Computation of Electromagnetic Torque in a Double Rotor Switched Reluctance Motor Using Flux Tube Methods

Abstract

:1. Introduction

2. Computational Procedure Using Flux Tube Analysis

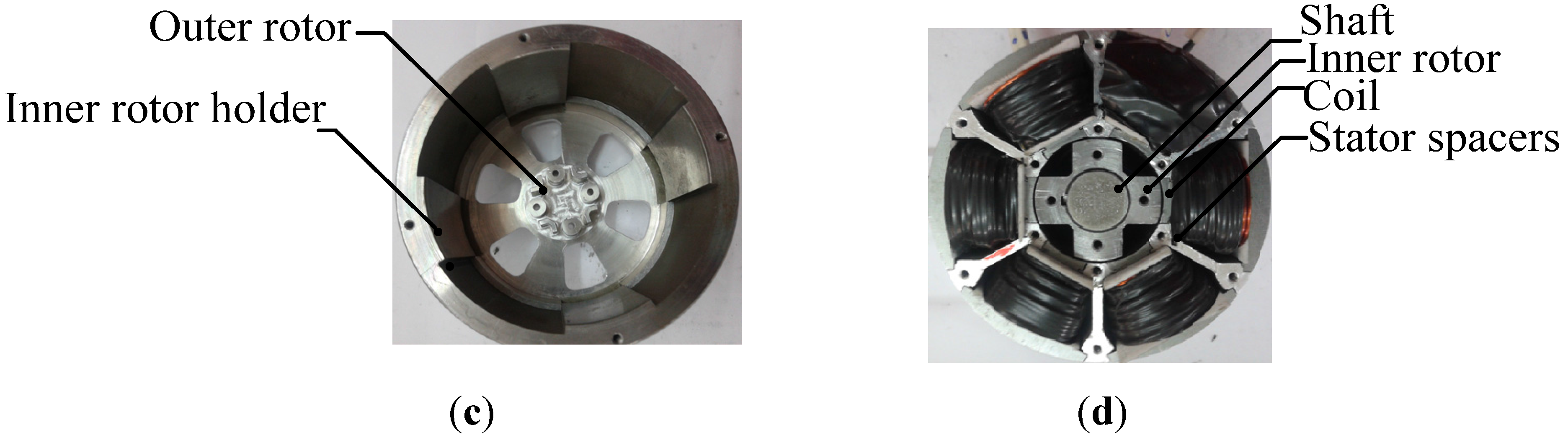

2.1. Structural Configuration

| Parameter | Value |

|---|---|

| Number of stator poles | 6 |

| Number of rotor poles | 4 (dual) |

| Outer diameter | 80 mm |

| Outer rotor inner diameter | 66.6 mm |

| Air gap length | 0.5 mm |

| Inner rotor outer diameter | 51.9 mm |

| Shaft diameter | 7 mm |

| Stack length (Lstk) | 40 mm |

| Material | SS400 |

| Turns per phase (N) | 80 |

| Rated current (i) | 16.33 A |

| Power | 100 W |

| Torque | 1.6 N-m |

| Voltage | 80 V |

| Outer rotor pole arc Inner rotor pole arc | 35 deg 45 deg |

| Stator inner surface pole arc Stator outer surface pole arc | 30 deg 50 deg |

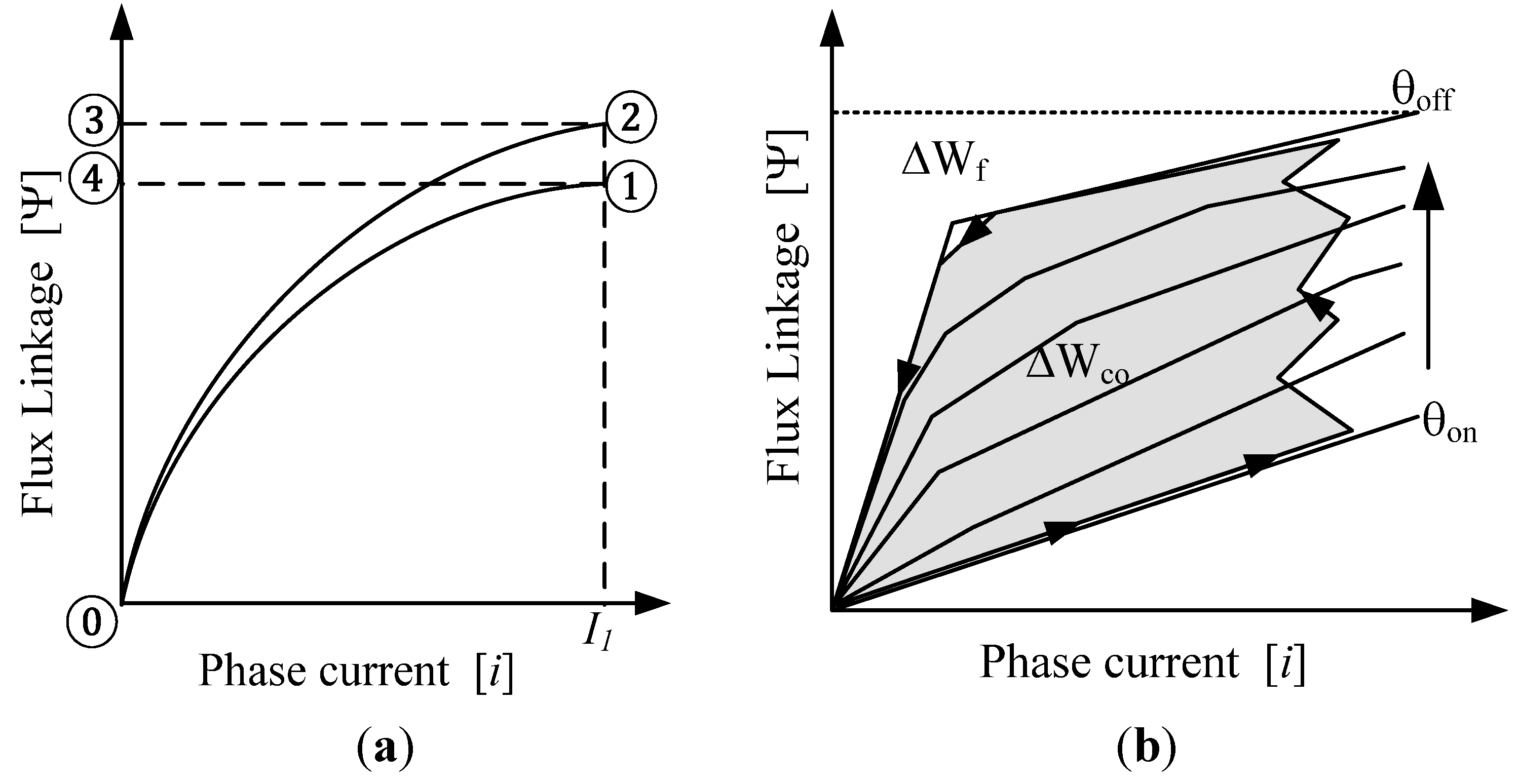

2.2. Energy Conversion from the First Principles

2.3. Inductance Computation Based on Energy Relations

2.4. Voltage Equation Computation

2.5. Electromagnetic Torque Equation Computation

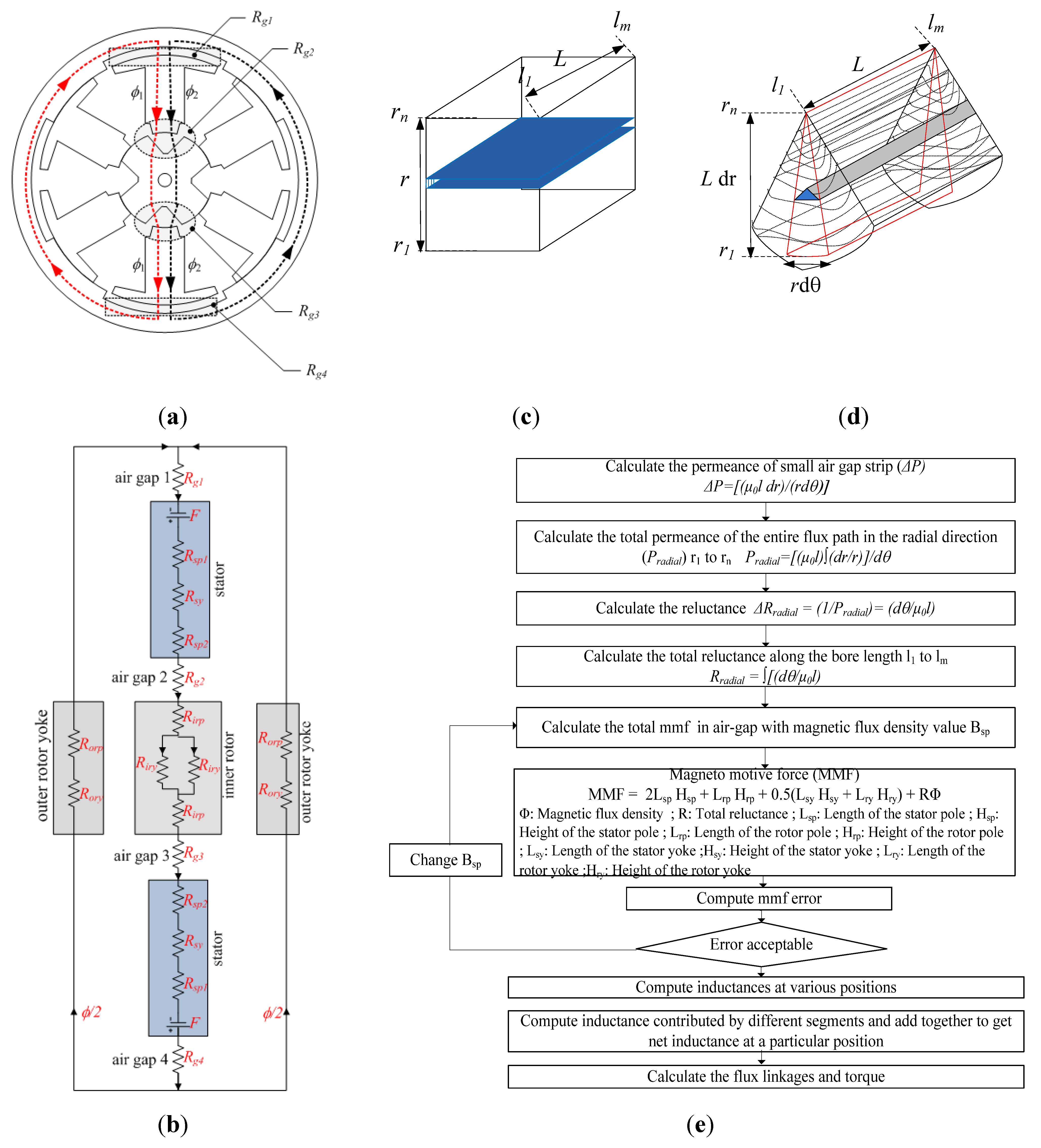

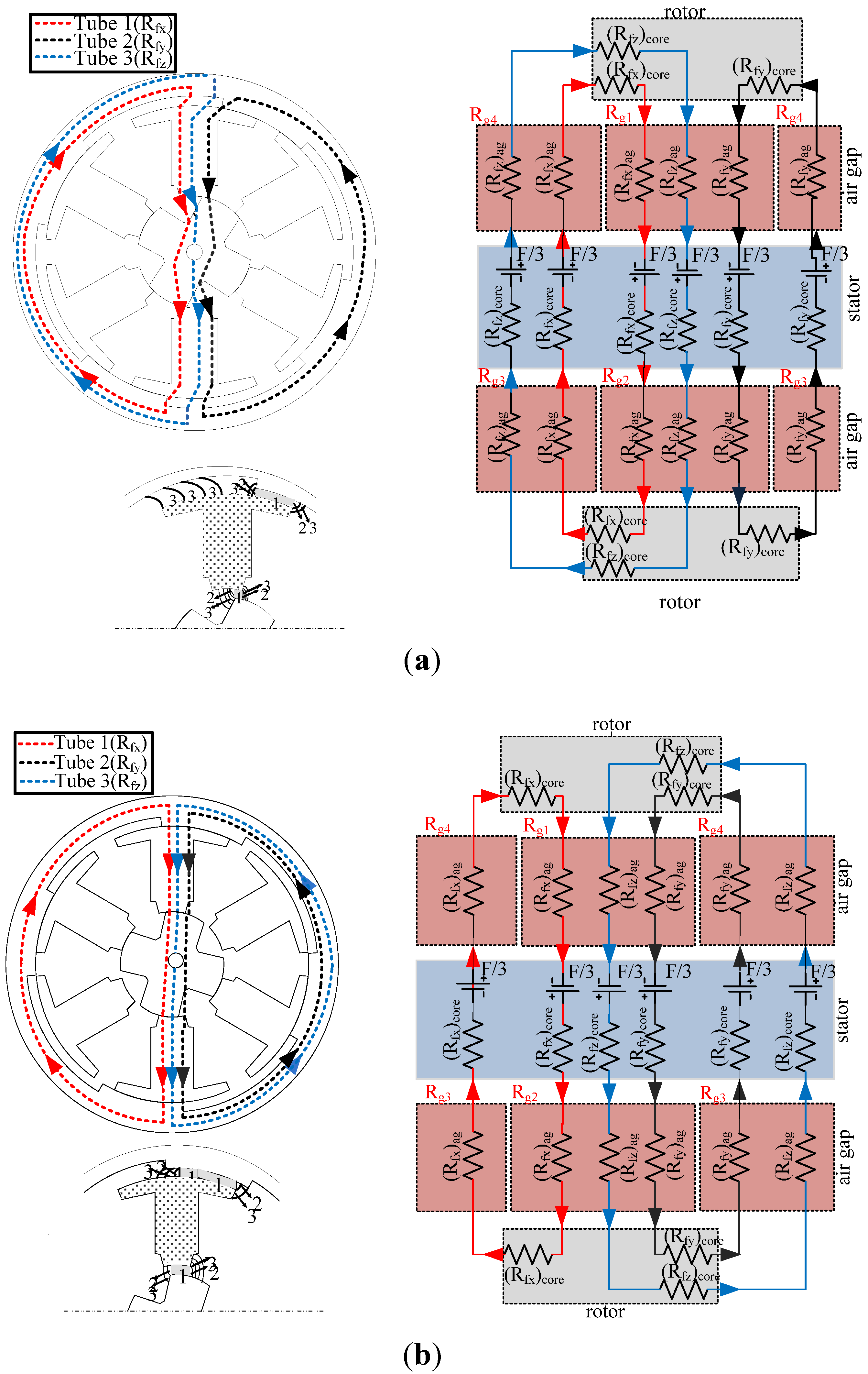

2.6. Equivalent Magnetic Circuit for Analysis

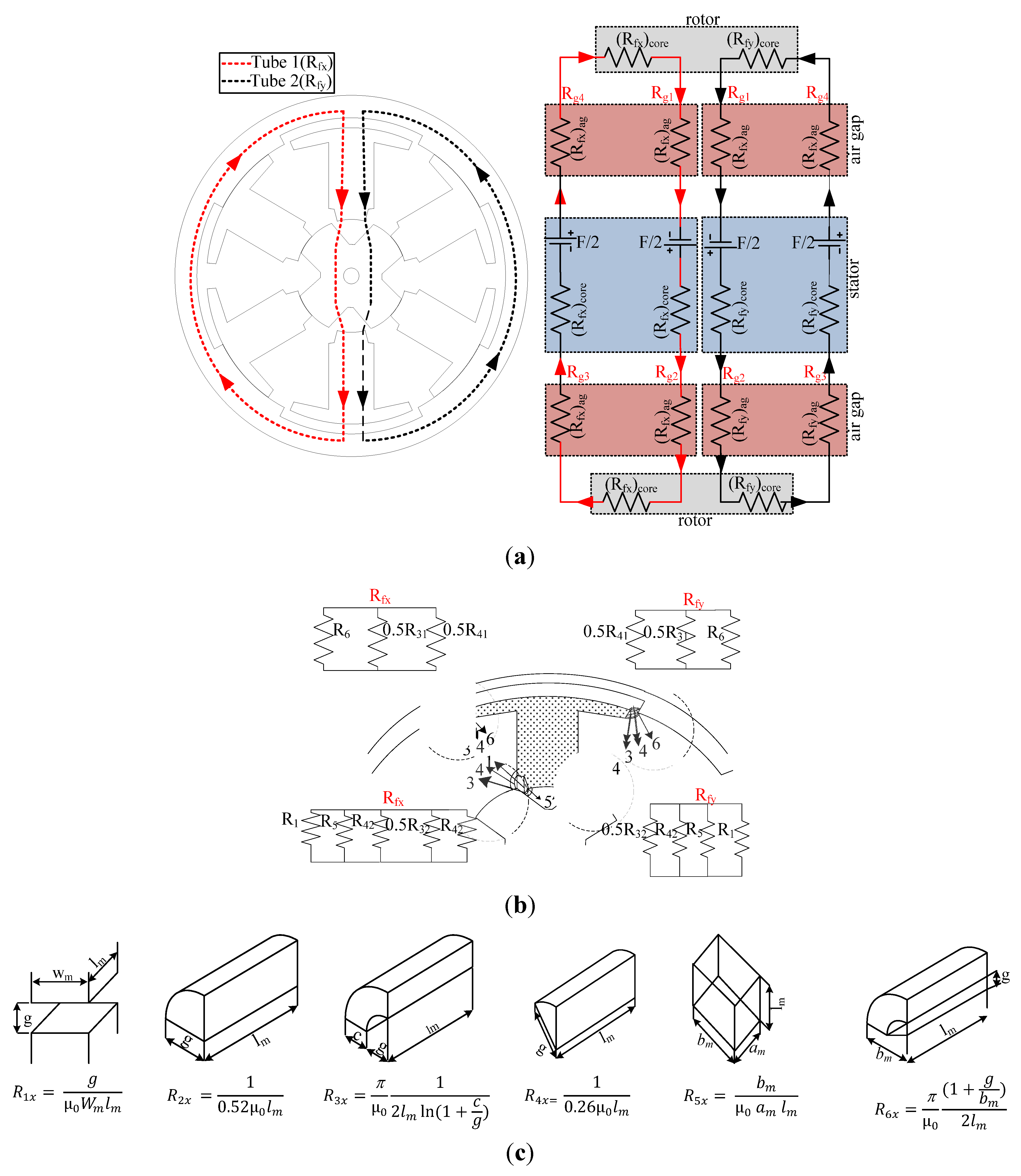

2.6.1. Unaligned Position Computation

2.6.2. Partial Aligned Computation

2.6.3. Aligned Position Computation

3. Comparative Evaluations

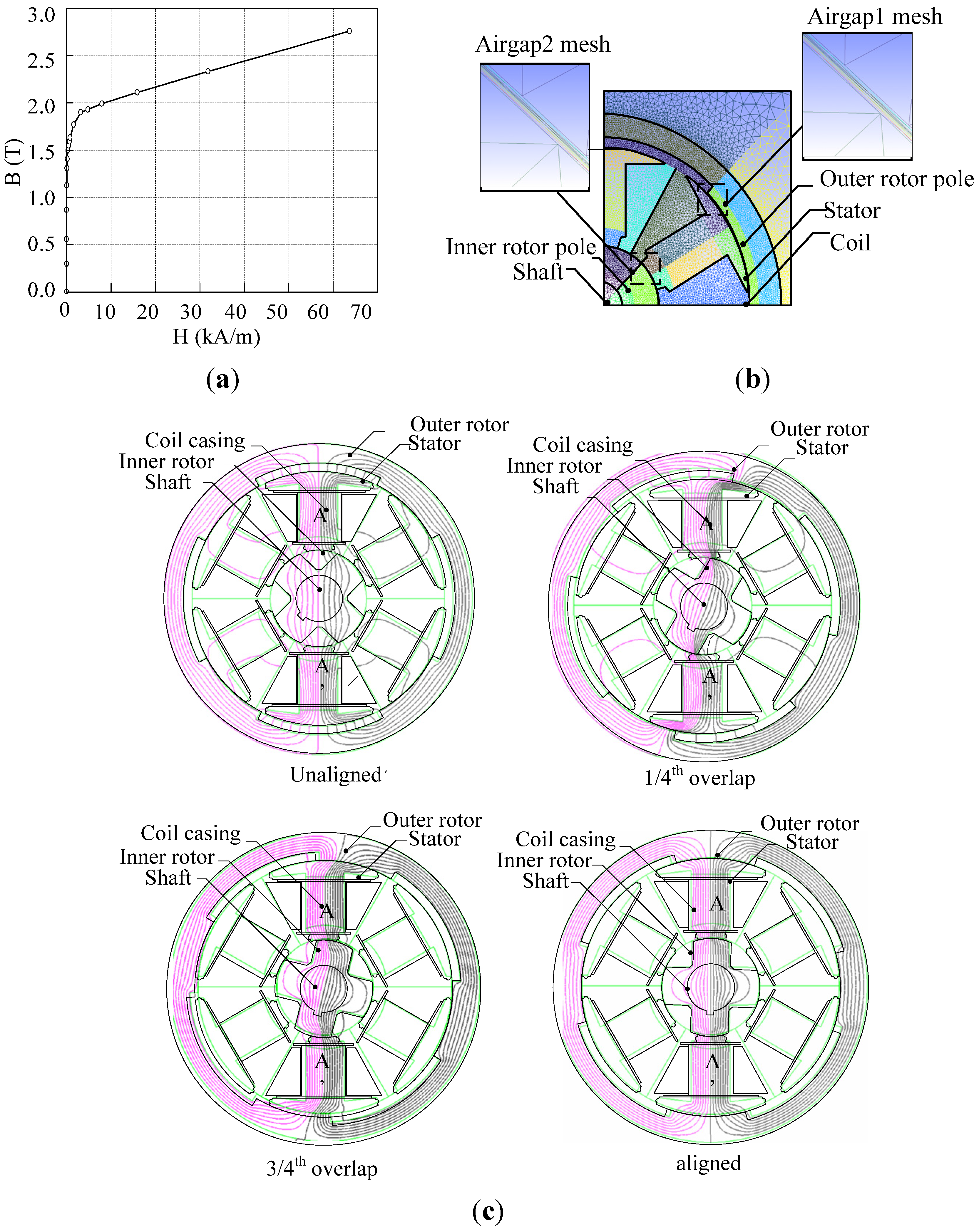

3.1. FEM Simulation

3.2. Experimental Evaluation

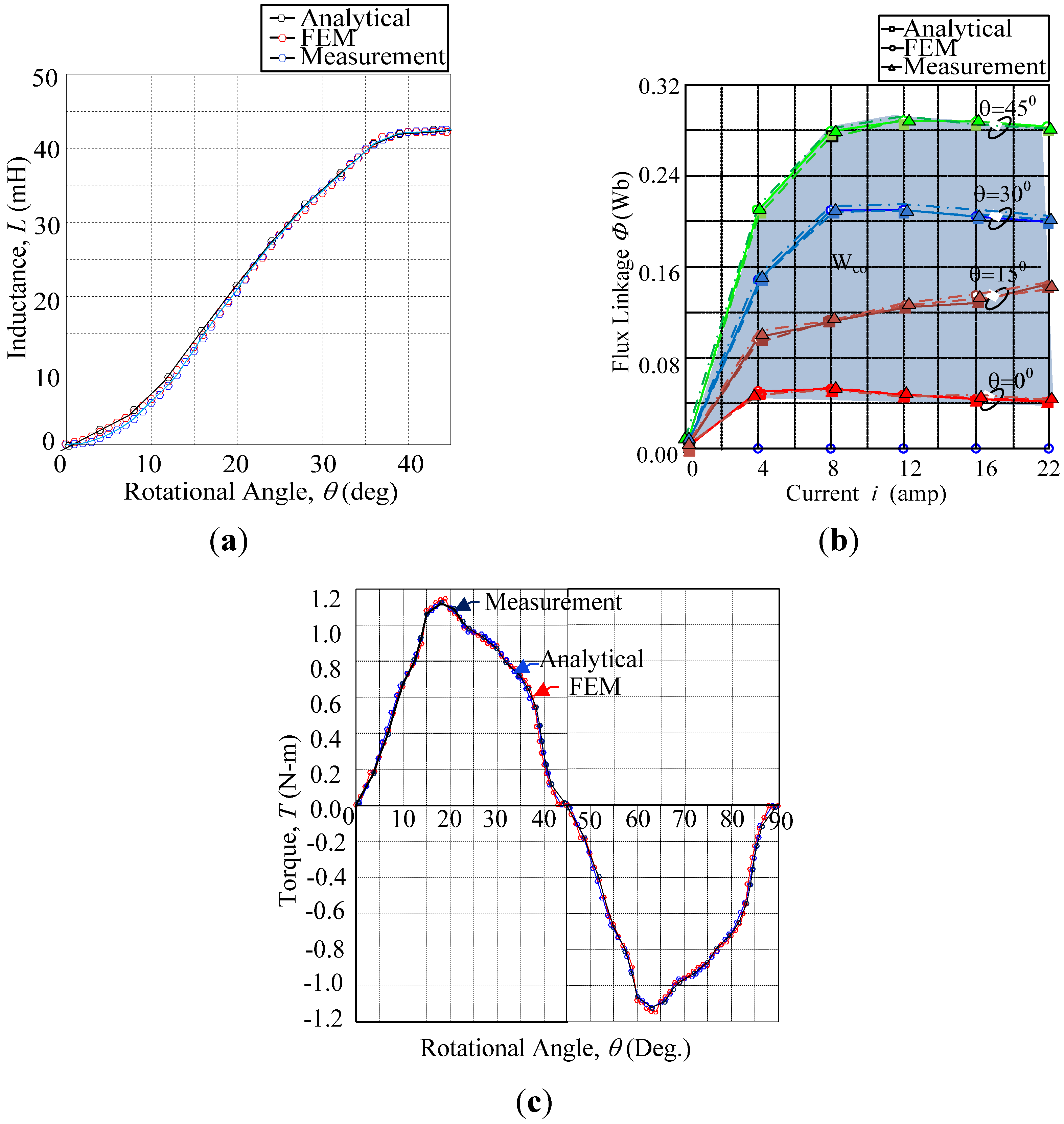

4. Results and Discussion

| Computation Method | Inductance (mH) | Tavg (N-m) | |||

| unaligned | 1/4th aligned | 3/4th aligned | aligned | ||

| Analytical | 3.96 | 20.36 | 30.40 | 35.9 | 0.947 |

| FEM | 4.01 | 20.15 | 30.43 | 35.7 | 0.953 |

| Measurement | 3.98 | 20.38 | 30.38 | 36.3 | 0.949 |

5. Conclusions

References

- Miller, T.J.E. Switched Reluctance Motors and Their Control; Magna Physic and Clarendon Press: Oxford, UK, 1993. [Google Scholar]

- Aravind, C.V.; Norhisam, M.; Aris, I.; Marhabhan, M.H.; Ahmad, D. Double Rotor Switched Reluctance Motors: Fundamentals and Magnetic Circuit Analysis. In Proceedings of the IEEE Student Conference on Research and Development (SCORED2011), Cyberjaya, Malaysia, 19–20 December 2011.

- Norhisam, M.; Norafiza, M.; Syafiq, M.; Aris, I.; Nirei, M.; Wakiwaka, H.; Abdul Razak, J. Design and Analysis of Slot Type Embedded Permanent Magnet Generator. J. Ind. Technol. 2009, 18, 1–14. [Google Scholar]

- Norhisam, M.; Norafiza, M.; Syafiq, M.; Aris, I.; Nirei, M.; Wakiwaka, H.; Abdul Razak, J. Comparison on Performance of Two Types Permanent Magnet Generator. J. Jpn. Soc. Electromagn. Mech. 2009, 17, S73–S76. [Google Scholar]

- Norhisam, M.; Alias, K.; Firdaus, R.N.; Mahmod, S.; Mariun, N.; Abdul Razak, J. Comparison of Thrust Characteristics of Linear Oscillatory Actuators. In Proceedings of the IEEE 1st International Power and Energy Conference (PECon '06), Putra Jaya, Malaysia, 28–29 November 2006; pp. 470–475.

- Norhisam, M.; Syafiq, M.; Syafiq, I.; Abdul, R.J. Design and analysis of a single phase slot-less permanent magnet generator. In Proceedings of the IEEE 2nd International Power and Energy Conference (PECon '08), Johor Bahru, Malaysia, 1–3 December 2008; pp. 1082–1085.

- Radun, A. Analytically computing the flux linked by a switched reluctance motor phase when the stator and rotor poles overlap. IEEE Trans. Magn. 2000, 36, 1996–2003. [Google Scholar] [CrossRef]

- Kokernak, J.M.; Torrey, D.A. Magnetic circuit model for the mutually coupled switched-reluctance machine. IEEE Trans. Magn. 2000, 36, 500–507. [Google Scholar] [CrossRef]

- Lin, D.; Zhou, P.; Stanton, S.; Cendes, Z.J. An analytical circuit model of switched reluctance motors. IEEE Trans. Magn. 2009, 45, 5368–5374. [Google Scholar] [CrossRef]

- Chi, H.P.; Lin, R.L.; Chen, J.F. A simplified Flux linkage model for Switched Reluctance Motors. IEE Proc. Elect. Power Appl. 2005, 152, 577–583. [Google Scholar] [CrossRef]

- Aravind, C.V.; Norhisam, M.; Aris, I.; Marhabhan, M.H. Analytical design of the double rotor switched reluctance motor with optimal pole arc values. Int. Rev. Electr. Eng. 2012, 7, 3314–3324. [Google Scholar]

- Lawrenson, P.J.; Stephenson, J.M.; Blenkinsop, P.T.; Corda, J.; Fulton, N.N. Variable-speed switched reluctance motors. Proc. Inst. Electr. Eng. 1980, 127, 253–265. [Google Scholar]

- Kameari, A. Local force calculation in 3D FEM with edge elements. Int. J. Appl. Electromagn. Mater. 1993, 3, 231–240. [Google Scholar]

- Gieras, J.F.; Wing, M. Permanent Magnet Motor Technology, 2nd ed.; Marcel Dekker, Inc.: New York, NY, USA, 2002. [Google Scholar]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Vaithilingam, C.A.; Misron, N.; Zare, M.R.; Aris, I.; Marhaban, M.H. Computation of Electromagnetic Torque in a Double Rotor Switched Reluctance Motor Using Flux Tube Methods. Energies 2012, 5, 4008-4026. https://doi.org/10.3390/en5104008

Vaithilingam CA, Misron N, Zare MR, Aris I, Marhaban MH. Computation of Electromagnetic Torque in a Double Rotor Switched Reluctance Motor Using Flux Tube Methods. Energies. 2012; 5(10):4008-4026. https://doi.org/10.3390/en5104008

Chicago/Turabian StyleVaithilingam, Chockalingam Aravind, Norhisam Misron, Mohammad Reza Zare, Ishak Aris, and Mohammad Hamiruce Marhaban. 2012. "Computation of Electromagnetic Torque in a Double Rotor Switched Reluctance Motor Using Flux Tube Methods" Energies 5, no. 10: 4008-4026. https://doi.org/10.3390/en5104008