Cost-Based Design and Selection of Point Absorber Devices for the Mediterranean Sea

Abstract

:1. Introduction

- (i)

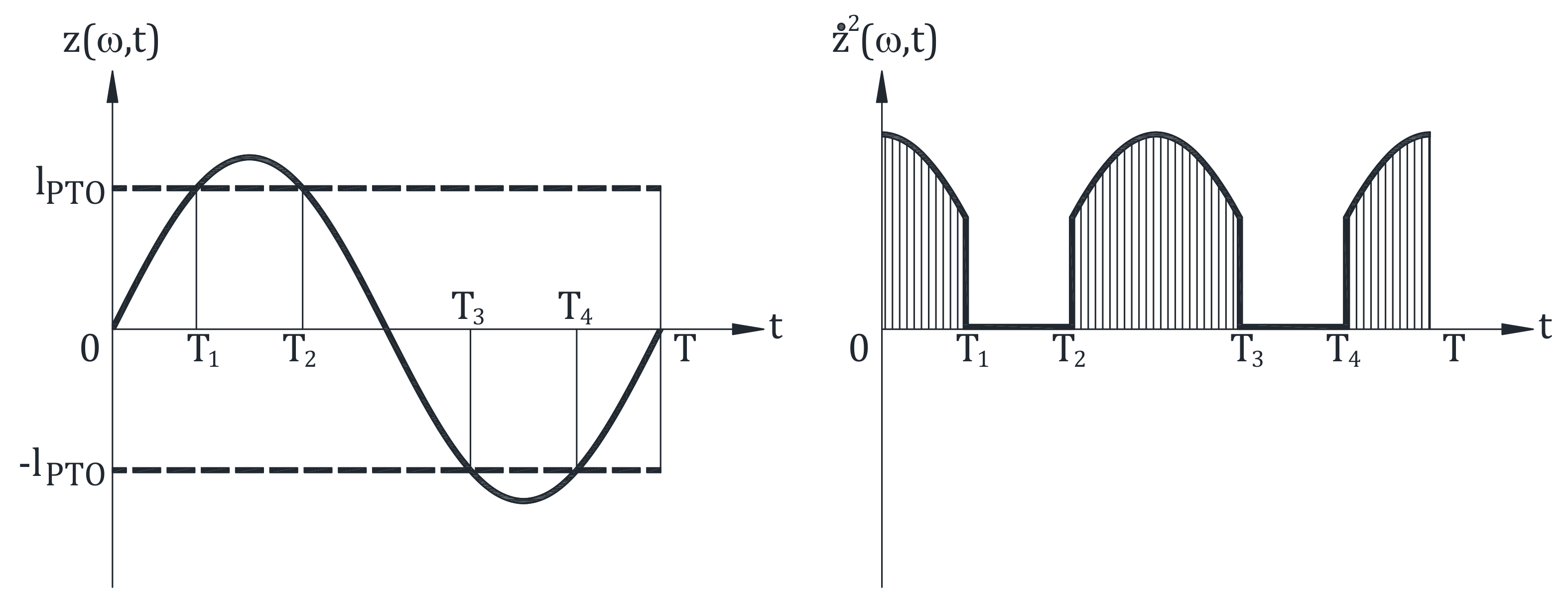

- Two point absorber configurations, mainly consisting of a floating buoy plus an optional fully submerged mass, required to properly tune the device heave natural frequency with dominant sea states at the candidate deployment site, are investigated by a purposely developed programme in Matlab [18]. Particularly, the hydrodynamic model of the floating buoy is developed accounting for the WEC operational profile and the PTO mechanical restraint, in terms of free stroke length, provided by the permanent magnet linear generator.

- (ii)

- A new procedure to select the optimum WEC design, that allows minimizing the , is outlined and applied to several candidate deployment sites, located in the Mediterranean Sea, to investigate the incidence of available energy and metocean conditions on the attained power production and cost.

- (iii)

- The incidence of PTO free stroke length and WEC operational profile on power production and is analysed, to investigate the impact on annual power production and costs.

- (iv)

- Some guidelines to select, in the preliminary design phase, the optimum point absorber configuration that allows minimizing the , are provided.

2. Review of Point Absorber Technology

- (i)

- The WEC device consists of a floating buoy, with a bullet-type configuration, plus an optional fully submerged mass, connected by means of a tensioned line to a PTO unit, lying on the seabed and equipped with a gravity-based foundation;

- (ii)

- The PTO consists of a direct driven permanent magnet linear generator, modelled in the frequency domain by an additional damping and a spring stiffness;

- (iii)

- Phase control is applied, to properly tune the device heave natural frequency, maximize the power production and minimize the LCoE, with reference to dominant sea states at candidate deployment sites.

3. Method

3.1. Hydrodynamic Model

3.2. Permanent Magnet Linear Generator Model

3.3. Power Production Assessment

3.4. Levelised Cost of Energy Assessment

4. Main Data for Cost-Based Design

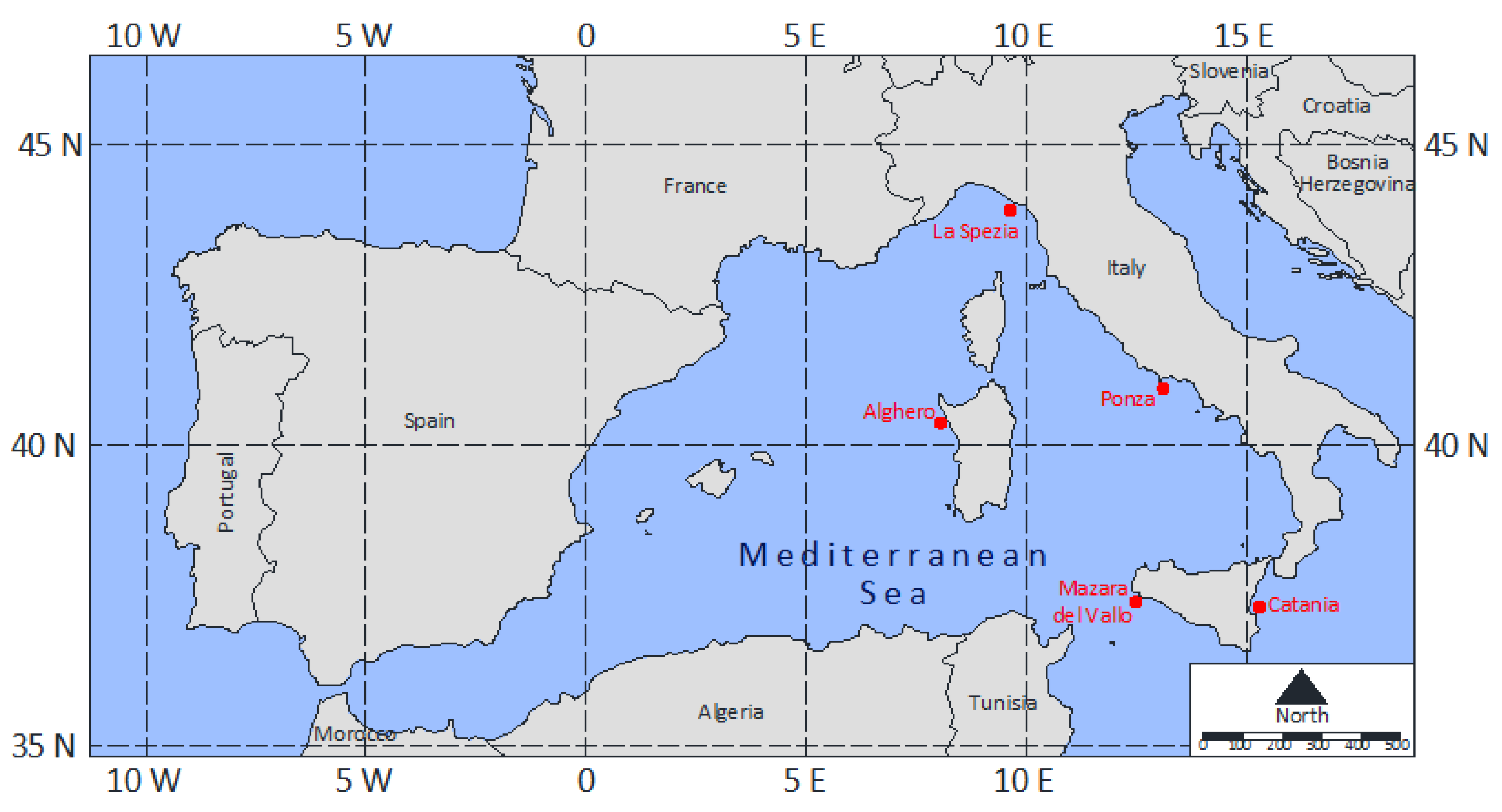

4.1. Selection of Candidate Deployment Sites

4.2. Capital, Maintenance and Decommisioning Costs

5. Results

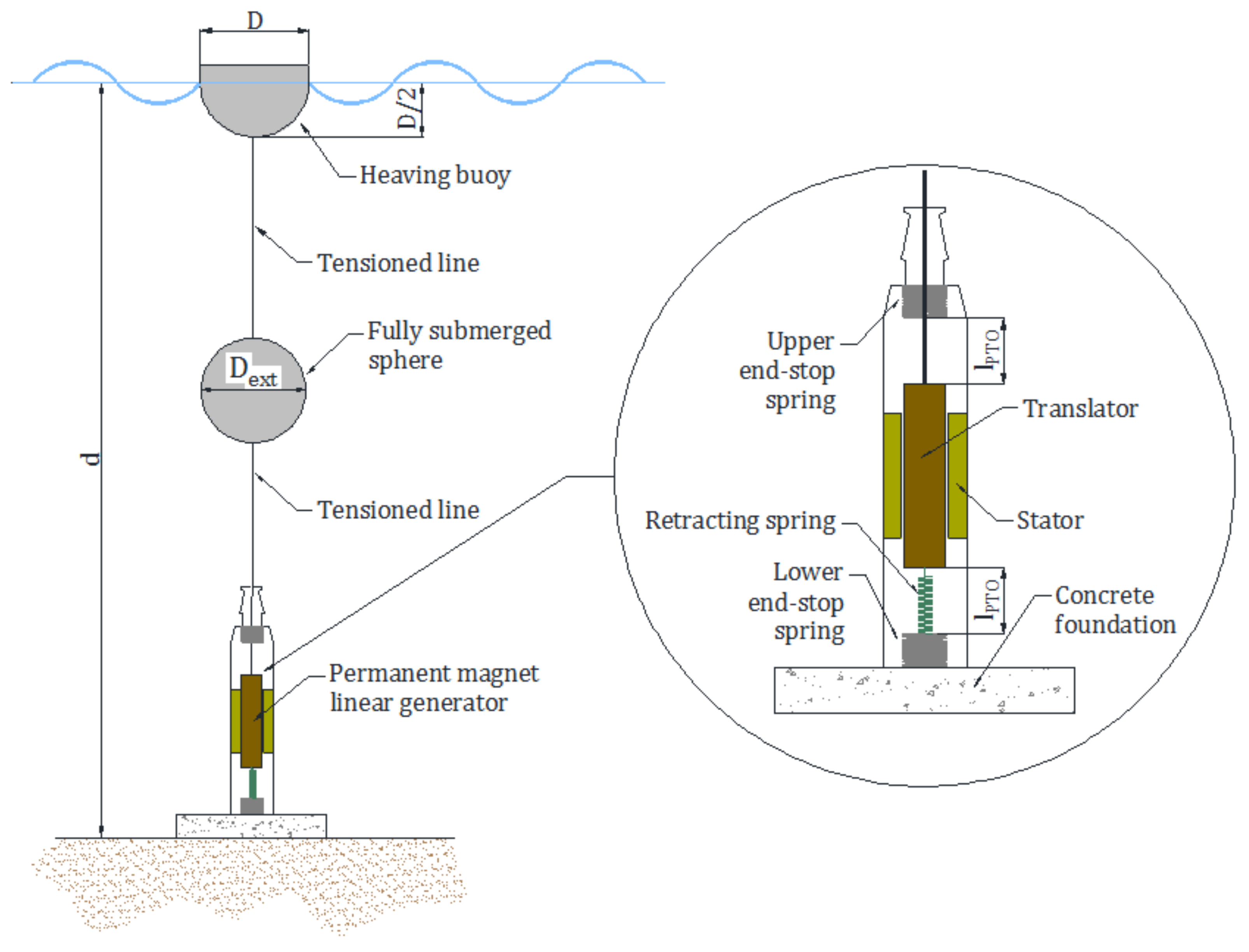

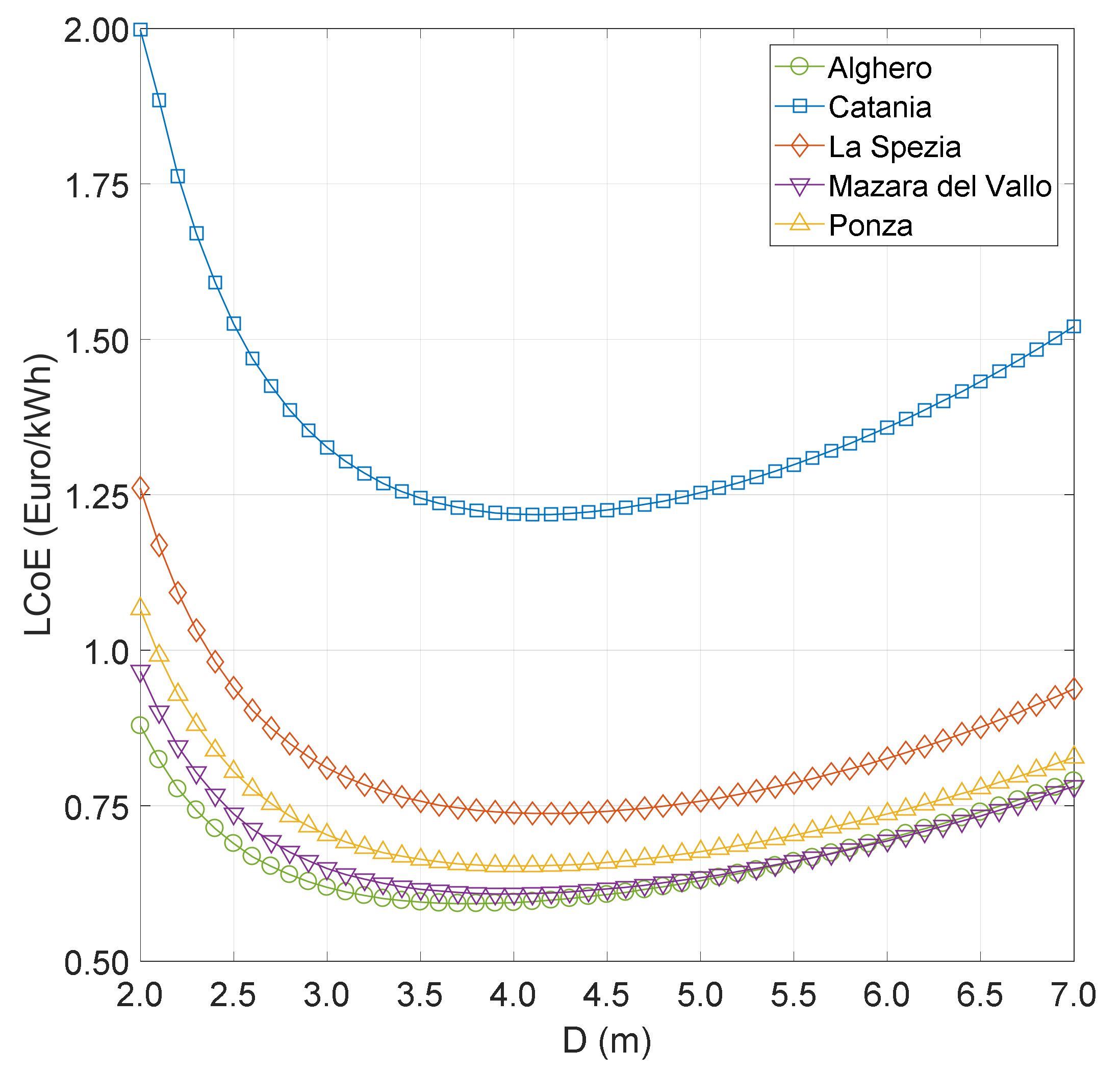

5.1. WEC Sizing without the Fully Submerged Mass

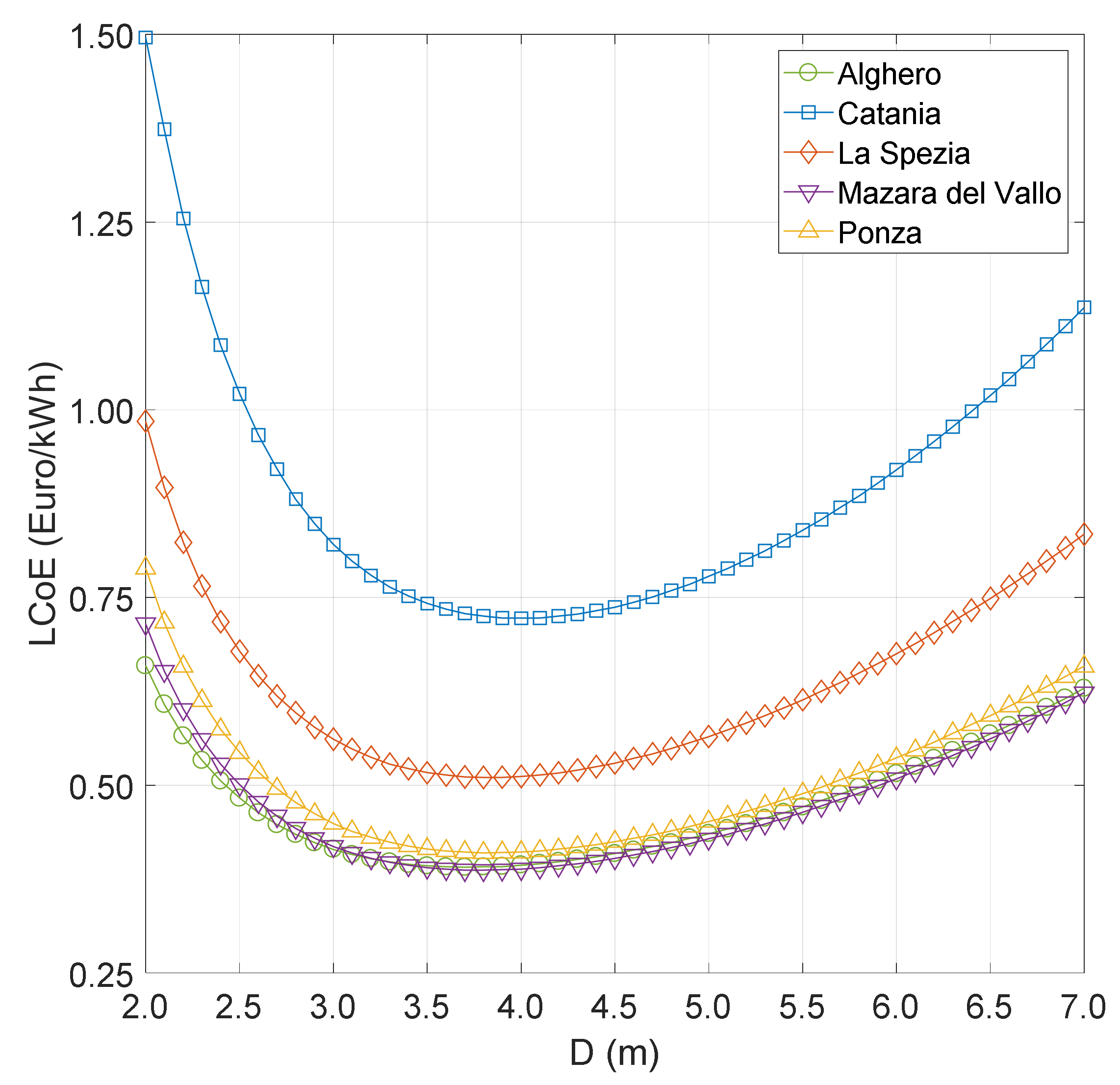

5.2. WEC Sizing with the Fully Submerged Mass

6. Discussion

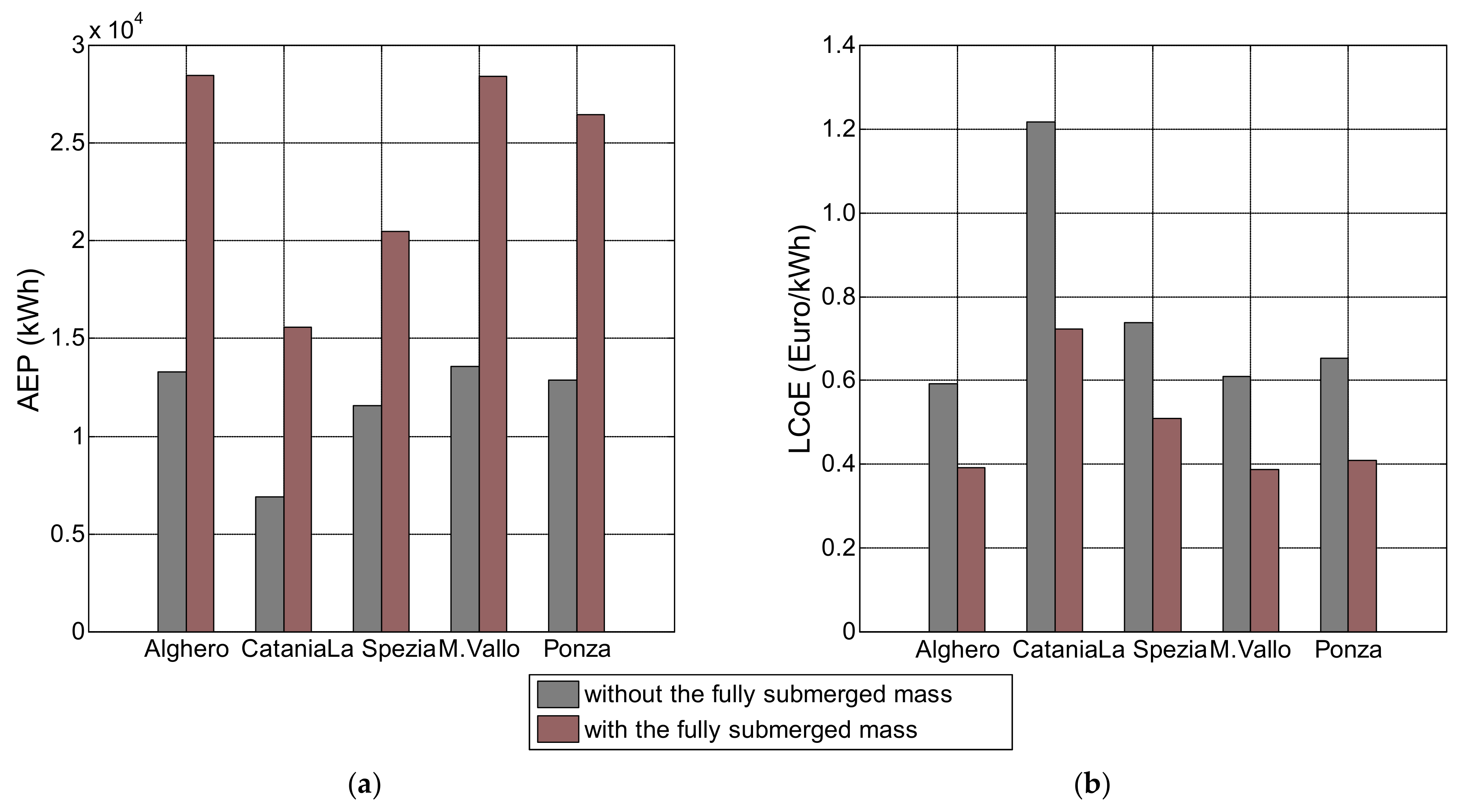

6.1. Incidence of Fully Submerged Mass on Cost-Based Design

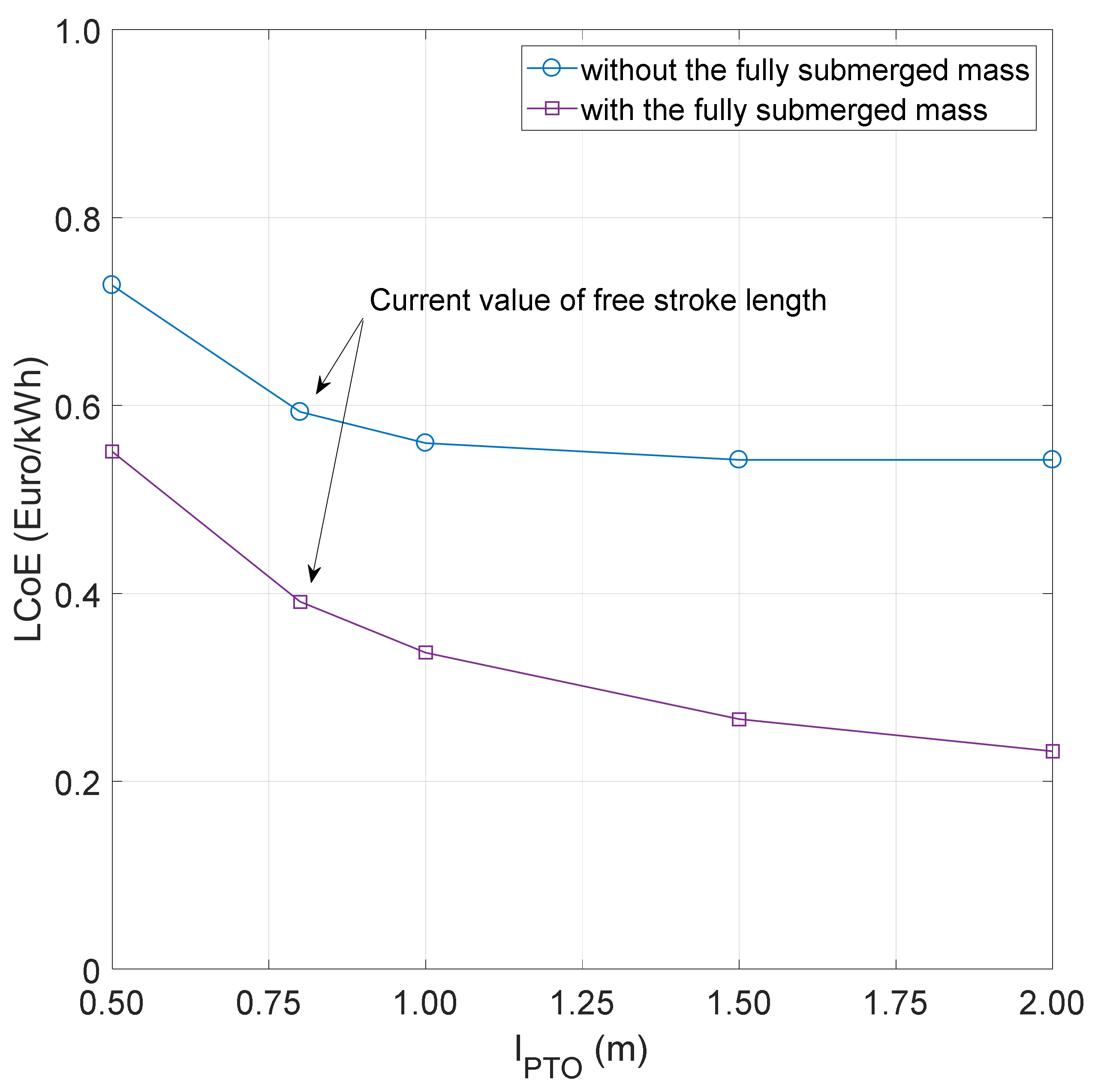

6.2. PTO Free Stroke Length

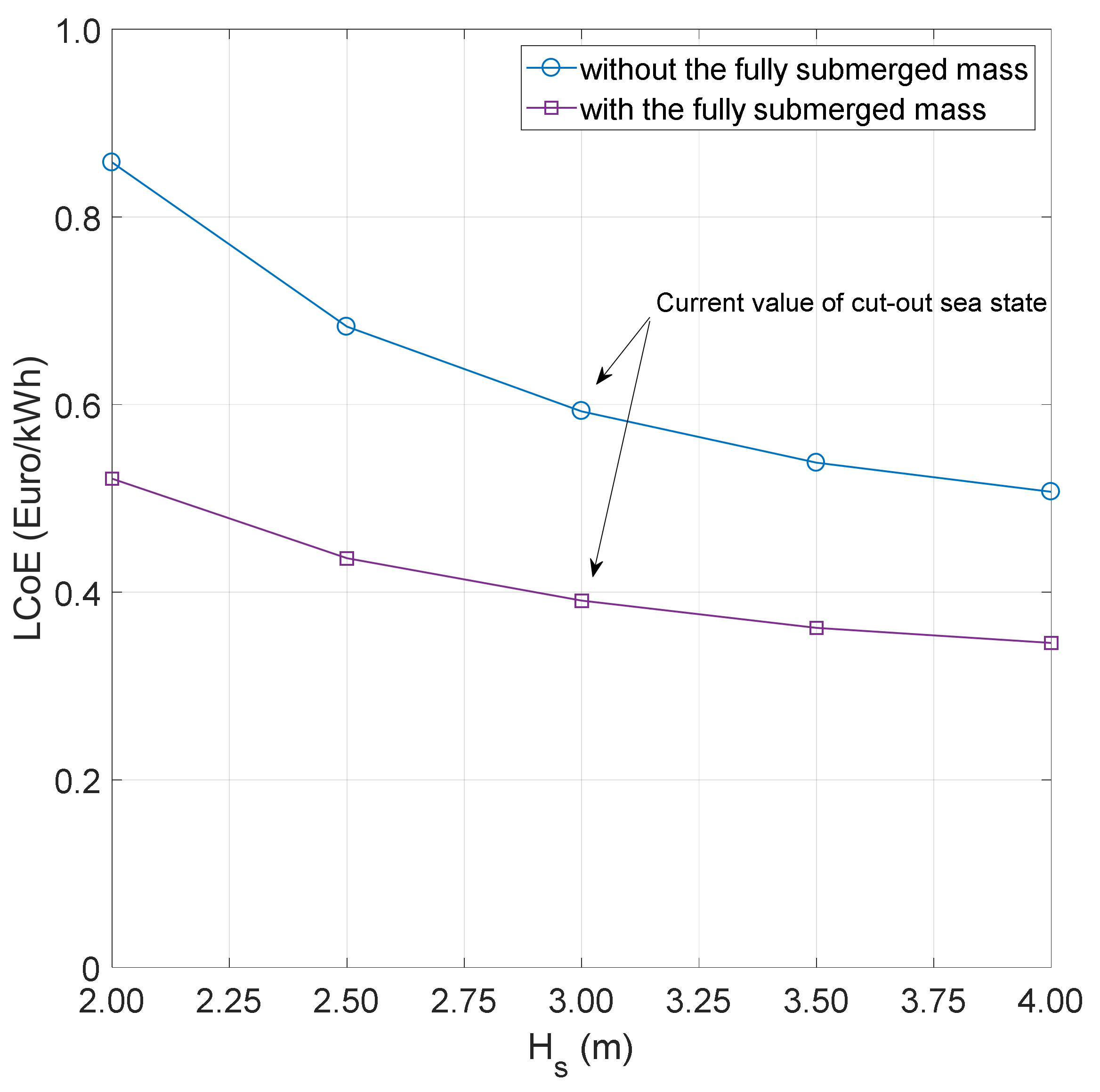

6.3. WEC Operational Profile

6.4. Some Recommendations for WEC Design

- (i)

- Power production mainly depends on metocean conditions at the deployment site. Nevertheless, actual results show that the decrease rate of diminishes with the available wave power per unit length of wave front, as reported in Figure 9, with reference to WEC devices without and with the fully submerged mass. In fact, the LCoE is almost constant from 3.5 up to about 6.0 kW/m2, which implies that the expected cost of energy is almost comparable at Ponza, Mazara del Vallo and Alghero, even if ranges from 3.73 up to 5.79 kW/m2. This outcome is mainly due to the heave motion restraint provided by the PTO unit, so that the incoming wave energy cannot be completely harnessed in the most energetic sea states.

- (ii)

- Power production is mainly affected by the free stroke length of the permanent magnet linear generator, as in the most energetic sea states only part of the wave cycle is effective. In this respect, this vertical motion restraint has to be properly accounted in the most energetic sea states, as detailed in the Appendix, to correctly estimate the AEP and the .

- (iii)

- Floating buoy dimensions have to be properly selected by minimizing the , on the basis of wave statistics at the candidate deployment site. Particularly, the power production depends on the “cut-out” sea state that has to be selected by properly balancing the WEC operational profile and all technical issues related to the extreme loads in harsh weather conditions on the floating buoy, the mooring connection line and the PTO unit. Actual results show that a 3 m “cut-out” significant wave height is a reasonable design value for point absorbers in the Mediterranean Sea, as a further increase of the maximum significant wave height yields to a moderate decrease of the .

- (iv)

- There is a strong relation between the PTO free stroke length and the fully submerged mass. In fact, a low free stroke length of about 0.8 m is suitable for WEC devices without the fully submerged mass. On the contrary, if the floating buoy is equipped with a fully submerged mass, in order to properly tune the device heave natural frequency depending on dominant sea states at the deployment site, consistent reductions of can be achieved by increasing the PTO free stroke length. Current results show that for point absorbers equipped with the fully submerged mass and deployed in the Mediterranean Sea the free stroke length should be increased up to at least 1.5 m, i.e., one half the “cut-out” significant wave height.

- (v)

7. Conclusions

- (i)

- A new hydrodynamic model for point absorbers with a fully submerged mass was developed. It accounts for the WEC operational profile, in terms of “cut-out” sea state, and the heave motion restraint provided by the permanent magnet linear generator when the translator mass hits the upper/lower end-stop springs, as detailed in the Appendix A.

- (ii)

- The new procedure, devoted to select the most suitable WEC device, characterized by the minimum , was applied to several candidate deployment sites, verifying that the only wave power per unit length of wave front is not sufficient to correctly characterize the site, in terms of power production and costs.

- (iii)

- The incidence on the AEP and the of the PTO free stroke length and the WEC operational profile was investigated. It was found that current PTOs, with a free stroke length equal to 0.8 m, are suitable for point absorbers without the fully submerged mass. On the contrary, it is suggested to increase the free stroke length up to 1.5 m for WEC devices equipped with the fully submerged mass, due to the increased heave motion amplitude in harsh weather conditions.

- (iv)

- Some guidelines to reduce the , to properly tune the PTO mechanical properties and select, at least in a preliminary project phase, the most suitable point absorber configuration are provided.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| List of Abbreviations | |

| AEP | Annualized Energy Production |

| LCoE | Levelised Cost of Energy |

| PTO | Power Take-Off |

| RAO | Response Amplitude Operator |

| WEC | Wave Energy Converter |

| List of Symbols | |

| Frequency-dependent hydrodynamic damping coefficient | |

| Power Take-Off damping coefficient | |

| d | Width of stator side |

| Magnetic field in a tooth | |

| Capacity factor | |

| Wave group celerity | |

| Floating buoy diameter | |

| Diameter of fully submerged mass | |

| Yearly available energy | |

| Voltage | |

| Heave exciting force | |

| Heave motion transfer function | |

| Significant wave height of the i-th sea state | |

| Wave power per unit length of wave front | |

| Available wave power per unit length of wave front | |

| Restoring stiffness | |

| Power Take-Off restoring stiffness | |

| Power Take-Off free stroke length | |

| Mass of floating buoy | |

| Frequency-dependent added mass of floating buoy | |

| Mass plus added mass of the fully submerged body | |

| Device expected lifetime | |

| Ratio of annual operating costs to device rated power | |

| Absorbed power | |

| Absorbed power if the entire wave cycle is effective | |

| Absorbed power if only part of the wave cycle is effective | |

| Total number of poles | |

| Probability of occurrence of the sea state | |

| Winding ratio | |

| Device rated power | |

| Real part of a complex number | |

| Generator reactive resistance | |

| Circuit external resistance | |

| Discount rate | |

| Ratio of capital costs to device rated power | |

| Ratio of decommissioning costs to device rated power | |

| Wave spectrum | |

| Peak period of the j-th sea state | |

| Mean wave period | |

| Time | |

| Generator polar pair width | |

| Tooth width | |

| Heave motion amplitude | |

| Heave motion velocity | |

| Heave motion acceleration | |

| List of Greek Symbols | |

| Peak enhancement factor of wave spectrum | |

| Sea surface elevation | |

| Wave amplitude | |

| Electrical efficiency | |

| Magnetic flux | |

| Magnetic flux amplitude | |

| Corrective factor of the absorber power | |

| Wave circular frequency | |

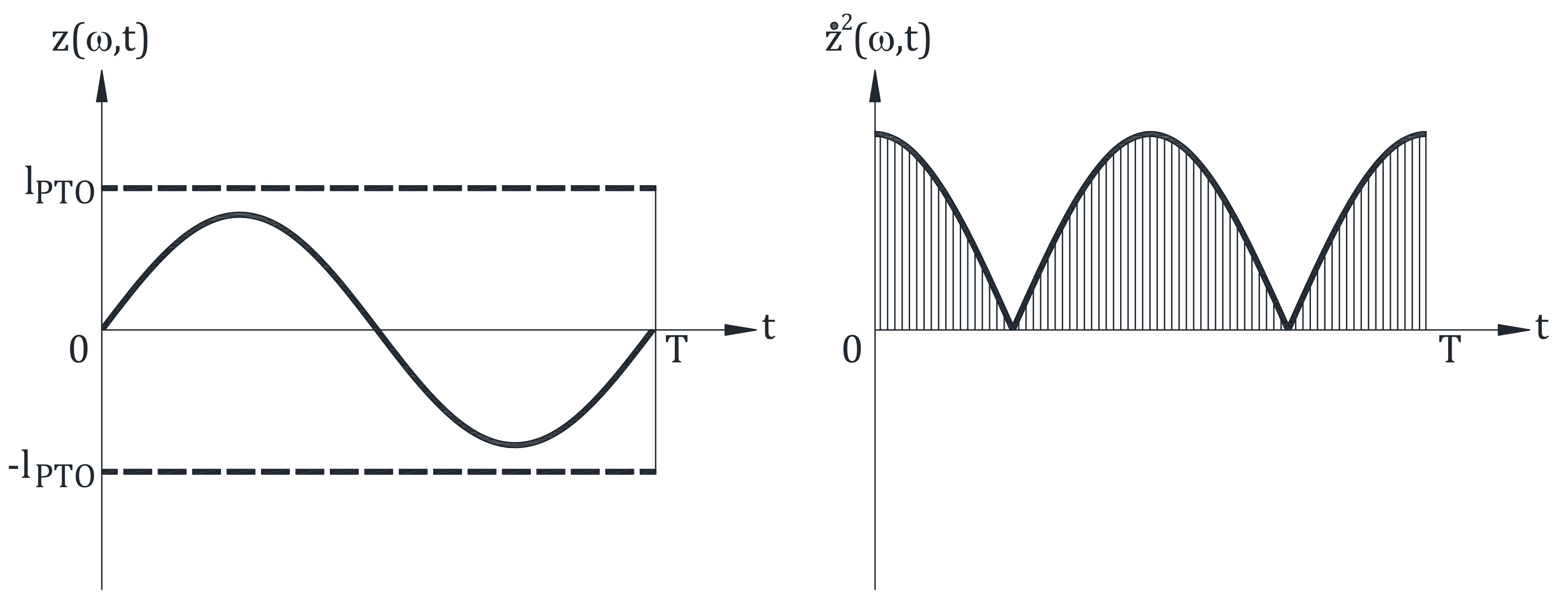

Appendix A. Power Production Assessment

References

- Falcão, A.F.O. Wave energy utilization: A review of the technologies. Renew. Sustain. Energy Rev. 2010, 14, 899–918. [Google Scholar] [CrossRef]

- Salter, S.H. Wave power. Nature 1974, 249, 720–724. [Google Scholar] [CrossRef]

- Vantorre, M.; Banasiak, R.; Verhoeven, R. Modelling of hydraulic performance and wave energy extraction by a point absorber in heave. Appl. Ocean Res. 2004, 26, 61–72. [Google Scholar] [CrossRef]

- Falnes, J. A review of wave-energy extraction. Mar. Struct. 2007, 20, 185–201. [Google Scholar] [CrossRef]

- Vicente, P.C.; António, F.D.; Gato, L.M.C.; Justino, P.A.P. Dynamics of arrays of floating point-absorber wave energy converters with inter-body and bottom slack-mooring connections. Appl. Ocean Res. 2009, 31, 267–281. [Google Scholar] [CrossRef]

- Nunes, G.; Valério, D.; Beirão, P.; Sá da Costa, J. Modelling and control of a wave energy converter. Renew. Energy 2011, 36, 1913–1921. [Google Scholar] [CrossRef]

- Ocean Energy Systems. International Levelised Cost of Energy for Ocean Energy Technologies; Report; International Energy Agency: Paris, France, 2015. [Google Scholar]

- European Commission. European Commission Decision C (2014) 4995; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- De Backer, G. Hydrodynamic Design Optimization of Wave Energy Converters Consisting of Heaving Point Absorbers. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2009. [Google Scholar]

- Bachynski, E.E.; Young, Y.L.; Yeung, R.W. Analysis and optimization of a tethered wave energy converter in irregular waves. Renew. Energy 2012, 48, 133–145. [Google Scholar] [CrossRef]

- Yu, Y.-H.; Li, Y.; Hallet, K.; Hotimsky, C. Design and Analysis for a Floating Oscillating Surge Wave Energy Converter; National Renewable Energy Laboratory Report NREL/CP-5000-61283; National Renewable Energy Laboratory: Golden, CO, USA, 2014; pp. 1–11.

- Piscopo, V.; Benassai, G.; Cozzolino, L.; Della Morte, R.; Scamardella, A. A new optimization procedure of heaving point absorber hydrodynamic performances. Ocean Eng. 2016, 116, 242–259. [Google Scholar] [CrossRef]

- Piscopo, V.; Benassai, G.; Della Morte, R.; Scamardella, A. Towards a cost-based design of heaving point absorbers. Int. J. Mar. Energy 2017, 18, 15–29. [Google Scholar] [CrossRef]

- Salter, S.H.; Taylor, J.R.M.; Caldwell, N.J. Power conversion mechanisms for wave energy. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2002, 216, 1–27. [Google Scholar] [CrossRef]

- Benassai, G.; Campanile, A.; Piscopo, V.; Scamardella, A. Mooring control of semi-submersible structures for wind turbines. Procedia Eng. 2014, 70, 132–141. [Google Scholar] [CrossRef]

- Benassai, G.; Campanile, A.; Piscopo, V.; Scamardella, A. Ultimate and accidental limit state design for mooring systems of floating wind turbines. Ocean. Eng. 2014, 92, 64–74. [Google Scholar] [CrossRef]

- Benassai, G.; Campanile, A.; Piscopo, V.; Scamardella, A. Optimization of Mooring Systems for Floating Offshore Wind Turbines. Coast. Eng. J. 2015, 57, 1550021-1–1550021-19. [Google Scholar] [CrossRef]

- MathWorks. Matlab User Guide R2017b. Available online: www.mathworks.com (accessed on 4 December 2017).

- Mekhiche, M.; Edwards, K.A. Ocean power technologies PowerBuoy®: System-level design, development and validation methodology. In Proceedings of the 2nd Marine Energy Technology Symposium, Seattle, WA, USA, 15–18 April 2014; pp. 1–9. [Google Scholar]

- Danielson, O. Wave Energy Conversion—Linear Synchronous Permanent Magnet Generator. Ph.D. Thesis, Acta Universitatis Upsaliensis, Uppsala, Sweden, 2006. [Google Scholar]

- Drew, B.; Plummer, A.R.; Sahinkaya, M.N. A review of wave energy converter technology. Proc. Inst. Mech. Eng. A J. Power Energy 2009, 223, 887–902. [Google Scholar] [CrossRef]

- Falnes, J.; Budal, K. Wave-power conversion by point absorbers. Norw. Mar. Res. 1978, 6, 2–11. [Google Scholar]

- Gaspar, J.F.; Calvário, M.; Kamarlouei, M.; Guedes Soares, C. Power take-off concept for wave energy converters based on oil-hydraulic transformer units. Renew. Energy 2016, 86, 1232–1246. [Google Scholar] [CrossRef]

- Lejerskog, E.; Boström, C.; Hai, L.; Waters, R.; Leijon, M. Experimental results on power absorption from a wave energy converter at Lysekil wave energy research site. Renew. Energy 2015, 77, 9–14. [Google Scholar] [CrossRef]

- Bozzi, S.; Moreno Miquel, A.; Antonini, A.; Passoni, G.; Archetti, R. Modelling of a Point Absorber for Energy Conversion in Italian Seas. Energies 2013, 6, 3033–3051. [Google Scholar] [CrossRef] [Green Version]

- Archetti, R.; Moreno Miquel, A.; Antonini, A.; Passoni, G.; Bozzi, S.; Gruosso, G.; Scarpa, F.; Bizzozero, F.; Giassi, M. Designing a point-absorber wave energy converter for the Mediterranean Sea. In Energia, Ambiente e Innovazione—Speciale Ocean Energy: Ongoing Research in Italy; ENEA Agenzia Nazionale per le Nuove Tecnologie, L’energia e lo Sviluppo Economico Sostenibile: Rome, Italy, 2015; pp. 76–85. [Google Scholar]

- Lok, K.; Stallard, T.; Stansby, P.; Jenkins, N. Optimisation of a Clutch-Rectified Power Take Off System for a Heaving Wave Energy Device in Irregular Waves with Experimental Comparison. Int. J. Mar. Energy 2014, 8, 1–16. [Google Scholar] [CrossRef]

- Hulme, A. The wave forces acting on a floating hemisphere undergoing forced periodic oscillations. J. Fluid. Mech. 1982, 121, 443–463. [Google Scholar] [CrossRef]

- Chen, X.B.; Diebold, L.; Doutreleau, Y. New Green-Function Method to Predict Wave-Induced Ship Motions and Loads. In Proceedings of the Twenty-Third Symposium on Naval Hydrodynamics, Val de Reuil, France, 17–22 September 2000; pp. 66–81. [Google Scholar]

- Newman, J.N. Marine Hydrodynamics; MIT Press: Cambridge, MA, USA, 1977. [Google Scholar]

- El-hami, M.; Glynne-Jones, P.; White, N.M.; Hill, M.; Beeby, S.; James, E.; Brwon, A.D.; Ross, J.N. Design and fabrication of a new vibration-based electromechanical power generator. Sensor. Actuator A Phys. 2001, 92, 335–342. [Google Scholar] [CrossRef]

- Guizzi, G.L.; Manno, M.; Manzi, G.; Salvatori, M.; Serpella, D. Preliminary study on a kinetic energy recovery system for sailing yachts. Renew. Energy 2014, 62, 216–225. [Google Scholar] [CrossRef] [Green Version]

- Thorburn, K.; Leijon, M. Farm size comparison with analytical model of linear generator wave energy converters. Ocean. Eng. 2007, 34, 908–916. [Google Scholar] [CrossRef]

- Ekström, R.; Ekergård, B.; Leijon, M. Electrical damping of linear generators for wave energy converters—A review. Renew. Sustain. Energy Rev. 2015, 42, 116–128. [Google Scholar] [CrossRef]

- Ulvgård, L.; Sjökvist, L.; Göteman, M.; Leijon, M. Line Force and Damping at Full and Partial Stator Overlap in a Linear Generator for Wave Power. J. Mar. Sci. Eng. 2016, 4, 81. [Google Scholar] [CrossRef]

- Bachynski, E.E.; Moan, T. Point absorber design for a combined wind and wave energy converter on a tension-leg support structure. In Proceedings of the 32nd ASME International Conference on Ocean, Offshore and Arctic Engineering, Nantes, France, 9–14 June 2013; pp. 1–10. [Google Scholar]

- Blanco, M.; Moreno-Torres, P.; Lafoz, M.; Ramírez, D. Design Parameter Analysis of Point Absorber WEC via an Evolutionary-Algorithm-Based Dimensioning Tool. Energies 2015, 8, 11203–11233. [Google Scholar] [CrossRef] [Green Version]

- Crabb, J. Synthesis of a directional wave climate. In Power from Sea Waves; Academic Press: London, UK, 2000; pp. 41–74. [Google Scholar]

- Rusu, E. Evaluation of the Wave Energy Conversion Efficiency in Various Coastal Environments. Energies 2014, 7, 4002–4018. [Google Scholar] [CrossRef]

- Hong, Y.; Eriksson, M.; Boström, C.; Waters, R. Impact of generator stroke length on energy production of a direct drive wave energy converter. Energies 2016, 9, 730. [Google Scholar] [CrossRef]

- Belmont, M.R. Increases in the average power output of wave energy converters using quiescent period predictive control. Renew. Energy 2010, 35, 2812–2820. [Google Scholar] [CrossRef]

- Ringwood, J.V.; Bacelli, G.; Fusco, F. Energy-maximizing control of wave-energy converters: The development of control system technology to optimize their operation. IEEE Contr. Syst. Mag. 2014, 34, 30–55. [Google Scholar] [CrossRef]

- Hultman, E.; Ekergård, B.; Tobias, K.; Salar, D.; Leijon, M. Preparing the Uppsala University Wave Energy Converter Generator for Large-Scale Production. In Proceedings of the 5th International Conference on Ocean Energy, Halifax, NS, Canada, 4–6 November 2014; pp. 1–12. [Google Scholar]

- Myhr, A.; Bjerkseter, C.; Ågotnes, A.; Nygaard, T.A. Levelised cost of energy for offshore wind turbines in a life cycle perspective. Renew. Energy 2014, 66, 714–728. [Google Scholar] [CrossRef]

- Stansby, P.K.; Carpintero, E.; Moreno, T.; Stallard, T. Large capacity multi-float configurations for the wave energy converter M4 using a time-domain linear diffraction model. Appl. Ocean Res. 2017, 68, 53–64. [Google Scholar] [CrossRef]

- Liberti, L.; Carillo, A.; Sannino, G. Wave energy resource assessment in the Mediterranean, the Italian perspective. Renew. Energy 2013, 50, 938–949. [Google Scholar] [CrossRef]

- Det Norske Veritas. Recommended Practice DNV-RP-C205 Environmental Conditions and Environmental Loads; Det Norske Veritas: Hamburg, Germany, 2010. [Google Scholar]

- Danielson, O.; Erikkson, M.; Leijon, M. Study of a longitudinal flux permanent magnet linear generator for wave energy converter. Int. J. Energy Res. 2006, 30, 1130–1145. [Google Scholar] [CrossRef]

- Previsic, M. The Future Potential of Wave Power in the United States; United States Department of Energy: Washington, DC, USA, 2012.

- Falcão, A.F.O. Modelling and control of oscillating-body wave energy converters with hydraulic power take-off and gas accumulator. Ocean Eng. 2007, 34, 2021–2032. [Google Scholar] [CrossRef]

| Item | Material | Current Unit Cost | Unit Cost Range |

|---|---|---|---|

| Permanent magnets | Neodymium-Iron-Boron | 80 €/kg | 60–100 €/kg |

| Stator | Electrical steel | 2 €/kg | 1.5–2.5 €/kg |

| Translator | Electrical steel | 2 €/kg | 1.5–2.5 €/kg |

| Rim | Aluminium alloy | 5 €/kg | 4–6 €/kg |

| Cables (16 mm2) | Electrical copper | 5 €/m | 4–6 €/m |

| Foundation | Marine concrete | 300 €/m3 | 200–400 €/m3 |

| Manufacturing 1 | -- | 25 €/h | --- |

| Floating buoy 2 | Normal Strength Steel | 4 €/kg | 3–4 €/kg |

| Deployment Site | Latitude | Longitude | γ (---) | J (kW/m) | Java (kW/m) |

|---|---|---|---|---|---|

| Alghero | 40°32′54″ N | 08°06′24″ N | 1.86 | 12.53 | 5.79 |

| Catania | 37°26′18″ N | 15°08′48″ N | 2.20 | 2.58 | 2.16 |

| La Spezia | 43°55′12″ N | 09°49′06″ N | 2.02 | 3.75 | 2.98 |

| Mazara del Vallo | 37°31′00″ N | 12°32′00″ N | 1.84 | 5.25 | 4.52 |

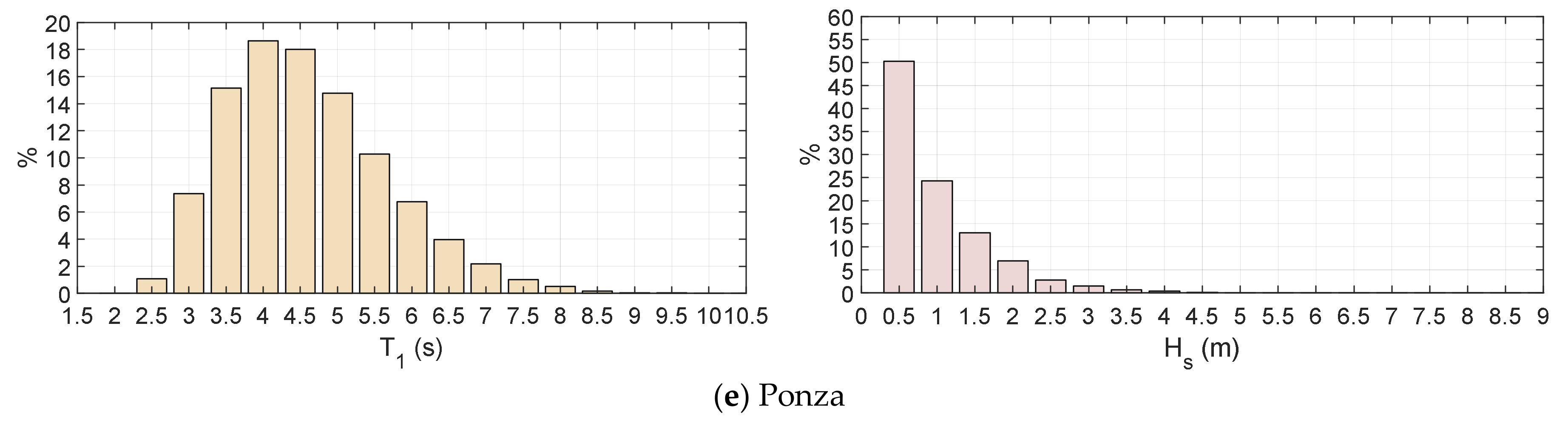

| Ponza | 40°52′00″ N | 12°57′00″ N | 2.15 | 4.46 | 3.73 |

| Rated power | 10 | kW | |

| Design speed | 0.70 | m/s | |

| Efficiency | 0.86 | --- | |

| Upper/lower stroke length | 0.8 | m | |

| Magnetic field in a tooth | 1.76 | T | |

| Tooth width | 8 | mm | |

| Width of stator side | 400 | mm | |

| Total number of poles | 100 | --- | |

| Winding ratio | 1.2 | --- | |

| Number of cables in a slot | 6 | --- | |

| Resistive load | 4.1 | Ω | |

| Generator polar pair width | 100 | mm |

| Item | Material | Quantity | Unit Cost | Cost (€) |

|---|---|---|---|---|

| Permanent magnets | Neodymium-Iron-Boron | 115 kg | 80 €/kg | 9200 |

| Stator | Electrical steel | 766 kg | 2 €/kg | 1532 |

| Translator | Electrical steel | 432 kg | 2 €/kg | 864 |

| Rim | Aluminium alloy | 13 kg | 15 €/kg | 195 |

| Cables (16 mm2) | Electrical copper | 1096 m | 5 €/m | 5480 |

| Foundation | Marine concrete | 15 m3 | 300 €/m3 | 4500 |

| Manufacturing | --- | 100 h | 25 €/h | 2500 |

| Item | Symbol | Equation/Value | Unit |

|---|---|---|---|

| Capital cost to power ratio | €/kW | ||

| Decommissioning cost to power ratio | €/kW | ||

| Annual operating cost to power ratio | €/kW | ||

| Discount rate | 0.07 | --- | |

| Device expected lifetime | years |

| Location | D (m) | AEP (kWh) | CF (---) | SCI (€/kWh) | SDC (€/kWh) | OM (€/kWh) | LCoE (€/kWh) |

|---|---|---|---|---|---|---|---|

| Alghero | 3.7 | 13,289 | 0.152 | 5668 | 1134 | 283 | 0.593 |

| Catania | 4.1 | 6900 | 0.079 | 6048 | 1210 | 302 | 1.218 |

| La Spezia | 4.2 | 11,587 | 0.132 | 6149 | 1230 | 307 | 0.738 |

| Mazara del Vallo | 4.0 | 13,587 | 0.155 | 5949 | 1190 | 297 | 0.609 |

| Ponza | 4.1 | 12,871 | 0.147 | 6048 | 1210 | 302 | 0.653 |

| Location | D (m) | AEP (kWh) | CF (---) | SCI (€/kWh) | SDC (€/kWh) | OM (€/kWh) | LCoE (€/kWh) | Dext (m) |

|---|---|---|---|---|---|---|---|---|

| Alghero | 3.8 | 28,501 | 0.325 | 8021 | 1604 | 401 | 0.387 | 4.2 |

| Catania | 4.0 | 15,592 | 0.178 | 8105 | 1621 | 405 | 0.722 | 4.1 |

| La Spezia | 3.8 | 20,468 | 0.234 | 7515 | 1503 | 376 | 0.510 | 3.7 |

| Mazara del Vallo | 3.8 | 28,437 | 0.325 | 7915 | 1583 | 396 | 0.387 | 4.1 |

| Ponza | 3.8 | 26,480 | 0.302 | 7811 | 1562 | 391 | 0.410 | 4.0 |

| lPTO (m) | D (m) | AEP (kWh) | CF (---) | SCI (€/kWh) | SDC (€/kWh) | OM (€/kWh) | LCoE (€/kWh) |

|---|---|---|---|---|---|---|---|

| 0.5 | 3.8 | 10,652 | 0.122 | 5579 | 1116 | 279 | 0.728 |

| 0.8 | 4.0 | 13,289 | 0.152 | 5668 | 1134 | 283 | 0.593 |

| 1.0 | 3.8 | 14,521 | 0.166 | 5853 | 1171 | 293 | 0.560 |

| 1.5 | 3.8 | 14,997 | 0.171 | 5853 | 1171 | 293 | 0.542 |

| 2.0 | 3.8 | 14,997 | 0.171 | 5853 | 1171 | 293 | 0.542 |

| lPTO (m) | D (m) | AEP (kWh) | CF (---) | SCI (€/kWh) | SDC (€/kWh) | OM (€/kWh) | LCoE (€/kWh) | Dext (m) |

|---|---|---|---|---|---|---|---|---|

| 0.5 | 3.6 | 18,997 | 0.217 | 7529 | 1506 | 376 | 0.551 | 3.9 |

| 0.8 | 3.8 | 28,501 | 0.325 | 8021 | 1604 | 401 | 0.387 | 4.2 |

| 1.0 | 3.8 | 34,002 | 0.388 | 8242 | 1648 | 412 | 0.337 | 4.4 |

| 1.5 | 4.0 | 46,479 | 0.531 | 8904 | 1781 | 445 | 0.266 | 4.8 |

| 2.0 | 4.1 | 55,356 | 0.632 | 9254 | 1851 | 463 | 0.232 | 5.0 |

| HS (m) | D (m) | AEP (kWh) | CF (---) | SCI (€/kWh) | SDC (€/kWh) | OM (€/kWh) | LCoE (€/kWh) |

|---|---|---|---|---|---|---|---|

| 2.0 | 4.0 | 9636 | 0.110 | 5949 | 1190 | 297 | 0.858 |

| 2.5 | 3.9 | 11,910 | 0.136 | 5853 | 1171 | 293 | 0.683 |

| 3.0 | 3.7 | 13,289 | 0.152 | 5668 | 1134 | 283 | 0.593 |

| 3.5 | 3.7 | 14,640 | 0.167 | 5668 | 1134 | 283 | 0.538 |

| 4.0 | 3.7 | 15,527 | 0.177 | 5668 | 1134 | 283 | 0.507 |

| HS (m) | D (m) | AEP (kWh) | CF (---) | SCI (€/kWh) | SDC (€/kWh) | OM (€/kWh) | LCoE (€/kWh) | Dext (m) |

|---|---|---|---|---|---|---|---|---|

| 2.0 | 3.8 | 21,401 | 0.244 | 8021 | 1604 | 401 | 0.521 | 4.2 |

| 2.5 | 3.8 | 25,545 | 0.292 | 8021 | 1604 | 401 | 0.436 | 4.2 |

| 3.0 | 3.8 | 28,501 | 0.325 | 8021 | 1604 | 401 | 0.387 | 4.2 |

| 3.5 | 3.7 | 30,407 | 0.347 | 7930 | 1586 | 396 | 0.362 | 4.2 |

| 4.0 | 3.7 | 31,821 | 0.363 | 7930 | 1586 | 396 | 0.346 | 4.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piscopo, V.; Benassai, G.; Della Morte, R.; Scamardella, A. Cost-Based Design and Selection of Point Absorber Devices for the Mediterranean Sea. Energies 2018, 11, 946. https://doi.org/10.3390/en11040946

Piscopo V, Benassai G, Della Morte R, Scamardella A. Cost-Based Design and Selection of Point Absorber Devices for the Mediterranean Sea. Energies. 2018; 11(4):946. https://doi.org/10.3390/en11040946

Chicago/Turabian StylePiscopo, Vincenzo, Guido Benassai, Renata Della Morte, and Antonio Scamardella. 2018. "Cost-Based Design and Selection of Point Absorber Devices for the Mediterranean Sea" Energies 11, no. 4: 946. https://doi.org/10.3390/en11040946