Impact of Turbulence Intensity and Equivalence Ratio on the Burning Rate of Premixed Methane–Air Flames

Abstract

:1. Introduction

2. Direct Numerical Simulation

3. Flame Configuration and Initialization

| Φ | (K) | (K) | (m/s) | (mm) | |||||

|---|---|---|---|---|---|---|---|---|---|

| 1.0 | 300 | 0.055 | 0.220 | 0.137 | 0.120 | 0.507 | 0.36 | 0.94–96.7 | |

| 0.9 | 300 | 0.049 | 0.221 | 0.133 | 0.111 | 0.426 | 0.40 | 1.27–81.4 | |

| 0.8 | 300 | 0.044 | 0.223 | 0.122 | 0.099 | 0.329 | 0.46 | 2.01–105.2 | |

| 0.7 | 300 | 0.039 | 0.224 | 0.108 | 0.088 | 0.228 | 0.56 | 3.84–159.7 | |

| 0.6 | 300 | 0.034 | 0.225 | 0.093 | 0.076 | 0.136 | 0.78 | 9.84–409.2 |

| Cases | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (m/s) | 2.0 | 4.0 | 6.0 | 8.0 | 10.0 | 12.0 | 14.0 | 16.0 | 18.0 | 20.0 | 22.0 |

| τ (ms) | 1.60 | 0.80 | 0.53 | 0.40 | 0.32 | 0.27 | 0.23 | 0.20 | 0.18 | 0.16 | 0.15 |

| Re | 410 | 821 |

4. Results and Discussion

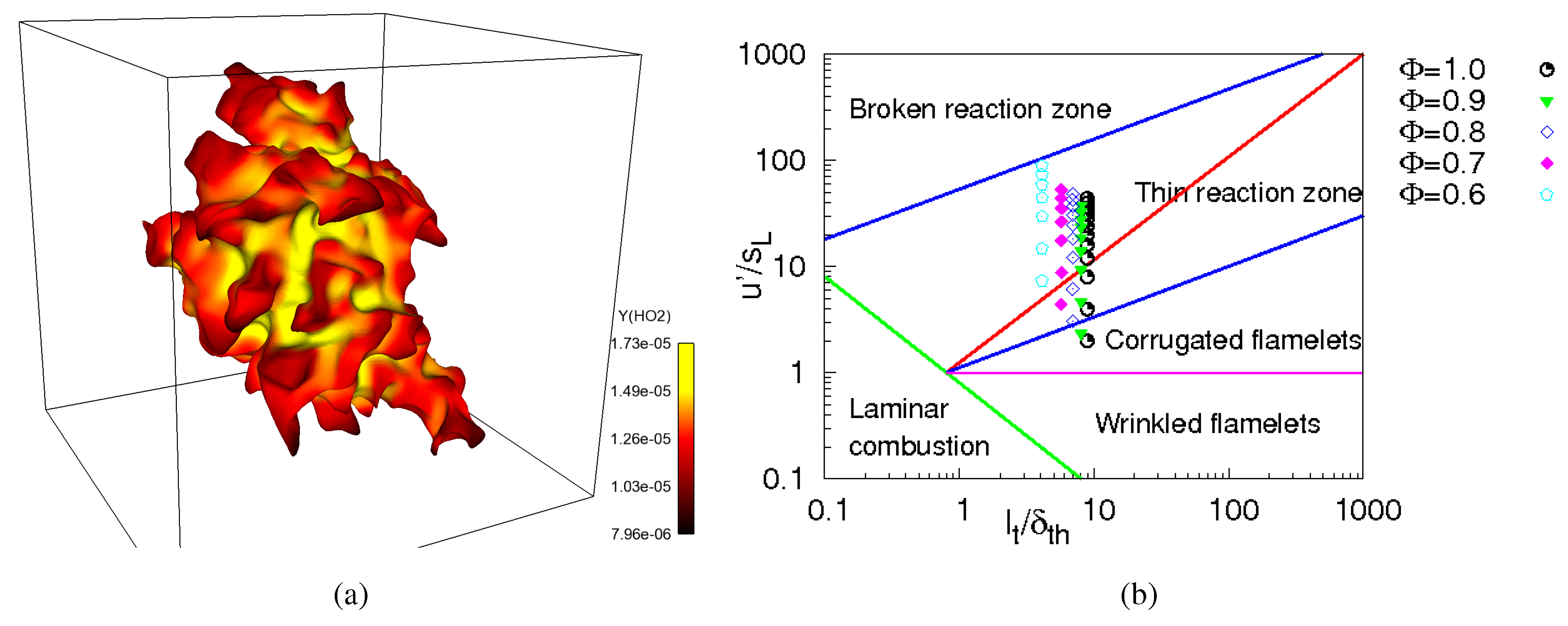

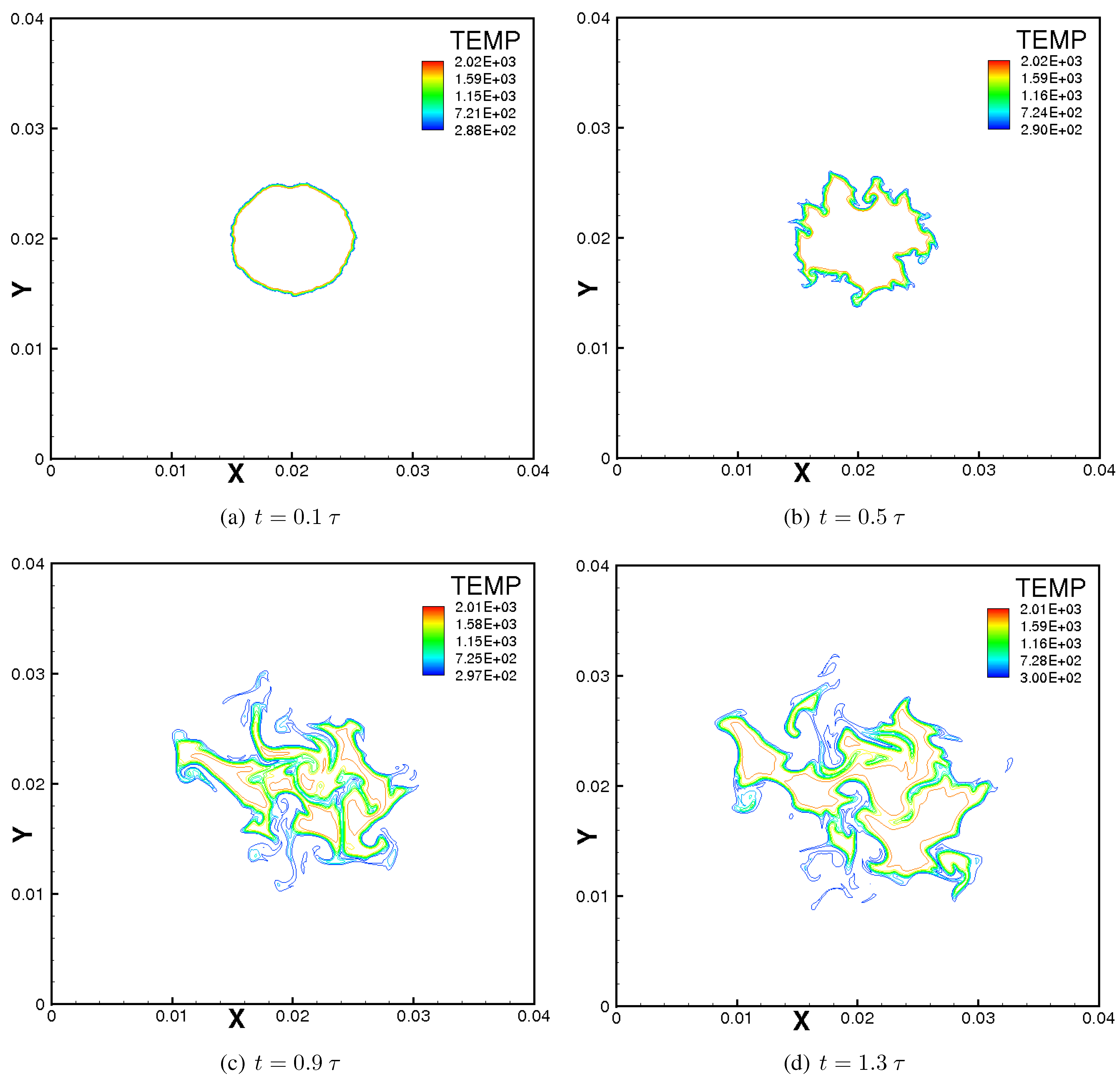

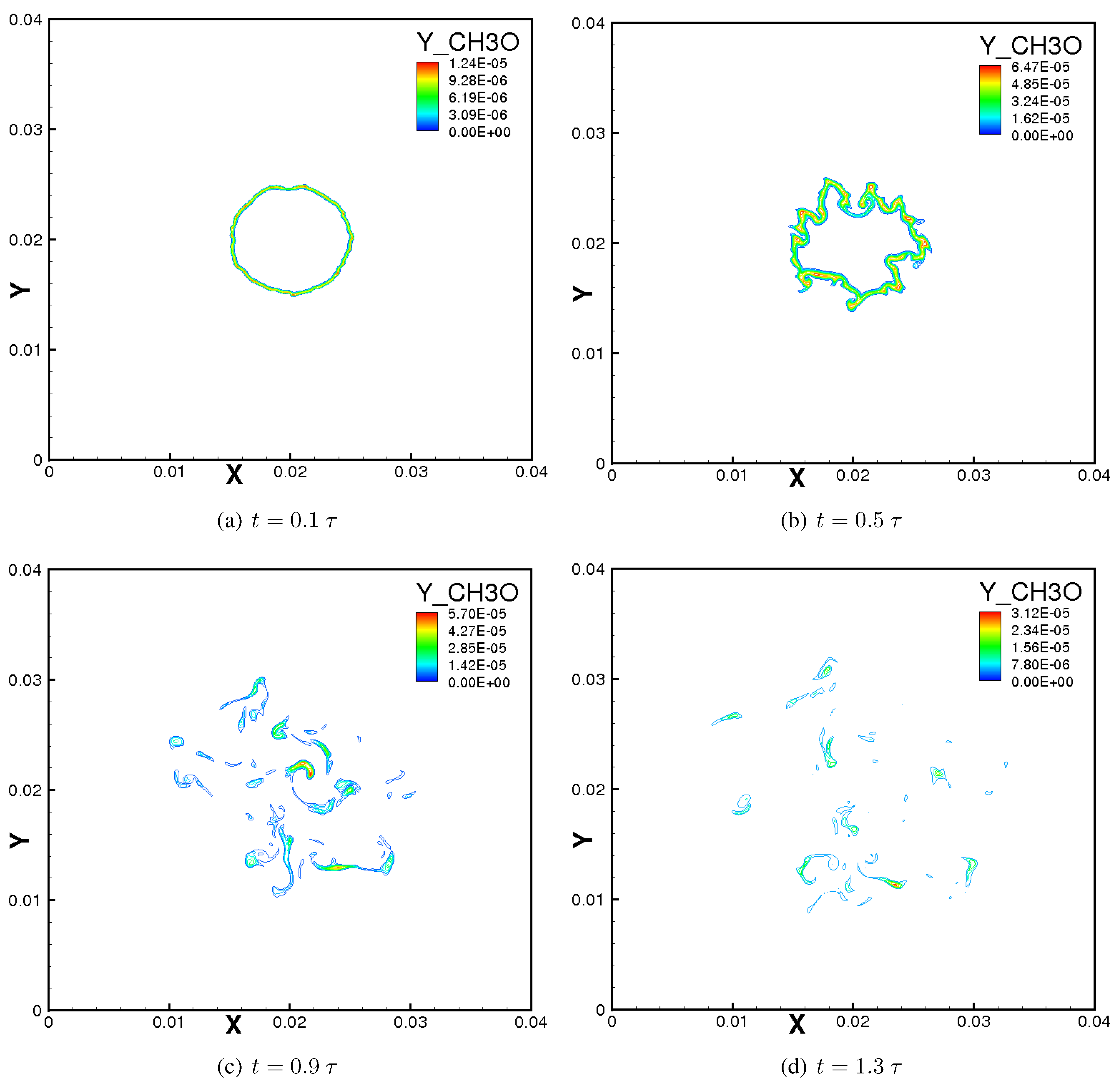

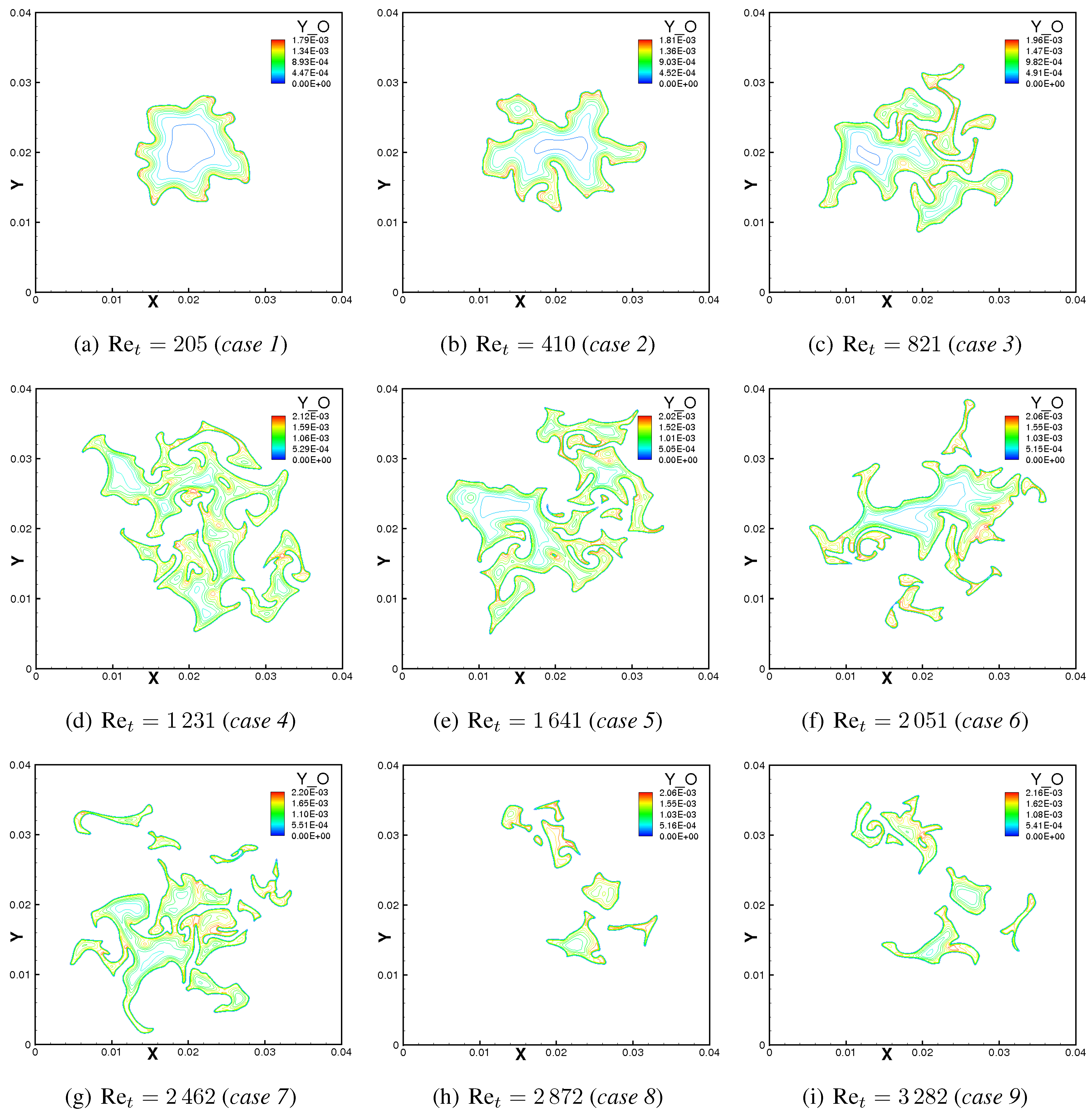

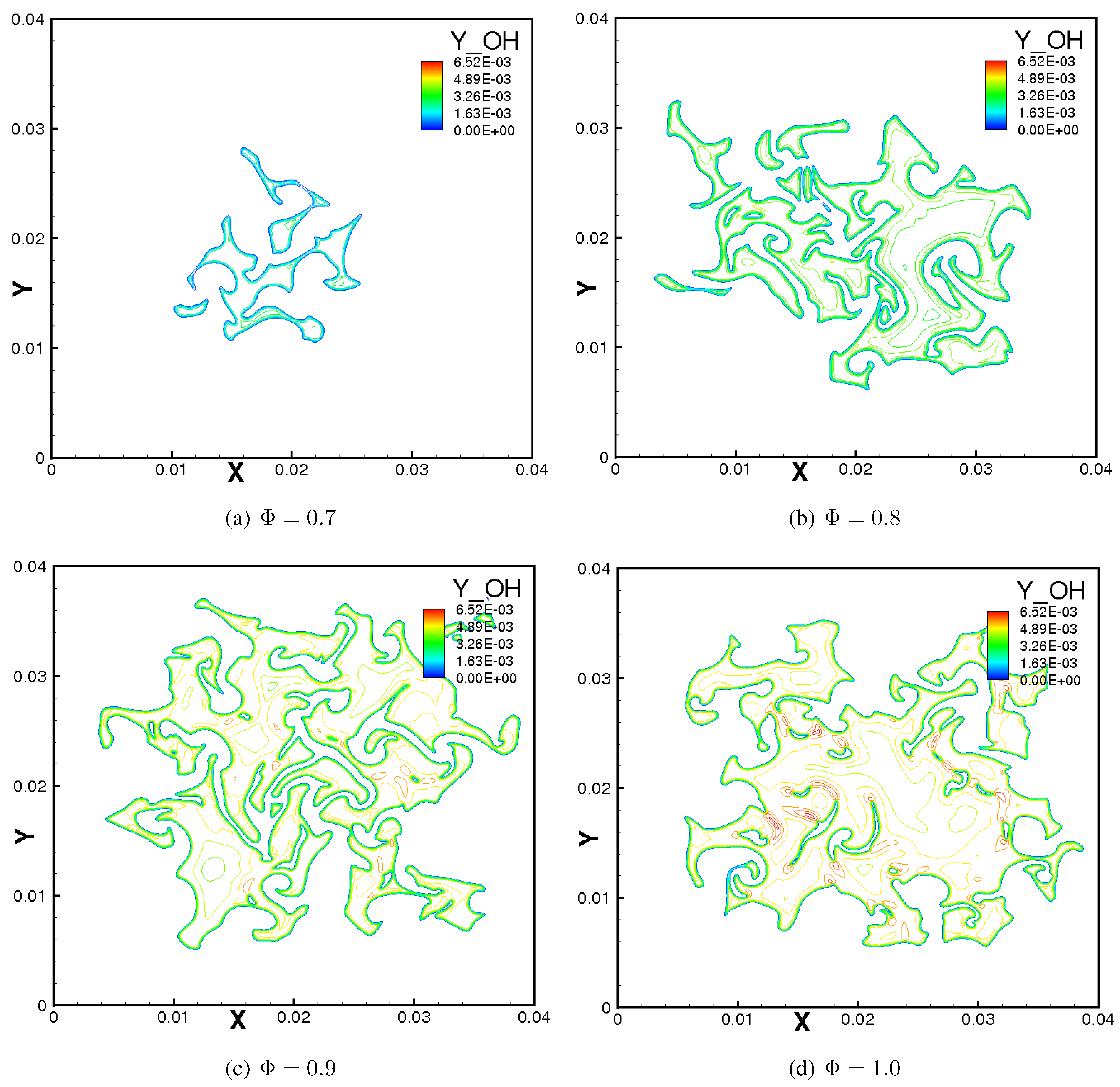

4.1. Turbulent Flame Structure

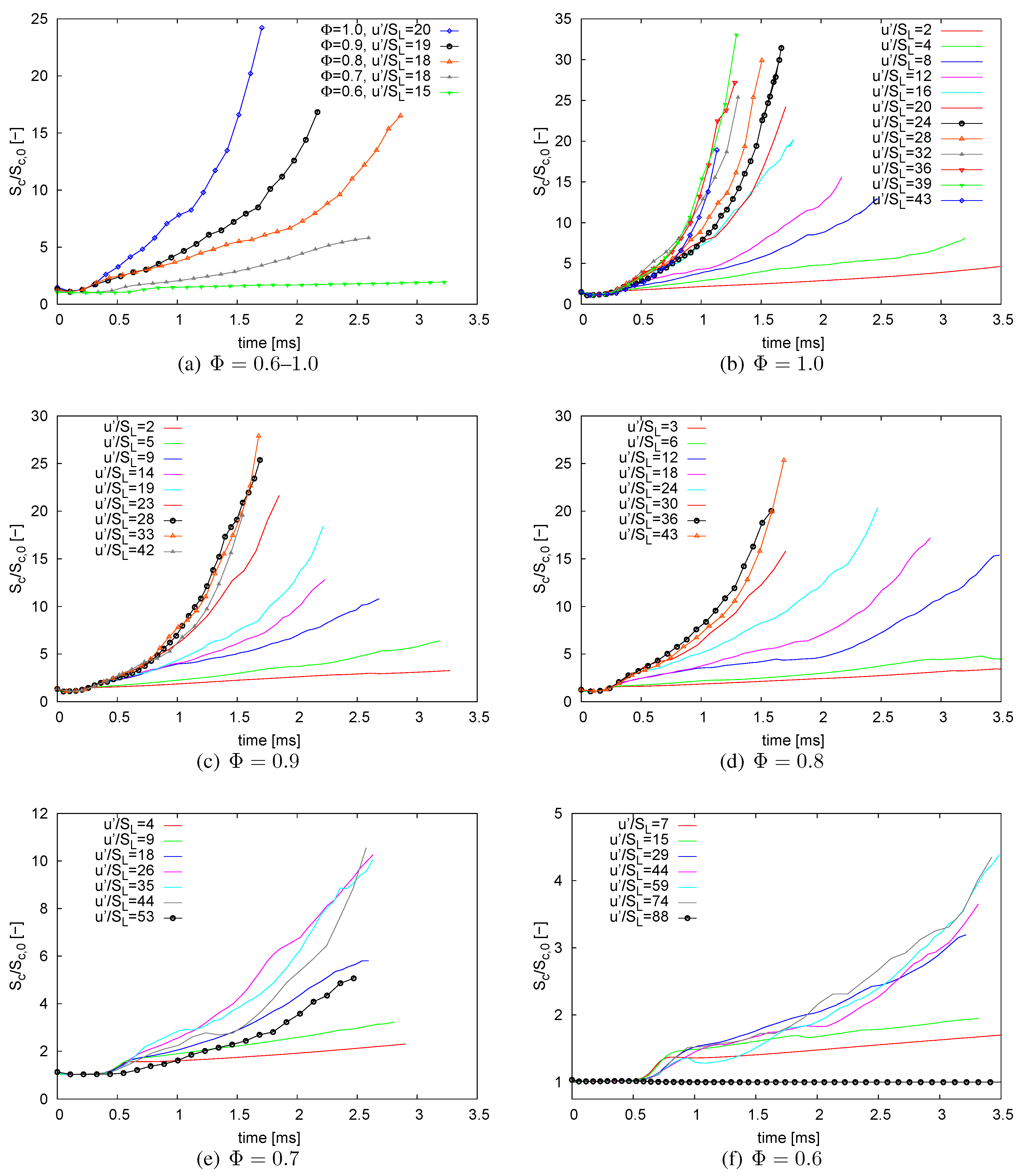

4.2. Turbulent Burning Velocity

5. Concluding Remarks

Acknowledgements

References

- Abdel-Gayed, R.; Bradley, D.; Lawes, M.; Lung, F. Premixed turbulent burning during explosions. Proc. Combust. Inst. 1986, 21, 497–504. [Google Scholar] [CrossRef]

- Abdel-Gayed, R.; Bradley, D.; Lawes, M. Turbulent burning velocities: A general correlation in terms of straining rates. Proc. R. Soc. Lond. 1987, A414, 389–413. [Google Scholar] [CrossRef]

- Driscoll, J. Turbulent premixed combustion: Flamelet structure and its effects on turbulent burning velocities. Prog. Energy Combust. Sci. 2008, 34, 91–134. [Google Scholar] [CrossRef]

- Peters, N. The turbulent burning velocity for large-scale and small-scale turbulence. J. Fluid Mech. 1999, 384, 107–132. [Google Scholar] [CrossRef]

- Abdel-Gayed, R.; Bradley, D. Criteria for turbulent propagation limits of premixed flames. Combust. Flame 1985, 62, 61–68. [Google Scholar] [CrossRef]

- Kozachenko, L.; Kuznetsov, I. Burning velocity in a turbulent stream of a homogeneous mixture. Combust. Explos. Shock Waves 1965, 1, 22–30. [Google Scholar] [CrossRef]

- Bradley, D. How fast can we burn? Proc. Combust. Inst. 1993, 24, 247–262. [Google Scholar] [CrossRef]

- Shy, S.; Jang, R.; Tang, C. Simulation of turbulent burning velocities using aqueous autocatalytic reactions in a near-homogeneous turbulence. Combust. Flame 1996, 105, 54–62. [Google Scholar] [CrossRef]

- Shy, S.; Lin, W.; Wei, J. An experimental correlation of turbulent burning velocities for premixed turbulent methane—air combustion. Proc. R. Soc. Lond. 2000, 456, 1997–2019. [Google Scholar] [CrossRef]

- Shy, S.; Lin, W.; Peng, K. High-intensity turbulent premixed combustion: General correlations of turbulent burning velocities in a new cruciform burner. Proc. Combust. Inst. 2000, 28, 561–568. [Google Scholar] [CrossRef]

- Cant, S. Direct Numerical Simulation of premixed turbulent flames. Philos. Trans. R. Soc. A Lond. 1999, 357, 3583–3604. [Google Scholar] [CrossRef]

- Yaldizli, M.; Mehravaran, K.; Mohammad, H.; Jaberi, F. The structure of partially premixed methane flames in high-intensity turbulent flows. Combust. Flame 2008, 154, 692–714. [Google Scholar] [CrossRef]

- Jenkins, K.; Cant, R. Curvature effects on flame kernels in a turbulent environment. Proc. Combust. Inst. 2002, 29, 2023–2029. [Google Scholar] [CrossRef]

- Haworth, D.; Blint, R.; Cuenot, B.; Poinsot, T. Numerical simulations of turbulent propane-air combustion with nonhomogenous reactants. Combust. Flame 2000, 121, 395–417. [Google Scholar] [CrossRef]

- Bell, J.; Day, M.; Grcar, J. Numerical Simulation of Premixed Turbulent Methane Combustion. Proc. Combust. Inst. 2002, 29, 1987–1993. [Google Scholar] [CrossRef]

- Chen, J.H.; Choudhary, A.; de Supinski, B.; DeVries, M.; Hawkes, E.R.; Klasky, S.; Liao, W.K.; Ma, K.L.; Mellor-Crummey, J.; Podhorszki, N.; et al. Terascale direct numerical simulations of turbulent combustion using S3D. Comput. Sci. Discov. 2009, 2, 31. [Google Scholar] [CrossRef]

- Tanahashi, M.; Nada, Y.; Ito, Y.; Miyauchi, T. Local flame structure in the well stirred reactor regime. Proc. Combust. Inst. 2002, 29, 2041–2049. [Google Scholar] [CrossRef]

- Sankaran, R.; Hawkes, E.; Chen, J. Structure of a spatially developing turbulent lean methane-air Bunsen flame. Proc. Combust. Inst. 2006, 31, 1291–1298. [Google Scholar] [CrossRef]

- Bell, J.; Day, M.; Shepherd, I.; Johnson, M.; Cheng, R.; Grcar, J.; Beckner, V.; Lijewski, M. Numerical Simulation of a laboratory scale turbulent V-flame. Proc. Natl. Acad. Sci. USA 2005, 102, 10006–10011. [Google Scholar] [CrossRef] [PubMed]

- Bell, J.; Day, M.; Grcar, J.; Lijewski, M.; Driscoll, J.; Filatyev, S. Numerical simulation of a laboratory-scale turbulent slot flame. Proc. Combust. Inst. 2007, 31, 1299–1307. [Google Scholar] [CrossRef]

- Veynante, D.; Vervisch, L. Turbulent combustion modeling. Prog. Energy Combust. Sci. 2002, 28, 193–266. [Google Scholar] [CrossRef]

- Thévenin, D.; Behrendt, F.; Maas, U.; Przywara, B.; Warnatz, J. Development of a parallel direct simulation code to investigate reactive flows. Comput. Fluids 1996, 25, 485–496. [Google Scholar] [CrossRef]

- Kee, R.; Miller, J.; Jefferson, T. Chemkin, a General Purpose Problem-Independent Transportable FORTRAN Chemical Kinetics Code Package; Technical Report SAND80-8003; Sandia National Laboratry: Albuquerque, NM, USA, 1980. [Google Scholar]

- Ern, A.; Giovangigli, V. Eglib Server and User’s Manual. Available online: http://www.cmap.polytechnique.fr/www.eglib (accessed on 1 June 2009).

- Kuo, K. Principles of Combustion; John Wesley & Sons, Inc.: New York, NY, USA, 2005. [Google Scholar]

- Laverdant, A. Notice d’utilisation du Programme SIDER (PARCOMB3D); Technical Report RT 2/13635 DEFA; The French Aerospace Laboratry, ONERA: Chatillon, French, 2008. [Google Scholar]

- Fru, G.; Janiga, G.; Thévenin, D. Direct Numerical Simulation of highly turbulent premixed flames burning methane. In Direct and Large-Eddy Simulation VIII; Kuerten, H., Ed.; ERCOFTAC Series; Springer-Verlag: Eindhoven, The Netherlands, 2011; pp. 327–332. [Google Scholar]

- Fru, G.; Janiga, G.; Thévenin, D. Simulation of turbulent combustion processes under realistic conditions. In DEISA Digest 2011; Turunen, A., Lederer, H., Autio, T., Pyysalo, S., Morgan, N., Rötkönen, P., Eds.; Extreme Computing in Europe Series; DEISA Media: Garching, Germany, 2011; pp. 20–22. [Google Scholar]

- Honein, A.; Moin, P. Higher entropy conservation and numerical stability of compressible turbulence simulations. J. Comput. Phys. 2004, 201, 531–545. [Google Scholar] [CrossRef]

- Baum, M.; Poinsot, T.; Thévenin, D. Accurate boundary conditions for multicomponent reactive flows. J. Comput. Phys. 1995, 116, 247–261. [Google Scholar] [CrossRef]

- Hilbert, R.; Thévenin, D. Influence of differential diffusion on maximum flame temperature in turbulent nonpremixed hydrogen/air flames. Combust. Flame 2004, 138, 175–187. [Google Scholar] [CrossRef]

- Klein, M.; Sadiki, A.; Janicka, J. A digital filter based generation of inflow data for spatially developing direct numerical or large eddy simulations. J. Comput. Phys. 2003, 186, 652–665. [Google Scholar] [CrossRef]

- Kempf, A.; Klein, M.; Janicka, J. Efficient generation of initial and inflow-conditions for transient flows in arbitrary geometries. Flow Turbul. Combust. 2005, 74, 67–84. [Google Scholar] [CrossRef]

- Smooke, M.D.; Giovangigli, V. Formulation of the premixed and nonpremixed test problems. In Reduced Kinetic Mechanism and Asymptotic Approximations for Methane-Air Flames; Smooke, M.D., Ed.; Springer-Verlag: New York, NY, USA, 1991; Volume 384, pp. 1–28. [Google Scholar]

- James, S.; Jaberi, F. Large scale simulations of two-dimensional nonpremixed methane jet flames. Combust. Flame 2000, 123, 465–487. [Google Scholar] [CrossRef]

- Fru, G.; Janiga, G.; Thévenin, D. Direct Numerical Simulation of turbulent methane flames with and without volume viscosity. In 8th Euromech Fluid Mechanics Conference (EFMC-8), Munich, Germany, 13–16 September 2010. paper MS2–9.

- Rutland, C.; Ferziger, J.; El-Thary, S. Full numerical simulations and modeling of turbulent premixed flames. Proc. Combust. Inst. 1990, 23, 621–627. [Google Scholar] [CrossRef]

- Bédat, B.; Egolfopoulos, F.; Poinsot, T. Direct Numerical Simulation of heat release and NOx formation in turbulent non premixed flames. Combust. Flame 1999, 119, 69–83. [Google Scholar] [CrossRef]

- Abdel-Gayed, R.; Al-khishali, K.; Bradley, D. Turbulent Burning Velocities and Flame Straining in Explosions. Proc. R. Soc. Lond. 1984, A391, 393–414. [Google Scholar] [CrossRef]

- Poinsot, T.; Echekki, T.; Mungal, M. A study of the laminar flame tip and implications for premixed turbulent combustion. Combust. Sci. Technol. 1992, 81, 45–73. [Google Scholar] [CrossRef]

- Im, H.; Chen, J. Effects of flow transients on the burning velocity of laminar hydrogen/air premixed flames. Proc. Combust. Inst. 2000, 28, 1833–1840. [Google Scholar] [CrossRef]

- Sankaran, R.; Im, H. Effect of hydrogen addition on the flammability limit of stretched methane/air premixed flames. In Proceedings of the Third Joint Meeting of the U.S. Section of the Combustion Institute, Chicago, IL, USA, March 2003; pp. 1–6.

- Zistl, C.; Hilbert, R.; Janiga, G.; Thévenin, D. Increasing the efficiency of post-processing for turbulent reacting flows. Comput. Visual. Sci. 2009, 12, 383–395. [Google Scholar] [CrossRef]

- Poinsot, T.; Veynante, D. Theoretical and Numerical Combustion, 2nd ed.; R.T. Edwards, Inc.: Philadelphia, PA, USA, 2005. [Google Scholar]

- Warnatz, J.; Maas, U.; Dibble, R.W. Combustion: Physical and Chemical Fundamentals, Modeling and Simulations, Experiments, Pollutant Formation, 3rd ed.; Springer: Berlin, Germany, 2001. [Google Scholar]

- Abdel-Gayed, R.; Bradley, D.; Hamid, N.; Lawes, M. Lewis number effects on turbulent burning velocity. Proc. Combust. Inst. 1985, 20, 505–512. [Google Scholar] [CrossRef]

- Shepherd, I.; Cheng, R. The burning rate of premixed flames in moderate and intense turbulence. Combust. Flame 2001, 127, 2066–2075. [Google Scholar] [CrossRef]

- Pocheau, A. Front propagation in a turbulent medium. Europhys. Lett. 1992, 20, 404–406. [Google Scholar] [CrossRef]

- Shalaby, H.; Thévenin, D. Statistically significant results for the propagation of a turbulent flame kernel using direct numerical simulation. Flow Turbul. Combust. 2010, 84, 357–367. [Google Scholar] [CrossRef]

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Fru, G.; Thévenin, D.; Janiga, G. Impact of Turbulence Intensity and Equivalence Ratio on the Burning Rate of Premixed Methane–Air Flames. Energies 2011, 4, 878-893. https://doi.org/10.3390/en4060878

Fru G, Thévenin D, Janiga G. Impact of Turbulence Intensity and Equivalence Ratio on the Burning Rate of Premixed Methane–Air Flames. Energies. 2011; 4(6):878-893. https://doi.org/10.3390/en4060878

Chicago/Turabian StyleFru, Gordon, Dominique Thévenin, and Gábor Janiga. 2011. "Impact of Turbulence Intensity and Equivalence Ratio on the Burning Rate of Premixed Methane–Air Flames" Energies 4, no. 6: 878-893. https://doi.org/10.3390/en4060878