Linear Active Disturbance Rejection Control of Waste Heat Recovery Systems with Organic Rankine Cycles

Abstract

:1. Introduction

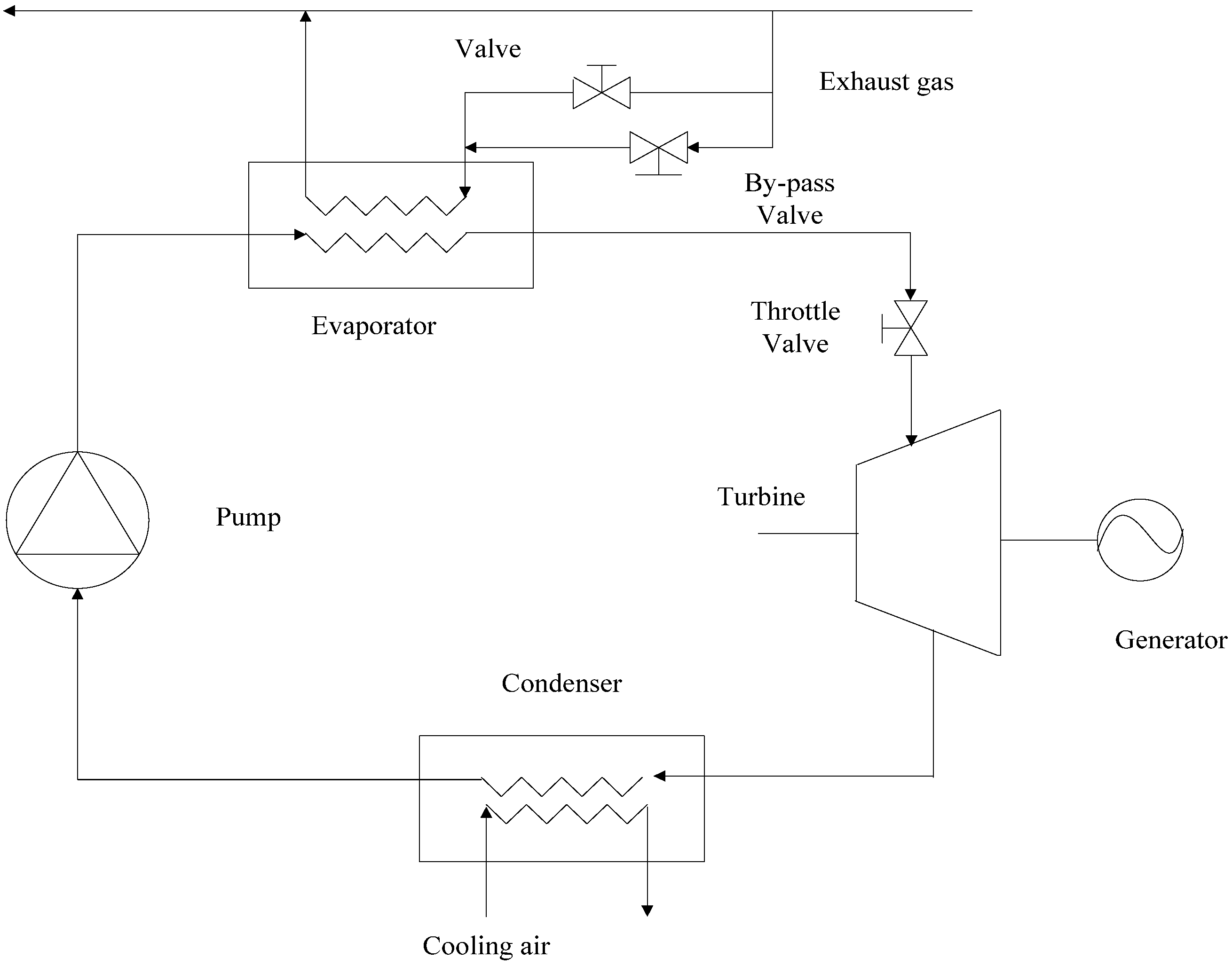

2. System Description

3. Model Development via Parameter Identification

4. LADRC Algorithm

4.1. Extended State Observer Design

4.2. Control Algorithm

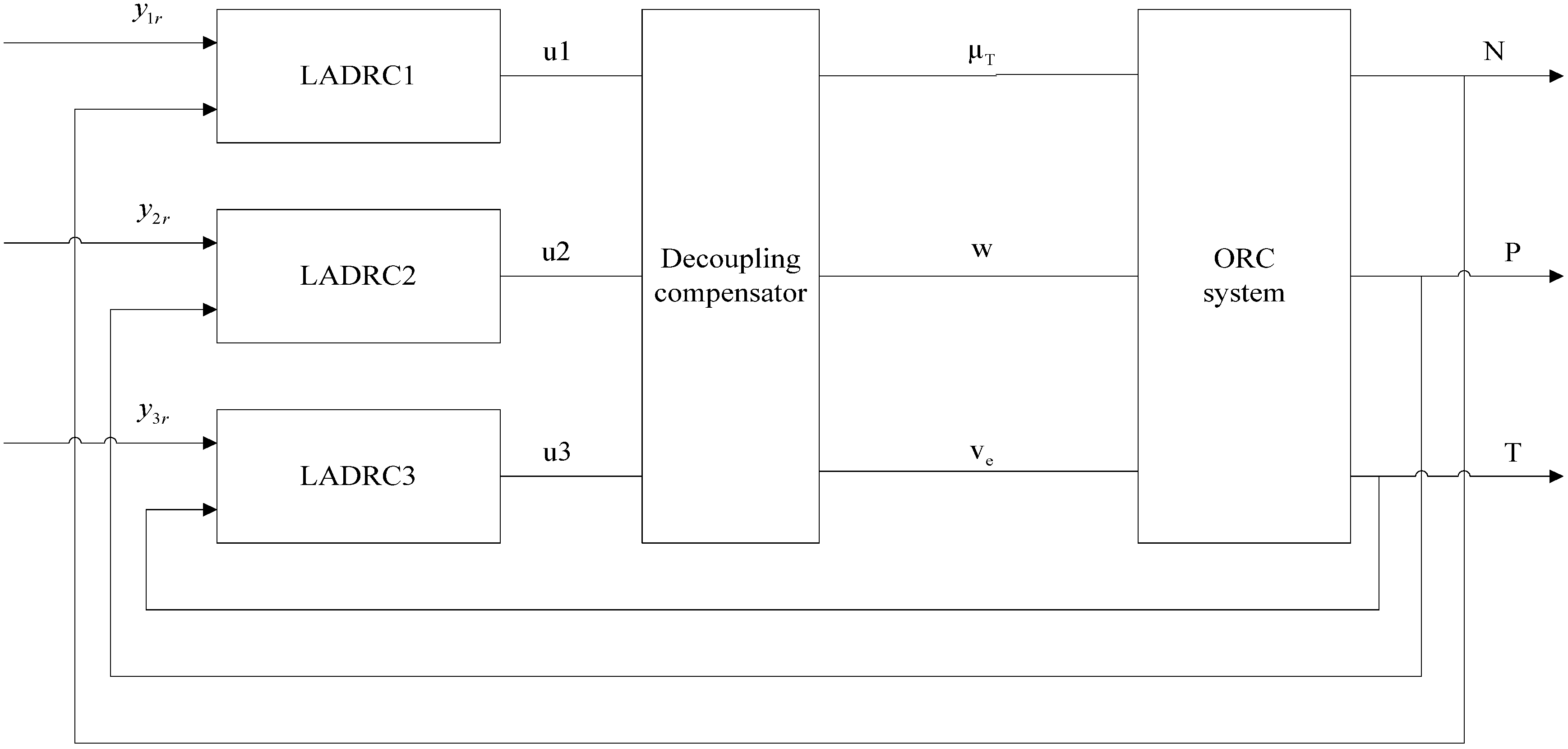

4.3. LADRC of an ORC Process

- Step 1:

- Collect and record the measured data of the ORC output and input , .

- Step 2:

- Obtain the transfer function model by a least-square parameter identification algorithm.

- Step 3:

- Apply the static decoupling method to the coupled system model.

- Step 4:

- Design the linear extended state observers for the LADRC controllers.

- Step 5:

- Tune the control parameter according to the original plant information.

- Step 6:

- Select the observer tuning parameter as in (9), and controller tuning parameter in (12) based on the bandwidth requirement of the closed-loop system.

5. Simulation Studies

5.1. Tracking Ability Test

5.1.1. Tracking the Set-point of Power Output

5.1.2. Tracking the Set-point of Evaporator Pressure

5.1.3. Tracking the Set-point of Evaporator Temperature

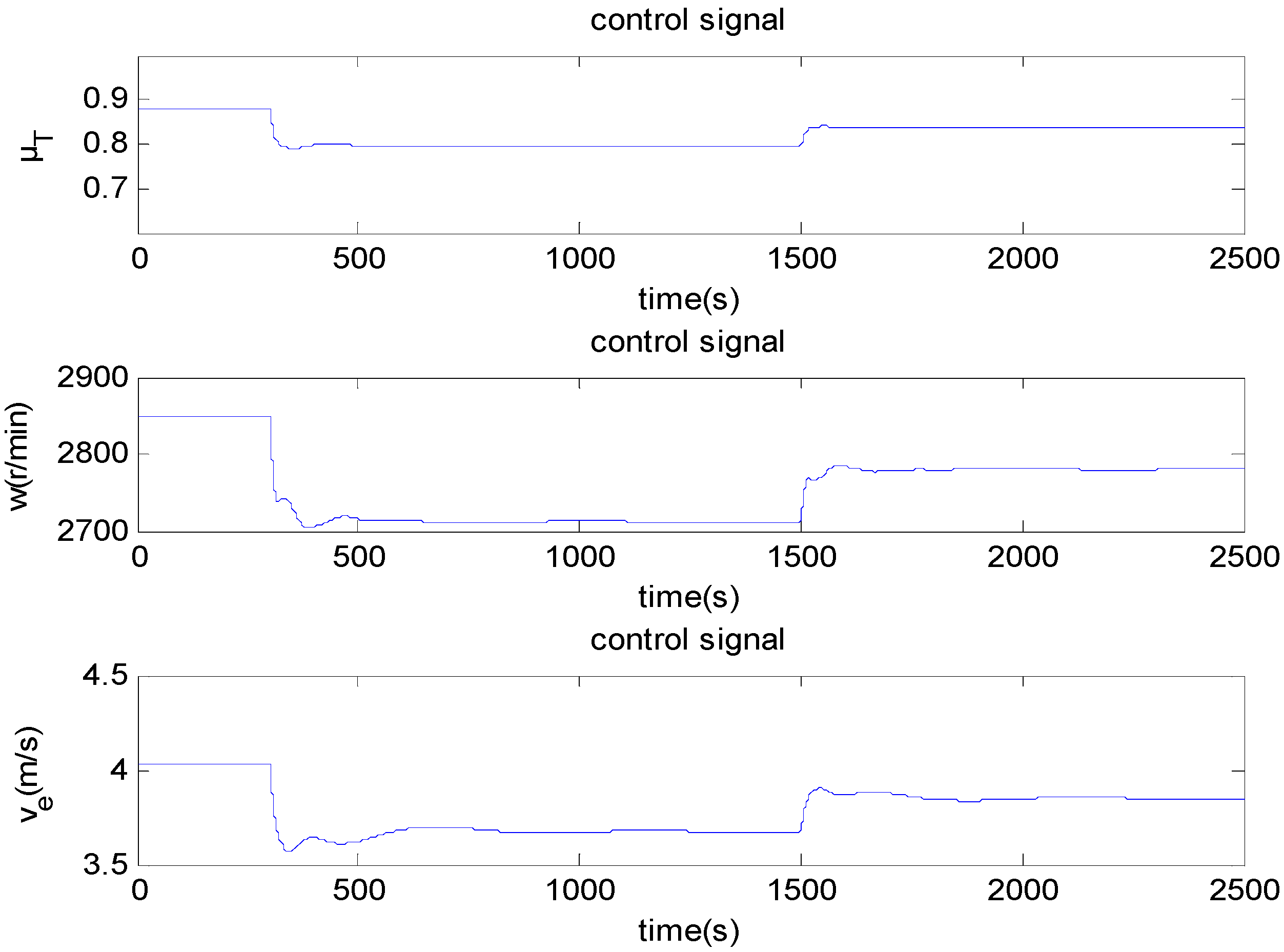

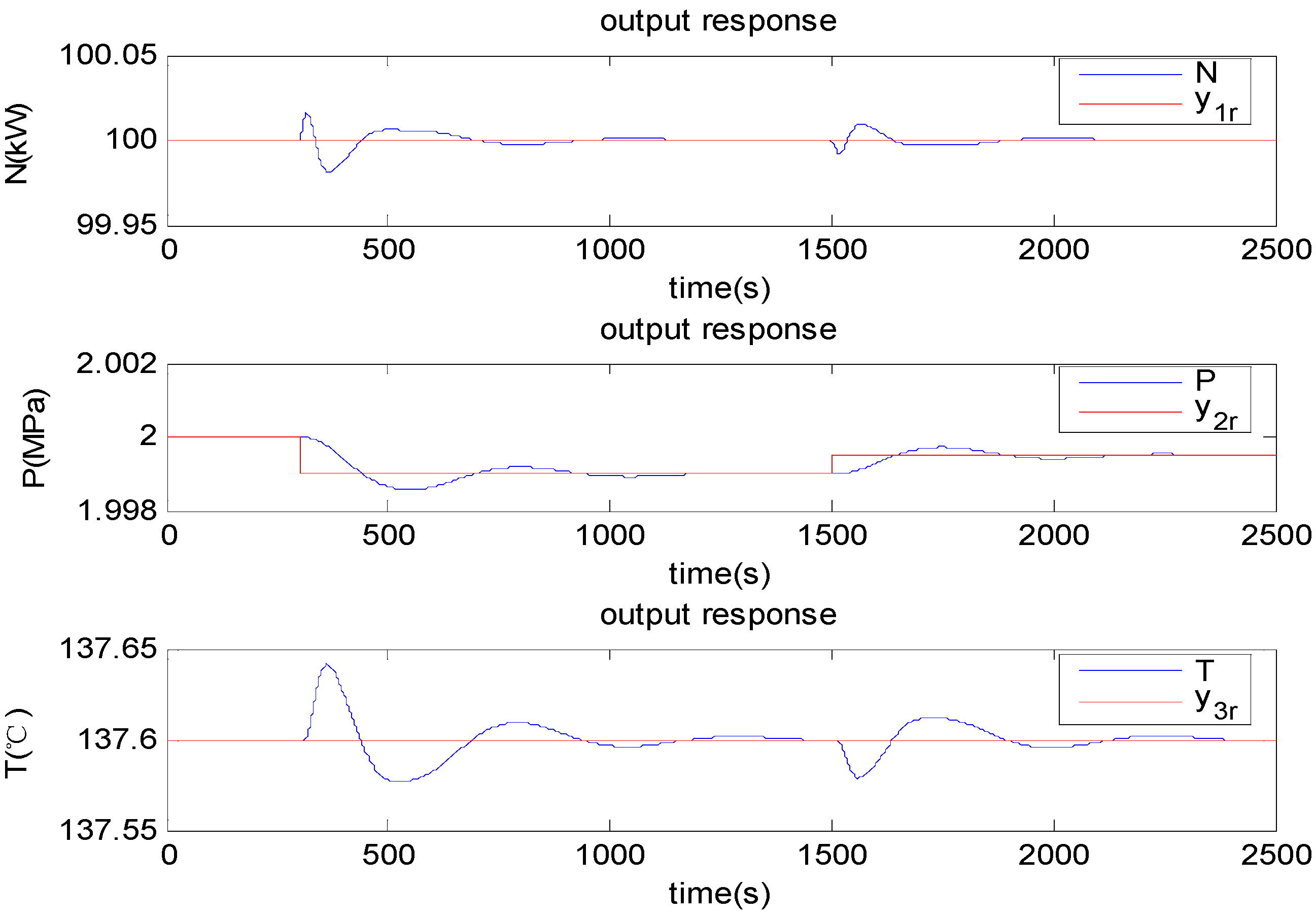

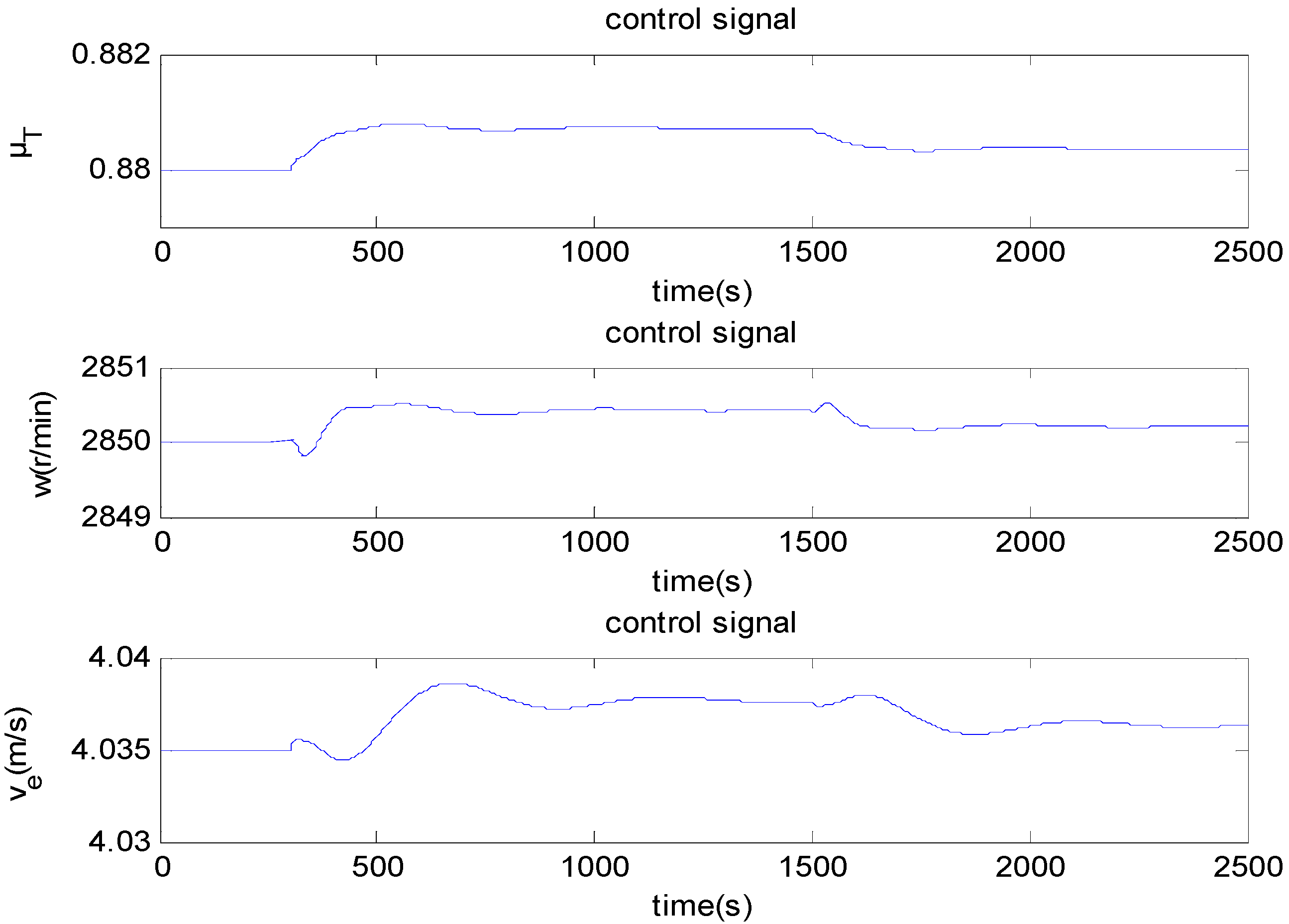

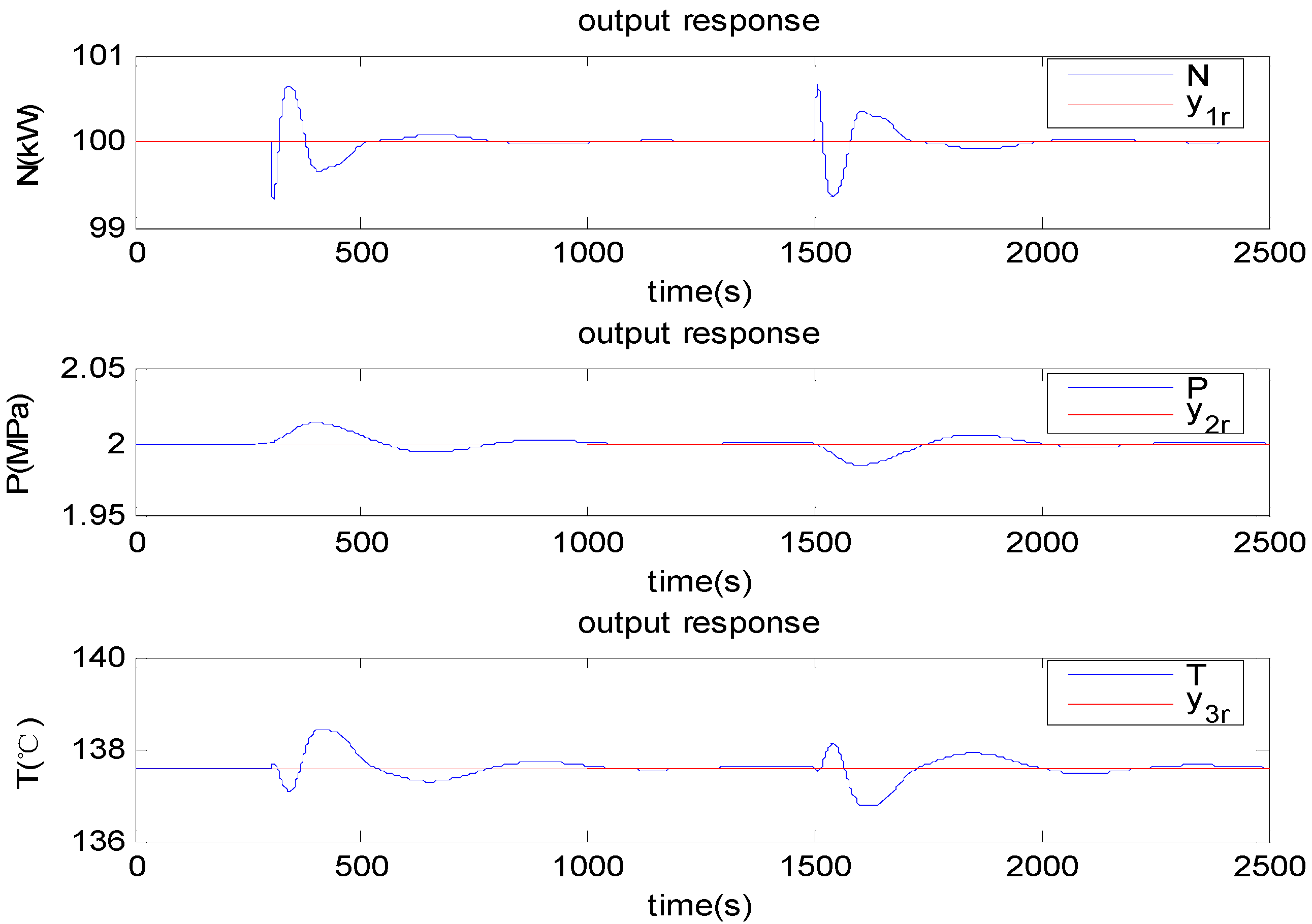

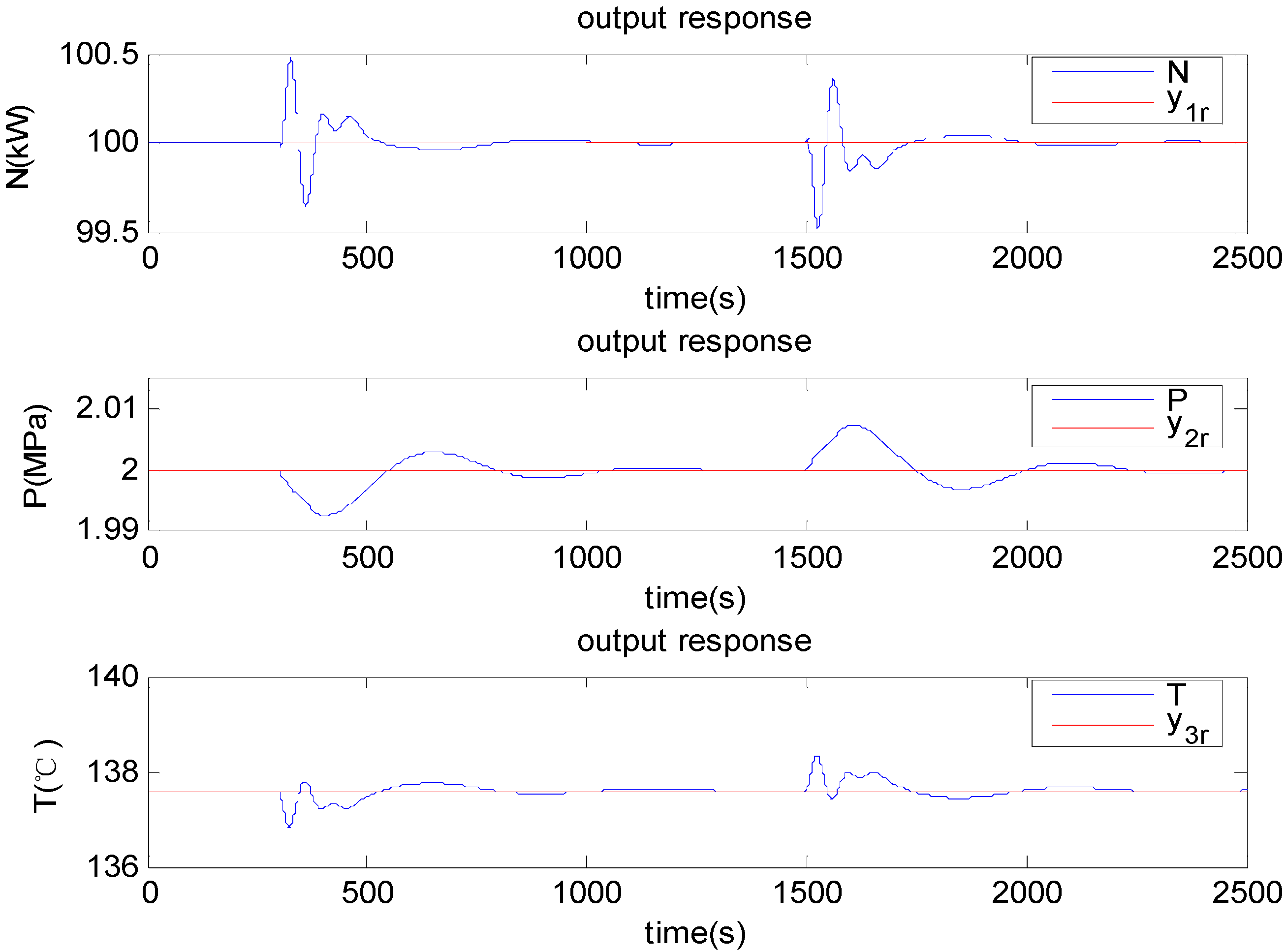

5.2. Disturbance Rejection Test

5.2.1. Disturbance in the Throttle Valve Position

5.2.2. Disturbance to the Velocity of Exhaust Gas

6. Conclusions

Nomenclature

| N | Output power [kW] | k | Controller gain value |

| P | Throttle pressure [MPa] | λ | Characteristic polynomial |

| T | Outlet temperature of evaporator [°C] | A,B,C,D | System matrices |

| Throttle valve position [%] | I | Identity matrix | |

| w | Motor speed for pump [r/min] | ORC | Organic Rankine cycle |

| v | Velocity [m/s] | LADRC | Linear active disturbance rejection control |

| y | Controlled vector | ||

| u | Manipulated vector | ||

| b | Input gain | Subscripts | |

| L | Observer gain vector | r | Set-point |

| ω | Controller bandwidth | c | Controller |

| α | Polynomial coefficients | o | Observer |

| t | Time [s] | e | Exhaust gas |

| , φ | State variable coefficient matrix | i | The ith loop |

| x | State variable/vector | ||

| External disturbance |

Acknowledgments

References

- Hung, T.C.; Shai, T.Y.; Wang, S.K. A review of Organic Rankine Cycles (ORCs) for the recovery of low-grade waste heat. Appl. Energy 1997, 6, 661–667. [Google Scholar] [CrossRef]

- Tchanche, B.F.; Lambrinos, G.; Frangoudakis, A.; Papadakis, G. Low-grade heat conversion into power using Organic Rankine Cycles—a review of various applications. Renew. Sustain. Energy Rev. 2011, 15, 3963–3979. [Google Scholar] [CrossRef]

- Wang, E.H.; Zhang, H.G.; Fan, B.Y.; Ouyang, M.G. Study of working fluid selection of organic Rankine cycle (ORC) for engine waste heat recovery. Energy 2011, 36, 3406–3418. [Google Scholar] [CrossRef]

- Hung, T.C.; Wang, S.K.; Kuo, C.H.; Pei, B.S.; Tsai, K.F. A study of organic working fluids on system efficiency of an ORC using low-grade energy sources. Energy 2010, 35, 1403–1411. [Google Scholar] [CrossRef]

- Luján, J.M.; Serrano, J.R.; Dolz, V.; Sánchez, J. Model of the expansion process for R245fa in an Organic Rankine Cycle (ORC). Appl. Therm. Eng. 2012, 40, 248–257. [Google Scholar] [CrossRef]

- Wei, D.H.; Lu, X.S.; Lu, Z.; Gu, J.M. Dynamic modeling and simulation of an Organic Rankine Cycle (ORC) system for waste heat recovery. Appl. Therm. Eng 2008, 28, 1216–1224. [Google Scholar] [CrossRef]

- Quoilin, S.; Aumann, R.; Grill, A.; Schuster, A.; Lemort, V.; Spliethoff, H. Dynamic modeling and optimal control strategy of waste heat recovery Organic Rankine Cycles. Appl. Energy 2011, 88, 2183–2190. [Google Scholar] [CrossRef]

- Vaja, I.; Gambarotta, A. Dynamic model of an organic Rankine cycle system. Part I—Mathematical description of main components. In Proceedings of 23rd International Conference on Efficiency, Cost, Optimization, Simulation and Environment Impact of Energy, Lausanne, Switzerland, 14–17 June 2010.

- Vaja, I.; Gambarotta, A. Dynamic Model of an Organic Rankine Cycle System. Part II—The full Model: Description and Validation. In Proceedings of 23rd International Conference on Efficiency, Cost, Optimization, Simulation and Environment Impact of Energy, Lausanne, Switzerland, 14–17 June 2010.

- Wei, D.H.; Lu, X.S.; Lu, Z.; Gu, J.M. Performance analysis and optimization of Organic Rankine Cycle (ORC) for waste heat recovery. Energy Convers. Manag. 2007, 48, 1113–1119. [Google Scholar] [CrossRef]

- Clemente, S.; Micheli, D.; Reini, M.; Taccan, R. Energy efficiency analysis of Organic Rankine Cycles with scroll expanders for cogenerative applications. Appl. Energy 2012, 97, 792–801. [Google Scholar] [CrossRef]

- Quoilin, S.; Lemort, V.; Lebrun, J. Experimental study and modeling of an Organic Rankine Cycle using scroll expender. Appl. Energy 2010, 87, 1260–1268. [Google Scholar] [CrossRef]

- Lemort, V.; Quoilin, S.; Cuevas, C.; Lebrun, J. Testing and modeling a scroll expander integrated into an Organic Rankine Cycle. Appl. Therm. Eng. 2009, 29, 3094–3102. [Google Scholar] [CrossRef]

- Desai, N.B.; Bandyopadhyay, S. Process integration of organic Rankine cycle. Energy 2009, 34, 1674–1686. [Google Scholar] [CrossRef]

- Zhang, J.H.; Zhang, W.F.; Hou, G.L.; Fang, F. Dynamic modeling and multivariable control of Organic Rankine Cycle in waste heat utilizing processes. Comput. Math. Appl. 2012, 64, 908–921. [Google Scholar] [CrossRef]

- Zhang, J.H.; Li, Y.; Wang, Z.F.; Hou, G.L. Dynamic characteristics and predictive control for evaporator. In Proceedings of the 2011 International Conference on Advanced Mechatronic Systems, Zhengzhou, China, 11–13 August 2011; pp. 513–518.

- Hou, G.L.; Sun, R.; Hu, G.Q.; Zhang, J.H. Supervisory predictive control of evaporator in Organic Rankine Cycle (ORC) system for waste heat recovery. In Proceedings of the 2011 International Conference on Advanced Mechatronic Systems, Zhengzhou, China, 11–13 August 2011; pp. 306–311.

- Han, J. Nonlinear state error feedback control. Control Des. 1995, 10, 221–225. [Google Scholar]

- Zhou, W.K.; Gao, Z.Q. An active disturbance rejection approach to tension and velocity regulations in web processing lines. In Proceedings of 16th IEEE International Conference on Control Applications, Singapore, 1–3 October 2007; pp. 842–848.

- Zheng, Q.; Dong, L.; Gao, Z. Control and Time-Varying Rotation Rate Estimation of Vibrational MEMS Gyroscopes. In Proceedings of IEEE Multi-conference on Systems and Control, Singapore, 1–3 October 2007; pp. 118–123.

- Huang, H.P.; Wu, L.Q.; Han, J.Q.; Gao, F.; Lin, Y.J. A new synthesis method for unit coordinated control system in thermal power plant-ADRC control scheme. In Proceedings of 2004 International Conference on Power System Technology, Singapore, 21–24 November 2004; pp. 133–138.

- Dong, L.L.; Zhang, Y.; Gao, Z.Q. A robust decentralized load frequency controller for interconnected power systems. ISA Trans. 2012, 51, 410–419. [Google Scholar] [CrossRef]

- Gao, Z.Q. Scaling and parameterization based controller tuning. In Proceedings of American Control Conference, Denver, CO, USA, 4–6 June 2003; pp. 4996–4996.

- Goforth, F.; Zheng, Q.; Gao, Z.Q. A novel practical control approach for rate independent hysteretic systems. ISA Trans. 2012, 51, 477–484. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Q.; Chen, Z.Z.; Gao, Z.Q. A practical approach to disturbance decoupling control. Control. Eng. Pract. 2009, 17, 1016–1025. [Google Scholar] [CrossRef]

- Ananth, I.; Chidambaram, M. Closed-loop identification of transfer function model for unstable systems. J. Franklin Inst. 1999, 1055–1061. [Google Scholar] [CrossRef]

- Haley, T.A.; Mulvaney, S.J. On-line system identification and control design of an extrusion cooking process: Part 1. System identification. Food Control. 2000, 11, 103–120. [Google Scholar] [CrossRef]

- Xiao, Y.S.; Ding, F.; Zhou, Y.; Li, M.; Dai, J.Y. On consistency of recursive least squares identification algorithms for controlled auto-regression models. Appl. Math. Model. 2008, 32, 2207–2215. [Google Scholar] [CrossRef]

- Zheng, Q.; Chen, Z.Z.; Gao, Z.Q. A dynamic decoupling control approach and its applications to chemical processes. In Proceedings of American Control Conference, New York, NY, USA, 9–13 July 2007; pp. 5176–5181.

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Feng, J.; Zhou, Y.; Fang, F.; Yue, H. Linear Active Disturbance Rejection Control of Waste Heat Recovery Systems with Organic Rankine Cycles. Energies 2012, 5, 5111-5125. https://doi.org/10.3390/en5125111

Zhang J, Feng J, Zhou Y, Fang F, Yue H. Linear Active Disturbance Rejection Control of Waste Heat Recovery Systems with Organic Rankine Cycles. Energies. 2012; 5(12):5111-5125. https://doi.org/10.3390/en5125111

Chicago/Turabian StyleZhang, Jianhua, Jiancun Feng, Yeli Zhou, Fang Fang, and Hong Yue. 2012. "Linear Active Disturbance Rejection Control of Waste Heat Recovery Systems with Organic Rankine Cycles" Energies 5, no. 12: 5111-5125. https://doi.org/10.3390/en5125111