Current State of Development of Electricity-Generating Technologies: A Literature Review

Abstract

:1. Summary

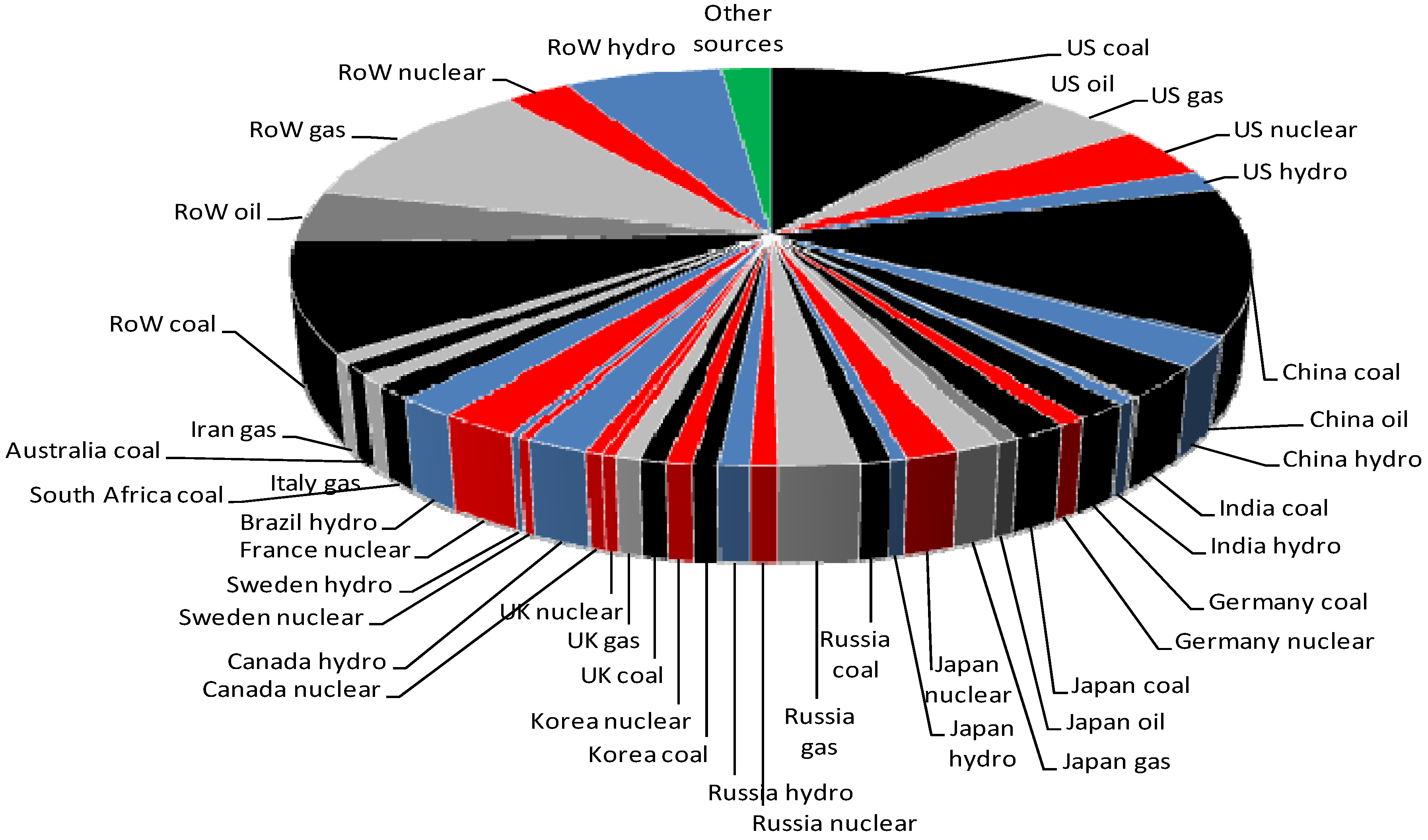

| Technology | Annual generation a (TWhel/y) | Capacity factor b (%) | Mitigation potential c (GtCO2) | Energy requirements d (kWhth/kWhel) | CO2 emissions (g/kWhel) | Generating cost (US¢/kWh) | Barriers |

|---|---|---|---|---|---|---|---|

| Coal | 7,755 | 70–90 | 2.6–3.5 e,f | 900 e,f | 3–6 g | Greenhouse gas emissions | |

| Oil | 1,096 | 60–90 | 2.6–3.5 h | 700 h | 3–6 g | Resource constraints | |

| Gas | 3,807 | ≈ 60 | 2–3 e,f,i | 450 e,f,i | 4–6 g | Fuel price | |

| Carbon capture and storage | - | n.a. | 150–250 j.k | 2–2.5 + 0.3–1 l | 170–280 f,l,m | 3–6 + 0–4 n,o,p | Energy penalty, large-scale storage, late deployment |

| Nuclear fission q | 2,793 | 86 r | > 180 | 0.12 s | 65 s | 3–7 g,t | Waste disposal, proliferation, public acceptance |

| Large hydro | 3,121 | 41 | 200–300 u | 0.1 v | 45–200 v,w | 4–10 g,t | Resource potential, social and environmental impact |

| Small hydro | ≈250 | ≈50 | ≈100 ? | n.a. | 45 v | 4–20 g,t,x | Resource potential |

| Wind | 260 y | 24.5 | ≈450–500 | 0.05 z | ≈65 z,aa | 3–7 g | Variability and grid integration |

| Solar-photovoltaic | 12 ab | 15 | 25–200 ? | 0.4/1–0.8/1 ac | 40/150 – 100/200 ac | 10–20 g,t,ad | Generating cost |

| Concentrating Solar | ≈1 | 20–40 | 25–200 ? | 0.3 h | 50–90 h | 15–25 g,t,ae | Generating cost |

| Geothermal | 60 | 70–90 | 25–500 ? | n.a. | 20–140 af | 6–8 ag | Uncertain field capacity |

| Biomass | 240 ah | 60 ah | ≈ 100 | 2.3–4.2 ai | 35–85 ai | 3–9 t,ah | Efficiency, feedstock availability, cost |

2. Rationale

- –

- its technical principle,

- –

- the total potential of its global energy sources,

- –

- its capacity factor and capacity credit,

- –

- life-cycle characteristics, such as kWh-specific greenhouse gas emissions, or embodied energy, over the lifetime of the installations,

- –

- the scale at which the technology is currently deployed,

- –

- the contribution it currently makes to global electricity supply,

- –

- the cost of its current electricity output,

- –

- the extent of subsidisation by governments (in a separate section), and

- –

- technical and other challenges.

3. Introduction

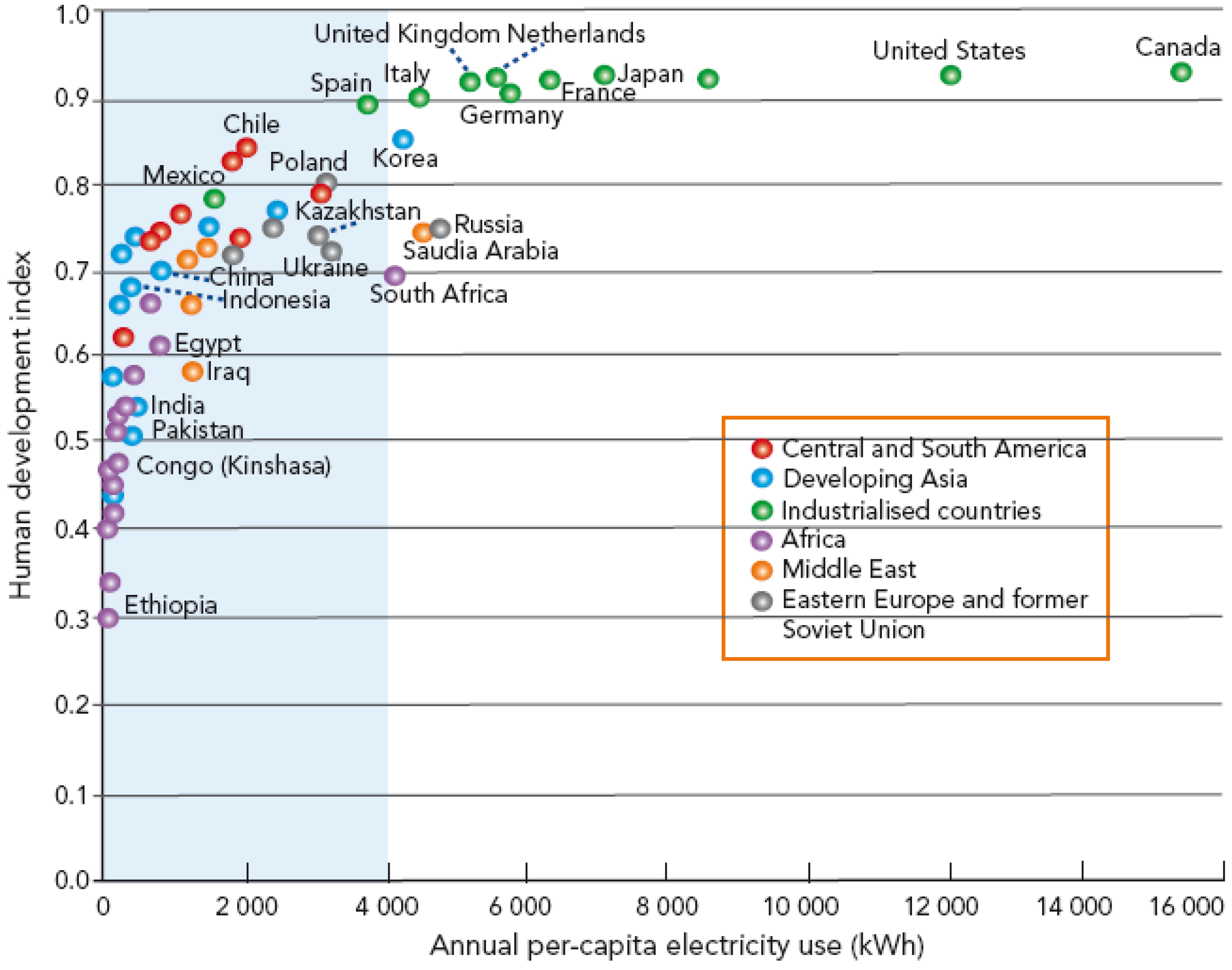

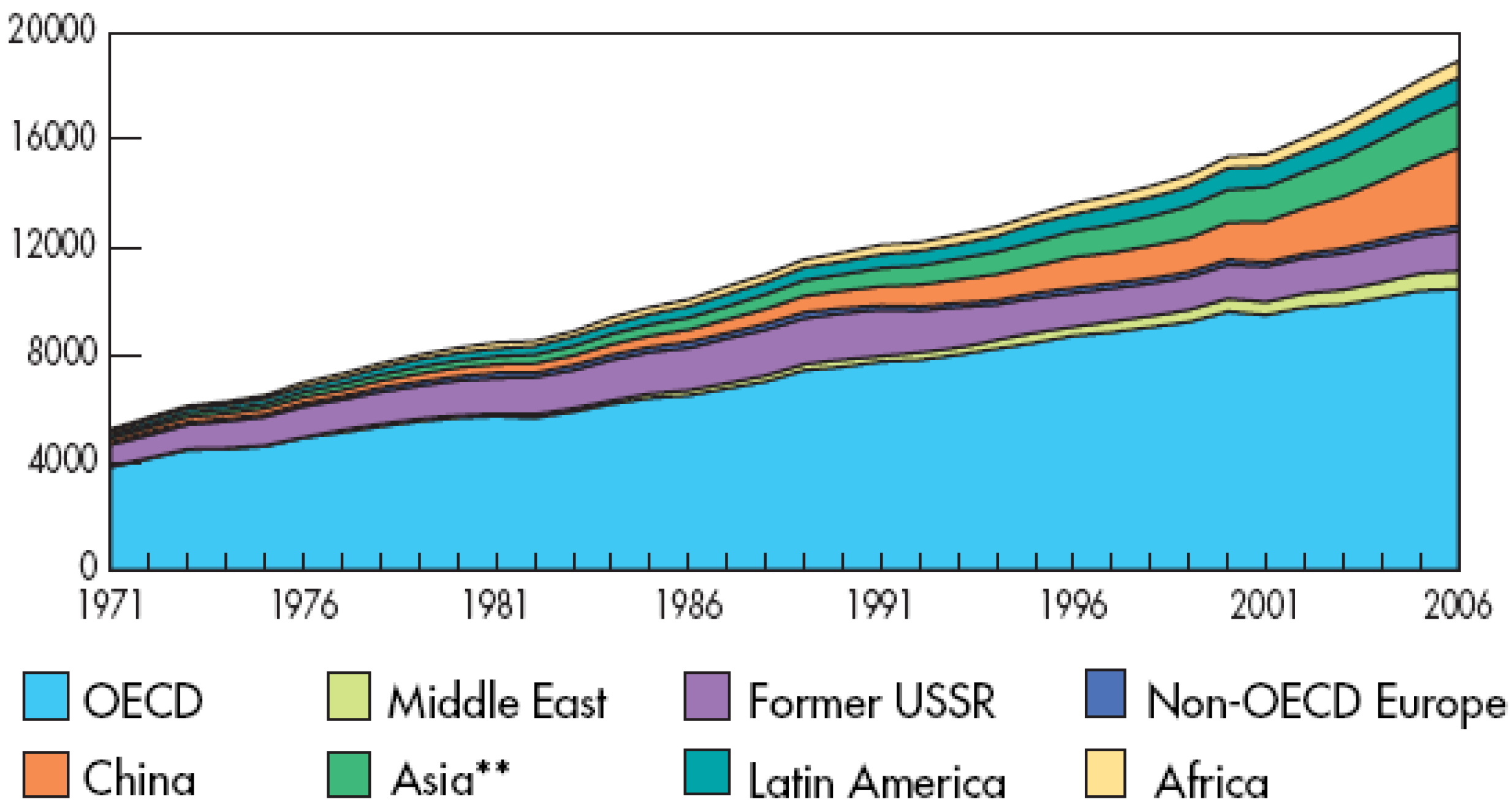

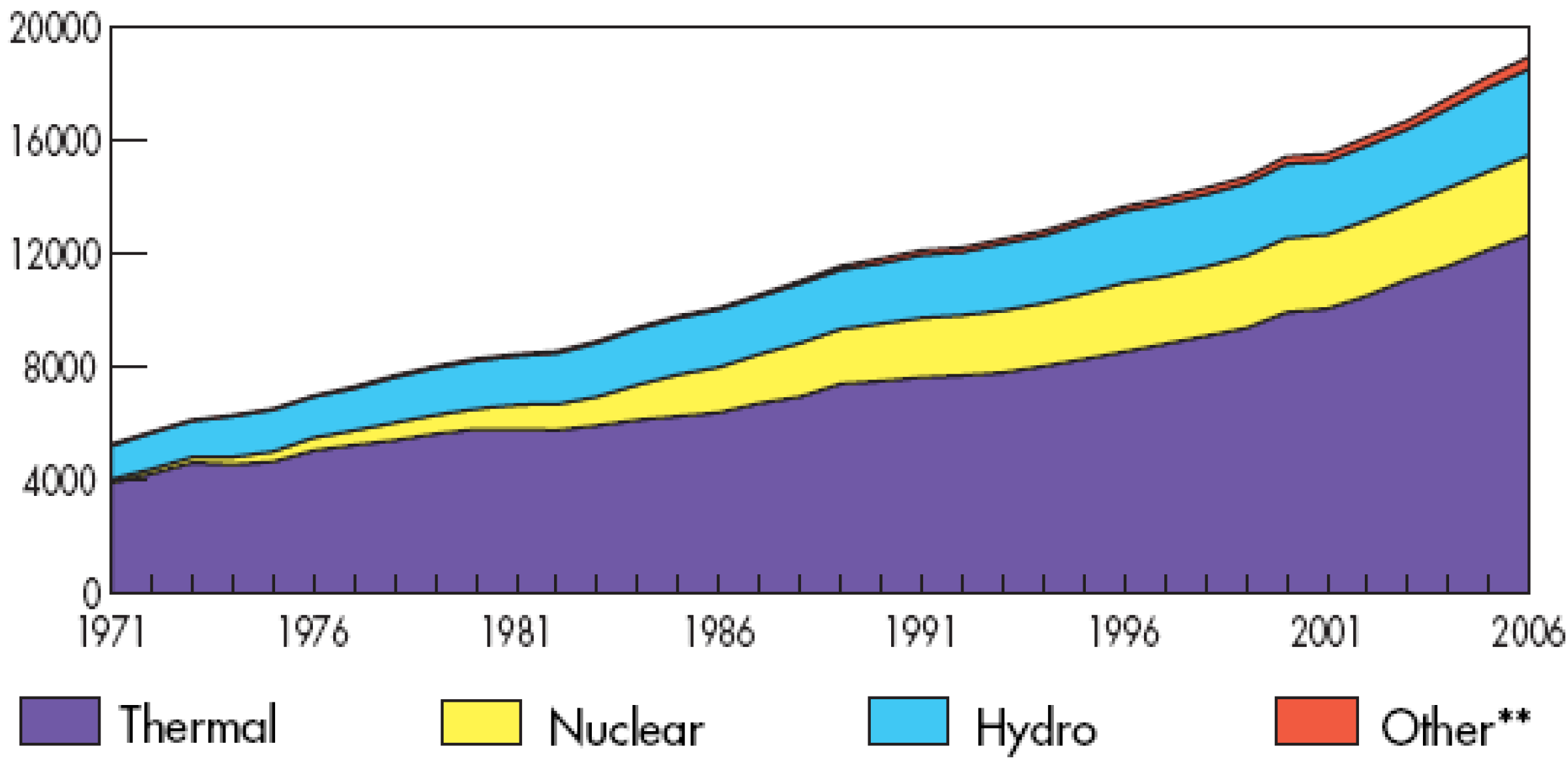

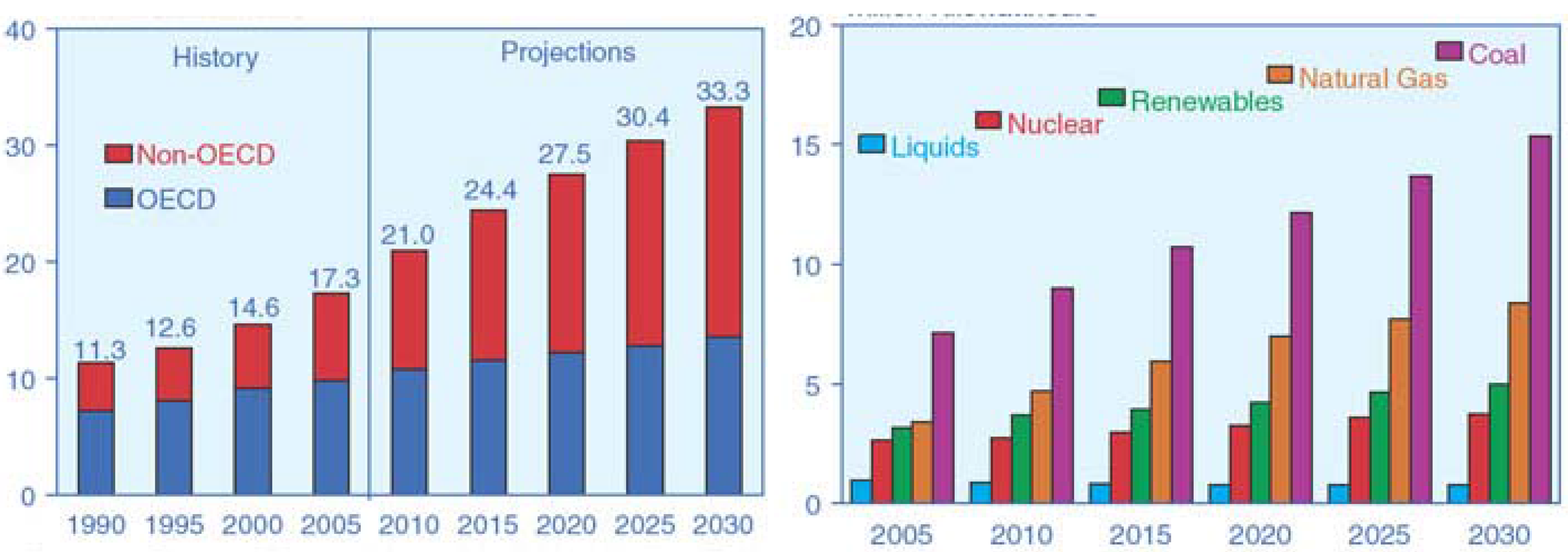

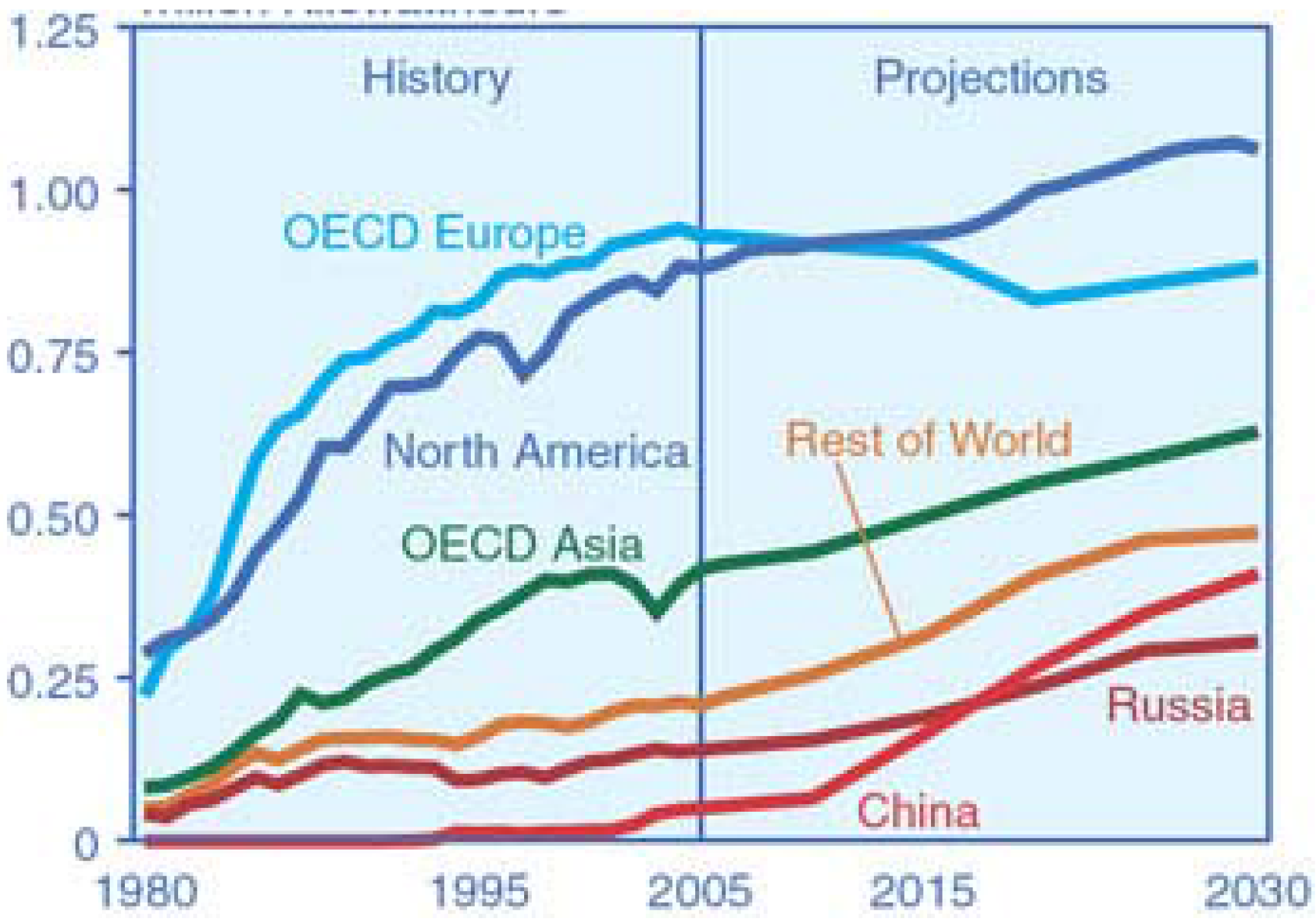

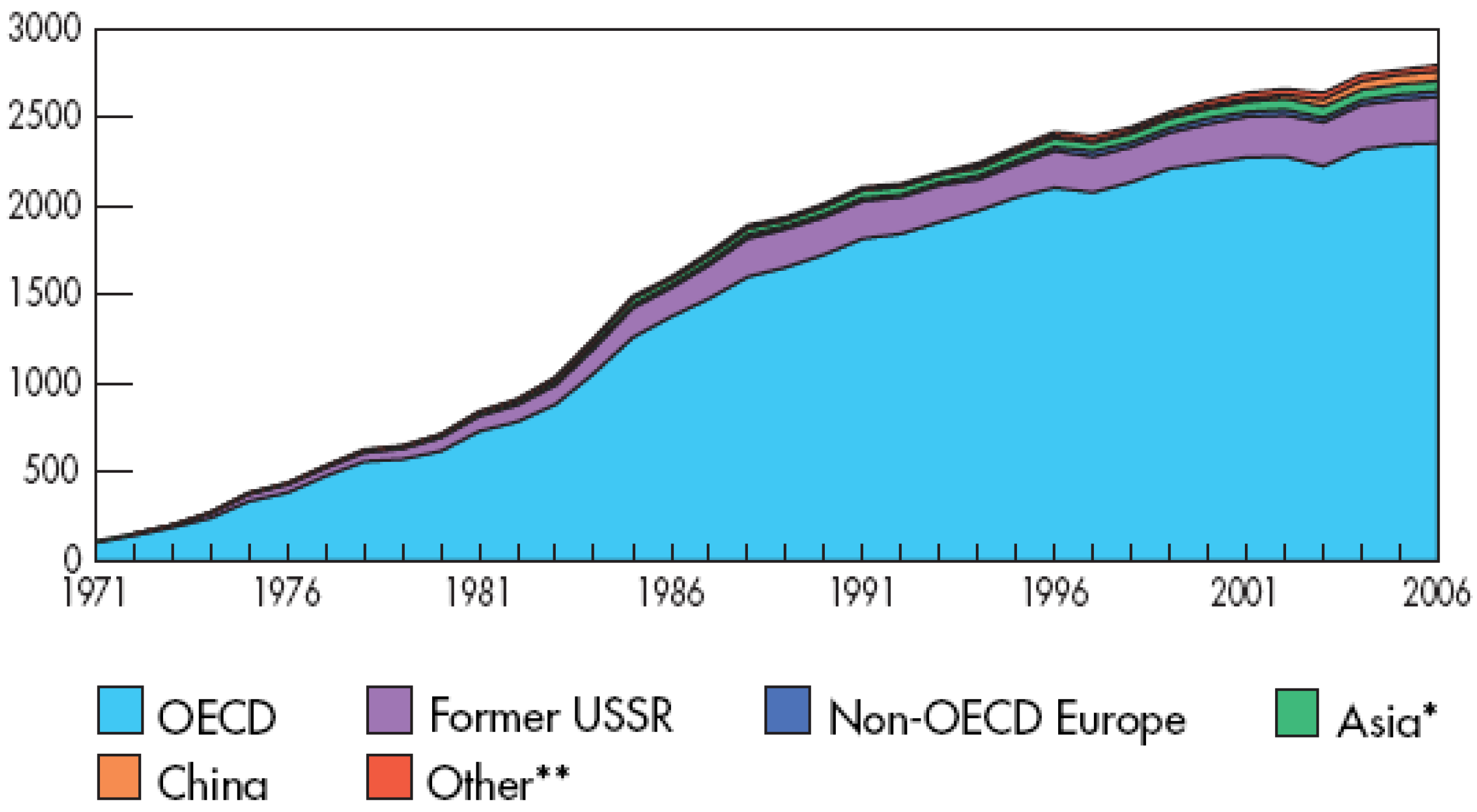

3.1. Role of Electricity in World Energy Needs

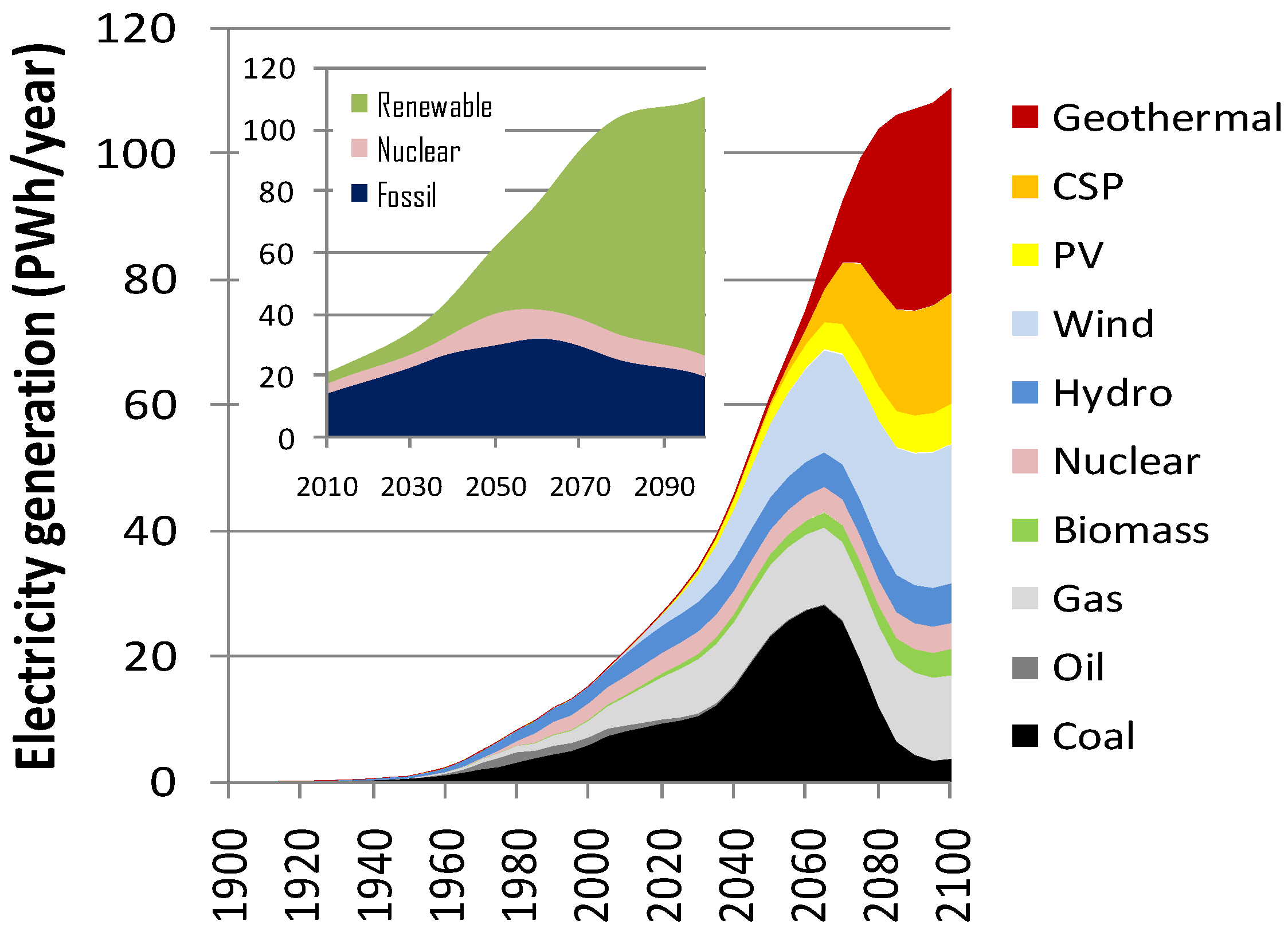

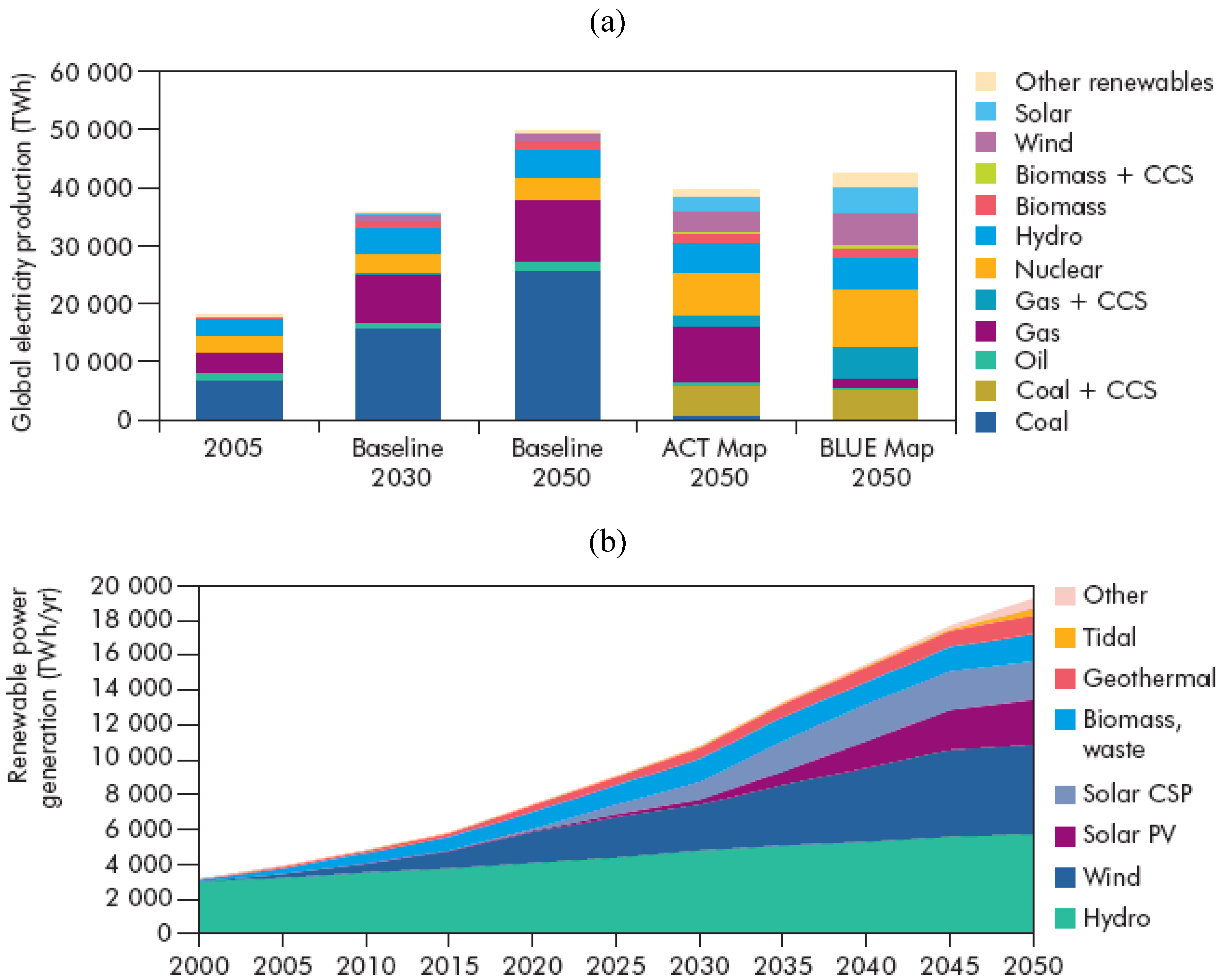

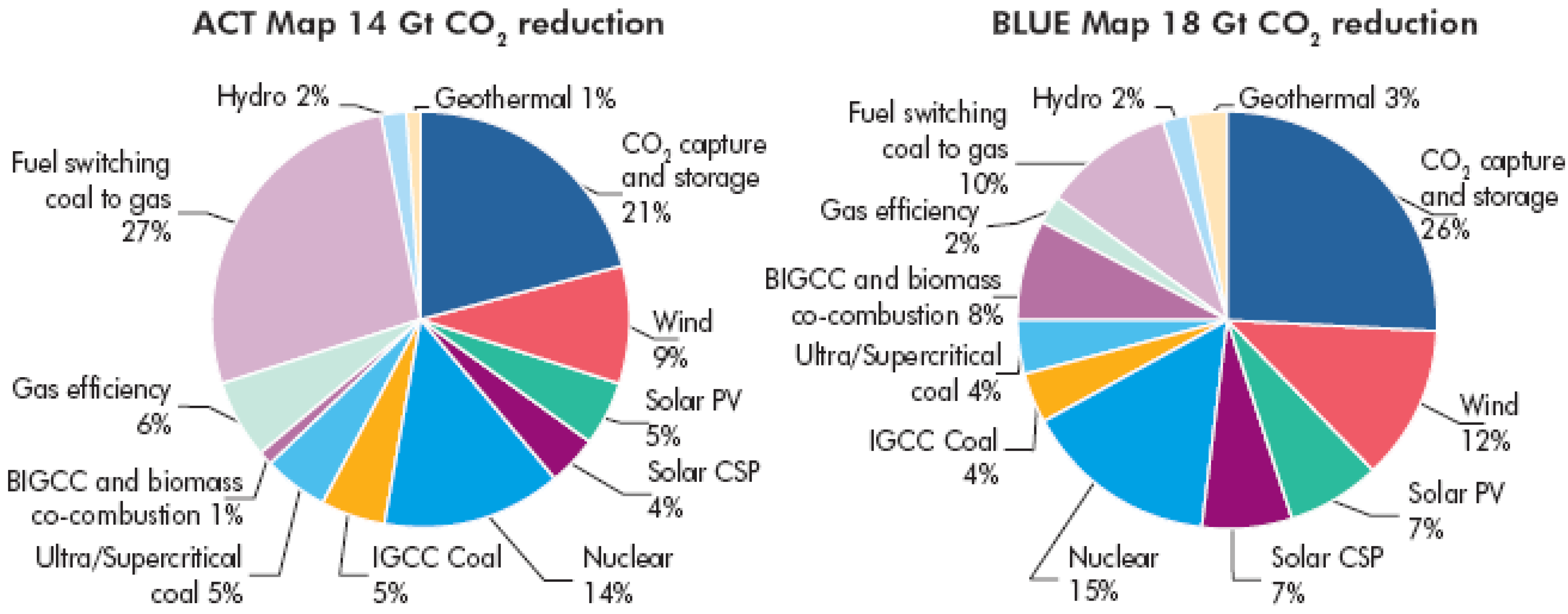

3.2. Demand Projections and Scenarios

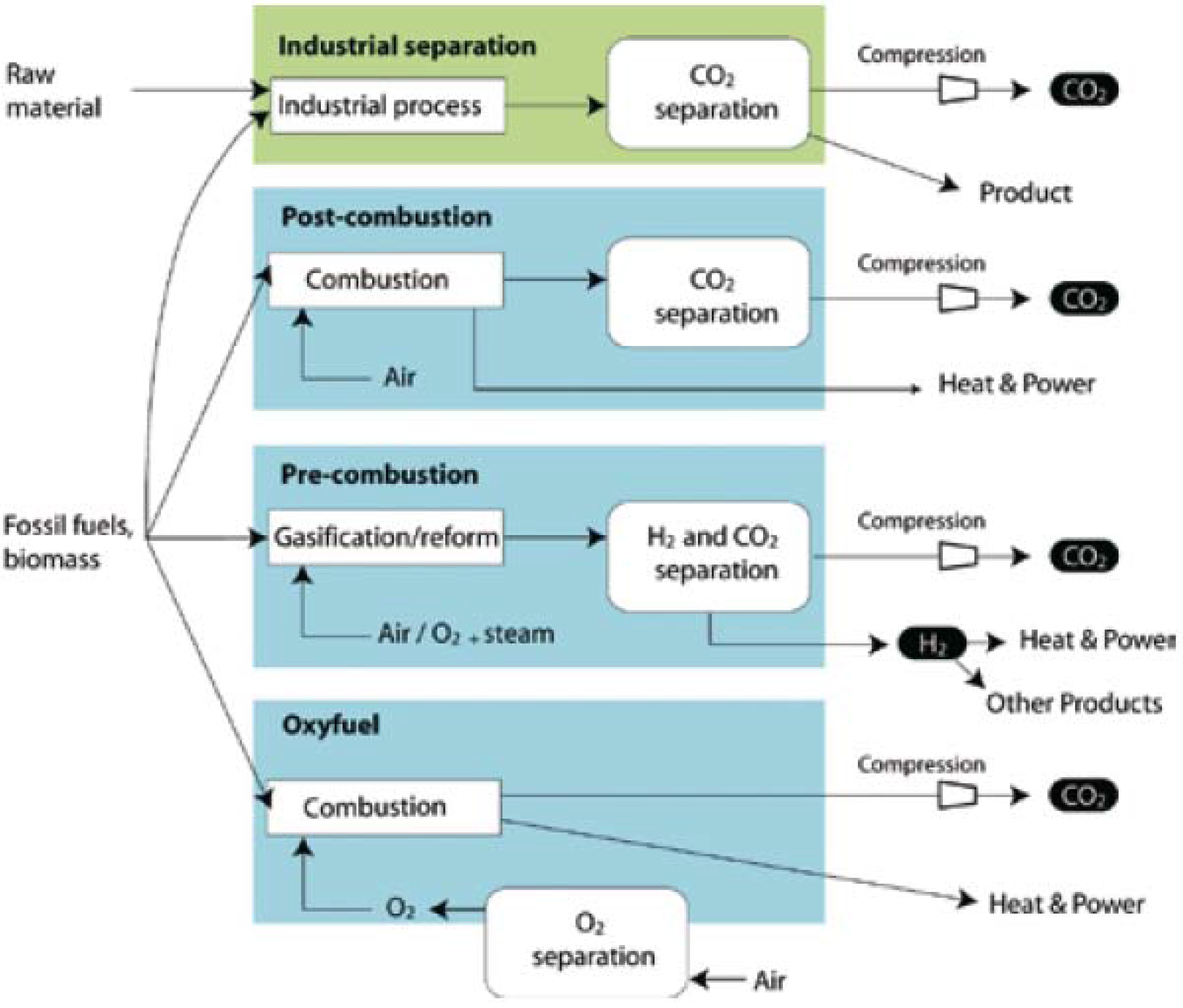

4. Carbon Capture and Storage

4.1. Potential of Resource

4.2. Post-combustion Capture

4.2.1. Technical principle

4.2.2. Capacity and load characteristics

4.2.3. Life-cycle characteristics

4.2.4. Current scale of deployment

4.2.5. Cost of electricity output

4.2.6. Technical challenges

4.3. Pre-combustion Capture

4.3.1. Technical principle

4.3.2. Capacity and load characteristics

4.3.3. Life-cycle characteristics

4.3.4. Current scale of deployment

4.3.5. Cost of electricity output

4.3.6. Technical challenges

4.4. Oxyfuel capture

4.4.1. Technical principle

4.4.2. Capacity and load characteristics

4.4.3. Life-cycle characteristics

4.4.4. Current scale of deployment

4.4.5. Cost of electricity output

4.4.6. Technical challenges

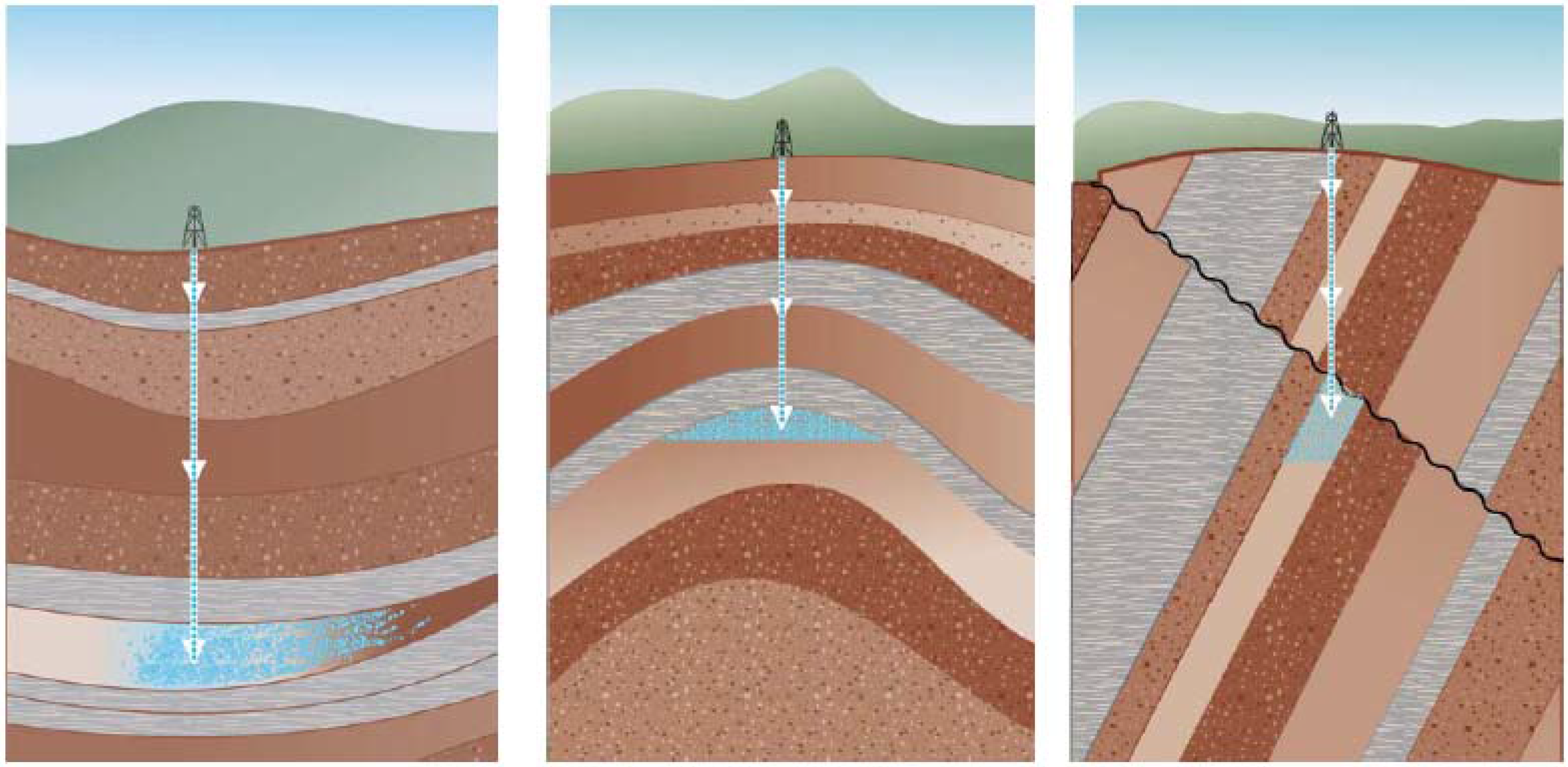

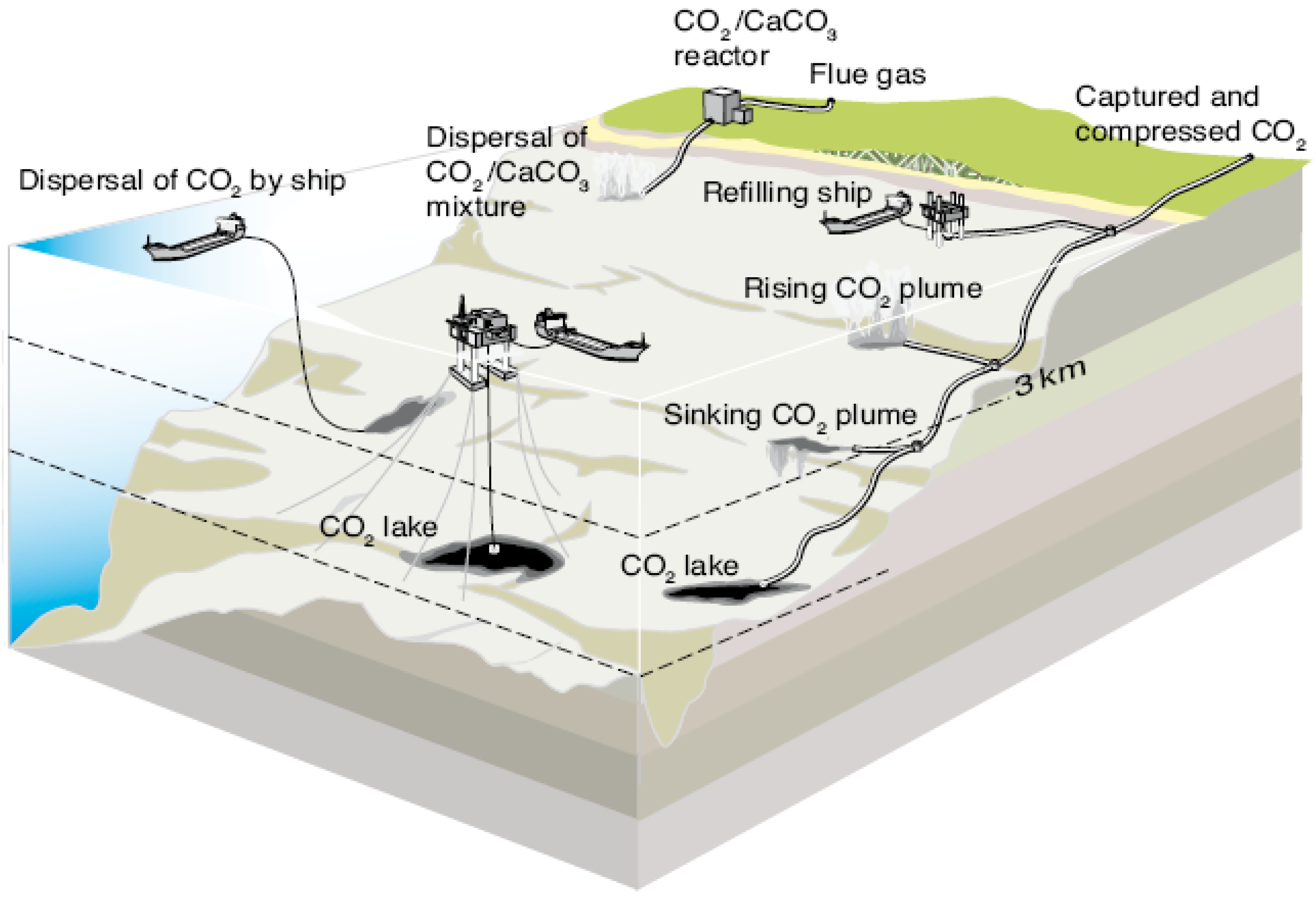

4.5. Geological Storage

4.5.1. Technical principle

4.5.2. Capacity and load characteristics

4.5.3. Life-cycle characteristics

4.5.4. Current scale of deployment

4.5.5. Contribution to global electricity supply

4.5.6. Cost of electricity output

2.1.1. Technical challenges

5. Nuclear Fission

5.1. Summary

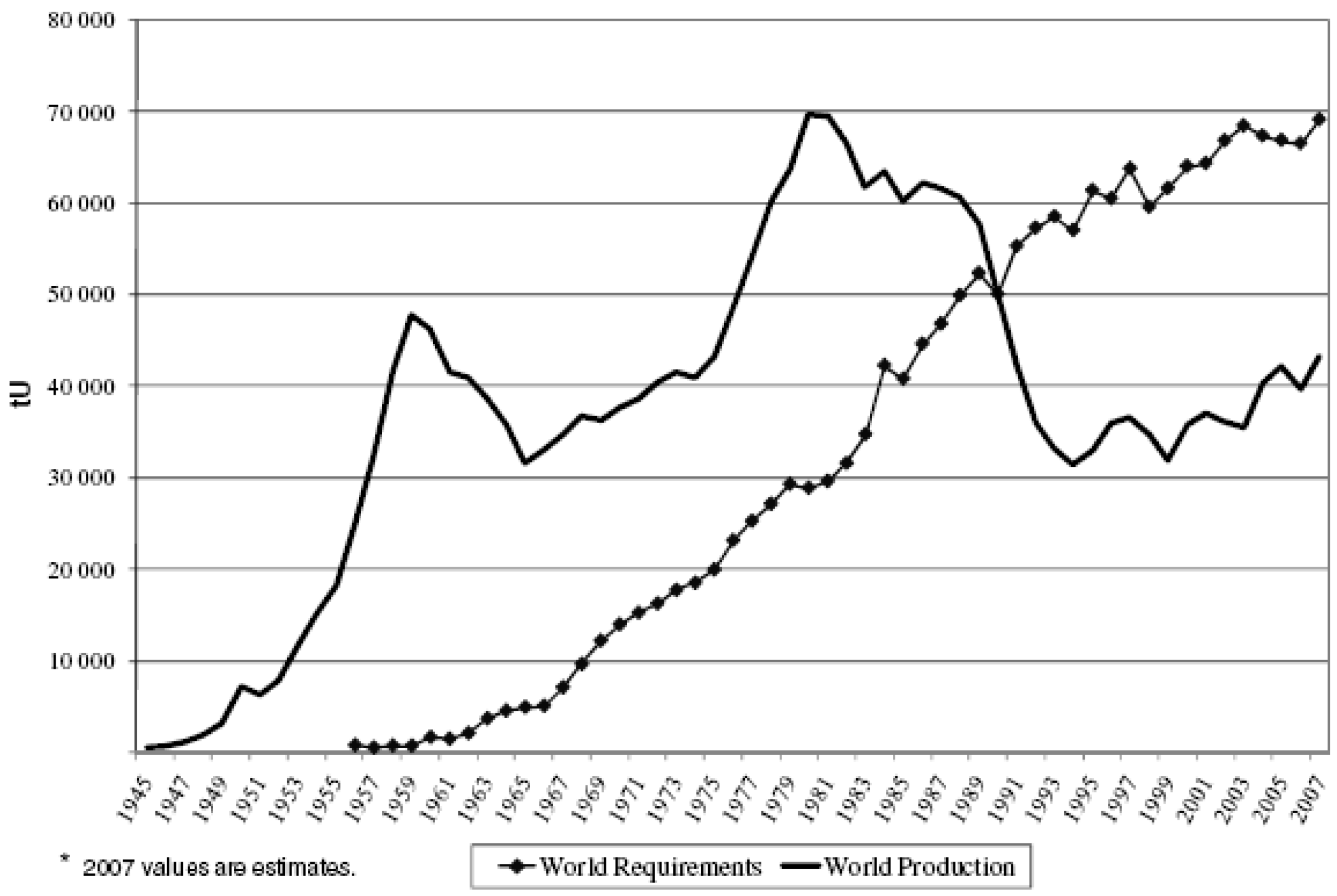

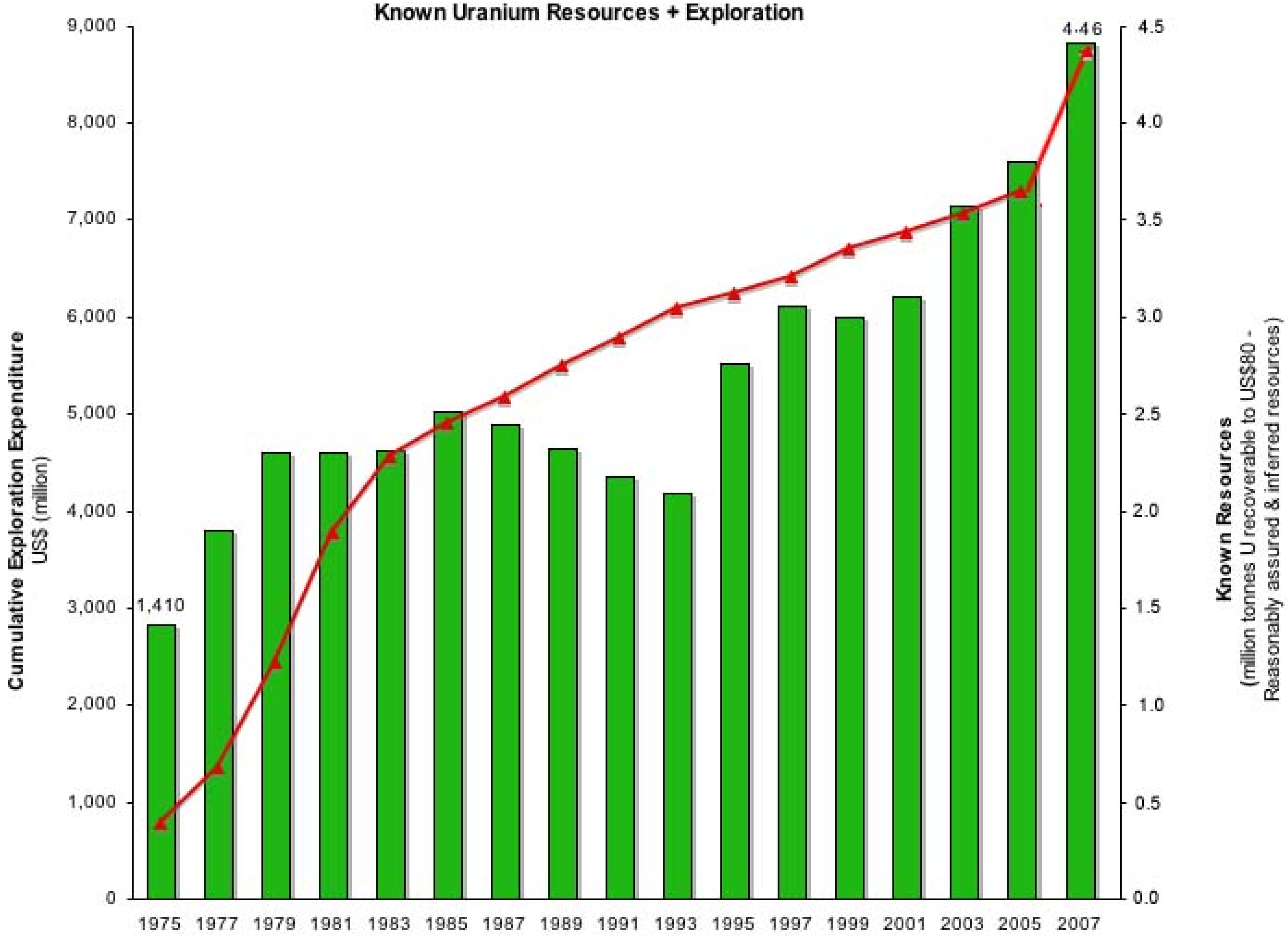

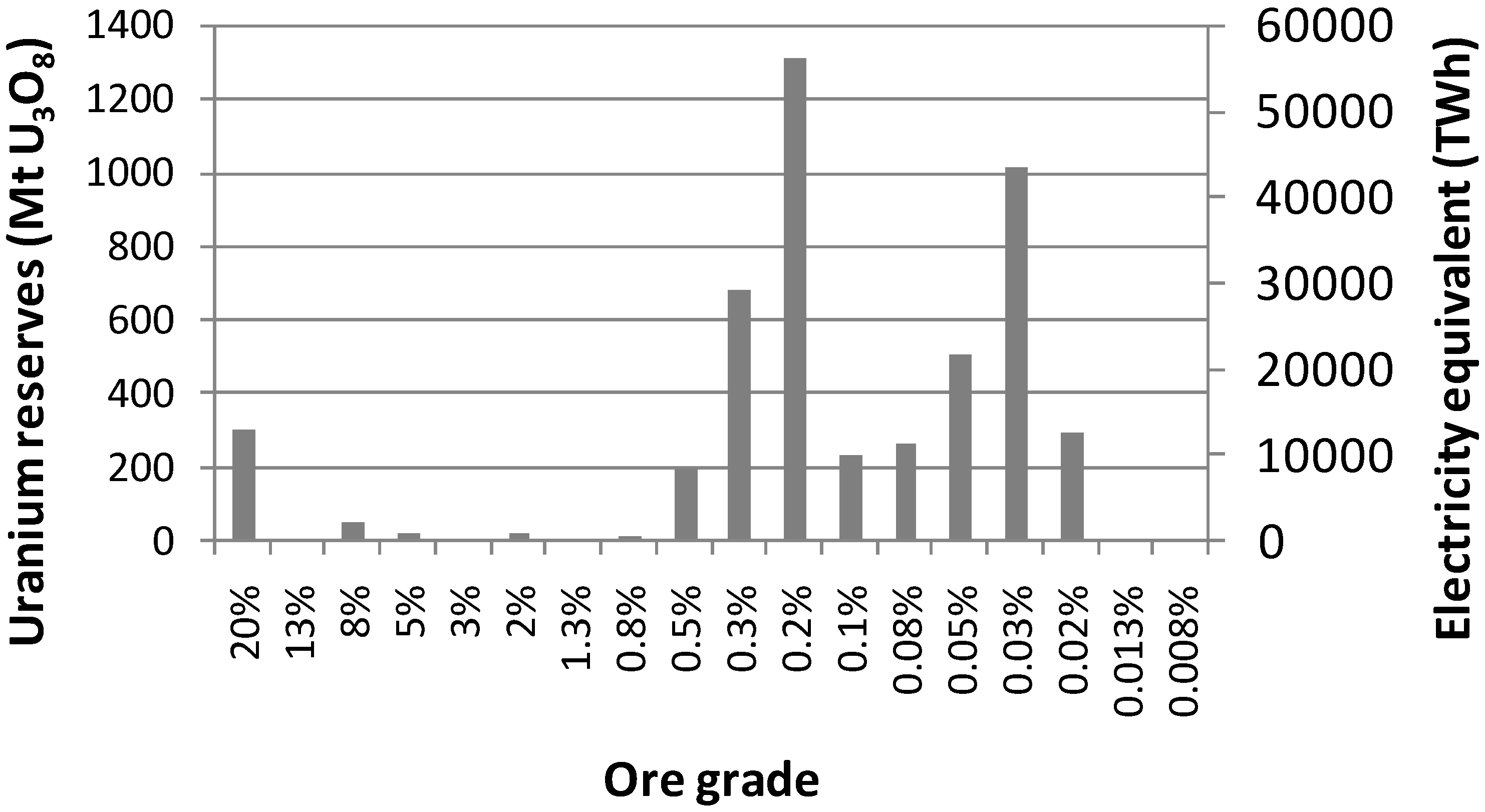

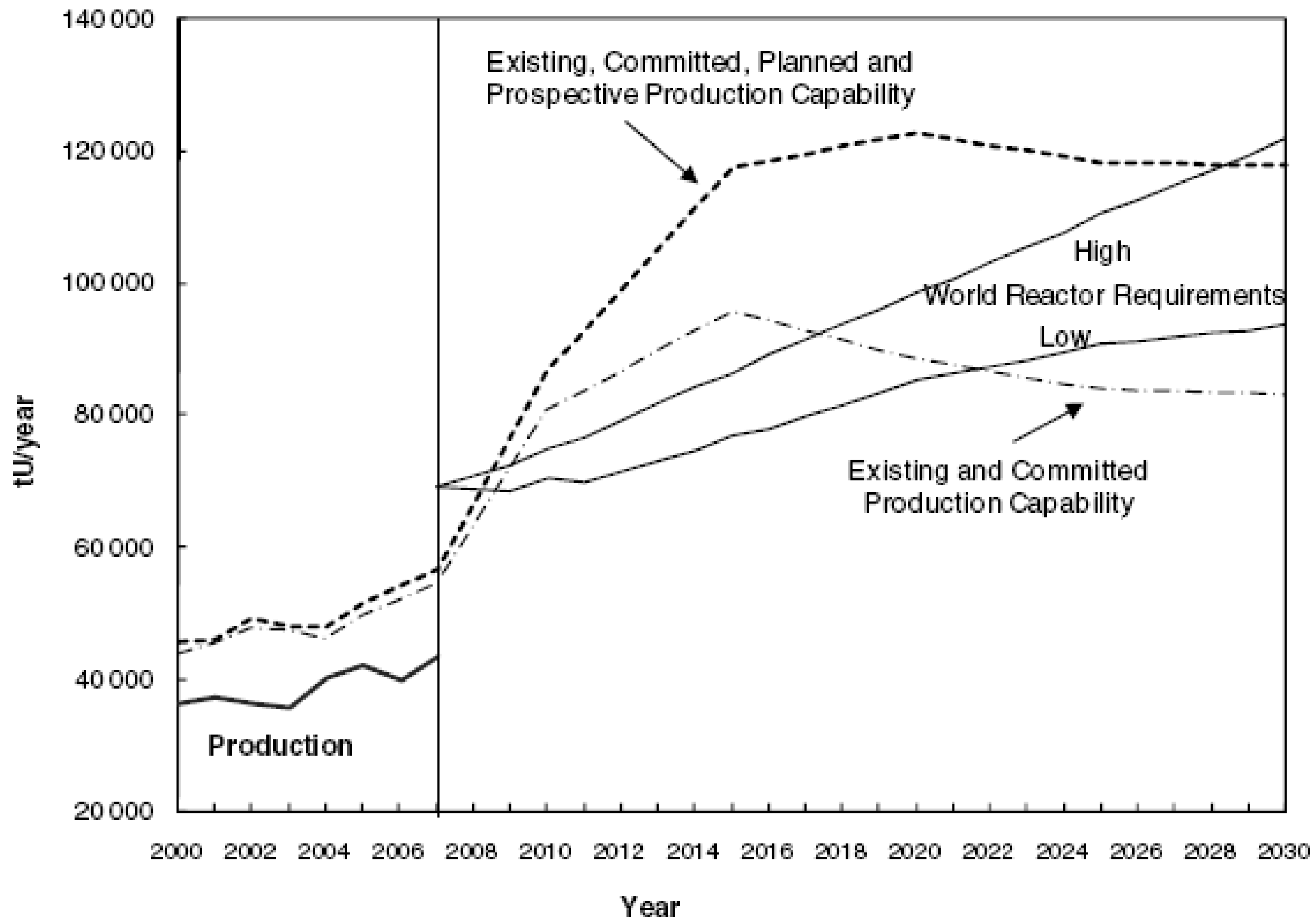

5.2. Global potential of resource

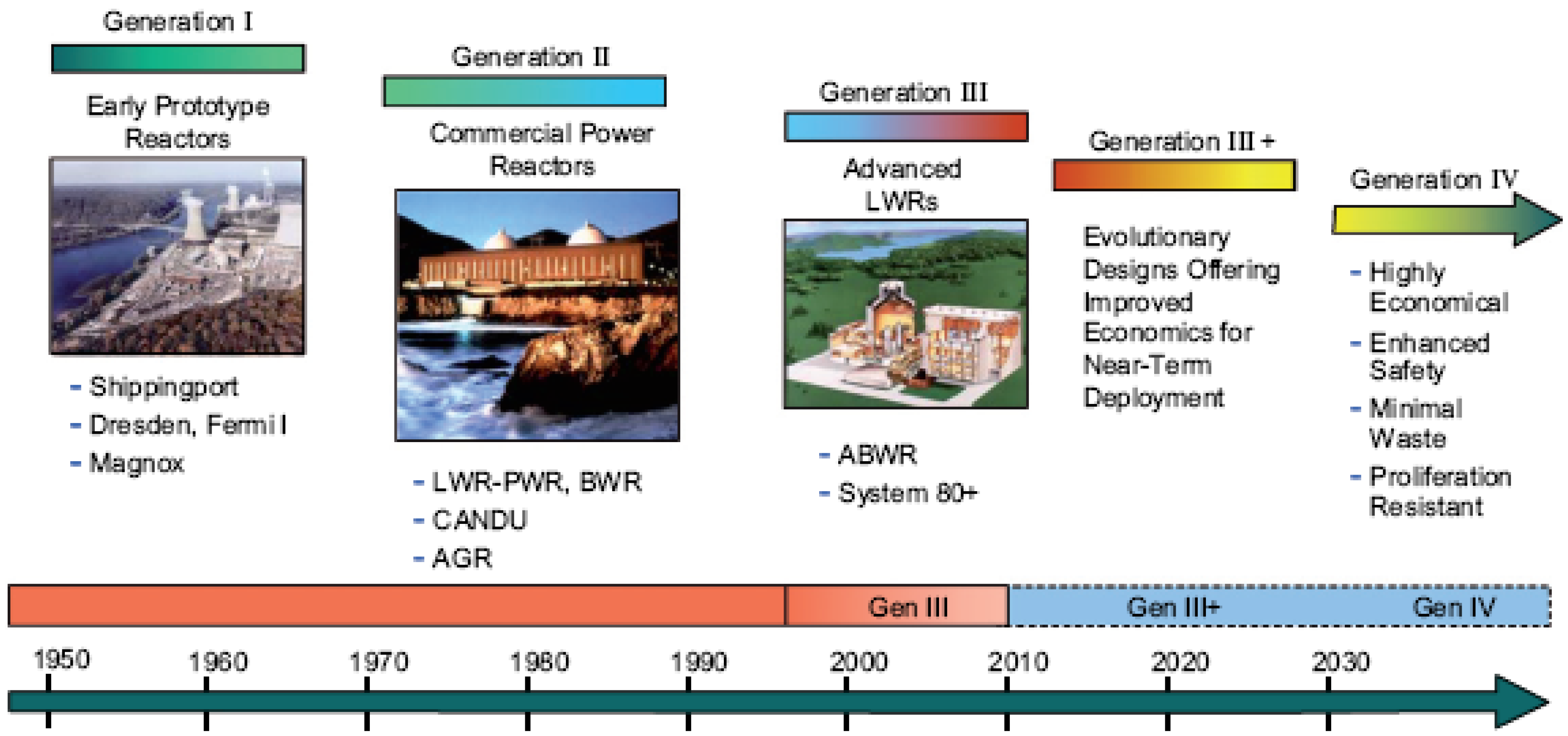

5.3. Generation-II and -III reactors

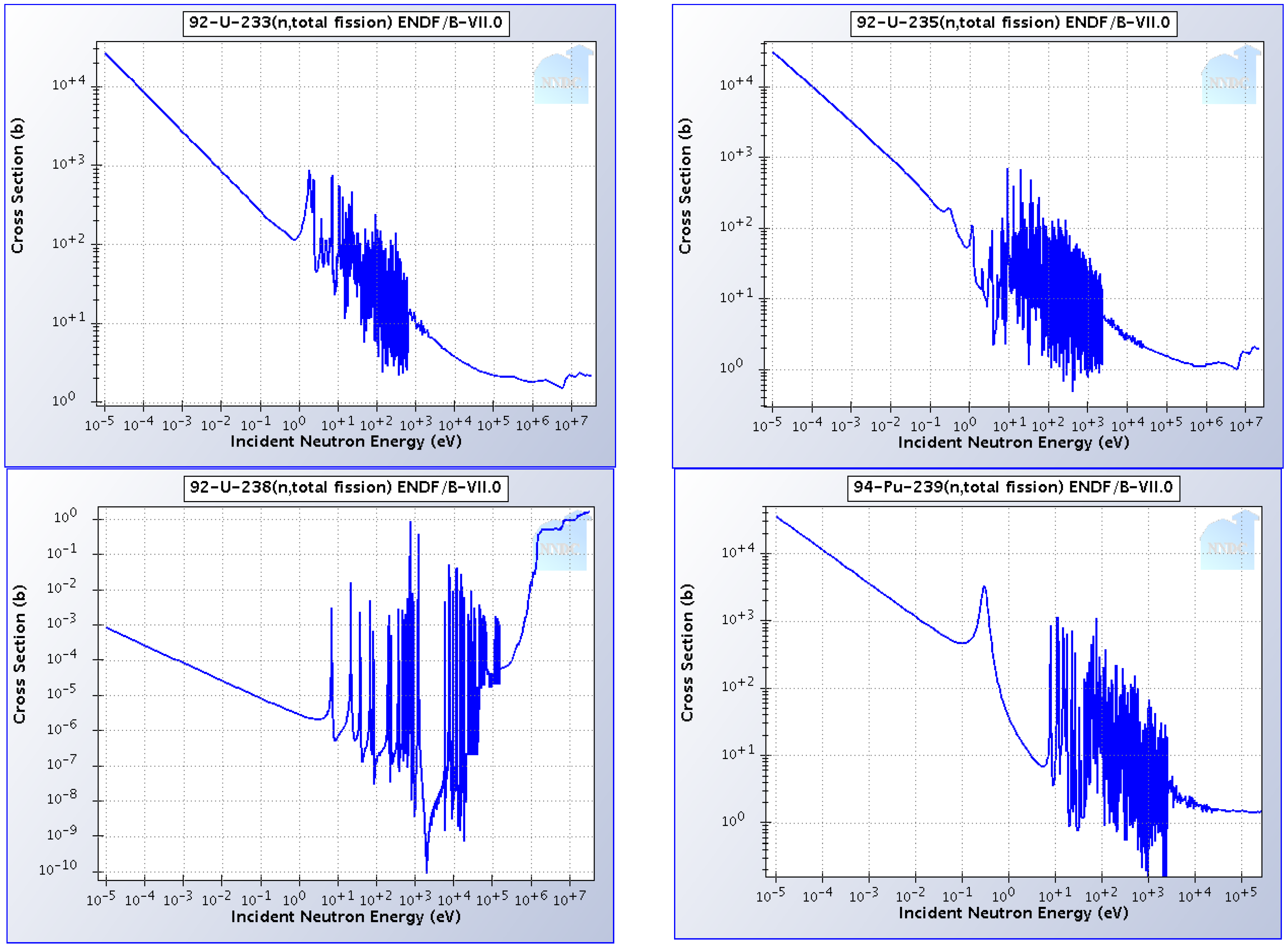

5.3.1. Technical principle

|

5.3.2. Capacity and load characteristics

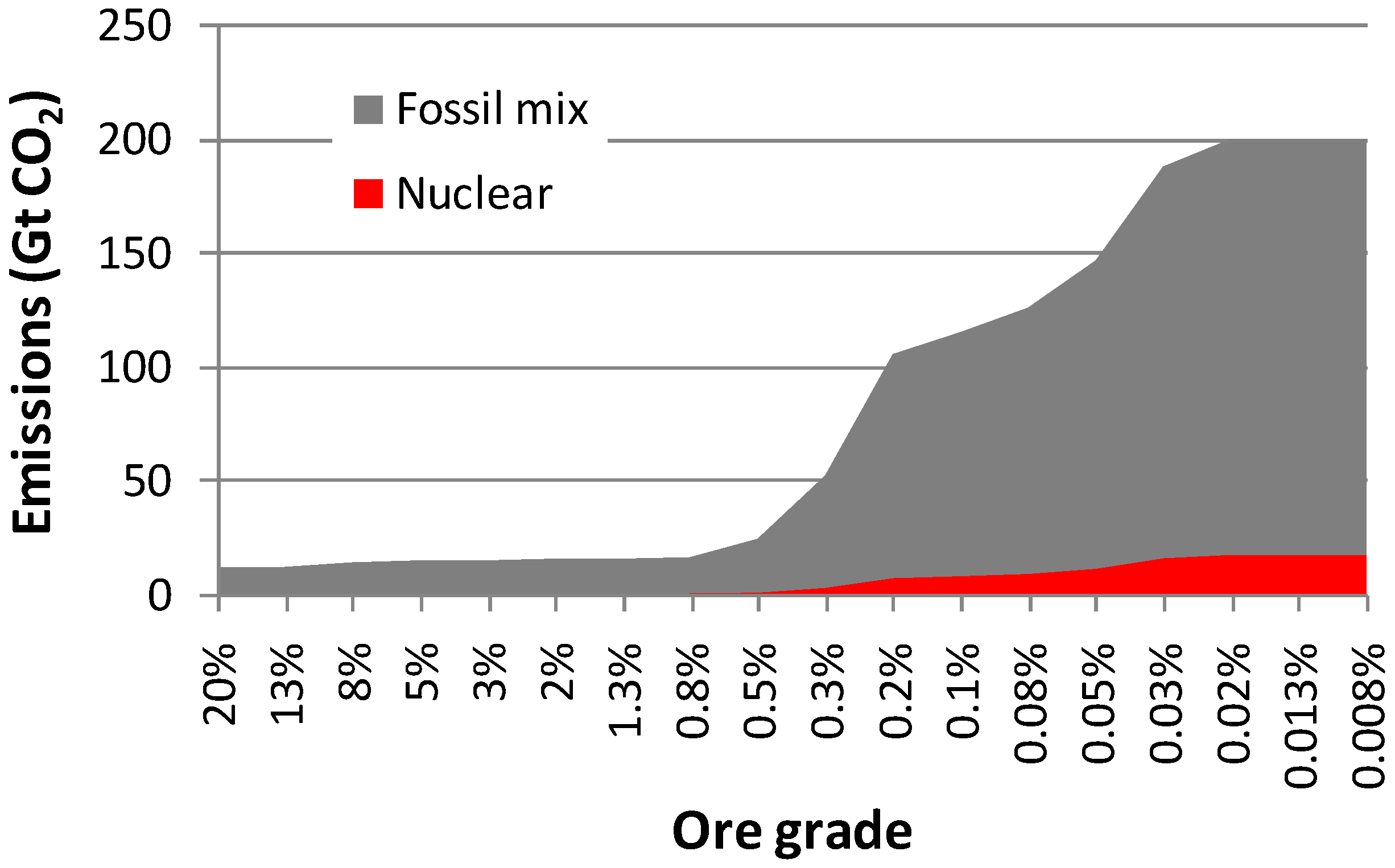

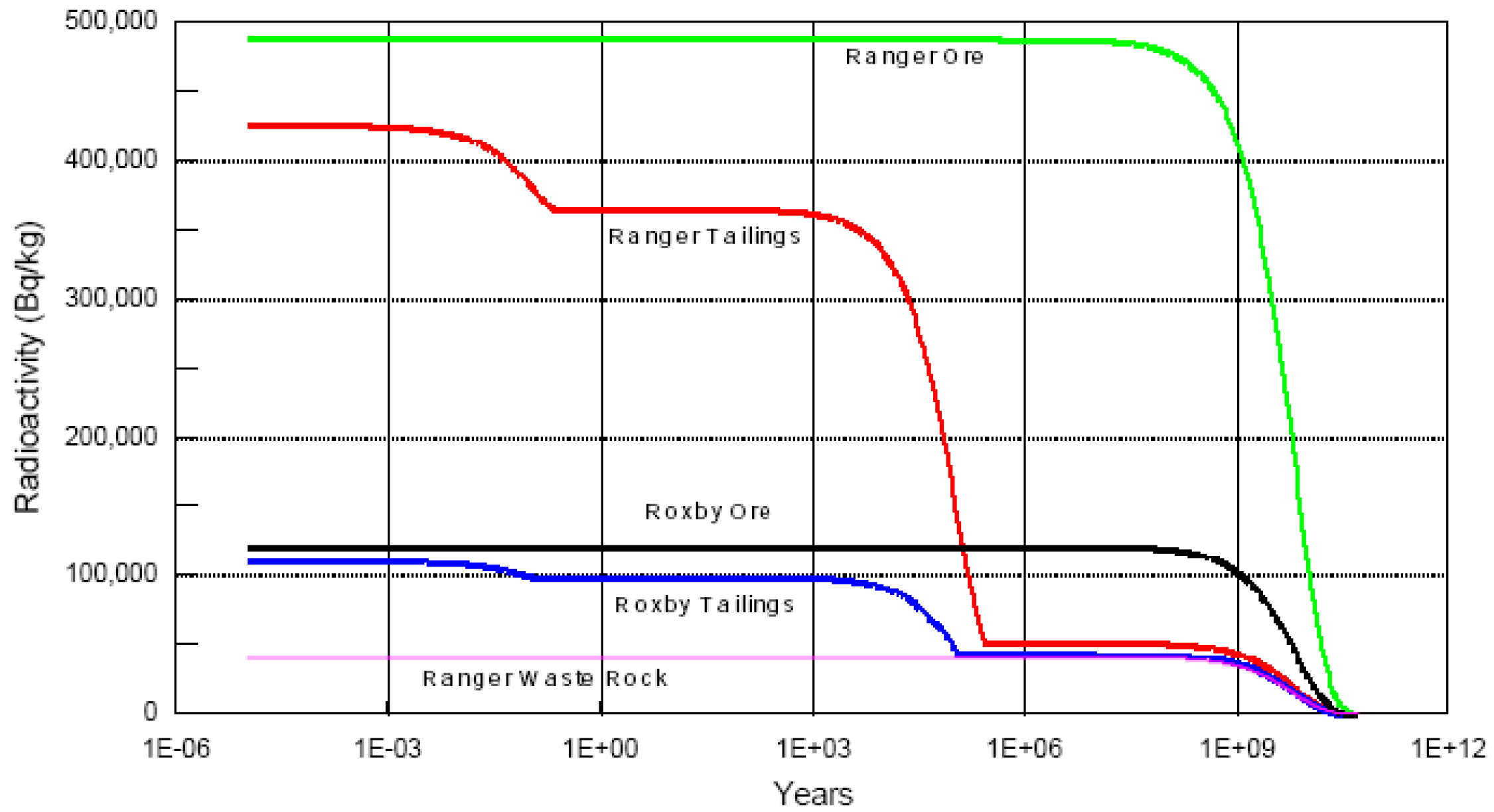

5.3.3. Life-cycle characteristics

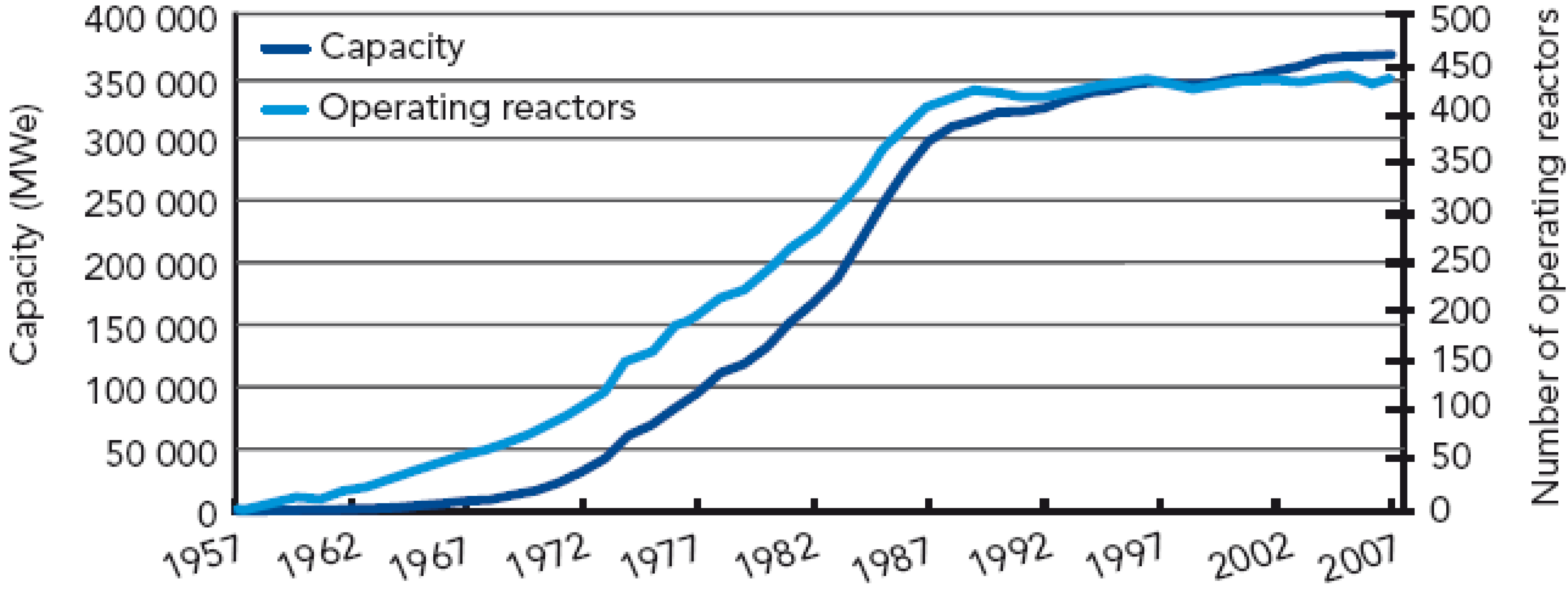

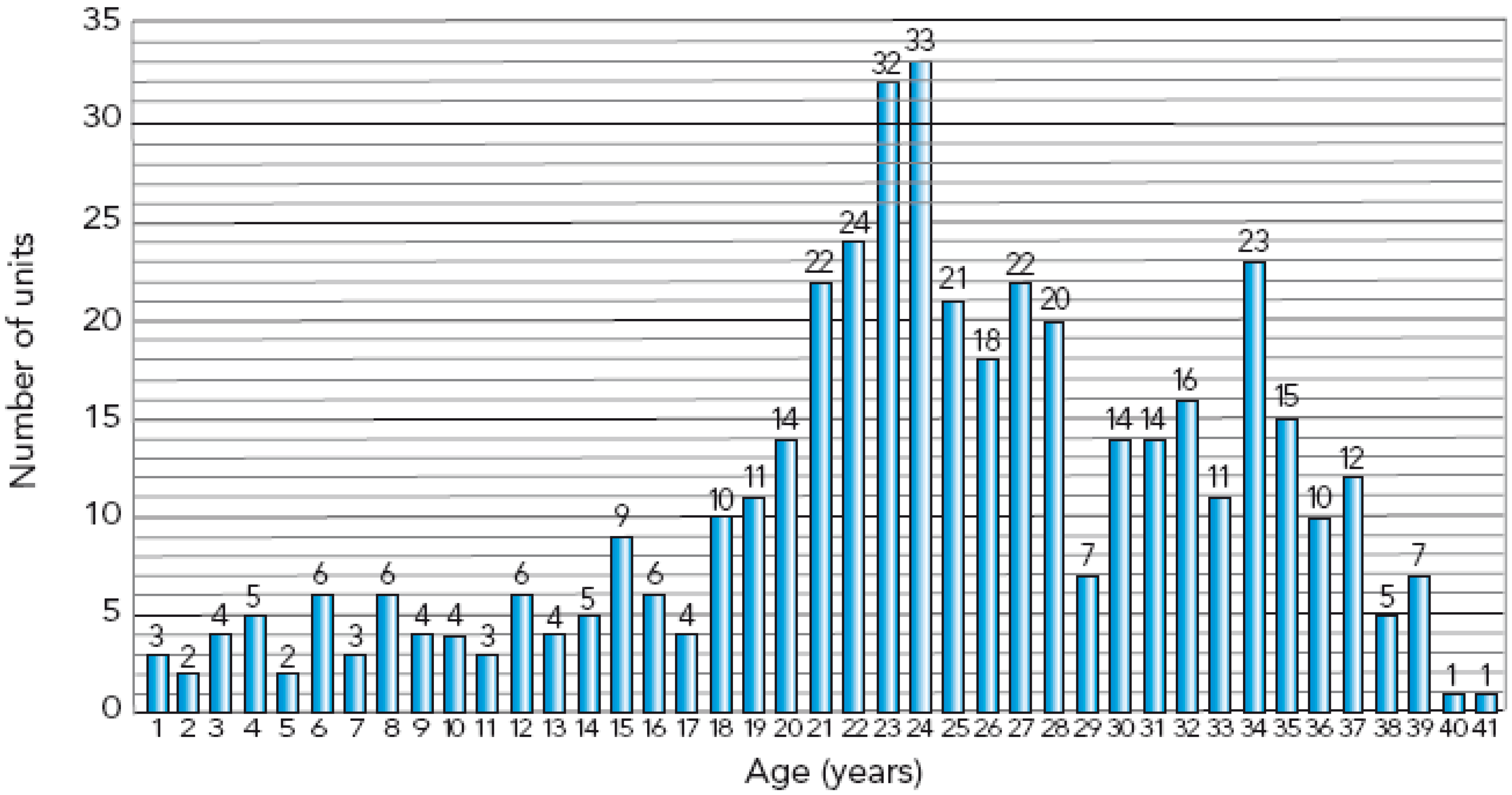

5.3.4. Current scale of deployment

5.3.5. Contribution to global electricity supply

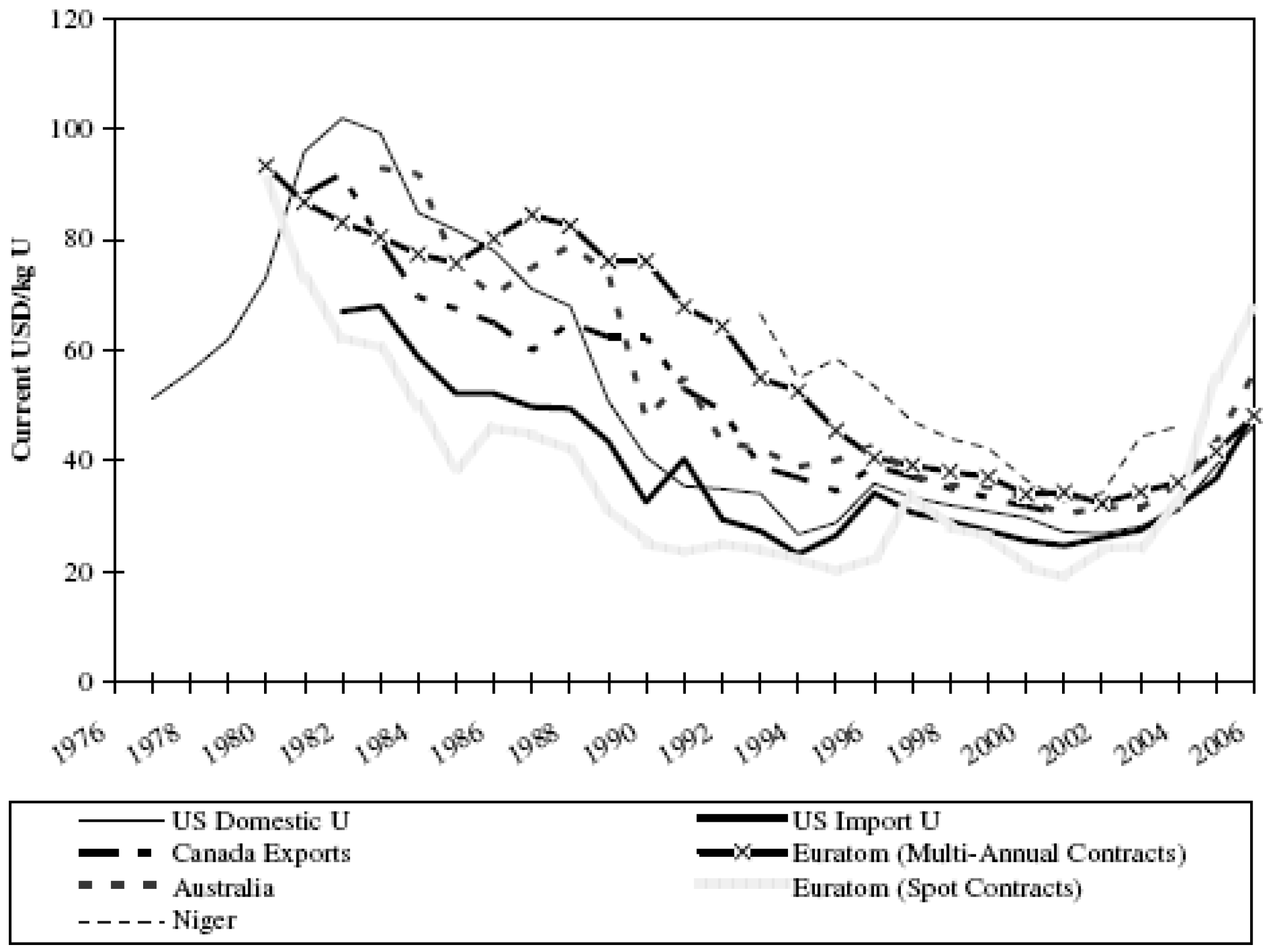

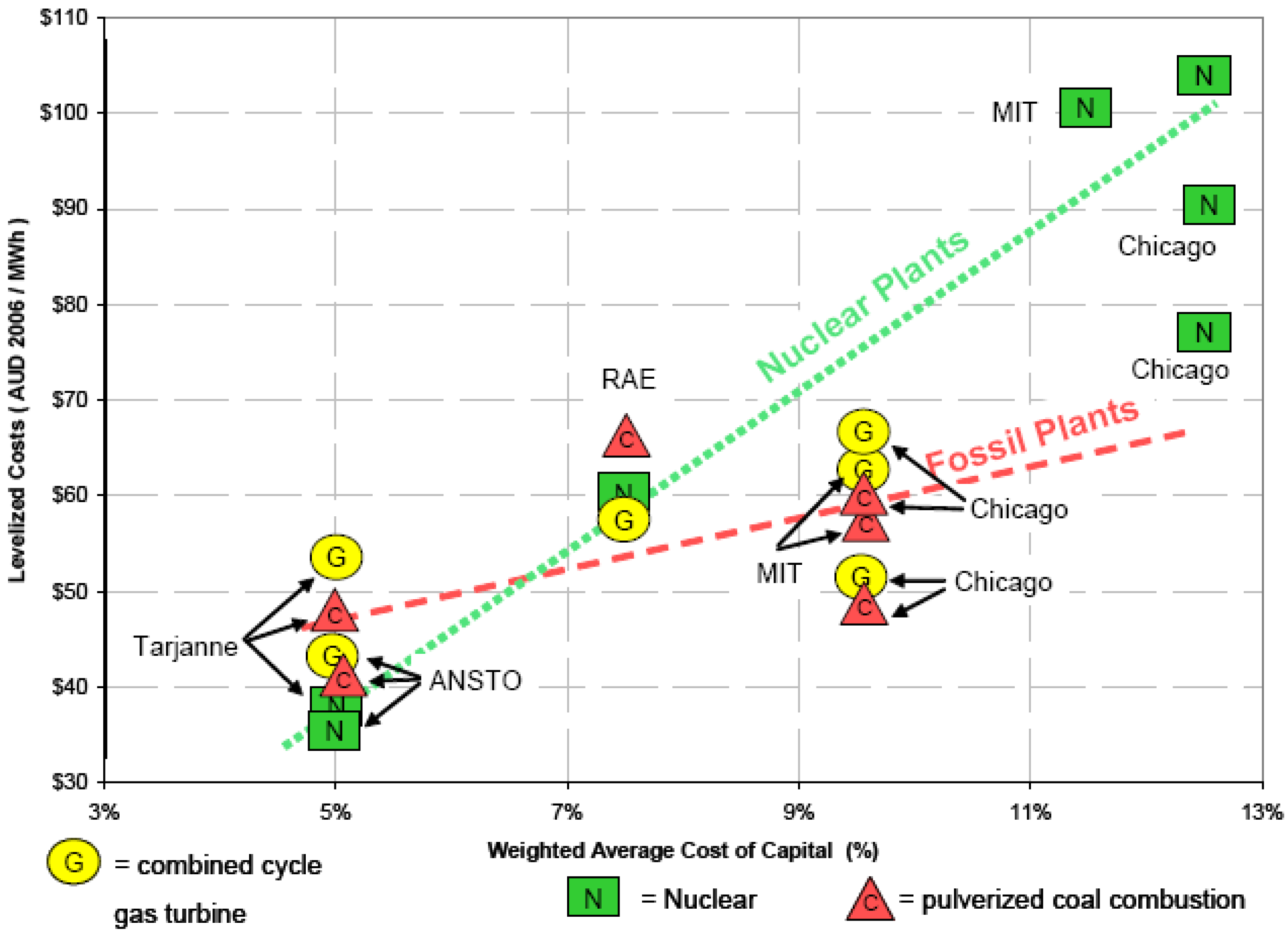

5.3.6. Cost of electricity output

5.3.7. Technical challenges

5.4. Generation-IV reactors

- improve nuclear safety,

- improve proliferation resistance,

- minimise waste and

- natural resource sustainability,

| Type | passive safety | resource sustainability | waste minimisation | proliferation resistance | competitive power | Comments |

|---|---|---|---|---|---|---|

| Gen III+ LWR | ✓ | ✓ | ✓ | |||

| FBR | ✓ | ✓ | ✓ | |||

| MSR | ✓ | ✓ | ✓ | Can use on-site reprocessing | ||

| MPBR | ✓ | ✓ | ✓ | Spent fuel can be transmuted a | ||

| ADS | ✓ | ✓ | ✓ | ✓b | Minor contribution to power generation |

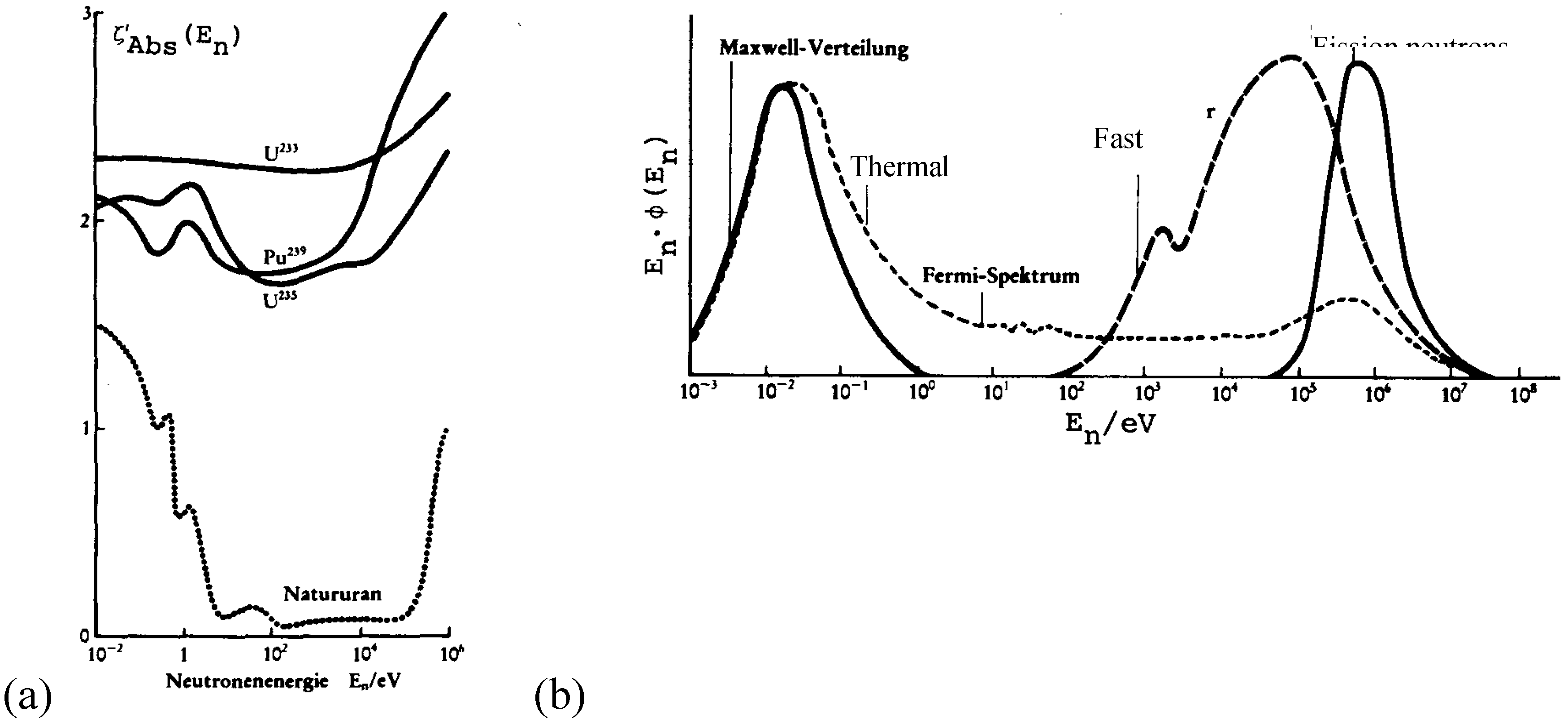

5.4.1. Technical principle

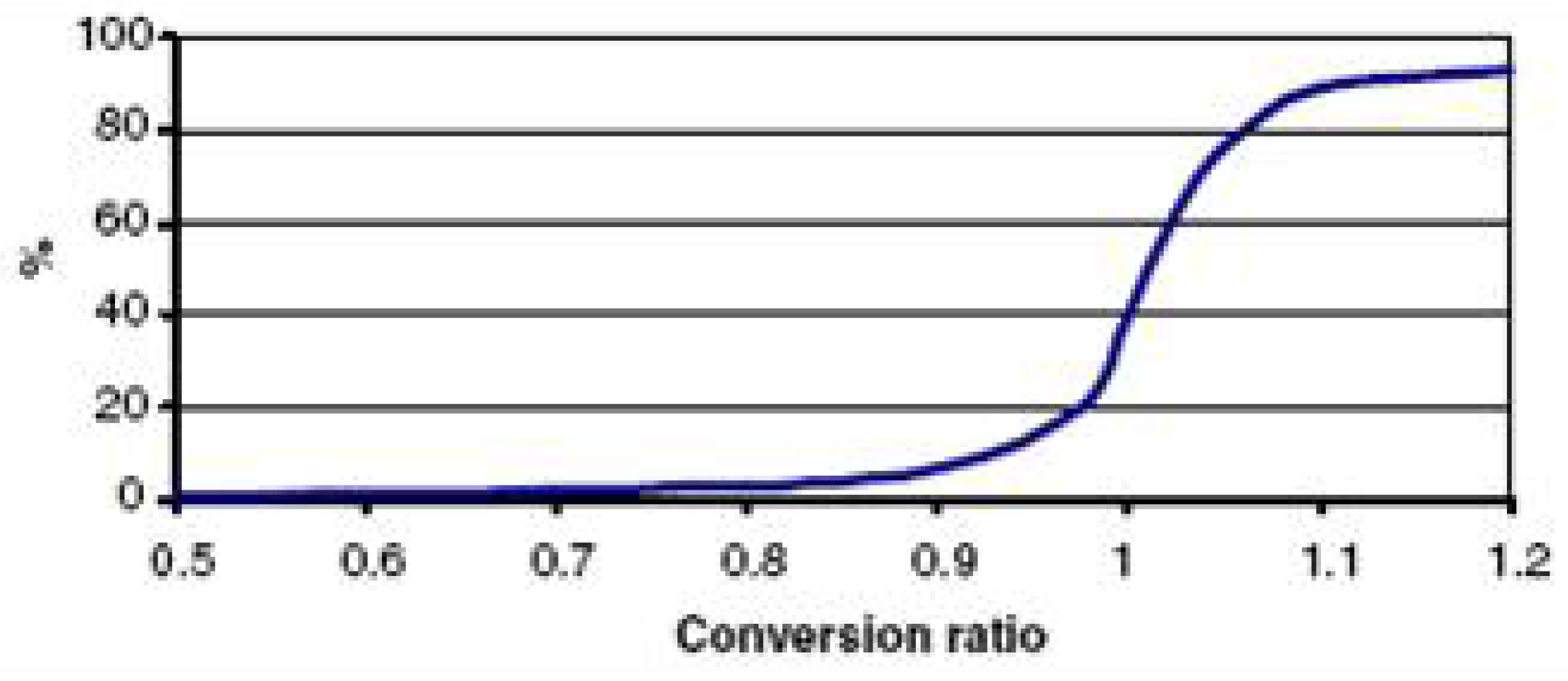

5.4.1.1. Breeding

| System | Abbreviation | Neutron Spectrum | Coolant | Maximum Temperature (°C) | Pressure | Fuel | Fuel Cycle | Output (MWe) | Output |

|---|---|---|---|---|---|---|---|---|---|

| Gas-cooled fast reactor | GFR | Fast | Helium | 850 | High | U-238, MOX | In situ closed | 288 | Electricity, hydrogen production |

| Liquid metal (e.g., Pb) cooled fast reactor | LMFR | Fast | Pb-Bi | 550–800 | Low | U-238, MOX | Closed, regional | 50–150, 300–400, 1200 | Electricity, hydrogen production |

| Molten-salt reactor | MSR | Epithermal | Floride salts | 700–800 | Low | UF6 in salt | In situ closed | 1000 | Electricity, hydrogen production |

| Sodium-cooled fast reactor | SFR | Fast | Sodium | 550 | Low | U-238, MOX | Closed | 300–1500 | Electricity |

| Supercritical, water-cooled reactor | SCWR | Thermal; fast | Water | 510–550 | Very high | UO2 | Open (th), closed (f) | 1500 | Electricity |

| Very high-temperature gas-cooled reactor (as in the GA system) | VHTR | Thermal | Helium | 1000 | High | UO2 | Open | 250 | Electricity, hydrogen production |

5.4.1.2. Fast reactors

5.4.1.3. Fast and thermal breeder reactors

5.4.1.4. High burnup

5.4.1.5. Passive safety–The pebble bed and molten salt reactors

5.4.1.6. High-temperature heat – nuclear hydrogen

5.4.1.7. Thorium fuel cycle

5.4.1.8. Subcritical reactors

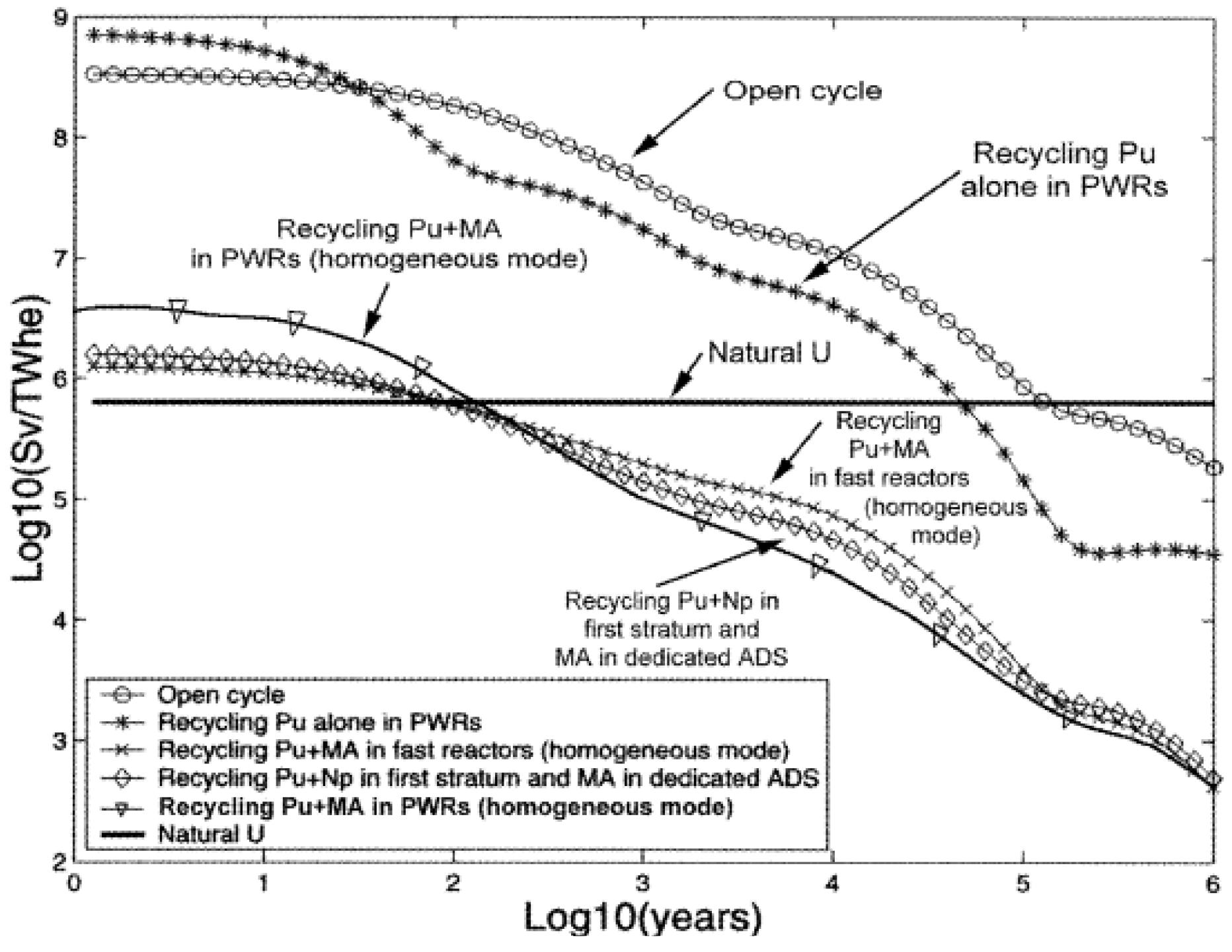

5.4.1.9. Transmutation

5.4.2. Capacity and load characteristics

5.4.3. Life-cycle characteristics

5.4.4. Current scale of deployment

5.4.5. Contribution to global electricity supply

5.4.6. Cost of electricity output

5.4.7. Technical challenges

| Generation-IV goal | VHTR | GFR | SFR | LFR | SCWR | MSR |

|---|---|---|---|---|---|---|

| Efficient electricity generation | Very high | High | High | High | High | High |

| Flexibility: availability of high-temperature process heat | Very high | High | Low | Low | Low | Low |

| Sustainability: creation of fissile material | Medium/low | High | High | High | Low | Medium/low |

| Sustainability: transmutation of waste | Medium | Very high | Very high | Very high | Low | High |

| Potential for “passive” safety | High | Very low | Medium/low | Medium | Very low | Medium |

| Current technical feasibility | High | Medium/low | High | Medium | Medium/low | Low |

6. Hydroelectric Power

6.1. Summary

6.2. Global Potential of Resource

6.3. Dam and run-of-river plants

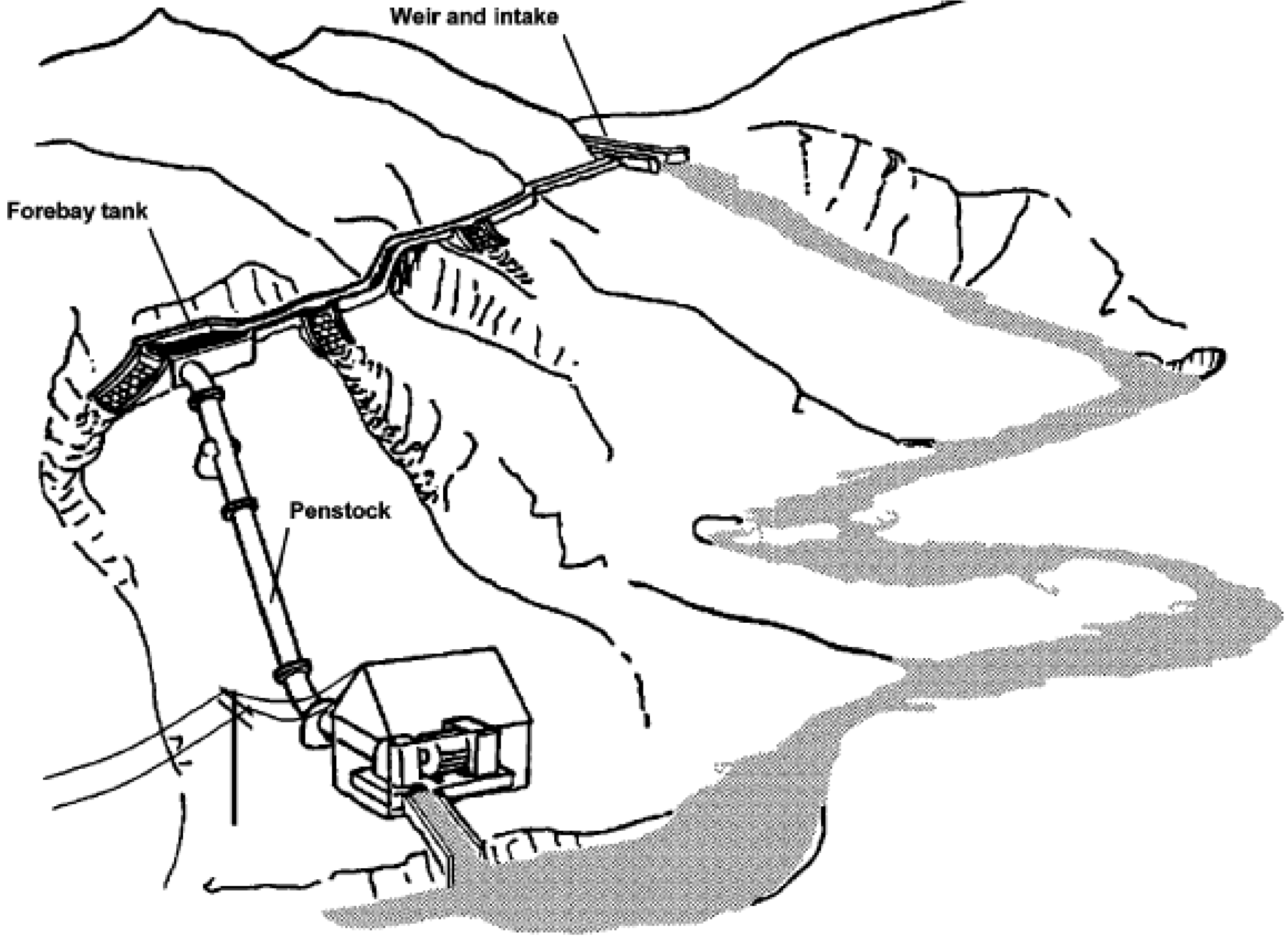

6.3.1. Technical principle

6.3.2. Capacity and load characteristics

6.3.3. Life-cycle characteristics

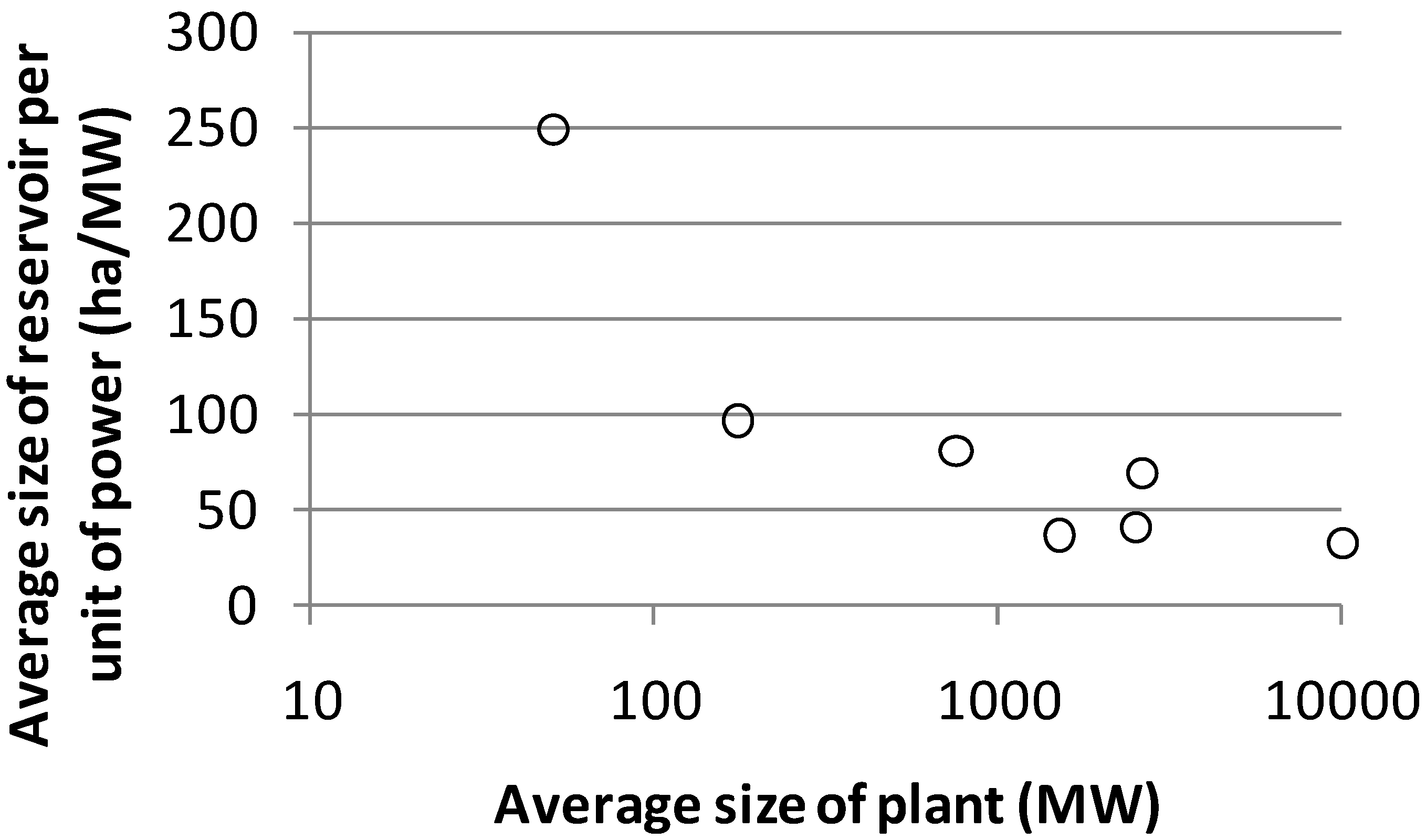

6.3.4. Current scale of deployment

| Name | Country | Year of completion | Total Capacity (MW) | Max annual electricity production (TWh) | Area flooded (km2) | Load factor (%) |

|---|---|---|---|---|---|---|

| Three Gorges | China | 2009 | 22,500 | >100 | 632 | 62 |

| Itaipu | Brazil/Paraguay | 1984/1991/2003 | 14,000 | 90 | 1,350 | 73 |

| Guri | Venezuela | 1986 | 10,200 | 46 | 4,250 | 51 |

| Tucuruí | Brazil | 1984 | 8,370 | 21 | 29 | |

| Robert-Bourassa | Canada | 1981 | 7,722 | |||

| Sayano Shushenskaya | Russia | 1985/1989 | 6,400 | 26.8 | 48 | |

| Krasnoyarskaya | Russia | 1972 | 6,000 | 20.4 | 2,000 | 39 |

| Grand Coulee | United States | 1942/1980 | 6,809 | 22.6 | 38 | |

| Churchill Falls | Canada | 1971 | 5,429 | 35 | 6,988 | 74 |

| Longtan Dam | China | 2009 | 4,900 | 18.7 | 34 | |

| Bratskaya | Russia | 1967 | 4,500 | 22.6 | 57 | |

| Ust Ilimskaya | Russia | 1980 | 4,320 | 21.7 | 57 | |

| Yaciretá | Argentina/Paraguay | 1998 | 4,050 | 19.2 | 1,600 | 54 |

| Tarbela Dam | Pakistan | 1976 | 3,478 | 13 | 43 | |

| Ertan Dam | China | 1999 | 3,300 | 17.0 | 59 | |

| Ilha Solteira | Brazil | 1974 | 3,200 | |||

| Xingó | Brazil | 1994/1997 | 3,162 | |||

| Gezhouba Dam | China | 1988 | 3,115 | 17.01 | 62 | |

| Nurek Dam | Tajikistan | 1979/1988 | 3,000 | 11.2 | 43 | |

| La Grande-4 | Canada | 1986 | 2,779 | |||

| W.A.C. Bennett | Canada | 1968 | 2,730 | |||

| Chief Joseph | United States | 1958/73/79 | 2,620 | |||

| Volzhskaya | Russia | 1961 | 2,541 | 12.3 | 55 | |

| Niagara Falls | United States | 1961 | 2,515 | |||

| Paulo Afonso IV | Brazil | 1955 | 2,462 | |||

| Chicoasen | Mexico | 1980 | 2,430 | |||

| La Grande-3 | Canada | 1984 | 2,418 | |||

| Atatürk Dam | Turkey | 1990 | 2,400 | 8.9 | 42 | |

| Zhiguliovskay | Russia | 1957 | 2,300 | 10.5 | 52 | |

| Iron Gates-I | Romania/Serbia | 1970 | 2,192 | 13 | 68 | |

| Caruachi | Venezuela | 2006 | 2,160 | 12.95 | 68 | |

| John Day Dam | United States | 1971 | 2,160 | |||

| Aswan | Egypt | 1970 | 2,100 | 11 | 60 | |

| Itumbiara | Brazil | 1980 | 2,082 | |||

| Hoover Dam | United States | 1936/1961 | 2,080 | |||

| Cahora Bassa | Mozambique | 1975 | 2,075 | |||

| The Dalles Dam | United States | 1981 | 2,038 | |||

| Karun I Dam | Iran | 1976 | 2,000 | |||

| Karun II Dam | Iran | 2001 | 2,000 | |||

| Karun III Dam | Iran | 2007 | 2,000 | 4.1 | 23 | |

| Lijiaxia Dam | China | 2000 | 2,000 |

6.3.5. Contribution to global electricity supply

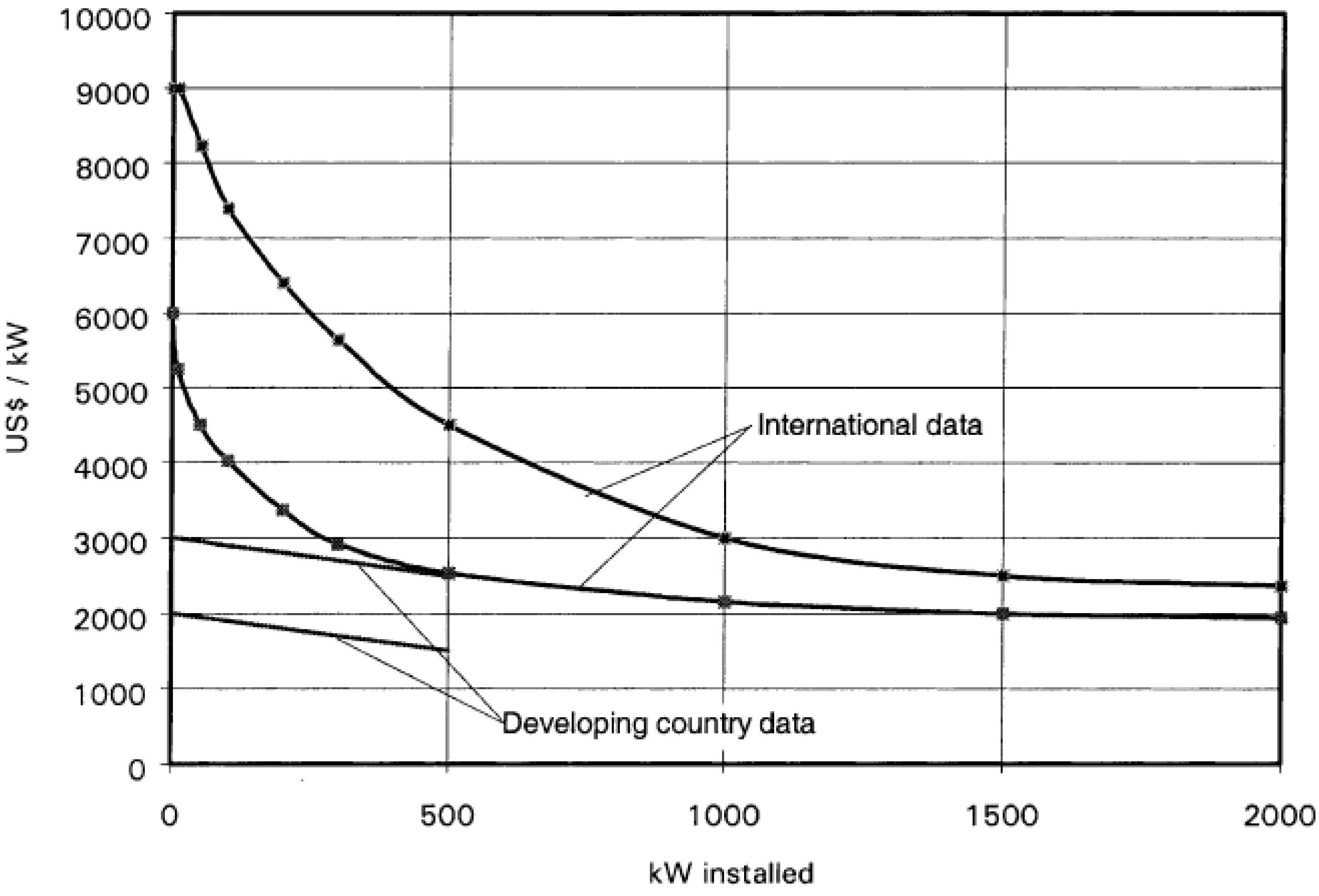

6.3.6. Cost of electricity output

6.3.7. Technical and other challenges

- –

- displacement of residents from flooded areas,

- –

- transformation of traditional land use,

- –

- sedimentation and eutrophication of reservoirs, scouring of downstream riverbeds,

- –

- disturbance and fragmentation of faunal habitat, obstruction of fish passage, thermal pollution, disruption of reproductive cycles, and changes in fish species composition,

- –

- large accidental dam failures or purposeful attacks on large dams.

7. Wind energy

7.1. Summary

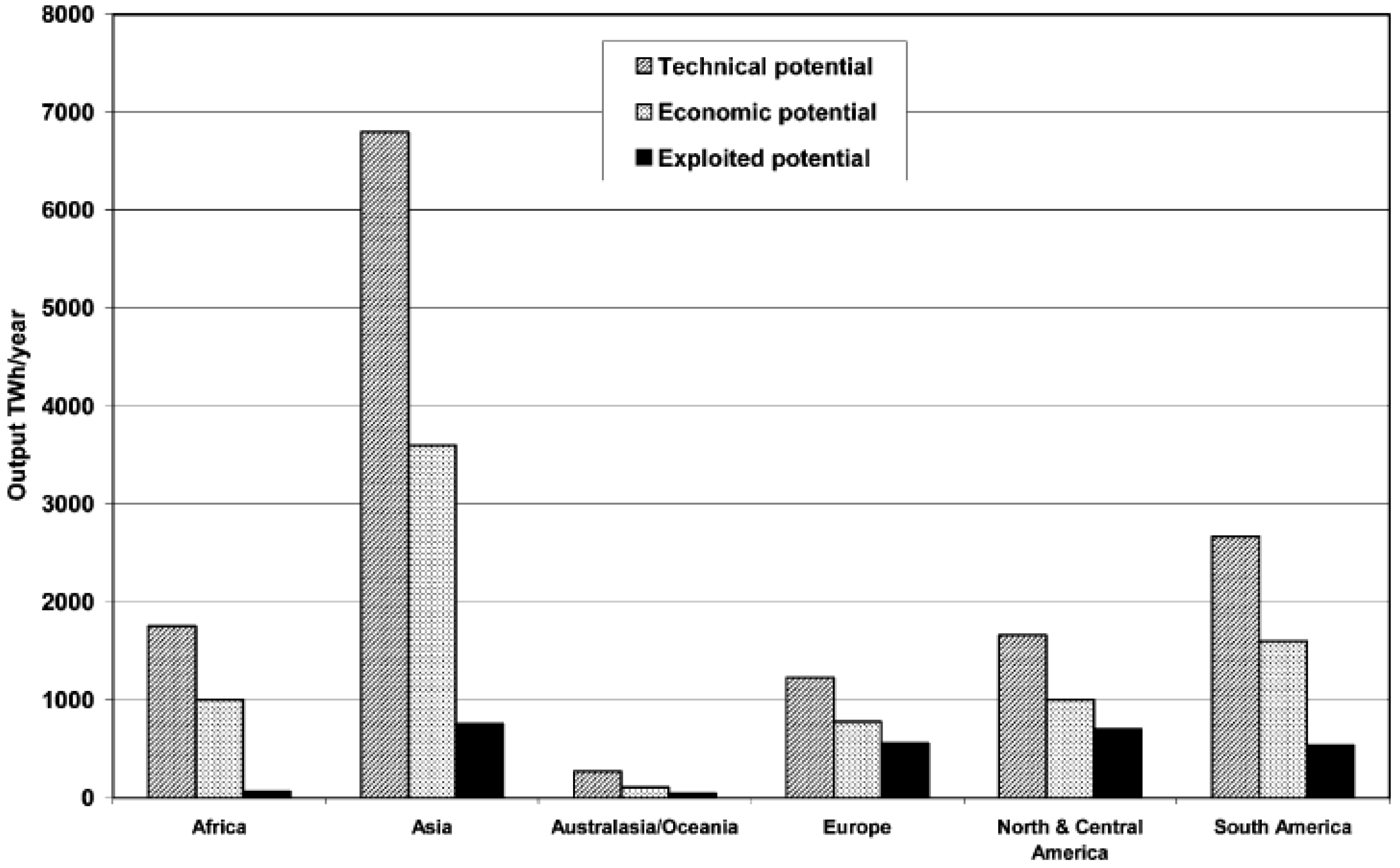

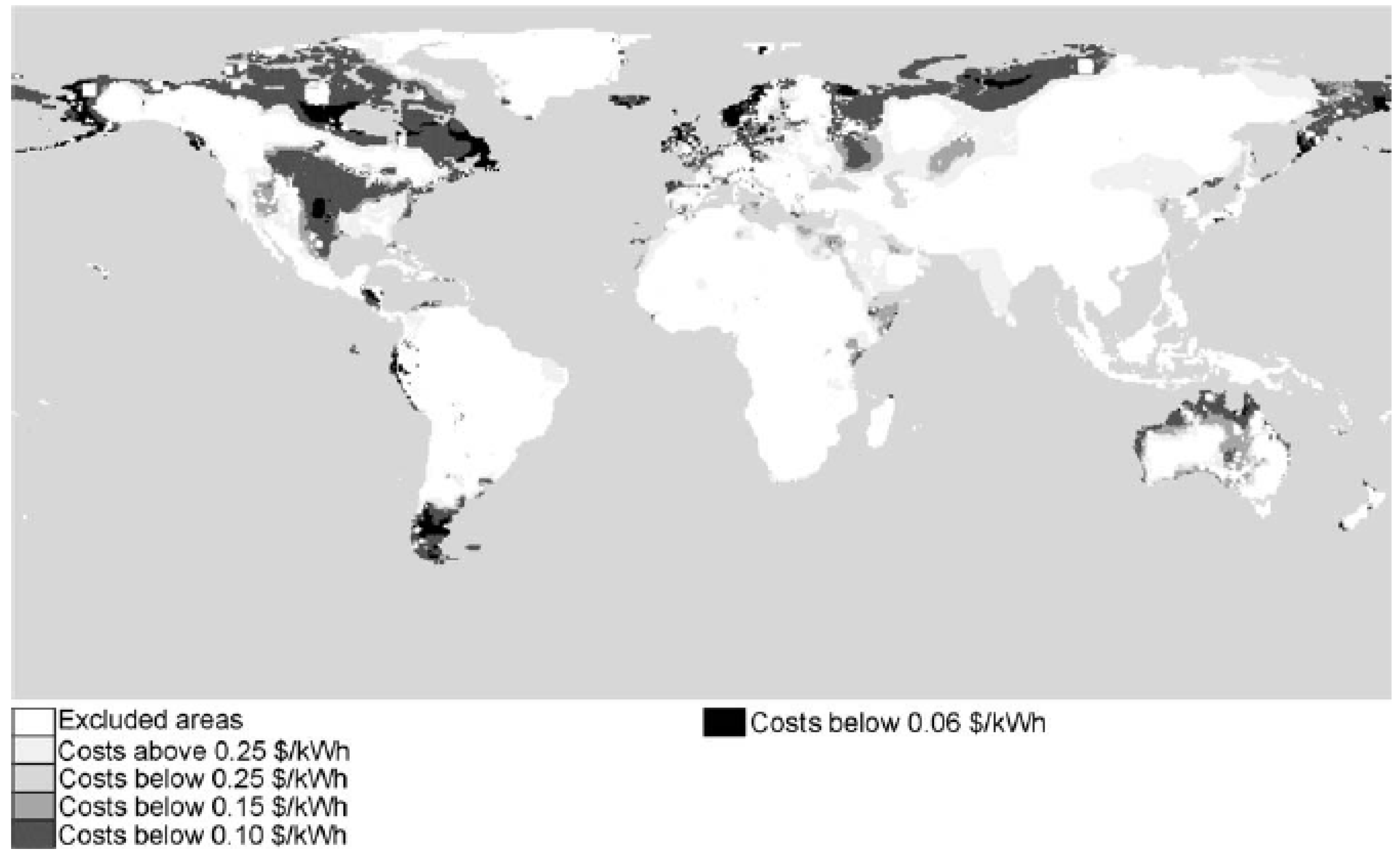

7.2. Global potential of resource

- -

- the theoretical potential (the energy content of global wind),

- -

- the geographical potential of on-shore wind (excluding land areas with wind speeds below 4 m/s (if the cut-off point had been 6 m/s, areas with current wind turbine installations would have been excluded), and those unavailable for turbine installation, such as nature reserves and areas with other functions urban areas, high altitudes above 2,000 m with low air density (Table 1 in [198] provides suitability factors, which show the percentage of a land area available for wind turbine installation),

- -

- the technical potential (extrapolating wind data to hub height, considering wake effects and realistic power densities in MW/km2, applying average capacity factors, subtracting down time), and

- -

- the economic potential given cost of alternative sources (calculating rated turbine power optimised for grid cell wind conditions, regressing capital cost and turbine output as a function of rated power and an economies-of-scale factor).

7.3. Wind energy converters

7.3.1. Technical principle

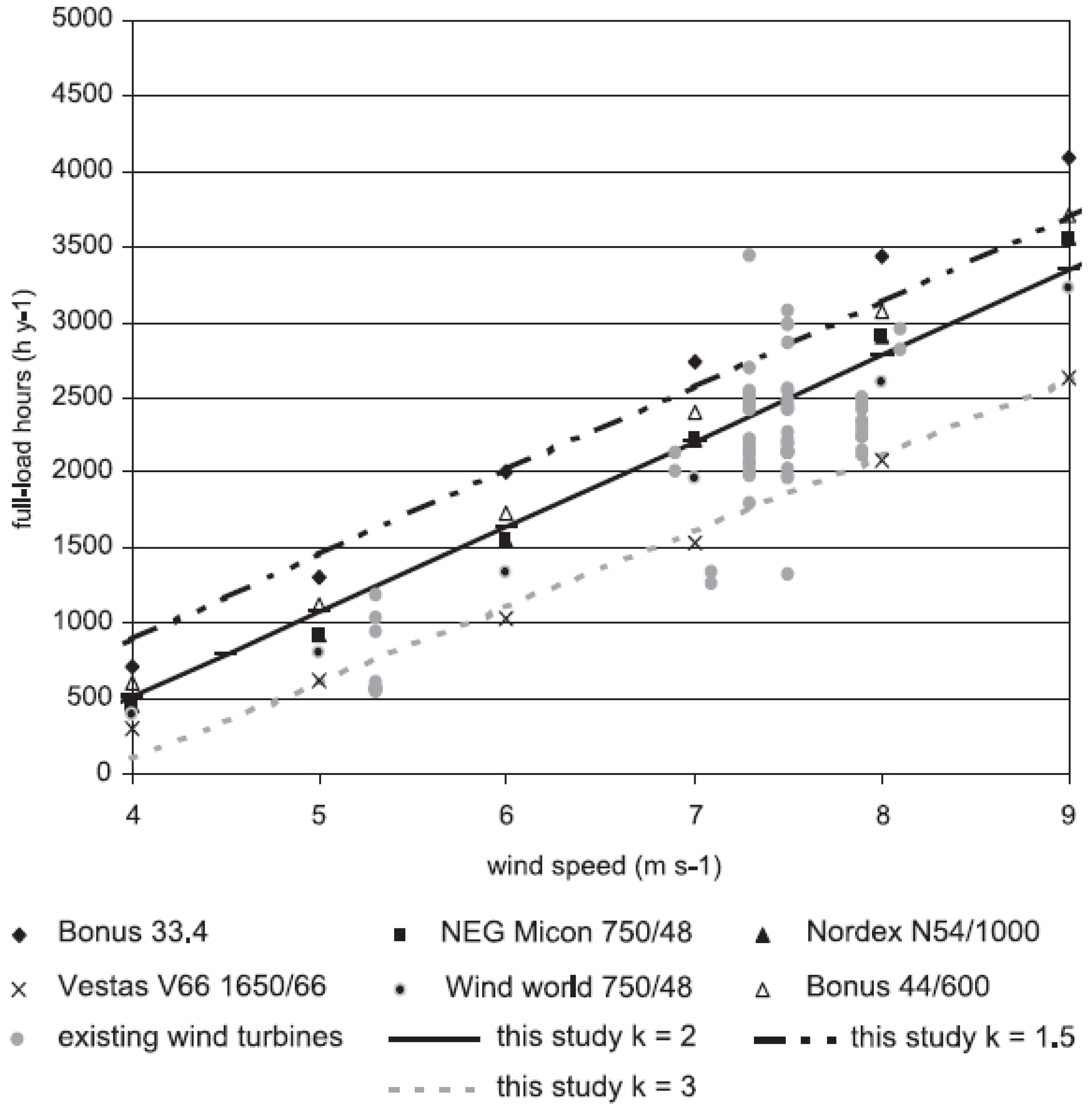

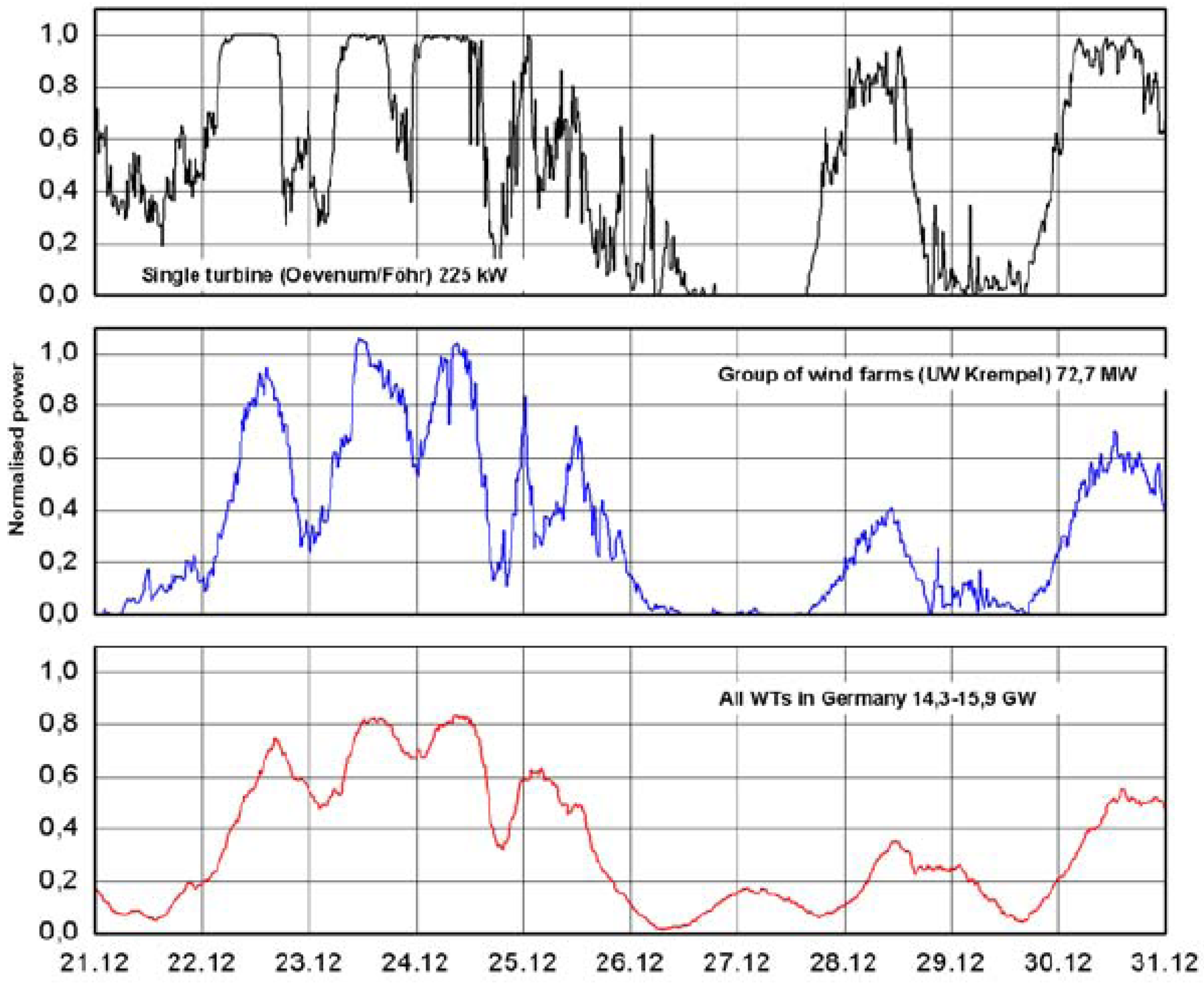

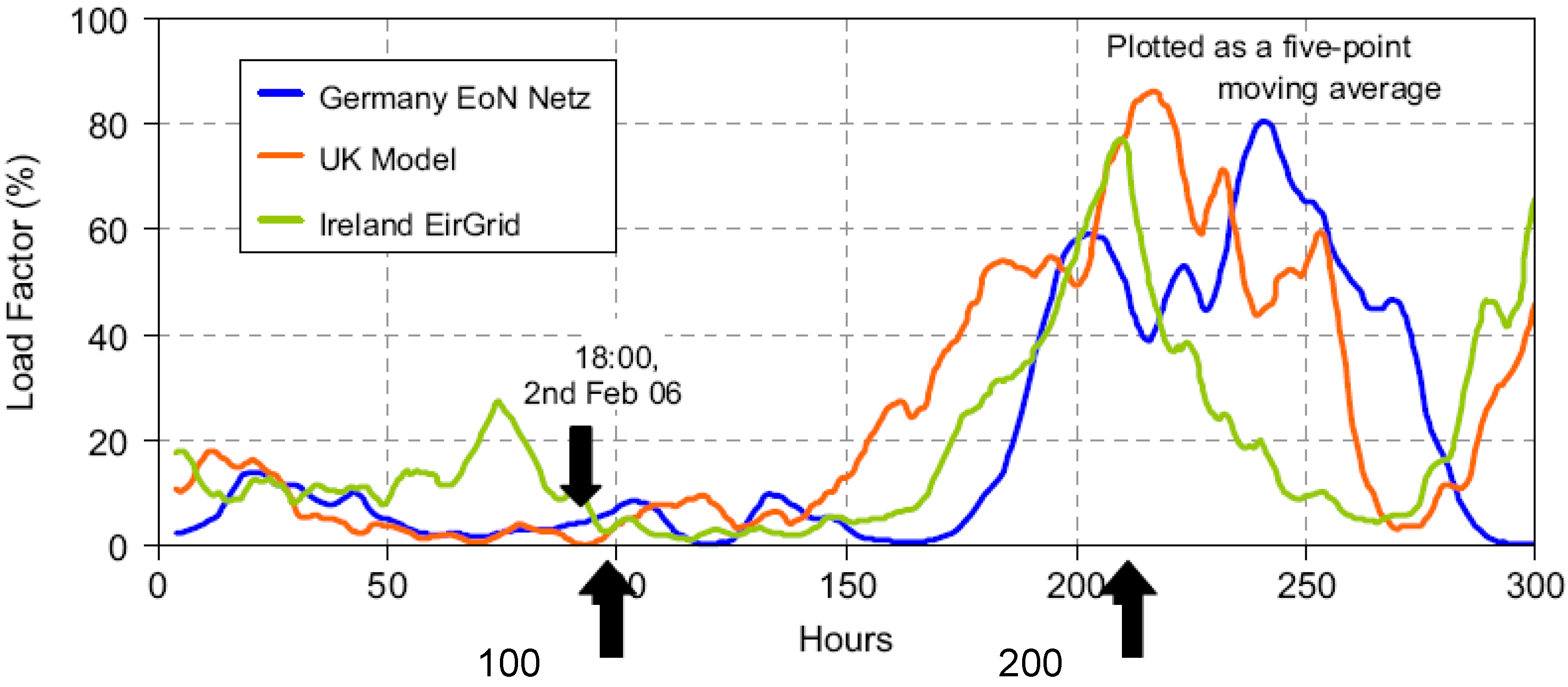

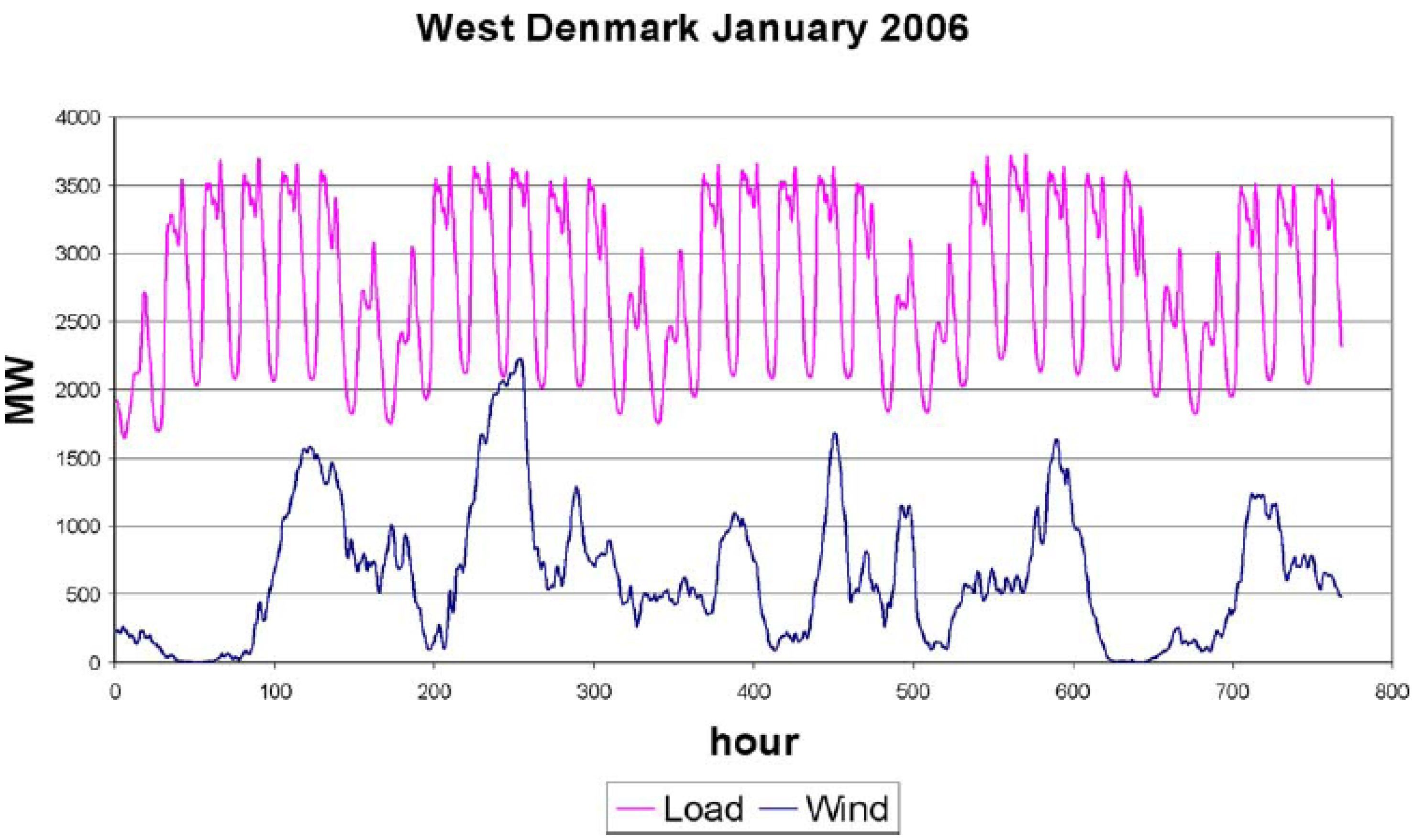

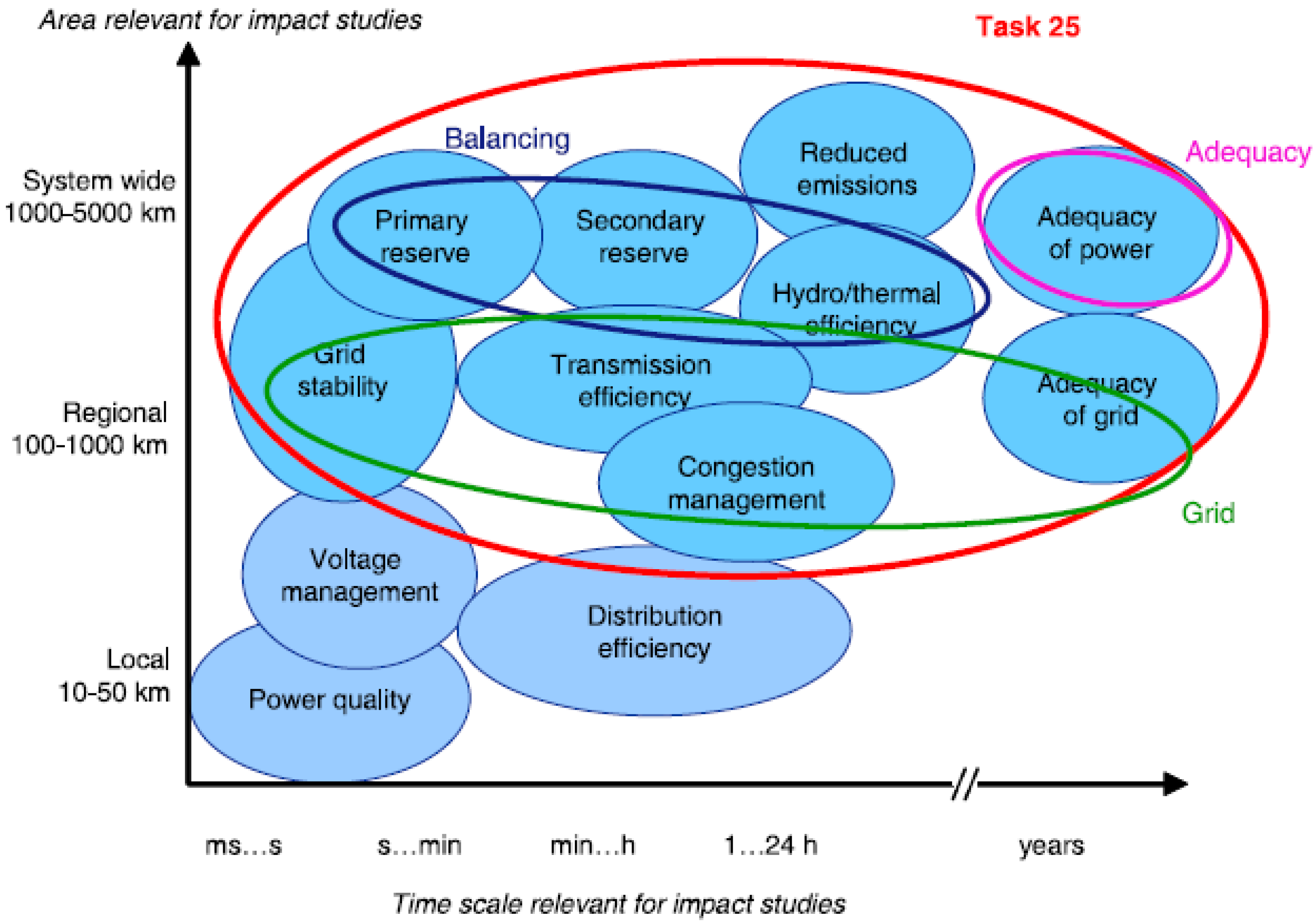

7.3.2. Capacity and load characteristics

7.3.3. Life-cycle characteristics

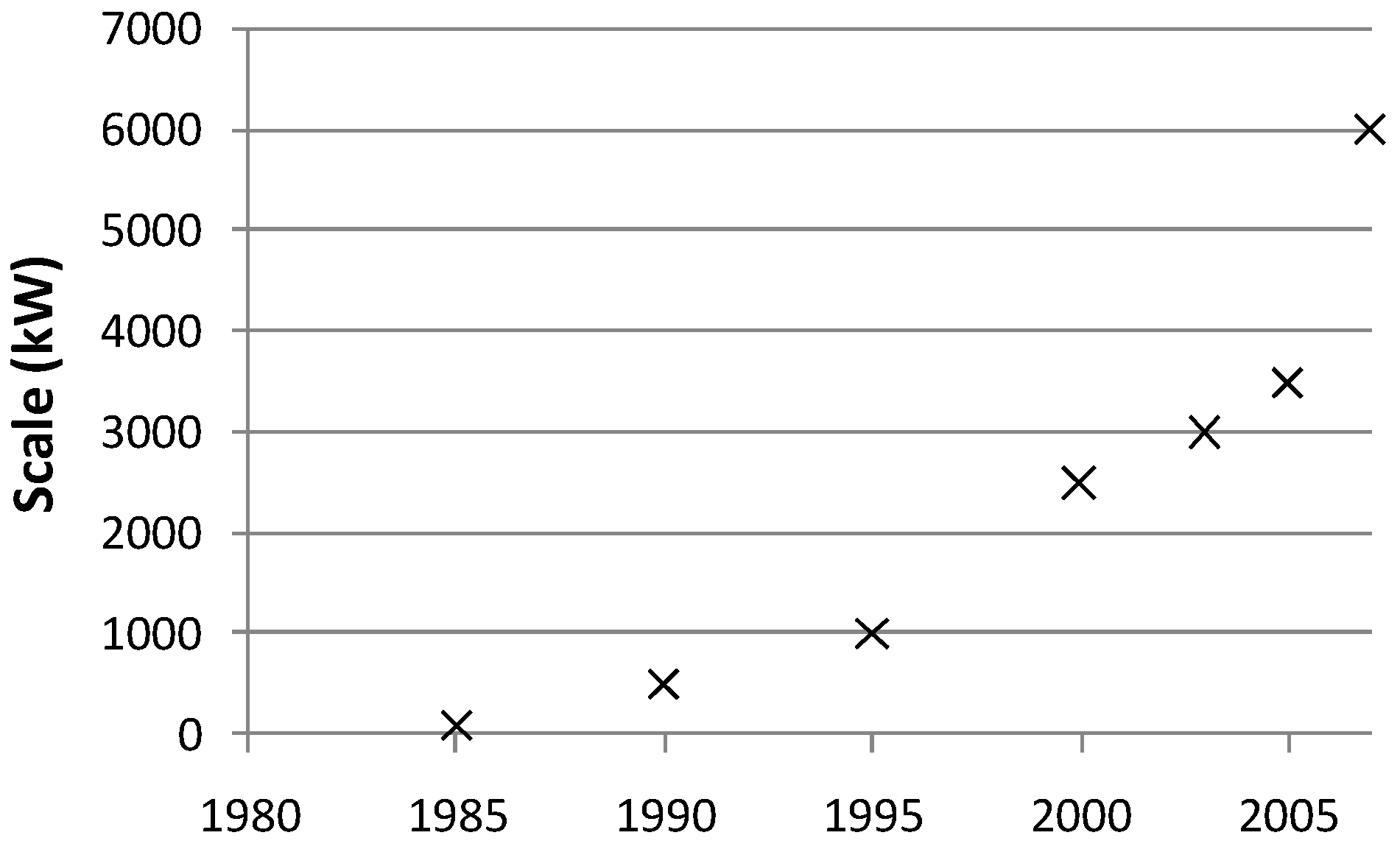

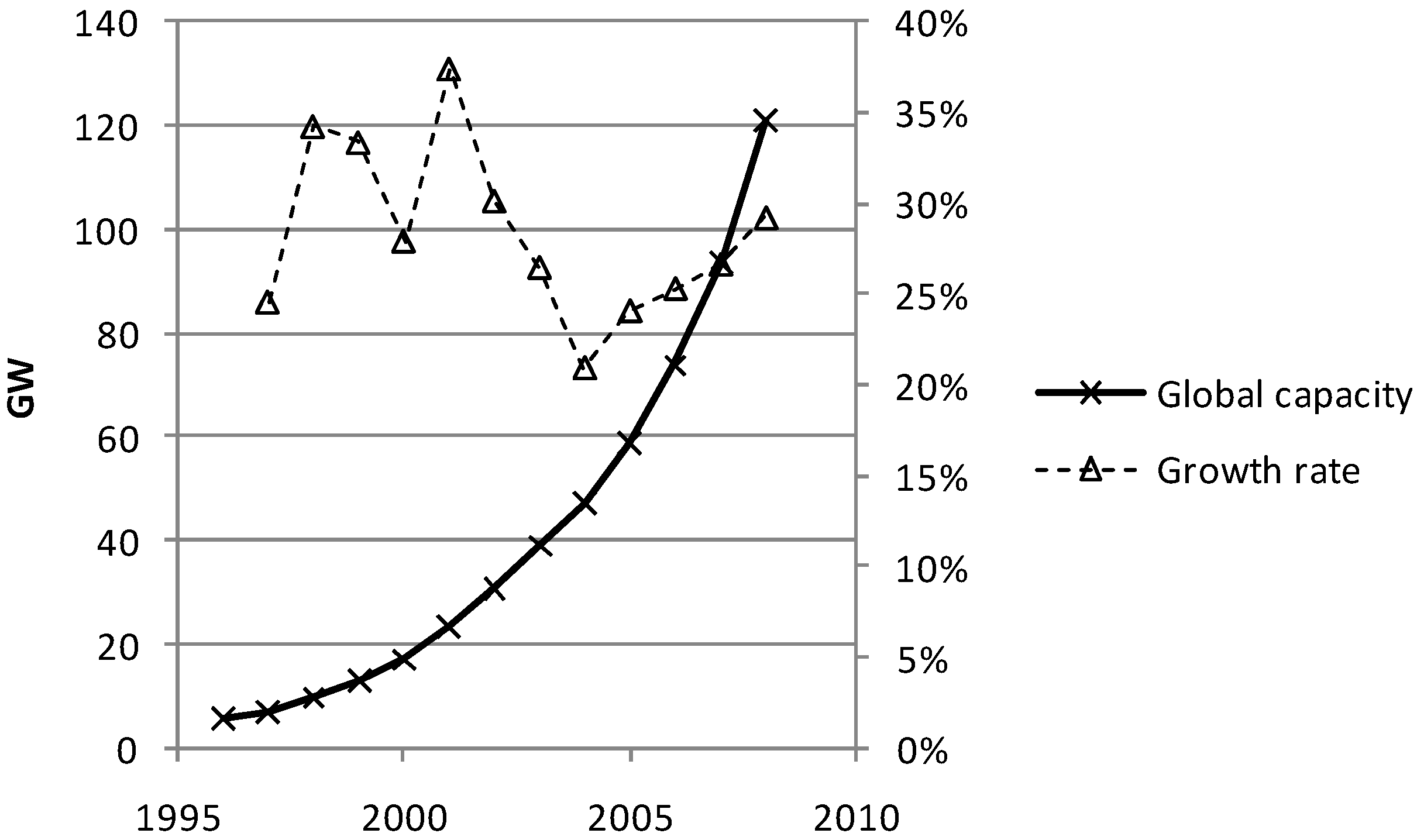

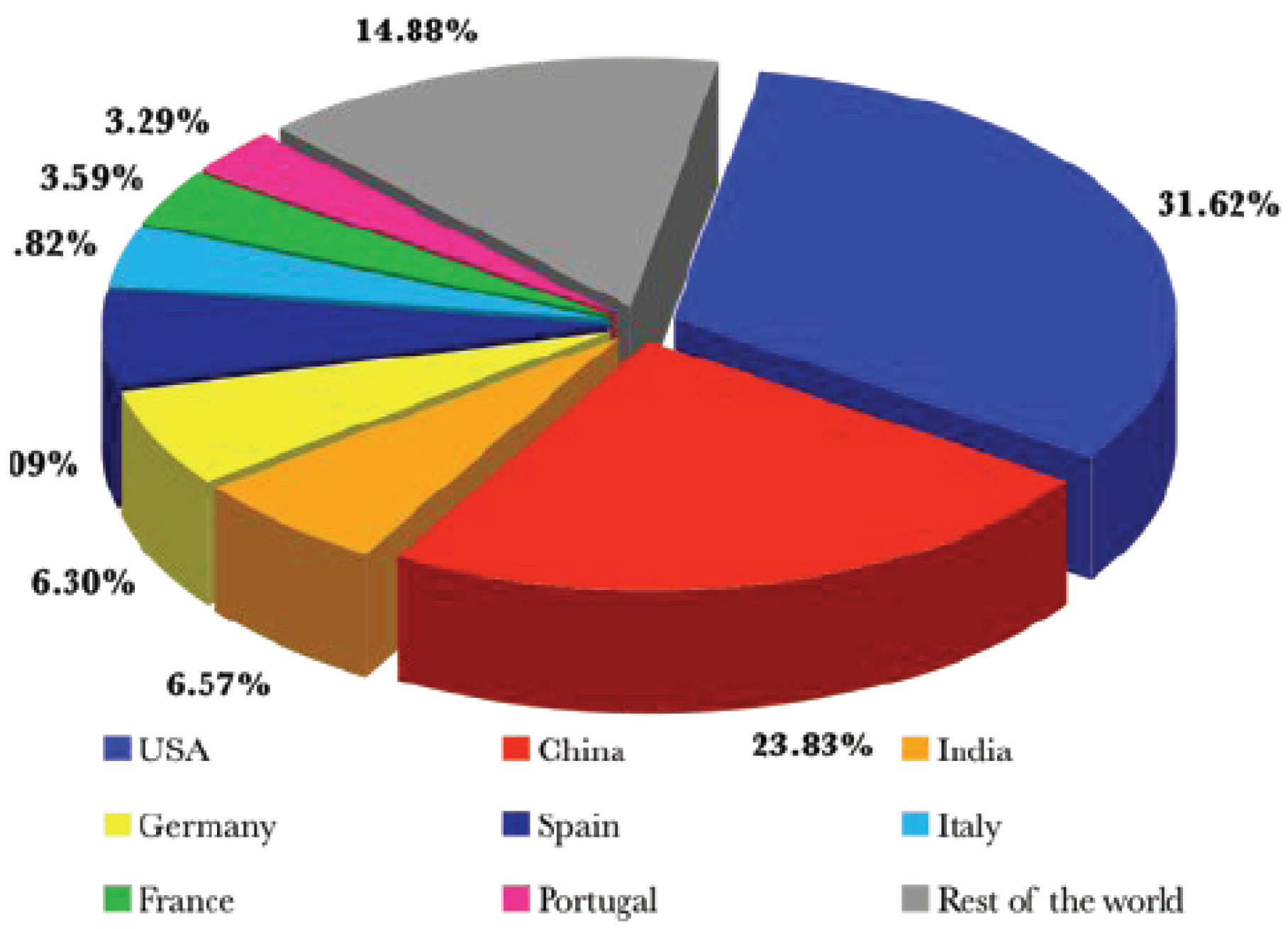

7.3.4. Current scale of deployment

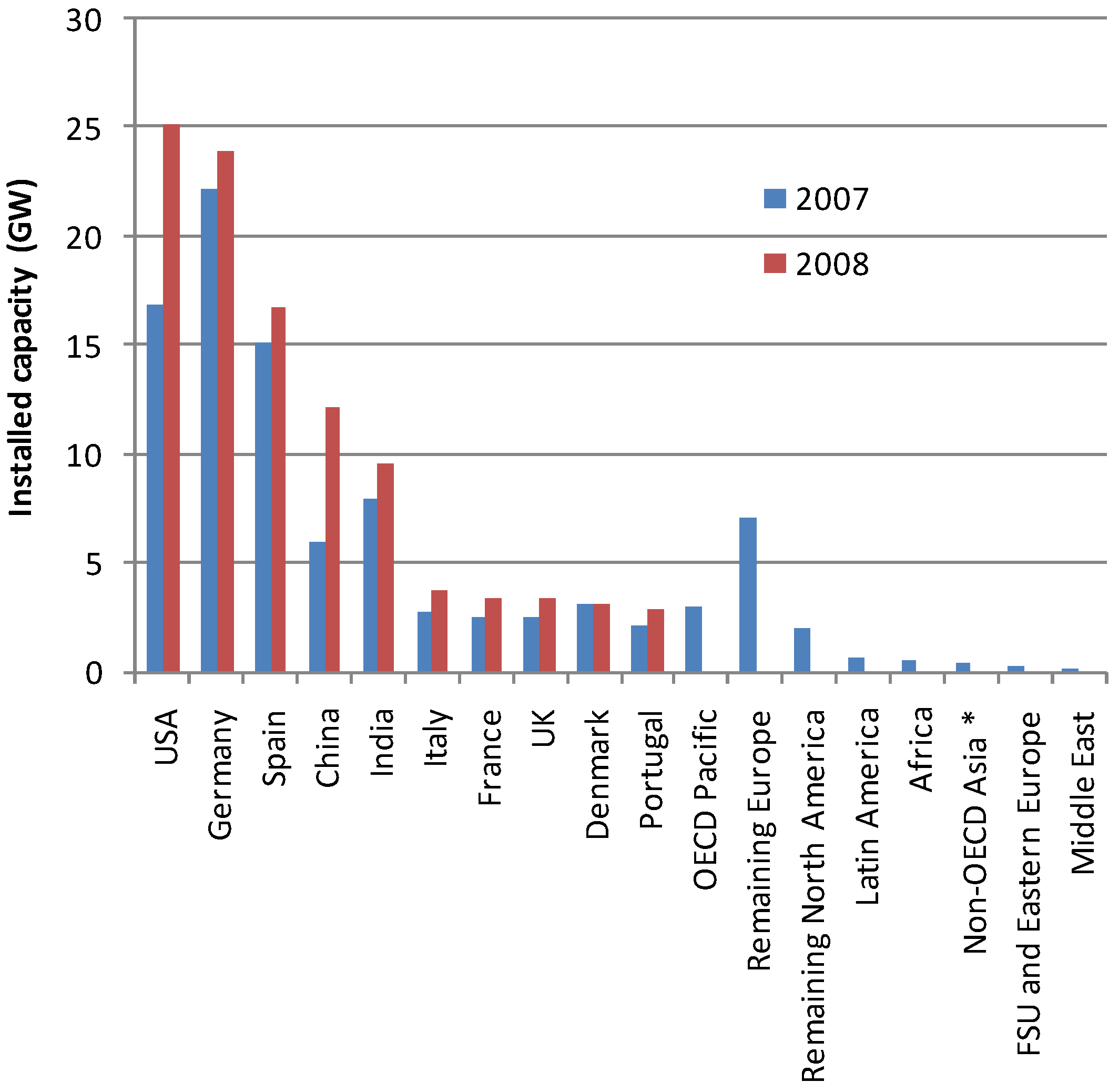

7.3.5. Contribution to global electricity supply

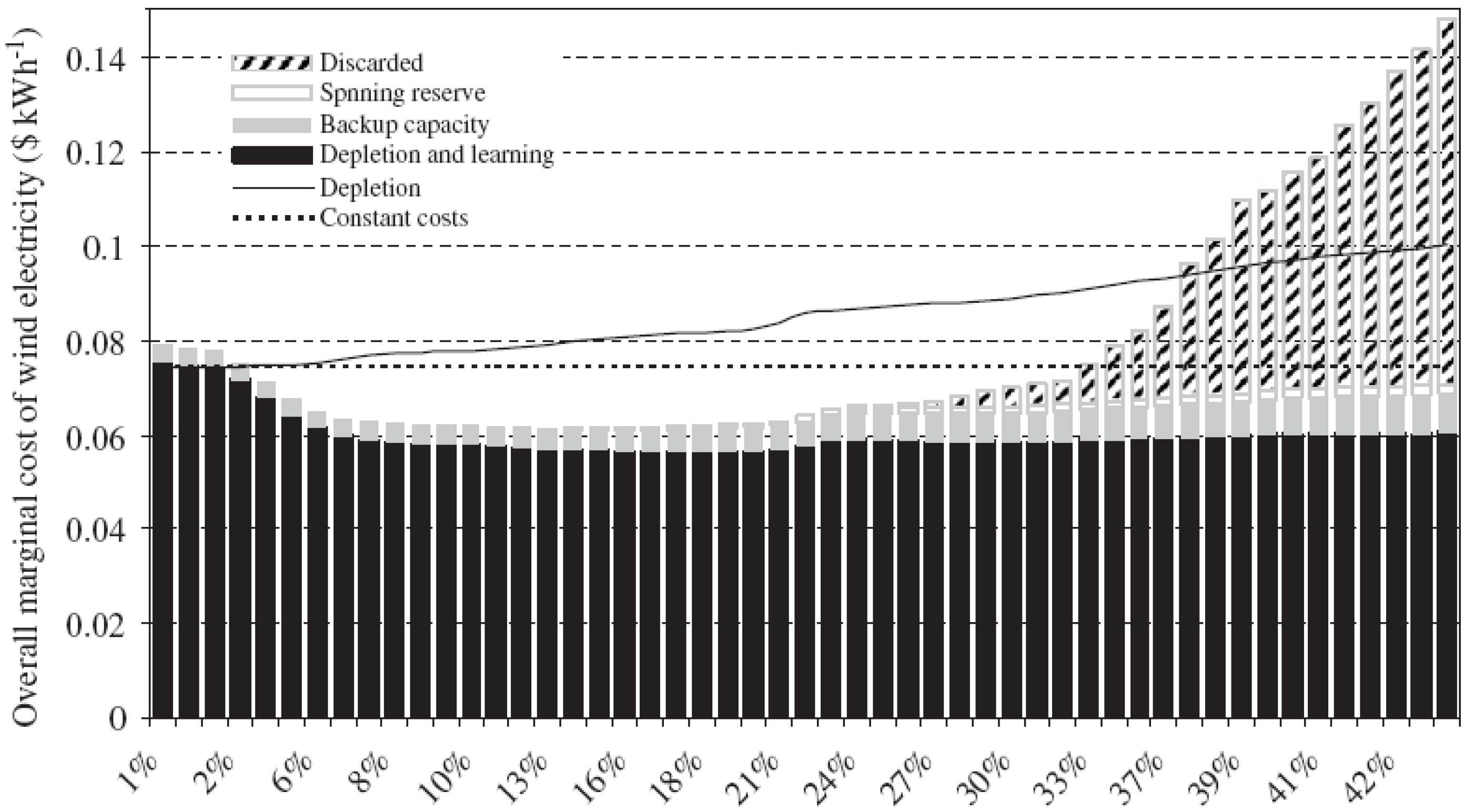

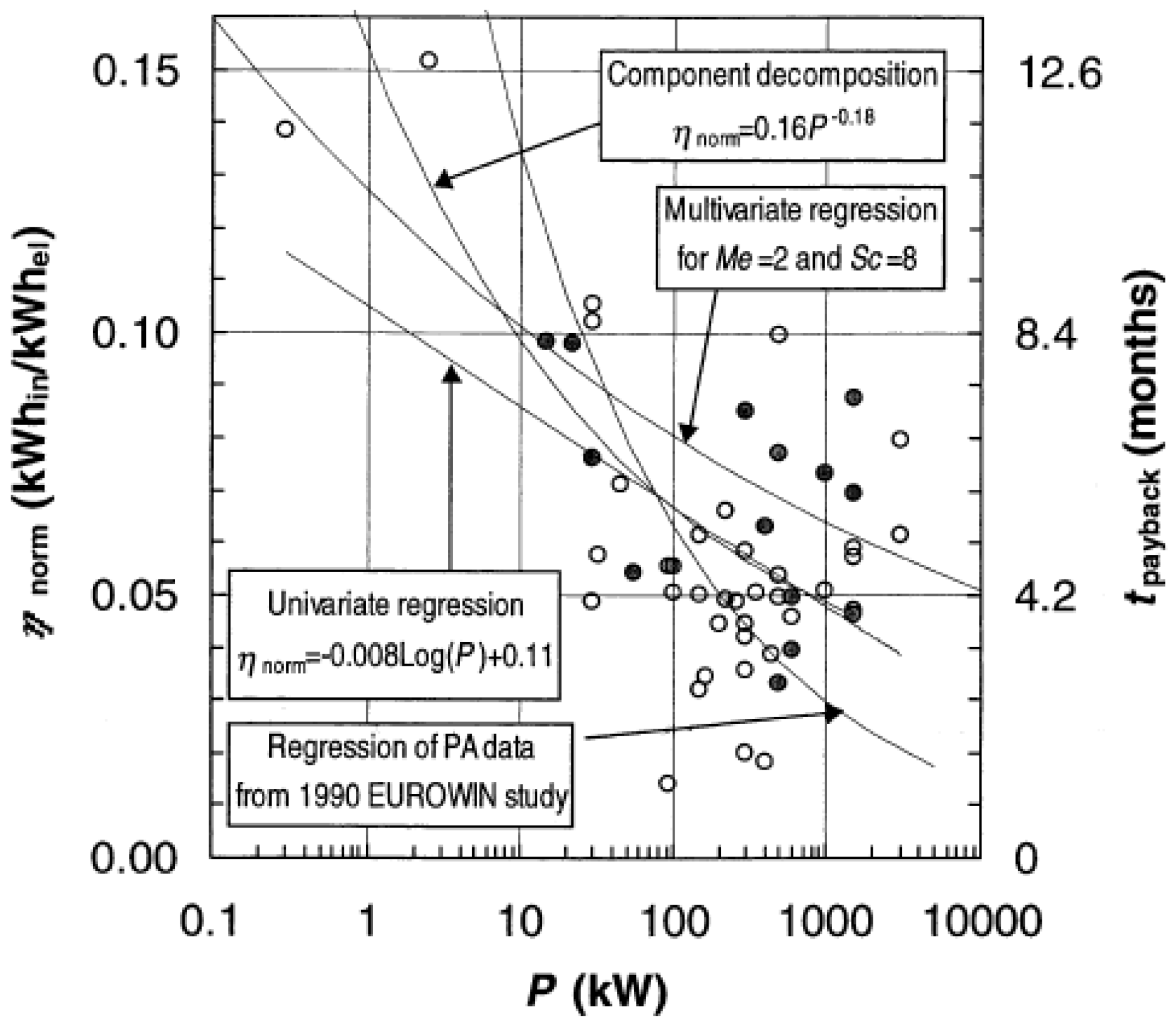

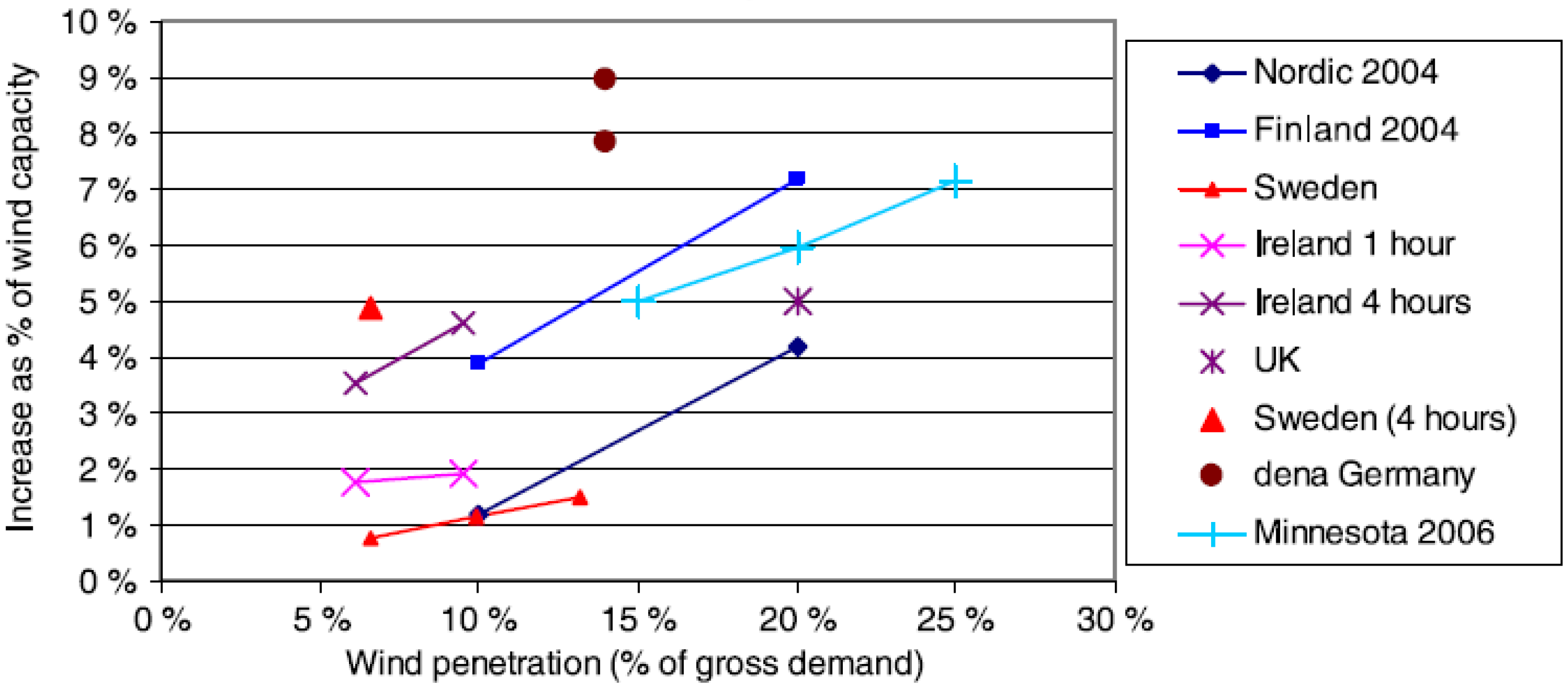

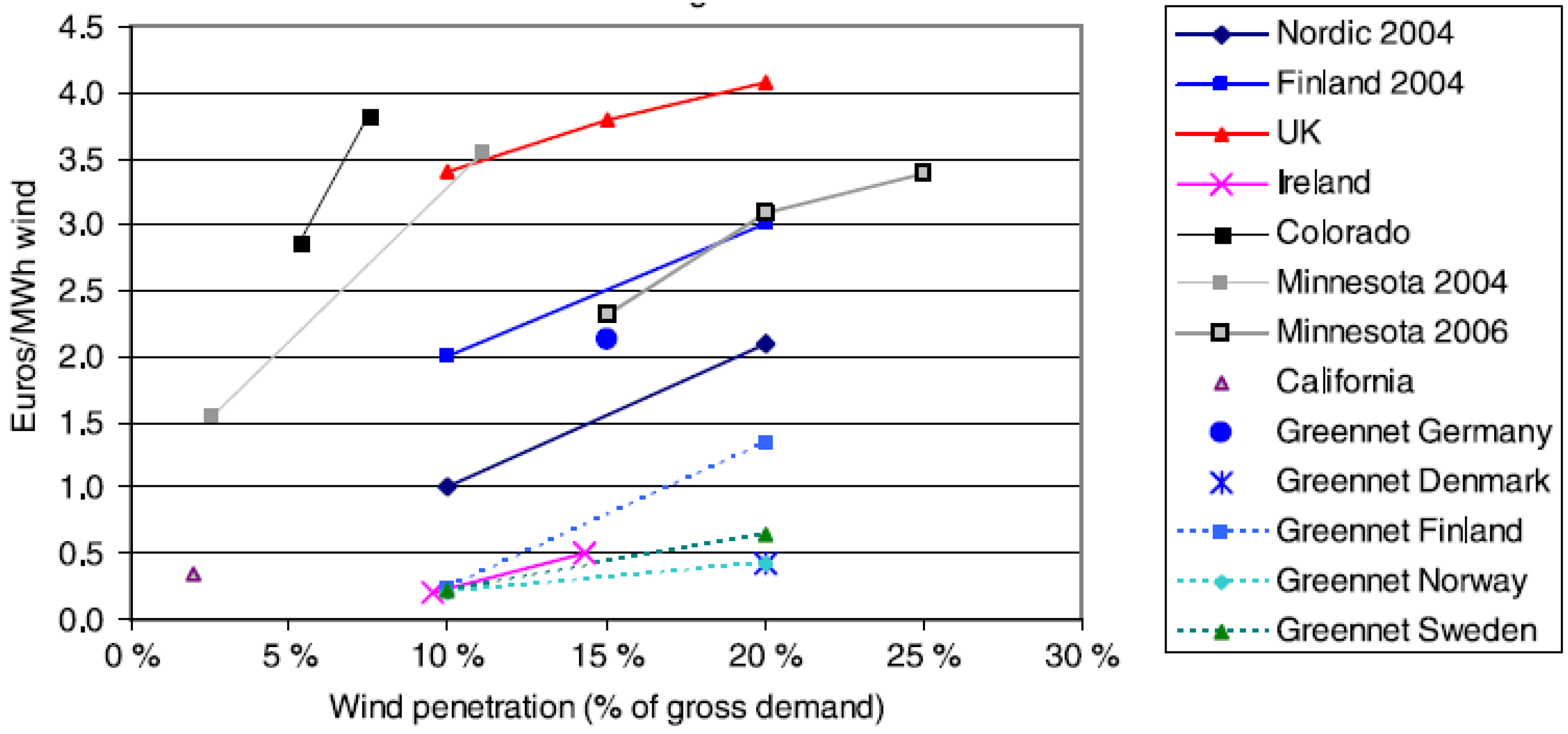

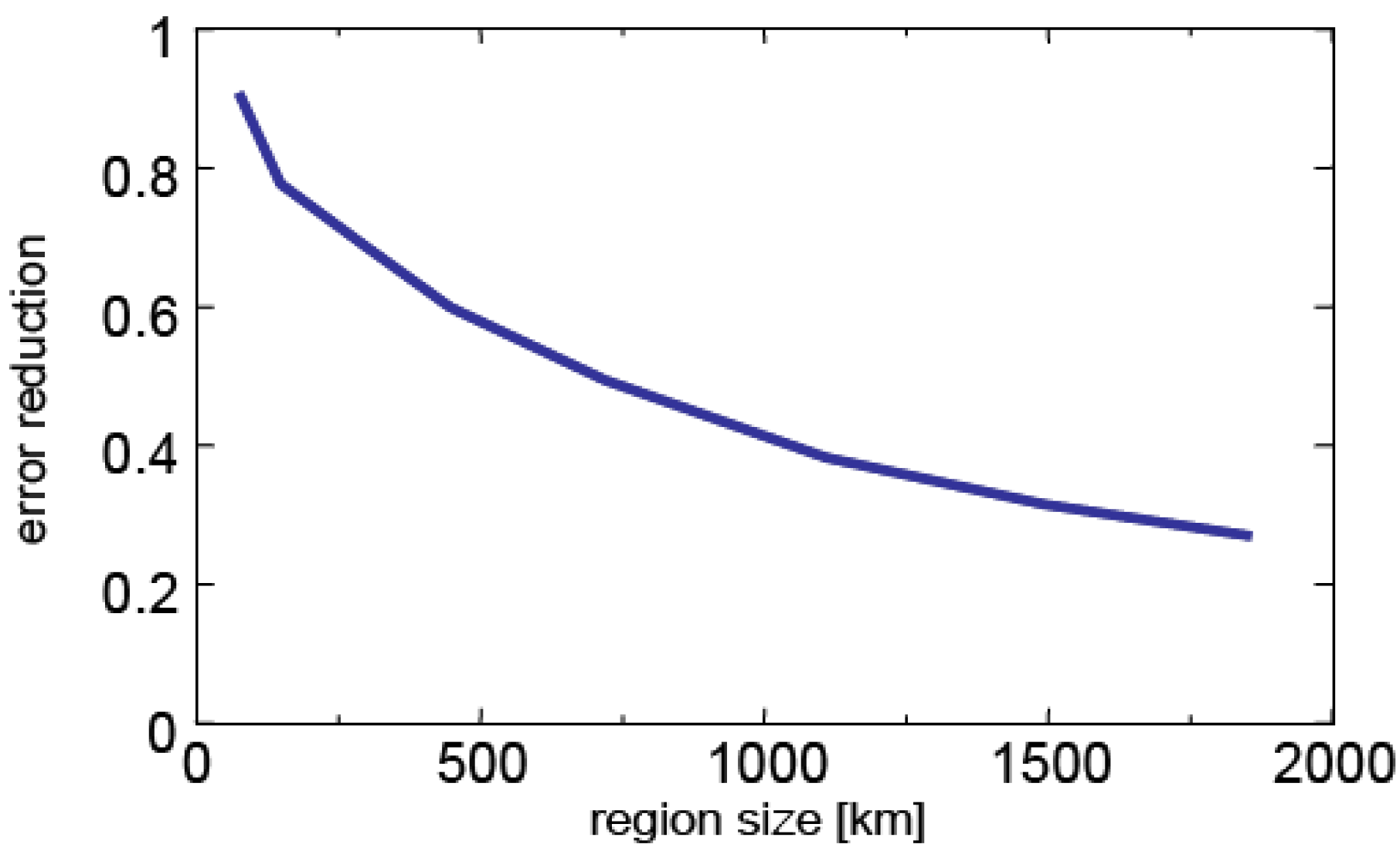

7.3.6. Cost of electricity output

7.3.7. Technical challenges

8. Photovoltaic power

8.1. Summary

8.2. Global potential of resource

| Progress ratio, pr | 0.7 | 0.75 | 0.8 | 0.85 | 0.9 |

| Breakeven cumulative production, nb (GWP) | 23 | 48 | 148 | 957 | 39700 |

| Breakeven cumulative production, as % of 3300 GW, the present world capacity | 0.7% | 1.5% | 4.5% | 29.0% | 1200% |

| Cost of reaching breakeven, Cb ($ billion) | 37 | 74 | 211 | 1240 | 46800 |

| Cost of producing nb – n0, if unit cost were already at breakeven, (nb – n0) cb ($ billion) | 22 | 47 | 147 | 956 | 39700 |

| Cost gap, Cb – (nb – n0) cb ($ billion) | 15 | 27 | 64 | 288 | 7110 |

| Cost gap (% of cost of reaching breakeven) | 41% | 36% | 30% | 23% | 15% |

| Avoided damage of nb – n0 (at 0.25 $/WP, in $ billion) | 5 | 12 | 37 | 239 | 9920 |

| Avoided damage (% of cost gap) | 37% | 44% | 58% | 83% | 140% |

8.3. Photovoltaic cells, modules and systems

8.3.1. Technical principle

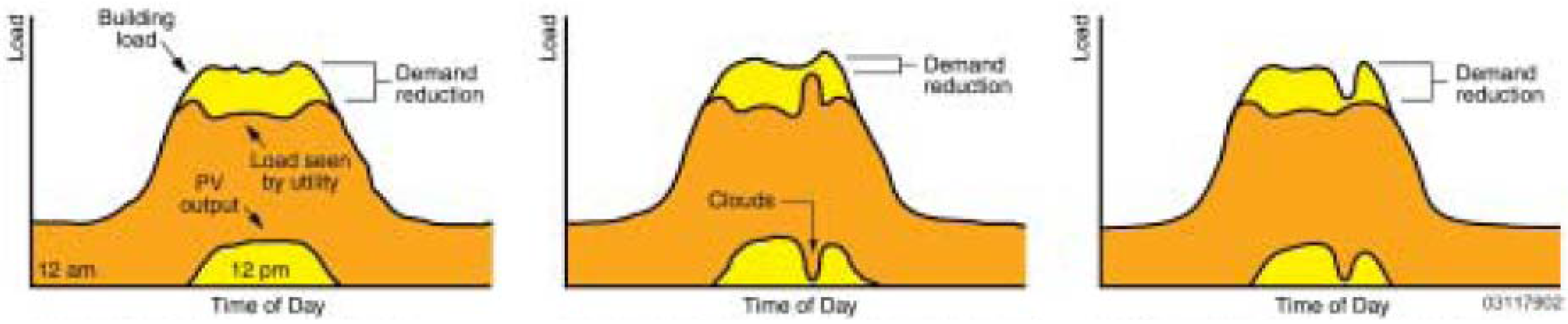

8.3.2. Capacity and load characteristics

8.3.3. Life-cycle characteristics

|

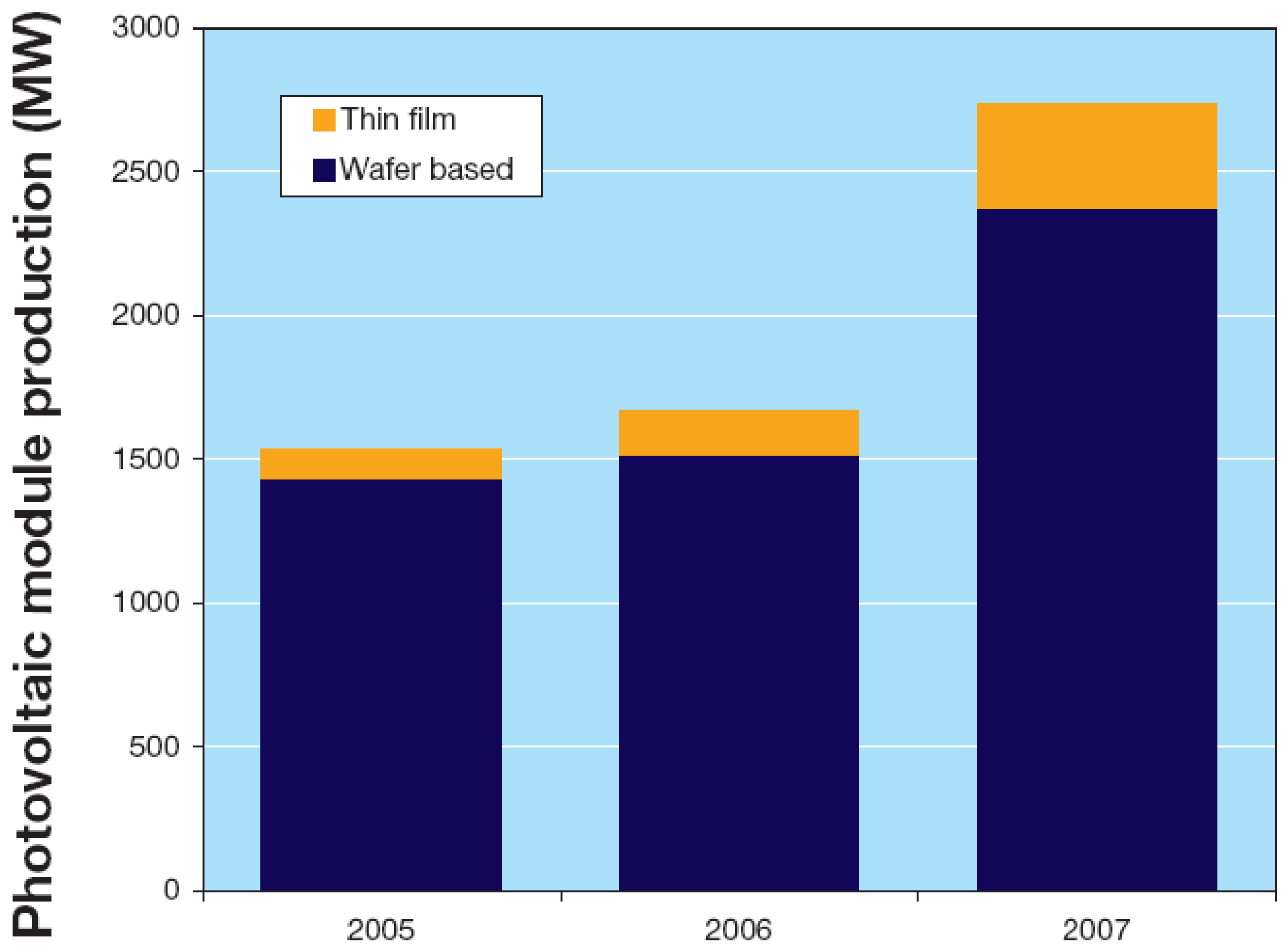

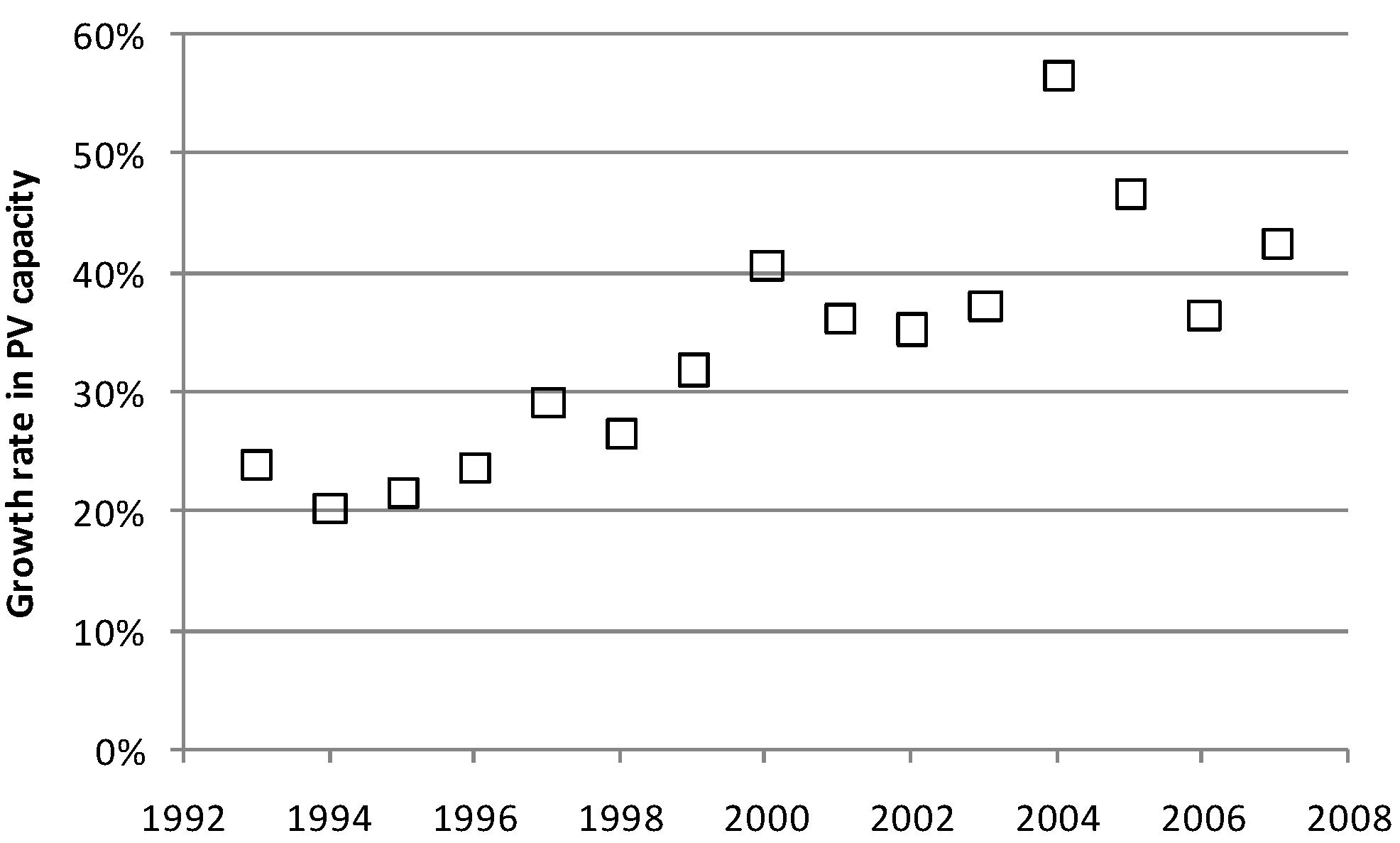

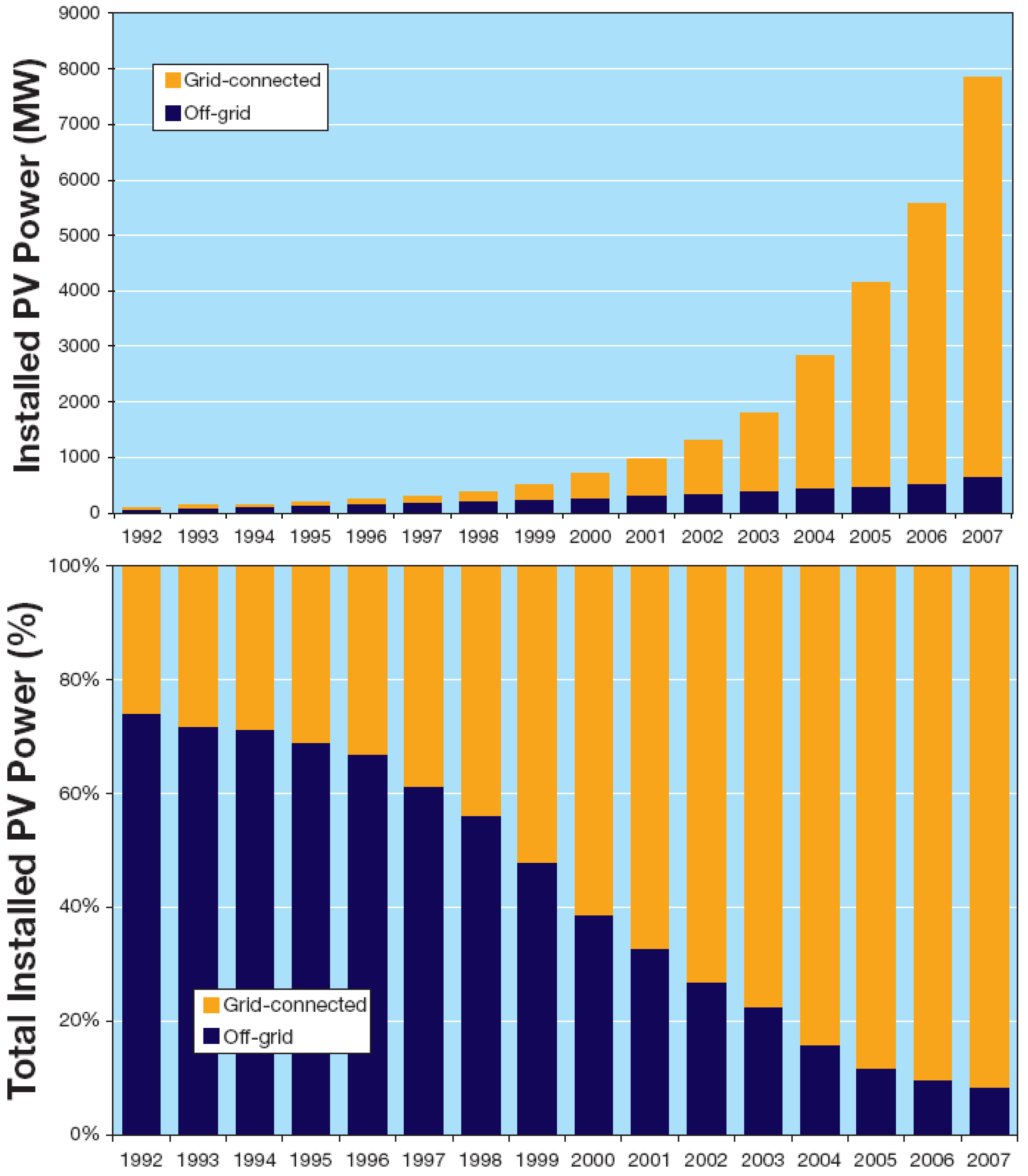

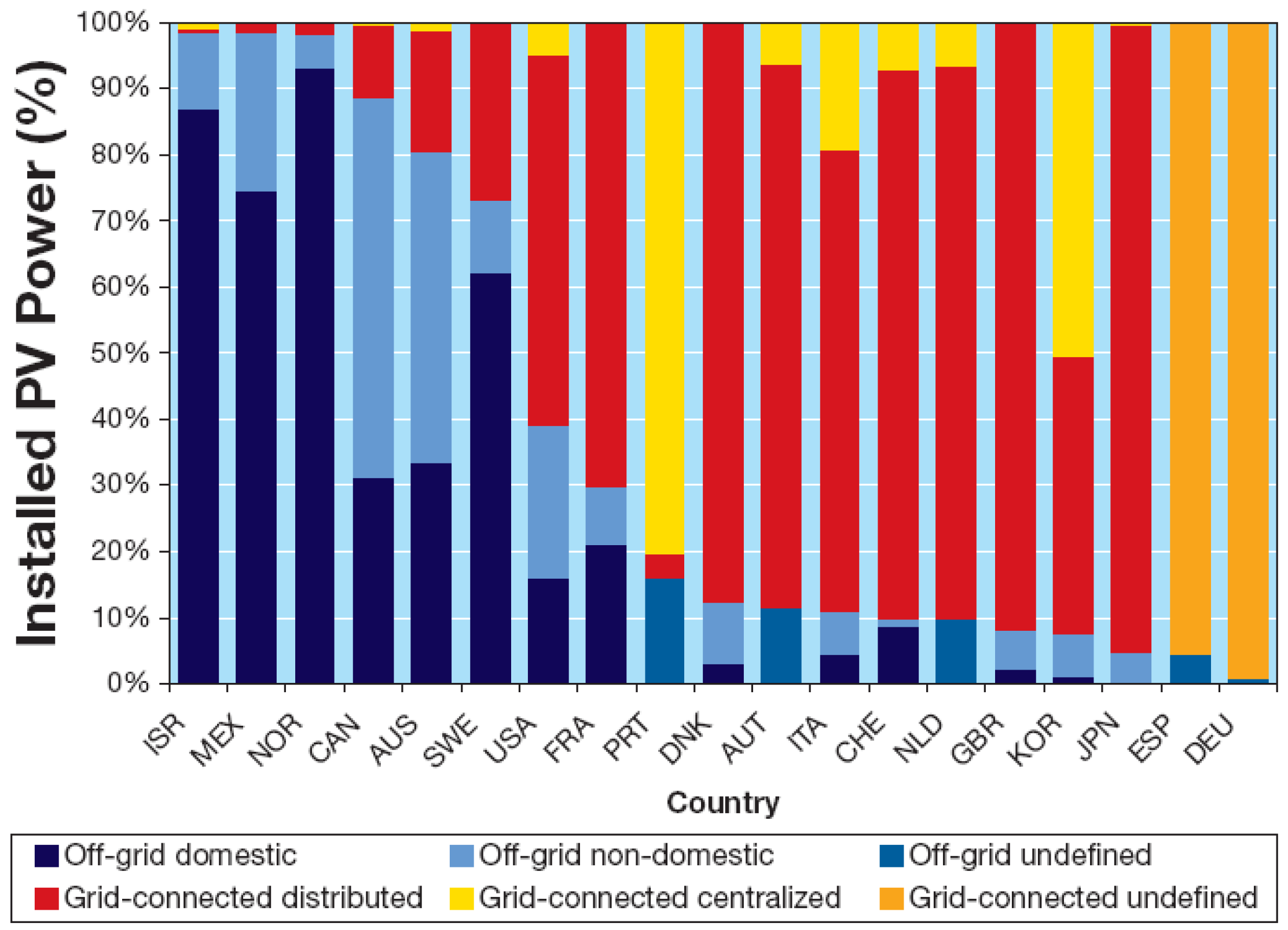

8.3.4. Current scale of deployment

8.3.5. Contribution to global electricity supply

8.3.6. Cost of electricity output

8.3.7. Technical challenges

9. Concentrating solar power

9.1. Summary

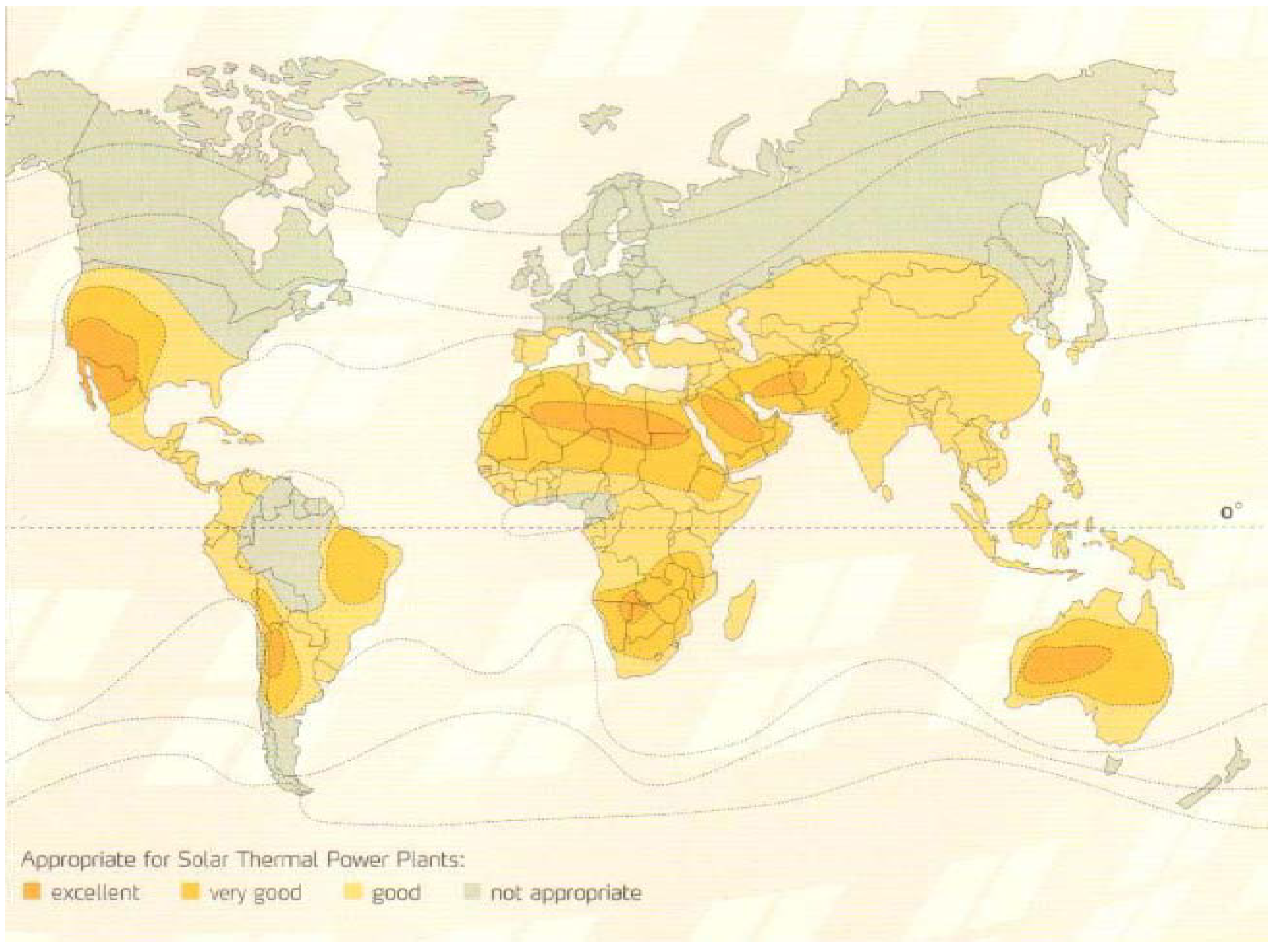

9.2. Global potential of resource

9.3. Solar-thermal troughs, dishes, towers, and Linear Fresnel systems

9.3.1. Technical principle

9.3.2. Capacity and load characteristics

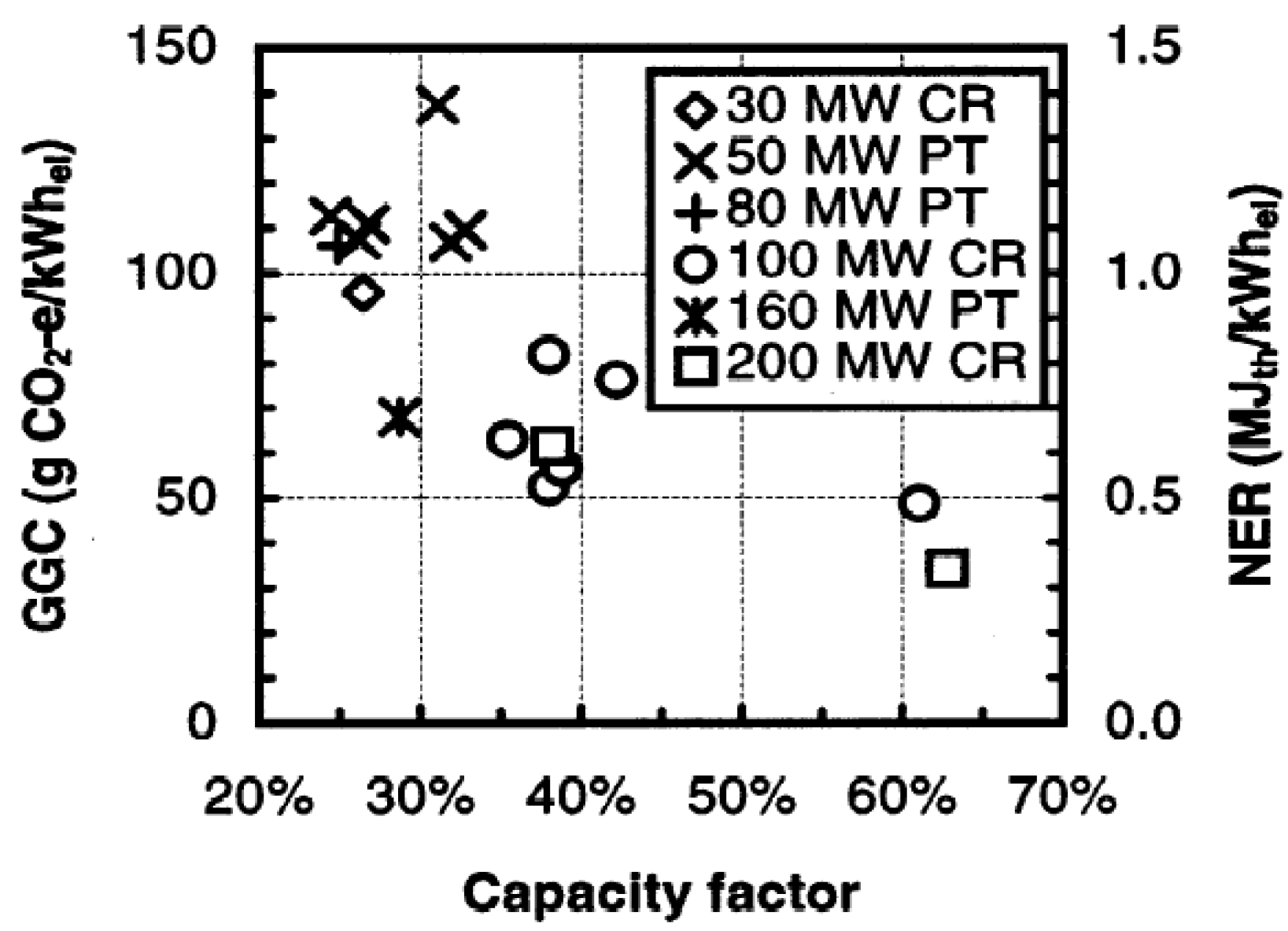

9.3.3. Life-cycle characteristics

9.3.4. Current scale of deployment

9.3.5. Contribution to global electricity supply

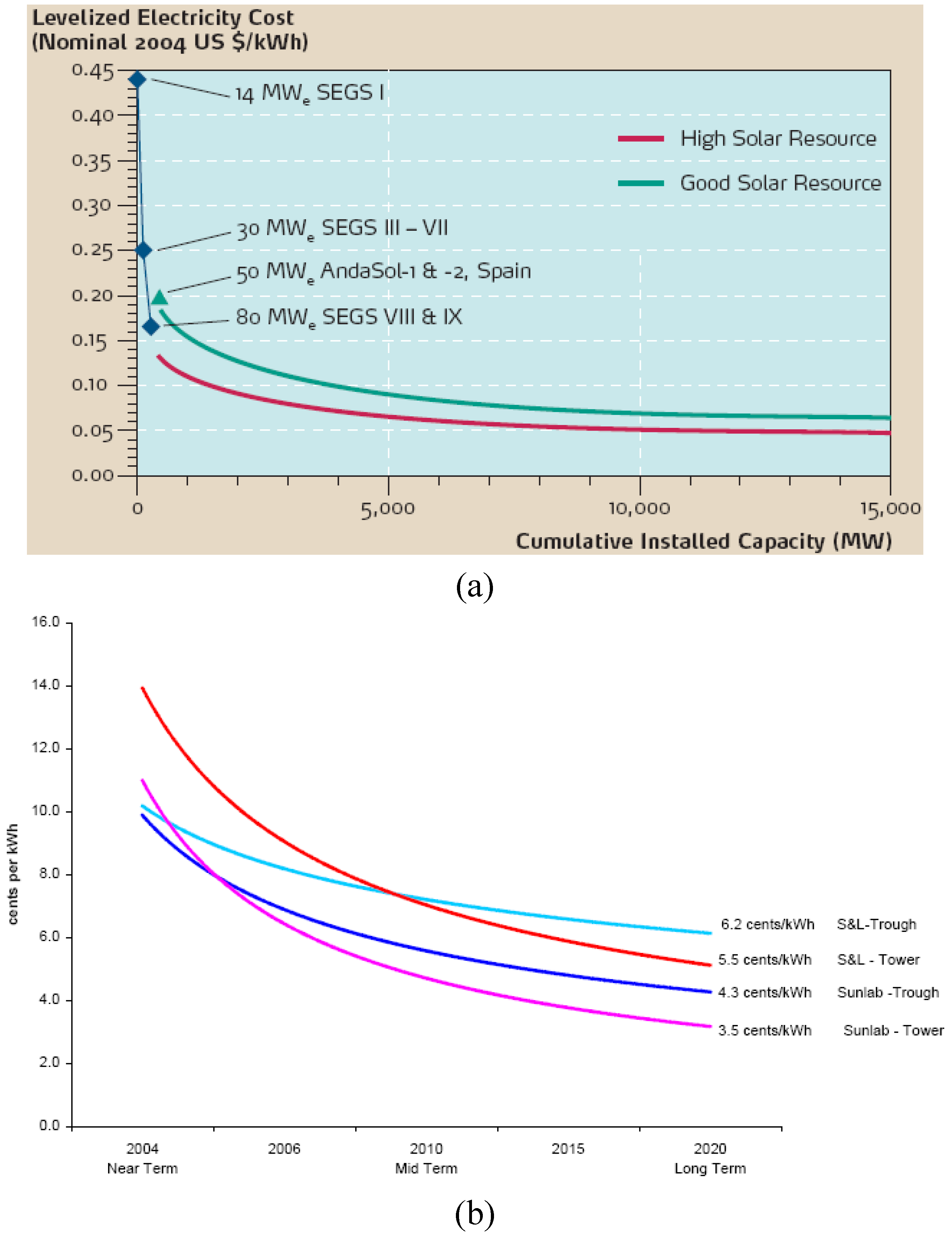

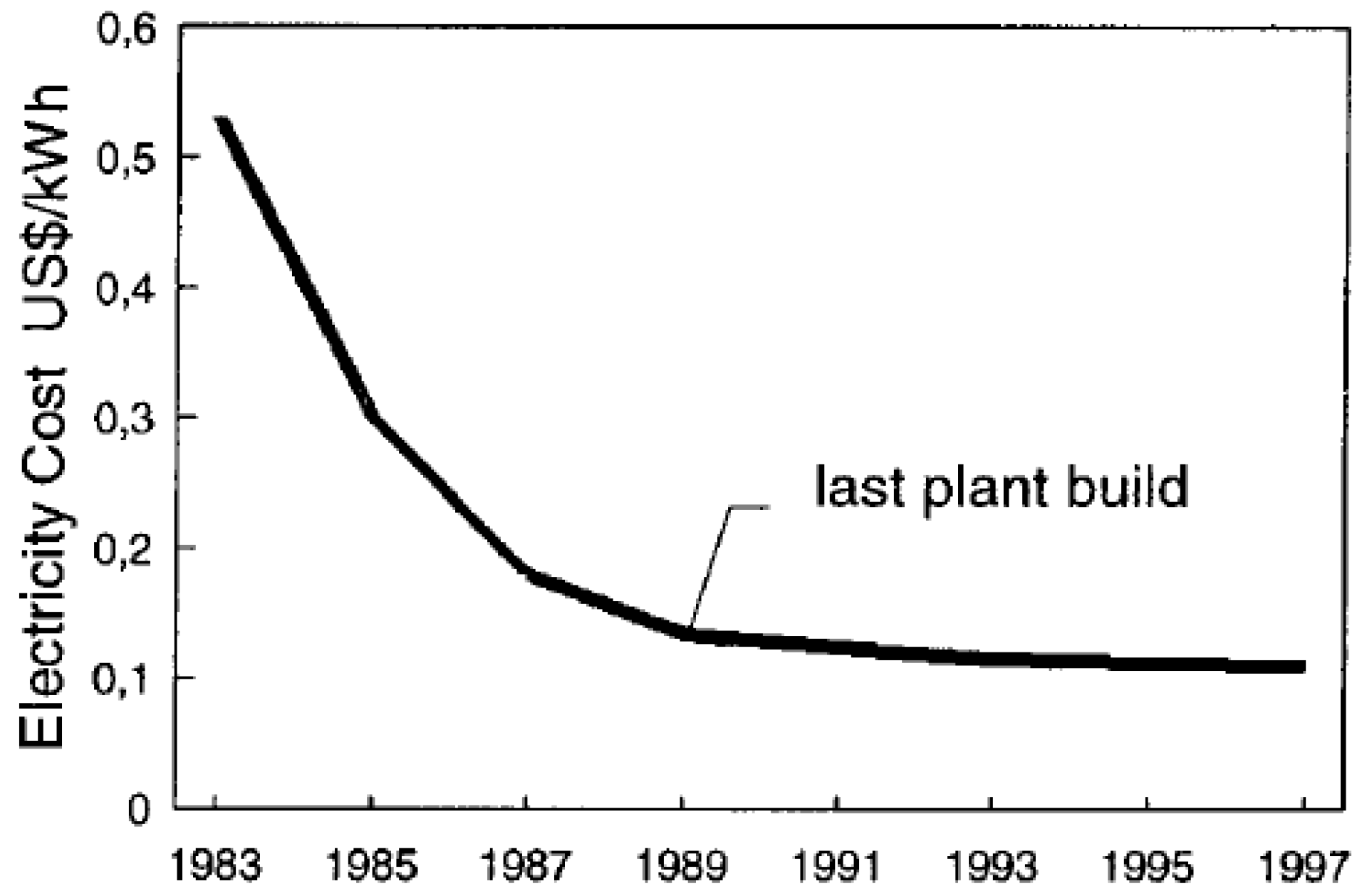

9.3.6. Cost of electricity output

9.3.7. Technical challenges

10. Geothermal power

10.1. Summary

10.2. Global potential of resource

10.3. Geothermal power plants

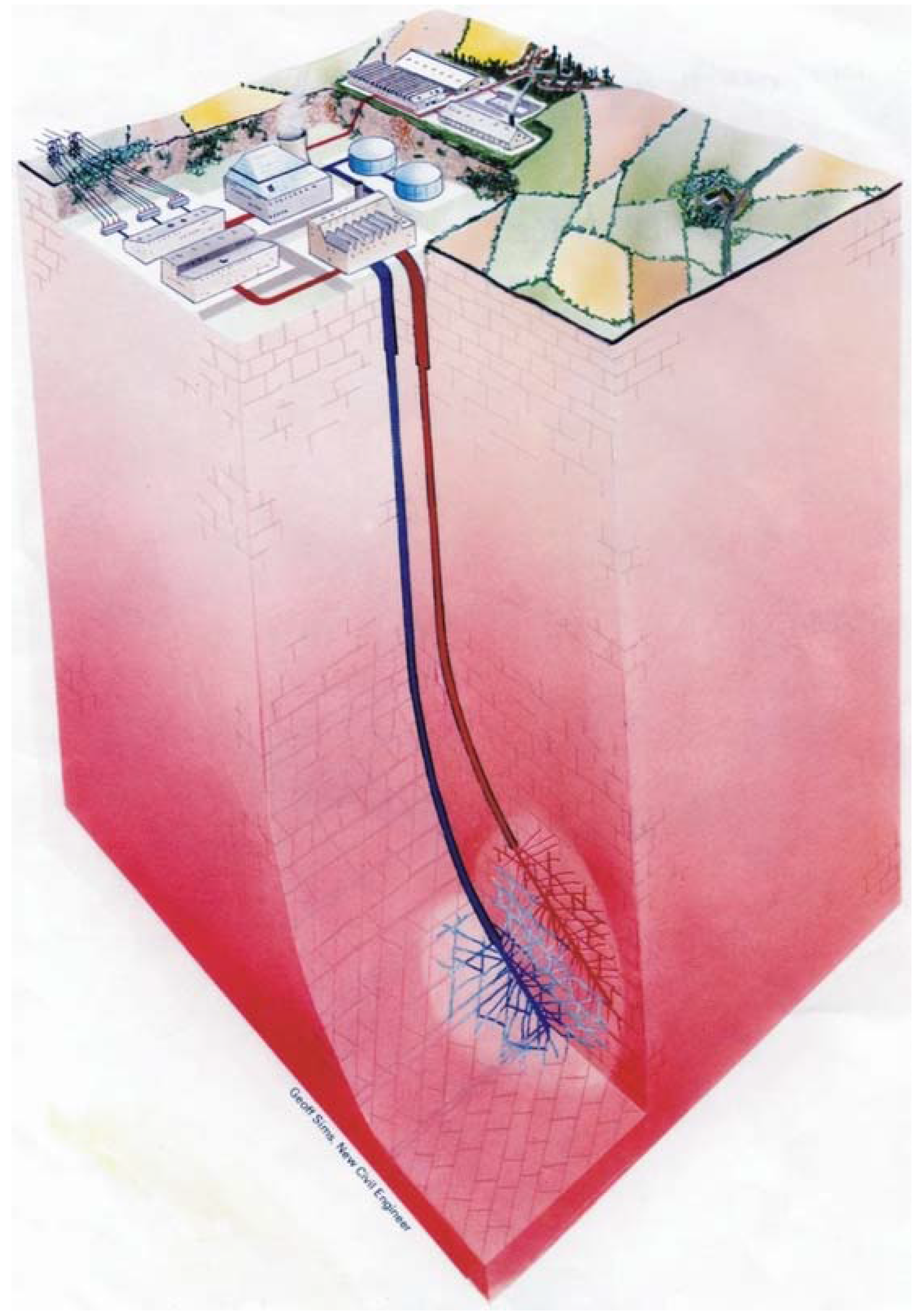

10.3.1. Technical principle

10.3.2. Capacity and load characteristics

10.3.3. Life-cycle characteristics

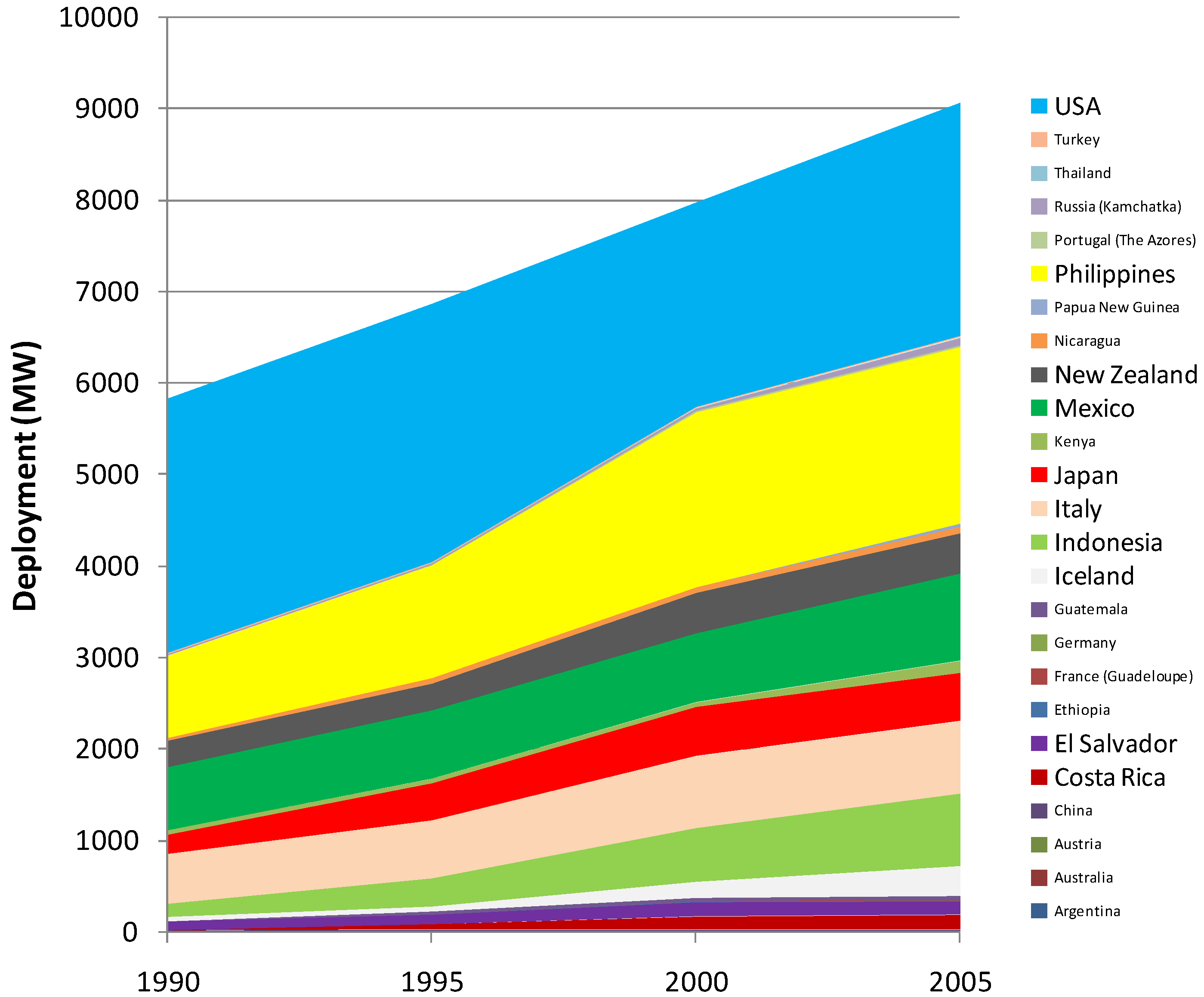

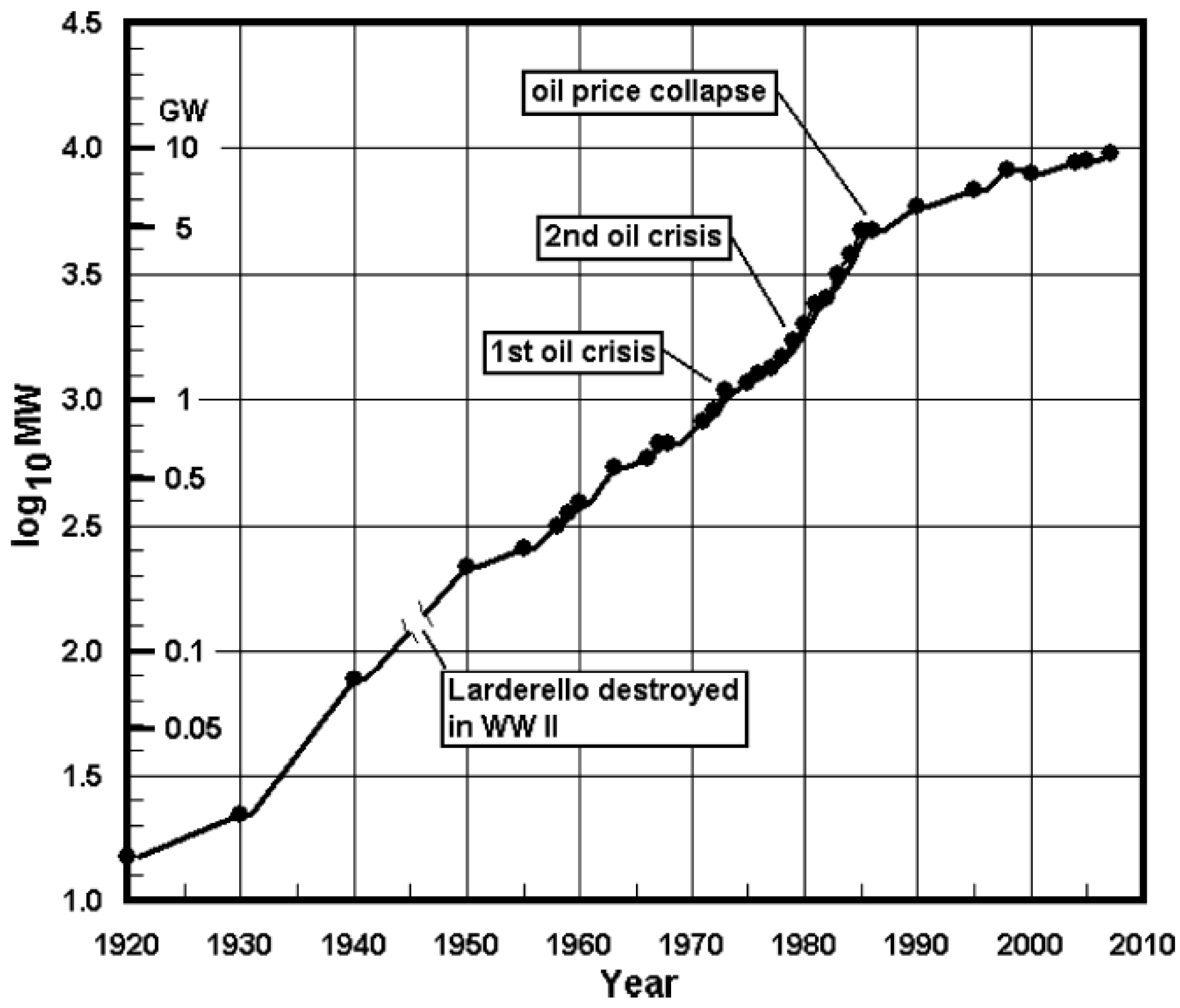

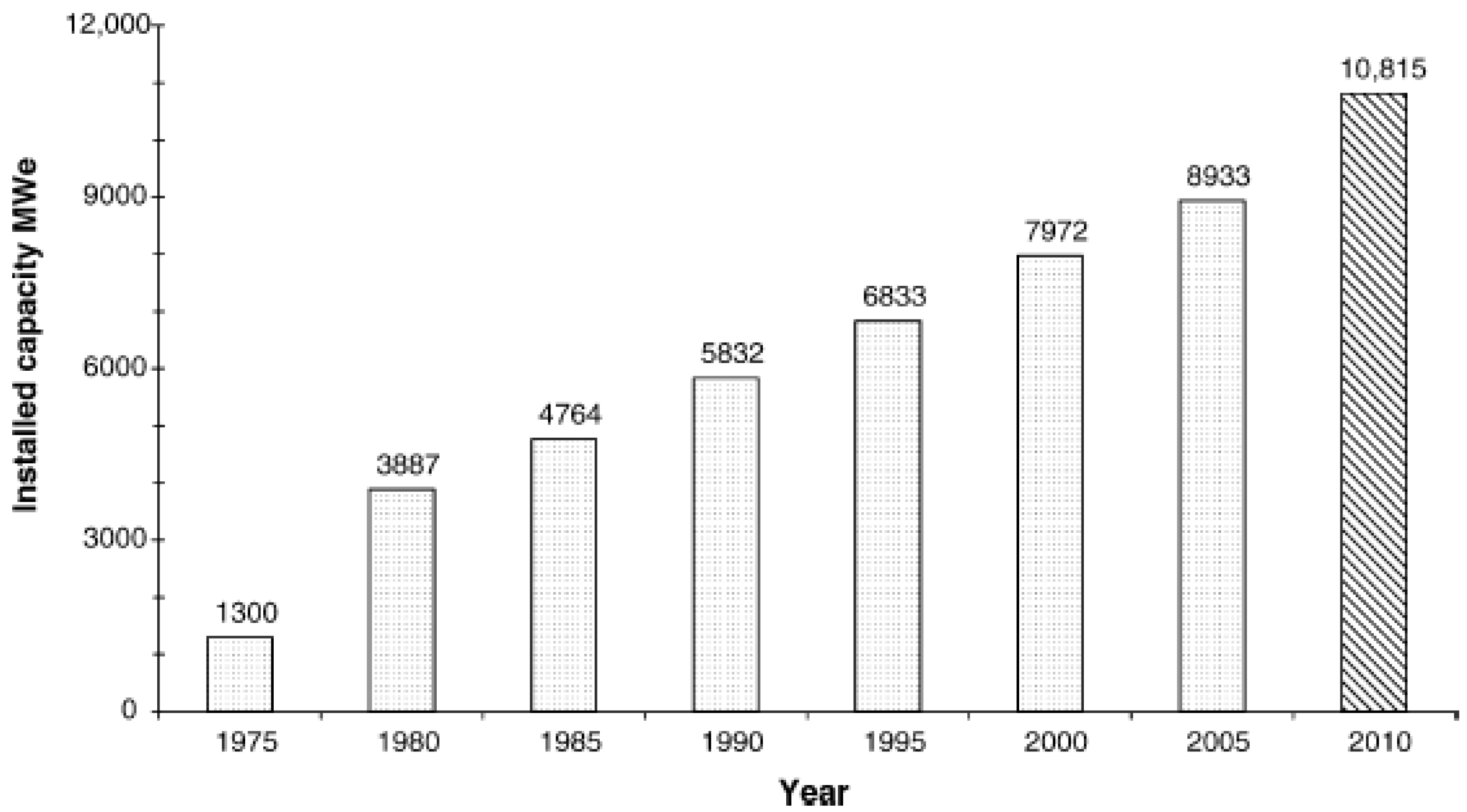

10.3.4. Current scale of deployment

10.3.5. Contribution to global electricity supply

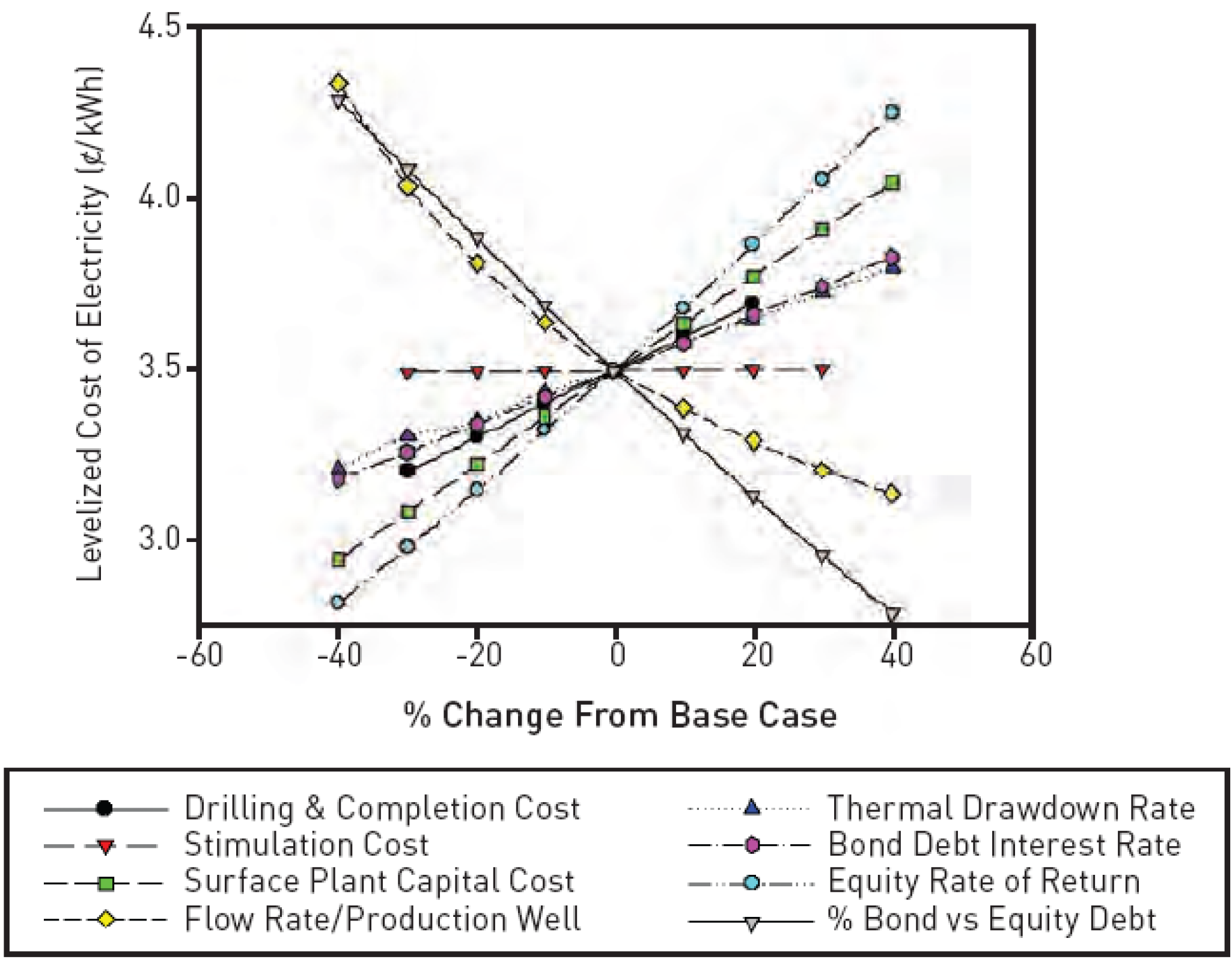

10.3.6. Cost of electricity output

10.3.7. Technical challenges

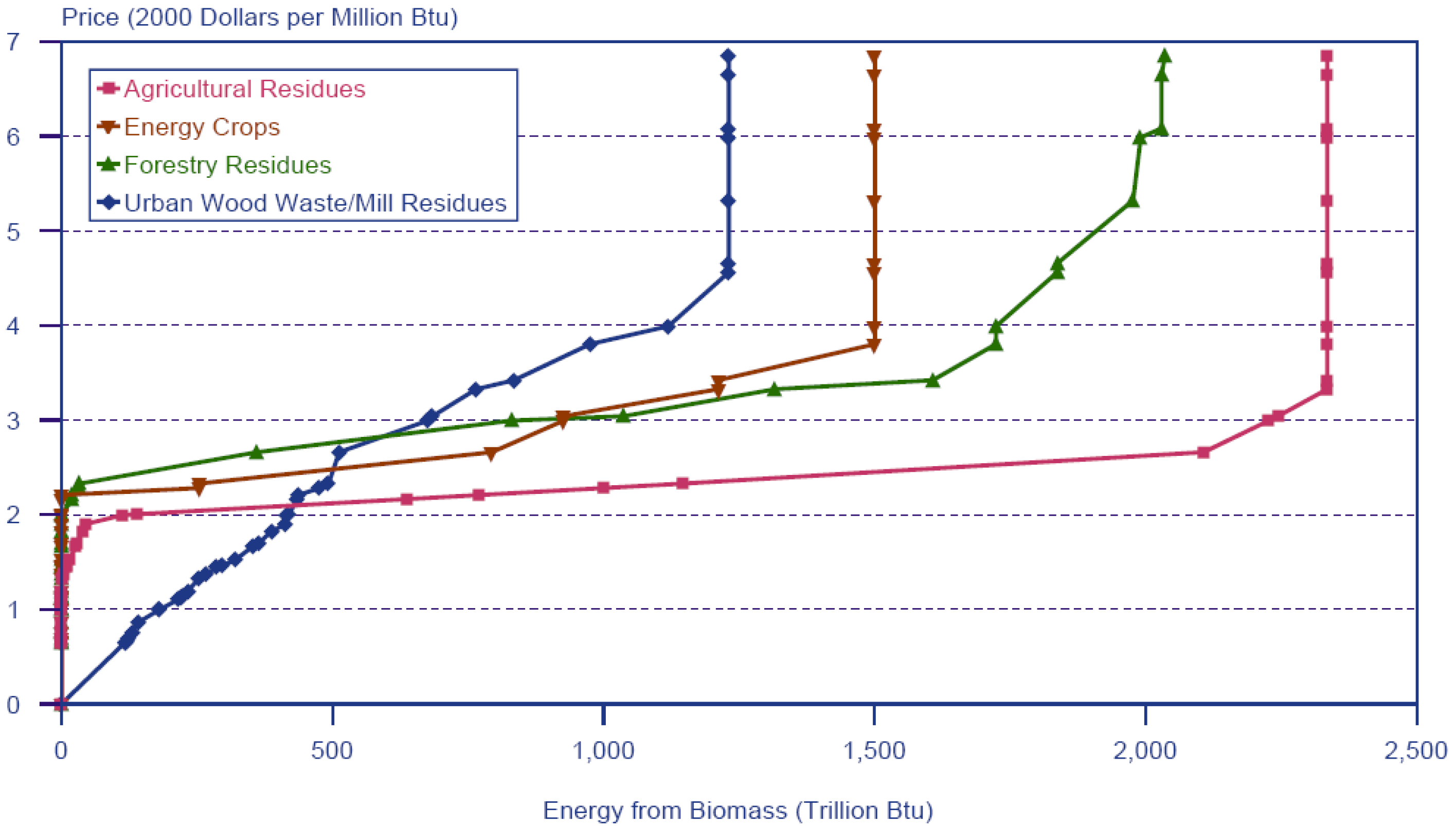

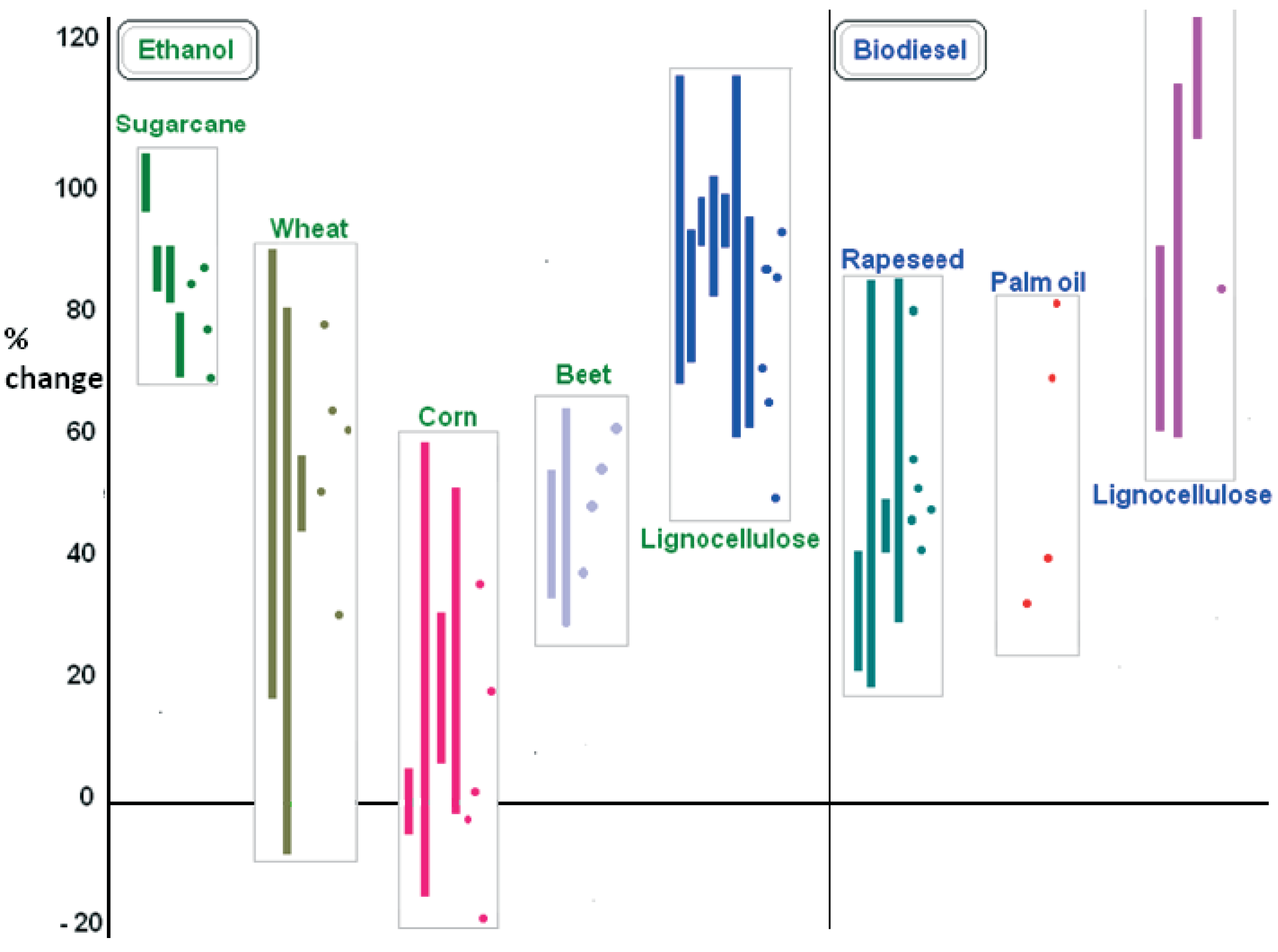

11. Biomass

11.1. Summary

11.2. Global potential of resource

11.3. Biomass-fired and co-fired power plants

11.3.1. Technical principle

11.3.2. Capacity and load characteristics

11.3.3. Life-cycle characteristics

11.3.4. Current scale of deployment

11.3.5. Contribution to global electricity supply

11.3.6. Cost of electricity output

11.3.7. Technical and other challenges

Acknowledgement

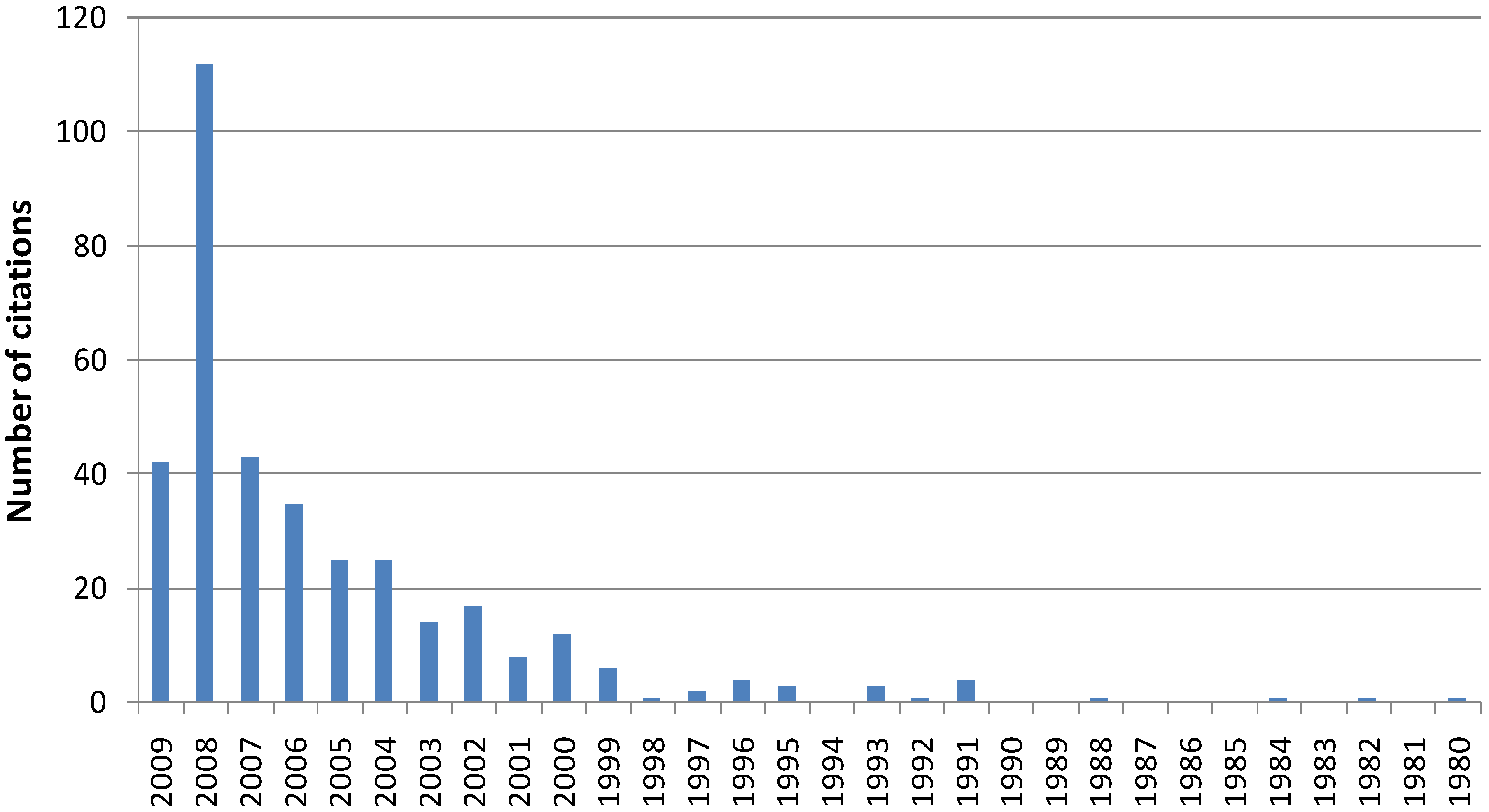

References and Notes

- World Energy Assessmemt: 2004 Update; United Nations Development Programme: New York, NY, USA, 2004.

- Energy Technology Perspectives; International Energy Agency: Paris, France, 2008.

- Krewitt, W. External cost of energy—Do the answers match the questions? Looking back at 10 years of ExternE. Energ. Policy 2002, 30, 839–848. [Google Scholar]

- Lenzen, M. Uncertainty of end-point impact measures: implications for decision-making. Int. J. Life Cycle Assess. 2006, 11, 189–199. [Google Scholar] [CrossRef]

- Azar, C.; Sterner, T. Discounting and distributional considerations in the context of global warming. Ecol. Econ. 1996, 19, 169–184. [Google Scholar] [CrossRef]

- Gowdy, J.M.; McDaniel, C.N. One world, one experiment: addressing the biodiversity-economics conflict. Ecol. Econ. 1995, 15, 181–192. [Google Scholar] [CrossRef]

- Heal, G. Discounting and climate change. Climatic Change 1997, 37, 335–343. [Google Scholar] [CrossRef]

- Lind, R.C. Intergenerational equity, discounting, and the role of cost-benefit analysis in evaluating global climate policy. Energ. Policy 1995, 23, 379–389. [Google Scholar] [CrossRef]

- Newell, R.G.; Pizer, W.A. Uncertain discount rates in climate policy analysis. Energ. Policy 2004, 32, 519–529. [Google Scholar] [CrossRef]

- Nordhaus, W.D. Discounting in economics and climate change. Climatic Change 1997, 37, 315–328. [Google Scholar] [CrossRef]

- Philibert, C. The economics of climate change and the theory of discounting. Energ. Policy 1999, 27, 913–927. [Google Scholar] [CrossRef]

- Emerging Risks in the 21st Century; OECD Nuclear Energy Agency: Paris, France, 2003.

- Högselius, P. Spent nuclear fuel policies in historical perspective: An international comparison. Energ. Policy 2009, 37, 254–263. [Google Scholar] [CrossRef]

- Falk, J.; Green, J.; Mudd, G. Australia, uranium and nuclear power. Int. J. Environ. Stud. 2006, 63, 845–857. [Google Scholar] [CrossRef]

- Égré, D.; Senécal, P. Social impact assessment of large dams throughout the world: lessons learned over two decades. Impact Assessment and Project Appraisal 2003, 21, 215–224. [Google Scholar] [CrossRef]

- Firestone, J.; Kempton, W. Public opinion about large offshore wind power: Underlying factors. Energ. Policy 2007, 35, 1584–1598. [Google Scholar] [CrossRef]

- Key World Energy Statistics; International Energy Agency: Paris, France, 2008.

- Oliver, T. Clean fossil-fuelled power generation. Energ. Policy 2008, 36, 4310–4316. [Google Scholar] [CrossRef]

- Franco, A.; Diaz, A.R. The future challenges for "clean coal technologies": Joining efficiency increase and pollutant emission control. Energ. Policy 2009, 34, 348–354. [Google Scholar]

- Edwards, P.P.; Kuznetsov, V.L.; David, W.I.F.; Brandon, N.P. Hydrogen and fuel cells: Towards a sustainable energy future. Energ. Policy 2008, 36, 4356–4362. [Google Scholar] [CrossRef]

- Hall, P.J. Energy storage: The route to liberation from the fossil fuel economy? Energ. Policy 2008, 36, 4363–4367. [Google Scholar] [CrossRef] [Green Version]

- Hall, P.J.; Bain, E.J. Energy-storage technologies and electricity generation. Energ. Policy 2008, 36, 4352–4355. [Google Scholar] [CrossRef] [Green Version]

- Salgi, G.; Lund, H. System behaviour of compressed-air energy-storage in Denmark with a high penetration of renewable energy sources. Appl. Energ. 2008, 85, 182–189. [Google Scholar] [CrossRef]

- Hinnels, M. Combined heat and power in industry and buildings. Energ. Policy 2008, 36, 4522–4526. [Google Scholar] [CrossRef]

- Blarke, M.B.; Lund, H. The effectiveness of storage and relocation options in renewable energy systems. Renewable Energy 2008, 33, 1499–1507. [Google Scholar] [CrossRef]

- Mueller, M.; Wallace, R. Enabling science and technology for marine renewable energy. Energ. Policy 2008, 36, 4376–4382. [Google Scholar] [CrossRef]

- Llewellyn Smith, C.; Ward, D. Fusion. Energ. Policy 2008, 36, 4331–4334. [Google Scholar] [CrossRef]

- Nakicenovic, N.; Swart, R. Special Report on Emissions Scenarios; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2000.

- Lenzen, M.; Wachsmann, U. Wind energy converters in Brazil and Germany: an example for geographical variability in LCA. Appl. Energ. 2004, 77, 119–130. [Google Scholar] [CrossRef]

- Pehnt, M. Dynamic life cycle assessment (LCA) of renewable energy technologies. Renewable Energy 2006, 31, 55–71. [Google Scholar] [CrossRef]

- Projected cost of generating electricity; Organisation for Economic Co-operation and Development Nuclear Energy Agency, International Energy Agency: Paris, France, 2005.

- Harding, J. Economics of nuclear power and proliferation risk in a carbon-constrained world. Electricity J. 2007, 20, 65–76. [Google Scholar] [CrossRef]

- Technical Summary; Carbon Dioxide Capture and Storage; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2005.

- Lenzen, M. Life cycle energy and greenhouse gas emissions of nuclear energy: A review. Energ. Conv. Manage. 2008, 49, 2178–2199. [Google Scholar] [CrossRef]

- Weisser, D. A guide to life-cycle greenhouse gas (GHG) emissions from electric supply technologies. Energy 2007, 32, 1543–1559. [Google Scholar] [CrossRef]

- Lenzen, M. Greenhouse gas analysis of solar-thermal electricity generation. Solar Energ. 1999, 65, 353–368. [Google Scholar] [CrossRef]

- Well-To-Wheels Analysis of Future Automotive Fuels and Powertrains in the European Context-Description and Detailed Energy and Ghg Balance of Individual Pathways; 3.0, WTT App 2 v30 181108; Joint Research Centre, European Council for Automotive R&D, concawe: Ispra, Italy, 2008.

- Estimating the Future Trends in the Cost of CO2 Capture Technologies; 2006/6; International Energy Agency Greenhouse Gas R&D Programme: Stoke Orchard, Cheltenham, UK, 2006.

- Odeh, N.A.; Cockerill, T.T. Life cycle GHG assessment of fossil fuel power plants with carbon capture and storage. Energ. Policy 2008, 36, 367–380. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Aaberg, M.; Singh, B.; Strømman, A.H. Life-cycle Assessment of carbon dioxide capture for enhanced oil recovery. Chin. J. Chem. Eng. 2008, 16, 343–353. [Google Scholar] [CrossRef]

- Rubin, E.S.; Chen, C.; Rao, A.B. Cost and performance of fossil fuel power plants with CO2 capture and storage. Energ. Policy 2007, 35, 4444–4454. [Google Scholar] [CrossRef]

- Blake, E.M. U.S. capacity factors: leveled off at last. Nuclear News 2006, 49, 26–31. [Google Scholar]

- Riahi, K.; Rubin, E.S.; Taylor, M.R.; Schrattenholzer, L.; Hounshell, D. Technological learning for carbon capture and sequestration technologies. Energ. Econ. 2004, 26, 539–564. [Google Scholar] [CrossRef]

- Sovacool, B.K. Valuing the greenhouse gas emissions from nuclear power: A critical survey. Energ. Policy 2008, 36, 2950–2963. [Google Scholar] [CrossRef]

- Lim, E.; Rumble, E.; Ramachandran, G. Review and Comparison of Recent Studies for Australian Electricity Generation Planning; to the Prime Minister's Uranium Mining, Processing and Nuclear Energy Review (UMPNER); Electric Power Research Institute: Palo Alto, USA, 2006. [Google Scholar]

- Hydropower and the World's Energy Future; International Hydropower Association, IEA Hydropower Agreement, International Commission on Large Dams, and Canadian Hydropower Association: Compton, UK, Paris, France, and Ottawa, Canada, 2000.

- Lenzen, M.; Dey, C.; Hardy, C.; Bilek, M. Life-Cycle Energy Balance and Greenhouse Gas Emissions of Nuclear Energy in Australia; http://www.isa.org.usyd.edu.au/publications/documents/ISA_Nuclear_Report.pdf; ISA, University of Sydney: Sydney, Australia, 2006. [Google Scholar]

- Dos Santos, M.A.; Rosa, L.P.; Sikar, B.; Sikar, E.; Dos Santos, E.O. Gross greenhouse gas fluxes from hydro-power reservoir compared to thermo-power plants. Energ. Policy 2006, 34, 481–488. [Google Scholar] [CrossRef]

- Nouni, M.R.; Mullick, S.C.; Kandpal, T.C. Techno-economics of micro-hydro projects for decentralized power supply in India. Energ. Policy 2006, 34, 1161–1174. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, X.; Liu, J. The trend of small hydropower development in China. Renewable Energy 2009, 34, 1078–1083. [Google Scholar] [CrossRef]

- World Wind Energy Report; www.wwindea.org; World Wind Energy Association: Bonn, Germany, 2008.

- Lenzen, M.; Munksgaard, J. Energy and CO2 analyses of wind turbines - review and applications. Renewable Energy 2002, 26, 339–362. [Google Scholar] [CrossRef]

- Roth, H.; Brückl, O.; Held, A. Windenergiebedingte CO2-Emissionen konventioneller Kraftwerke; 50; Lehrstuhl für Energiewirtschaft und Anwendungstechnik: München, Germany, 2005. [Google Scholar]

- Trends in Photovoltaic Applications; T1-17; International Energy Agency: Paris, France, 2008.

- van der Zwaan, B.; Rabl, A. The learning potential of photovoltaics: implications for energy policy. Energ. Policy 2004, 32, 1545–1554. [Google Scholar] [CrossRef]

- Eichhammer, W.; Morin, G.; Lerchenmüller, H.; Stein, W.; Szewczuk, S. Assessment of the World Bank / GEF Strategy for the Market Development of Concentrating Solar Power; World Bank Global Environment Facility: Washington, D.C., USA, 2005. [Google Scholar]

- Ármannsson, H.; Fridriksson, T.; Kristjánsson, B.R. CO2 emissions from geothermal power plants and natural geothermal activity in Iceland. Geothermics 2005, 34, 286–296. [Google Scholar] [CrossRef]

- Kagel, A. A handbook on the externalities, employment, and economics of geothermal energy; Geothermal Energy Association: Washington D.C., USA, 2006. [Google Scholar]

- Biomass for Power Generation and CHP; OECD/IEA: Paris, France, 2007.

- Maza, A.; Villaverde, J. The world per capita electricity consumption distribution: Signs of convergence? Energ. Policy 2008, 36, 4255–4261. [Google Scholar] [CrossRef]

- Nuclear Energy Outlook; No. 6348; OECD Nuclear Energy Agency: Paris, France, 2008.

- Pasternak, A.D. Global Energy Futures and Human Development: A Framework for Analysis; UCRL-ID-140773; Lawrence Livermore National Laboratory: Los Alamos, USA, 2000. [Google Scholar]

- Toth, F.L.; Rogner, H.-H. Oil and nuclear power: Past, present, and future. Energ. Econ. 2006, 28, 1–25. [Google Scholar]

- World Energy Outlook 2008; International Energy Agency: Paris, France, 2008.

- Energy Information Administration, Electricity. In International Energy Outlook; U.S. Department of Energy: Washington D.C., USA, 2008. available online: http://www.eia.doe.gov/oiaf/ieo/electricity.html (accessed on 1 February 2010).

- Energy Information Administration, Appendix I - Comparisons with International Energy Agency and IEO2007 projections. In International Energy Outlook; U.S. Department of Energy: Washington D.C.,USA, 2008. available online: http://www.eia.doe.gov/oiaf/ieo/appi.html (accessed on 1 February 2010).

- Riahi, K.; Barreto, L.; Rao, S.; Rubin, E.S.; Rubin, E.S.; Keith, D.W.; Gilboy, C.F.; Wilson, M.; Morris, T.; Gale, J.; Thambimuthu, K. Towards fossil-based electricity systems with integrated CO2 capture: Implications of an illustrative long-term technology policy. In Greenhouse Gas Control Technologies; Elsevier Science: Oxford, UK, 2005; Vol. 7, pp. 921–929. [Google Scholar]

- Gibbins, J.; Chalmers, H. Carbon capture and storage. Energ. Policy 2008, 36, 4317–4322. [Google Scholar] [CrossRef]

- IEA GHG. Geologic Storage of Carbon Dioxide - Staying Safely Underground; www.ieagreen.org.uk/glossies/geostoragesfty.pdf; International Energy Agency Greenhouse Gas R&D Programme: Stoke Orchard, Cheltenham, UK, 2008. [Google Scholar]

- IPCC. Summary for Policymakers; Carbon Dioxide Capture and Storage; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2005. [Google Scholar]

- Viebahn, P.; Nitsch, J.; Fischedick, M.; Esken, A.; Schüwer, D.; Supersberger, N.; Zuberbühler, U.; Edenhofer, O. Comparison of carbon capture and storage with renewable energy technologies regarding structural, economic, and ecological aspects in Germany. Int. J. Greenhouse Gas Control 2007, 1, 121–133. [Google Scholar] [CrossRef]

- Pehnt, M.; Henkel, J. Life cycle assessment of carbon dioxide capture and storage from lignite power plants. Int. J. Greenhouse Gas Control 2009, 3, 49–66. [Google Scholar] [CrossRef]

- Diesendorf, M. Can geosequestration save the coal industry? In Transforming Power: Energy as a Social Project; Byrne, J., Glover, L., Toly, N., Eds.; Energy an Environmental Policy Series, 2006; pp. 223–248. [Google Scholar]

- Shackley, S.; Waterman, H.; Godfroij, P.; Reiner, D.; Anderson, J.; Draxlbauer, K.; Flach, T. Stakeholder perceptions of CO2 capture and storage in Europe: Results from a survey. Energ. Policy 2007, 35, 5091–5108. [Google Scholar] [CrossRef]

- Wall, T.F. Combustion processes for carbon capture. Proc. Combust. Inst. 2007, 31, 31–47. [Google Scholar] [CrossRef]

- Kvamsdal, H.M.; Jordal, K.; Bolland, O. A quantitative comparison of gas turbine cycles with CO2 capture. Energy 2007, 32, 10–24. [Google Scholar] [CrossRef]

- Balat, M. The Future of Clean Coal. In Future Energy; Elsevier: Oxford, UK, 2008; pp. 25–40. [Google Scholar]

- Jordal, K. Benchmarking of power cycles with CO2 capture--The impact of the selected framework. Int. J. Greenhouse Gas Control 2008, 2, 468–477. [Google Scholar] [CrossRef]

- Riahi, K.; Rubin, E.S.; Schrattenholzer, L. Prospects for carbon capture and sequestration technologies assuming their technological learning. Energy 2004, 29, 1309–1318. [Google Scholar] [CrossRef]

- Anderson, S. Prospects for carbon capture and storage technologies. Annu. Rev. Environ. Resour. 2004, 29, 109–142. [Google Scholar] [CrossRef]

- Rubin, E.S.; Yeh, S.; Antes, M.; Berkenpas, M.; Davison, J. Use of experience curves to estimate the future cost of power plants with CO2 capture. Int. J. of Greenhouse Gas Control 2007, 1, 188–197. [Google Scholar] [CrossRef]

- Davison, J. Performance and costs of power plants with capture and storage of CO2. Energy 2007, 32, 1163–1176. [Google Scholar] [CrossRef]

- CO2 capture and storage; OECD/IEA: Paris, France, 2006.

- Spath, P.L.; Mann, M. Biomass Power and Conventional Fossil Systems With and Without Co2 Sequestration-Comparing the Energy Balance, Greenhouse Gas Emissions and Economics; TP-510-32575; US National Renewable Energy Laboratory: Golden, USA, 2004. [Google Scholar]

- Tondeur, D.; Teng, F.; Trevor, M.L. Carbon Capture and Storage for Greenhouse Effect Mitigation. In Future Energy; Elsevier: Oxford, UK, 2008; pp. 303–331. [Google Scholar]

- Damen, K.; van Troost, M.; Faaij, A.; Turkenburg, W. A comparison of electricity and hydrogen production systems with CO2 capture and storage-Part B: Chain analysis of promising CCS options. Prog. Energ. Combust. Sci. 2007, 33, 580–609. [Google Scholar] [CrossRef]

- Chen, C.; Rubin, E.S. CO2 control technology effects on IGCC plant performance and cost. Energ. Policy 2009, 37, 915–924. [Google Scholar] [CrossRef]

- Muradov, N.Z.; Veziroğlu, T.N. "Green" path from fossil-based to hydrogen economy: An overview of carbon-neutral technologies. Int. J. Hydrogen Energ. 2008, 33, 6804–6839. [Google Scholar] [CrossRef]

- Jordal, K.; Anheden, M.; Yan, J.; Strömberg, L. Oxyfuel combustion for coal-fired power generation with CO2 capture – Opportunities and challenges. Greenhouse Gas Control Technol. 2005, 7, 201–209. [Google Scholar]

- Yang, H.; Xu, Z.; Fan, M.; Gupta, R.; Slimane, R.B.; Bland, A.E.; Wright, I. Progress in carbon dioxide separation and capture: A review. J. Environ. Sci. 2008, 20, 14–27. [Google Scholar] [CrossRef]

- National Energy Technology Laboratory. Oxy-fuel combustion; www.netl.doe.gov/publications/factsheets/rd/R&D127.pdf; Office of Fossil Energy, U.S. Department of Energy: Morgantown, USA, 2008.

- Romeo, L.M.; Abanades, J.C.; Escosa, J.M.; Paño, J.; Giménez, A.; Sánchez-Biezma, A.; Ballesteros, J.C. Oxyfuel carbonation/calcination cycle for low cost CO2 capture in existing power plants. Energ. Conv. Manage. 2008, 49, 2809–2814. [Google Scholar] [CrossRef]

- Aspelund, A.; Mølnvik, M.J.; De Koeijer, G. Ship transport of CO2. Chem. Eng. Res. Design 2006, 84, 847–855. [Google Scholar] [CrossRef]

- Lenzen, M.; Neugebauer, H.J. Measurements of radon concentration and the role of earth tides in a gypsum mine in Walferdange, Luxembourg. Health Phys. 1999, 77, 154–162. [Google Scholar] [CrossRef] [PubMed]

- Zakkour, P.; Haines, M. Permitting issues for CO2 capture, transport and geological storage: A review of Europe, USA, Canada and Australia. Int. J. Greenhouse Gas Control 2007, 1, 94–100. [Google Scholar] [CrossRef]

- Uranium 2007: Resources, Production and Demand; No. 6345; OECD Nuclear Energy Agency and International Atomic Energy Agency: Paris, France, 2008.

- Pasztor, J. What role can nuclear power play in mitigating global warming? Energ. Policy 1991, 19, 98–109. [Google Scholar] [CrossRef]

- Krupnick, A.J.; Markandya, A.; Nickell, E. The external costs of nuclear power: ex ante damages and lay risks. Amer. J. Agr. Econ. 1993, 75, 1273–1279. [Google Scholar] [CrossRef]

- Nuclear Energy and the Kyoto Protocol; OECD Nuclear Energy Agency: Paris, France, 2002.

- Energy Information Administration, Mid-term prospects for nuclear electricity generation in China, India and the United States. In International Energy Outlook; U.S. Department of Energy: Washington D.C., USA, 2008. available online: http://www.eia.doe.gov/oiaf/ieo/negen.html (accessed on 1 February 2010).

- Mortimer, N. Nuclear power and global warming. Energ. Policy 1991, 19, 76–78. [Google Scholar] [CrossRef]

- Mortimer, N. Nuclear power and carbon dioxide-the fallacy of the nuclear industry's new propaganda. The Ecologist 1991, 21, 129–132. [Google Scholar]

- Storm van Leeuwen, J.W.; Smith, P. Nuclear Power - the Energy Balance; http://www.stormsmith.nl/; Chaam, Netherlands, 2005. [Google Scholar]

- Diesendorf, M. Is nuclear energy a possible solution to global warming? Soc. Alternatives 2007, 26, 8–11. [Google Scholar]

- Mudd, G.M.; Diesendorf, M. Sustainability of uranium mining and milling: Toward quantifying resources and eco-efficiency. Environ. Sci. Technol. 2008, 42, 2624–2630. [Google Scholar] [CrossRef] [PubMed]

- IAEA. Global Uranium Resources to Meet Projected Demand; available online: http://www.iaea.org/NewsCenter/News/2006/uranium_resources.htmlVienna, Austria, 2006.

- World Nuclear Association. Supply of Uranium; 75; available online: http://www.worldnuclear.org/info/inf75.htmWorld Nuclear Association: London, UK, 2008.

- Uranium Information Centre. Australia's uranium deposits and prospective mines; http://www.uic.com/pmine.htmUranium Information Centre: Melbourne, Australia, 2006.

- Donaldson, D.M.; Betteridge, G.E. Forum-Nuclear power and global warming. Energ. Policy 1991, 19, 76–78. [Google Scholar] [CrossRef]

- Tokimatsu, K.; Kosugi, T.; Asami, T.; Williams, E.; Kaya, Y. Evaluation of lifecycle CO2 emissions from the Japanese electric power sector in the 21st century under various nuclear scenarios. Energ. Policy 2006, 34, 833–852. [Google Scholar] [CrossRef]

- Energy Information Administration, Uranium supplies are sufficient to power reactors worldwide through 2030. In International Energy Outlook; U.S. Department of Energy: Washington D.C., USA, 2008. p www.eia.doe.gov/oiaf/ieo/uranium.html.

- Kidd, S. Uranium-Resources, Sustainability and Environment; 17th World Energy Council Congress; Houston, USA, 1998; World Energy Council, Ed.; Internet site http://www.worldenergy.org/wecgeis/publications/default/tech_papers/17th_congress/3_2_12.aspHouston, USA, 1998.

- Uranium 2007: Resources, Production and Demand; OECD: Paris, France, 2008.

- Diesendorf, M.; Christoff, P. CO2 Emissions from the Nuclear Fuel Cycle. 2006. http://www.energyscience.org.au/FS02%20CO2%20Emissions.pdf; energyscience.org.au.

- Salvatores, M. The physics of transmutation in critical or subcritical reactors. C. R. Phys. 2002, 3, 999–1012. [Google Scholar] [CrossRef]

- Fthenakis, V.M.; Kim, H.C. Greenhouse-gas emissions from solar electric and nuclear power: a life-cycle study. Energ. Policy 2007, 35, 2549–2557. [Google Scholar] [CrossRef]

- Environmental Activities in Uranium Mining and Milling; OECD Nuclear Energy Agency: Paris, France, 1999.

- Mudd, G.M. Uranium Mining: Australia and Globally. 2006. available online: http://www.energyscience.org.au/FS06%20Uranium%20Mining.pdf; energyscience.org.au.

- Mudd, G.M. Radon sources and impacts: a review of mining and non-mining issues. Rev. Environ. Sci. Biotechnol. 2008, 7, 325–353. [Google Scholar] [CrossRef]

- World Nuclear Association. Radiation and Nuclear Energy; 5; http://www.world-nuclear.org/info/inf05.htmWorld Nuclear Association: London, UK, 2006.

- Mudd, G.M. Remediation of Uranium mill tailings wastes in Australia : A critical review. In Process of 2000 Contaminated Sites Remediation Conference; CSIRO Centre for Groundwater Studies: Melbourne, Australia, 2000; Vol. 2, pp. 777–784. [Google Scholar]

- Mudd, G.M. Radon releases from Australian uranium mining and milling projects: assessing the UNSCEAR approach. Journal of Environmental Radioactivity 2008, 99, 288–315. [Google Scholar] [CrossRef] [PubMed]

- Mudd, G.M.; Patterson, J. The Rum Jungle U-Cu project: A critical evaluation of environmental monitoring and rehabilitation success. In Uranium, Mining and Hydrogeology - 5th International Conference; Freiberg, Germany, 2008; pp. 317–327. [Google Scholar]

- Uranium Information Centre. Environmental rehabilitation of the Mary Kathleen Uranium Mine; # 6; Uranium Information Centre: Melbourne, Australia, 1996. [Google Scholar]

- Uranium Information Centre. Environmental Management and Rehabilitation of the Nabarlek Uranium Mine; # 5; Uranium Information Centre: Melbourne, Australia, 1999. [Google Scholar]

- Uranium Information Centre. Former Australian uranium mines; http://www.uic.com/fmine.htm; Uranium Information Centre: Melbourne, Australia, 2006. [Google Scholar]

- Mudd, G.M. Personal communication, 2009.

- Nilsson, J.-A.; Randhem, J. Environmental impacts and health aspects in the mining industry. Master Thesis, Chalmers University, Göteborg, Sweden, 2008. [Google Scholar]

- Ragheb, M. Environmental Radiation. In Nuclear, Plasma and Radiological Engineering; https://netfiles.uiuc.edu/mragheb/www/NPRE%20402%20ME%20405%20Nuclear%20Power%20Engineering/Environmental%20Radiation.pdfUniversity of Illinois: Urbana-Champaign, 2007.

- World Nuclear Association. In Situ Leach (ISL) Mining of Uranium; 03; http://www.world-nuclear.org/info/inf27.htmWorld Nuclear Association: London, UK, 2003.

- Mudd, G.M. Critical review of acid in-situ leach uranium mining: 1. USA and Australia. Environ. Geol. 2001, 41, 390–403. [Google Scholar]

- Mudd, G.M. Critical review of acid in-situ leach uranium mining: 2. Soviet Block and Asia. Environ. Geol. 2001, 41, 404–416. [Google Scholar] [CrossRef]

- Penner, S.S.; Seiser, R.; Schultz, K.R. Steps towards passively safe, proliferation-resistant nuclear power. Prog. Energ. Combust. Sci. 2008, 34, 275–287. [Google Scholar] [CrossRef]

- Weisser, D.; Howells, M.; Rogner, H.-H. Nuclear power and post-2012 energy and climate change policies. Environ. Sci. Policy 2008, 11, 467–477. [Google Scholar] [CrossRef]

- Deutch, J.M.; Forsberg, C.W.; Kadak, A.C.; Kazimi, M.S.; Moniz, E.J.; Parsons, J.E.; Du, Y.; Pierpoint, L. The Future of Nuclear Power – Update of the MIT 2003 Report; Massachusetts Institute of Technology: Boston, USA, 2009. [Google Scholar]

- Nuclear power; OECD/IEA: Paris, France, 2007.

- Bezat, J.-M.; Le Hir, P.; Kempf, H. France trusts in nuclear future. The Guardian Weekly, 2007; 28–29. [Google Scholar]

- Marcus, G.H. Innovative nuclear energy systems and the future of nuclear power. Progress in Nuclear Energy 2008, 50, 92–96. [Google Scholar] [CrossRef]

- Abu-Khader, M.M. Recent advances in nuclear power: A review. Prog. Nucl. Energy 2009, 51, 225–235. [Google Scholar] [CrossRef]

- World Nuclear Association. The Economics of Nuclear Power; 02; http://www.world-nuclear.org/info/inf02.htmWorld Nuclear Association: London, UK, 2006.

- Cantor, R.; Hewlett, J. The economics of nuclear power. Resour. Energ. 1988, 10, 315–335. [Google Scholar] [CrossRef]

- Fetter, S.; Bunn, M.; Van der Zwaan, B.; Holdren, J.P. The Economics of Reprocessing Vs Direct Disposal of Spent Nuclear Fuel; Belfer Center for Science and International Affairs, Harvard Kennedy School: Cambridge, USA, 2003. [Google Scholar]

- Gittus, J.H. Introducing Nuclear Power to Australia; ANSTO - Australian Nuclear Science and Technology Organisation: Canberra, Australia, 2006. [Google Scholar]

- Neij, L. Cost development of future technologies for power generation-A study based on experience curves and complementary bottom-up assessments. Energ. Policy 2008, 36, 2200–2211. [Google Scholar] [CrossRef]

- Martinez-Val, J.M.; Piera, M. Nuclear fission sustainability with hybrid nuclear cycles. Energ. Conv. Manage. 2007, 48, 1480–1490. [Google Scholar] [CrossRef]

- Trends in the Nuclear Fuel Cycle; OECD Nuclear Energy Agency: Paris, France, 2001.

- Market Competition in the Nuclear Industry; No. 6246; OECD Nuclear Energy Agency and International Atomic Energy Agency: Paris, France, 2008.

- Abánades, A.; Pérez-Navarro, A. Engineering design studies for the transmutation of nuclear wastes with a gas-cooled pebble-bed ADS. Nucl. Eng. Des. 2007, 237, 325–333. [Google Scholar] [CrossRef]

- Abram, T.; Ion, S. Generation-IV nuclear power: A review of the state of the science. Energ. Policy 2008, 36, 4323–4330. [Google Scholar] [CrossRef]

- Fricke, J.; Borst, W.L. Energie; R. Oldenbourg Verlag: München, Germany, 1984. [Google Scholar]

- World Nuclear Association. Thorium; 62; http://www.world-nuclear.org/info/inf62.htmlWorld Nuclear Association: London, UK, 2008.

- Salvatores, M. Transmutation: Issues, innovative options and perspectives. Prog. Nucl. Energ. 2002, 40, 375–402. [Google Scholar] [CrossRef]

- Salvatores, M. Fuel cycle strategies for the sustainable development of nuclear energy: The role of accelerator driven systems. Nucl. Instrum. Meth. Phys. Res. A 2006, 562, 578–584. [Google Scholar] [CrossRef]

- Salvatores, M. Nuclear fuel cycle strategies including Partitioning and Transmutation. Nucl. Eng. Des. 2005, 235, 805–816. [Google Scholar] [CrossRef]

- Schneider, E.A.; Deinert, M.R.; Cady, K.B. Burnup simulations and spent fuel characteristics of ZRO2 based inert matrix fuels. J. Nucl. Mater. 2007, 361, 41–51. [Google Scholar] [CrossRef]

- Medvedev, P.G.; Frank, S.M.; O'Holleran, T.P.; Meyer, M.K. Dual phase MgO-ZrO2 ceramics for use in LWR inert matrix fuel. J. Nucl. Mater. 2005, 342, 48–62. [Google Scholar] [CrossRef]

- Sokolov, F.; Nawada, H.P. Viability of Inert Matrix Fuel in Reducing Plutonium Amounts in Reactors; IAEA-TECDOC-1516, Nuclear Fuel Cycle and Materials Section, International Atomic Energy Agency: Vienna, Austria, 2006. [Google Scholar]

- Murty, K.S.; Charit, I. Structural materials for Gen-IV nuclear reactors: Challenges and opportunities. J. Nucl. Mater. 2008, 383, 189–195. [Google Scholar] [CrossRef]

- Driver, D. Making a material difference in energy. Energ. Policy 2008, 36, 4302–4309. [Google Scholar] [CrossRef]

- Kosnik, L. The potential of water power in the fight against global warming in the US. Energ. Policy 2008, 36, 3252–3265. [Google Scholar] [CrossRef]

- Kaldellis, J.K. The contribution of small hydro power stations to the electricity generation in Greece: Technical and economic considerations. Energ. Policy 2007, 35, 2187–2196. [Google Scholar] [CrossRef]

- Huang, H.; Yan, Z. Present situation and future prospect of hydropower in China. Renew. Sustain. Energy Rev. 2009, 13, 1652–1656. [Google Scholar] [CrossRef]

- Purohit, P. Small hydro power projects under clean development mechanism in India: A preliminary assessment. Energ. Policy 2008, 36, 2000–2015. [Google Scholar] [CrossRef]

- Paish, O. Small hydro power: technology and current status. Renew. Sustain. Energy Rev. 2002, 6, 537–556. [Google Scholar] [CrossRef]

- Hall, D.G.; Cherry, S.J.; Reeves, K.S.; Lee, R.D.; Carroll, G.R.; Sommers, G.L.; Verdin, K.L. Water Energy Resources of the United States With Emphasis on Low Head/Low Power Resources; U.S. Department of Energy: Idaho Falls, USA, 2004.

- Nfah, E.M.; Ngundam, J.M. Feasibility of pico-hydro and photovoltaic hybrid power systems for remote villages in Cameroon. Renewable Energy 2009, 34, 1445–1450. [Google Scholar] [CrossRef]

- Égré, D.; Milewski, J.C. The diversity of hydropower projects. Energ. Policy 2002, 30, 1225–1230. [Google Scholar] [CrossRef]

- Williams, A.A. Pumps as turbines for low cost micro hydro power. Renewable Energy 1996, 9, 1227–1234. [Google Scholar] [CrossRef]

- Rosa, L.P.; Schaeffer, R. Greenhouse gas emissions from hydroelectric reservoirs. Ambio 1993, 22, 164–165. [Google Scholar]

- Rudd, J.W.M.; Harris, R.; Kelly, C.A.; Hecky, R.E. Are hydroelectric reservoirs significant sources of greenhouse gases? Ambio 1993, 22, 246–248. [Google Scholar]

- Rosa, L.P.; Schaeffer, R. Global warming potentials - the case of emissions from dams. Energ. Policy 1995, 23, 149–158. [Google Scholar] [CrossRef]

- Rashad, S.M.; Ismail, M.A. Environmental-impact assessment of hydro-power in Egypt. Appl. Energ. 2000, 65, 285–302. [Google Scholar] [CrossRef]

- Lima, I.B.T.; Ramos, F.M.; Bambace, L.A.W.; Rosa, R.R. Methane emissions from large dams as renewable energy resources: A developing nation perspective. Mitigation and Adaptation Strategies for Global Change 2008, 13, 1573–1596. [Google Scholar]

- Osborne, J. When small is beautiful: Boom time for small hydro? Refocus 2002, 3, 46–48. [Google Scholar]

- Montes, G.M.; López, M.S.; Gámez, M.R.; Ondina, A.M. An overview of renewable energy in Spain - the small hydro-power case. Renew. Sustain. Energy Rev. 2005, 9, 521–534. [Google Scholar] [CrossRef]

- Draisey, I. Working together: Understanding the effects of small hydropower. Refocus 2002, 3, 58–59. [Google Scholar] [CrossRef]

- Hydropower in green pricing schemes: a sustainable source of power? Refocus 2001, 2, 46–47.

- Armand, F. Assessment of Further Opportunities for R&D; IEA Hydropower Agreement: Paris, France, 2000. [Google Scholar]

- Rangel, L.F. Competition policy and regulation in hydro-dominated electricity markets. Energ. Policy 2008, 36, 1292–1302. [Google Scholar] [CrossRef]

- Silva, E.L. Supply adequacy in electricity markets based on hydro systems - the Brazilian case. Energ. Policy 2006, 34, 2002–2011. [Google Scholar] [CrossRef]

- Jenssen, L.; Gjermundsen, T. Financing of small-scale hydropower projects; IEA Hydropower Agreement: Paris, France, 2000. [Google Scholar]

- Lenzen, M. Sustainable island businesses: a case study of Norfolk Island. J. Clean. Prod. 2008, 16, 2018–2035. [Google Scholar] [CrossRef]

- Bakos, G.C. Feasibility study of a hybrid wind/hydro power-system for low-cost electricity production. Appl. Energ. 2002, 72, 599–608. [Google Scholar] [CrossRef]

- Jenssen, L.; Mauring, K.; Gjermundsen, T. Economic risk- and sensitivity analyses for small scale hydropower projects; Technical Report; IEA Hydropower Agreement: Paris, France, 2000. [Google Scholar]

- Vidal, J. Indian hydro work stops. The Guardian Weekly, 2009; 11. [Google Scholar]

- Fawthrop, T. Mekong dam threatens wildlife and fisheries. The Guardian Weekly, 2009; 11. [Google Scholar]

- IHA. Survey of the environmental and social impacts and the effectiveness of mitigation measures in hydropower development; IEA Hydropower Agreement: Paris, France, 2000. [Google Scholar]

- Tilt, B.; Braun, Y.; He, D. Social impacts of large dam projects: A comparison of international case studies and implications for best practice. J. Environ. Manage. 2008, 90, S249–S257. [Google Scholar] [CrossRef] [PubMed]

- McNally, A.; Magee, D.; Wolf, A.T. Hydropower and sustainability: Resilience and vulnerability in China's powersheds. J. Environ. Manage. 2008, 90, S286–S293. [Google Scholar] [CrossRef] [PubMed]

- Swirbul, C. US hydropower dams: Environmental solution or problem? Refocus 2001, 2, 18–20. [Google Scholar] [CrossRef]

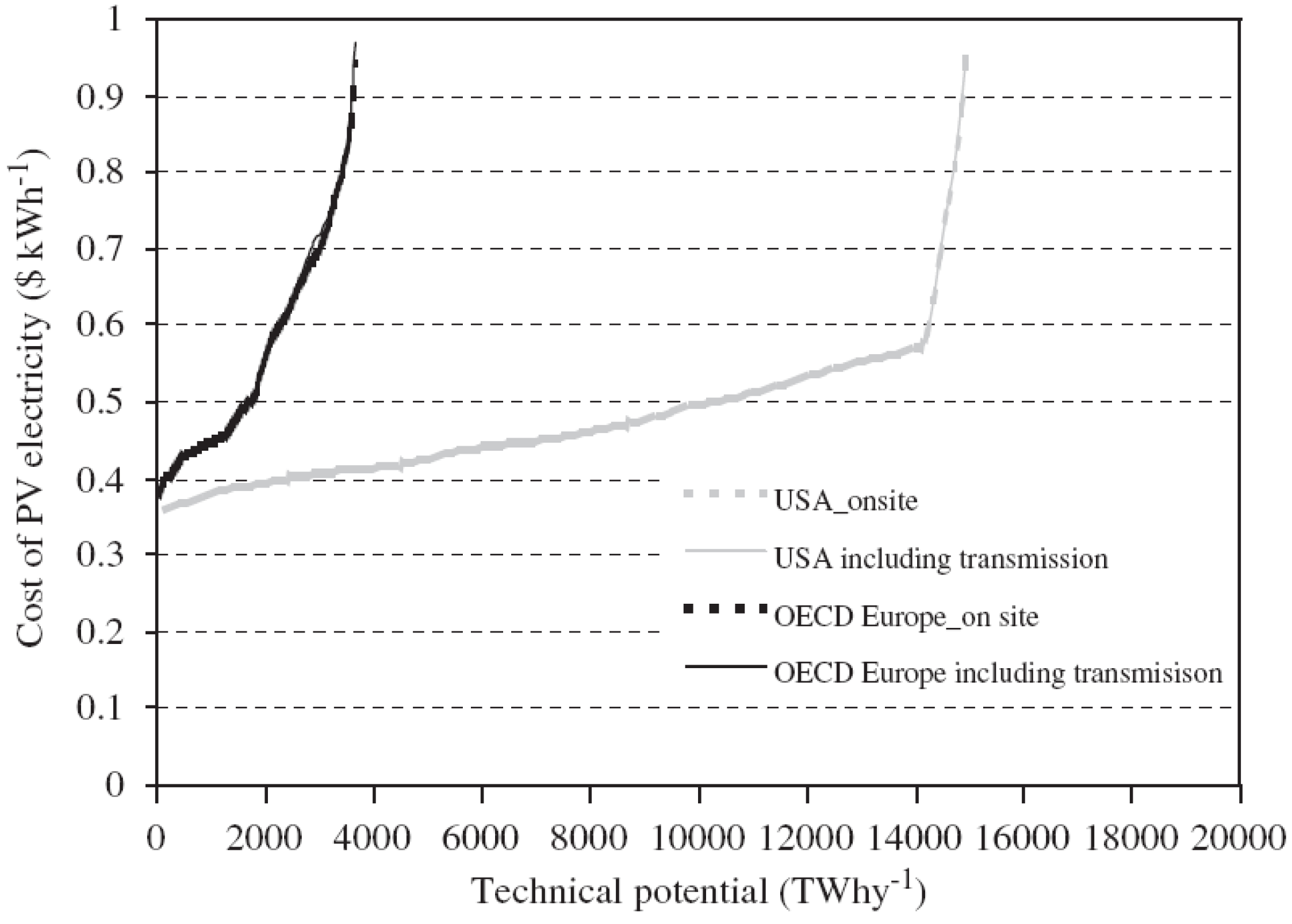

- Hoogwijk, M.M.; Van Vuuren, D.; De Vries, B.J.M.; Turkenburg, W.C. Exploring the impact on cost and electricity production of high penetration levels of intermittent electricity in OECD Europe and the USA, results for wind energy. Energy 2007, 32, 1381–1402. [Google Scholar] [CrossRef]

- Jha, A. Saharan sun to power European supergrid. The Guardian, 2008. [Google Scholar]

- Østergaard, P.A. Geographic aggregation and wind power output variance in Denmark. Energy 2008, 33, 1453–1460. [Google Scholar] [CrossRef]

- Schott AG. Memorandum on Solar Thermal Power Plant Technology; Schott AG: Mainz, Germany, 2005. [Google Scholar]

- Cherigui, A.N.; Mahmah, B.; Harouadi, F.; Belhamel, M.; Chader, S.; M'Raoui, A.; Etievant, C. Solar hydrogen energy: The European-Maghreb connection. A new way of excellence for a sustainable energy development. Int. J. Hydrogen Energy 2009, 34, 4934–4940. [Google Scholar]

- Global Wind Energy Outlook; Global Wind Energy Council: Brussels, Belgium, 2008.

- Archer, C.L.; Jacobson, M.Z. Evaluation of global wind power. J. Geophys. Res. 2005, 110, D12110:1–D12110:20. [Google Scholar]

- Hoogwijk, M.M.; De Vries, B.J.M.; Turkenburg, W.C. Assessment of the global and regional geographical, technical and economic potential of onshore wind energy. Energ. Econ. 2004, 26, 889–919. [Google Scholar] [CrossRef]

- 20% Wind Energy by 2030; DOE/GO-102008-2567; U.S. Department of Energy: Oak Ridge, USA, 2008.

- Carolin Mabel, M.; Fernandez, E. Growth and future trends of wind energy in India. Renew. Sustain. Energy Rev. 2008, 12, 1745–1757. [Google Scholar] [CrossRef]

- Xia, C.; Song, Z. Wind energy in China: Current scenario and future perspectives. Renew. Sustain. Energy Rev. 2009, 13, 1966–1974. [Google Scholar]

- Kempton, W.; Archer, C.L.; Dhanju, A.; Garvine, R.W.; Jacobson, M.Z. Large CO2 reductions via offshore wind power matched to inherent storage in energy end-uses. Geophys. Res. Lett. 2007, 34, L02817:1–L02817:5. [Google Scholar]

- Snyder, B.; Kaiser, M.J. Ecological and economic cost-benefit analysis of offshore wind energy. Renewable Energy 2009, 34, 1567–1578. [Google Scholar] [CrossRef]

- Holttinen, H. Estimating the impacts of wind power on power systems - summary of IEA Wind collaboration. Environ. Res. Lett. 2008, 3, 025001:1–025001:6. [Google Scholar] [CrossRef]

- Resch, G.; Held, A.; Faber, T.; Panzer, C.; Toro, F.; Haas, R. Potentials and prospects for renewable energies at global scale. Energ. Policy 2008, 36, 4048–4056. [Google Scholar] [CrossRef]

- Ackermann, T.; Söder, L. An overview of wind energy - status 2002. Renew. Sustain. Energy Rev. 2002, 6, 67–128. [Google Scholar] [CrossRef]

- Archer, C.L.; Jacobson, M.Z. Supplying baseload power and reducing transmission requirements by interconnecting wind farms. J. Appl. Meteorol. Climatol. 2007, 46, 1701–1717. [Google Scholar] [CrossRef]

- Holttinen, H.; Milligan, M.; Kirby, B.; Acker, T.; Neimane, V.; Molinski, T. Using standard deviation as a measure of increased operational reserve requirement for wind power. Wind Eng. 2008, 32, 355–378. [Google Scholar] [CrossRef]

- Oswald, J.; Raine, M.; Ashraf-Ball, H. Will British weather provide reliable electricity? Energ. Policy 2008, 36, 3212–3225. [Google Scholar] [CrossRef]

- Weigt, H. Germany’s wind energy: The potential for fossil capacity replacement and cost saving. Appl. Energ. 2008, 86, 1857–1863. [Google Scholar]

- Holttinen, H.; Lemström, B.; Meibom, P.; Bindner, H.; Orths, A.; Van Hulle, F.; Ensslin, C.; Tiedemann, A.; Hofmann, L.; Winter, W.; Tuohy, A.; O'Malley, M.; Smith, P.; Pierik, J.; Tande, J.O.; Estanqueiro, A.; Ricardo, J.; Gomez, E.; Smith, J.C.; Söder, L.; Strbac, G.; Shakoor, A.; Smith, J.C.; Parsons, B.; Milligan, M.; Wan, Y.H. Design and operation of power systems with large amounts of wind power; VTT: Helsinki, Finland, 2007. [Google Scholar]

- Archer, C.L.; Jacobson, M.Z. Spatial and temporal distributions of U.S. winds and wind power at 80 m derived from measurements. J. Geophys. Res. 2003, 108, 4289:1–4289:20. [Google Scholar]

- Söder, L. On limits for wind power generation. Int. J. Global Energy Issue. 2004, 21, 243–254. [Google Scholar] [CrossRef]

- Söder, L.; Hofmann, L.; Orths, A.; Holttinen, H.; Wan, Y.H.; Tuohy, A. Experience from wind integration in some high penetration areas. IEEE Trans. Energ. Conv. 2007, 22, 4–12. [Google Scholar]

- Pavlak, A. The economic value of wind energy. Electricity J. 2008, 21, 46–50. [Google Scholar] [CrossRef]

- Diesendorf, M. The Base-Load Fallacy; energyscience.org.au, 2007. [Google Scholar]

- Holttinen, H.; Meibom, P.; Orths, A.; O'Malley, M.; Ummels, B.C.; Tande, J.O.; Estanqueiro, A.; Gomez, E.; Smith, J.C.; Ela, E. Impacts of large amounts of wind power on design and operation of power systems, results of IEA collaboration. Process of 7th International Workshop on Large Scale Integration of Wind Power and on Transmission Networks for Offshore Wind Farms; Madrid, Spain, 2008. Internet site http://windintegrationworkshop.org/previous_workshops.html.

- Strbac, G.; Shakoor, A.; Black, M.; Pudjianto, D.; Bopp, T. Impact of wind generation on the operation and development of the UK electricity systems. Elec. Power Syst. Res. 2007, 77, 1214–1227. [Google Scholar] [CrossRef]

- Martin, B.; Diesendorf, M. Calculating the capacity credit of wind power. In Fourth Biennial Conference of the Simulation Society of Australia; University of Queensland, 1980. [Google Scholar]

- Milligan, M.; Porter, K. Determining the capacity value of wind: an updated survey of methods and implementation; NREL/CP-500-43433; National Renewable Energy Laboratory: Golden, USA, 2008. [Google Scholar]

- DeCarolis, J.F.; Keith, D.W. The economics of large-scale wind power in a carbon constrained world. Energ. Policy 2006, 34, 395–410. [Google Scholar] [CrossRef]

- Østergaard, P.A. Transmission grid requirements wit scattered and fluctuating renewable electricity-sources. Appl. Energ. 2003, 76, 247–255. [Google Scholar] [CrossRef]

- Sovacool, B.K.; Lindboe, H.H.; Odgaard, O. Is the Danish wind energy model replicable for other countries? Electricity J. 2008, 21, 27–28. [Google Scholar] [CrossRef]

- Lund, H. Large-scale integration of wind power into different energy systems. Energy 2005, 30, 2402–2412. [Google Scholar] [CrossRef]

- Wagner, H.J.; Pick, E. Energy yield ratio and cumulative energy demand for wind energy converters. Energy 2004, 29, 2289–2295. [Google Scholar] [CrossRef]

- Pehnt, M.; Oeser, M.; Swider, D.J. Consequential environmental system analysis of expected offshore wind electricity production in Germany. Energy 2008, 33, 747–759. [Google Scholar] [CrossRef]

- Jha, A. Brawny wind turbines set for German offshore debut. The Guardian Weekly, 2009; 10. [Google Scholar]

- Joselin Herbert, G.M.; Iniyan, S.; Sreevalsan, E.; Rajapandian, S. A review of wind energy technologies. Renew. Sustain. Energy Rev. 2007, 11, 1117–1145. [Google Scholar] [CrossRef]

- Bolinger, M.; Wiser, R. Wind power price trends in the United States: Struggling to remain competitive in the face of strong growth. Energ. Policy 2009, 37, 1061–1071. [Google Scholar] [CrossRef]

- Wind; OECD/IEA: Paris, France, 2008.

- Blanco, M.I. The economics of wind energy. Renew. Sustain. Energy Rev. 2008, 13, 1372–1382. [Google Scholar]

- Welch, J.B.; Venkateswaran, A. The dual sustainability of wind energy. Renew. Sustain. Energy Rev. 2008, 13, 1121–1126. [Google Scholar]

- Smit, T.; Junginger, M.; Smits, R. Technological learning in offshore wind energy: Different roles of the government. Energ. Policy 2007, 35, 6431–6444. [Google Scholar] [CrossRef]

- Benitez, L.E.; Benitez, P.C.; Van Kooten, G.C. The economics of wind power with energy storage. Energ. Econ. 2008, 30, 1973–1989. [Google Scholar] [CrossRef]

- Smith, J.C.; Milligan, M.; DeMeo, E.A.; Parsons, B. Utility wind integration and operating impact state of the art. IEEE Trans. Power Syst. 2007, 22, 900–908. [Google Scholar] [CrossRef]

- Hirst, E.; Hild, J. The value of wind power as a function of wind capacity. Electricity J. 2004, 17, 11–20. [Google Scholar] [CrossRef]

- Martin, B.; Diesendorf, M. Optimal mix in electricity grids containing wind power. Elec. Power Energ. Syst. 1982, 4, 155–161. [Google Scholar] [CrossRef]

- Ilex, X.; Strbac, G. Quantifying the system cost of additional renewables in 2020; Ilex Energy Consulting: Oxford, UK, 2002. [Google Scholar]

- Lund, H.; Kempton, W. Integration of renewable energy into the transport and electricity sectors through V2G. Energ. Policy 2008, 36, 3578–3587. [Google Scholar] [CrossRef]

- Tavner, P. Wind power as a clean-energy contributor. Energ. Policy 2008, 36, 4397–4400. [Google Scholar] [CrossRef]

- Zoellner, J.; Schweizer-Ries, P.; Wemheuer, C. Public acceptance of renewable energies: Results from case studies in Germany. Energ. Policy 2008, 36, 4136–4141. [Google Scholar] [CrossRef]

- Kurokawa, K.; Komoto, K.; van der Vleuten, P.; Faiman, D. Energy from the Desert-Practical proposals for Very Large Scale Photovoltaic Systems; Earthscan: London, UK, 2006. [Google Scholar]

- Ito, M.; Kato, K.; Sugihara, H.; Kichimi, T.; Song, J.; Kurokawa, K. A preliminary study on potential for very large-scale photovoltaic power generation (VLS-PV) system in the Gobi desert from economic and environmental viewpoints. Solar Energ. Mater. Solar Cells 2003, 75, 507–517. [Google Scholar] [CrossRef]

- Zweibel, K.; Mason, J.; Fthenakis, V.M. A solar grand plan. Sci. Amer. 2008, 298, 64–73. [Google Scholar] [CrossRef] [PubMed]

- Trevisani, L.; Fabbri, M.; Negrini, F. Long-term scenarios for energy and environment: Energy from the desert with very large solar plants using liquid hydrogen and superconducting technologies. Fuel Process. Technol. 2006, 87, 157–161. [Google Scholar] [CrossRef]

- Global Market Outlook for Photovoltaics until 2012; European Photovoltaic Industry Association: Brussels, Belgium, 2008.

- IEA, Healthy markets, but room for improvement. PV Power, 2008; 4–5.

- Fthenakis, V.; Mason, J.E.; Zweibel, K. The technical, geographical, and economic feasibility for solar energy to supply the energy needs of the US. Energ. Policy 2009, 37, 387–399. [Google Scholar] [CrossRef]

- Raugei, M.; Frankl, P. Life cycle impacts and costs of photovoltaic systems: Current state of art and future outlooks. Energy 2009, 34, 392–399. [Google Scholar] [CrossRef]

- Hoffmann, W. PV solar electricity industry: Market growth and perspective. Solar Energ. Mater. Solar Cells 2006, 90, 3285–3311. [Google Scholar] [CrossRef]

- PV snapshot; www.iea-pvps.orgInternational Energy Agency: Paris, France, 2009.

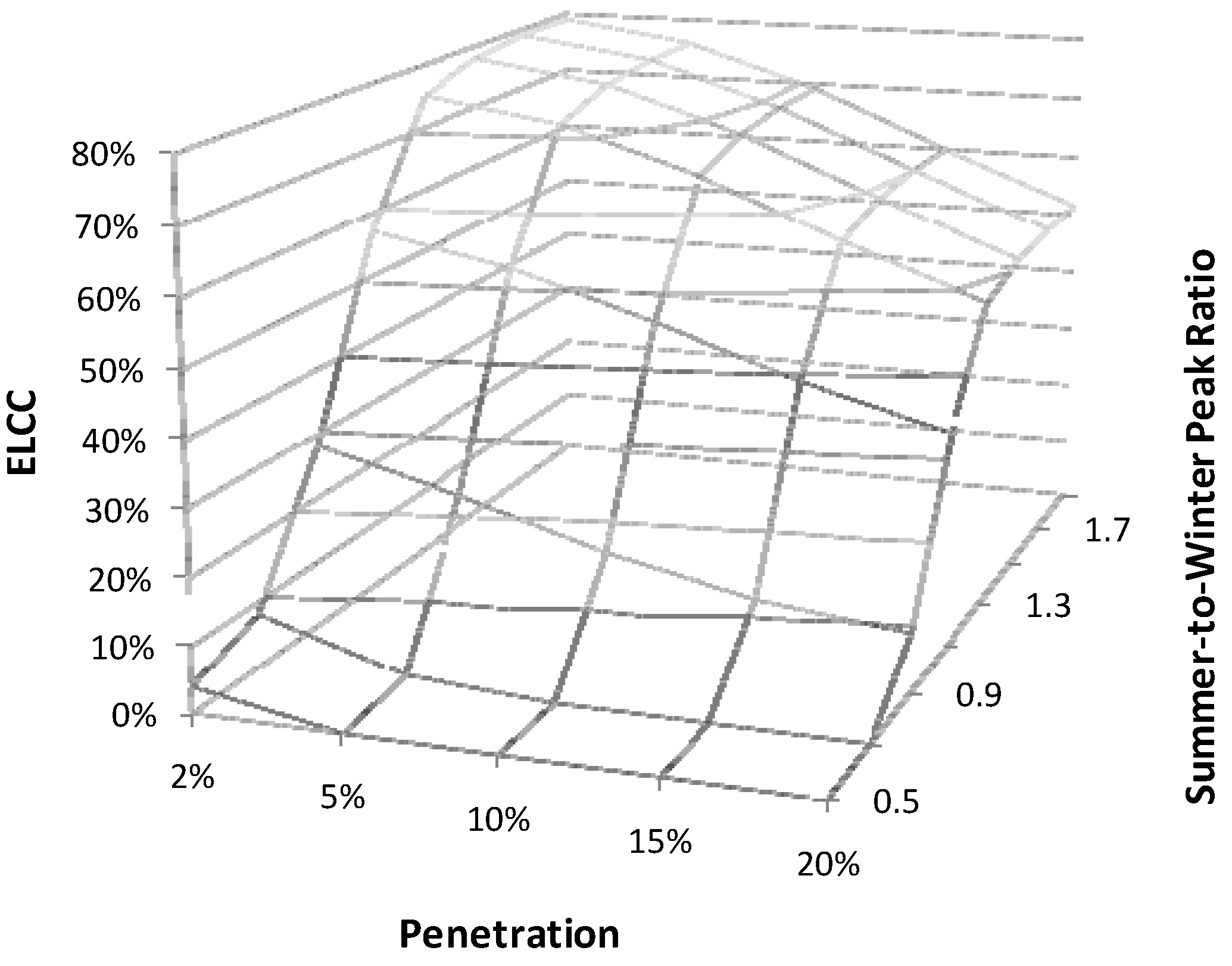

- Perez, R.; Margolis, R.; Kmiecik, M.; Schwab, M.; Perez, M. Update: Effective Load-Carrying Capacity of photovoltaics in the United States; NREL/CP-620-40068; National Renewable Energy Laboratory: Springfield, USA, 2006. [Google Scholar]

- Rüther, R.; Knob, P.J.; da Silva Jardim, C.; Rebechi, S.H. Potential of building integrated photovoltaic solar energy generators in assisting daytime peaking feeders in urban areas in Brazil. Energ. Conv. Manage. 2008, 49, 1074–1079. [Google Scholar] [CrossRef]

- Pelland, S.; Abboud, I. Comparing photovoltaic capacity value metrics: a case study of the City of Toronto. Prog. Photovoltaics 2008, 16, 715–724. [Google Scholar] [CrossRef]

- Herig, C. Using Photovoltaics to Preserve California's Electricity Capacity Reserves; NREL/BR-520-31179; National Renewable Energy Laboratory: Springfield, USA, 2001. [Google Scholar]

- Crawford, R.; Treloar, G.; Fuller, R.; Bazilian, M. Life-cycle energy analysis of building integrated photovoltaic systems (BiPVs) with heat recovery unit. Renew. Sustain. Energy Rev. 2006, 10, 559–575. [Google Scholar] [CrossRef]

- Fthenakis, V.M.; Kim, H.C. CdTe photovoltaics: Life cycle environmental profile and comparisons. Thin Solid Films 2007, 515, 5961–5963. [Google Scholar] [CrossRef]

- Celik, A.N.; Muneer, T.; Clarke, P. A review of installed solar photovoltaic and thermal collector capacities in relation to solar potential for the EU-15. Renewable Energy 2009, 34, 849–856. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Z. The development and application practice of wind-solar energy hybrid generation systems in China. Renew. Sustain. Energy Rev. 2008, 13, 1504–1512. [Google Scholar]

- IEA, PV industry landscape becoming truly global. PV Power, 2008; 2–3.

- Bagnall, D.M.; Boreland, M. Photovoltaic technologies. Energ. Policy 2008, 36, 4390–4396. [Google Scholar] [CrossRef]

- Mondol, J.D.; Yohanis, Y.G.; Norton, B. Optimising the economic viability of grid-connected photovoltaic systems. Appl. Energ. 2009, 86, 985–999. [Google Scholar] [CrossRef]

- Mehos, M. Task I: Solar Thermal Electric Systems; www.solarpaces.org/Tasks/Task1/task_i.htmNational Renewable Energy Laboratories, 2007.

- Trieb, F.; Nitsch, J.; Kronshage, S.; Schillings, C.; Brischke, L.-A.; Knies, G.; Czisch, G. Combined solar power and desalination plants for the Mediterranean region-sustainable energy supply using large-scale solar thermal power plants. Desalination 2002, 153, 39–46. [Google Scholar] [CrossRef]

- Morse, F.H. The Global Market Initiative (GMI) for Concentrating Solar Power (CSP). In ASES Conference; Portland, USA, 2004. [Google Scholar]

- Brakmann, G.; Aringhoff, R.; Geyer, M.; Teske, S. Concentrated Solar Power; www.solarpaces.org/Library/CSP_Documents/Concentrated-Solar-Thermal-Power-Plants-2005.pdfEuropean Solar Thermal Industry Association: Birmingham, UK, 2005.

- DLR. European Concentrated Solar Thermal Road-Mapping; SES6-CT-2003-502578; Deutsches Zentrum für Luft- und Raumfahrt e.V.: Köln, Germany, 2005. [Google Scholar]

- Aringhoff, R.; Geyer, M.; Morse, F.H. The Concentrating Solar Power Global Market Initiative; http://www.solarpaces.org/_Libary/GMI_10.pdfEuropean Solar Thermal Power Industry Association, IEA SolarPACES, and U.S. Solar Energy Industry Associations: Washington D.C., USA, 2004.

- Trieb, F. Competitive solar thermal power stations until 2010-the challenge of market introduction. Renewable Energy 2000, 19, 163–171. [Google Scholar] [CrossRef]

- Concentrating Solar Power for the Mediterranean region; Deutsches Zentrum für Luft- und Raumfahrt e.V.: Stuttgart, Germany, 2005.

- Broesamle, H.; Mannstein, H.; Schillings, C.; Trieb, F. Assessment of solar electricity potentials in North Africa based on satellite data and a geographic information system. Solar Energ. 2001, 70, 1–12. [Google Scholar] [CrossRef]

- Ummel, K.; Wheeler, D. Desert Power: The Economics of Solar Thermal Electricity for Europe, North Africa, and the Middle East; 156; Center for Global Development: Washington D.C., USA, 2008. [Google Scholar]

- Lovegrove, K.; Luzzi, A. Solar Thermal Power Systems. In Encyclopedia of Physical Science and Technology; 2002; Vol. 15, pp. 223–235. [Google Scholar]

- Montes, M.J.; Abánades, A.; Martínez-Val, J.M. Performance of a direct steam generation solar thermal power plant for electricity production as a function of the solar multiple. Solar Energ. 2008, 679, 679–689. [Google Scholar]

- Concentrated Solar Thermal Energy; Directorate J-Energy-European Commission: Luxembourg, Luxembourg, 2004.

- Kaneff, S. Solar thermal process heat and electricity generation performance and costs for the ANU 'Big Dish' technology - a comparison with LUZ system costs; EP-RR-57; Energy Research Centre, Research School of Physical Sciences & Engineering, Institute of Advanced Studies, The Australian National University: Canberra, Australia, April 1992. [Google Scholar]

- Pilkington. Status report on solar trough power plants; Pilkington Solar International GmbH: Köln, Germany, 1996. [Google Scholar]

- Mills, D.R.; Morrison, G.L. Compact Linear Fresnel Reflector solar thermal powerplants. Solar Energ. 2000, 68, 263–283. [Google Scholar] [CrossRef]

- Mills, D. Advances in solar thermal electricity technology. Solar Energ. 2004, 76, 19–31. [Google Scholar] [CrossRef]

- Schramek, P.; Mills, D.R. Multi-tower solar array. Solar Energ. 2003, 75, 249–260. [Google Scholar] [CrossRef]

- Schramek, P.; Mills, D.R. Heliostats for maximum ground coverage. Energy 2004, 29, 701–713. [Google Scholar] [CrossRef]

- Trieb, F. Concentrating Solar Power for Europe, Middle East and North Africa – A roadmap to 2050. In Hannover Messe; Hannover, Germany, 2007. [Google Scholar]

- Trieb, F.; Müller-Steinhagen, H. Concentrating solar power for seawater desalination in the Middle East and North Africa. Desalination 2008, 220, 165–183. [Google Scholar] [CrossRef]

- Trieb, F.; Müller-Steinhagen, H.; Kern, J.; Scharfe, J.; Kabariti, M.; Al Taher, A. Technologies for large scale seawater desalination using concentrated solar radiation. Desalination 2009, 235, 33–43. [Google Scholar] [CrossRef]

- Solar Millennium. The Parabolic Trough Power Plants Andasol 1 to 3; Solar Millennium AG: Erlangen, Germany, 2009. [Google Scholar]

- Lenzen, M.; Treloar, G. Differential convergence of life-cycle inventories towards upstream production layers. J. Ind. Ecol. 2003, 6, 137–160. [Google Scholar] [CrossRef]

- Caldés, N.; Varela, M.; Santamaría, M.; Sáez, R. Economic impact of solar thermal electricity deployment. Energ. Policy 2009, 37, 1628–1636. [Google Scholar] [CrossRef]

- Lenzen, M.; Dey, C.J. Economic, energy and emissions impacts of some environmentally motivated consumer, technology and government spending options. Energ. Econ. 2002, 24, 377–403. [Google Scholar] [CrossRef]

- Dey, C.; Mills, D.R.; Morrison, G.L. Operation of a CLFR research apparatus. In ANZSES Annual Conference; Geelong, Australia, 1999. [Google Scholar]

- Concentrating Solar Power - from research to implementation; European Commission: Luxembourg, Luxembourg, 2007.

- Tsoutsous, T.; Gekas, V.; Marketaki, K. Technical and economical evaluation of solar thermal power generation. Renewable Energy 2003, 28, 873–886. [Google Scholar] [CrossRef]

- Beerbaum, S.; Weinrebe, G. Solar thermal power generation in India - a techno-economic analysis. Renewable Energy 2000, 21, 153–174. [Google Scholar] [CrossRef]

- Quaschning, V. Technical and economical system comparison of photovoltaic and concentrating solar thermal power systems depending on annual global irradiation. Solar Energ. 2004, 77, 171–178. [Google Scholar] [CrossRef]

- Assessment of Parabolic Trough and Power Tower Solar Technology Cost and Performance Forecasts; LAA-2-32458-01; Sargent & Lundy LLC Consulting Group; NREL/SR-550-34440; National Renewable Energy Laboratory: Golden, USA, 2003.

- Lovegrove, K.; Luzzi, A.; Soldiani, I.; Kreetz, H. Developing ammonia based thermochemical energy storage for dish power plants. Solar Energ. 2004, 76, 331–337. [Google Scholar] [CrossRef]

- Dahl, J.K.; Buechler, K.J.; Finley, R.; Stanislaus, T.; Weimer, A.W.; Lewandowski, A.; Bingham, C.; Smeets, A.; Schneider, A. Rapid solar-thermal dissociation of natural gas in an aerosol flow reactor. Energy 2004, 29, 715–725. [Google Scholar] [CrossRef]

- Kodama, T. High-temperature solar chemistry for converting solar heat to chemical fuels. Prog. Energ. Combust. Sci. 2003, 29, 567–597. [Google Scholar] [CrossRef]

- Lodhi, M.A.K. Helio-hydro and helio-thermal production of hydrogen. Int. J. Hydrogen Energy 2004, 29, 1099–1113. [Google Scholar]

- Stein, W. Solar Thermal Project; www.det.csiro.au/science/r_h/solarthermal.htmCSIRO: Canberra, Australia, 2005.

- DiPippo, R. Geothermal Power Generating Systems. In Geothermal Power Plants (Second Edition); Butterworth-Heinemann: Oxford, 2008; pp. 79–80. [Google Scholar]

- DiPippo, R. Worldwide State of Geothermal Power Plant Development as of May 2007. In Geothermal Power Plants (Second Edition); Butterworth-Heinemann: Oxford, 2008; pp. 413–432. [Google Scholar]

- MIT. The Future of Geothermal Energy; Massachusetts Institute of Technology: Boston, USA, 2006. [Google Scholar]

- Blodgett, L.; Slack, K. Geothermal 101: Basics of Geothermal Energy Production and Use; Geothermal Energy Association: Washington, USA, 2009. [Google Scholar]

- Taylor, M.A. The State of Geothermal Technology; Geothermal Energy Association: Washington, USA, 2007. [Google Scholar]

- DiPippo, R. Binary Cycle Power Plants. In Geothermal Power Plants (Second Edition); Butterworth-Heinemann: Oxford, 2008; pp. 157–189. [Google Scholar]

- DiPippo, R. Single-Flash Steam Power Plants. In Geothermal Power Plants (Second Edition); Butterworth-Heinemann: Oxford, 2008; pp. 81–112. [Google Scholar]

- DiPippo, R. Double-Flash Steam Power Plants. In Geothermal Power Plants (Second Edition); Butterworth-Heinemann: Oxford, 2008; pp. 113–133. [Google Scholar]

- DiPippo, R. Dry-Steam Power Plants. In Geothermal Power Plants (Second Edition); Butterworth-Heinemann: Oxford, 2008; pp. 135–156. [Google Scholar]

- Bertani, R. World geothermal power generation in the period 2001-2005. Geothermics 2005, 34, 651–690. [Google Scholar] [CrossRef]

- Dickson, M.H.; Fanelli, M. What is Geothermal Energy? http://www.geothermal-energy.org/geo/geoenergy.phpIstituto di Geoscienze e Georisorse: Pisa, Italy, 2004.

- DiPippo, R. Environmental Impact of Geothermal Power Plants. In Geothermal Power Plants (Second Edition); Butterworth-Heinemann: Oxford, 2008; pp. 385–410. [Google Scholar]

- Imroz Sohel, M.; Sellier, M.; Brackney, L.J.; Krumdieck, S. Efficiency improvement for geothermal power generation to meet summer peak demand. Energ. Policy 2009, 37, 3370–3376. [Google Scholar] [CrossRef]

- Sanner, B.; Bussmann, W. Current status, prospects and economic framework of geothermal power production in Germany. Geothermics 2003, 32, 429–438. [Google Scholar] [CrossRef]

- Stefánsson, V. Investment cost for geothermal power plants. Geothermics 2002, 31, 263–272. [Google Scholar] [CrossRef]

- Gawell, K.; Greenberg, G. Update on world geothermal development; http://www.geo-energy.org/publications/reports/GEA%20World%20Update%202007.pdfGeothermal Energy Association: Washington, DC, USA, 2007.

- Kagel, A.; Bates, D.; Gawell, K. A guide to geothermal energy and the environment; Geothermal Energy Association: Washington D.C., USA, 2007. [Google Scholar]

- DiPippo, R. The Geysers Dry-Steam Power Plants, Sonoma and Lake Counties, California, U.S.A. In Geothermal Power Plants (Second Edition); Butterworth-Heinemann: Oxford, 2008; pp. 277–297. [Google Scholar]

- IGA. Installed Generating Capacity; http://www.geothermal-energy.org/geoworld/geoworld.php?sub=elgenInternational Geothermal Association: Reykjavik, Iceland, 2009.

- GEA. Factors affecting costs of geothermal power development; Geothermal Energy Association: Washington D.C., USA, 2005. [Google Scholar]

- Hansson, J.; Berndes, G.; Johnsson, F.; Kjärstad, J. Co-firing biomass with coal for electricity generation--An assessment of the potential in EU27. Energ. Policy 2009, 37, 1444–1455. [Google Scholar] [CrossRef]

- Taylor, G. Biofuels and the biorefinery concept. Energ. Policy 2008, 36, 4406–4409. [Google Scholar] [CrossRef]

- Gokcol, C.; Dursun, B.; Alboyaci, B.; Sunan, E. Importance of biomass energy as alternative to other sources in Turkey. Energ. Policy 2009, 37, 424–431. [Google Scholar] [CrossRef]

- Siriwardhana, M.; Opathella, G.K.C.; Jha, M.K. Bio-diesel: Initiatives, potential and prospects in Thailand: A review. Energ. Policy 2009, 37, 554–559. [Google Scholar] [CrossRef]

- UN-Energy. Sustainable Bioenergy: A Framework for Decision-Makers; http://esa.un.org/un-energy/pdf/susdev.Biofuels.FAO.pdfUnited Nations: New York, USA, 2007.

- Righelato, R.; Spracklen, D.V. Carbon Mitigation by Biofuels or by Saving and Restoring Forests? Science 2007, 318, 902. [Google Scholar] [PubMed]

- Nonhebel, S. Energy from agricultural residues and consequences for land requirements for food production. Agr. Syst. 2007, 94, 586–592. [Google Scholar] [CrossRef]

- Lal, R. Land area for establishing biofuel plantations. Energ. Sustain. Dev. 2006, 10, 67–79. [Google Scholar] [CrossRef]

- Sims, R.E.H.; Taylor, M.; Saddler, J.; Mabee, W. From 1st- to 2nd-Generation Biofuel Technologies; International Energy Agency: Paris, France, 2008. [Google Scholar]

- Goldemberg, J.; Guardabassi, P. Are biofuels a feasible option? Energ. Policy 2009, 37, 10–14. [Google Scholar] [CrossRef]

- Demirbas, A. Biofuels sources, biofuel policy, biofuel economy and global biofuel projections. Energ. Conv. Manage. 2008, 49, 2106–2116. [Google Scholar] [CrossRef]

- Field, C.B.; Campbell, J.E.; Lobell, D.B. Biomass energy: the scale of the potential resource. Trend. Ecol. Evolut. 2008, 23, 65–72. [Google Scholar] [CrossRef]

- Perlack, R.D.; Wright, L.L.; Turhollow, A.F.; Graham, R.L.; Stokes, B.J.; Erbach, D.C. Biomass as a feedstock for a bioenergy and bioproducts industry: The technical feasibility of a billion-ton annual supply; US Department of Energy, US Department of Agriculture: Oak Ridge, USA, 2005.

- Haq, Z. Biomass for electricity generation. http://www.eia.doe.gov/oiaf/analysispaper/biomass/pdf/biomass.pdfU.S. Department of Energy, Energy Information Administration: Washington D.C., USA, 2003.

- Knight, B.; Westwood, A. World biomass review: Biomass as a global power source. Refocus 2004, 5, 42–44. [Google Scholar] [CrossRef]

- Hoogwijk, M.; Faaij, A.; de Vries, B.; Turkenburg, W. Exploration of regional and global cost-supply curves of biomass energy from short-rotation crops at abandoned cropland and rest land under four IPCC SRES land-use scenarios. Biomass Bioenerg. 2009, 33, 26–43. [Google Scholar] [CrossRef]

- Hoogwijk, M.; Faaij, A.; Eickhout, B.; de Vries, B.; Turkenburg, W. Potential of biomass energy out to 2100, for four IPCC SRES land-use scenarios. Biomass Bioenerg. 2005, 29, 225–257. [Google Scholar] [CrossRef]

- Smeets, E.; Faaij, A.P.C.; Lewandowski, I. A quickscan of global bio-energy potentials to 2050; NWS-E-2004-109; Copernicus Institute - Department of Science, Technology and Society: Utrecht University, Netherlands, 2004. [Google Scholar]

- Hoogwijk, M.; Faaij, A.; van den Broek, R.; Berndes, G.; Gielen, D.; Turkenburg, W. Exploration of the ranges of the global potential of biomass for energy. Biomass Bioenerg. 2003, 25, 119–133. [Google Scholar] [CrossRef]

- Moore, R.B. Algal Biofuels Industry. Adelaide, Australia, 2009. [Google Scholar]

- Kelly-Yong, T.L.; Lee, K.T.; Mohamed, A.R.; Bhatia, S. Potential of hydrogen from oil palm biomass as a source of renewable energy worldwide. Energ. Policy 2007, 35, 5692–5701. [Google Scholar] [CrossRef]

- Thornley, P.; Upham, P.; Huang, Y.; Rezvani, S.; Brammer, J.; Rogers, J. Integrated assessment of bioelectricity technology options. Energ. Policy 2009, 37, 890–903. [Google Scholar] [CrossRef]

- Soimakallio, S.; Mäkinen, T.; Ekholm, T.; Pahkala, K.; Mikkola, H.; Paappanen, T. Greenhouse gas balances of transportation biofuels, electricity and heat generation in Finland—Dealing with the uncertainties. Energ. Policy 2009, 37, 80–90. [Google Scholar] [CrossRef]

- Su, C.-L.; Lee, Y.-M. Development status and life cycle inventory analysis of biofuels in Taiwan. Energ. Policy 2009, 37, 754–758. [Google Scholar] [CrossRef]

- Searchinger, T.; Heimlich, R.; Houghton, R.H.; Dong, F.; Elobeid, A.; Fabiosa, J.; Togkoz, S.; Hayes, D.; Yu, T. Use of US croplands for biofuels increases greenhouse gases through emissions from land use change. Science 2008, 319, 1238–1240. [Google Scholar]

- Fargione, J.; Hill, J.; Tilman, D.; Polasky, S.; Hawthorne, P. Land clearing and the biofuel carbon debt. Science 2008, 319, 1235–1238. [Google Scholar] [CrossRef] [PubMed]

- Wicke, B.; Dornburg, V.; Junginger, M.; Faaij, A. Different palm oil production systems for energy purposes and their greenhouse gas implications. Biomass Bioenerg. 2008, 32, 1322–1337. [Google Scholar] [CrossRef]

- Foran, B.; Lenzen, M.; Dey, C. Balancing Act - A Triple Bottom Line Account of the Australian Economy; http://www.isa.org.usyd.edu.auCSIRO Resource Futures and The University of Sydney: Canberra, ACT, Australia, 2005.

- Gagnon, L.; Bélanger, C.; Uchiyama, Y. Life-cycle assessment of electricity generation options: The status of research in 2001. Energ. Policy 2002, 30, 1267–1278. [Google Scholar] [CrossRef]

- Ovando, P.; Caparrós, A. Land use and carbon mitigation in Europe: A survey of the potentials of different alternatives. Energ. Policy 2009, 37, 992–1003. [Google Scholar] [CrossRef]

- Fthenakis, V.; Kim, H.C. Land use and electricity generation: A life-cycle analysis. Renew. Sustain. Energy Rev. 2009, 13, 1465–1474. [Google Scholar] [CrossRef]

- Thornley, P.; Rogers, J.; Huang, Y. Quantification of employment from biomass power plants. Renewable Energy 2008, 33, 1922–1927. [Google Scholar] [CrossRef]

- Skytte, K.; Meibom, P.; Henriksen, T.C. Electricity from biomass in the European union-With or without biomass import. Biomass Bioenerg. 2006, 30, 385–392. [Google Scholar] [CrossRef]

- Münster, M.; Lund, H. Use of waste for heat, electricity and transport—Challenges when performing energy system analysis. Energy 2009, 34, 636–644. [Google Scholar] [CrossRef]

- Altman, I.; Johnson, T. Organization of the current U.S. biopower industry: A template for future bioenergy industries. Biomass Bioenerg 2009, 33, 779–784. [Google Scholar] [CrossRef]

- De, S.; Assadi, M. Impact of cofiring biomass with coal in power plants-A techno-economic assessment. Biomass Bioenerg. 2009, 33, 283–293. [Google Scholar] [CrossRef]

- Gan, J.; Smith, C.T. A comparative analysis of woody biomass and coal for electricity generation under various CO2 emission reductions and taxes. Biomass Bioenerg. 2006, 30, 296–303. [Google Scholar] [CrossRef]

- United Nations, Soaring biofuel demand driving up agricultural prices, says UN-backed report. UN News, 2007.

- Wang, L.; Weller, C.L.; Jones, D.D.; Hanna, M.A. Contemporary issues in thermal gasification of biomass and its application to electricity and fuel production. Biomass Bioenerg. 2008, 32, 573–581. [Google Scholar] [CrossRef]

- Fowler, P.; Krajačić, G.; Lončar, D.; Duić, N. Modeling the energy potential of biomass-H2RES. Int. J. Hydrogen Energy 2009, 34, 7027–7040. [Google Scholar] [CrossRef]

- Yin, C.; Rosendahl, L.A.; Kær, S.K. Grate-firing of biomass for heat and power production. Prog. Energ. Combust. Sci. 2008, 34, 725–754. [Google Scholar] [CrossRef]

- Taylor, G. Bioenergy for heat and electricity in the UK: A research atlas and roadmap. Energ. Policy 2008, 36, 4383–4389. [Google Scholar] [CrossRef]

- Bunn, M.; Malin, M.B. Enabling a nuclear revival – and managing its risks. Innovations 2009, 4, 173–191. [Google Scholar] [CrossRef]

© 2010 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Lenzen, M. Current State of Development of Electricity-Generating Technologies: A Literature Review. Energies 2010, 3, 462-591. https://doi.org/10.3390/en3030462

Lenzen M. Current State of Development of Electricity-Generating Technologies: A Literature Review. Energies. 2010; 3(3):462-591. https://doi.org/10.3390/en3030462