1. Introduction

Among various enhanced oil recovery (EOR) methods, polymer flooding has been considered as an attractive alternative to conventional waterflooding for many reservoirs [

1,

2,

3]. It is also one of the most mature EOR techniques because relatively minor modifications need be made to a waterflood to enable polymer injection and recovery of additional oil. Polymers provide mobility control to yield a more stable displacement and a sharper front by increasing the viscosity of the injected aqueous phase.

The economic success of polymer flooding is particularly susceptible to injection rate or injectivity, which is directly related in turn to the viscosity of the injection fluids [

4]. The viscosity can be affected by a number of factors such as polymer concentration, temperature, and salinity [

5,

6]. In addition, polymers are of interest in EOR applications because of their rheological properties in dilute solutions. Polymeric additives usually make the displacement fluids exhibit non-Newtonian rheological behavior. Normally, polymer solutions used in EOR processes are shear-thinning or pesudoplastic fluids in a viscometer, whose apparent viscosity decreases in a reservoir with increasing shear rate. Some polymer solutions may exhibit pseudodilatant behavior in porous media [

7,

8]. The shear-thinning behavior is beneficial from the standpoint of injectivity, because the viscosity near the injection well is lower due to higher shear rate, which provides more favorable injectivity. Once the polymer moves far into the reservoir, shear rates decline and the viscosity increases, which provides the desired mobility control. However, shear-thinning may be undesirable in terms of sweep efficiency and resulting oil recovery, especially in heterogeneous reservoirs.

The rheological properties of polymer systems under reservoir conditions have been recognized as one of the most important factors governing the success of a polymer flood. Shear-thinning behavior may impair sweep and oil recovery by inducing instability and/or exacerbating velocity contrast [

3]. However, Seright [

9] suggested that the vertical sweep efficiency using shear-thinning fluids is not expected to be dramatically different from that for Newtonian or shear-thickening fluids for practical conditions during polymer floods. In spite of possible sweep impairment, effects of shear-thinning behavior on the oil recovery have not been investigated in detail.

When polymer flooding is considered, it is required to evaluate rheological properties of the polymer solution and their effects on the performance of the process. Although fluid viscosity is a critical property in many polymer applications, there is relatively little published information regarding multi-phase shear-thinning fluid flow in the reservoir or numerical modeling for such analyses [

3,

10]. Accurate assessment of the potential for polymer flooding projects requires a detailed model on the viscosity of polymer solution as a function of shear rates.

The objective of this work was to evaluate polymer flood processes associated with polymer solutions by adopting a shear-thinning viscosity model for use in reservoir simulation. From simulations using Newtonian and non-Newtonian models, the changes in oil recovery are investigated for multi-layered heterogeneous reservoirs. Parameters considered in this study include coefficients of a shear-thinning viscosity model, heterogeneities of permeability, and the degree of crossflow among layers which are expected to induce different shear rates and affect polymer injection and flood performance in result.

2. Mathematical Theory

2.1. Flow and Viscosity Model

Among the most advanced chemical EOR simulators, a general simulator named UTCHEM has proven to be particularly useful for modeling multicomponent and multiphase transport processes [

11]. UTCHEM has been extensively verified by comparing to analytical solutions of simple problems such as Buckley-Leverett flow and tracer transport in the quarter of a 5-spot and experimental measurements for its ability to predict the flow of fluids through the reservoir. Thus, UTCHEM will be used in this study to investigate shear-thinning effects in various reservoir models during the simulation of multi-dimensional polymer flood processes for enhanced recovery of remaining oil. The basic mass conservation equation for components can be written as follows [

12]:

where

κ is component index,

l is phase index including water (

) and oil (

) phases,

φ is porosity,

is overall concentration of component

κ (volume fraction),

is density of component

κ (ML

−3),

is number of phases,

is concentration of component

κ in phase

l (volume fraction),

is Darcy flux of phase

l (Lt

−1),

is saturation of phase

l,

is total source/sink term for component

κ (volume of component

κ per unit volume of porous media per unit time),

is dispersion tensor. The overall concentration (

) denotes the volume of component

κ summed over all phases.

The phase flux from Darcy’s law is:

where

k is the intrinsic permeability tensor,

h the vertical depth,

the relative permeability,

the viscosity, and

the specific weight for phase

l. Relative permeabilities are modeled based on Corey functions with parameters of endpoint (

), exponent (

), and residual saturation (

).

Liquid phase viscosities are important parameters to determine phase fluxes given by Equation (2). The viscosity of polymer solutions at zero shear rate,

, depends on the effective salinity and polymer concentration and has traditionally been modeled by the Flory-Huggins equation:

where

is the polymer concentration in aqueous phase and

is the brine viscosity,

’s are constants,

is the effective salinity, and

is the slope of

vs. on a log-log plot. The following equations should be used to calculate the effective salinity:

where

and

are anion and divalent cation concentration in the aqueous phase and

is a parameter magnifying the strength of divalent cation concentration.

The apparent viscosity decreases with increased shear rate because the polymer molecules are able to align themselves with the shear field to reduce internal friction. An appreciation of the shear-thinning properties of polymer solutions and the calculation of shear rate for each phase leads to apparent viscosity for the solution in the given reservoir conditions. Meter model is used to account the reduction in the apparent viscosity of shear-thinning fluids as a function of shear rate (

):

where

is an empirical coefficient, and

is the value of shear rate where polymer viscosity is reduced by half. Two primary parameters in Meter’s equation are

and

. The shear rate for phase

l is modeled by:

where

is the empirical shear rate coefficient and

is the appropriate average permeability. The injectivity of a well,

I, is defined as:

where

is the volumetric injection rate into the well and

is pressure drop between the bottom-hole flowing pressure and reference pressure [

4]. In this study,

is considered as a pressure drop at the well block.

2.2. Sweep Impairment

According to AlSofi

et al. [

3], shear thinning affects sweep mainly by exacerbating the velocity contrast and/or inducing instability. Velocity contrast can be regarded as an additional preferential penetration of shear-thinning fluids in comparison to a Newtonian fluid. A shear-thinning fluid has higher tendency to flow in the high permeability layer due to lower viscosity at higher shear. Some of the previous work deals with an experiment on the core where the effects of shear-thinning behavior are included [

9,

13]. These studies have shown that understanding and modeling of polymer rheology in porous media are also important for successful implementation of polymer flood though viscosity of the polymer solution is of far greater relevance to sweep. This study has tried to capture the effects of non-Newtonian fluid on the sweep, oil recovery, and injectivity in the heterogeneous multilayered reservoir.

3. Modeling

While many experimental studies have examined the rheological stability of EOR polymers, very few of the data have been employed for a quantitative investigation of the effects of shear-rate dependence on polymer transport in a reservoir and on the performance of polymer EOR processes. The simulation scheme of UTCHEM, together with the apparent viscosity calculation equation allows a more quantitative prediction of the shear-rate effects.

The problem concerns the performance of a polymer flooding process in a three-dimensional oil reservoir that includes the reservoir height, i.e., gravity and capillary forces are simultaneously considered. The computational domain consists of a hypothetical site of one-quarter of an injection-well-centered five-spot. The modeled system used in this study is a square reservoir with a horizontal area of 450 × 450 ft2 and a vertical thickness of 25 ft. Vertically, the simulation domain consists of five layers; and each layer is discretized into 15 × 15 grid blocks. Each grid block has dimensions of 30, 30, and 5 ft for x, y, and z directions, respectively. The outer boundary is represented as a noflow and adiabatic boundary to simulate symmetry in an array.

The model assumes that the reservoir is originally saturated with oil and water. Initial saturations of water and oil were assumed constant everywhere in the reservoir at 0.38 and 0.62, respectively. The viscosities of brine and oil are 0.73 cp and 40 cp at reservoir condition, respectively.

Permeability heterogeneity is one of the most important factors that leads to low sweep efficiency in oil recovery from petroleum reservoirs. The largest changes in reservoir permeability typically occur in the vertical direction. Simulation studies were performed for simplified five-layer reservoir model. Horizontal permeabilities are given in

Table 1 from the top to the bottom-layers. The average permeability is 100 md. The permeability contrast in vertical to horizontal direction (

) is set to be 0.0 to 1.0 to examine the effects of crossflow between layers.

Table 1.

Permeability of layers.

Table 1.

Permeability of layers.

| Cases | Horizontal Permeabilities (md) | σ(lnk) |

|---|

| uniform | 100, 100, 100, 100, 100 | 0 |

| low contrast | 149, 122, 100, 82, 67 | 0.3156 |

| medium contrast | 272, 165, 100, 61, 37 | 0.7882 |

| high contrast | 739, 272, 100, 37, 14 | 1.5697 |

Water or polymer solution is pumped into the injection well at constant flow rates qinj = 1000 ft3/day and continued over a simulation period of 1825 days. The reservoir fluids are recovered from the production well constrained with pressure at 100 psia, the same pressure as the initial reservoir pressure.

In order to clarify the effects of shear-rate dependence during the flow of polymer solution through the reservoir, comparisons were made among results from simulations under different fluid and reservoir models of polymer flood. Input parameters for the simulations are mainly obtained from an earlier simulation study presented in the reference [

14] and define the physical properties of reservoir, fluid properties, and chemical properties, as given in

Table 2.

Table 2.

Input parameters for simulation. (a) properties of reservoir rock and fluids; (b) polymer properties.

(a)

| Rock | porosity (φ) | 0.20 |

| depth | 2000 ft |

| permeability (k) | horizontal () | 100 md |

| ratio (kv/kh) | 0.0–1.0 |

| compressibility (cr) | 0 psi−1 |

| Relative permeability | endpoint () | water () | 0.2 |

| oil () | 1.0 |

| exponent () | water () | 1.5 |

| oil () | 2.0 |

| residual saturation () | water () | 0.2 |

| oil () | 0.2 |

| Fluids | viscosity (μ) | water (μw) | 0.73 cp |

| oil (μo) | 40 cp |

| density (ρ) | water (ρw) | 0.43353 psi/ft |

| oil (ρo) | 0.385839 psi/ft |

| compressibility | water (cw) | 0 psi−1 |

| oil (co) | 0 psi−1 |

(b)

| Viscosity | parameters for zero shear viscosity | Ap1 | 38.47 wt%−1 |

| Ap2 | 1600 wt%−2 |

| Ap3 | 0 wt%−3 |

| parameters for effective salinity | βp for CSEP | 20 |

| CSEP, min | 0.01 meq/mL |

| slope of vs. CSEP | −0.3 |

| parameters for shear rate dependence | | 130 |

| 280 s−1 |

| 1.0–2.6 |

4. Results and Discussion

The model evaluated the flow of brine associated with polymer and oil through a reservoir during the process. In the runs, oil of 40 cp was displaced with brine or brine with polymer injected at constant rate. Polymer concentration changes from 0.1 to 0.0%, being graded in the chase water. The salinities of reservoir connate water and injected water are same.

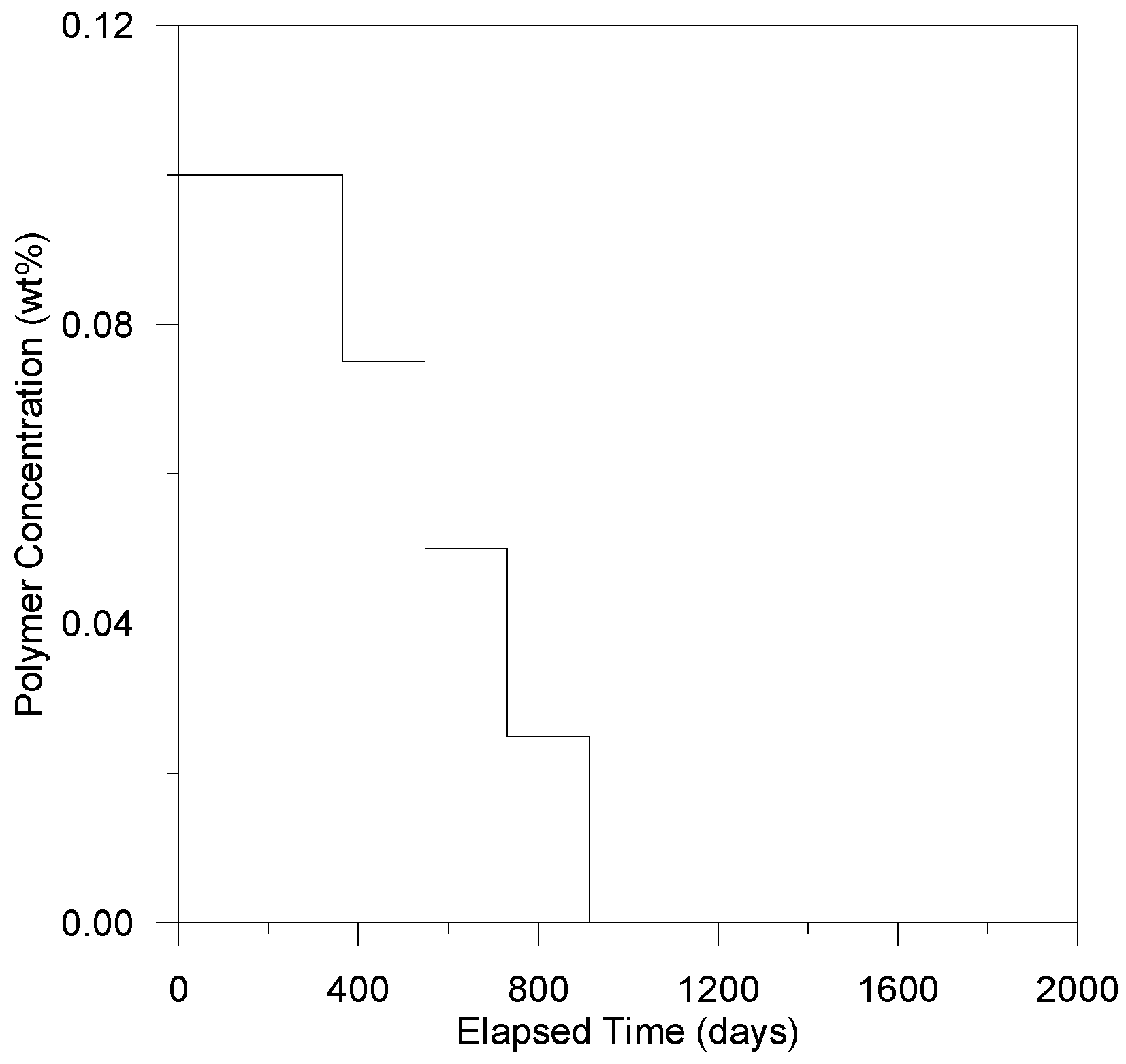

Figure 1 shows concentration data used in the simulations. To understand the effects of various parameters on the oil recovery, simulation was performed with the injection sequence of polymer flooding followed by waterflooding.

Figure 1.

History of polymer concentration in the injecting water.

Figure 1.

History of polymer concentration in the injecting water.

4.1. Dependency

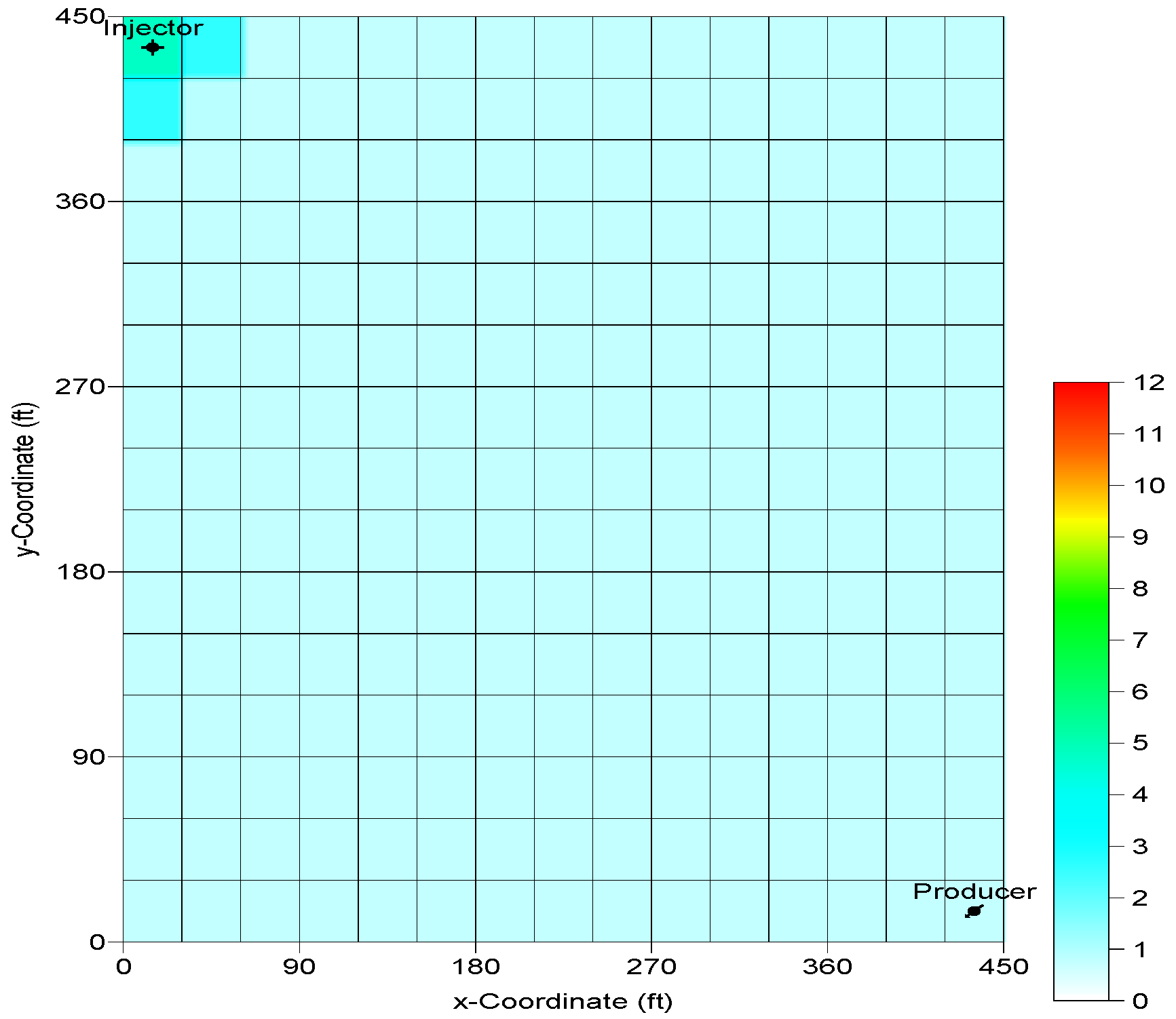

The simulation results obtained from the highly heterogeneous case with

and 2.6 are compared.

Figure 2 and

Figure 3 shows the saturation of oil phase and viscosity in the aqueous phase for layers 1, 3 and 5 at 1283 days or 0.9057 pore volume injected. Due to permeability heterogeneity, a clear velocity contrast exists between layers. Therefore, shear-thinning property of polymer solution affects front location and production performance. For the case of

, a greater distance separates the fronts between the most and least permeable layers.

Comparisons of aqueous phase viscosities in layers 1, 3, and 5 predicted from the simulations are given in

Figure 3. Due to permeability of each layer, the fronts were at various distances from the injection well. Injection of shear-thinning fluid leads to significantly lower viscosity near the injection well where shear rate is higher. The viscosity decreases gradually behind the front due to higher shear rate near the injection well irrespective of almost same polymer concentration. However, the viscosity of Newtonian fluid is directly proportional to the polymer concentration in aqueous phase.

Figure 2.

Oil phase saturation of layers 1, 3, and 5 at 1,283 days for and with different : (a) ; (b) .

Figure 2.

Oil phase saturation of layers 1, 3, and 5 at 1,283 days for and with different : (a) ; (b) .

Figure 3.

Water phase viscosity of layers 1, 3, and 5 at 1,283 days for and with different . (a) ; (b) .

Figure 3.

Water phase viscosity of layers 1, 3, and 5 at 1,283 days for and with different . (a) ; (b) .

Figure 4 compares estimated polymer concentrations in layer 5 for Newtonian and shear-thinning solutions. At later time, the concentration at the front located far from the injection well is equal to or less than the injection concentration due to dispersion inside the reservoir. However, the viscosity increases due to lower shear rate as the front of shear-thinning fluid has a certain distance from the injection well and moves at much lower velocity to the production well. A comparison of the two viscosity distribution indicates a clear difference between the floods with the Newtonian and shear-thinning fluids.

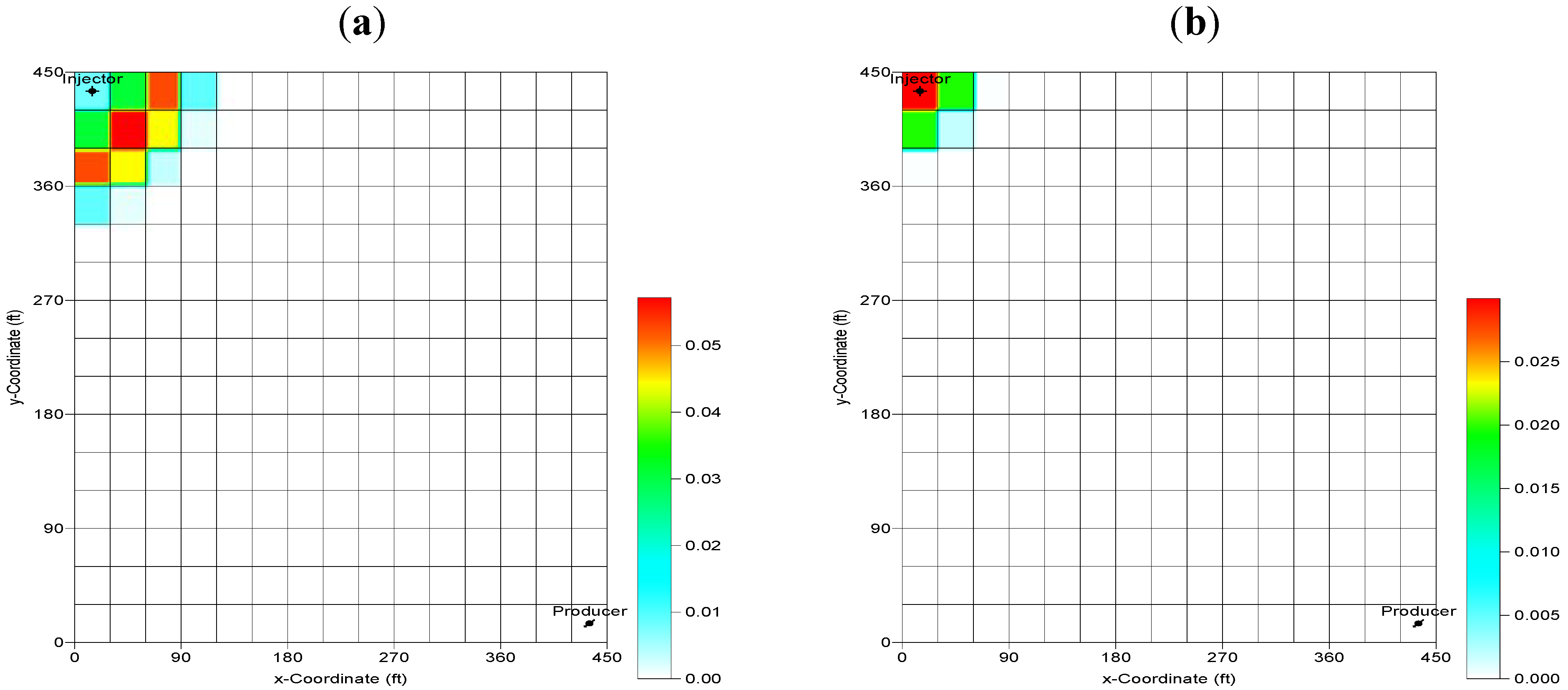

Several cases were studied in which the sensitivity of oil recovery and water-oil ratio to the consideration of in evaluating fluid viscosity and heterogeneity of layered reservoir was determined. Differences in oil recovery and water-oil ratio were compared over production period.

Simulation studies on the performance of polymer flood have been carried out with the dependency of fluid viscosities on the parameter in the reservoir without crossflow. Four cases were considered in which the parameters were varied from 1.0 (Newtonian) to 2.6.

Figure 4.

Polymer concentration in water phase of layer 5 at 1,283 days for and with different . (a) . (b) .

Figure 4.

Polymer concentration in water phase of layer 5 at 1,283 days for and with different . (a) . (b) .

Figure 5a–d show oil recovery and water-oil ratio in ft

3/ft

3 of polymer flood predicted from simulations for constant flow rate. As can be seen, oil recovery decreases less than 3% by non-Newtonian behavior in homogeneous reservoir.

Figure 5.

History of production wells obtained from simulations for with different and permeability heterogeneity. (a) ; (b) ; (c) ; (d) .

Figure 5.

History of production wells obtained from simulations for with different and permeability heterogeneity. (a) ; (b) ; (c) ; (d) .

The results become a lot more sensitive to change in values as become larger. Reservoir heterogeneity seems to have a pronounced effect on the tertiary oil recovery efficiency. For the case of , the cumulative oil recovery decreases more than 22% from 0.5699 to 0.4379. For highly heterogeneous reservoir, the recovery decreases more than 30%. Shear-thinning properties also increase water-oil ratio. This observation results from the fact that rapid increase in WOR occurs due to polymer solution’s preferential penetration into high permeability layer due to lower viscosity near the injection well. Therefore, a larger decrease in oil recovery is observed for shear-thinning fluid injected into highly-heterogeneous reservoirs.

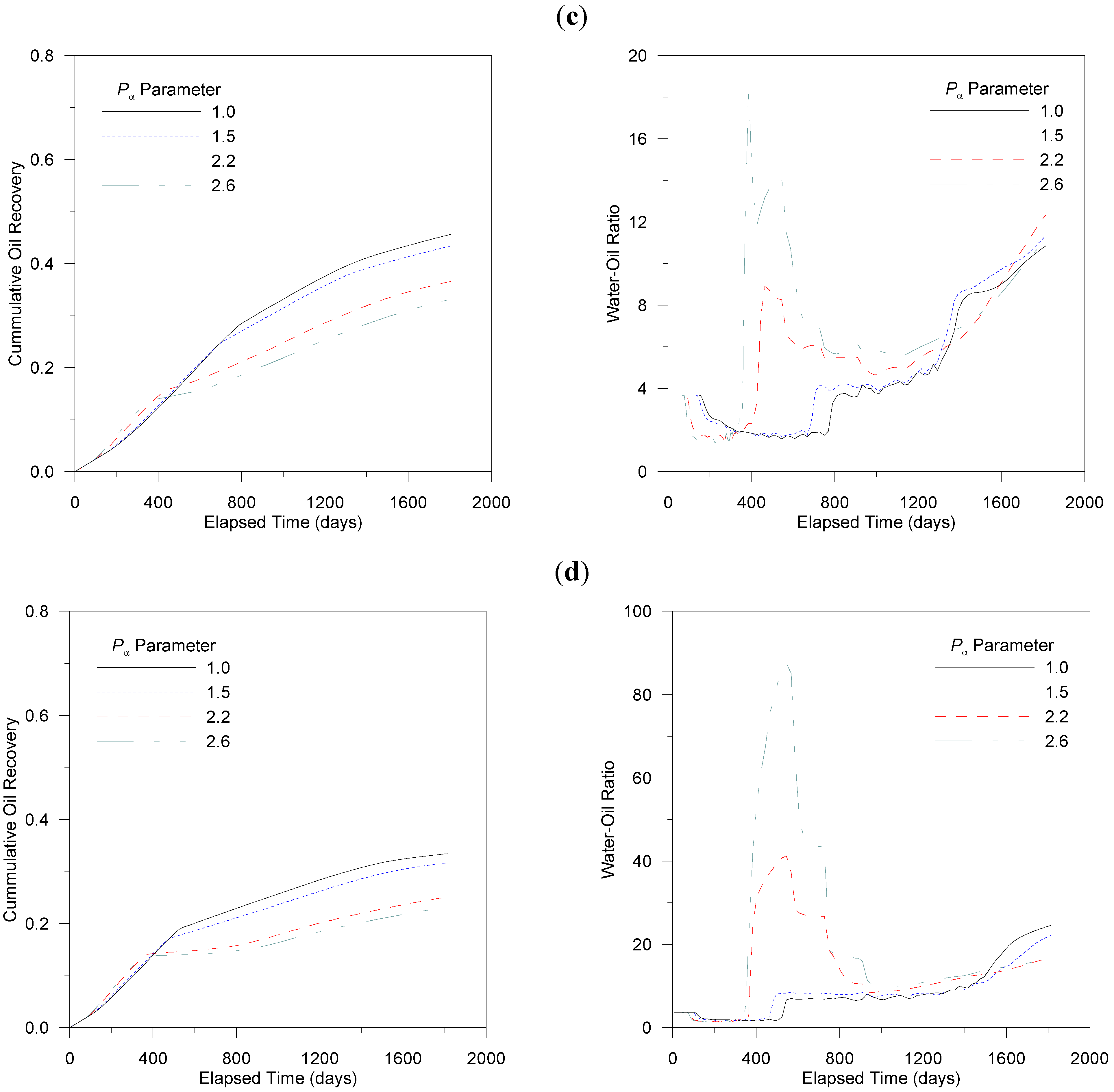

4.2. Crossflow

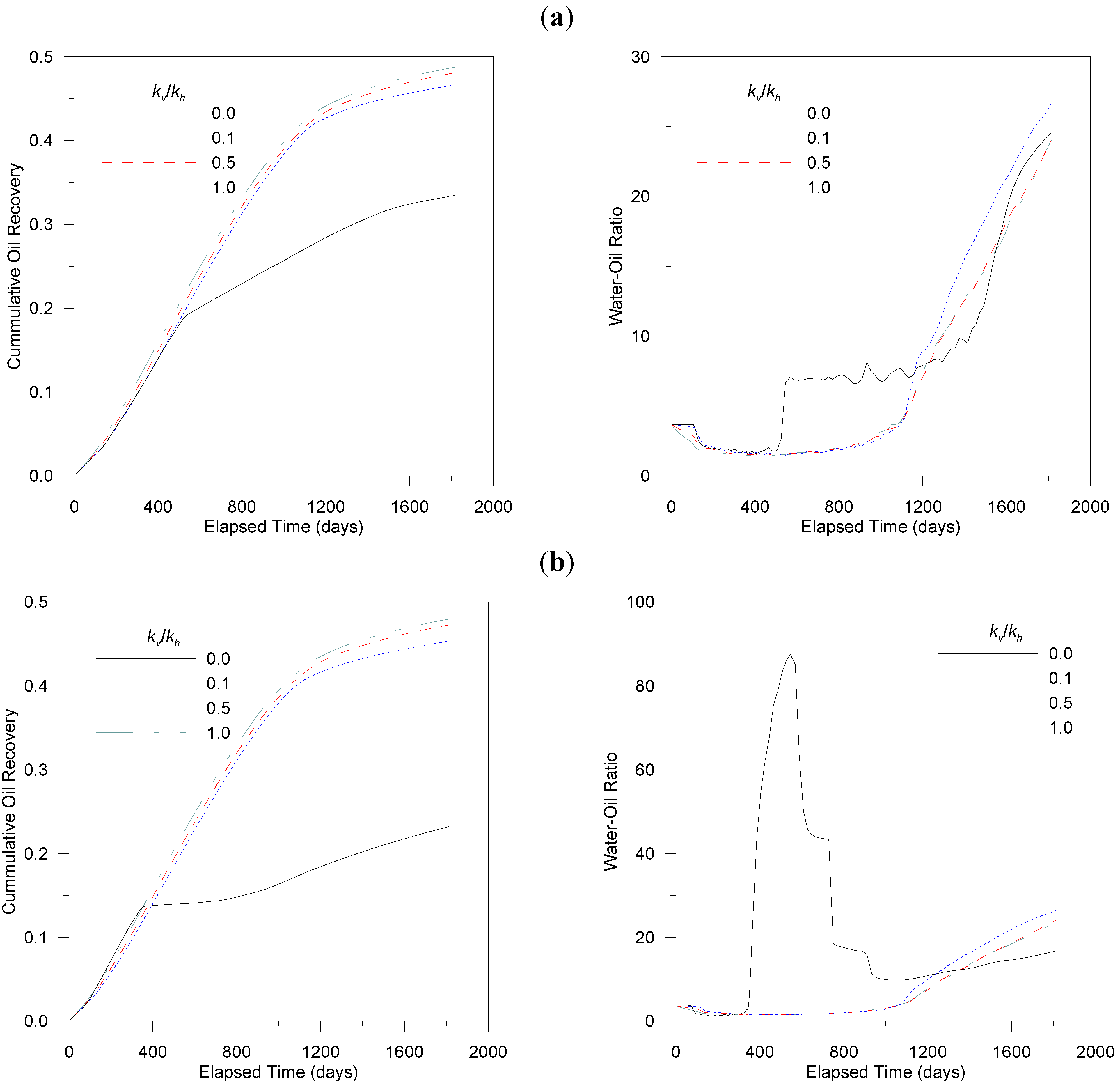

In attempts to investigate effects of crossflow, four cases of polymer flooding were run in which the ratio of vertical to horizontal permeability was varied from 0.0 to 1.0.

Figure 5a,b show results of polymer flood

for a highly heterogeneous reservoir of

in which the relative difference among results are largest.

As shown in

Figure 6, lower oil recovery and rapid increase in WOR are obtained with smaller

value. When polymer solution is injected into a stratified reservoir with layers of widely differing permeability, the oil recovery is dominated by crossflow due to combined effects of viscosity-derived pressure gradients and gravity. Sufficient vertical permeability allows injected fluid to induce crossflow in reservoir. As the vertical permeability increases, oil migrates to other layers more easily, where it is swept by the displacing water to the producing well. An increased oil recovery and decreased WOR is obtained due to an increase in the degree of crossflow.

Figure 6.

History of production wells obtained from simulations for heterogeneous reservoir of with different and . (a) (Newtonian fluid); (b) .

Figure 6.

History of production wells obtained from simulations for heterogeneous reservoir of with different and . (a) (Newtonian fluid); (b) .

The larger is, the clearer this trend becomes. A comparison of oil recovery indicates that the higher value of results in increasing recovery more than 45% from 0.3345 to 0.4874 for Newtonian fluid and more than twice from 0.2321 to 0.4793 for . However, the changes in cumulative oil recovery and WOR become smaller if is larger than 0.1. These results again demonstrate that the parameters of a viscosity model must be taken into account when estimating the performance of polymer floods.

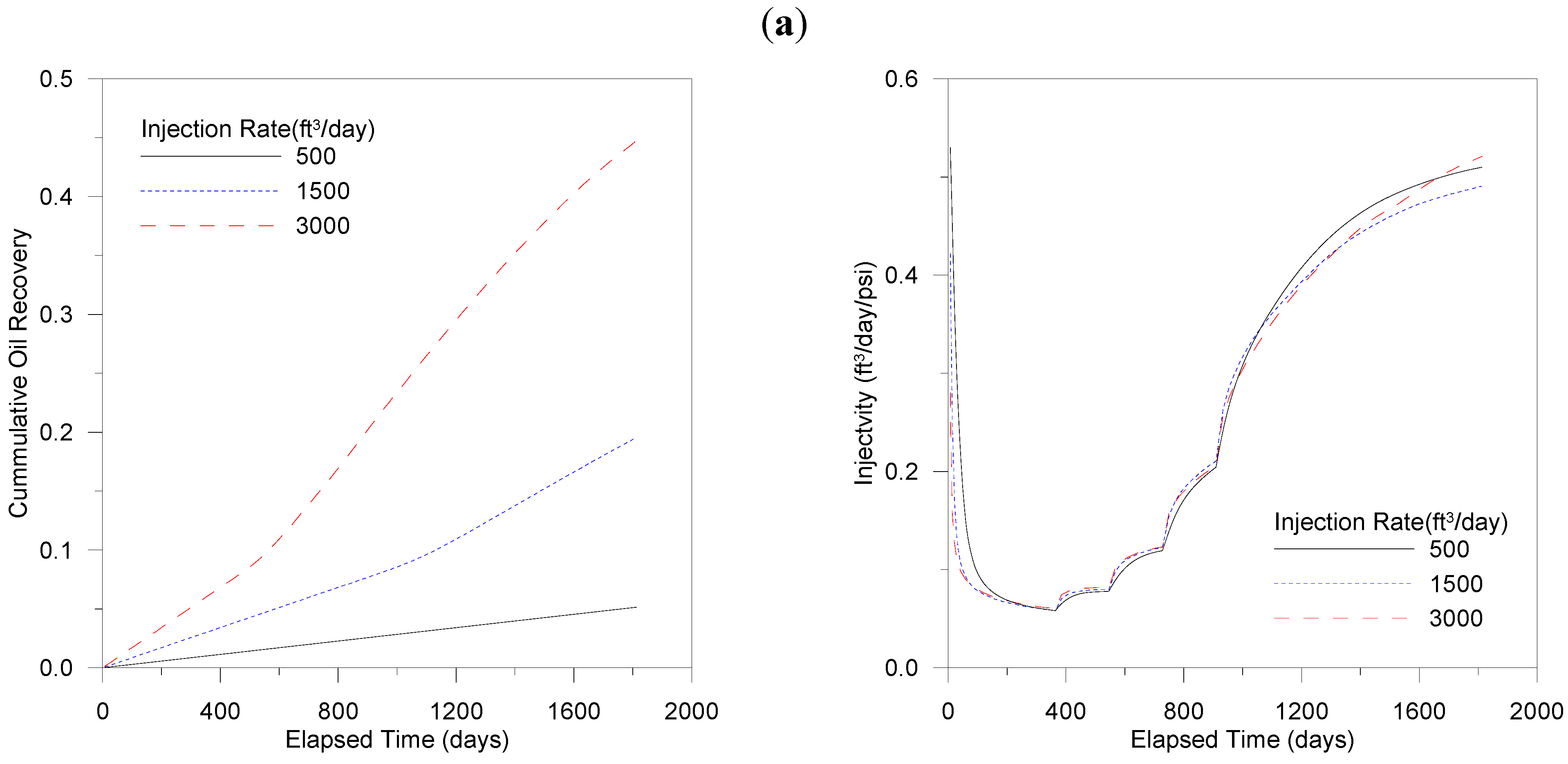

4.3. Injection Rate

The viscosity behavior of polymer solution in the reservoir was also studied at different injection rates. The aim of this simulation was to evaluate the oil recovery and injection pressure given values with different injection or production flow rates. The calculations were performed for well and reservoir configuration which is the same as the base case (uniform permeability). The flow rates are changed to 500, 1500, and 3000 ft3/day, which correspond to 0.15, 0.45, and 0.90 pore volume injected during the simulation period, respectively.

Figure 7a,b compare oil recovery and injectivity from the numerical calculations for

= 1.5 and 2.6. For the case of

which is close to Newtonian polymer solution, the range in injection pressure is proportionally increased with increased injection rate as expected from Darcy’s law and the injectivity remains almost same. The larger the

value is, the lower the injectivity is. The average injection pressure increased by 6.3 times from 5714 psi to 35,999 psi for

and only 3.3 times from 6516 psi to 21,800 psi for

during initial 2.5 years of polymer injection. Therefore, considerable differences in injectivity are obtained with various flow rates for

. If maximum injection pressure constraint is imposed on the injection well to avoid fracturing, the oil recovery will be lower in the case of injecting Newtonian fluid.

Figure 7.

History of injection and production wells obtained from simulations for homogeneous reservoir with different . (a) ; (b) .

Figure 7.

History of injection and production wells obtained from simulations for homogeneous reservoir with different . (a) ; (b) .

The results suggest that, everything else being the same, the use of polymer solution with large (i.e., high shear-thinning) is a promising flow condition due to relatively improved injectivity. This observation emphasizes the importance of ensuring that the adequate viscosity model is used, taking into account the shear-thinning effects at high flow rate.

5. Conclusions

Though viscosity of the polymer solution is of far more importance to sweep, the understanding and modeling of rheology of polymer solutions are also important for an accurate prediction of polymer flood in a heterogeneous multilayered reservoir. Through extensive simulations in a hypothetical 5-point pattern reservoir with a viscosity model including shear-thinning effects, the effects of various parameters of viscosity model, reservoir, and operation on the performance of polymer flood are examined. From a series of polymer flooding simulations carried out in this work in order to evaluate the oil recovery efficiency of a polymer flooding process in a reservoir, the following conclusions were derived through numerical evaluation of the results.

The simulation scheme with the viscosity reduction at higher shear rate allows a more quantitative prediction of reservoir performance. Shear-thinning behavior does not affect the oil recovery significantly for homogeneous reservoir. However, oil recovery decreases a lot for larger values due to velocity contrast among layers as reservoir heterogeneity becomes larger. With an increase in the degree of crossflow, oil migrates to other layers more easily due to higher sweep by the displacing fluid. This trend becomes clearer by considering shear-thinning behavior of polymer solution. Non-Newtonian fluid rheology also affects the injectivity directly because different pressure gradient alter the apparent viscosity of displacing fluid due to change in flow rate and shear rate. From numerical study carried out with various injection rates, it was observed that a shear-thinning fluid with large coefficient would increase injectivity significantly, though at low flow rates, shear-thinning impact is limited. The results from extensive simulations demonstrate that the parameters of a viscosity model must be taken into account when estimating the performance of polymer floods.