Mitigation of Hot-Spots in Photovoltaic Systems Using Distributed Power Electronics

Abstract

:1. Introduction

2. Hot-Spotting and Ageing in PV Systems

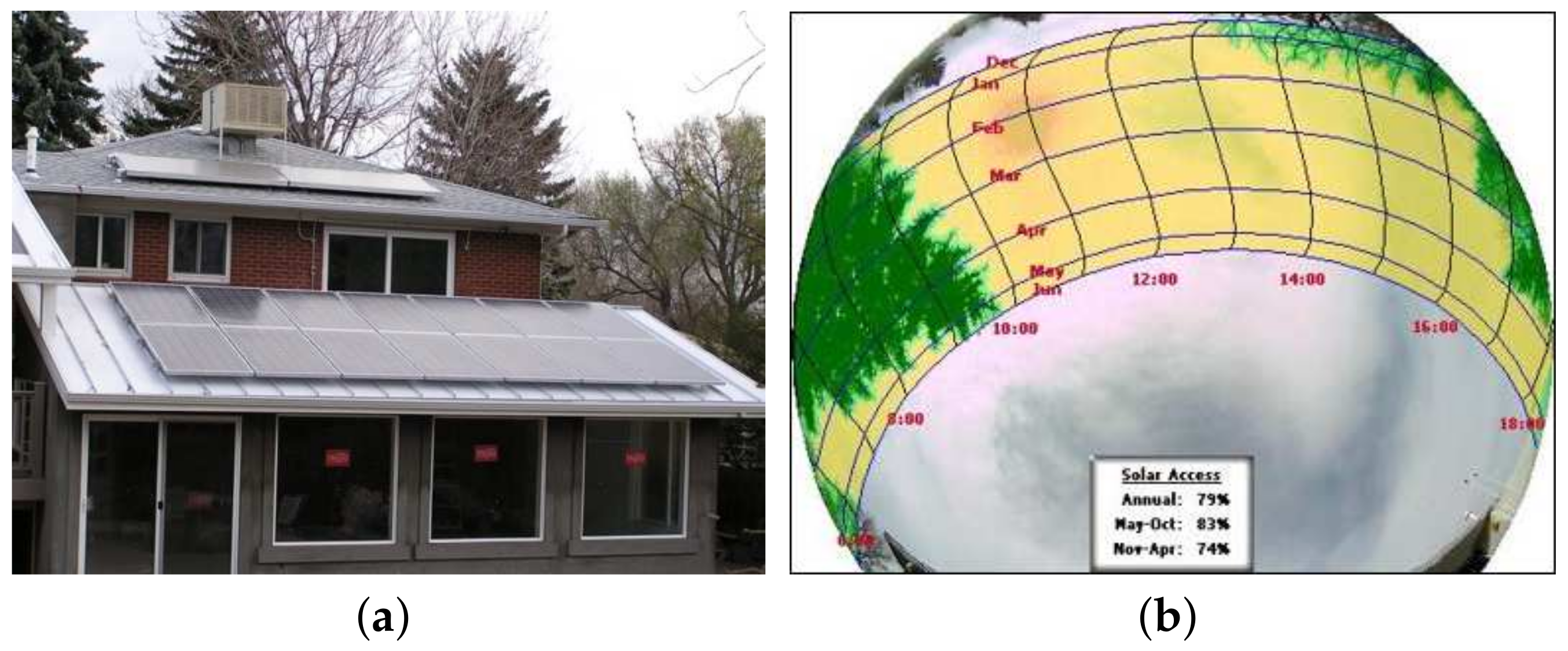

2.1. Representative Rooftop System

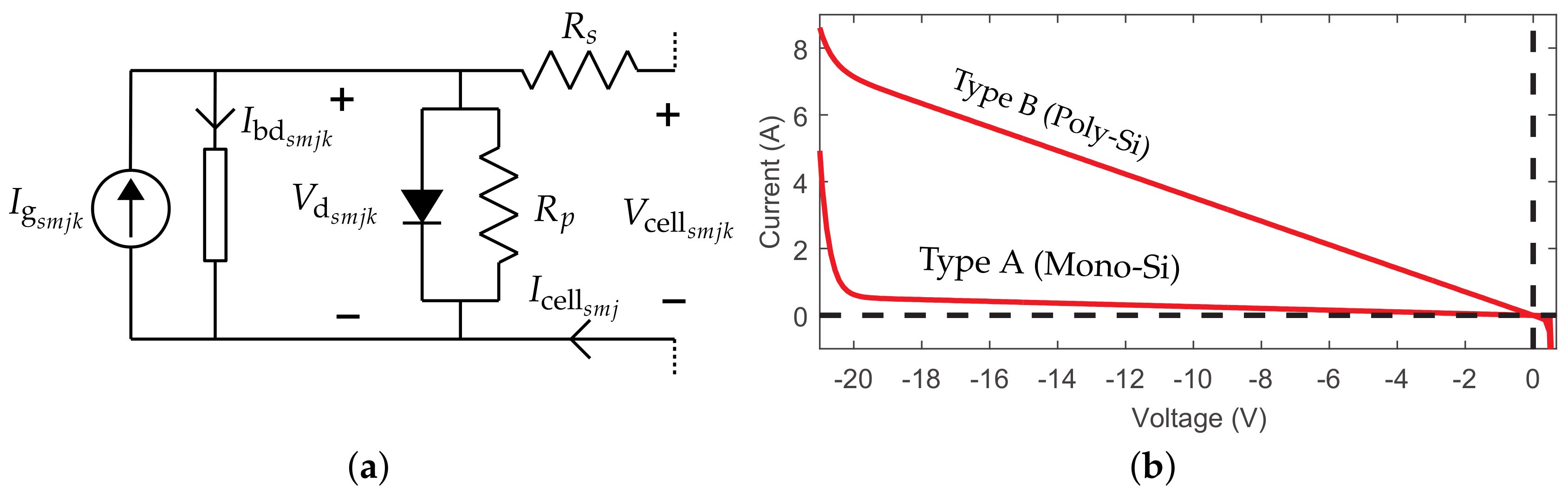

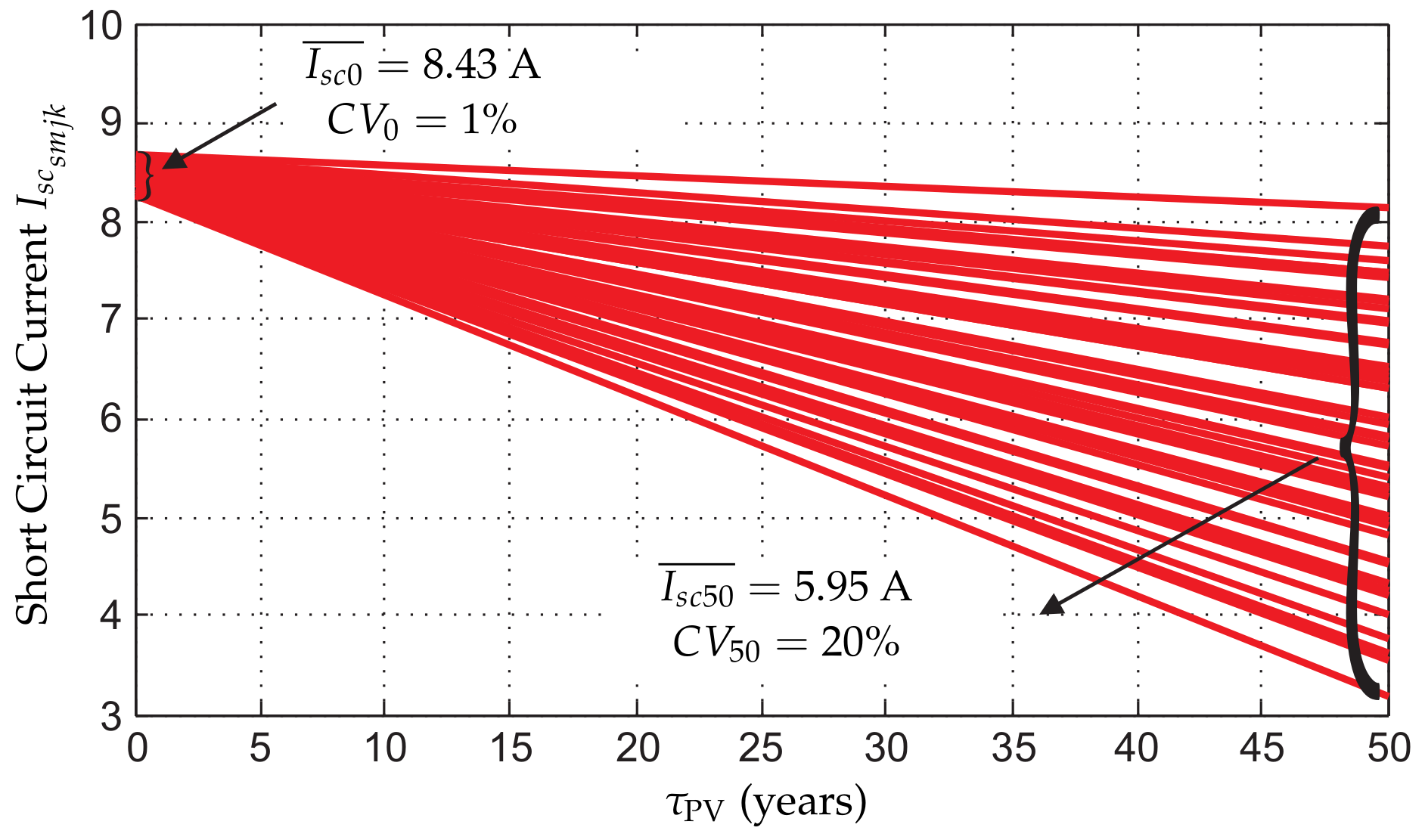

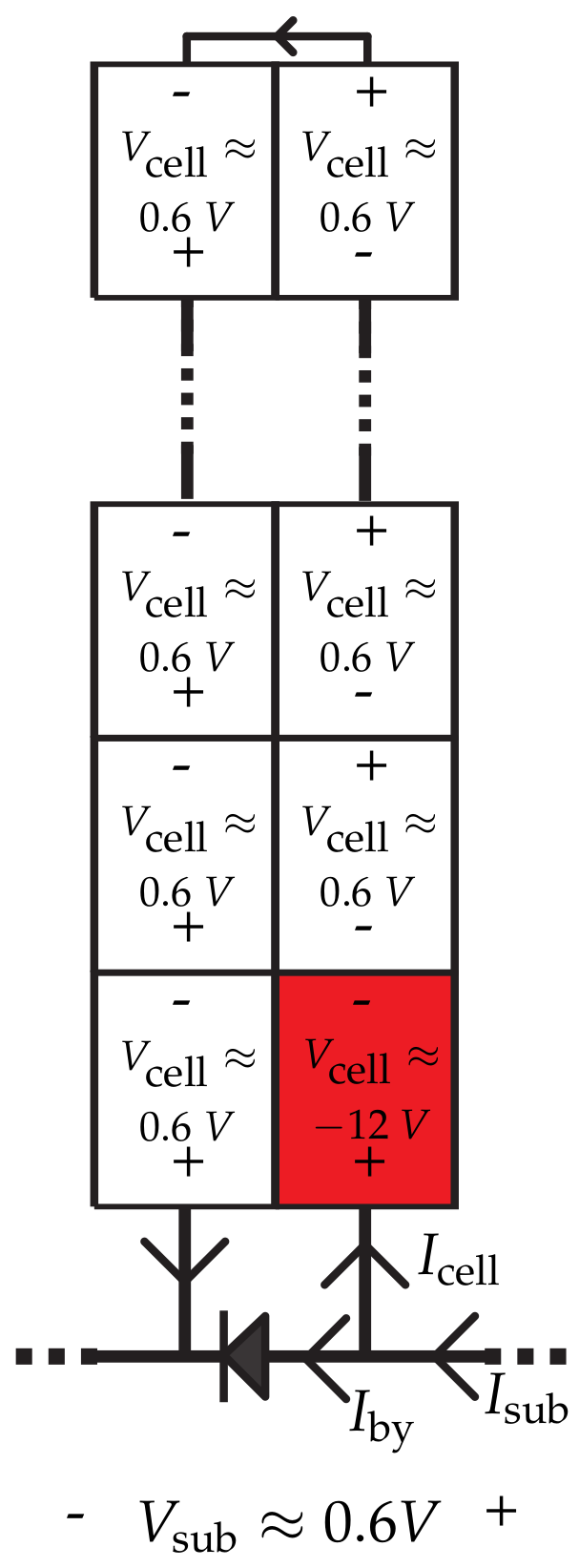

2.2. Cell-Level Modeling and Simulation

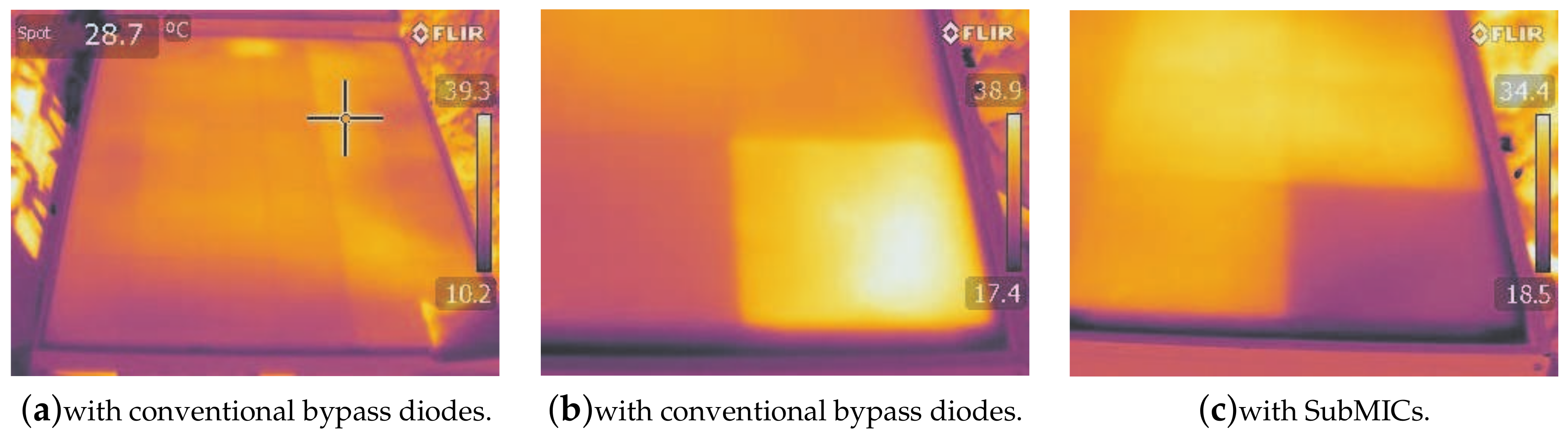

2.3. Hot-Spotting and Accelerated Ageing

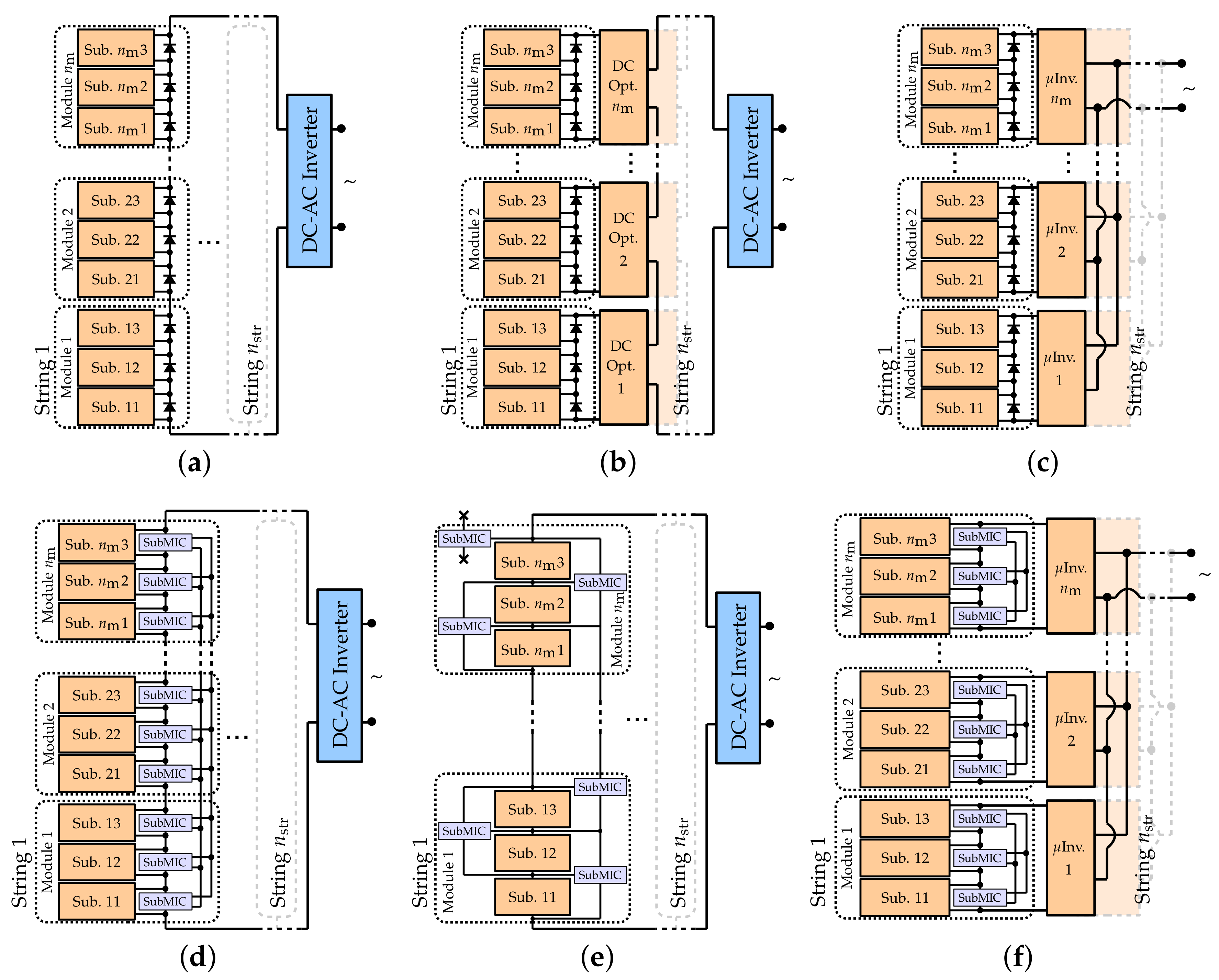

3. Distributed Power Conversion Architectures

4. Simulation Results

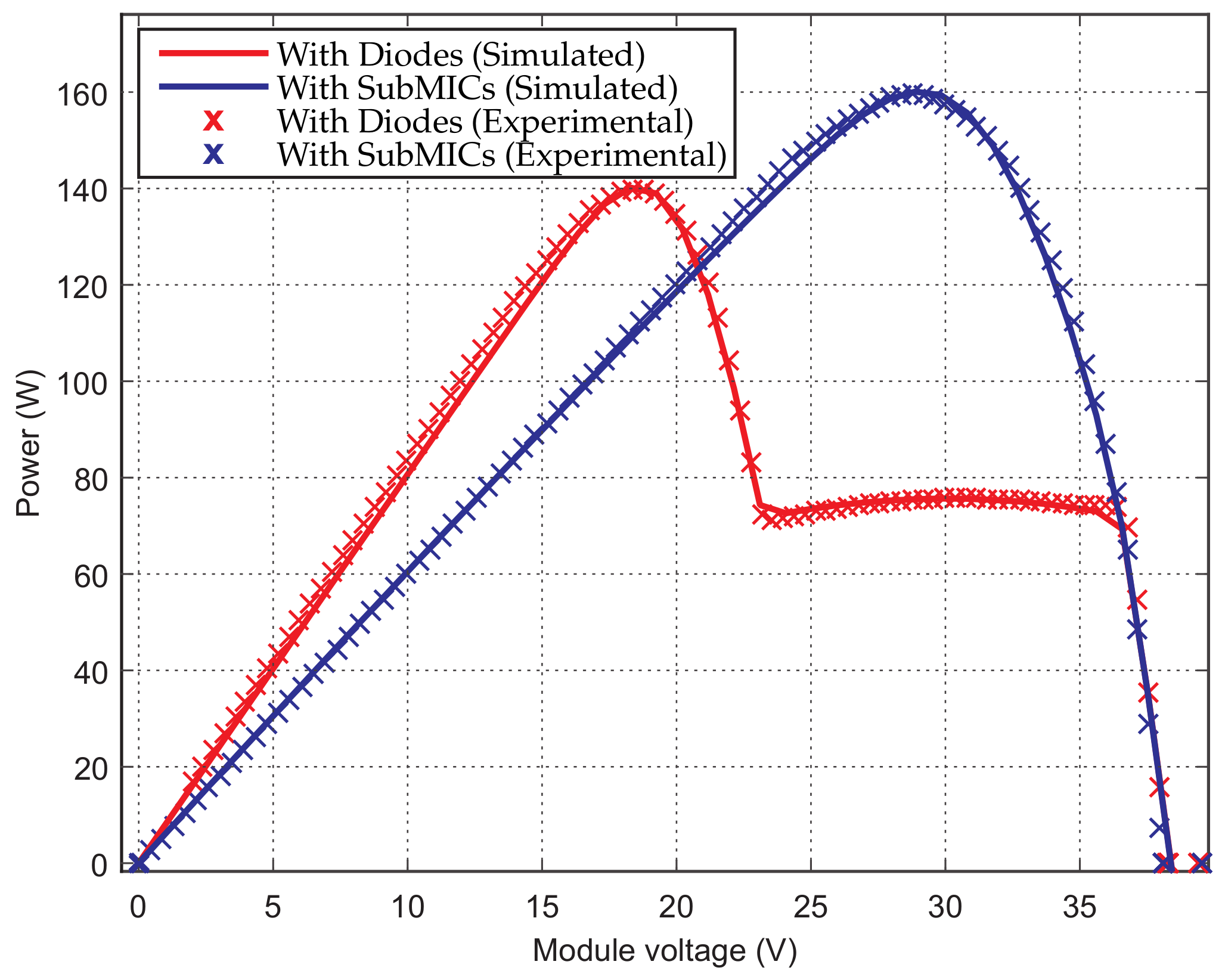

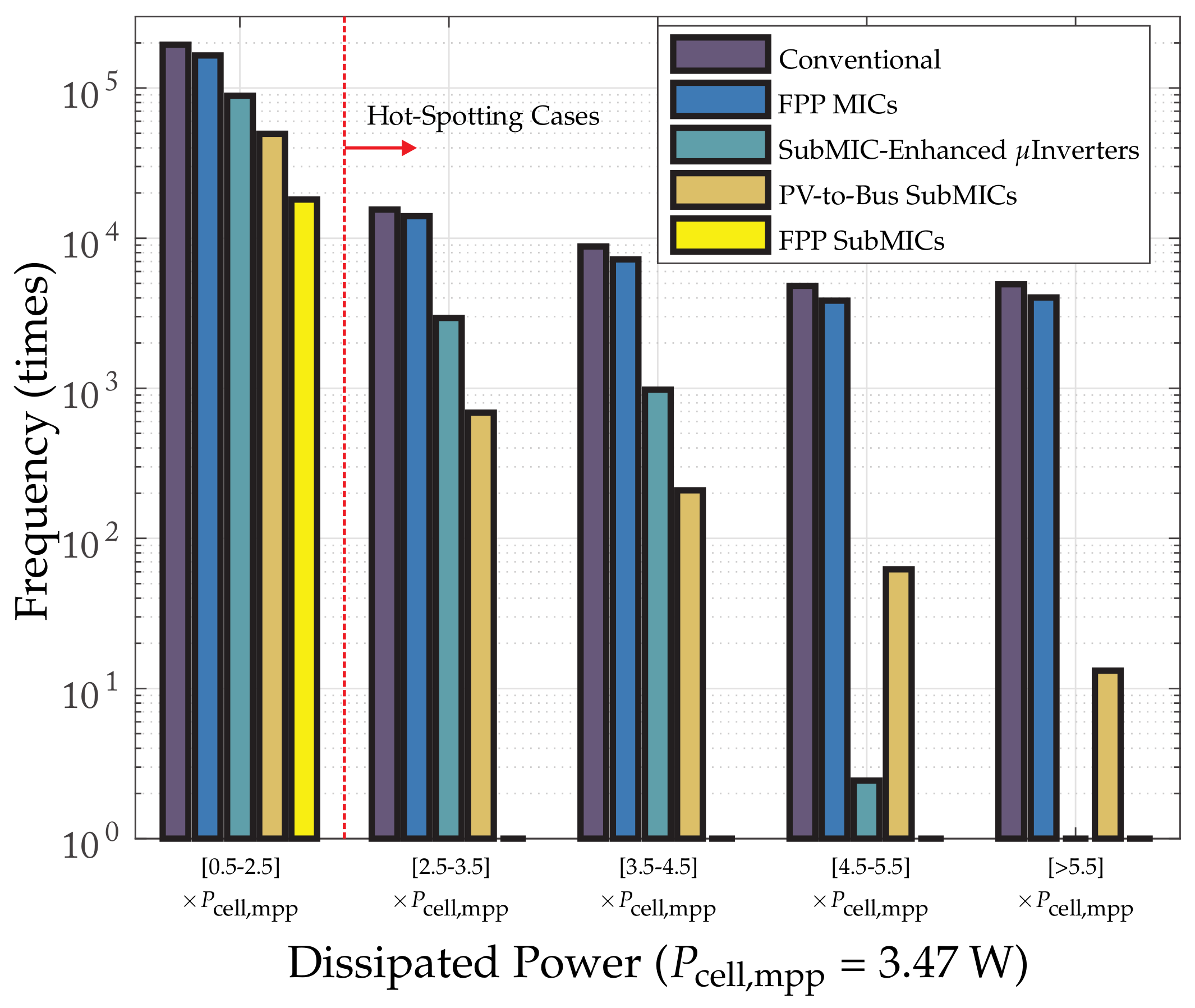

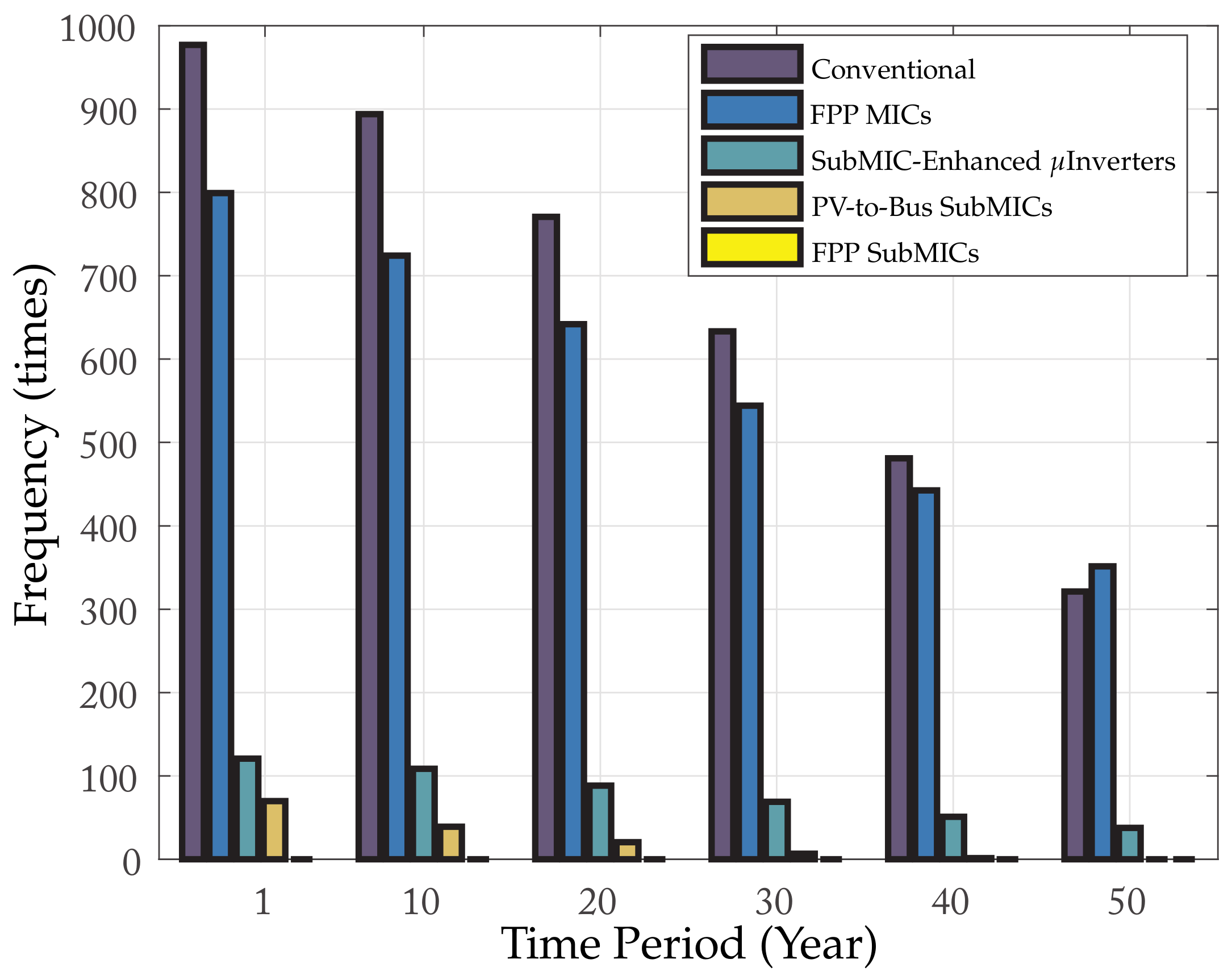

4.1. Hot-Spotting in PV Systems Affected by Partial Shading

4.2. Hot-Spotting in PV Systems Affected by Partial Shading Considering Accelerated Degradation

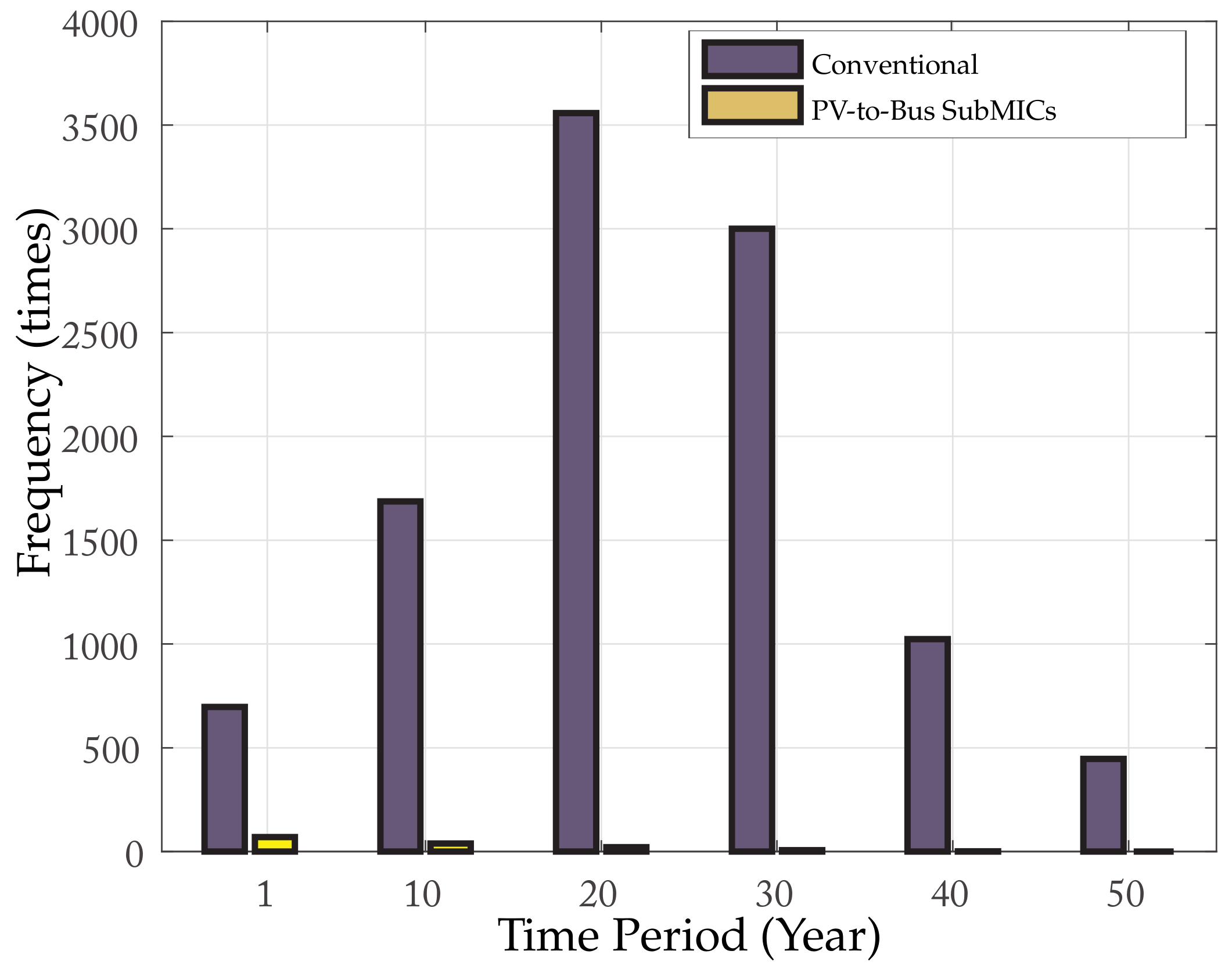

4.3. Hot-Spotting in Mono-Si PV Systems Affected by Partial Shading Considering Accelerated Degradation

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| PV | Photovoltaics |

| MPP | Maximum power point |

| STC | Standard test conditions |

| CV | Coefficient of variation |

| DC | Direct current |

| FPP | Full power processing |

| DPP | Differential power processing |

| MIC | Module integrated converter |

| SubMIC | Submodule integrated converter |

Appendix A. Experimental Results

References

- Deline, C. Partially shaded operation of multi-string photovoltaic systems. In Proceedings of the IEEE Photovoltaic Specialists Conference (PVSC), Honolulu, HI, USA, 20–25 June 2010; pp. 394–399. [Google Scholar]

- Olalla, C.; Deline, C.; Maksimovic, D. Performance of Mismatched PV Systems with Submodule Integrated Converters. IEEE J. Photovolt. 2014, 4, 396–404. [Google Scholar] [CrossRef]

- Islam, H.; Mekhilef, S.; Shah, N.; Soon, T.; Seyedmahmousian, M.; Horan, B.; Stojcevski, A. Performance Evaluation of Maximum Power Point Tracking Approaches and Photovoltaic Systems. Energies 2018, 11, 365. [Google Scholar] [CrossRef]

- Kim, K.A.; Krein, P.T. Hot Spotting and Second Breakdown Effects on Reverse I-V Characteristics for Mono-Crystalline Si Photovoltaics. In Proceedings of the IEEE Energy Conversion Congress and Exposition, ECCE’13, Denver, CO, USA, 15–19 September 2013; pp. 1007–1014. [Google Scholar]

- Kim, K.A.; Krein, P.T. Reexamination of Photovoltaic Hot Spotting to Show Inadequacy of the Bypass Diode. IEEE J. Photovolt. 2015, 5, 1435–1441. [Google Scholar] [CrossRef]

- Sun, K.; Zhang, L.; Xing, Y.; Guerrero, J.M. A Distributed Control Strategy Based on DC Bus Signaling for Modular Photovoltaic Generation Systems with Battery Energy Storage. IEEE Trans. Power Electron. 2011, 26, 3032–3045. [Google Scholar] [CrossRef]

- Deline, C.; Meydbray, J.; Donovan, M. Photovoltaic Shading Testbed for Module-Level Power Electronics: 2014 Update; Technical Report Report No. TP-5J00-62471; National Renewable Energy Laboratory: Golden, CO, USA, 2014.

- Olalla, C.; Deline, C.; Clement, D.; Levron, Y.; Rodriguez, M.; Maksimovic, D. Performance of Power Limited Differential Power Processing Architectures in Mismatched PV Systems. IEEE Trans. Power Electron. 2015, 30, 618–631. [Google Scholar] [CrossRef]

- Carbone, R. PV Plants with Distributed MPPT founded on batteries. Sol. Energy 2015, 112, 910–923. [Google Scholar] [CrossRef]

- Olalla, C.; Deline, C.; Maksimovic, D. Modeling and simulation of conventionally wired photovoltaic systems based on differential power processing SubMIC-enhanced PV modules. In Proceedings of the IEEE Workshop on Control and Modeling for Power Electronics, Santander, Spain, 22–25 June 2014. [Google Scholar]

- Olalla, C.; Clement, D.; Maksimovic, D.; Deline, C. A Cell-Level Photovoltaic Model for High-Granularity Simulations. In Proceedings of the IEEE European Conference on Power Electronics and Applications (EPE-ECCE), Lille, France, 2–6 September 2013. [Google Scholar]

- Olalla, C.; Maksimovic, D.; Deline, C.; Martinez-Salamero, L. Impact of Distributed Power Electronics on the Lifetime and Reliability of PV Systems. Prog. Photovolt. Res. Appl. 2017, 25, 821–835. [Google Scholar] [CrossRef]

- MacAlpine, S.M.; Erickson, R.W.; Brandemuehl, M.J. Characterization of Power Optimizer Potential to Increase Energy Capture in Photovoltaic Systems Operating Under Nonuniform Conditions. IEEE Trans. Power Electron. 2013, 28, 2936–2945. [Google Scholar] [CrossRef]

- Deline, C.; Meydbray, J.; Donovan, M.; Forrest, J. Photovoltaic Shading Testbed for Module-Level Power Electronics; NREL Technical Report, NREL/TP-5200-54876; National Renewable Energy Laboratory: Golden, CO, USA, 2012.

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 3rd ed.; Wiley: New York, NY, USA, 2006; Volume 13. [Google Scholar]

- Kim, K.A.; Chenyang, X.; Lei, J.; Krein, P.T. A Dynamic Photovoltaic Model Incorporating Capacitive and Reverse-Bias Characteristics. IEEE J. Photovolt. 2013, 3, 1334–1341. [Google Scholar] [CrossRef]

- Bishop, J.W. Computer simulation of the effects of electrical mismatches in photovoltaic cell interconnection circuits. Sol. Cells 1988, 25, 73–89. [Google Scholar] [CrossRef]

- Quaschning, V.; Hanitsch, R. Numerical simulation of current-voltage characteristics of photovoltaic systems with shaded solar cells. Sol. Energy 1996, 56, 513–520. [Google Scholar] [CrossRef]

- IEC-61215. Terrestrial Photovoltaic (PV) Modules—Design Qualification and Type Approval; IEC: Geneva, Switzerland, 2016. [Google Scholar]

- Jordan, D.C.; Kurtz, S.R.; VanSant, K.; Newmiller, J. Compendium of photovoltaic degradation rates. Prog. Photovolt. Res. Appl. 2016, 24, 978–989. [Google Scholar] [CrossRef]

- Jordan, D.; Wohlgemuth, J.; Kurtz, S. Technology and Climate Trends in PV Module Degradation. In Proceedings of the 27th European Photovoltaic Solar Energy Conference and Exhibition, PVSEC, Frankfurt, Germany, 24–28 September 2012; pp. 3118–3124. [Google Scholar]

- Desombre, A. Methodology for a reliability study on photovoltaic modules. In Proceedings of the Photovoltaic Solar Energy Conference, Cannes, France, 27–31 October 1980; Springer: New York, NY, USA, 1981; pp. 741–745. [Google Scholar]

- Wohlgemuth, J.H.; Cunningham, D.W.; Monus, P.; Miller, J.; Nguyen, A. Long Term Reliability of Photovoltaic Modules. In Proceedings of the IEEE World Conference on Photovoltaic Energy Conversion, Waikoloa, HI, USA, 7–12 May 2006; Volume 2, pp. 2050–2053. [Google Scholar]

- Kurtz, S.; Whitfield, K.; TamizhMani, G.; Koehl, M.; Miller, D.; Joyce, J.; Wohlgemuth, J.; Bosco, N.; Kempe, M.; Zgonena, T. Evaluation of high-temperature exposure of photovoltaic modules. Prog. Photovolt. Res. Appl. 2011, 19, 954–965. [Google Scholar] [CrossRef]

- Bishop, J.W. Microplasma breakdown and hot-spots in silicon solar cells. Sol. Cells 1989, 26, 335–349. [Google Scholar] [CrossRef]

- Alonso-Garcia, M.C.; Ruiz, J.M.; Chenlo, F. Experimental study of mismatch and shading effects in the I-V characteristic of a photovoltaic module. Sol. Energy Mater. Sol. Cells 2006, 90, 329–340. [Google Scholar] [CrossRef]

- Breitenstein, O.; Rakotoniaina, J.P.; Al Rifai, M.H.; Werner, M. Shunt types in crystalline silicon solar cells. Prog. Photovolt. Res. Appl. 2004, 12, 529–538. [Google Scholar] [CrossRef]

- Breitenstein, O.; Bauer, J.; Bothe, K.; Kwapil, W.; Lausch, D.; Rau, U.; Schmidt, J.; Schneemann, M.; Schubert, M.C.; Wagner, J.M.; et al. Understanding junction breakdown in multicrystalline solar cells. J. Appl. Phys. 2011, 109, 071101. [Google Scholar] [CrossRef] [Green Version]

- Walker, G.; Sernia, P. Cascaded DC-DC converter connection of photovoltaic modules. IEEE Trans. Power Electron. 2004, 19, 1130–1139. [Google Scholar] [CrossRef]

- Wills, R.; Krauthamer, S.; Bulawka, A.; Posbic, J. The AC photovoltaic module concept. In Proceedings of the Intersociety Energy Conversion Engineering Conference, Honolulu, HI, USA, 27 July–1 August 1997; Volume 3, pp. 1562–1563. [Google Scholar]

- Pilawa-Podgurski, R.C.N.; Perreault, D.J. Submodule Integrated Distributed Maximum Power Point Tracking for Solar Photovoltaic Applications. IEEE Trans. Power Electron. 2013, 28, 2957–2967. [Google Scholar] [CrossRef]

- Deline, C.; Sekulic, B.; Stein, J.; Barkaszi, S.; Yang, J.; Kahn, S. Evaluation of Maxim module-Integrated electronics at the DOE Regional Test Centers. In Proceedings of the IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 0986–0991. [Google Scholar]

- Olalla, C.; Rodriguez, M.; Clement, D.; Maksimovic, D. Architectures and Control of Submodule Integrated DC-DC Converters for Photovoltaic Applications. IEEE Trans. Power Electron. 2012, 28, 2980–2997. [Google Scholar] [CrossRef]

- Giral, R.; Ramos-Paja, C.; Gonzalez, D.; Calvente, J.; Cid-Pastor, A.; Martinez-Salamero, L. Minimizing the effects of shadowing in a PV module by means of active voltage sharing. In Proceedings of the IEEE International Conference on Industrial Technology, Vina del Mar, Chile, 14–17 March 2010; pp. 943–948. [Google Scholar]

- Stauth, J.T.; Seeman, M.D.; Kesarwani, K. Resonant Switched-Capacitor Converters for Sub-module Distributed Photovoltaic Power Management. IEEE Trans. Power Electron. 2013, 28, 1189–1198. [Google Scholar] [CrossRef]

- Blumenfeld, A.; Cervera, A.; Peretz, M.M. Enhanced Differential Power Processor for PV Systems: Resonant Switched-Capacitor Gyrator Converter With Local MPPT. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 883–892. [Google Scholar] [CrossRef]

- Kim, K.A.; Shenoy, P.S.; Krein, P.T. Converter Rating Analysis for Photovoltaic Differential Power Processing Systems. IEEE Trans. Power Electron. 2015, 30, 1987–1997. [Google Scholar] [CrossRef]

- Shibin, Q.; Barth, C.B.; Pilawa-Podgurski, R.C.N. Enhancing Microinverter Energy Capture With Submodule Differential Power Processing. IEEE Trans. Power Electron. 2016, 31, 3575–3585. [Google Scholar]

- Vázquez, M.; Rey-Stolle, I. Photovoltaic module reliability model based on field degradation studies. Prog. Photovolt. Res. Appl. 2008, 16, 419–433. [Google Scholar] [CrossRef] [Green Version]

- Chamberlin, C.E.; Rocheleau, M.A.; Marshall, M.W.; Reis, A.M.; Coleman, N.T.; Lehman, P.A. Comparison of PV module performance before and after 11 and 20 years of field exposure. In Proceedings of the IEEE Photovoltaic Specialists Conference (PVSC), Seattle, WA, USA, 19–24 June 2011; pp. 101–105. [Google Scholar]

- Makrides, G.; Zinsser, B.; Schubert, M.; Georghiou, G.E. Performance loss rate of twelve photovoltaic technologies under field conditions using statistical techniques. Sol. Energy 2014, 103, 28–42. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory. Measurement and Instrumentation Data Center. 2012. Available online: http://www.nrel.gov/midc/ (accessed on 1 March 2017).

| Parameter | Poly-Si | Mono-Si |

|---|---|---|

| 8.1 A | 8.43 A | |

| 36.1 A | 37.2 A | |

| 7.3 A | 7.95 A | |

| 28.5 V | 30.2 V | |

| 2.83 | 36.8 | |

| 208 W | 240 W | |

| 3.47 W | 4 W | |

| # Cells | 60 | 60 |

| # Submodules | 3 | 3 |

| Architecture | # of Hot-Spots | Reduction (%) |

|---|---|---|

| Conventional | 34,077 | - |

| FPP MICs | 29,098 | 14.6% |

| SubMIC-Enhanced Inverters | 3922 | 88.5% |

| PV-to-Bus SubMICs | 973 | 97.1% |

| FPP SubMICs | 0 | 100% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olalla, C.; Hasan, M.N.; Deline, C.; Maksimović, D. Mitigation of Hot-Spots in Photovoltaic Systems Using Distributed Power Electronics. Energies 2018, 11, 726. https://doi.org/10.3390/en11040726

Olalla C, Hasan MN, Deline C, Maksimović D. Mitigation of Hot-Spots in Photovoltaic Systems Using Distributed Power Electronics. Energies. 2018; 11(4):726. https://doi.org/10.3390/en11040726

Chicago/Turabian StyleOlalla, Carlos, Md. Nazmul Hasan, Chris Deline, and Dragan Maksimović. 2018. "Mitigation of Hot-Spots in Photovoltaic Systems Using Distributed Power Electronics" Energies 11, no. 4: 726. https://doi.org/10.3390/en11040726