Electromagnetic Interference on Large Wind Turbines

Abstract

:1. Introduction

2. Classification of Interferences

| Class | Description | Condition |

|---|---|---|

| A | Continuous narrowband | Δfinterference < Δfreceiver |

| B | Continuous broadband | Δfinterference < Δfreceiver |

| C | Pulse modulated narrowband | Pulse-duration and -repetion |

| D | Pulsed broadband | Pulse-duration and -repetion |

3. EMI and Shielding for Wind Turbine Control Systems

| Damping | Description |

|---|---|

| 0–10 dB | Very low damping; no real shielding against electromagnetic interference. |

| 10–30 dB | Minimal shielding; slight interferences might by suppressed. |

| 30–60 dB | Average shielding for small problems in high frequency range; high shielding in the low frequency range. |

| 60–90 dB | Very good shielding of problems in hihg frequency domain. |

| 90–120 dB | Maximum shielding effectiveness that can be achieved with excellent shielding. |

4. EMI Measurements on Wind Turbines

4.1. General Aspects of EMI Measurement

4.2. Measurement of Lightning Originated EMI on Wind Turbines

5. Example to Define EMI Originating of a Wind Turbine Using Method-of-Moments

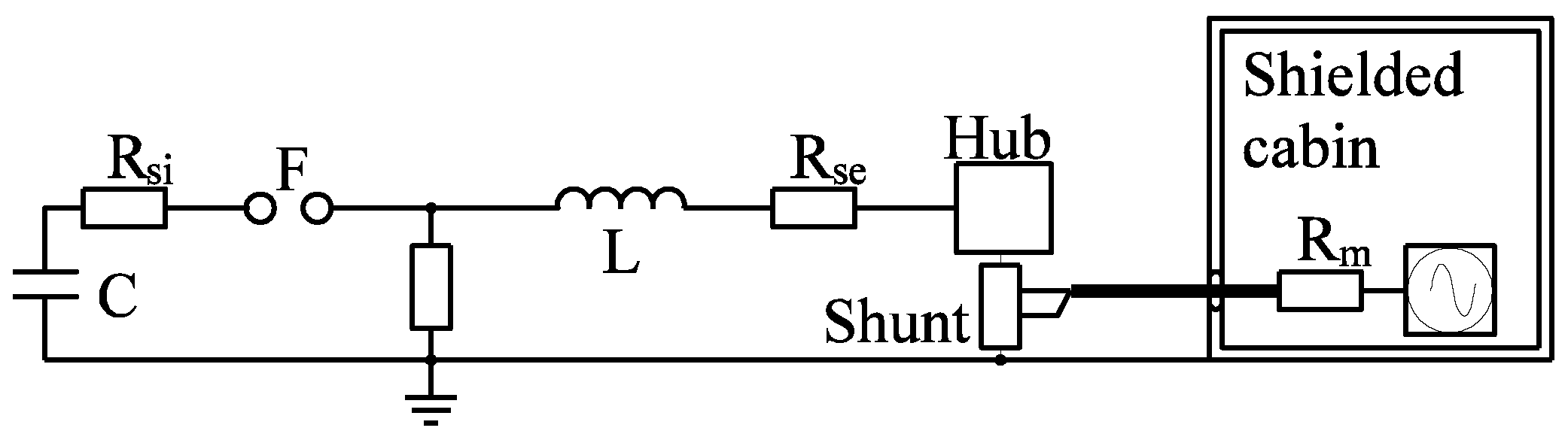

5.1. Wind Turbine Communication System

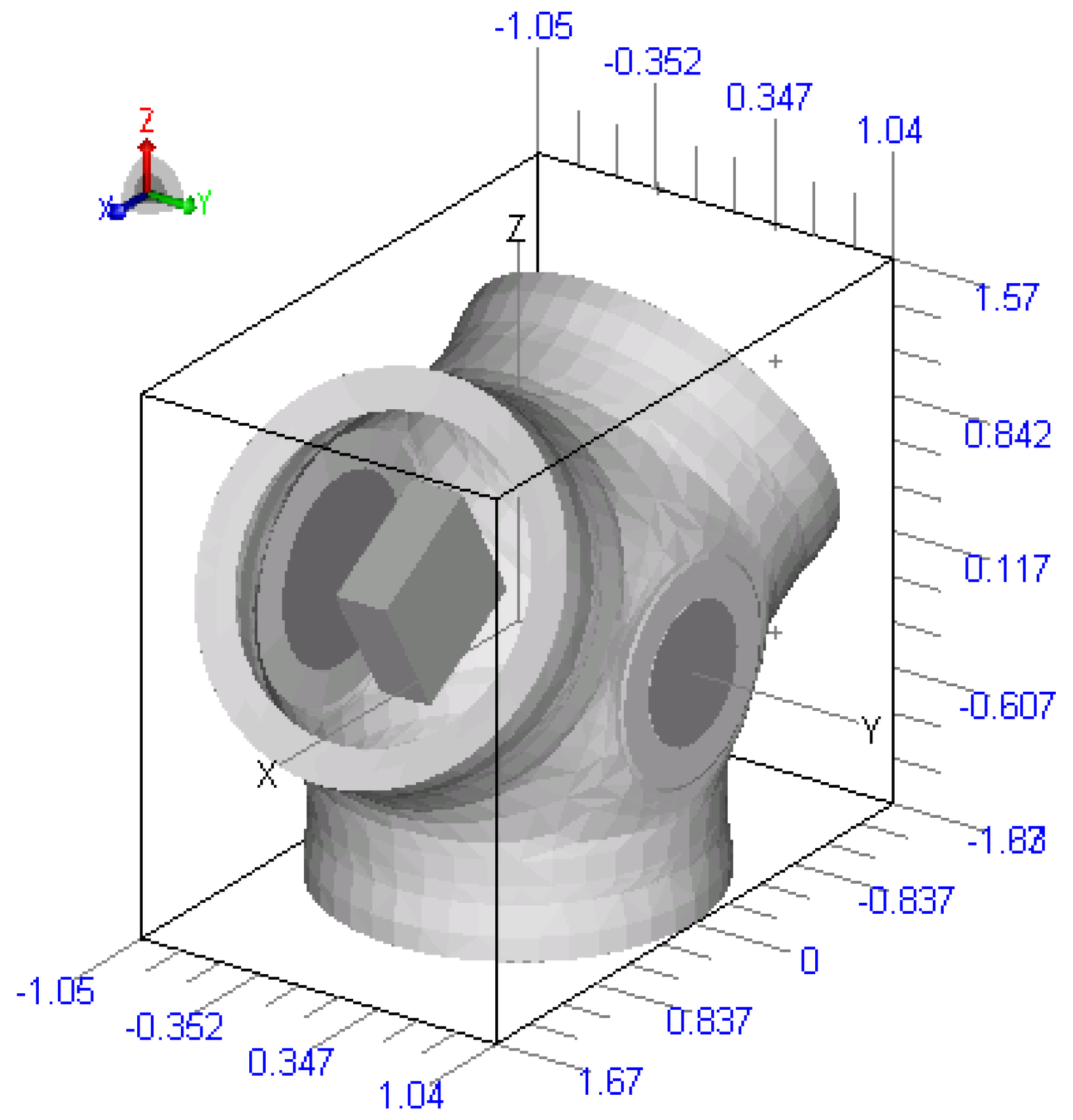

5.2. FEKO Model

5.3. Cast Iron Material under Electro-Magnetic Load

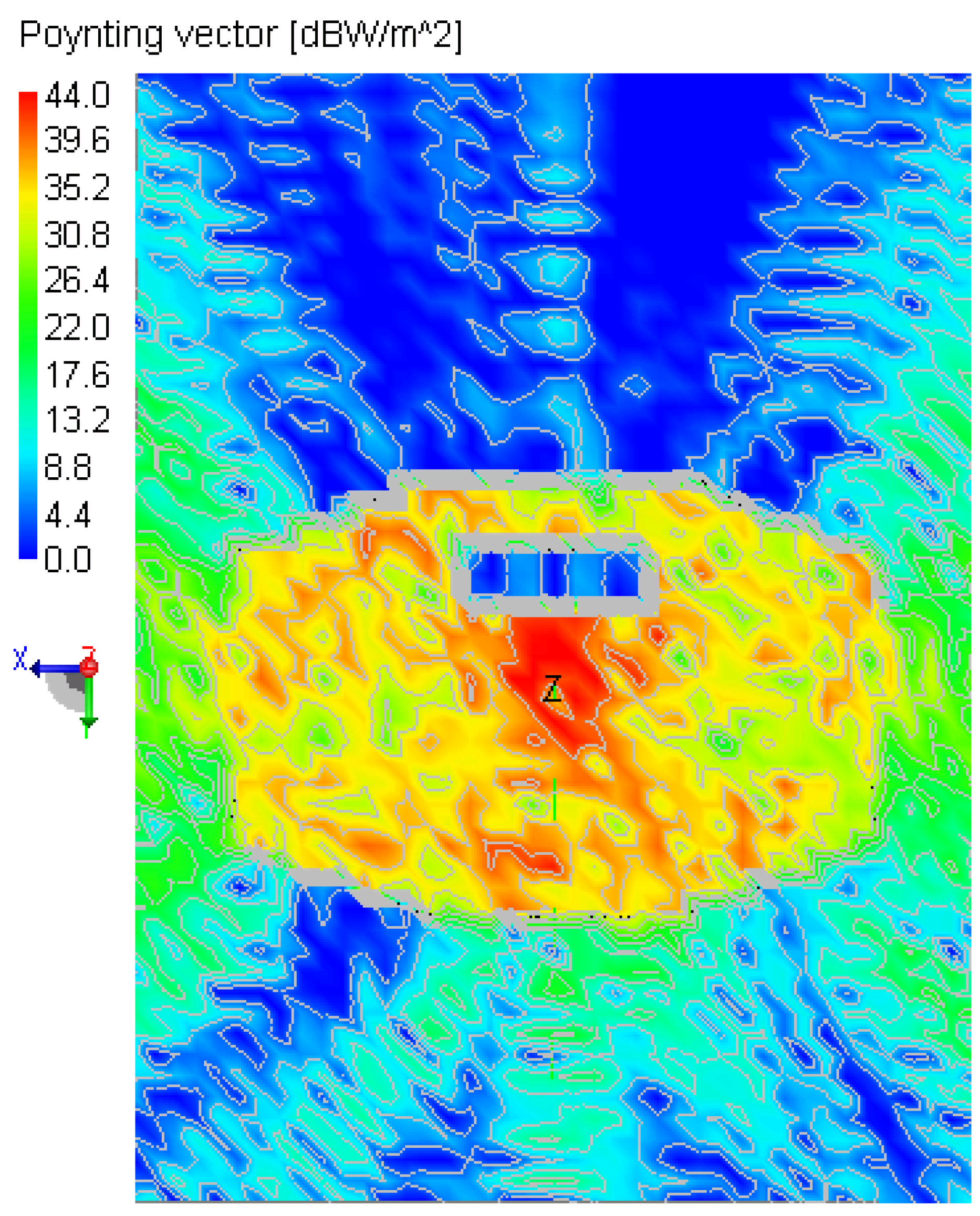

6. Simulation Results

- Location of the mega-watt wind turbine relative to the transmitter and receiver

- Characteristics (design and used material) of the rotor blade

- Signal frequency

- Receiver characteristics

- Radio wave propagation characteristics in the local atmosphere

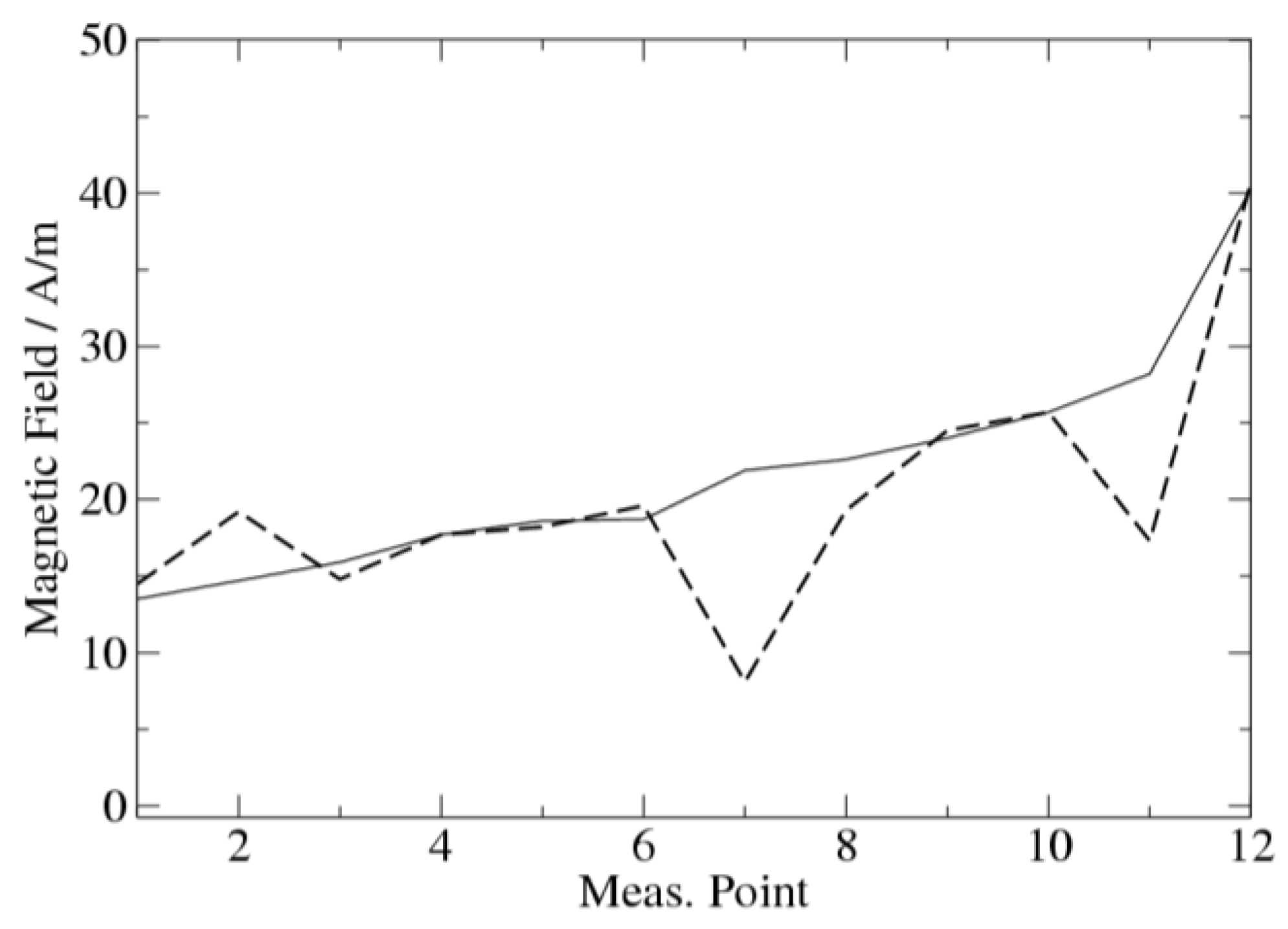

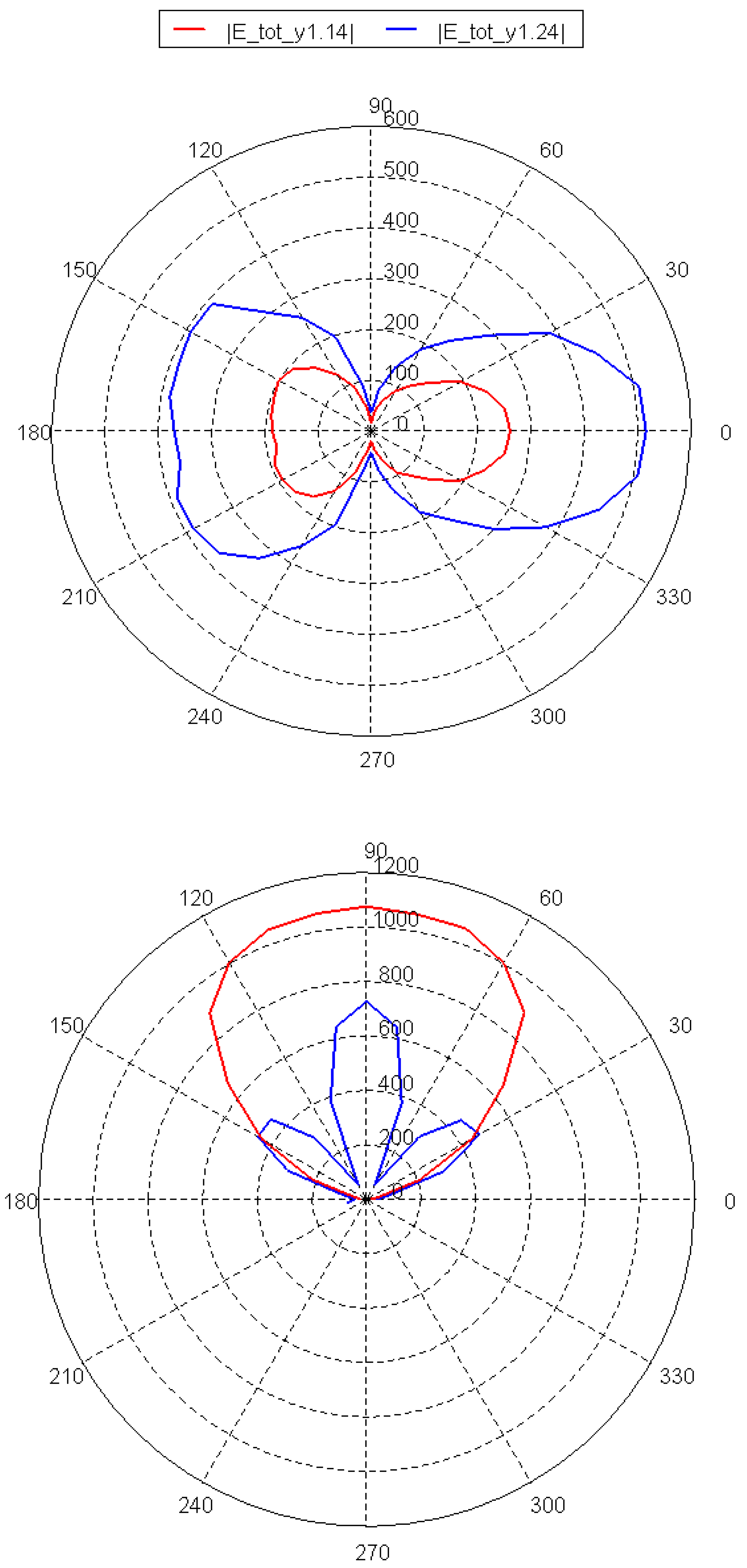

6.1. Antenna Inside Hub

6.2. Antenna Outside Hub

7. Conclusions

References and Notes

- Tennat, A.; Chambers, B. Radar Signature Control of Wind Turbine Generators. In Proceedings of the IEEE Antennas and Propagation Society International Symposium, Washington, DC, USA, July, 2005; pp. 489–492.

- Sengupta, D.L. Electromagnetic Interference from Wind Turbines. In Proceedings of the IEEE Antennas and Propagation Society International Symposium, Orlando, FL, USA, July, 1999; pp. 1984–1986.

- Cavecey, K.H.; Lee, L.Y. Television Interference due to Electromagnetic Scattering by the MOD-2 Wind Turbine Generators. In Proceedings of the IEEE Power Engineering Society Summer Meeting, Los Angeles, CA, USA, 1983.

- Frye, A. The Effects of Wind Energy Turbines on Military Surveillance Radar Systems. In Proceedings of the German Radar Symposium, Berlin, Germany, 2000; pp. 415–422.

- Lewke, B.; Krug, F.; Teichmann, R.; Loew, W.; Oberauer, A.; Kindersberger, J. The Influence of Lightning-Induced Field Distribution on the Pitch-Control-System of a Large Wind-Turbine Hub. In Proceedings of the European Wind Energy Conference, Athens, Greece, February, 2006.

- Krug, F.; Rasmussen, J.R.; Bauer, R.F.; Lemieux, D.; Schram, Ch.; Ahmann, U. Wind Turbine/Generator Drivetrain Condition Based Monitoring. In Proceedings of the European Wind Energy Conference, London, UK, November, 2004.

- Matsuzaki, R.; Todoroki, A. Wireless detection of internal delamination cracks in CFRP laminates using oscillating frequency changes. Composites Sci. Technol. 2005, 66, 407–416. [Google Scholar] [CrossRef]

- Krug, F.; Russer, P. Quasi-peak detector model for a time-domain measurement system. IEEE Trans. Electromagn. Compat. 2005, 47, 320–326. [Google Scholar] [CrossRef]

- Kodali, W.P. Principles, Measurements, Technologies, and Computer Models; Wiley: New York, NY, USA, 2001. [Google Scholar]

- Middleton, D. Statistical-physical models of electromagnetic interference. IEEE Trans. Electromagn. Compat. 1977, 19, 106–127. [Google Scholar] [CrossRef]

- Davenport, W.B.; Root, W.L. An Introduction to the Theory of Random Signals and Noise; Wiley: New York, NY, USA, 1987. [Google Scholar]

- Yoh, Y. A New lightning protection system for wind turbines using two ring-shaped electrodes. IEEJ Trans. Electr. Electron. Eng. 2006, 1, 314–319. [Google Scholar] [CrossRef]

- Gonschorek, K.H.; Singer, H. Elektromagnetische Verträglichkeit, 1st ed.; Teubner, B.G., Ed.; VDE-Verl: Stuttgart, Germany, 1992. [Google Scholar]

- Smolke, M. Beitrag zur Wirkung aperturbehafteter Schirme bei magnetischen Blitzimpulsfeldern. Ph.D. Thesis, Technical University of Dresden, Dresden, Germany, 1999. [Google Scholar]

- Krug, F.; Russer, P. The time-domain electromagnetic interference measurement system. IEEE Trans. Electromagn. Compat. 2003, 45, 330–338. [Google Scholar] [CrossRef]

- Diendorfer, G.; Mair, M.; Pichler, H. Blitzstrommessung am Sender Gaisberg. Schriftenreihe der Forschung im Verbund 2005, 89, 1–65. [Google Scholar]

- Rakov, V.A. Transient response of a tall object to lightning. IEEE Trans. Electromagn. Compat. 2001, 43, 654–661. [Google Scholar] [CrossRef]

- Krämer, S.; Puente Léon, F.; Lewke, B.; Méndez Hernández, Y. Lightning Impact Classification on Wind Turbine Blades Using Fiber Optic Measurement Systems. In Proceedings of the Windpower Conference, Los Angeles, CA, USA, June, 2007.

- Wada, A.; Yokoyama, S.; Hachiya, K.; Hirose, T. Observational Results of Lightning Flashes on the Nikaho-Kogen Wind Farm in Winter (2003-2004). In Proceedings of the XIVth International Symposium on High Voltage Engineering, Tsinghua University, Beijing, China, August, 2005; p. B26.

- OBO Bettermann GmbH & Co. Kg. Vorrichtung zur Erfassung von Stossströmen an Blitzableitern oder dergleichen. utility patent DE000009400656U1, 1995. [Google Scholar]

- Sørensen, T.; Jensen, F.V.; Raben, N.; Lykkegaard, J.; Saxov, J. Lightning Protection for Offshore Wind Turbines. In Proceedings of the 28th International Conference of Lightning Protection, Kanazawa, Japan, 2006; pp. 555–560.

- Krämer, S.; Puente Léon, F.; Lewke, B. Use of a Fiber-Optic Sensor System to Review Distributed Magnetic Field Simulation of a Wind Turbine. In Proceedings of the Asia-Pacific Symposium on Electromagnetic Compatibility, Singapore, 2008; pp. 192–195.

- Jackson, J.D. Klassische Elektrodynamik, 3rd ed.; de Gruyter: Berlin, Germany, 2002. [Google Scholar]

- Zinke, O.; Brunswig, H. Hochfrequenztechnik 1–Hochfrequenzfilter, Leitungen, Antennen, 6th ed.; Springer Verlag: Berlin, Germany, 2000. [Google Scholar]

- EM Software and Systems. FEKO User Manual, Suite 5.2, Stellenbosch, South Africa, 2006.

© 2009 by the authors. Licensee Molecular Diversity Preservation International, Basel, Switzerland This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Krug, F.; Lewke, B. Electromagnetic Interference on Large Wind Turbines. Energies 2009, 2, 1118-1129. https://doi.org/10.3390/en20401118

Krug F, Lewke B. Electromagnetic Interference on Large Wind Turbines. Energies. 2009; 2(4):1118-1129. https://doi.org/10.3390/en20401118

Chicago/Turabian StyleKrug, Florian, and Bastian Lewke. 2009. "Electromagnetic Interference on Large Wind Turbines" Energies 2, no. 4: 1118-1129. https://doi.org/10.3390/en20401118