Non-Intrusive Demand Monitoring and Load Identification for Energy Management Systems Based on Transient Feature Analyses

Abstract

:1. Introduction

2. Proposed Methods

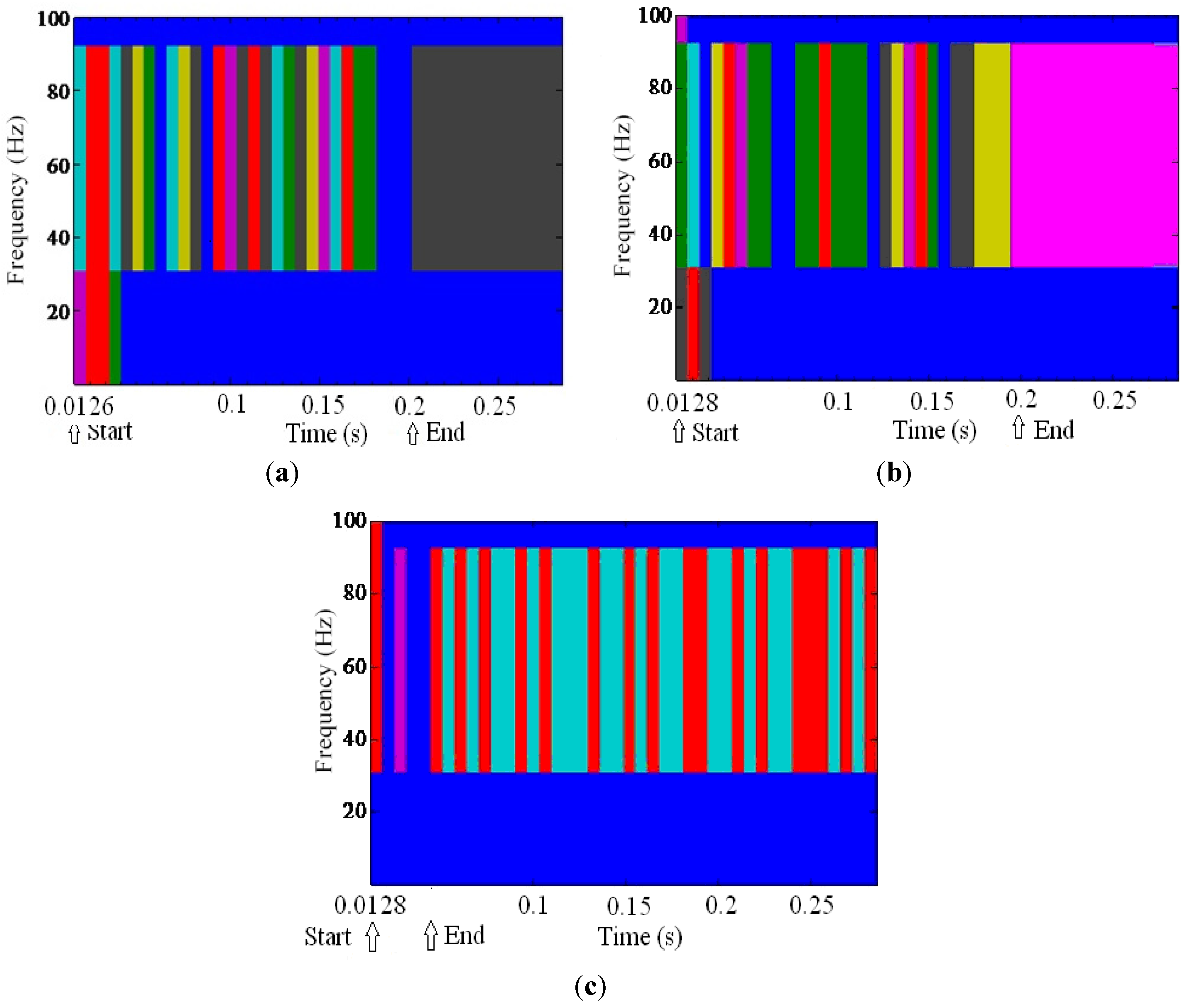

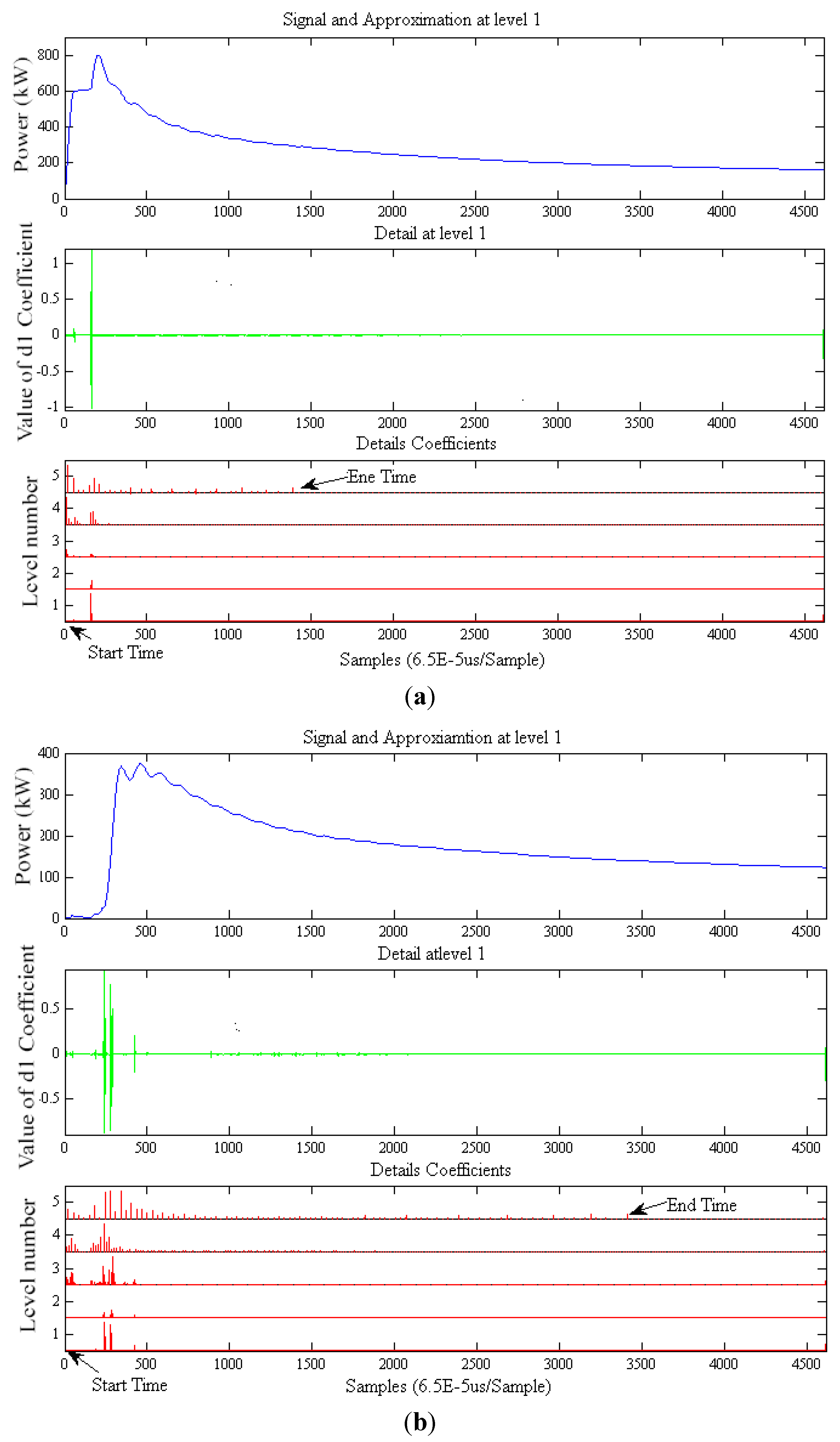

2.1. Transient Response Time

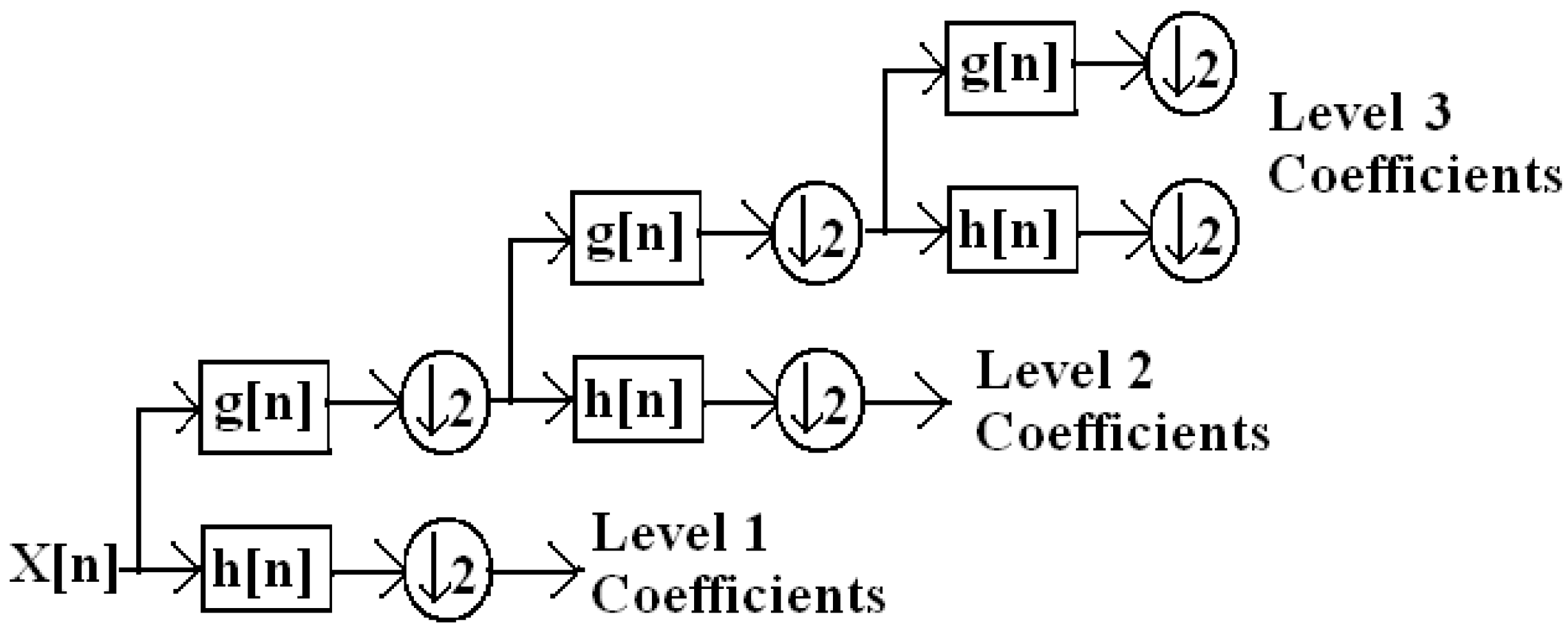

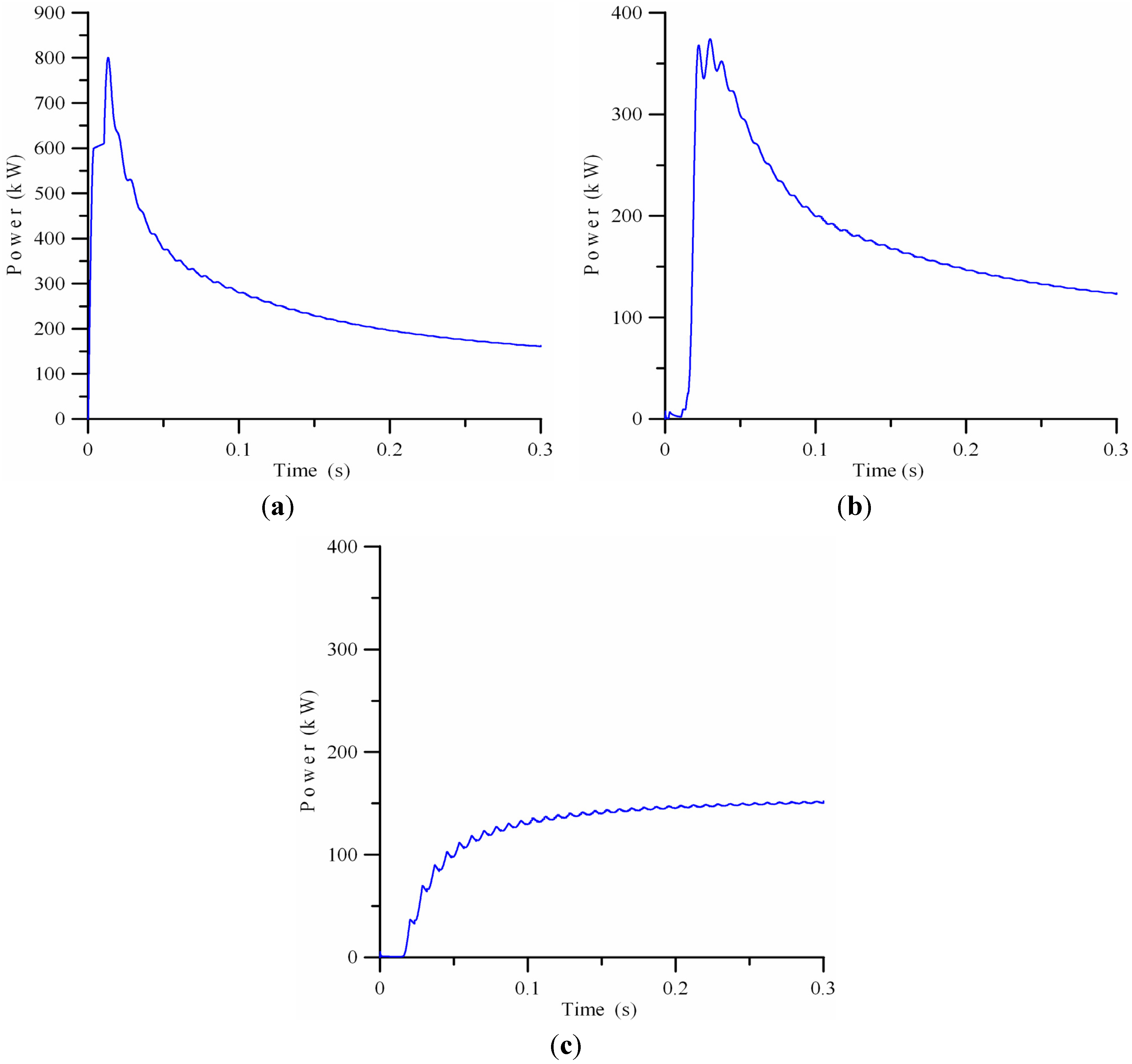

2.2. Transient Energy Algorithms

2.3. Multi-Layer Feedforward Neural Network

- (1)

- Input Layer: The number of input neurons is the same as that of the power signature information, including the real and reactive power (PQ), PQ and total harmonic distortion of the voltage and current (PQVTHDITHD), or transient response time and the transient energy signature (tTRUT) for comparisons. These power signatures are taken as input data from an electrical service entrance.

- (2)

- Output Layer: The number of output neurons is the same as that of the identified individual appliances. Each binary bit serves as a load indicator for the turn-ON/OFF status.

- (3)

- Hidden Layer: The proposed method uses only one hidden layer. Researchers have proposed various heuristic approaches to determine the number of neurons in the hidden layer [22]. The common number of neurons for the hidden layer is (number of input neurons + number of output neurons)/2 or (number of input neurons + number of output neurons)0.5. Simulation results show no significant difference between these two options.

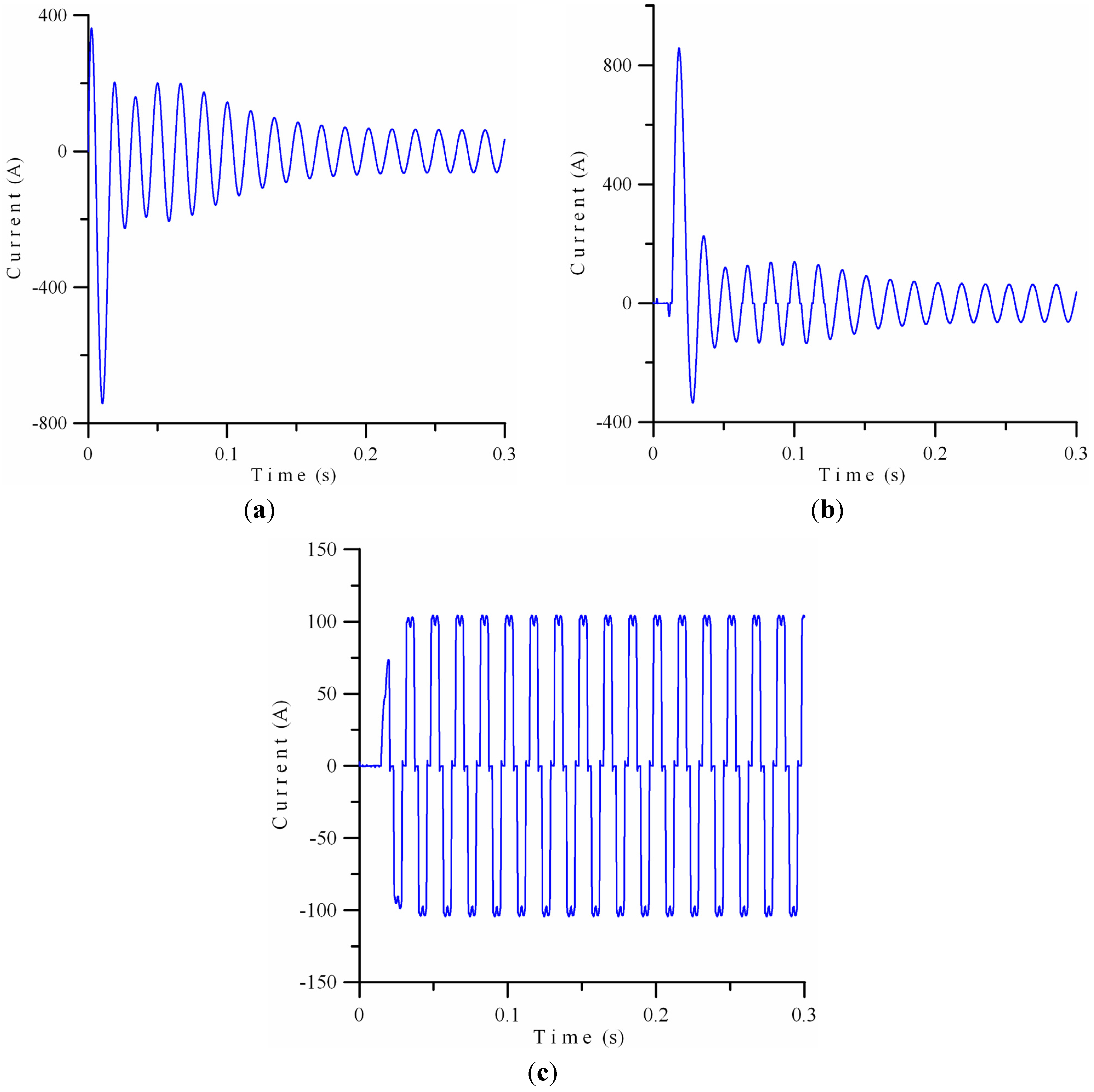

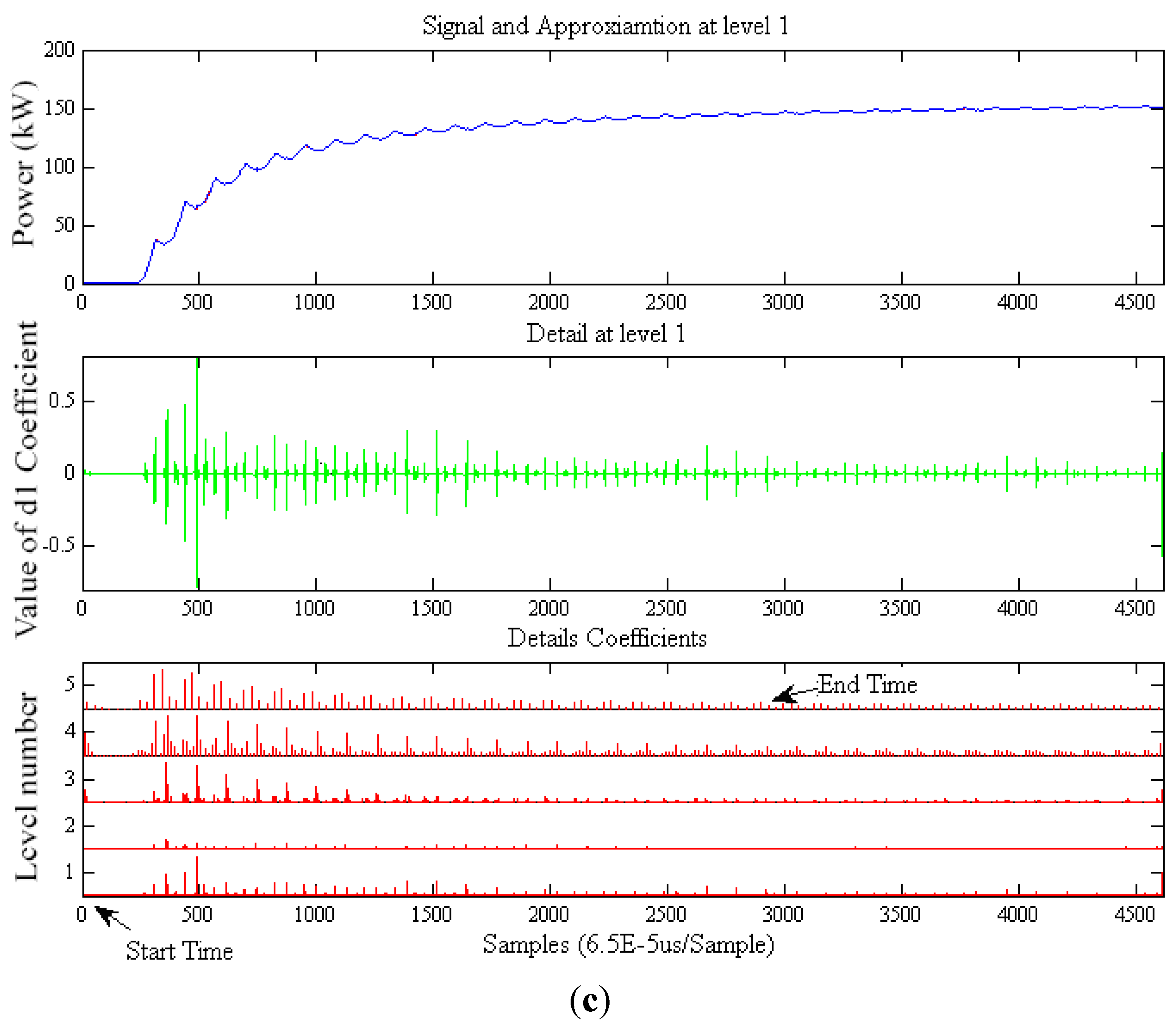

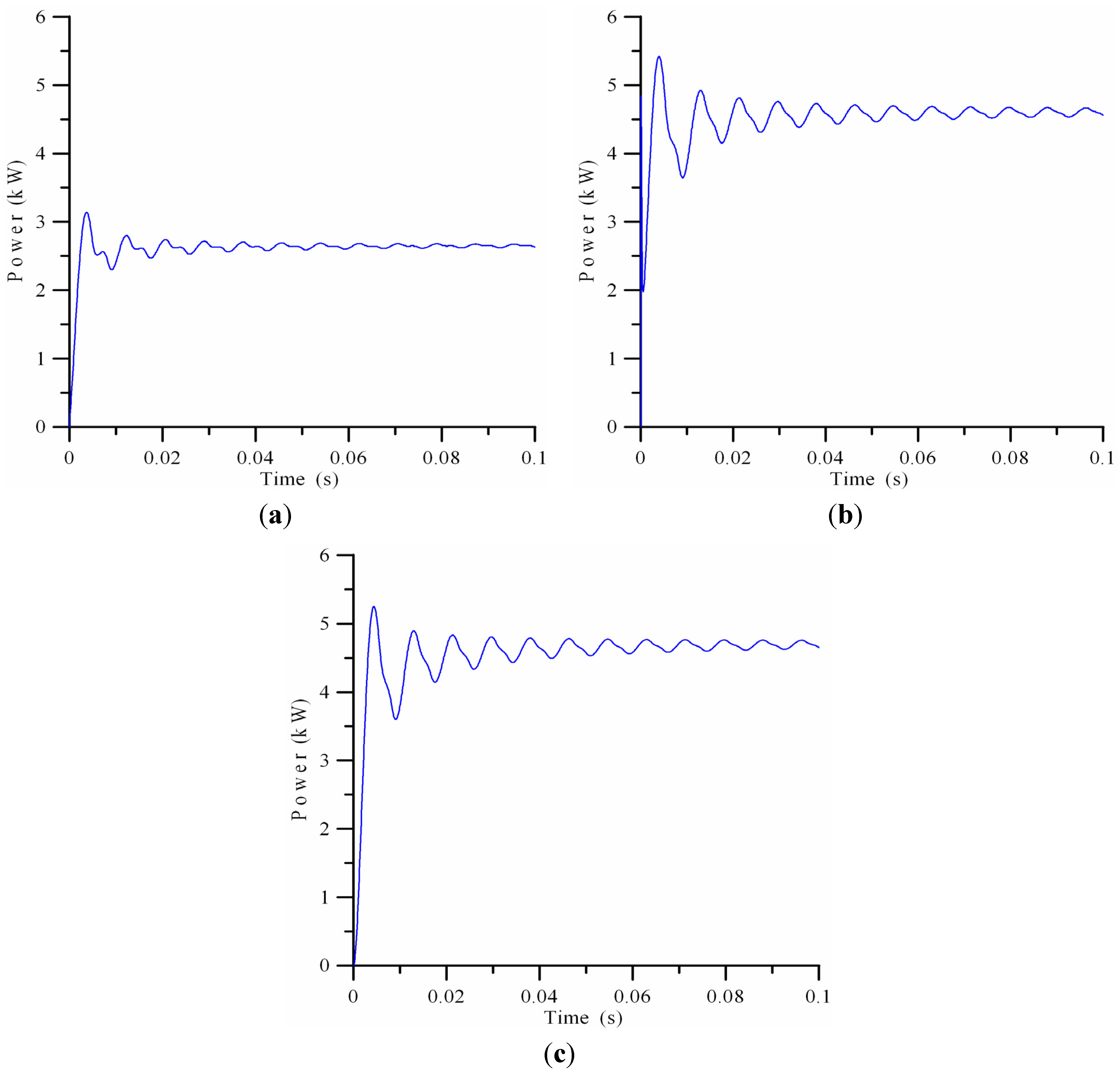

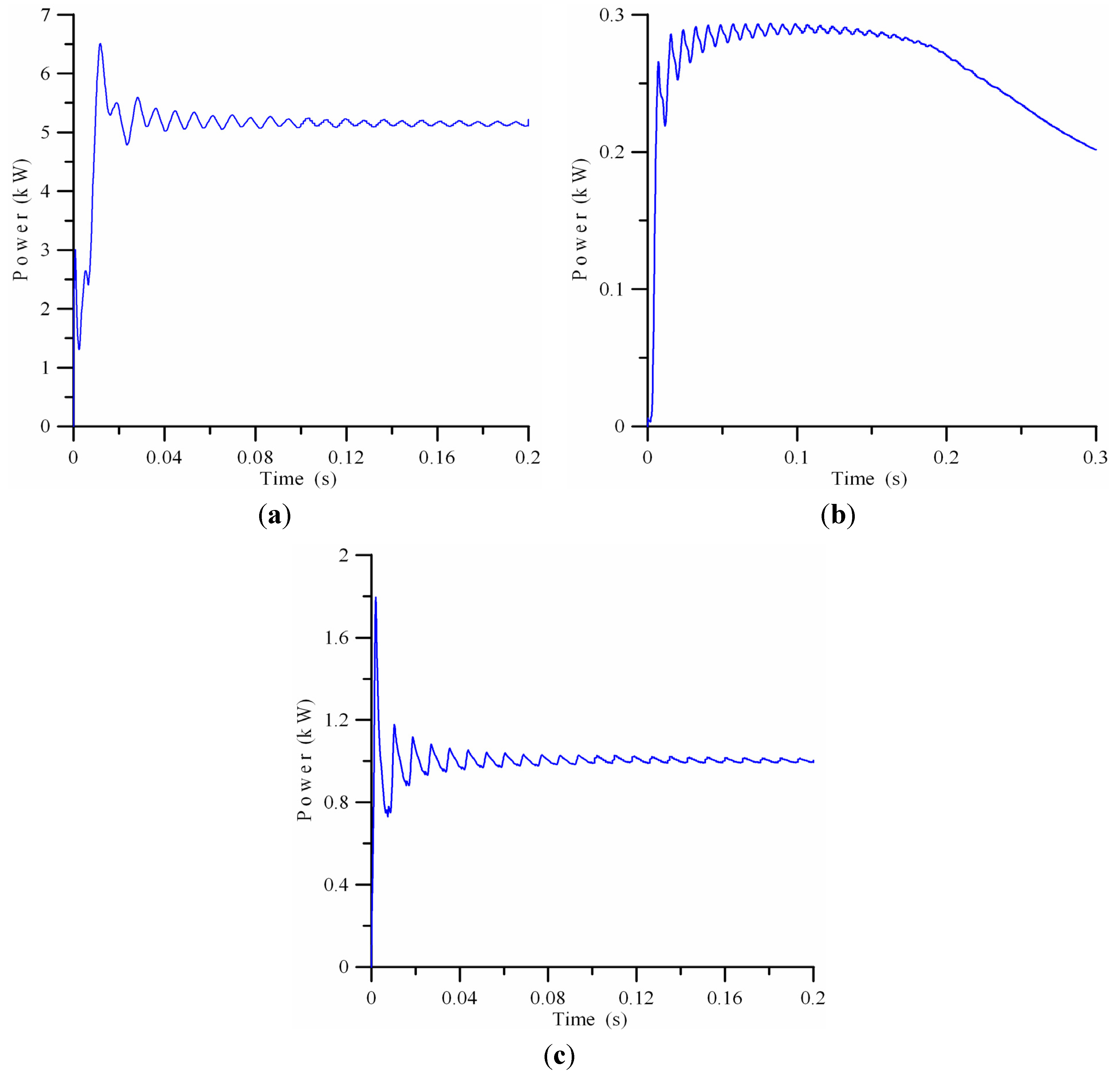

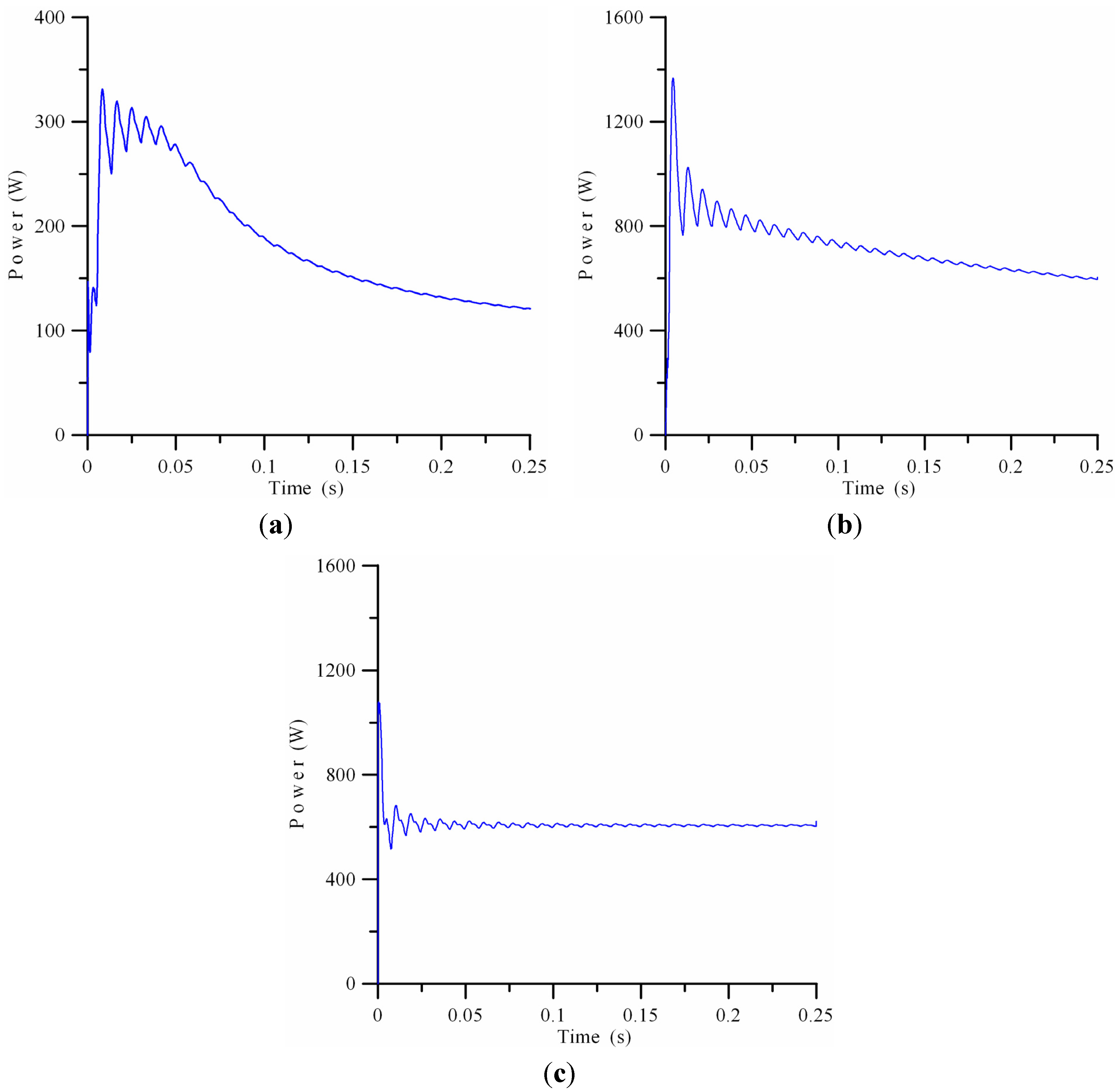

3. Transient Analyses

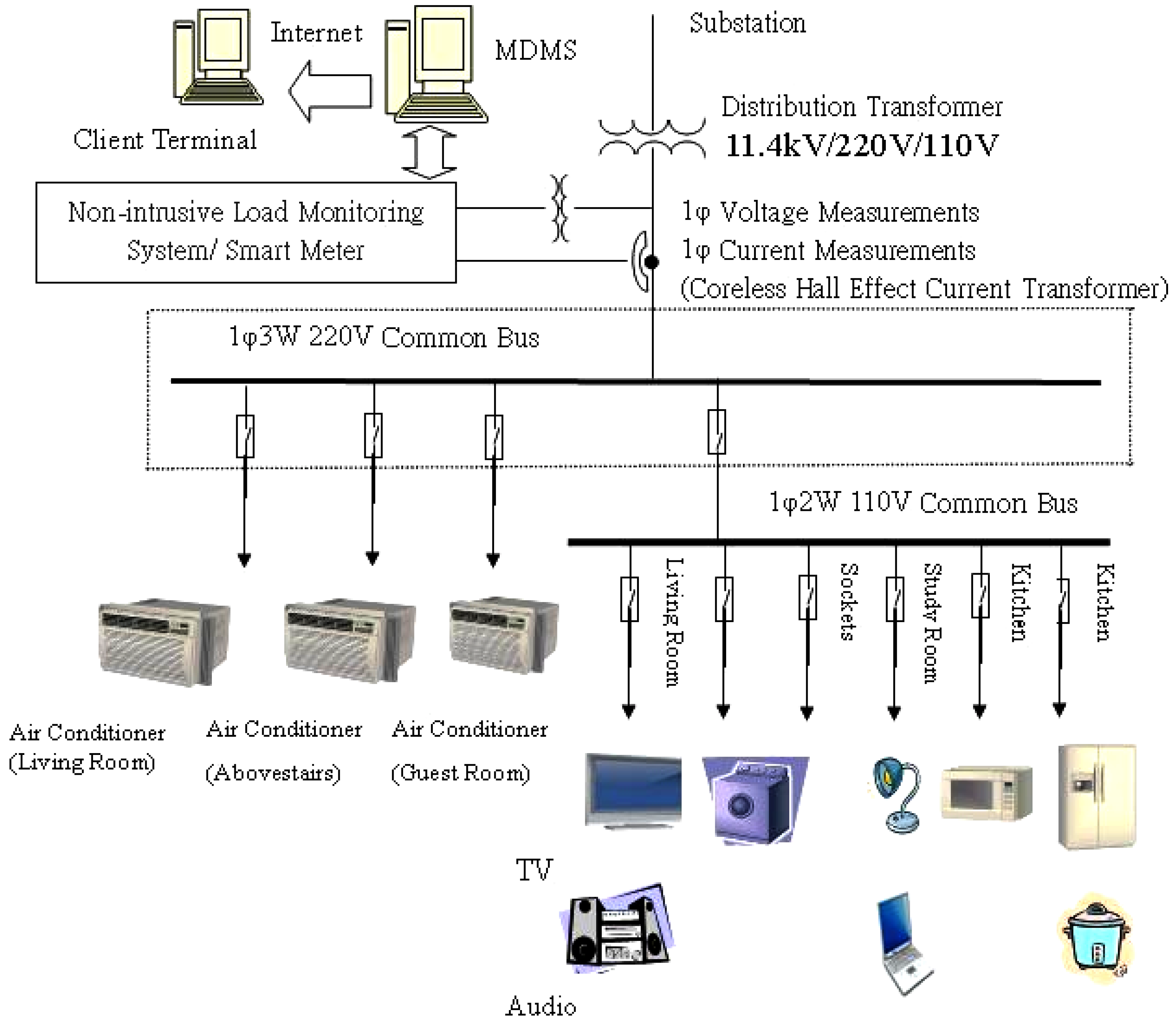

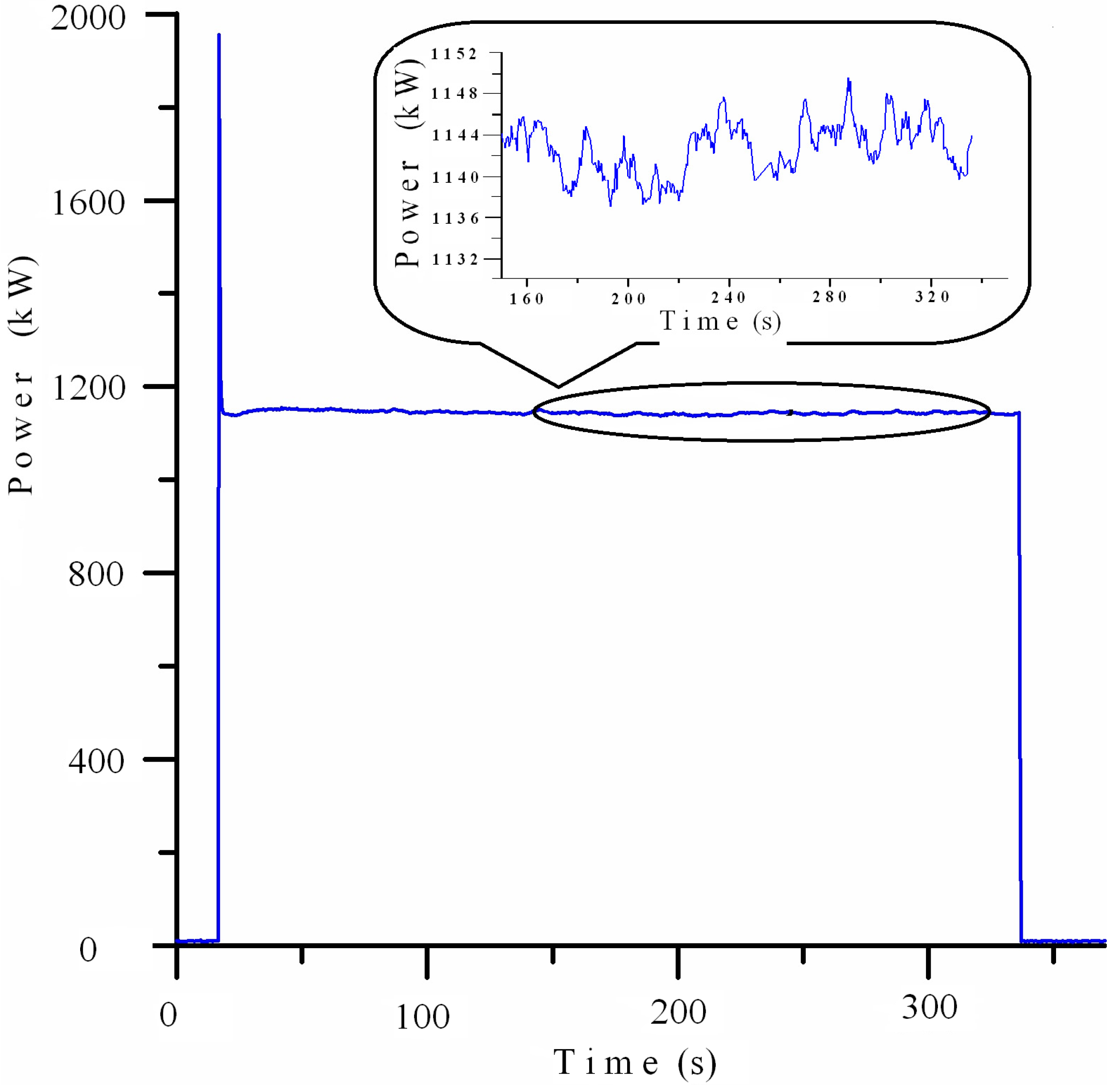

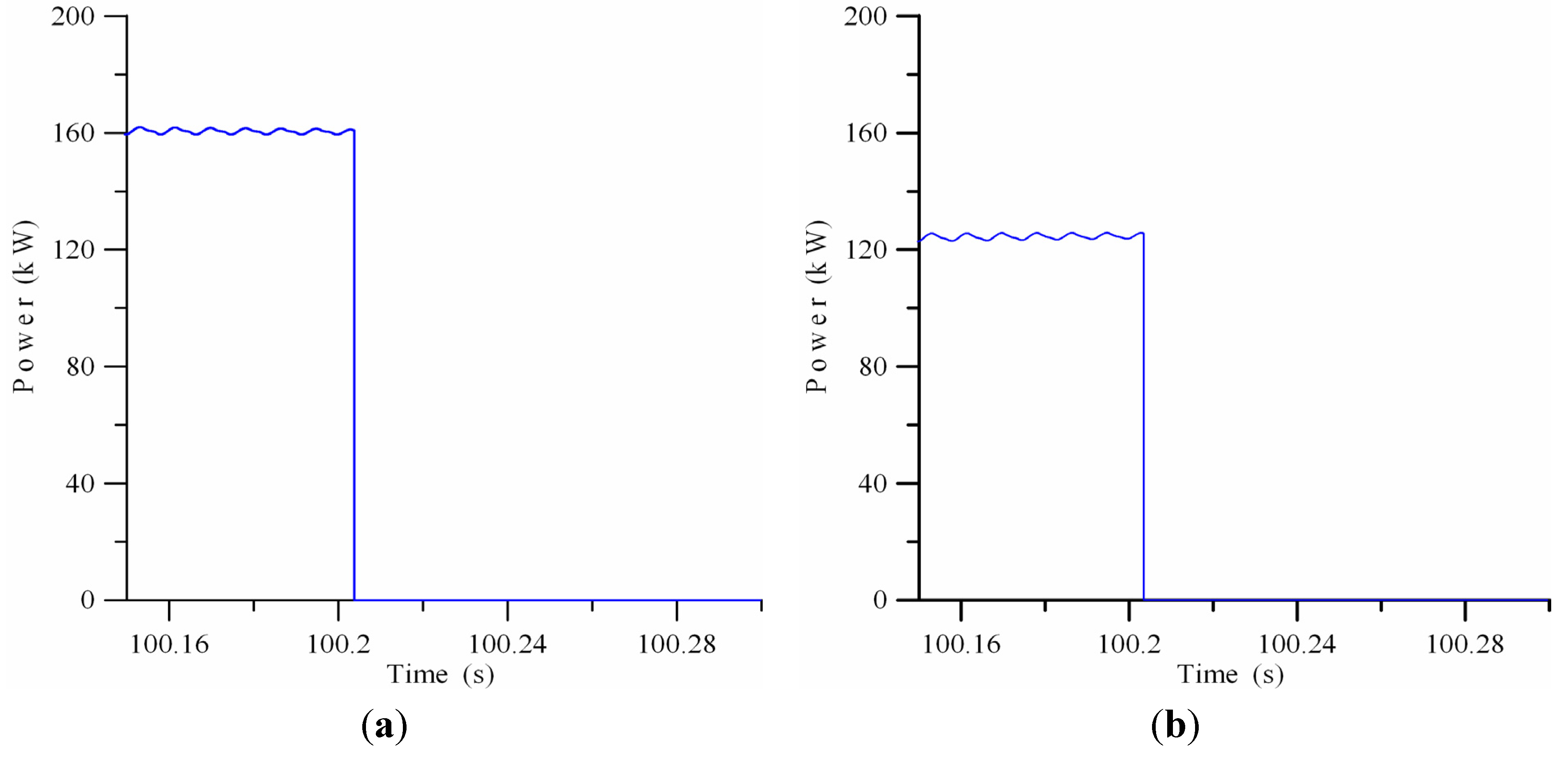

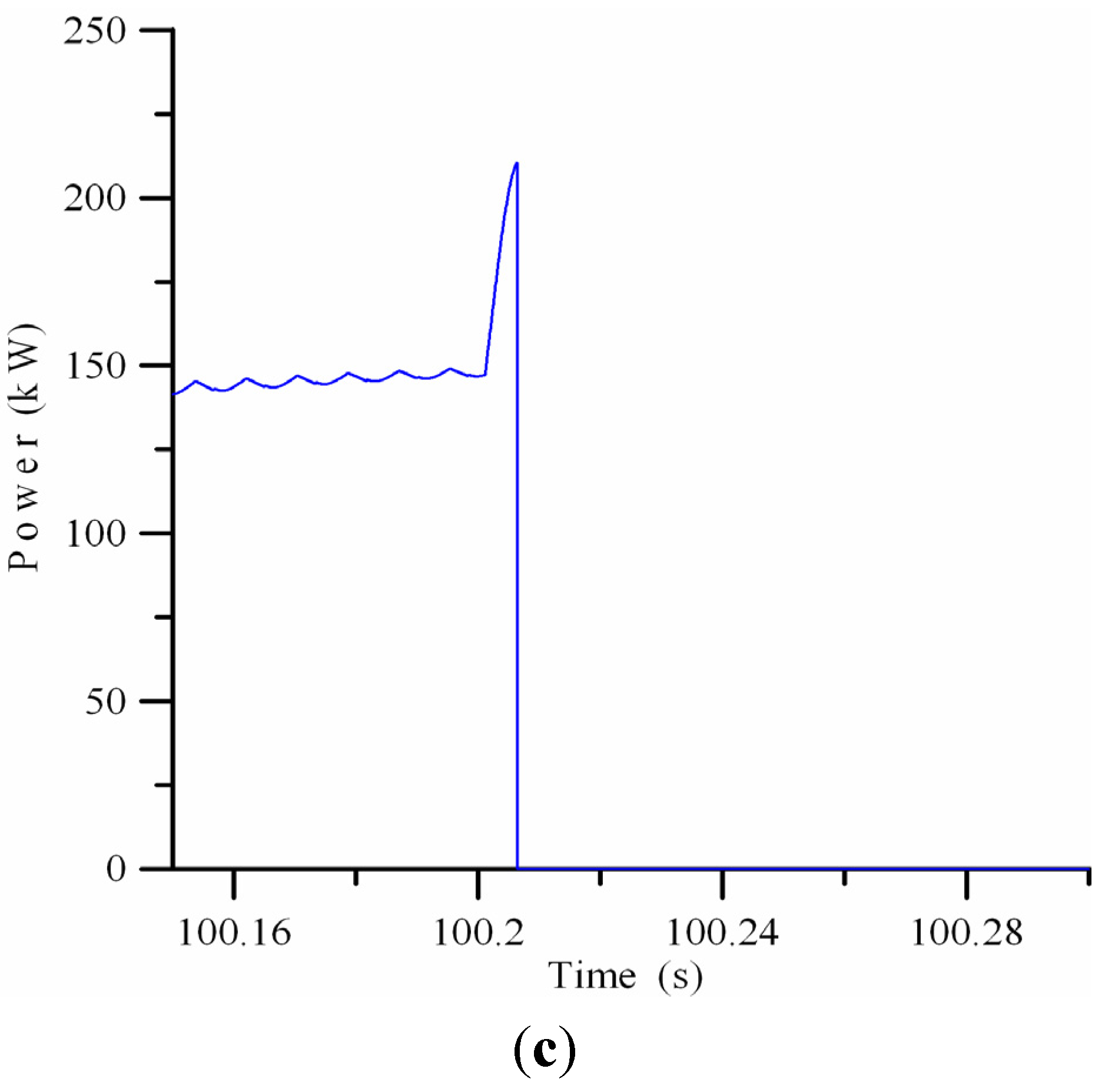

3.1. Data Acquisition and Measurement

3.2. Analysis and Comparison

4. Experimental Results

4.1. Case 1, EMTP Simulation

| Features | PQ | PQVTHDITHD | tTR UT (STFT) | tTR UT (DWT) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Items | Training | Test | Training | Test | Training | Test | Training | Test | |

| Recognition Accuracy (%) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| Time (s) | 1.7845 | 0.00562 | 2.685 | 0.0058 | 1.0781 | 0.00566 | 1.0779 | 0.00565 | |

| Number of Iterations | 123.1 | 224.3 | 80.1 | 79.7 | |||||

4.2. Case 2, EMTP Simulation for Different Loads with the Same Real Power and Reactive Power

| Features | PQ | PQVTHDITHD | tTR UT (STFT) | tTR UT (DWT) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Items | Training | Test | Training | Test | Training | Test | Training | Test | |

| Recognition Accuracy (%) | 66.667 | 53.030 | 85.56 | 60.683 | 96.970 | 83.333 | 100 | 92.121 | |

| Time (s) | 14.2089 | 0.00567 | 19.56 | 0.0060 | 1.7895 | 0.00564 | 1.7888 | 0.00566 | |

| Number of Iterations | 3000 | 3000 | 182.5 | 155.2 | |||||

4.3. Case 3, Experiment

| Features | PQ | PQVTHDITHD | tTR UT (STFT) | tTR UT (DWT) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Items | Training | Test | Training | Test | Training | Test | Training | Test | |

| Recognition Accuracy (%) | 98.485 | 92.424 | 100 | 94.69 | 98.485 | 93.940 | 100 | 96.970 | |

| Time (s) | 1.8502 | 0.00568 | 2.032 | 0.006 | 1.0782 | 0.00569 | 1.0783 | 0.00566 | |

| Number of Iterations | 201.5 | 211.2 | 80.9 | 81.3 | |||||

4.4. Case 4, Experiment for Different Loads with the Same Real Power and Reactive Power

| Features | PQ | PQVTHDITHD | tTR UT (STFT) | tTR UT (DWT) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Items | Training | Test | Training | Test | Training | Test | Training | Test | |

| Recognition Accuracy (%) | 68.182 | 48.485 | 90.561 | 70.230 | 98.485 | 78.788 | 98.485 | 83.333 | |

| Time (s) | 17.354 | 0.00567 | 20.542 | 0.0055 | 1.952 | 0.00561 | 1.885 | 0.00566 | |

| Number of Iterations | 3000 | 3000 | 210.2 | 190.4 | |||||

4.5. Case 5, Turn-off EMTP Simulation

| Features | tTR UT-OFF (STFT) | tTR UT-OFF (DWT) | |||

|---|---|---|---|---|---|

| Items | Training | Test | Training | Test | |

| Recognition Accuracy (%) | 100 | 100 | 100 | 100 | |

| Time (s) | 1.0578 | 0.0056 | 1.0385 | 0.00552 | |

| Number of Iterations | 78.5 | 73.6 | |||

5. Conclusions

Acknowledgments

References

- Chang, H.H. Genetic algorithms and non-intrusive energy management system based economic dispatch for cogeneration units. Energy 2011, 36(1), 181–190. [Google Scholar] [CrossRef]

- Hart, G.W. Nonintrusive appliance load monitoring. Proc. IEEE 1992, 80, 1870–1891. [Google Scholar] [CrossRef]

- Langhman, C.; Lee, K.; Cox, R.; Show, S.; Leeb, S.B.; Norford, L.; Armstrong, P. Power signature analysis. IEEE Power & Energy Mag. 2003, 1(2), 56–63. [Google Scholar] [CrossRef]

- Leeb, S.B. A Conjoint Pattern Recognition Approach to Nonintrusive Load Monitoring. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1993. [Google Scholar]

- Cole, A.I.; Albicki, A. Nonintrusive identification of electrical loads in a three-phase environment based on harmonic content. In Proceedings of 17th IEEE Instrumentation and Measurement Technology Conference, Baltimore, MD, USA, 1–4 May 2000; pp. 24–29.

- Hong, Y.Y.; Chou, J.H. Nonintrusive energy monitoring for microgrids using hybrid self-organizing feature-mapping networks. Energies 2012, 5, 2578–2593. [Google Scholar] [CrossRef]

- Cole, A.I.; Albicki, A. Data extraction for effective non-intrusive identification of residential power loads. In Proceedings of the IEEE Instrumentation and Measurement Technology Conference (IMTE/98), St. Paul, MN, USA, 18–21 May 1998; pp. 812–815.

- Cole, A.I.; Albicki, A. Algorithm for non-intrusive identification of residential appliances. In Proceedings of the IEEE International Symposium on Circuits and Systems (ISCAS’98), Monterey Conference Center, Monterey, CA, USA, 31 May–3 June 1998; pp. 338–341.

- Norford, L.K.; Leeb, S.B. Non-intrusive electrical load monitoring in commercial buildings based on steady-state and transient load-detection algorithm. Energy Build. 1996, 24, 51–64. [Google Scholar] [CrossRef]

- Lee, K.D.; Leeb, S.B.; Norford, L.K.; Armstrong, P.R.; Holloway, J.; Shaw, S.R. Estimation of variable-speed-drive power consumption from harmonic content. IEEE Trans. Energy Convers. 2005, 20(3), 566–574. [Google Scholar] [CrossRef]

- Shaw, S.R.; Leeb, S.B.; Norford, L.K.; Cox, R.W. Nonintrusive load monitoring and diagnostics in power systems. IEEE Trans. Instrum. Meas. 2008, 57(7), 1445–1454. [Google Scholar] [CrossRef]

- Marceau, M.L.; Zmeureanu, R. Nonintrusive load disaggregation computer program to estimate the energy consumption of major end users in residential buildings. Energy Convers. Manag. 2000, 41, 1389–1403. [Google Scholar] [CrossRef]

- Farinaccio, L.; Zmeureanu, R. Using a pattern recognition approach to disaggregate the total electricity consumption in a house into the major end-uses. Energy Build. 1999, 30, 245–259. [Google Scholar] [CrossRef]

- Srinivasan, D.; Ng, W.S.; Liew, A.C. Neural-network-based signature recognition for harmonic source identification. IEEE Trans. Power Deliv. 2006, 21(1), 398–405. [Google Scholar] [CrossRef]

- Roos, J.G.; Lane, I.E.; Lane, E.C.; Hanche, G.P. Using neural networks for non-intrusive monitoring of industrial electrical loads. In Proceedings of the IEEE Instrumentation and Measurement Technology Conference, Hamamatsu, Japan, 10–14 May 1994; pp. 1115–1118.

- Chang, H.H.; Yang, H.T.; Lin, C.L. Load identification in neural networks for a non-intrusive monitoring of industrial electrical loads. Lect. Notes Comput. Sci. 2008, 5236, 664–674. [Google Scholar]

- Zhao, C.; He, M.; Zhao, X. Analysis of transient waveform based on combined short time Fourier transform and wavelet transform. In Proceedings of the IEEE International Conference on Power System Technology, Singapore, 21–24 November 2004; pp. 1122–1126.

- Robertson, D.C.; Camps, O.I.; Mayer, J.S.; Gish, W.B. Wavelets and electromagnetic power system transients. IEEE Trans. Power Deliv. 1996, 11(2), 1050–1056. [Google Scholar] [CrossRef]

- Leeb, S.B.; Shaw, S.R.; Kirtly, J.L., Jr. Transient event detection in spectral envelop estimates for nonintrusive load monitoring. IEEE Trans. Power Deliv. 1995, 10(3), 1200–1210. [Google Scholar] [CrossRef]

- Khan, U.A.; Leeb, S.B.; Lee, M.C. A multiprocessor for transient event detection. IEEE Trans. Power Deliv. 1997, 12(1), 51–60. [Google Scholar] [CrossRef]

- Kosko, B. Neural Networks and Fuzzy Systems: A Dynamical Systems Approach to Machine Intelligence; Prentice-Hall: Englewood Cliff, NJ, USA, 1992. [Google Scholar]

- Hong, Y.Y.; Chen, B.Y. Locating switched capacitor using wavelet transform and hybrid principal component analysis network. IEEE Trans. Power Deliv. 2007, 22(2), 1145–1152. [Google Scholar] [CrossRef]

- Liao, C.C.; Yang, H.T.; Chang, H.H. Denoising techniques with a spatial noise-suppression method for wavelet-based power-quality monitoring. IEEE Trans. Instrum. Meas. 2011, 60(6), 1986–1996. [Google Scholar] [CrossRef]

- Chang, H.H.; Chen, K.L.; Tsai, Y.P.; Lee, W.J. A new measurement method for power signatures of non-intrusive demand monitoring and load identification. IEEE Trans. Ind. Appl. 2012, 48(2), 764–771. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Chang, H.-H. Non-Intrusive Demand Monitoring and Load Identification for Energy Management Systems Based on Transient Feature Analyses. Energies 2012, 5, 4569-4589. https://doi.org/10.3390/en5114569

Chang H-H. Non-Intrusive Demand Monitoring and Load Identification for Energy Management Systems Based on Transient Feature Analyses. Energies. 2012; 5(11):4569-4589. https://doi.org/10.3390/en5114569

Chicago/Turabian StyleChang, Hsueh-Hsien. 2012. "Non-Intrusive Demand Monitoring and Load Identification for Energy Management Systems Based on Transient Feature Analyses" Energies 5, no. 11: 4569-4589. https://doi.org/10.3390/en5114569