Movement Boundary Shape of Overburden Strata and Its Influencing Factors

Abstract

:1. Introduction

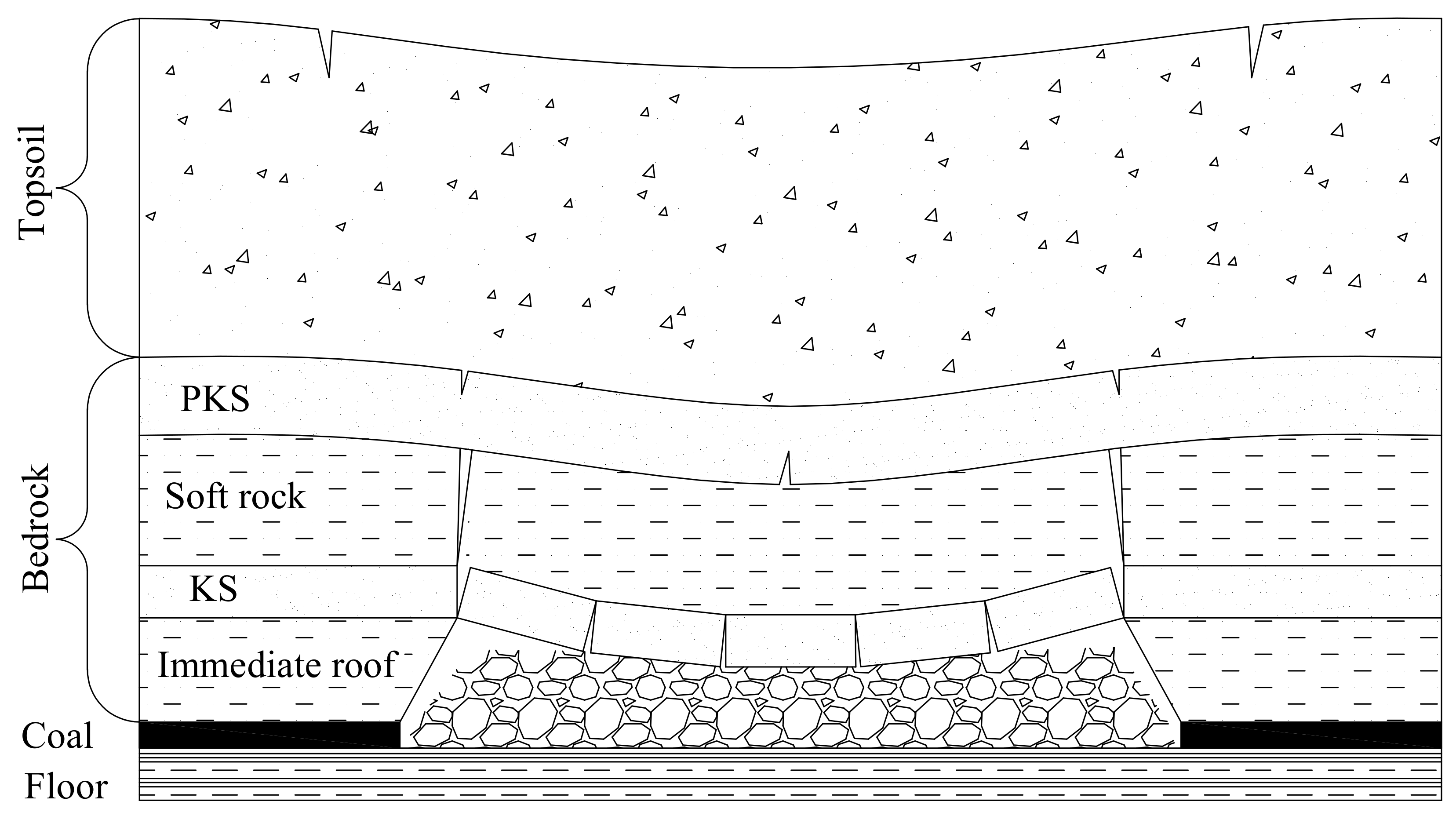

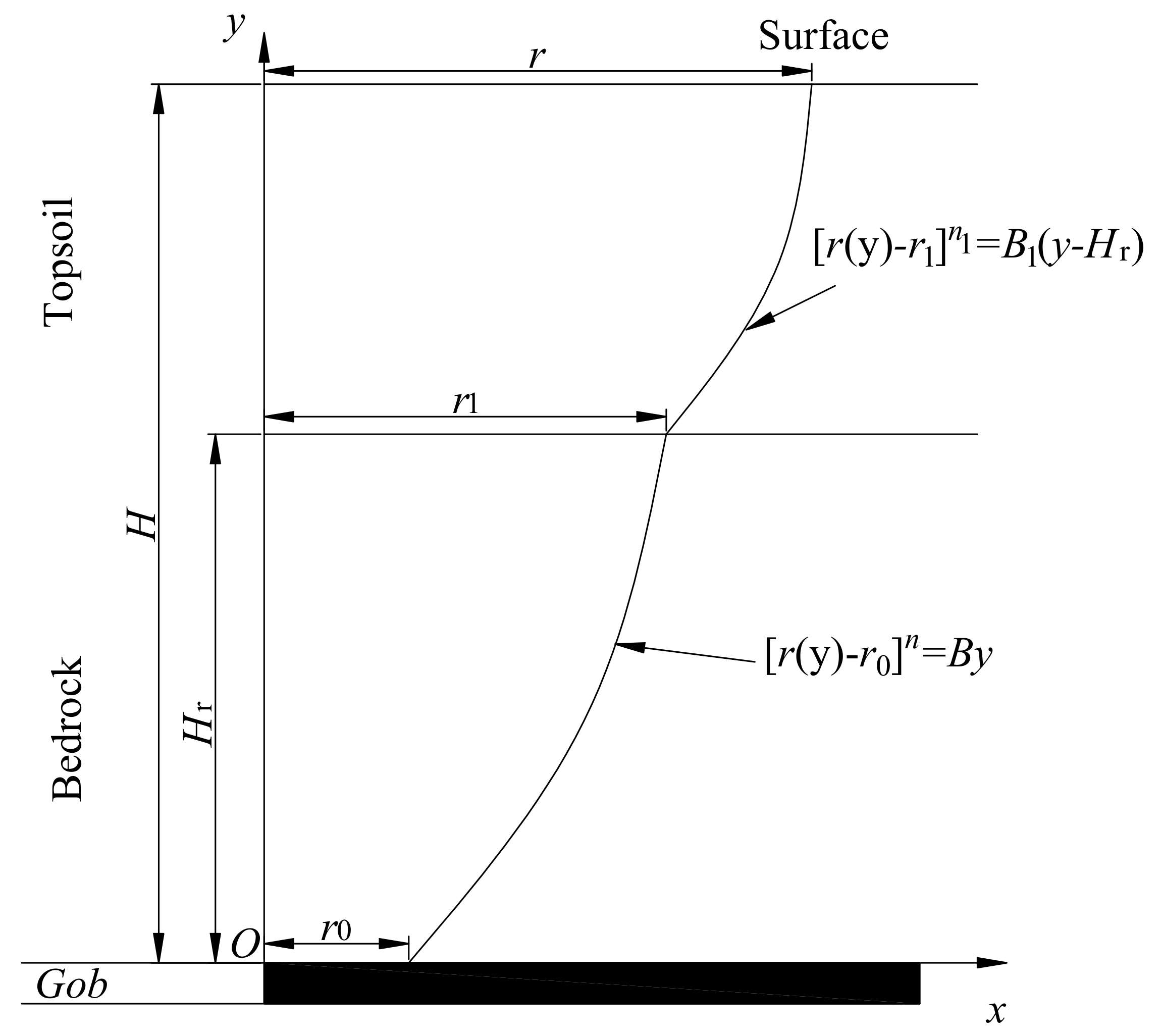

2. Theoretical Model

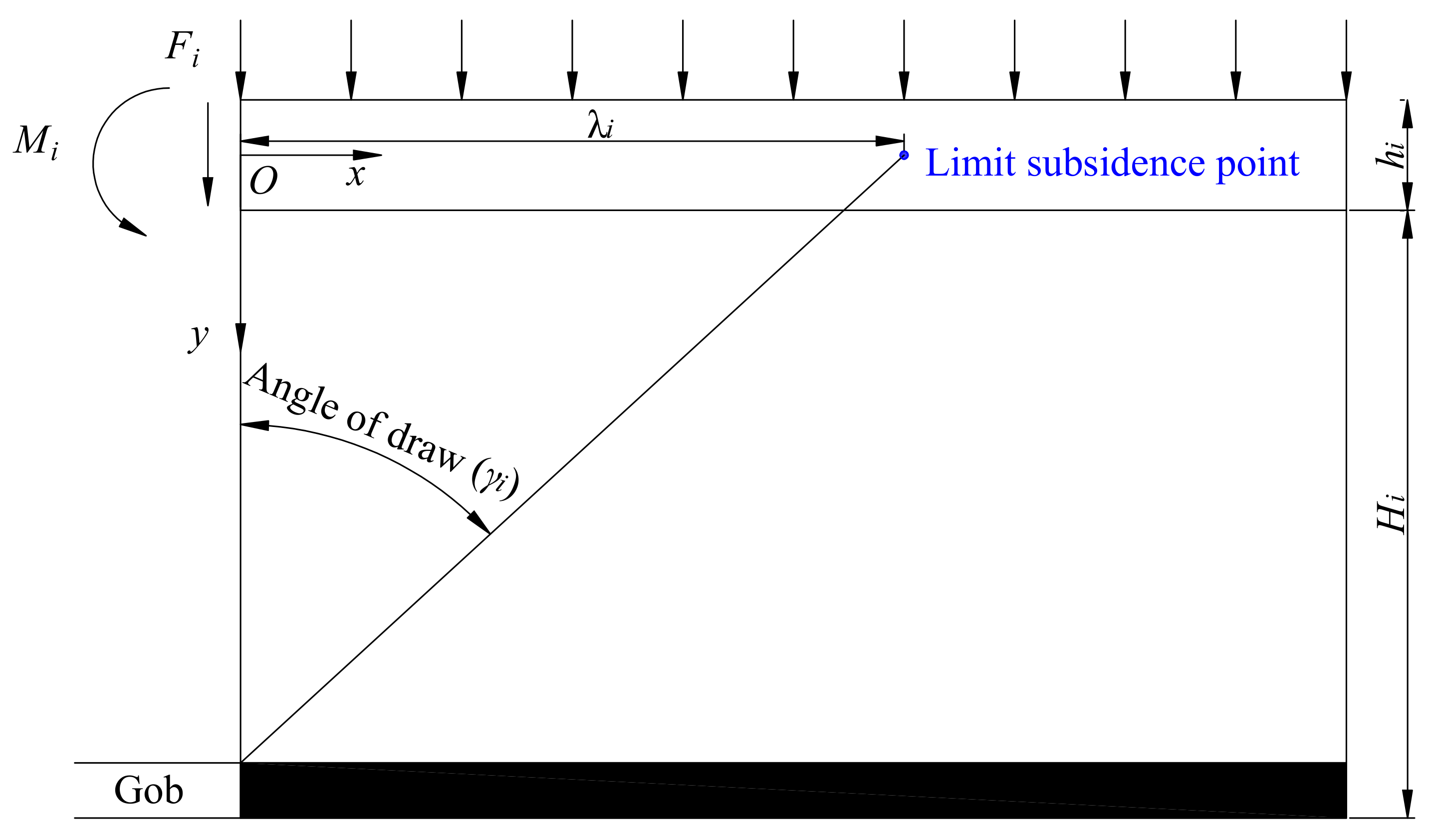

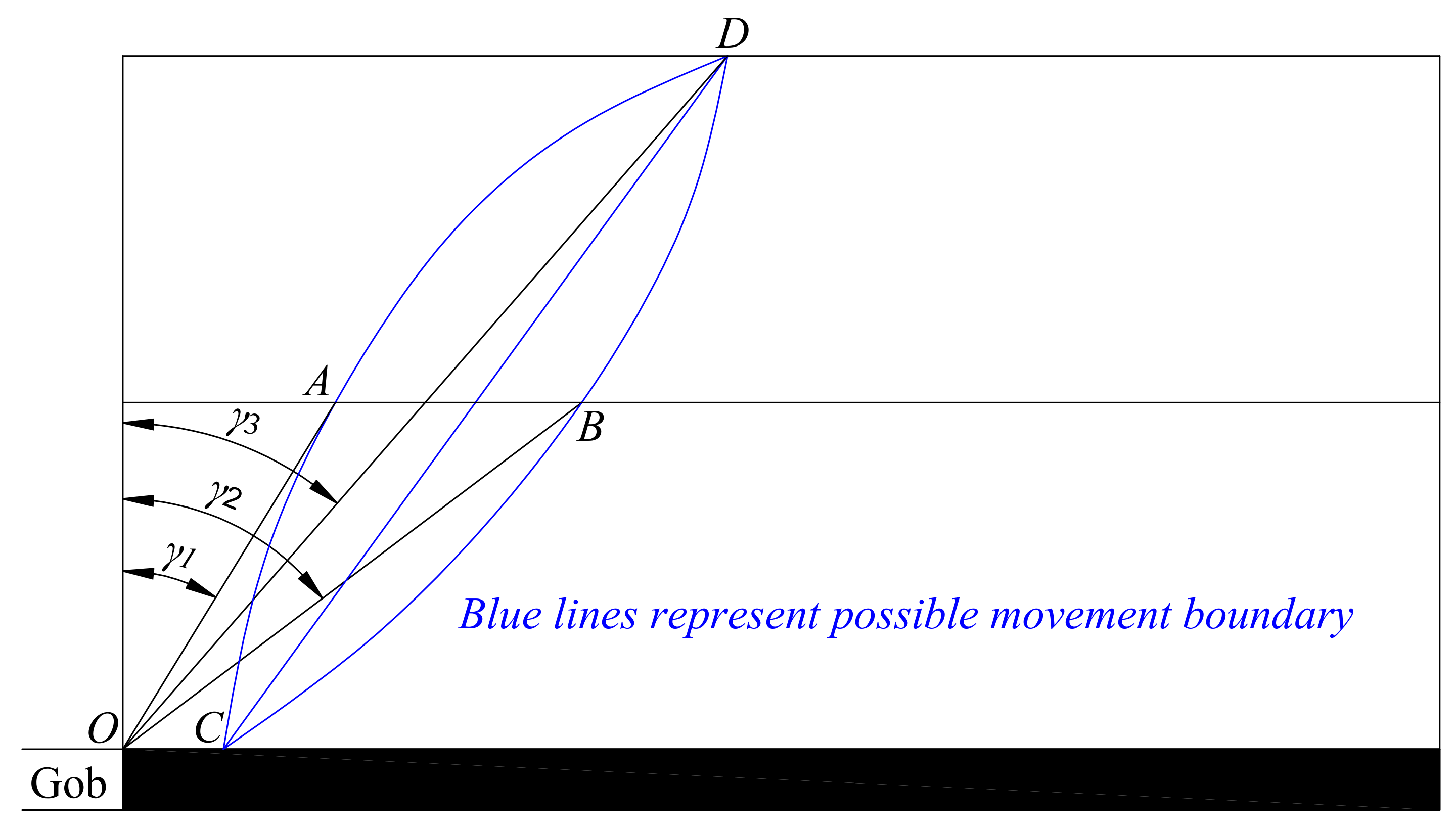

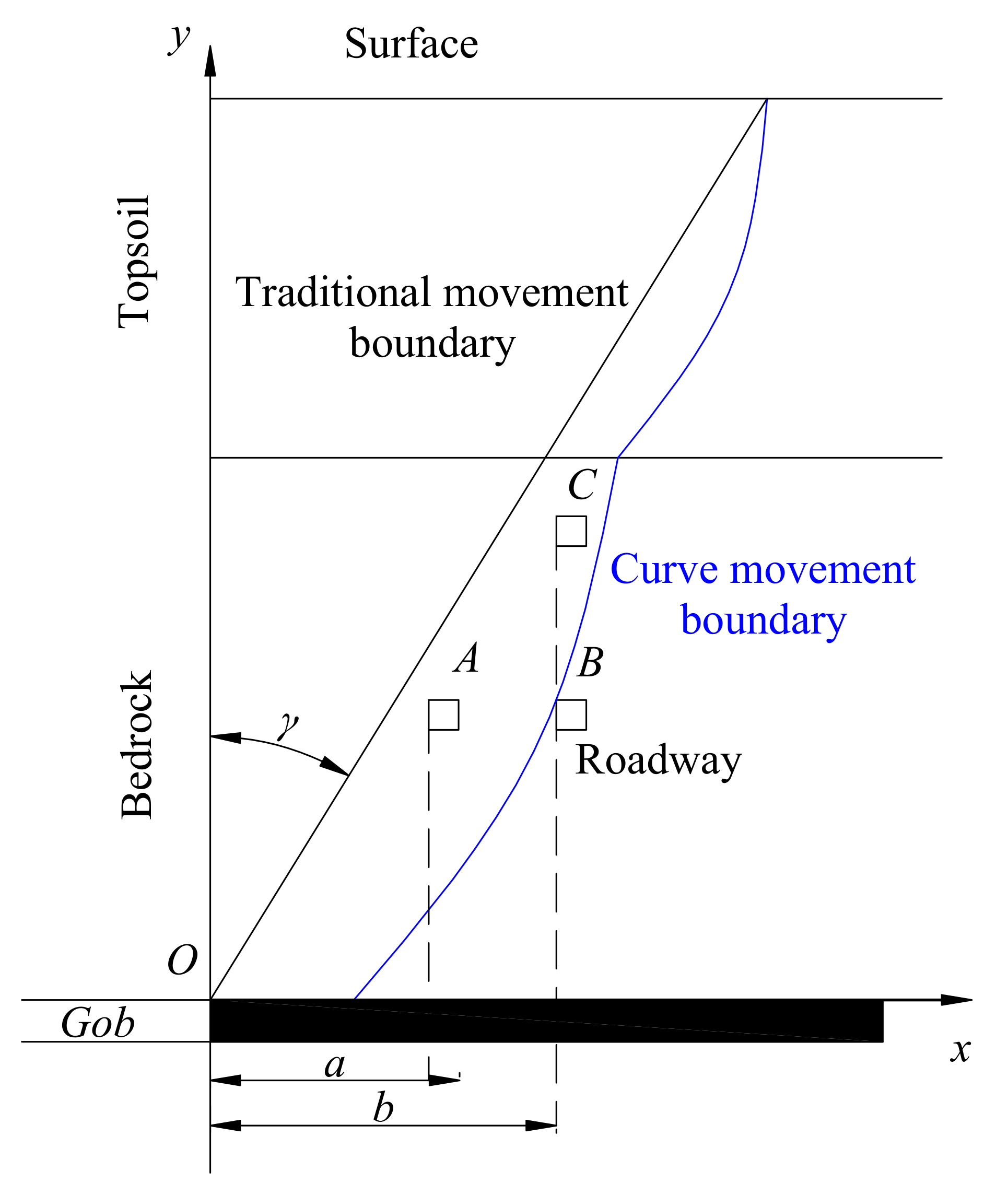

2.1. Movement Boundary Shape of Bedrock

2.2. Movement Boundary Shape of Topsoil

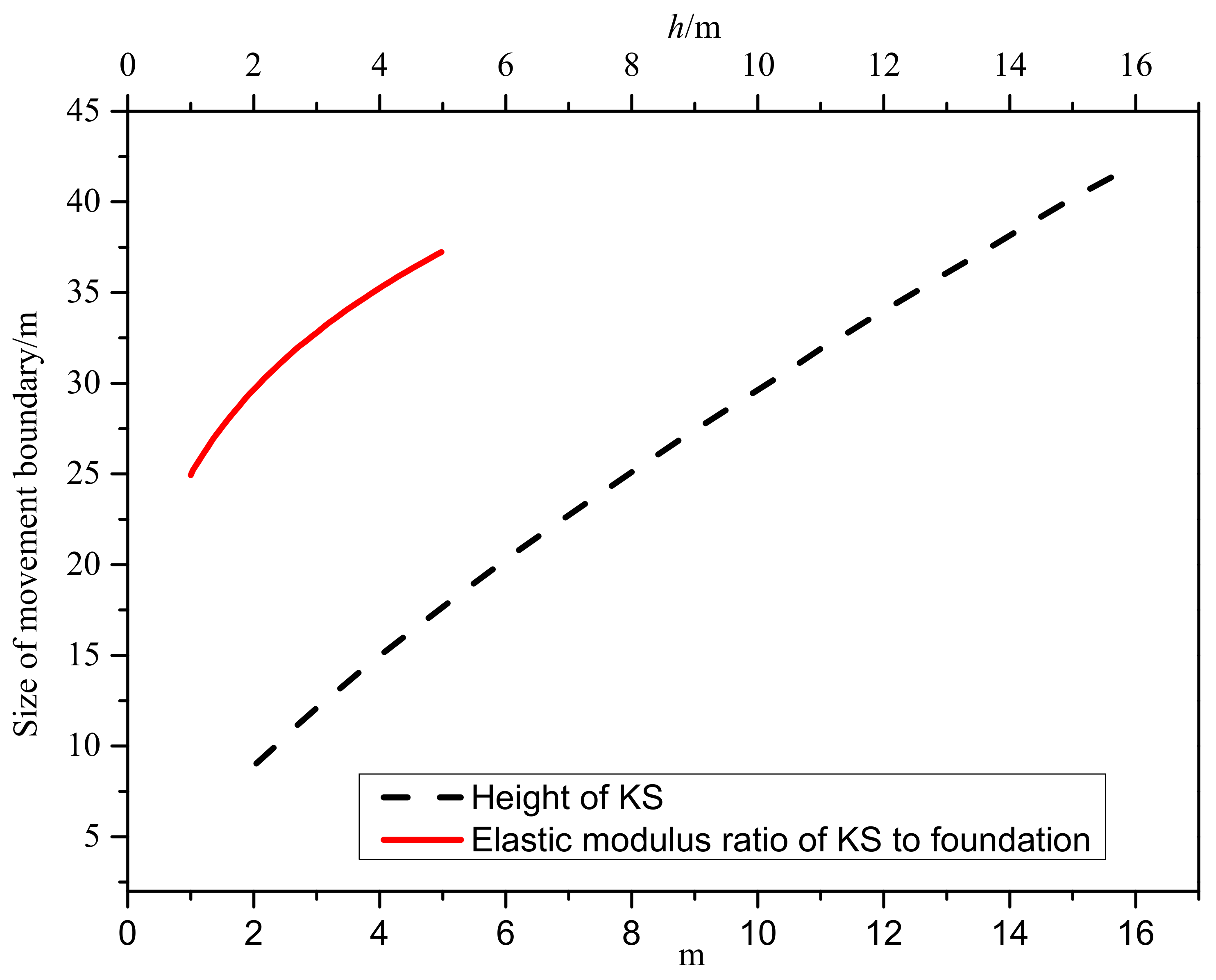

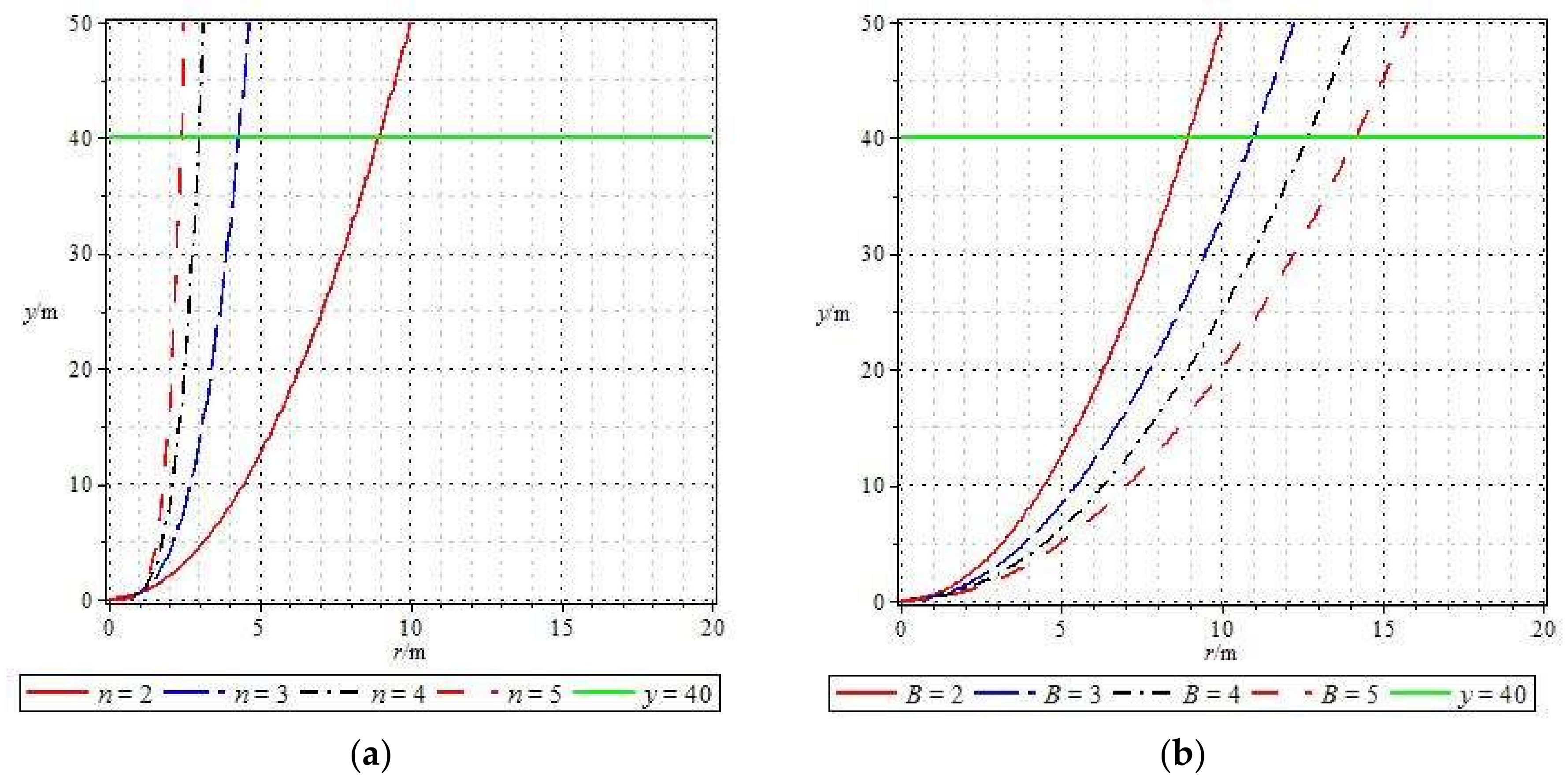

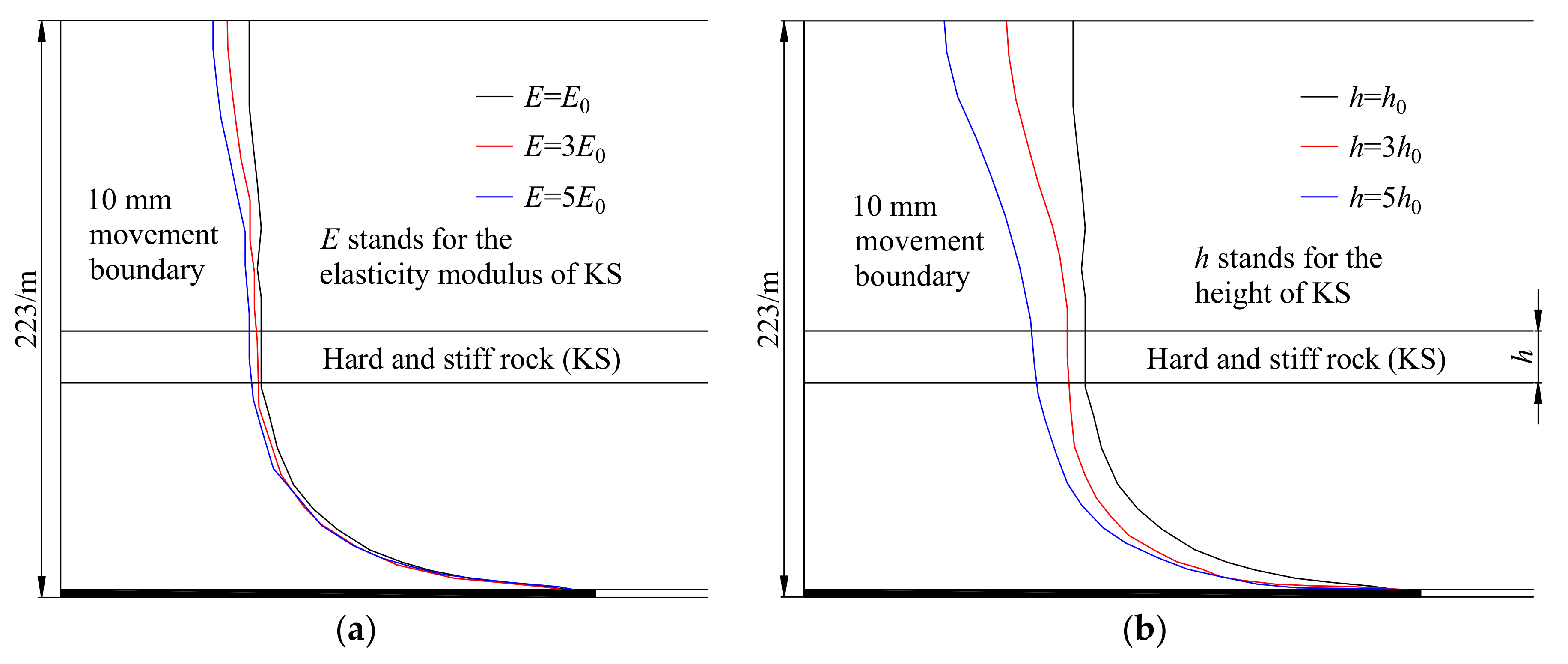

2.3. Parameter Study

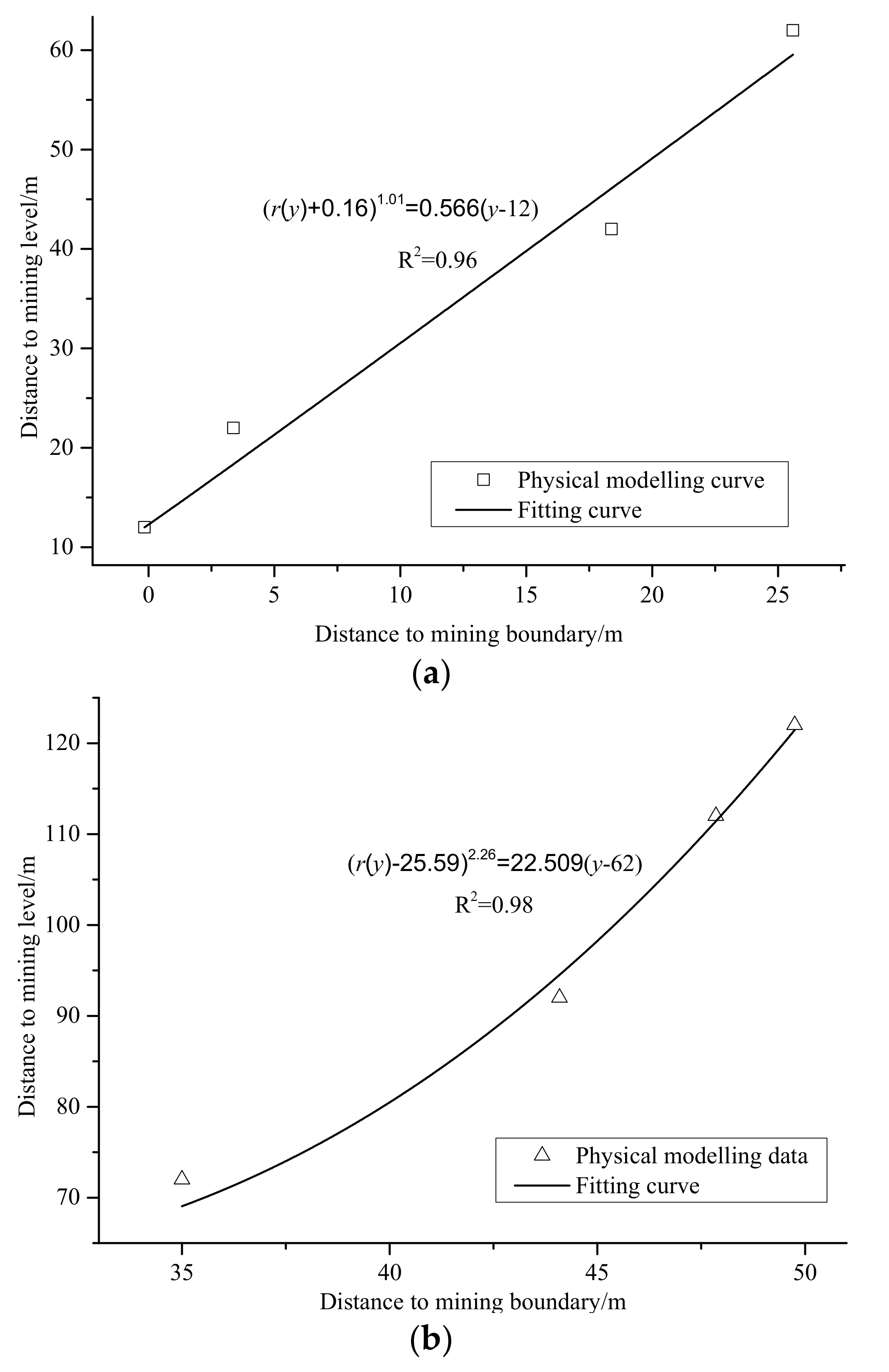

3. Movement Boundary Shape and Empirical Model

4. Model Verification

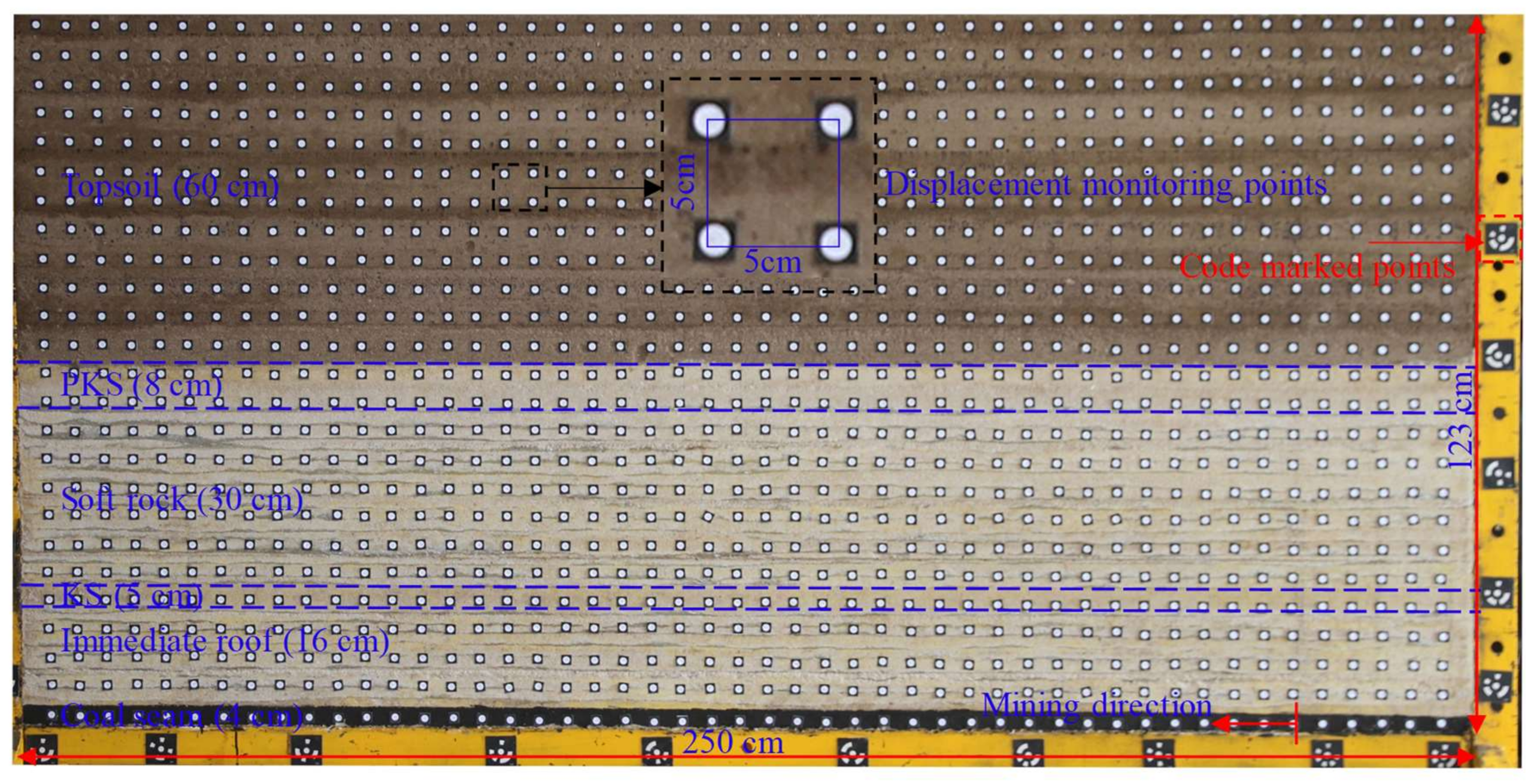

4.1. Physical Simulation

4.2. Numerical Simulation

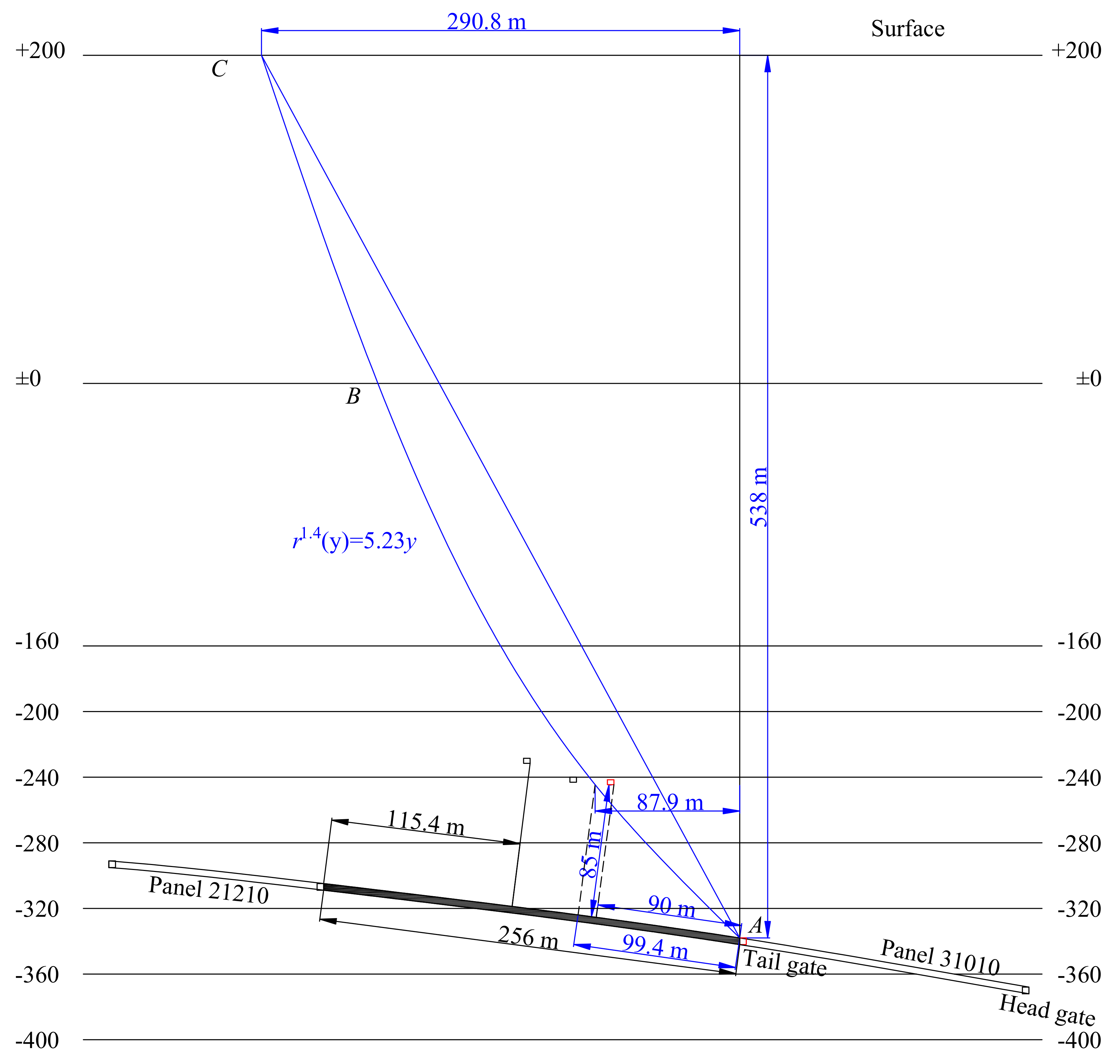

5. Model Application in Protective Coal Pillars

5.1. Design of Protective Coal Pillars

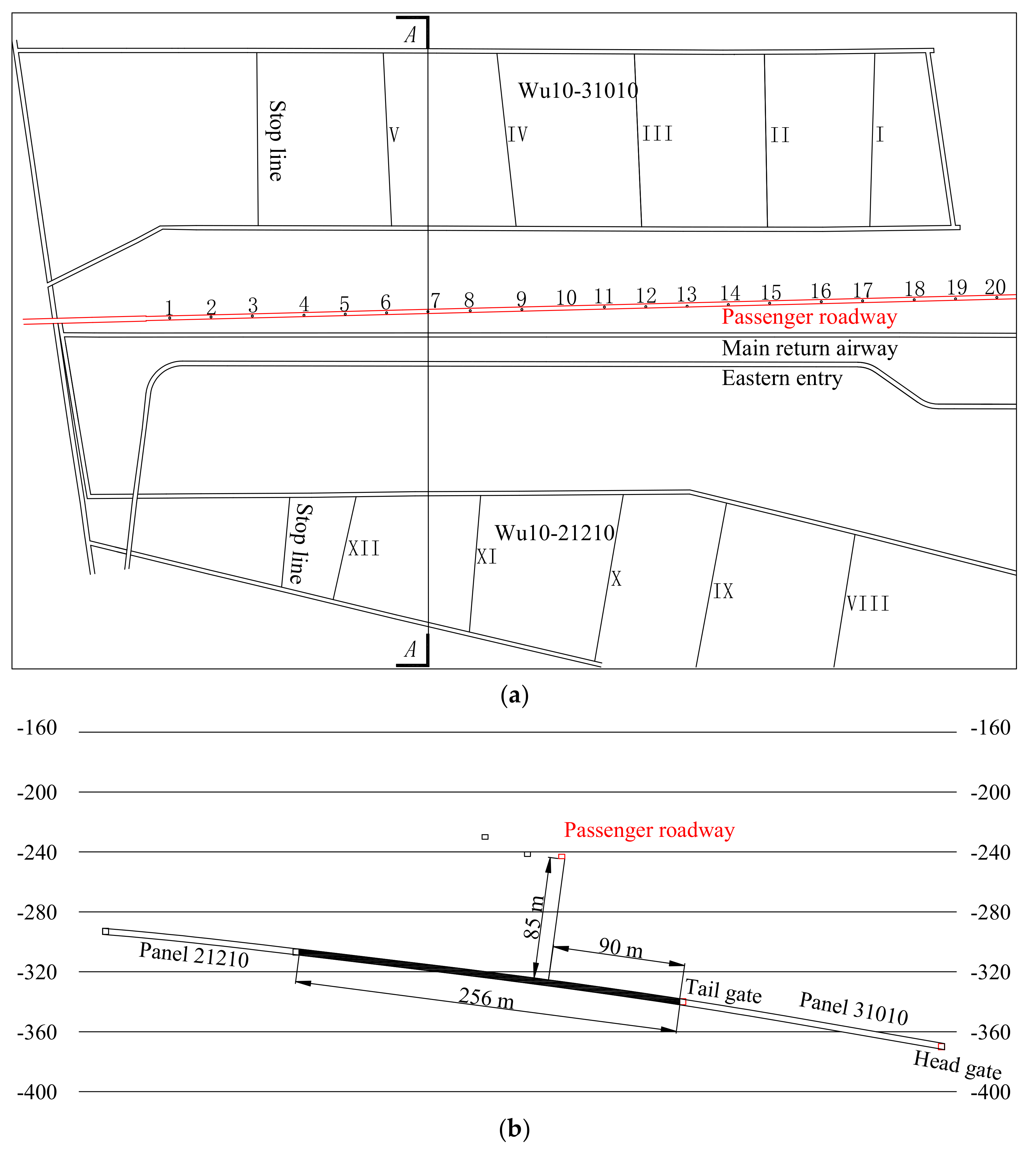

5.2. Mining Conditions

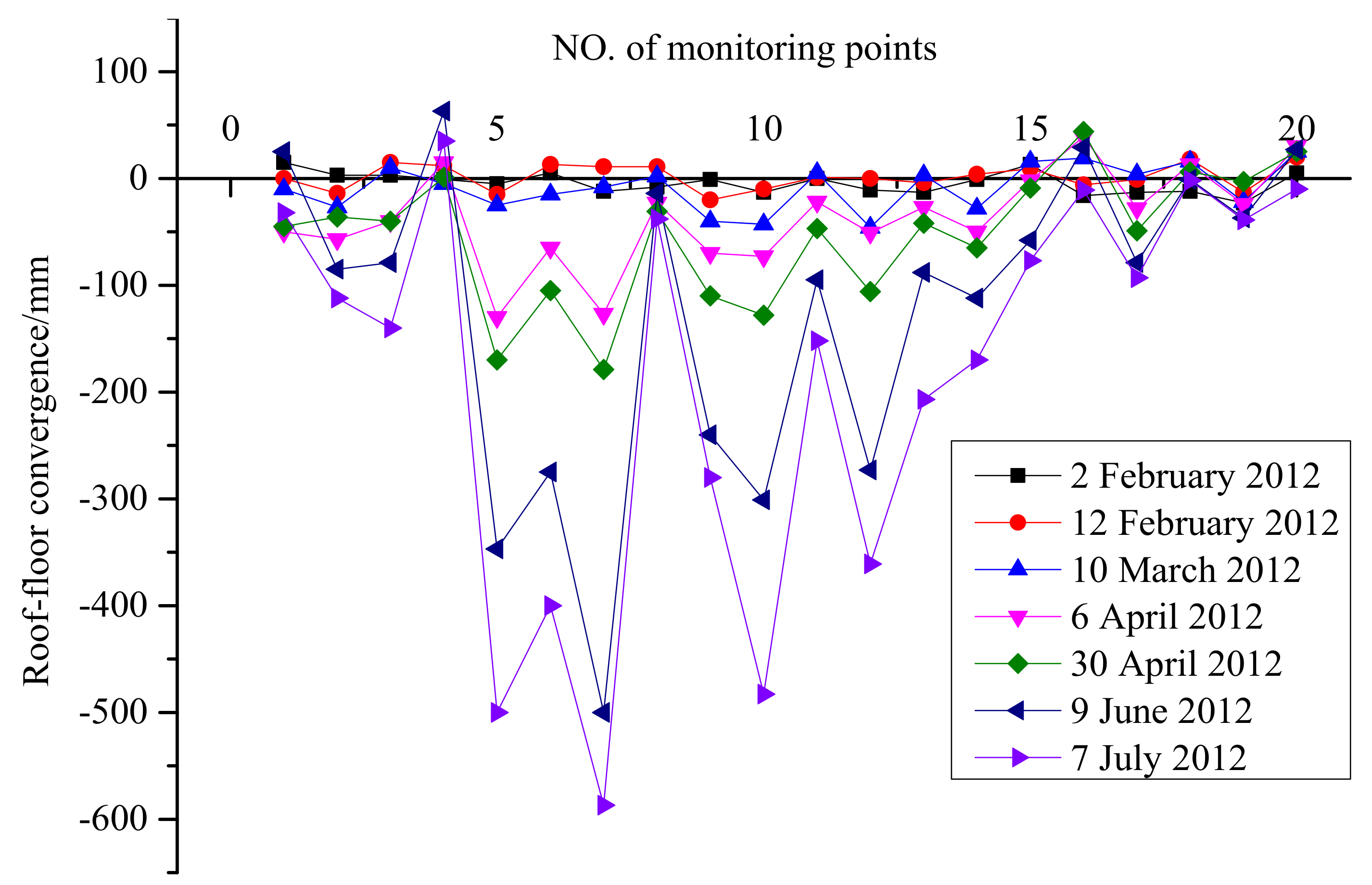

5.3. Field Measurement and Theoretical Analysis

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tiwary, R.K. Environmental impact of coal mining on water regime and its management. Water Air Soil Pollut. 2001, 132, 185–199. [Google Scholar] [CrossRef]

- Palchik, V. Formation of fractured zones in overburden due to longwall mining. Environ. Geol. 2003, 44, 28–38. [Google Scholar]

- Wright, I.A.; McCarthy, B.; Belmer, N.; Price, P. Subsidence from an underground coal mine and mine wastewater discharge causing water pollution and degradation of aquatic ecosystems. Water Air Soil Pollut. 2015, 226, 348–362. [Google Scholar] [CrossRef]

- Kratzsch, H. Mining Subsidence Engineering; Springer: Heidelberg, Germany, 1983; pp. 135–137. [Google Scholar]

- State Bureau of Coal Industry. Regulations of Coal Pillar Design and Extraction for Buildings, Water Bodies, Railways, Main Shafts and Roadways; Coal Industry Press: Beijing, China, 2000; pp. 46–47.

- Shu, D.M.; Bhattacharyya, A.K. Relationship between sub-surface and surface subsidence—A theoretical model. Min. Sci. Technol. 1990, 11, 307–319. [Google Scholar] [CrossRef]

- Dai, H.Y.; Teng, Y.H.; Lv, T.H.; Hu, J.Y. Analysis and control measures for the mining of dark shaft in dahuangshan coal mine. Min. Surv. 1999, 7–10. Available online: http://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFQ&dbname=CJFD9899&filename=KSCL901.002&uid=WEEvREcwSlJHSldRa1FhdkJkVWI2K1hRUnFrSXBsdWRma1ZmR2k3WFBlRT0=$9A4hF_YAuvQ5obgVAqNKPCYcEjKensW4ggI8Fm4gTkoUKaID8j8gFw!!&v=MTcwMTE0T1g2VHJIMDNlYk9jUmJtZFpPZHFFaTNuVnc9PUxqN0lZcnE0SDgvTXI0MHFGNTRPZmdnNXpoQVU0amg=. (accessed on 7 August 2017).

- Wang, F.; Xu, J.L.; Xie, J.L.; Guo, J.K.; Liu, D.L. Method of designing protective coal pillar on roof roadway based onmining induced stress boundary line. J. China Coal Soc. 2013, 38, 1917–1922. [Google Scholar]

- Aksoy, C.O.; Kose, H.; Onargan, T.; Koca, Y.; Heasley, K. Estimation of limit angle using laminated displacement discontinuity analysis in the Soma coal field, Western Turkey. Int. J. Rock Mech. Min. Sci. 2004, 41, 547–556. [Google Scholar] [CrossRef]

- Yu, Y.M.; Dai, H.Y.; He, Z.J. Mining design for shaft and industry square pillar and practice in No.6 coal mine in Changguang mining district. J. Min. Saf. Eng. 2008, 25, 202–206. [Google Scholar]

- Zhou, Z.; Li, Q.F. Safety coal pillar design of coal mining under railway. Miner. Eng. Res. 2012, 27, 23–27. [Google Scholar]

- Hong, M. Mountain village protection coal pillar stay and mining impact deformation prediction. Coal Chem. Ind. 2014, 37, 1–4. [Google Scholar]

- Abdallah, M.; Verdel, T. Behavior of a masonry wall subjected to mining subsidence, as analyzed by experimental designs and response surfaces. Int. J. Rock Mech. Min. Sci. 2017, 100, 199–206. [Google Scholar] [CrossRef]

- Sepehri, M.; Apel, D.B.; Hall, R.A. Prediction of mining-induced surface subsidence and ground movements at a Canadian diamond mine using an elastoplastic finite element model. Int. J. Rock Mech. Min. Sci. 2017, 100, 73–82. [Google Scholar] [CrossRef]

- Yao, X.L.; Whittaker, B.N.; Reddish, D.J. Influence of overburden mass behavioural properties on subsidence limit characteristics. Min. Sci. Technol. 1991, 13, 167–173. [Google Scholar] [CrossRef]

- Ren, G.; Li, J. A study of angle of draw in mining subsidence using numerical modeling techniques. Electron. J. Geotech. Eng. 2008, 13, 1–14. [Google Scholar]

- Deng, K.Z.; Ma, W.M. Influence of thickness on the moving Angle and the radius of influence. Min. Surv. 1989. Available online: http://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFQ&dbname=CJFD8589&filename=KSCL198901011&uid=WEEvREcwSlJHSldRa1FhdkJkVWI2K1hRUnFrSXBsdWRma1ZmR2k3WFBlRT0=$9A4hF_YAuvQ5obgVAqNKPCYcEjKensW4ggI8Fm4gTkoUKaID8j8gFw!!&v=MDI3MTQ5RVpZUjhlWDFMdXhZUzdEaDFUM3FUcldNMUZyQ1VSTEtmWk9Sc0Z5emhVYi9CTGo3SVlyS3hGdGpNcm8=. (accessed on 7 August 2017).

- Hao, Y.J.; Chen, S.H. Influence rule on hard rock seams to rocks defermation. Coal 2000, 9, 8–9. [Google Scholar]

- Yu, B.H.; Zhu, W.B.; Xu, J.L. Numerical simulation of surface subsidence induced by deep mining. J. Min. Saf. Eng. 2007, 24, 422–426. [Google Scholar]

- Wang, G.Y. Understanding of the boundary of subsidence basin in the overburden. Min. Surv. 1994, 35–36. Available online: http://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFQ&dbname=CJFD9495&filename=KSCL401.010&uid=WEEvREcwSlJHSldRa1FhdkJkVWI2K1hRUnFrSXBsdWRma1ZmR2k3WFBlRT0=$9A4hF_YAuvQ5obgVAqNKPCYcEjKensW4ggI8Fm4gTkoUKaID8j8gFw!!&v=MTUzOTE0T1g2VHJIMDNlYk9jUmJtZFpPZHBGaXJnVUE9PUxqN0lZcmU0SDgvTXJvOHFGNTRPZmdnNXpoQVU0amg=. (accessed on 7 August 2017).

- Gao, Y.F.; Shen, G.H. Rock mass structure and relationship between properties and deformation of rock strata. Min. Surv. 1988, 1. Available online: http://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFQ&dbname=CJFD8589&filename=KSCL198801006&uid=WEEvREcwSlJHSldRa1FhdkJkVWI2K1hRUnFrSXBsdWRma1ZmR2k3WFBlRT0=$9A4hF_YAuvQ5obgVAqNKPCYcEjKensW4ggI8Fm4gTkoUKaID8j8gFw!!&v=MjIwODBMajdJWXJLeEZ0bk1ybzlGWW9SOGVYMUx1eFlTN0RoMVQzcVRyV00xRnJDVVJMS2ZaT1JzRnl6aFZidlA=. (accessed on 7 August 2017).

- Dai, H.Y.; Lian, X.G.; Liu, J.Y.; Liu, Y.X.; Zhou, Y.M.; Deng, W.N.; Cai, Y.F. Model study of deformation induced by fully mechanized caving below a thick loess layer. Int. J. Rock Mech. Min. Sci. 2010, 47, 1027–1033. [Google Scholar]

- Wu, K.; Cheng, G.L.; Zhou, D.W. Experimental research on dynamic movement in strata overlying coal mines using similar material modeling. Arab. J. Geosci. 2015, 8, 6521–6534. [Google Scholar] [CrossRef]

- Yu, X.Y.; Zhang, E.Q. Mining Damages, 2nd ed.; China Coal Industry Publishing House: Beijing, China, 2010; pp. 53–55. [Google Scholar]

- Prusek, S.; Jędrzejec, E. Adjustment of the Budryk-Knothe theory to forecasting deformations of gateroads. Arch. Min. Sci. 2008, 53, 97–114. [Google Scholar]

- Gruszczyński, S. Standards and Thresholds for Impact Assessment; Springer: Heidelberg, Germany, 2008; pp. 185–202. [Google Scholar]

- Strzałkowski, P. Mathematical Model of Forecasting the Formation of Sinkhole Using Salustowicz’s Theory. Arch. Min. Sci. 2015, 60, 63–71. [Google Scholar]

- Jenike, A.W. Gravity Flow of Bulk Solids; Bulletin No. 108; Utah State University: Logan, UT, USA, 1961. [Google Scholar]

- Giunta, J.S. Flow patterns of granular materials in flat-bottom bins. J. Eng. Ind. 1969, 91, 406–413. [Google Scholar] [CrossRef]

- Blair-Fish, P.M.; Bransby, P.L. Flow patterns and wall stresses in a mass-flow bunker. J. Eng. Ind. 1973, 95, 17–26. [Google Scholar] [CrossRef]

- Moreea, S.B.M.; Nedderman, R.M. Exact stress and velocity distributions in a cohesionless material discharging from a conical hopper. Chem. Eng. Sci. 1996, 51, 3931–3942. [Google Scholar] [CrossRef]

- Mullins, W.W. Stochastic Theory of Particle Flow under Gravity. J. Appl. Phys. 1972, 43, 665–678. [Google Scholar] [CrossRef]

- Mullins, W.W. Nonsteady-state particle flow under gravity—An extension of the stochastic theory. J. Appl. Mech. 1974, 41, 49–68. [Google Scholar] [CrossRef]

- Bak, P.; Tang, C.; Wiesenfeld, K. Self-organized criticality. Phys. Rev. A 1988, 38, 364–374. [Google Scholar] [CrossRef]

- Watson, G.R.; Rotter, J.M. A finite element kinematic analysis of planar granular solids flow. Chem. Eng. Sci. 1996, 51, 3967–3978. [Google Scholar] [CrossRef]

- Sielamowicz, I.; Kowalewski, T.A.; Błoński, S. Central and eccentric granular material flows in bins/hoppers registered by DPIV optical technique. Acta Agrophys. 2004, 4, 519–531. [Google Scholar]

- Sielamowicz, I. Experimental analysis of granular material flows using the technique of digital particle image velocimetry. Eng. Trans. 2005, 53, 197–229. [Google Scholar]

- Sielamowicz, I.; Blonski, S.; Kowalewski, T.A. Optical technique DPIV in measurements of granular material flows, Part 1 of 3—Plane hoppers. Chem. Eng. Sci. 2005, 60, 589–598. [Google Scholar] [CrossRef]

- Szczepiński, W. A comparative analysis of theoretical models of gravity movements of cohesionless granular media. Eng. Trans. 2007, 55, 181–192. [Google Scholar]

- Sielamowicz, I.; Czech, M.; Kowalewski, T.A. Empirical description of granular flow inside a model silo with vertical walls. Biosyst. Eng. 2011, 108, 334–344. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, Y.; Ooi, J.Y. A numerical study of wall pressure and granular flow in a flat-bottomed silo. Powder Technol. 2015, 282, 43–54. [Google Scholar] [CrossRef]

- Nguyen, T.V.; Brennen, C.E.; Sabersky, R.H. Funnel flow in hoppers. J. Appl. Mech. 1980, 47, 729–735. [Google Scholar] [CrossRef]

- Litwiniszyn, J. Application of the equation of stochastic processes to mechanics of loose bodies. Arch. Mech. 1956, 8, 393–411. [Google Scholar]

- He, G.Q.; Yang, L.; Ling, G.D.; Jia, F.C.; Hong, D. Mining Subsidence Science; China University of Mining and Technology Press: Xuzhou, China, 1991; pp. 118–147. [Google Scholar]

- Department of mathematics, Tongji University. Advanced Mathematics, 5th ed.; Higher Education Press: Beijing, China, 2006; pp. 149–151. [Google Scholar]

- Qian, M.G.; Miao, X.X.; Xu, J.L. Theoretical study of key strata in ground control. J. China Coal Soc. 1996, 21, 225–230. [Google Scholar]

- Xu, J.L.; Qian, M.G. Study on the influence of key strata movement on subsidence. J. China Coal Soc. 2000, 25, 122–126. [Google Scholar]

- Xu, J.L.; Qian, M.G.; Zhu, W.B. Study on influence of primary key strata on surface dynamic subsidence. Chin. J. Rock Mech. Eng. 2005, 24, 787–791. [Google Scholar]

- Dzegniuk, B.; Hejmanowski, R.; Sroka, A. Evaluation of the Damage Hazard to Building Objects on the Mining Areas Considering the Deformation Course in Time. In Proceedings of the Xth International Congress of the International Society for Mine Surveying, Fremantle, Western Australia, 2–6 November 1997. [Google Scholar]

| No. | Rock Strata | Height | Material Ratio | Bulk Density | Elasticity Modulus | Poisson’s Ratio |

|---|---|---|---|---|---|---|

| m | Sand:CaCO3:Gypsum | kN/m3 | GPa | |||

| 1 | Topsoil | 60 | 850.91 kg sand and 85.1 kg saw dust | 12.0 | 0.00093 | 0.35 |

| 2 | PKS | 8 | 50:3:7 | 16.8 | 0.013974 | 0.20 |

| 3 | Soft rock 2 | 30 | 50:7:3 | 16.8 | 0.04790 | 0.28 |

| 4 | KS | 5 | 60:5:5 | 16.8 | 0.09581 | 0.22 |

| 5 | Soft rock 1 | 16 | 50:7:3 | 16.8 | 0.04790 | 0.28 |

| 6 | Coal seam | 4 | 70:7:3 | 16.8 | 0.01796 | 0.28 |

| No. | Strata | Density/(kg/m3) | Height/m | Bulk Modulus/GPa | Shear Modulus/GPa | Cohesion/MPa | Tensile Strength/MPa | Frictionangle/(°) |

|---|---|---|---|---|---|---|---|---|

| 1 | Coal floor | 2600 | 10 | 4.54 | 2.34 | 5 | 5 | 34 |

| 2 | Coal seam | 1600 | 3 | 1.52 | 0.78 | 1 | 1 | 23 |

| 3 | Immediate floor | 2500 | 80 | 2.00 | 1.20 | 2 | 2 | 33 |

| 4 | KS | 2600 | 20 | 6.67 | 4.00 | 4 | 5 | 40 |

| 5 | Soft rock | 2400 | 120 | 1.33 | 0.80 | 1 | 3 | 28 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, C.; Xu, J.; Wang, F.; Wang, F. Movement Boundary Shape of Overburden Strata and Its Influencing Factors. Energies 2018, 11, 742. https://doi.org/10.3390/en11040742

He C, Xu J, Wang F, Wang F. Movement Boundary Shape of Overburden Strata and Its Influencing Factors. Energies. 2018; 11(4):742. https://doi.org/10.3390/en11040742

Chicago/Turabian StyleHe, Changchun, Jialin Xu, Fei Wang, and Feng Wang. 2018. "Movement Boundary Shape of Overburden Strata and Its Influencing Factors" Energies 11, no. 4: 742. https://doi.org/10.3390/en11040742