Approaches for Safety Analysis of Gas-Pipeline Functionality in Terms of Failure Occurrence: A Case Study

Abstract

:1. Introduction

2. Materials

Analysis of Gas Network Failure for the Urban Agglomeration in the Southeastern Part of Poland

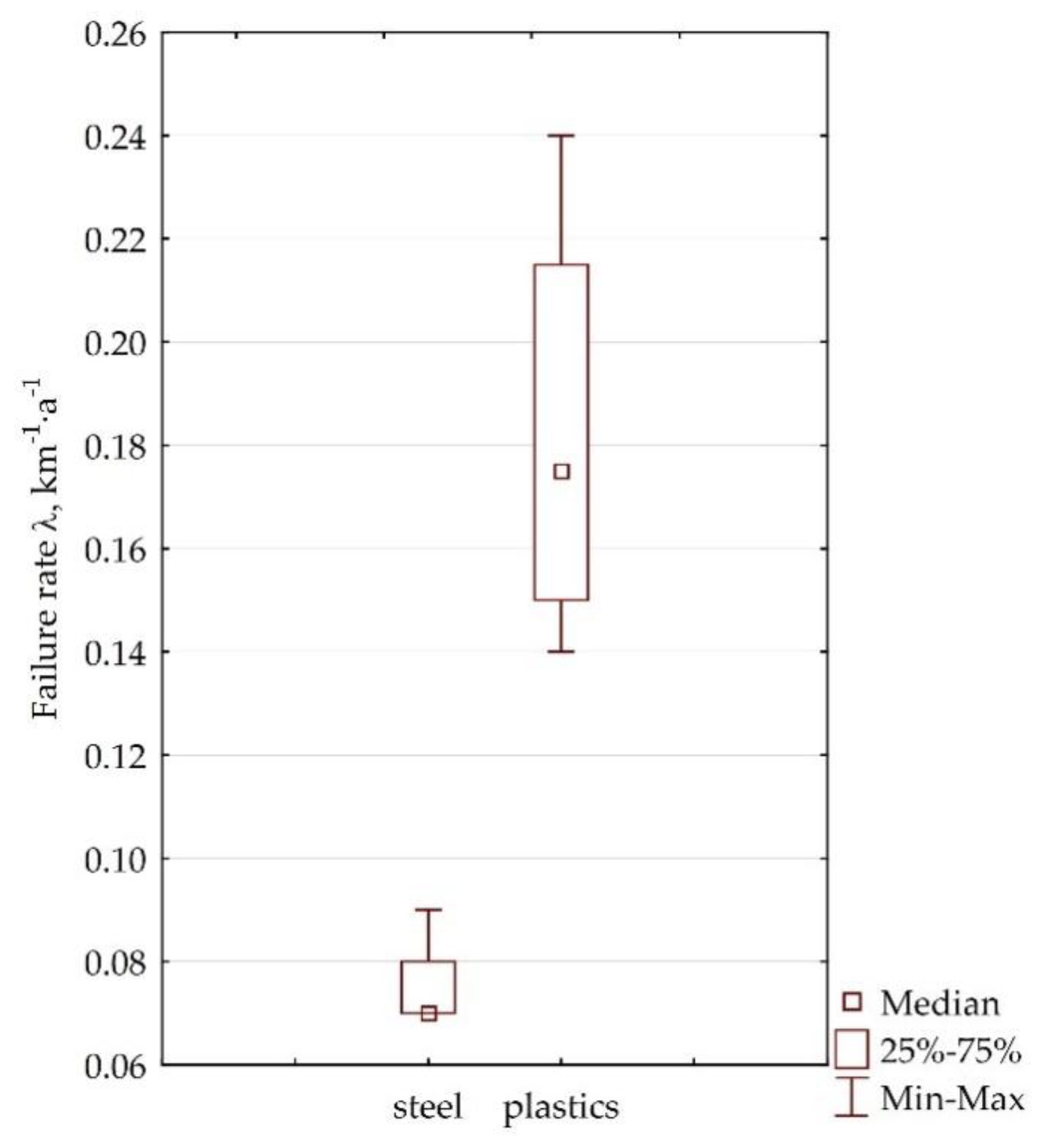

- Failure rate for pipelines made of steel: λsteel = 0.075 km−1·a−1.

- Failure rate for pipelines made of plastics: λp = 0.18 km−1·a−1.

3. Research of the Failure Stream in the Gas Network

3.1. Separation of Seasonal Fluctuations

3.2. Random Fluctuations

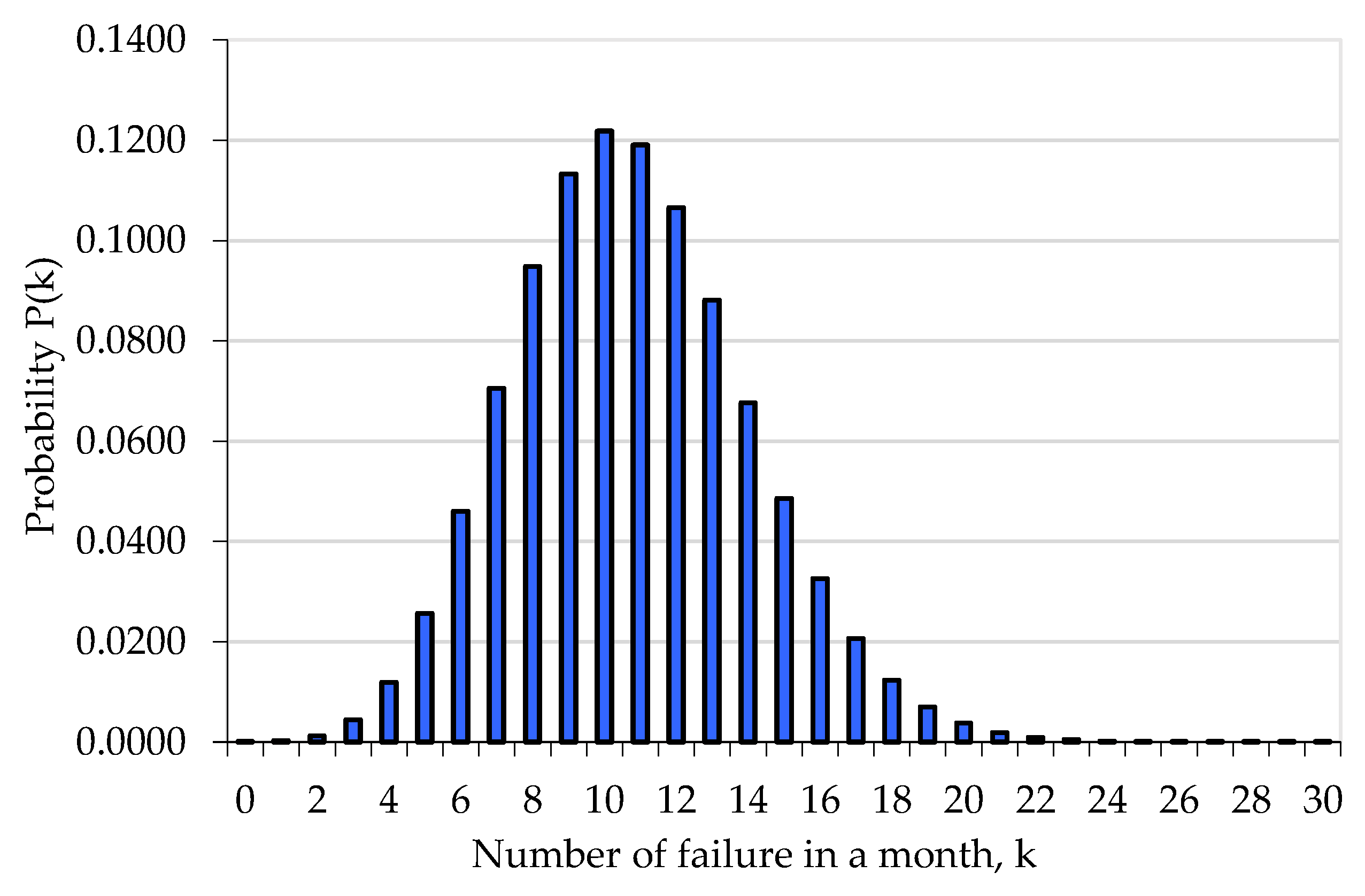

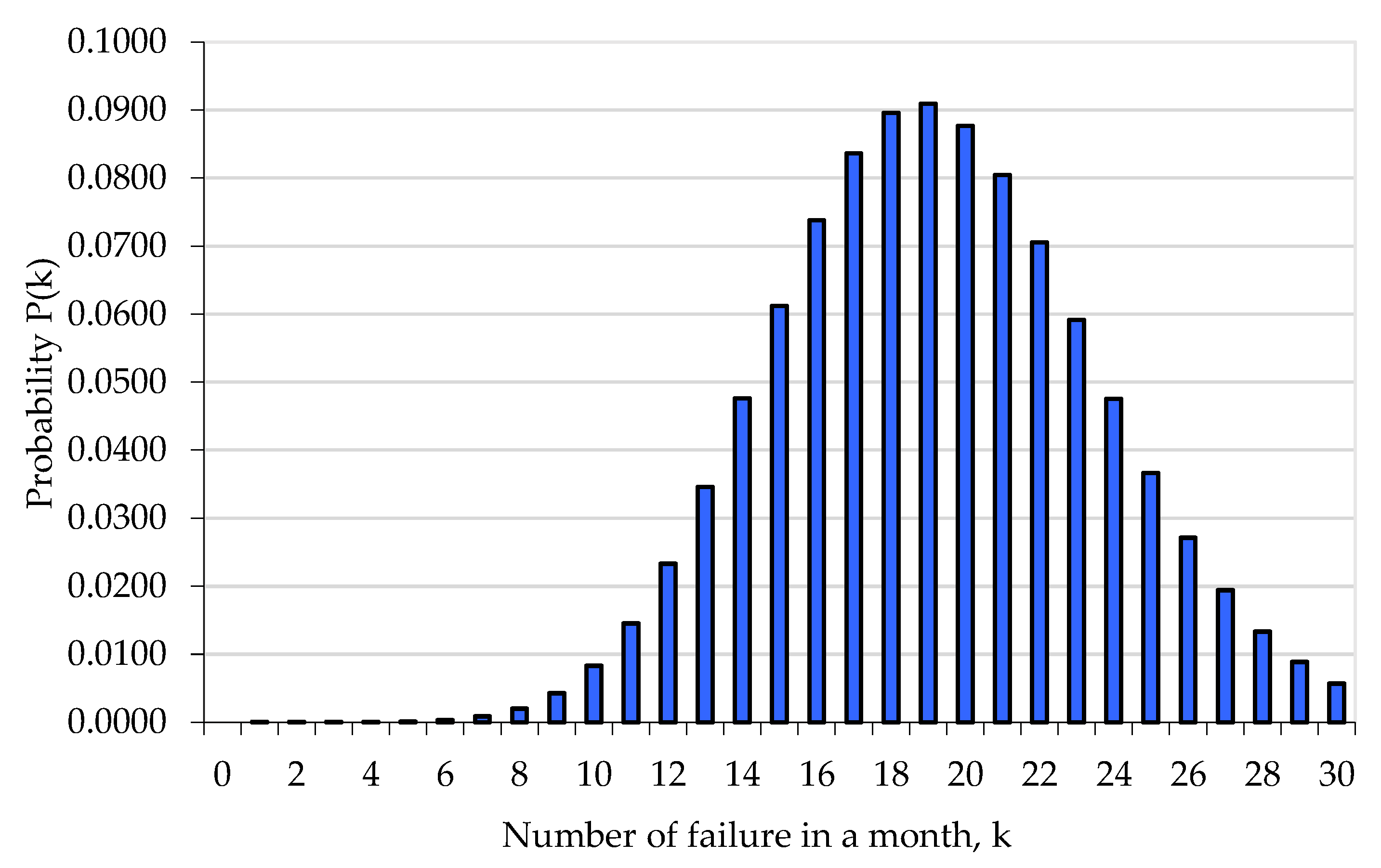

4. Determination of the Failure Stream for Distribution Gas Networks Using the Poisson Distribution

5. Forecasting Method of Acceptable Failure Consequences Using Homogeneous Markov Chain

6. Conclusions and Perspectives

- (a)

- On the basis of the values of the failure rate, it was found that the gas-pipeline network is characterized by a good technical state, which was confirmed by the authors’ previous studies in other gas supply systems [21,38]. The failure rate for pipelines made of steel is λsteel = 0.075 km−1·a−1, and the failure rate for pipelines made of plastics is λp = 0.18 km−1·a−1. A fairly high percentage of failure was caused by mechanical damage to both steel pipelines (67.92%) and plastic (95.28%), that is, failures caused as a result of human activity, as well as inaccurate and out-of-date spatial development plans, resulting in damage while building other infrastructure. The detailed analysis indicates that the higher failure rate of plastics concerned gas supply connections and was caused by inaccurate spatial development plans and a lack of proper performance of connections. In the case of pipes made of steel, modernization was performed over the last years, influencing the smaller failure rate.

- (b)

- The failure rate of the examined system showed the seasonality of failure occurrences in gas networks. In spring and summer months, the failure rate increases, and in autumn and winter months, it decreases. It seems advisable to increase the number of repair teams in the gas supply subsystems during periods of increased failure intensity, to increase the frequency of gas-pipeline inspections.

- (c)

- Simulation methods with the application of the Poisson distribution to determine the failure stream of the gas supply subsystem and forecasting method of acceptable failure consequences using the homogeneous Markov chain allow for correct classification of the subsystem elements for modernization or general renovation.

Author Contributions

Funding

Conflicts of Interest

References

- Abada, I.; Massol, O. Security of supply and retail competition in the European gas market. Some model based insights. Energy Policy 2011, 39, 4077–4088. [Google Scholar] [CrossRef]

- Fernandes, M.P.; Viegas, J.L.; Vieira, S.M. Segmentation of Residential Gas Consumers Using Clustering Analysis. Energies 2017, 10, 2047. [Google Scholar] [CrossRef]

- Hao, Y.-M.; Zhang, C.-S.; Shao, H.; Wang, M.-T. Baye network quantitative risk analysis for failure of natural gas pipelines. J. Northeast. Univ. 2011, 32, 321–325. [Google Scholar]

- Brown, N.; Crate, J.M. Analysis of a failure in a polyethylene gas pipe caused by squeeze off resulting in an explosion. J. Fail. Anal. Prev. 2012, 12, 30–36. [Google Scholar] [CrossRef]

- Biresselioglu, M.E.; Yelkenci, T.; Oz, I.O. Investigating the natural gas supply security: A new perspective. Energy 2015, 80, 168–176. [Google Scholar] [CrossRef]

- Costantini, V.; Gracceva, F.; Markandya, A. Security of energy supply: Comparing scenarios from a European perspective. Energy Policy 2007, 35, 210–226. [Google Scholar] [CrossRef] [Green Version]

- Flouri, M.; Karakosta, C.; Kladouchou, C. How does a natural gas supply interruption affect the EU gas security? A Monte Carlo simulation. Renew. Sustain. Energy Rev. 2015, 44, 785–796. [Google Scholar] [CrossRef]

- Fu, X.; Zhang, X. Failure probability estimation of gas supply using the central moment method in an integrated energy system. Appl. Energy 2018, 219, 1–10. [Google Scholar] [CrossRef]

- Geng, J.B.; Ji, Q.; Fan, Y. A dynamic analysis on global natural gas trade network. Appl. Energy 2014, 132, 23–33. [Google Scholar] [CrossRef]

- Majid, Z.A.; Mohsin, R.; Yaacob, Z.; Hassan, Z. Failure analysis of natural gas pipes. Eng. Fail. Anal. 2010, 17, 818–837. [Google Scholar] [CrossRef]

- Mohsin, R.; Majid, Z.A. Erosive failure of natural gas pipes. J. Pipeline Syst. Eng. 2014, 5, 818–837. [Google Scholar] [CrossRef]

- Guy, P.; Capelle, J.; Schmitt, C.; Mouwakeh, M. Domain failure assessment diagrams for defect assessment of gas pipes. In Proceedings of the 19th European Conference on Fracture: Fracture Mechanics for Durability, Reliability and Safety, Kazan, Russia, 26–31 August 2012. [Google Scholar]

- Lu, W.; Su, M.; Fath, B.D. A systematic method of evaluation of the Chinese natural gas supply security. Appl. Energy 2016, 165, 858–867. [Google Scholar] [CrossRef]

- Majid, Z.A.; Mohsin, R.; Yusof, M.Z. Experimental and computational failure analysis of natural gas pipe. Eng. Fail. Anal. 2012, 19, 32–42. [Google Scholar] [CrossRef]

- Luo, X.; Lu, S.; Shi, J.; Li, X.; Zheng, J. Numerical simulation of strength failure of buried polyethylene pipe under foundation settlement. Eng. Fail. Anal. 2015, 48, 144–152. [Google Scholar] [CrossRef]

- Mohsin, R.; Majid, Z.A.; Yusof, M.Z. Multiple failures of API 5L X42 natural gas pipe: Experimental and computational analysis. Eng. Fail. Anal. 2013, 34, 10–23. [Google Scholar] [CrossRef]

- Potocnik, P.; Govekar, E.; Grabec, I. Short-term natural gas consumption forecasting. In Proceedings of the 16th IASTED International Conference On Applied Simulation and Modelling, Palma de Mallorca, Spain, 29–31 August 2007; DeFelice, F., Ed.; IASTED: Calgary, AB, Canada, 2007; pp. 353–357. [Google Scholar]

- Shalaby, H.M.; Riad, W.T.; Alhazza, A.A.; Behbehani, M.H. Failure analysis of fuel supply pipeline. Eng. Fail. Anal. 2006, 13, 789–796. [Google Scholar] [CrossRef]

- Urbanik, M.; Tchórzewska-Cieślak, B. Ecological aspects of the natural gas use. Czasopismo Inżynierii Lądowej Środowiska i Architektury 2015, 62, 409–417. [Google Scholar] [CrossRef]

- Piegdon, I.; Tchorzewska-Cieslak, B.; Eid, M. Managing the risk of failure of the water supply network using the mass service system. Eksploat. Niezawodn. 2018, 2, 284–291. [Google Scholar] [CrossRef]

- Tchórzewska-Cieślak, B.; Pietrucha-Urbanik, K.; Urbanik, M. Analysis of the gas network failure prediction using the Monte Carlo simulation method. Eksploat. Niezawodn. 2016, 18, 254–259. [Google Scholar] [CrossRef]

- Tchórzewska-Cieślak, B. Method of Assessing of Risk of Failure in Water Supply System; European Safety and Reliability Conference (ESREL), Risk, Reliability and Societal Safety; Taylor & Francis: London, UK, 2007; Volume 2, pp. 1535–1539. [Google Scholar]

- Królikowska, J. Application of PHA method for assessing risk of failure on the example of sewage system in the city of Cracow. Annu. Set Environ. Prot. 2011, 13, 693–710. [Google Scholar]

- Ondrejka Harbulakova, V.; Estokova, A.; Stevulova, N.; Luptakova, A. Different aggressive media influence related to selected characteristics of concrete composites investigation. Int. J. Energy Environ. Eng. 2014, 5, 82. [Google Scholar] [CrossRef]

- Kent Muhlbauer, W. Pipeline Risk Management; Gulf Publishing Company: London, UK, 1992. [Google Scholar]

- Directive 2009/73/EC of the European Parliament and of the Council of 13 July 2009 concerning common rules for the internal market in natural gas and repealing Directive 2003/55/EC. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32009L0073 (accessed on 12 March 2018).

- European Gas Pipeline Incident Data Group (EGIG). 5–9th Reports of the European Gas Pipeline Incident Data Group (Period 1970–2013); Doc. No EGIG 14.R.0403; European Gas Pipeline Incident Data Group: Amsterdam, The Netherlands, 2002. [Google Scholar]

- European Gas Pipeline Incident Data Group (EGIG). 5–9th Reports of the European Gas Pipeline Incident Data Group (Period 1970–2013); Doc. No EGIG 11.R.0402; European Gas Pipeline Incident Data Group: Amsterdam, The Netherlands, 2005. [Google Scholar]

- European Gas Pipeline Incident Data Group (EGIG). 5–9th Reports of the European Gas Pipeline Incident Data Group (Period 1970–2013); Doc. No EGIG 08.TV-B.0502; European Gas Pipeline Incident Data Group: Amsterdam, The Netherlands, 2008. [Google Scholar]

- European Gas Pipeline Incident Data Group (EGIG). 5–9th Reports of the European Gas Pipeline Incident Data Group (Period 1970–2013); Doc. No EGIG 05.R.0002; European Gas Pipeline Incident Data Group: Amsterdam, The Netherlands, 2011. [Google Scholar]

- European Gas Pipeline Incident Data Group (EGIG). 5–9th Reports of the European Gas Pipeline Incident Data Group (Period 1970–2013); Doc. No EGIG 02.R.0058; European Gas Pipeline Incident Data Group: Amsterdam, The Netherlands, 2015. [Google Scholar]

- International Association of Oil & Gas Producers (OGP). Operating Management System Framework for Controlling Risk and Delivering High Performance in the Oil and Gas Industry; International Association of Oil & Gas Producers (OGP): London, UK, 2014. [Google Scholar]

- Martini, A.; Troncossi, M.; Rivola, A. Leak Detection in Water-Filled Small-Diameter Polyethylene Pipes by Means of Acoustic Emission Measurements. Appl. Sci. 2017, 7, 2. [Google Scholar] [CrossRef]

- Martini, A.; Troncossi, M.; Rivola, A. Vibroacoustic Measurements for Detecting Water Leaks in Buried Small-Diameter Plastic Pipes. J. Pipeline Syst. Eng. 2017, 8, 04017022. [Google Scholar] [CrossRef]

- Xu, C.; Gong, P.; Xie, J.; Shi, H.; Chen, G.; Song, G. An acoustic emission based multi-level approach to buried gas pipeline leakage localization. J. Loss Prevent. Proc. Ind. 2016, 44, 397–404. [Google Scholar] [CrossRef]

- Martini, A.; Troncossi, M.; Rivola, A. Automatic Leak Detection in Buried Plastic Pipes of Water Supply Networks by Means of Vibration Measurements. Shock Vib. 2015, 2015, 16530. [Google Scholar] [CrossRef]

- Meng, L.; Yuxing, L.; Wuchang, W.; Juntao, F. Experimental study on leak detection and location for gas pipeline based on acoustic method. J. Loss Prev. Proc. Ind. 2012, 25, 90–102. [Google Scholar] [CrossRef]

- Tchórzewska-Cieślak, B. Reliability of Selected Elements of the Natural Gas Supply Subsystem. Ph.D. Thesis, Cracow University of Technology, Cracow, Poland, 2002. [Google Scholar]

- Sobczyk, M. Statistics: Theoretical and Practical Aspects; Maria Curie-Skłodowska University: Lublin, Poland, 2006. [Google Scholar]

- Tchórzewska-Cieślak, B.; Rak, J. Analysis of Gas Networks Failure in Chosen Cities. In Proceedings of the XII Conference of Heat Engineers; PZITS: Solina, Poland, 2000. [Google Scholar]

- Tchórzewska-Cieślak, B.; Rak, J. Models of safety reliability of water supply systems using Markov processes. In II National Congress of Environmental Engineering; Committee of Environmental Engineering of the Polish Academy of Sciences: Lublin, Poland, 2005; Volume 32, pp. 519–528. [Google Scholar]

- Rak, J. Safety of Water Supply System; Polish Academy of Science: Warsaw, Poland, 2009. [Google Scholar]

- Tchorzewska-Cieslak, B.; Rak, J. Method of Identification of Operational States of Water Supply System; Environmental Engineering; Taylor & Francis: London, UK, 2009; Volume 3, pp. 521–526. [Google Scholar]

- Cox, D.R.; Miller, H.D. The Theory of Stochastic Processes; Chapman& Hall/CRC: Boca Raton, FL, USA, 1996. [Google Scholar]

- Davis, M.H.A. Markov Models and Optimization; Monographs on Statistics and Applied Probability 49; Chapman& Hall/CRC: Boca Raton, FL, USA, 1993. [Google Scholar]

- Grabski, F. Reliability and maintainability characteristics in semi-Markov model. J. Pol. Saf. Reliab. Assoc. 2016, 7, 79–85. [Google Scholar]

- Kolowrocki, K.; Soszynska-Budny, J. Modeling Complex Technical Systems Operation Processes. Reliab. Saf. Complex Tech. Syst. Process. 2011, 53–78. [Google Scholar] [CrossRef]

- Stark, M.R. Mathematical Foundations for Design; McGraw-Hill Book Company: New York, NY, USA, 1972. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tchórzewska-Cieślak, B.; Pietrucha-Urbanik, K.; Urbanik, M.; Rak, J.R. Approaches for Safety Analysis of Gas-Pipeline Functionality in Terms of Failure Occurrence: A Case Study. Energies 2018, 11, 1589. https://doi.org/10.3390/en11061589

Tchórzewska-Cieślak B, Pietrucha-Urbanik K, Urbanik M, Rak JR. Approaches for Safety Analysis of Gas-Pipeline Functionality in Terms of Failure Occurrence: A Case Study. Energies. 2018; 11(6):1589. https://doi.org/10.3390/en11061589

Chicago/Turabian StyleTchórzewska-Cieślak, Barbara, Katarzyna Pietrucha-Urbanik, Marek Urbanik, and Janusz R. Rak. 2018. "Approaches for Safety Analysis of Gas-Pipeline Functionality in Terms of Failure Occurrence: A Case Study" Energies 11, no. 6: 1589. https://doi.org/10.3390/en11061589