1.1. Overview

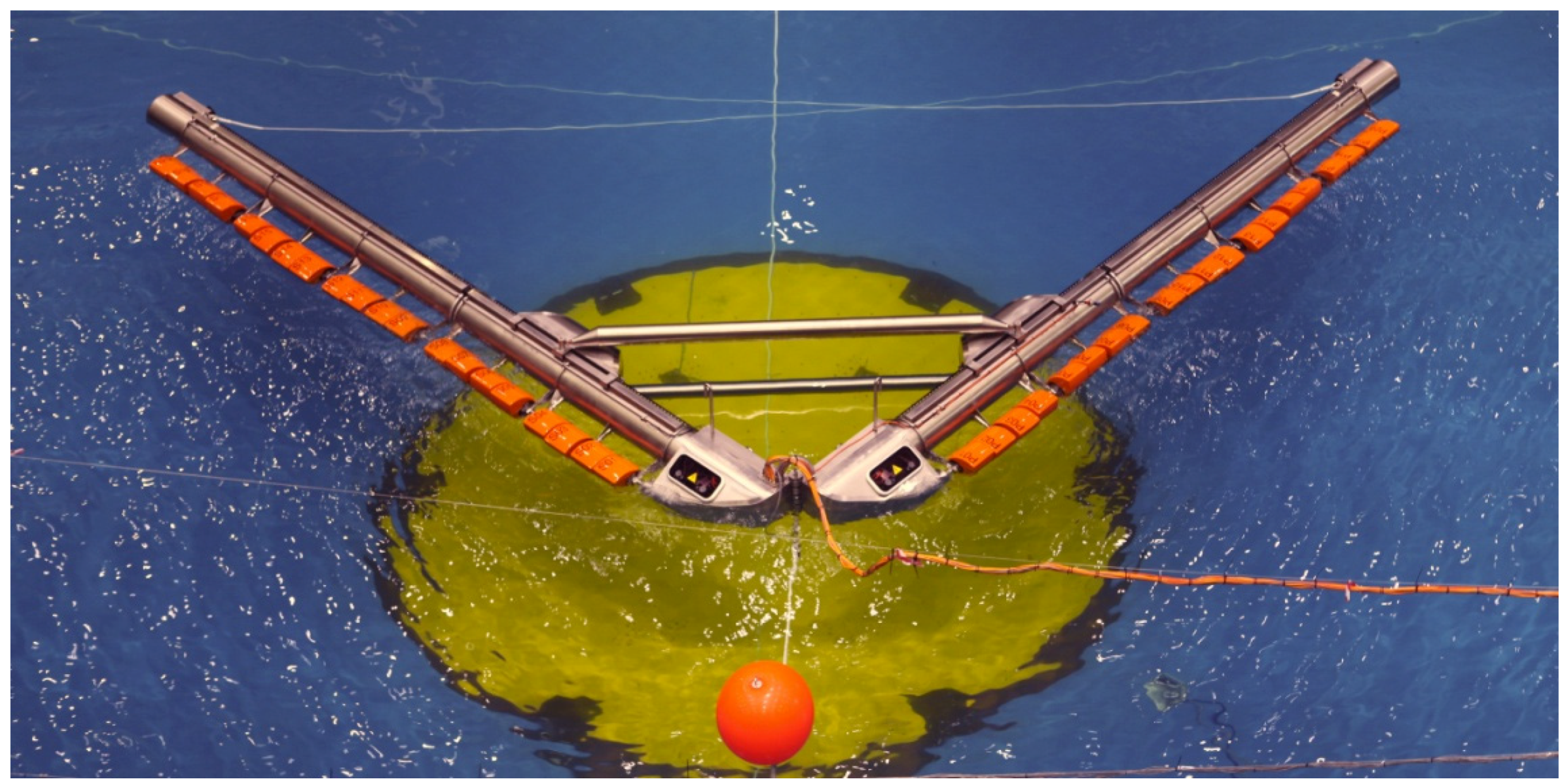

The performance of one rotor of the WEPTOS WEC model was investigated at Aalborg University prior to the extensive tests on the complete model at the Cantabria Coastal and Ocean Basin site (CCOB, Spain) in September 2011 [

6].

Table 1.

Overview of the non-dimensional performance (

η), rotational speed (

ω) and torque (

τ) in the power production wave states tested with an optimized linear and constant PTO loading in long-crested irregular waves [

1].

Table 1.

Overview of the non-dimensional performance (η), rotational speed (ω) and torque (τ) in the power production wave states tested with an optimized linear and constant PTO loading in long-crested irregular waves [1].

| Target Waves | Constant Loading | Linear Loading |

|---|

| WS | Hs | Tp | η | Hm0 | ω | τ | η | Hm0 | ω | τ |

|---|

| [m] | [s] | [-] | [m] | [rpm] | [Nm] | [-] | [m] | [rpm] | [Nm] |

|---|

| 1 | 0.047 | 1.06 | 0.39 | 0.041 | 4.19 | 2.94 | 0.43 | 0.042 | 3.81 | 3.51 |

| 2 | 0.084 | 1.28 | 0.26 | 0.074 | 8.2 | 4.6 | 0.32 | 0.077 | 7.0 | 6.5 |

| 3 | 0.118 | 1.51 | 0.17 | 0.104 | 9.2 | 6.3 | 0.21 | 0.102 | 7.7 | 8.0 |

| 4 | 0.165 | 1.72 | 0.11 | 0.143 | 9.4 | 8.4 | 0.11 | 0.147 | 8.2 | 9.6 |

| 5 | 0.212 | 1.92 | 0.08 | 0.171 | 8.5 | 10.0 | 0.06 | 0.207 | 7.5 | 12.7 |

| 6 | 0.043 | 1.16 | 0.34 | 0.037 | 2.7 | 3.3 | | | | |

| 7 | 0.085 | 1.45 | 0.19 | 0.078 | 5.8 | 5.8 | | | | |

| 8 | 0.128 | 1.74 | 0.11 | 0.113 | 6.2 | 7.8 | | | | |

| 9 | 0.171 | 2.03 | 0.06 | 0.143 | 6.2 | 8.8 | 0.06 | 0.162 | 6.2 | 9.2 |

| 10 | 0.214 | 2.32 | 0.03 | 0.171 | 5.2 | 9.5 | | | | |

| 11 | 0.085 | 1.72 | 0.12 | 0.074 | 2.8 | 6.8 | 0.13 | 0.078 | 3.9 | 6.2 |

| 12 | 0.128 | 2.03 | 0.07 | 0.103 | 3.7 | 7.9 | | | | |

| 0A | 0.04 | 0.97 | 0.48 | 0.035 | 3.5 | 2.6 | 0.37 | 0.033 | 2.9 | 2.3 |

| 0B | 0.035 | 0.9 | 0.57 | 0.027 | 2.4 | 2.2 | | | | |

These experimental tests were performed with 14 different power production wave states and five extreme wave states [

2]. However, the performance has only been assessed in seven of the 14 wave states with a linear PTO loading, while all of them have been used with a constant PTO loading (PTO controlled to achieve a constant torque on the axle for any rotational speed). In the assessment of the experimental data, the wave conditions are characterised by the target peak wave period,

Tp, and the estimate of the significant wave height,

Hm0, obtained through 3D wave analysis.

As it can be seen in

Table 1, the prototype performance is in general better with a linear PTO loading, except in the smallest wave conditions (WS 0A). The optimal performance with both PTO loadings will be used to estimate the performance of the WEPTOS WEC for in Hanstholm, while only the tests performed with a linear PTO loading will be used to estimate the

ω and

τ.

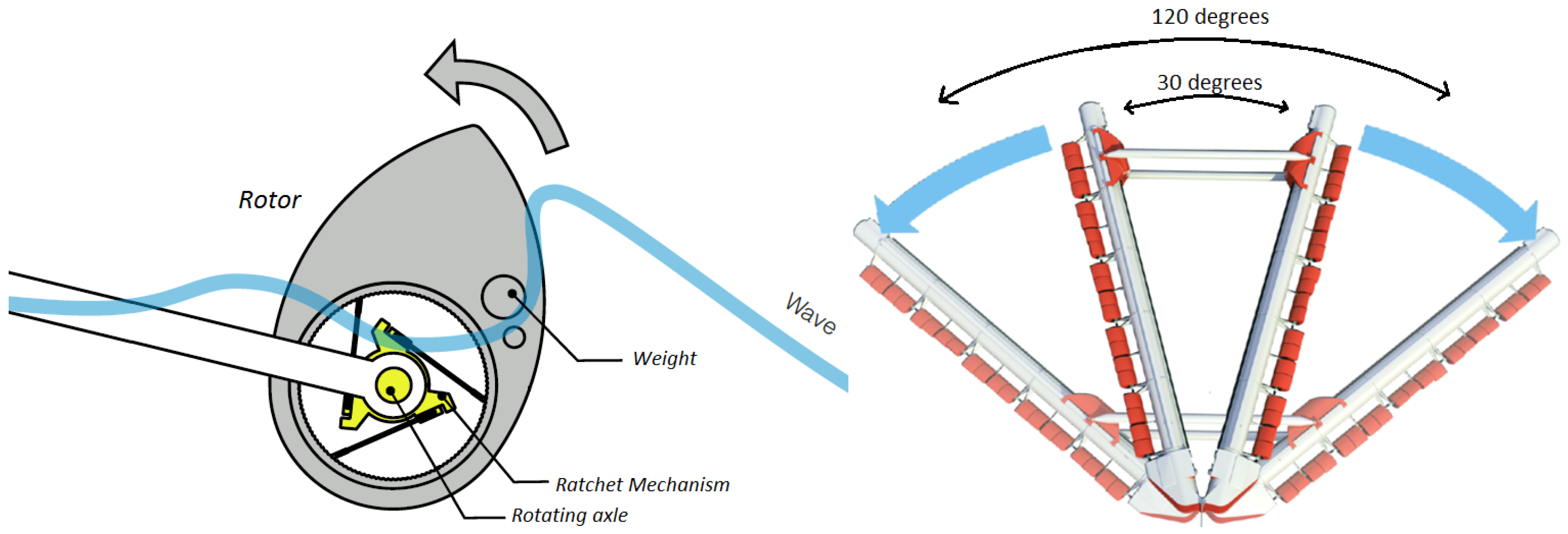

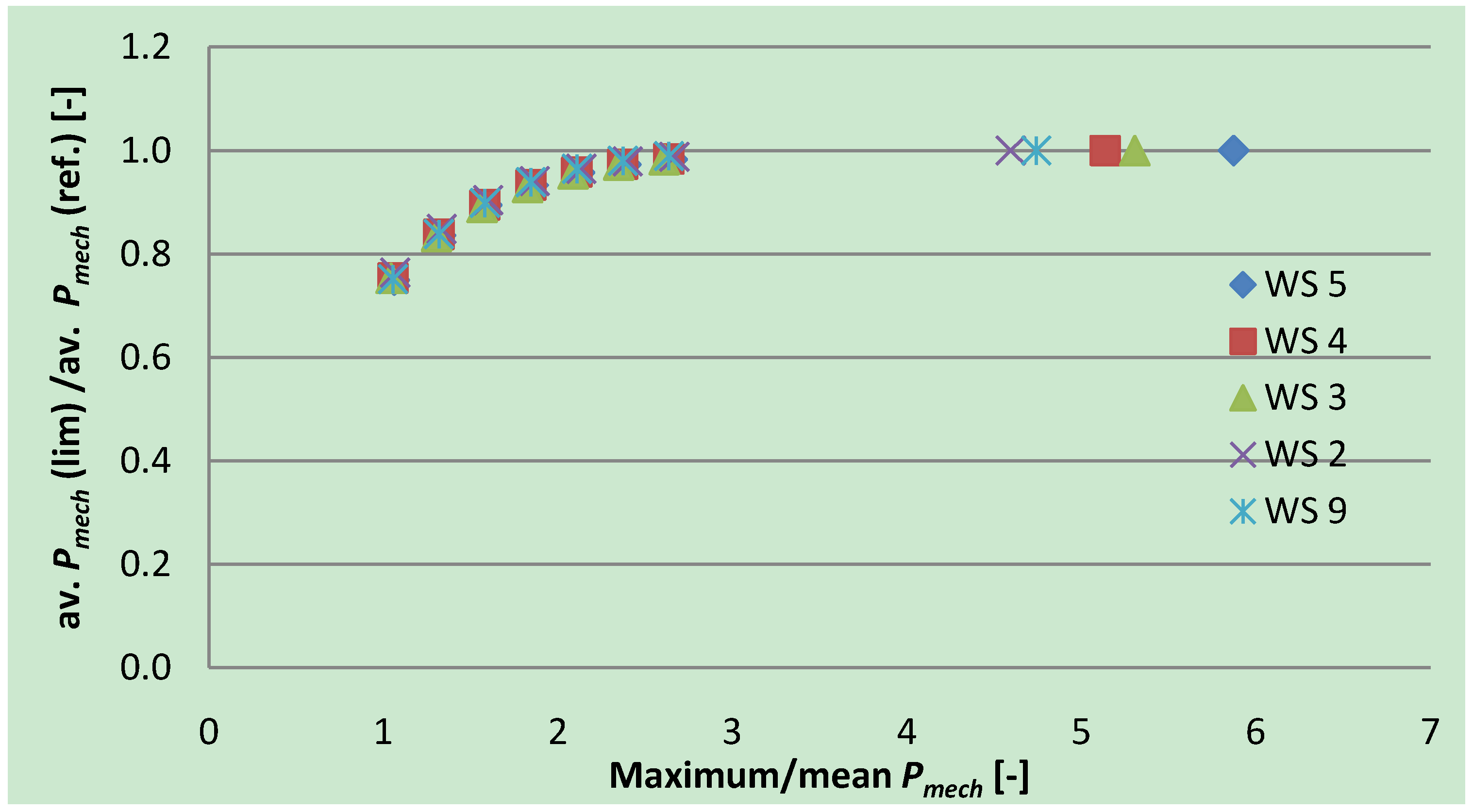

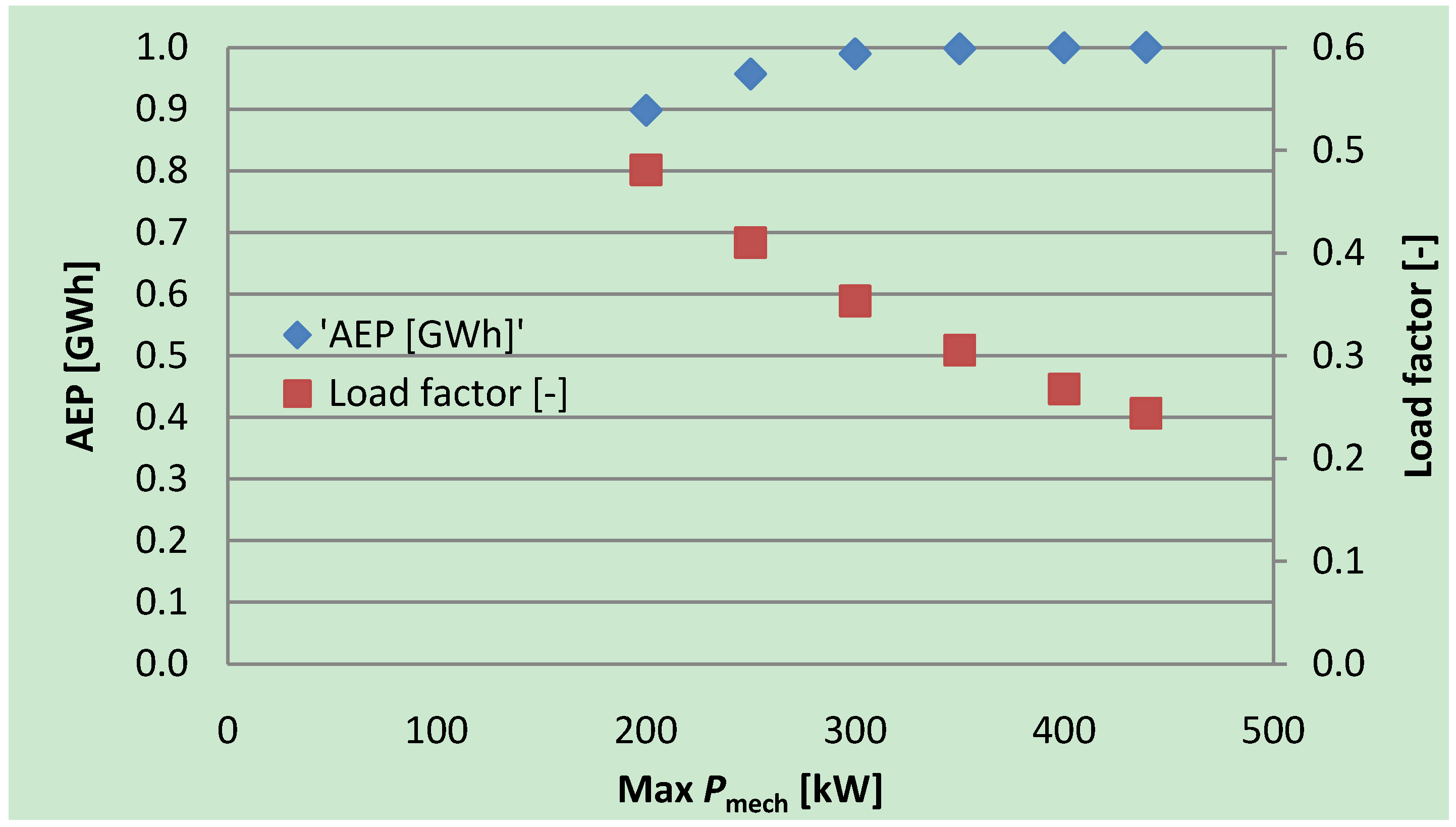

1.3. Maximum-to-Mean Ratio of the Mechanical Power

The maximum-to-mean ratio of the

Pmech in normal operation of the WEPTOS model is presented in

Figure 4 for five different wave states. Besides the measured and reference case, where

Pmech was not limited (outer right marker of each sample), the impact on limiting the maximum

Pmech of each sample to2.5, 2.3, 2.1, 1.9, 1.7, 1.5 and 1.3 times their mean value has been analysed. This corresponds to having a limited PTO capacity, which is relative to the average

Pmech in the corresponding time series of a wave state. So, the unlimited and limited maximum-to-mean

Pmech ratios are given in function of the relative average

Pmech (

Pmech with limitation/

Pmech of the reference).

Figure 4.

Impact on the performance in normal operating conditions, for 5 wave states with linear PTO loading, by limiting the maximum Pmech relative to the average Pmech of the unlimited case.

Figure 4.

Impact on the performance in normal operating conditions, for 5 wave states with linear PTO loading, by limiting the maximum Pmech relative to the average Pmech of the unlimited case.

The drop in performance is approximately the same in all the different wave states and it is considered quite low. In the case where the maximum-to-mean ratio is unlimited, the ratio is approximately 5, while if the ratio is forced to 1, between the maximum

Pmech and the average

Pmech in the unlimited case, only a drop in performance of 25% is experienced. This power levelling is considered small, especially as setting a limit to

Pmech in WS 5 will only induce a drop in performance in WS 5, but will almost not be felt in WS 4 [

8].

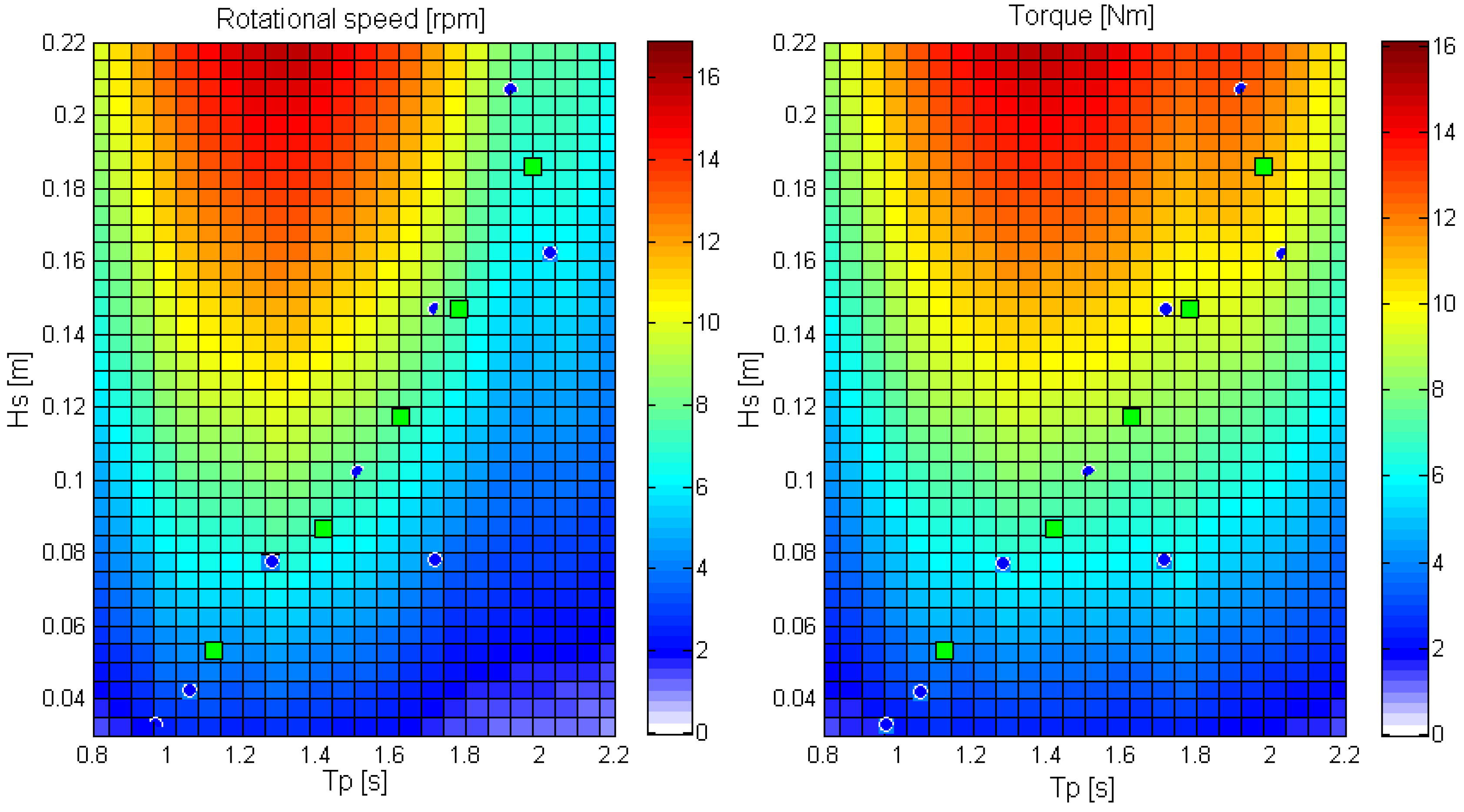

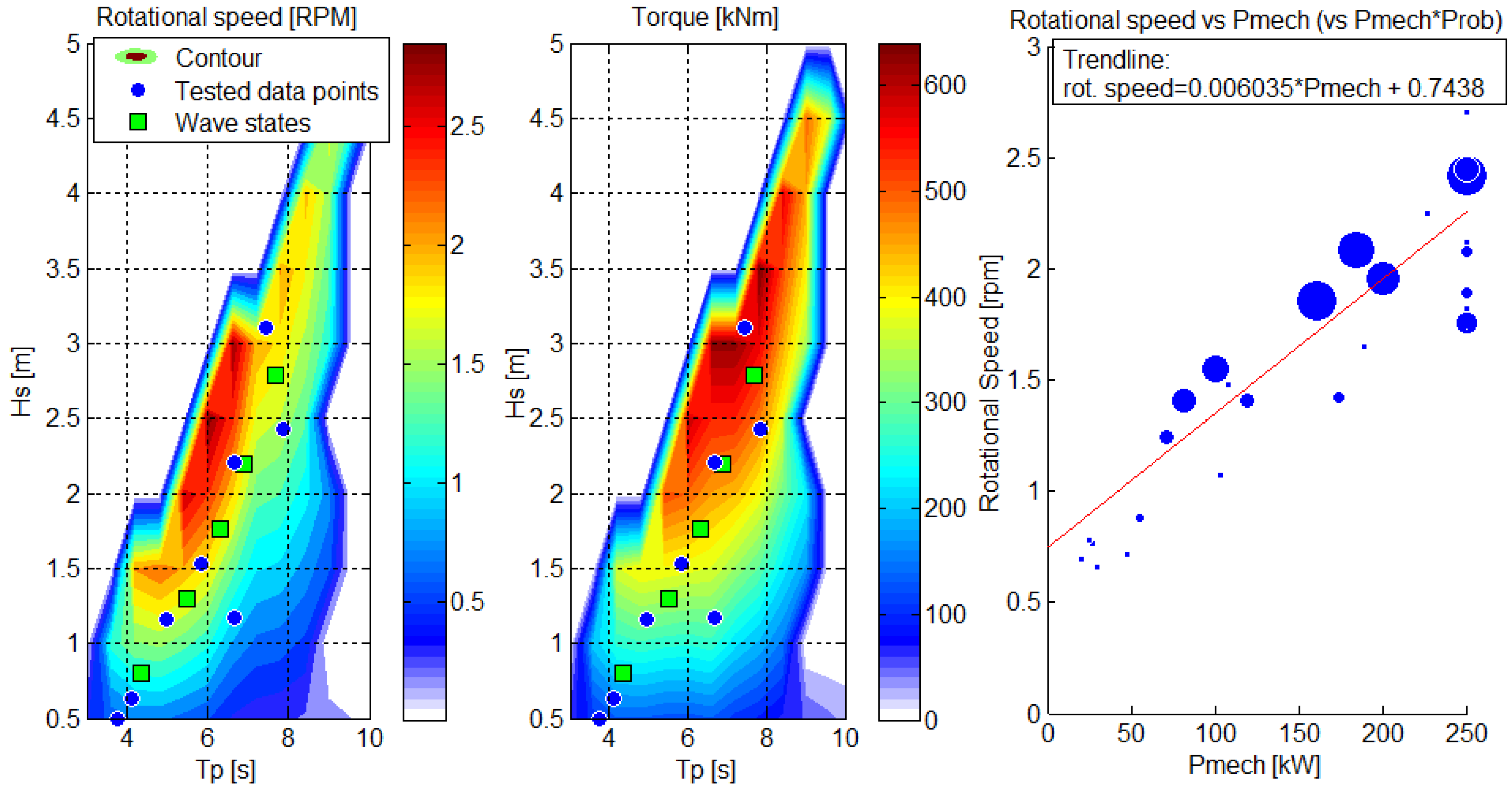

1.4. Rotational Speed and Torque on the Axle

The rotational speed (

ω) and torque (

τ) on each axle of the WEPTOS model have been measured with a linear PTO loading in eight different wave conditions. Although the data points are less abundant (only eight instead of 14) than those performed with a constant PTO loading, they still enable a good representation of

ω and

τ for the Hanstholm wave conditions. This can be seen in

Figure 5, where the wave states representing the wave conditions in Hanstholm (green squares) fall in between the tested wave conditions (blue dots). A surface fitting based on the experimental data points has been created in order to estimate the average

ω and average

τ for the wave conditions given in the scatter diagram for Hanstholm.

Figure 5.

Surface fit of the average rotational speed [rpm] (left) and average torque [Nm] (right) of the WEPTOS prototype with a linear PTO loading, based on the experimental data points (blue dots) and the scaled wave states representing Hanstholm (green dots).

Figure 5.

Surface fit of the average rotational speed [rpm] (left) and average torque [Nm] (right) of the WEPTOS prototype with a linear PTO loading, based on the experimental data points (blue dots) and the scaled wave states representing Hanstholm (green dots).

The average values of τ and ω appear to be dependent on the Hs as well as on the Tp as there does not seem to be any clear dependency relative to one or the other parameter. However, the distribution of ω and the distribution of τ appear to be similar, which is also to be expected as the τ is set as function of ω as they are obtained with a linear PTO loading. However, in this case even the absolute values (but not the units) are similar, which is a coincidence and will change when applying a different scaling ratio.

Table 2 presents the maximum, mean and maximum-to-mean ratio of

ω and

τ for 5 different wave states (tested with linear PTO loading). Wave state 1 and 11, in which the linear PTO loading was also assessed, are not included as the linear PTO loading did not perform better than the constant PTO loading in these wave conditions. This was most likely due to the response delay and setup of the linear PTO loading.

It appears that the maximum-to-mean ratio remains relatively constant, approximately 2.7 and 1.7 for ω and τ respectively. The average and maximum ω and τ are slightly scattered but generally of the same order of magnitude. The average values given here are significantly higher than the overall average ω, of 1.3 rpm, as these values are given for wave conditions in which the device would operate while the average also includes periods were the device is not operating.

Table 2.

Summary of the maximum, average and maximum-to-mean ratio of the rotational speed and torque for five different operational wave conditions of the WEPTOS model.

Table 2.

Summary of the maximum, average and maximum-to-mean ratio of the rotational speed and torque for five different operational wave conditions of the WEPTOS model.

| WS | Rotational Speed [rpm] | Torque [Nm] |

|---|

| Maximum | Mean | Maximum/Mean | Maximum | Mean | Maximum/Mean |

|---|

| 2 | 17.8 | 7.0 | 2.5 | 10.9 | 6.5 | 1.7 |

| 3 | 19.9 | 7.7 | 2.6 | 13.6 | 8.0 | 1.7 |

| 4 | 23.8 | 8.2 | 2.9 | 17.0 | 9.6 | 1.8 |

| 5 | 21.7 | 7.5 | 2.9 | 22.6 | 12.7 | 1.8 |

| 9 | 15.6 | 6.2 | 2.5 | 15.8 | 9.2 | 1.7 |

| | | Average | 2.7 | | Average | 1.7 |

1.5. Mooring Forces and Structural Bending Moments

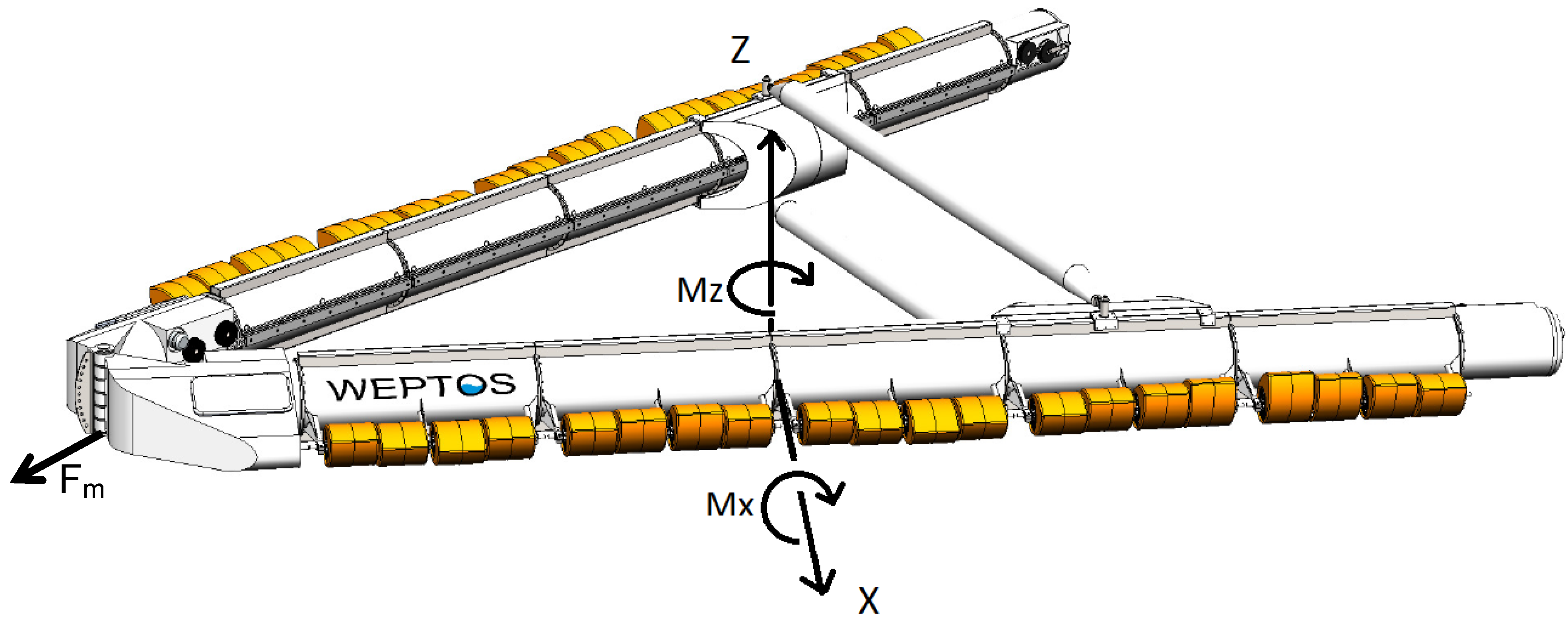

The mooring forces and structural bending moments have been assessed during 14 power production and five extreme wave conditions. In one of these extreme wave states the effect of changing the directional spreading and peak enhancement factor have also been investigated, which will be referred to as “alterated wave conditions” in the figures. The measured mooring forces and structural bending moments are presented in terms of the average of 1 out of 250 largest (positive and negative, when applicable) peaks relative to the measured significant wave height.

The mooring line was connected at the bottom of the front hinging point of the legs of the WEPTOS model by a hawser to a buoy, which was connected to the seabed. The resulting mooring stiffness in surge of the whole setup corresponded to approximately 1.56 kN/m. The axes around which the structural bending moments were measured are passing through the centre of the tube in between the second and third section of the prototype (between the 8

th and 9

th rotor), where a measuring flange equipped with strain gauges was installed, see

Figure 6. The horizontal bending moment

Mx (positive) corresponds to the bending moment resulting from a vertical downward force applied on the location of the flange, while the vertical bending moment

Mz (positive) corresponds to the bending moment resulting from in-side-out force on the flange.

Figure 6.

Indication of the location of the measurement of the mooring force (Fm) and structural bending moments (Mx and Mz) on the design of the WEPTOS WEC model.

Figure 6.

Indication of the location of the measurement of the mooring force (Fm) and structural bending moments (Mx and Mz) on the design of the WEPTOS WEC model.

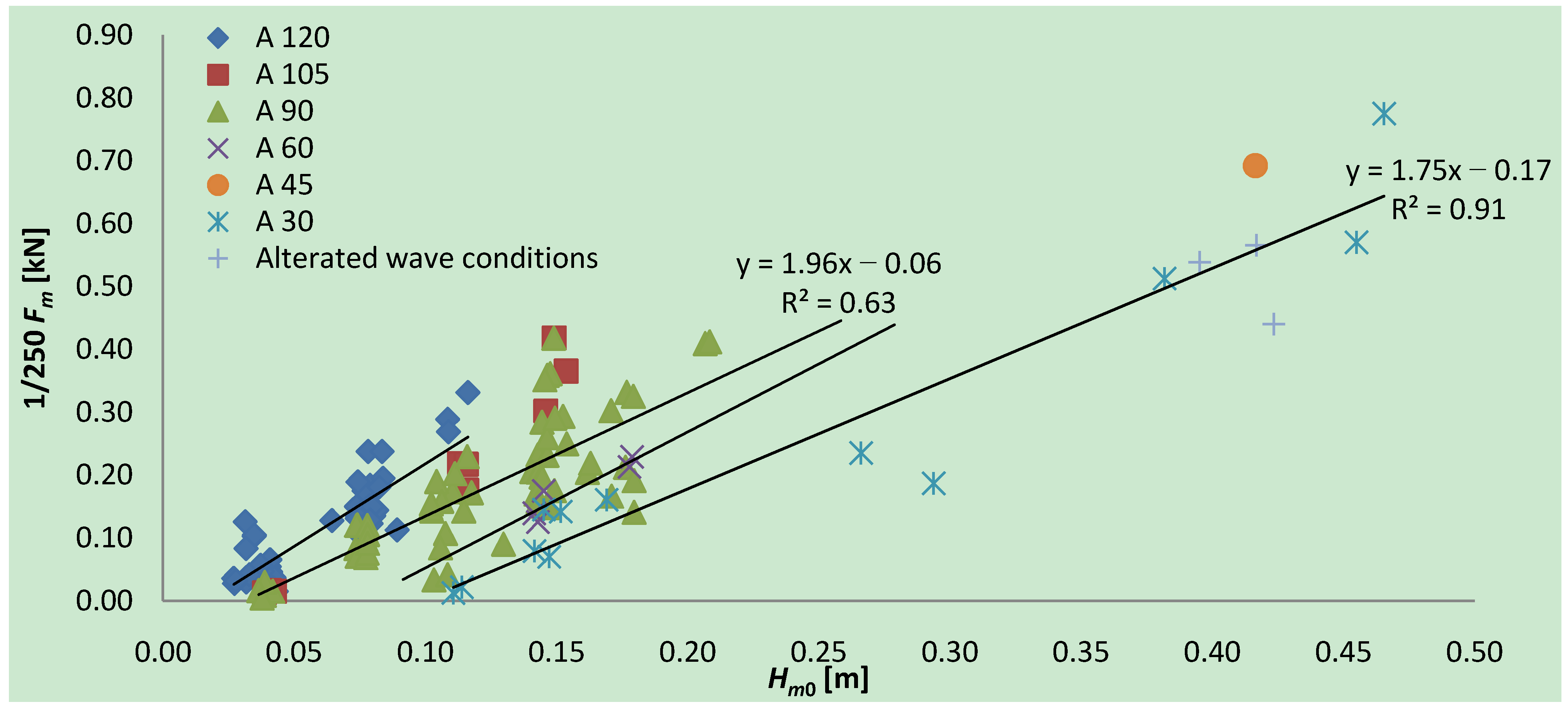

In case of the mooring force, the number of peaks that were recorded was limited (due to the slow motion response in surge) and therefore the 1/250th force corresponds to the largest event. The mooring forces are grouped relative to the corresponding opening angle of the device and are given for a large number of tests, regardless of other parameters such as the type of PTO loading.

Figure 7.

Measured 1/250 mooring forces (Fm) for different opening angles of the structure (with corresponding trend lines, values are given for A90 and A30).

Figure 7.

Measured 1/250 mooring forces (Fm) for different opening angles of the structure (with corresponding trend lines, values are given for A90 and A30).

The mooring forces seem to follow an increasing linear trend with Hm0, which is different for every opening angle of the structure. The linear trend lines for the different opening angles seem to have roughly the same steepness and to be translated with increasing Hm0 for decreasing opening angles. The mooring force (given in kN) trend line for an opening angle of 30° follows the relationship with Hm0 of: Fm = 1.75 × Hm0 − 0.17. The largest mooring force of 0.775 kN was found in the largest extreme wave test, which had a Hm0 of 0.466 m. The alterations to the wave conditions in extreme waves did not appear to have a significant impact on the mooring force; however, having an opening angle of 45° in extreme wave conditions increased the mooring forces significantly, by about 35%.

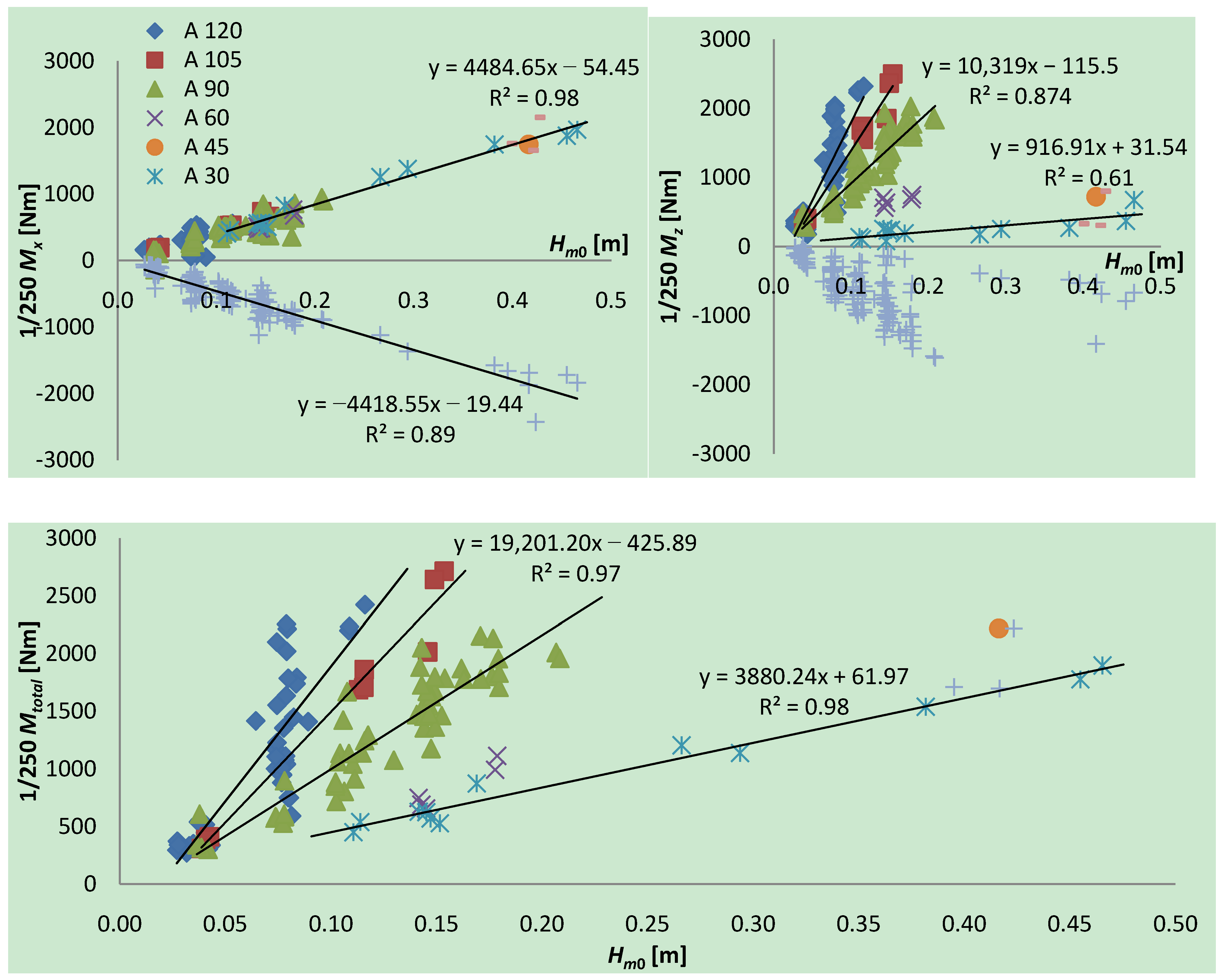

The horizontal, vertical and combined structural bending moments (

Mx,

Mz and

Mtotal) are given as a function of the opening angle of the device and for various tests in

Figure 8. Values of the resulting bending moment from a vast amount of tests are calculated by applying Equation (2) to the time series.

It can be seen that the Mx increases linearly with Hm0 independently of the opening angle. The maximum negative peaks of Mx are mostly in the same range as their positive counterpart and more precisely about 6% smaller for an opening angle of 30°. The influence of the spectral shape (G1 and G7) is again very limited, while here the directional spreading (S5) has increased Mx by about 15%, which corresponds to the highest recorded Mx of 2151 Nm.

Figure 8.

Measured 1/250 Mx (top left), measured Mz (top right, trend lines for A90 and A30) and combined 1/250 bending moment (bottom plot, trend lines for A90 and A30) in production and extreme wave conditions.

Figure 8.

Measured 1/250 Mx (top left), measured Mz (top right, trend lines for A90 and A30) and combined 1/250 bending moment (bottom plot, trend lines for A90 and A30) in production and extreme wave conditions.

Remarkably, Mz is significantly greater under power production wave conditions (large opening angles) than under the extreme wave conditions (characterized by a device with a 30° opening angle). This can clearly be seen by the decreasing steepness of the trend line of Mz relative to Hm0 for each opening angle. The maximum Mz (positive) are on average 19% smaller than the negative maximum peaks for an opening angle of 30°, but 33% larger for an opening angle of 90°. The spectral shape (G1 and G7) has almost no impact on Mz, while directional spreading (S5) can approximately double Mz with an opening angle of 30°, still resulting significantly lower than the Mz in power production wave conditions. The influence of alterations to the wave conditions are very coarse as only a very few amount of tests has been made.

The combined structural bending moment appears to be slightly larger in the power production wave conditions (2700 Nm) as in the extreme wave conditions (2218 Nm, they are characterized by a device with a 30° opening angles). This is due to the significant decrease in Mz with a decreasing opening angle. This is remarkable, as the need to over-dimension the structure to survive extreme conditions is as a result unnecessary. Directional spreading still appears to have a significant impact on Mtotal; however, the overall moment still appears to be lower than the moments in power production wave conditions. This shows that the survival mechanism, based on regulating the opening angle of the structure, is effective and can diminish the structural bending moments significantly. Note that the structural bending moments were only measured at one location on the legs and that they are believed to be very dependent on the location of the transversal beam. As the transversal beam changed position with the opening angle, the measured and given bending moment is probably not representative for the maximum bending moment on the whole structure, however it can be used for further calculations.