Nam conducted a system performance analysis through dynamic energy simulation of the heat pump system using solar and geothermal energy [

10]. Hwang et al. [

11] and Ozgener [

12,

13] conducted research to verify the feasibility of a hybrid system and the performance of the system through the experimental performance evaluation of the actual system.

In addition, various studies have been conducted to improve the performance of geothermal heat pump systems. Studies of the efficiency and optimal design of the geothermal heat exchanger, including studies by Park [

14] and Lee [

15], are being conducted. Park measured the changes in the ground temperature according to the burial depth for a geothermal heat pump system actually installed in a residential building, and analyzed the performance of the heat exchanger and cooling performance of the heat pump according to the ground temperature variation [

14]. Lee derived the optimal design method through an analysis of the design load and the actual usage data of the geothermal system with the main focus on electricity consumption and heating and cooling energy consumption of the building studied [

15].

Many studies have been conducted on the performance improvement of the heat pump system through integrated design with other heat source systems and complex operation in relation to the cause of the decrease in the efficiency of the geothermal heat pump system. In a study by Girard, a performance analysis was conducted by simulating a hybrid operation geothermal heat pump system and a general geothermal heat pump system to improve the performance of the hybrid operation of solar and geothermal heat pump systems [

16]. The problems of the operation of a geothermal source heat pump system were derived through an investigation of the building where the system was installed, a complex operation method with an absorption chiller-heater was then proposed to increase the share ratio of the geothermal heat pump system, and the method was evaluated through a simulation [

17]. Jung proposed an operation method of adding the coefficient of the performance to the operation points, which makes it possible to maximize the equipment efficiency of the geothermal heat pump system and take into account the equipment performance. Jung also suggested an operation method to maximize the use of the geothermal heat pump system through an integrated design with an existing heat source and improve energy efficiency, and conducted an evaluation of the method through a simulation [

18].

Although many studies on efficient design methods of an underground heat exchanger are being conducted, there has been a lack of research on the variable flow rate control of geothermal water and the operations utilizing it. Jung analyzed the pump energy consumption of a geothermal heat pump system according to the changes in the geothermal water flow rate of the geothermal heat pump system and the COP (Coefficient of Performance) of the heat pump unit [

19]. Song reported a variable flow rate control method of the geothermal circulation pump using the source side temperature difference of the geothermal heat pump and validated the application of the method through an empirical study [

20]. This study demonstrated the performance of the variable flow rate control method through a replacement of the circulation pump during the heating operation and verified the effectiveness for COP improvement of the geothermal heat pump system. On the other hand, the energy-saving effect and cooling performance have not been evaluated.

Therefore, this paper suggests a variable water flow rate control method of a geothermal circulation pump to improve the efficiency and energy savings of the geothermal heat pump system during the cooling operation. For this purpose, the proposed variable water flow rate control method was applied to the target building using the TRNSYS (Transient System Simulation Tool) program, and comparative analysis with the existing operation method was performed. The analyses of the indoor thermal environment, energy consumption of the geothermal circulation pump, and energy consumption of the geothermal heat pump system was then performed.

4. Modeling Dynamic Simulation

Transient Systems Simulations (TRNSYS) is a detailed building energy analysis program. The program was written for long-term cost reduction verification through a dynamic simulation of the solar thermal system developed by researchers at the University of Wisconsin in 1975, and is currently being used as the energy simulation and building energy analysis program involving HVAC (Heating, Ventilation, Air Conditioning) equipment, cogeneration system, and control system, including new and renewable energy in Europe and other countries around the world [

22,

23,

24].

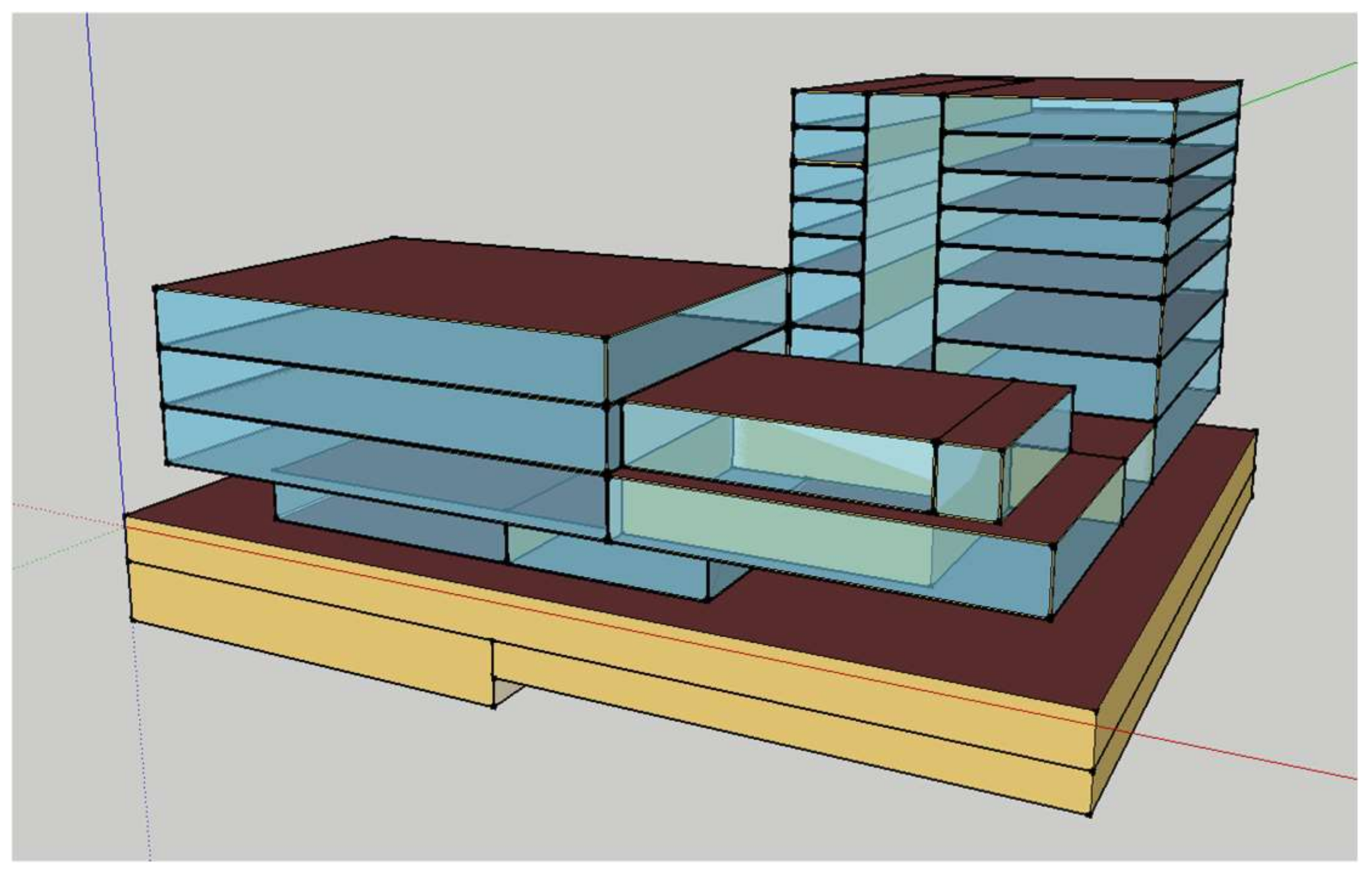

TRNSYS is a program suitable for detailed analysis of the systems that change over time. When the TRNSYS program is used, the user performs the simulation by connecting the components to each other. Components are being developed around the world and can be added after coding using the FORTRAN language. In this respect, TRNSYS has an advantage in that it is convenient when the user selects the system. The modeling of the target building was conducted using the Google Sketch Up program, as shown in

Figure 8.

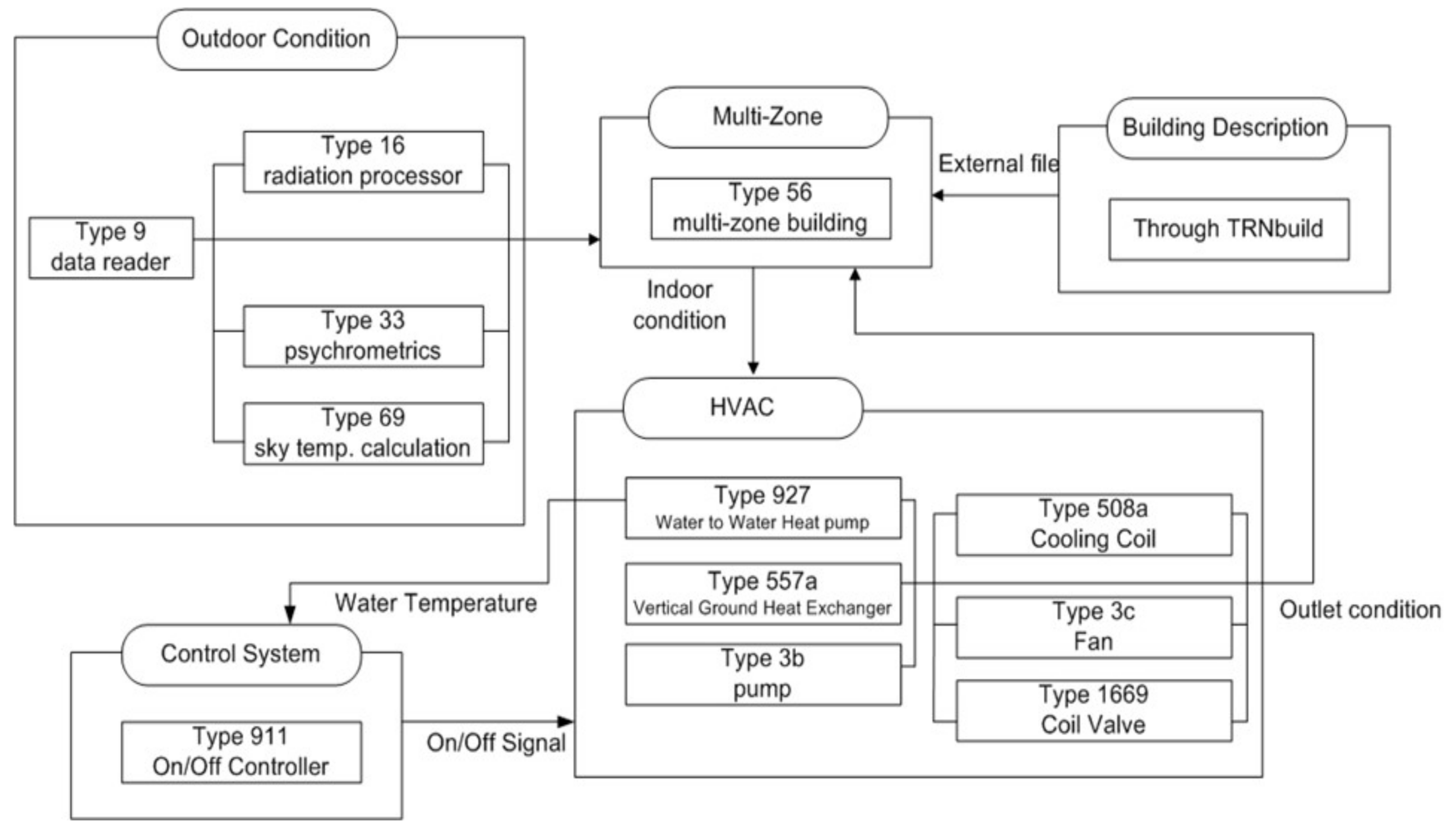

Table 4 lists the indoor load, temperature, and humidity conditions of the representative room used in the simulation. The following was performed to implement the geothermal heat pump system: the Type 927 water to water heat pump was used for the geothermal heat pump; the vertical heat exchanger Type 557a was used for the geothermal heat exchanger; and Type 3b was used for the geothermal circulation pump and cold water supply pump.

The existing operation method of the geothermal heat pump system of the target building is a constant water flow rate control based on the cold and hot water supply temperatures. This was selected as CASE 1, and the method reflecting the variable water flow rate control method of geothermal water circulation to improve the efficiency of the geothermal heat pump system was selected as CASE 2.

Table 5 summarizes the simulation CASE.

- (1)

Existing constant water flow rate control method (CASE 1)

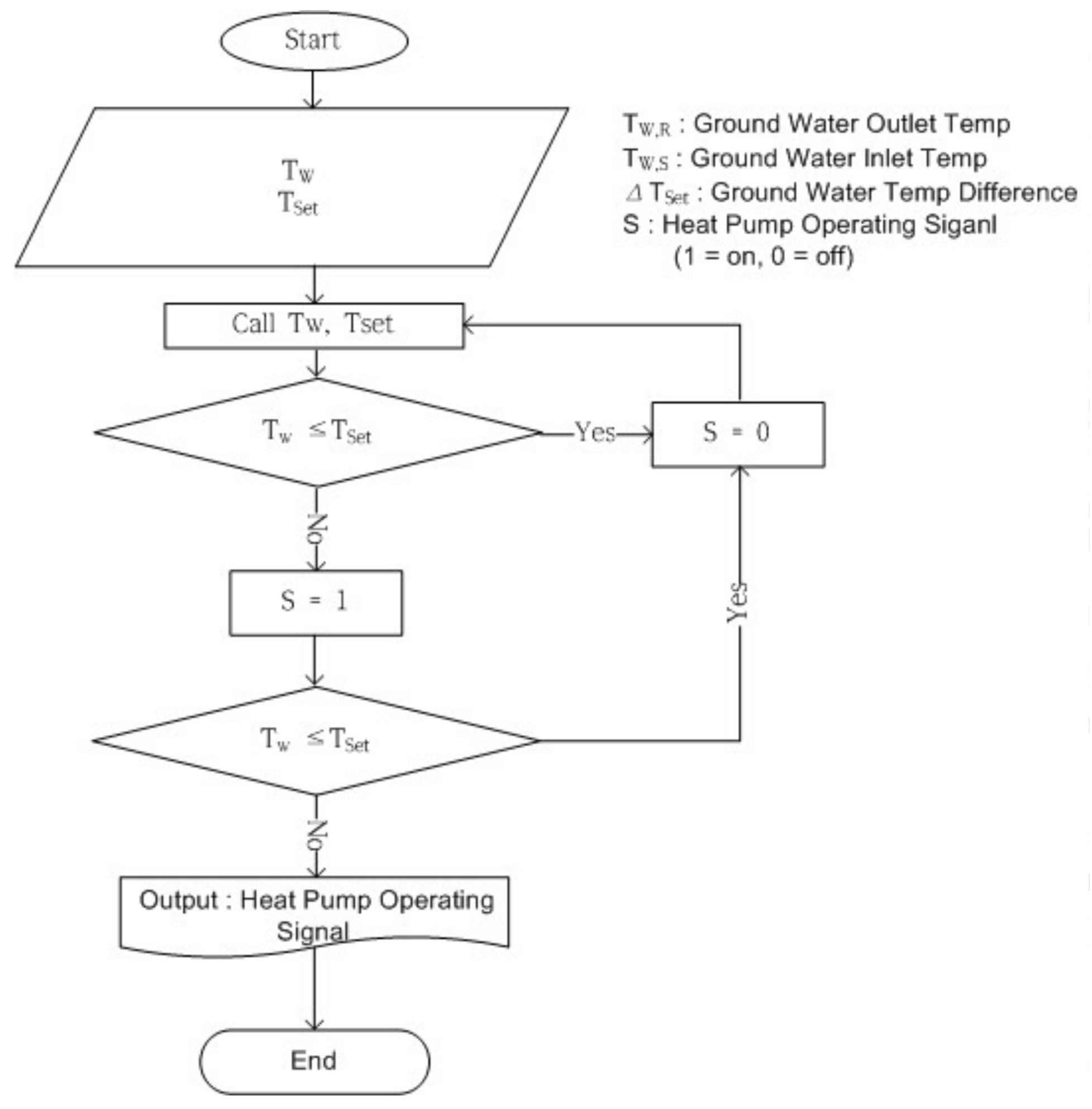

Figure 9 shows the simulation flow diagram of the operating number control according to the set temperature, which is the existing operation method of the target building. The water-to-water type heat pump Type 927 was used for the heat pump and the vertical heat exchanger Type 557a was used for the underground heat exchanger. Type 3b was used for the underground circulation pump and cold water supply pump. To control the set temperature of each geothermal heat pump, the set temperature of the heat pump was used as the controller input value and the on/off controller Type 911 was used.

- (2)

Proposed variable water flow rate control method (CASE 2)

For the variable water flow rate control method, the geothermal water temperature difference between the inlet and outlet was changed to the control point. The proportional controller Type 1669 was used to control the flow rate based on the circulation pump temperature difference. The equations were used to calculate the temperature difference and reflect the indoor temperature. The circulation pump was implemented using the variable speed pump Type 110 to analyze geothermal water flow rate control and changes in the pump energy consumption depending on the change in flow rate.

Figure 10 shows the variable water flow rate control method.

5. Results and Discussion

The conventional flow rate control method of the geothermal heat pump system of the target building provides a continuous supply at a constant flow rate regardless of the load by installing a constant speed pump. This method was selected as CASE 1. To improve the efficiency of the geothermal heat pump system, the variable geothermal water flow rate control method was applied, and it was selected as CASE 2.

Table 6 presents a summary of the simulation CASE.

- (1)

Indoor Thermal Environment

The indoor thermal environment when the geothermal water flow rate control of the geothermal heat pump system was applied was analyzed.

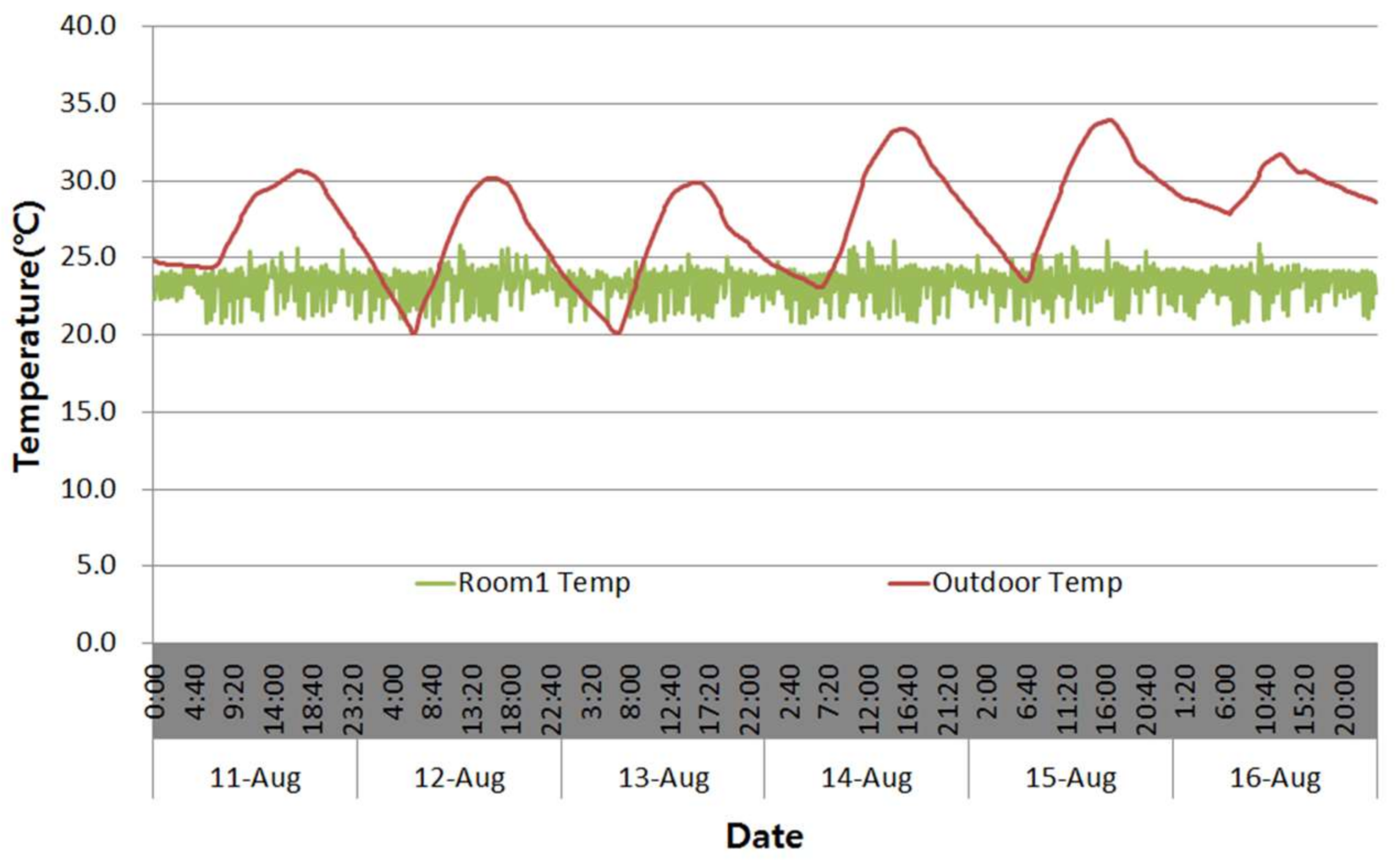

Figure 11 and

Figure 12 show the changes in the indoor temperature according to the CASE. The room temperature was set to 24 °C (±0.5 °C), which the temperature was maintained within the set temperature variation in CASE 1, which was the existing method, and CASE 2, where geothermal water flow rate control was applied.

- (2)

Geothermal Side Temperature

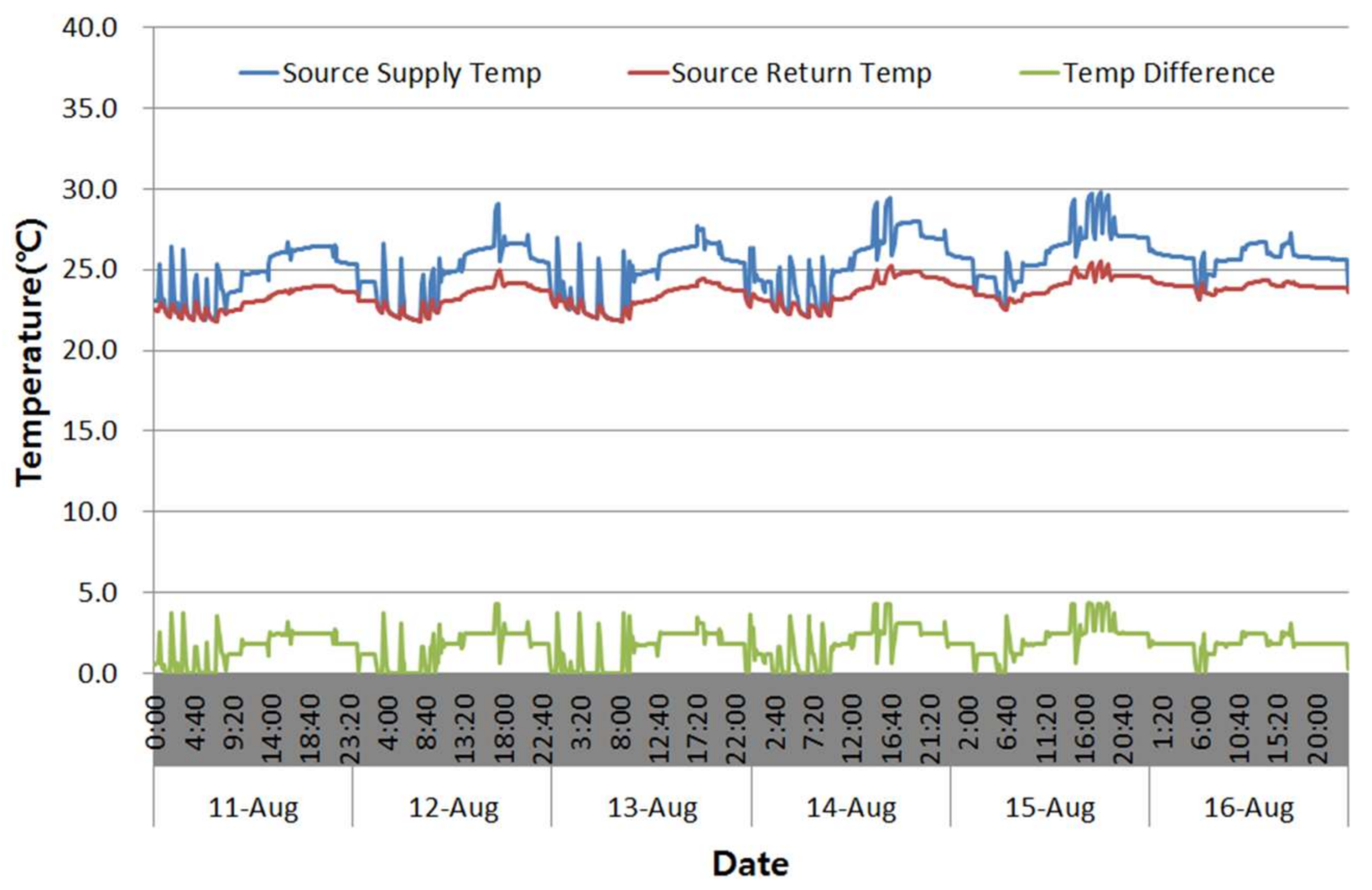

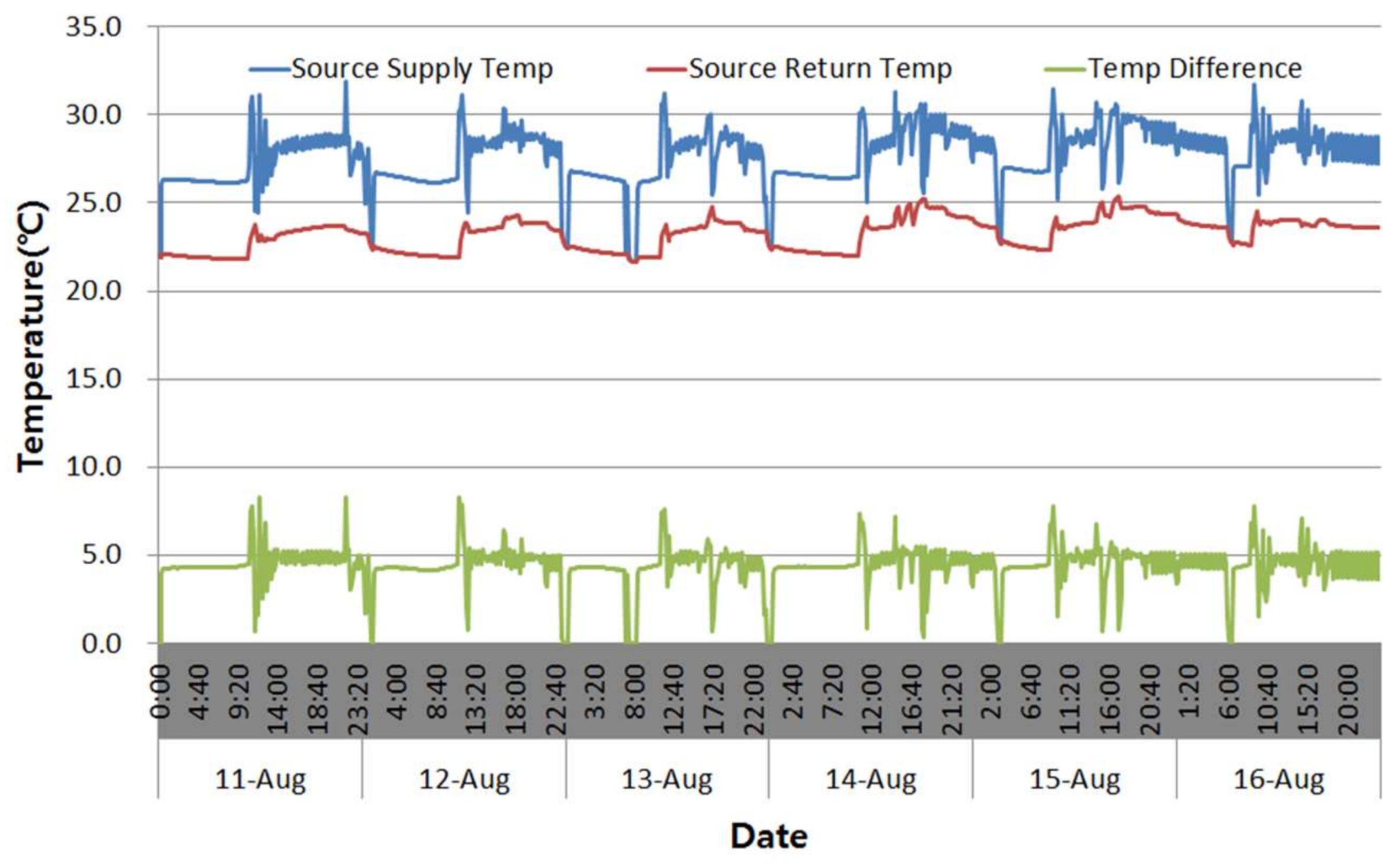

To analyze the geothermal water temperatures of the inlet and outlet of the geothermal heat pump,

Figure 13 and

Figure 14 present the changes in the geothermal water temperatures of the inlet and outlet. In CASE 1, the average temperature difference was approximately 1.7 °C. In CASE 2, because the flow rate was controlled by adjusting the geothermal water temperature difference so that it would be 5 °C (±0.5 °C), an average of approximately 4.3 °C was relatively stable.

- (3)

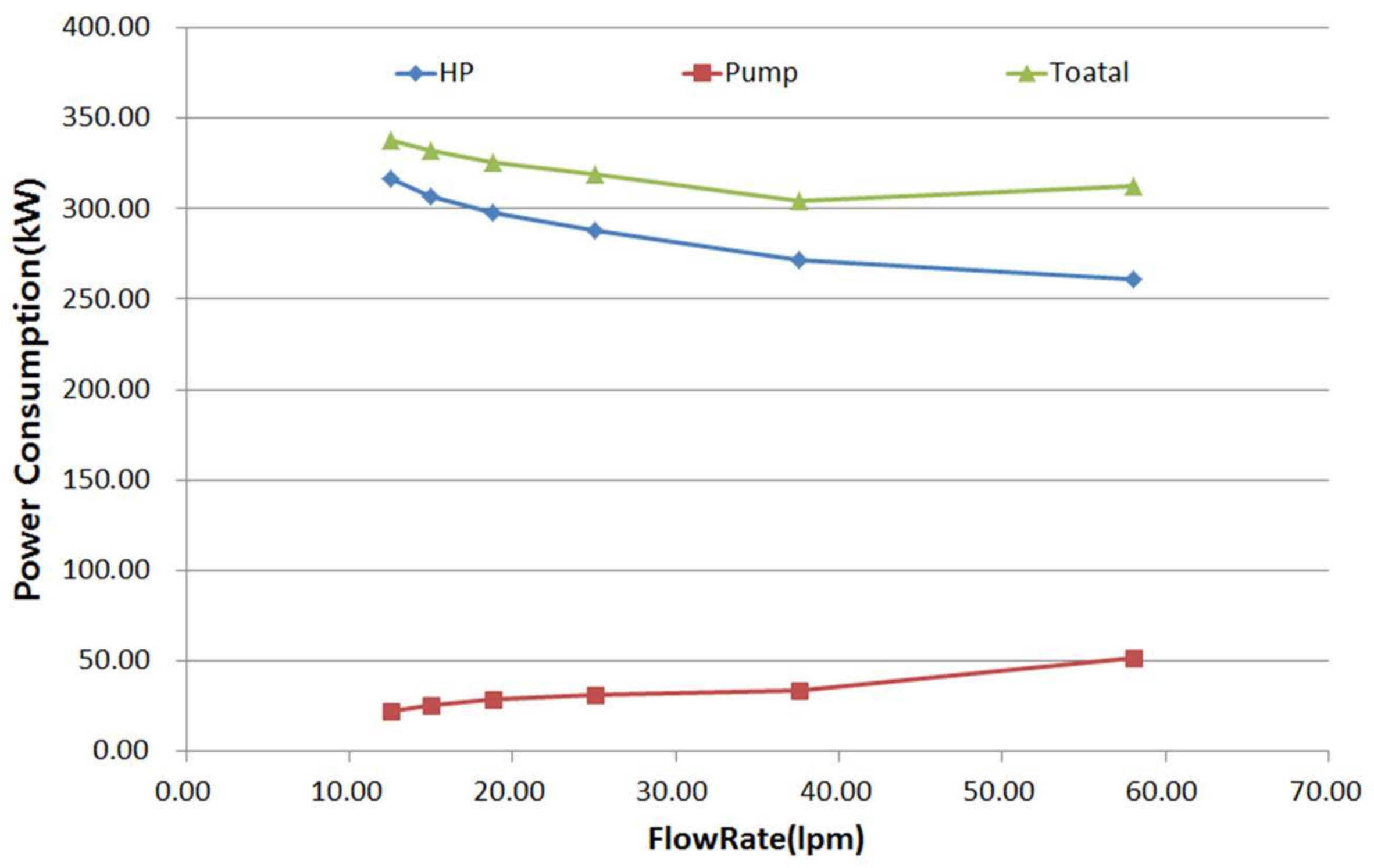

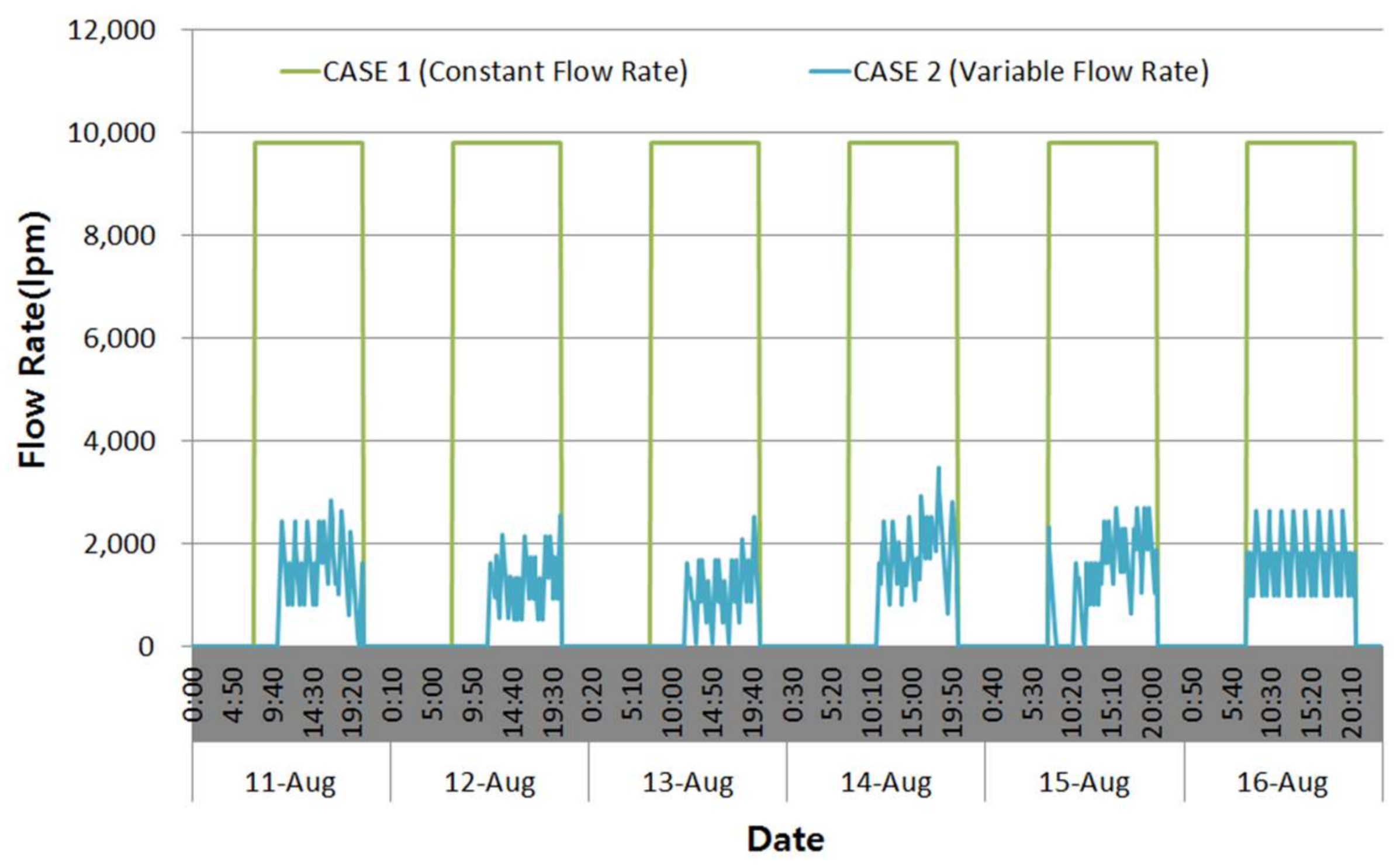

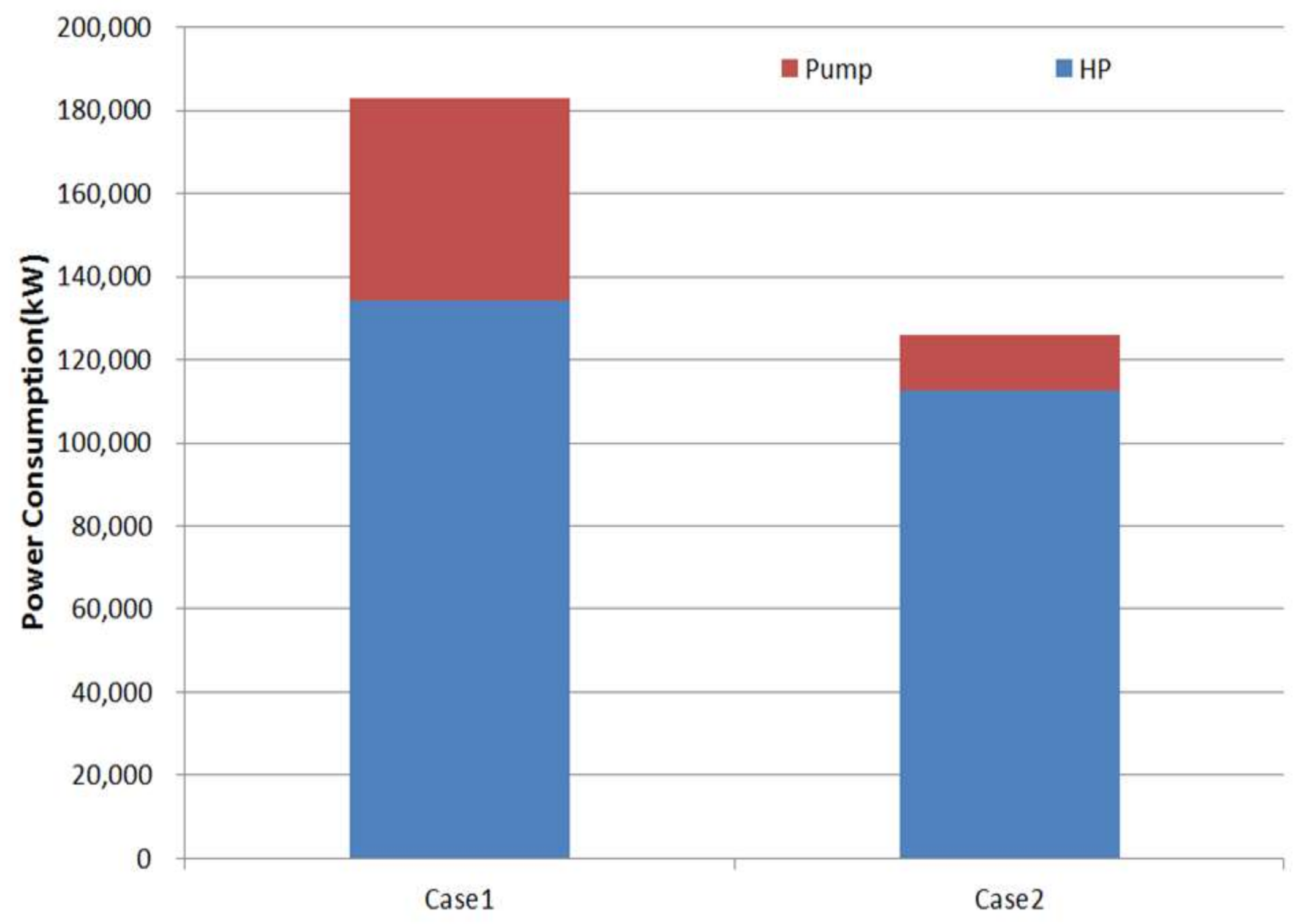

Water Flow rate and Energy Consumption

Figure 15 shows the geothermal water flow rate for each case. The flow rate in the variable flow rate control method is approximately 70% lower than the constant water flow rate method.

Figure 16 shows the heat pump and circulation pump energy consumption for each case to analyze the energy consumption when applying the geothermal water flow rate control method of the geothermal heat pump. The total energy consumption was 182,936 kW for CASE 1, in which the constant flow rate control method of the target building was used, and 125,919 kW for CASE 2, in which the geothermal circulation water flow control method was applied. The energy consumption of CASE 2 was 32% lower than CASE 1, and the energy consumption of the circulation pump is approximately 70% lower.

Table 7 lists detailed energy consumption values of the heat pump and circulation pump for each case.

6. Conclusions

This study examined the operation of the current problems of geothermal heat pump system and proposed a variable water flow rate control method of the circulation pump to improve the efficiency of the geothermal heat pump system and save energy during cooling operations. The proposed operation method was compared with the existing operation method using a simulation. The results of this study can be summarized as follows:

- (1)

After selecting the target building where the geothermal heat pump system was installed, the operation method of the heat pump system was investigated. The geothermal heat pump system of the target building was operated by on-off control according to the set temperature to adjust the load side return water temperature so that it can match the set temperature, and a constant flow rate was supplied continuously due to the constant speed pump of the geothermal circulation pump. If this operation method is used, the return water temperature of geothermal water circulation is adjusted, irrespective of the load. Therefore, unnecessary energy is consumed due to the continuous operation of the circulation pump. A variable flow rate control method of geothermal water circulation was proposed to solve this problem.

- (2)

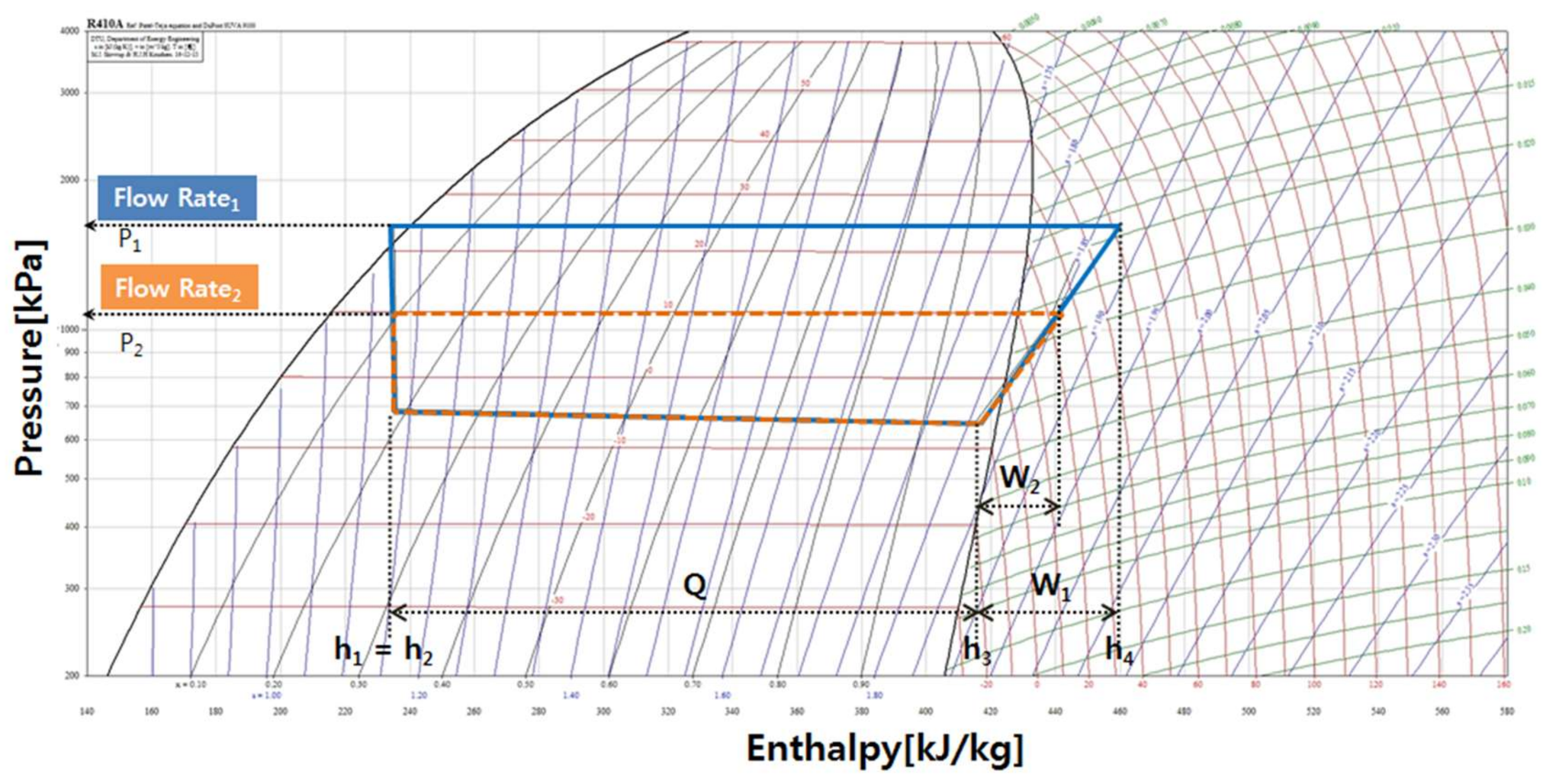

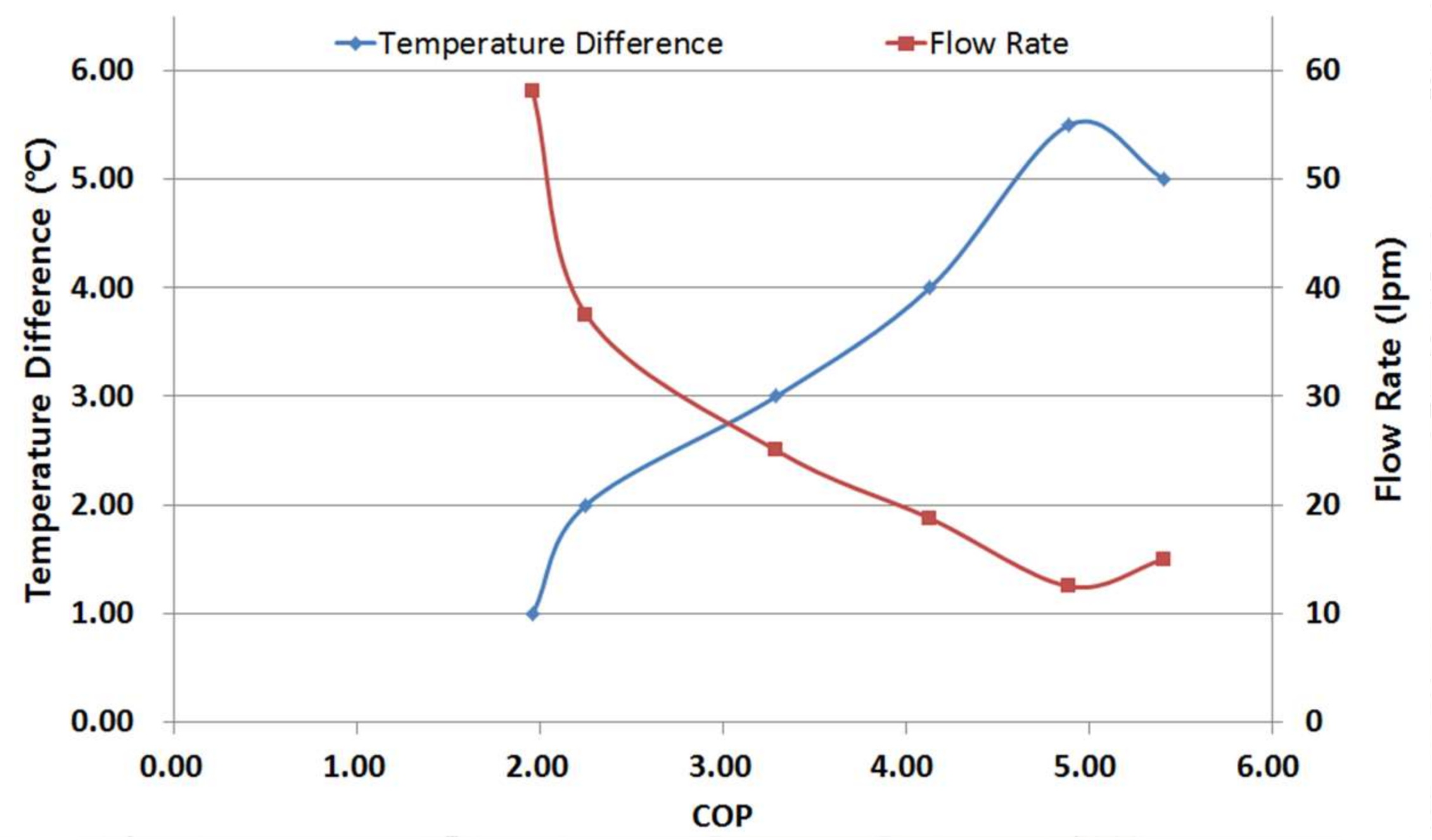

To control the geothermal water flow rate to reduce the energy consumption and improve the efficiency of the geothermal heat pump, this paper suggested a flow rate control method of the circulation pump by geothermal water temperature difference. An analysis of the COP according to the geothermal water temperature difference and an analysis of energy consumption of the heat pump and circulation pump according to the flow rate showed that the energy consumption was lowest and the efficiency was highest when the temperature difference was 5 °C.

- (3)

A variable flow rate control method of the heat pump system was proposed and the proposed variable flow rate control method was evaluated by a comparison with the existing constant flow rate control method of the target building. As a result, the total energy consumption was reduced by 57,017 kW compared to the existing flow rate control method and the energy consumption of the circulation pump system was reduced by 35,209 kW, which corresponds to an approximately 70% reduction.

In this study, the flow rate control method was applied and evaluated through simulations. Therefore, there is still a need to evaluate the effect when it is applied to actual buildings. In addition, because the flow control method was applied and evaluated only in summer, it will be necessary to apply the operation method in winter. In other words, future studies should apply the proposed flow rate control method to actual buildings and apply and evaluate it in winter to enable efficient control of the geothermal heat pump system.