Insulator Contamination Forecasting Based on Fractal Analysis of Leakage Current

Abstract

:1. Introduction

2. Calculation of the Fractal Variation Method and the Fractal Dimension

2.1. Fractal Theory

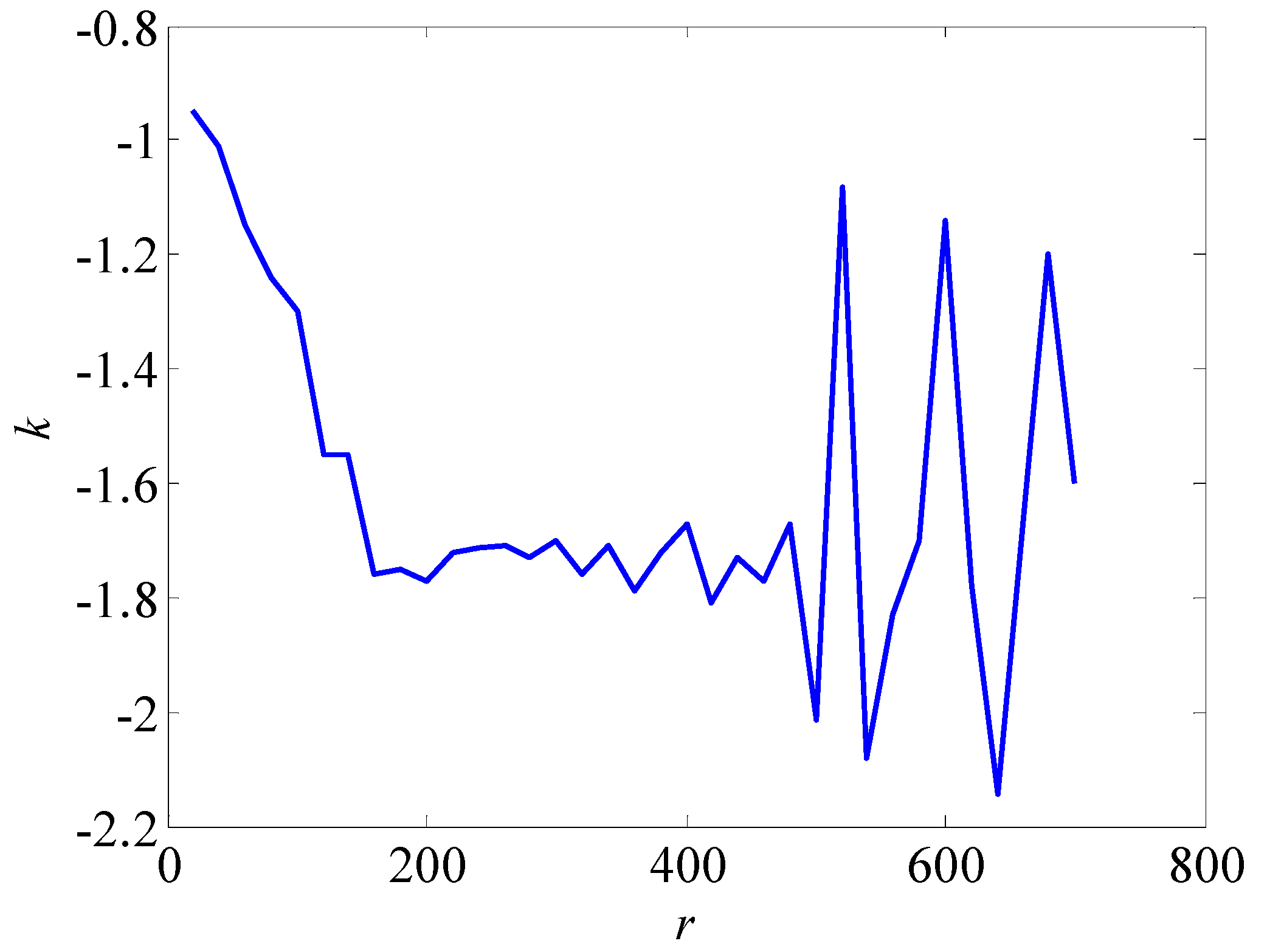

2.2. Calculation of the Fractal Dimension by the Conversion Method

- (1)

- The fractal curve L to be analyzed is obtained.

- (2)

- A rectangular box of width r is set to cover the fractal curve. The height of the rectangle is equal to the difference between the value of the highest point, max(L), and the value of the lowest point, min(L), of the fractal curve in the box. The rectangle is moved over all of the data points stepwise, the products of the height and width of each rectangle are summed to obtain the total area S(r):where M is the number of rectangle positions required to completely cover the data points.

- (3)

- The size of r is changed in series, and the above operation is repeated to obtain a series of S(r). The fractal curve range should be much larger than the rectangle width r in the above operation process. S(r) divided by r2 yields N(r) = S(r)/r2, where N (r) is the number of boxes of area of r2 required to cover part of the rough curve and is generally not an integer. This lack of requirement for an integer is one reason why this method is more accurate than the box-counting method.

- (4)

- The relation curve of lnN(r) and ln(1/r) is plotted, and the linear portion of the curve is fitted using the least-squares method. The slope of the line obtained is the fractal dimension D. For the linear relation of N(r) and r-D in the linear range:

3. Laboratory Test Program

3.1. Test Devices and Samples

3.2. Test Method

4. Analysis of the Test Results

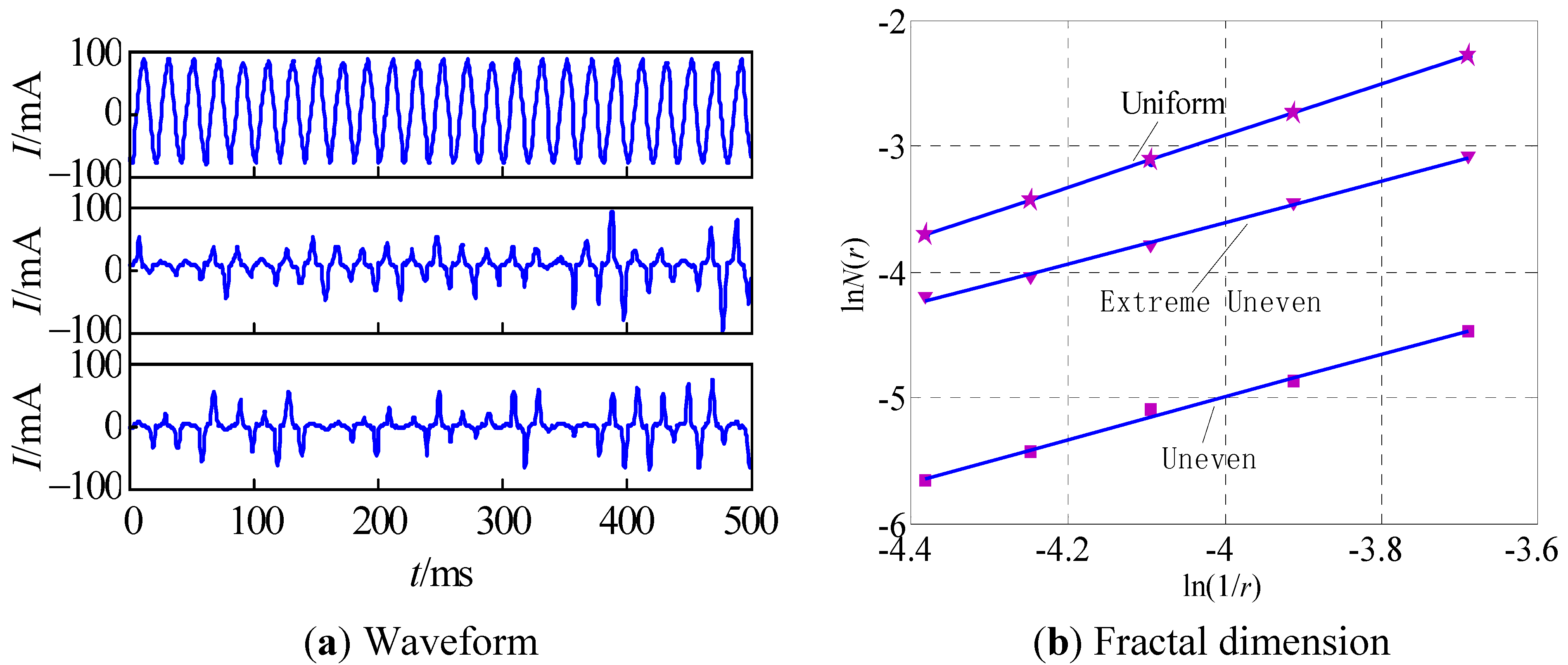

4.1. The Fractal Dimension Calculation of the Leakage Current Waveform

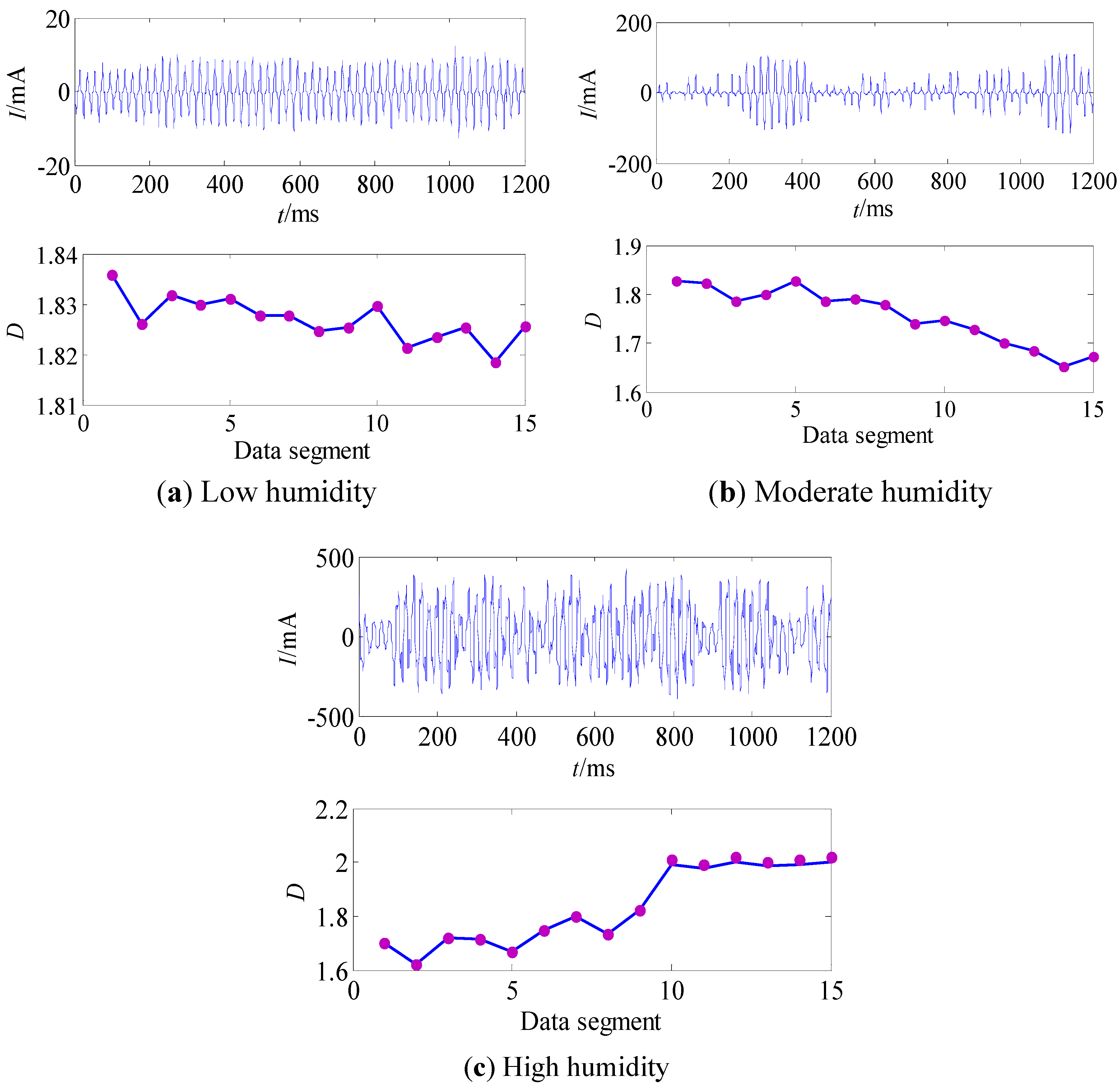

4.2. Relationship between the Fractal Dimension Indicators and the Humidity

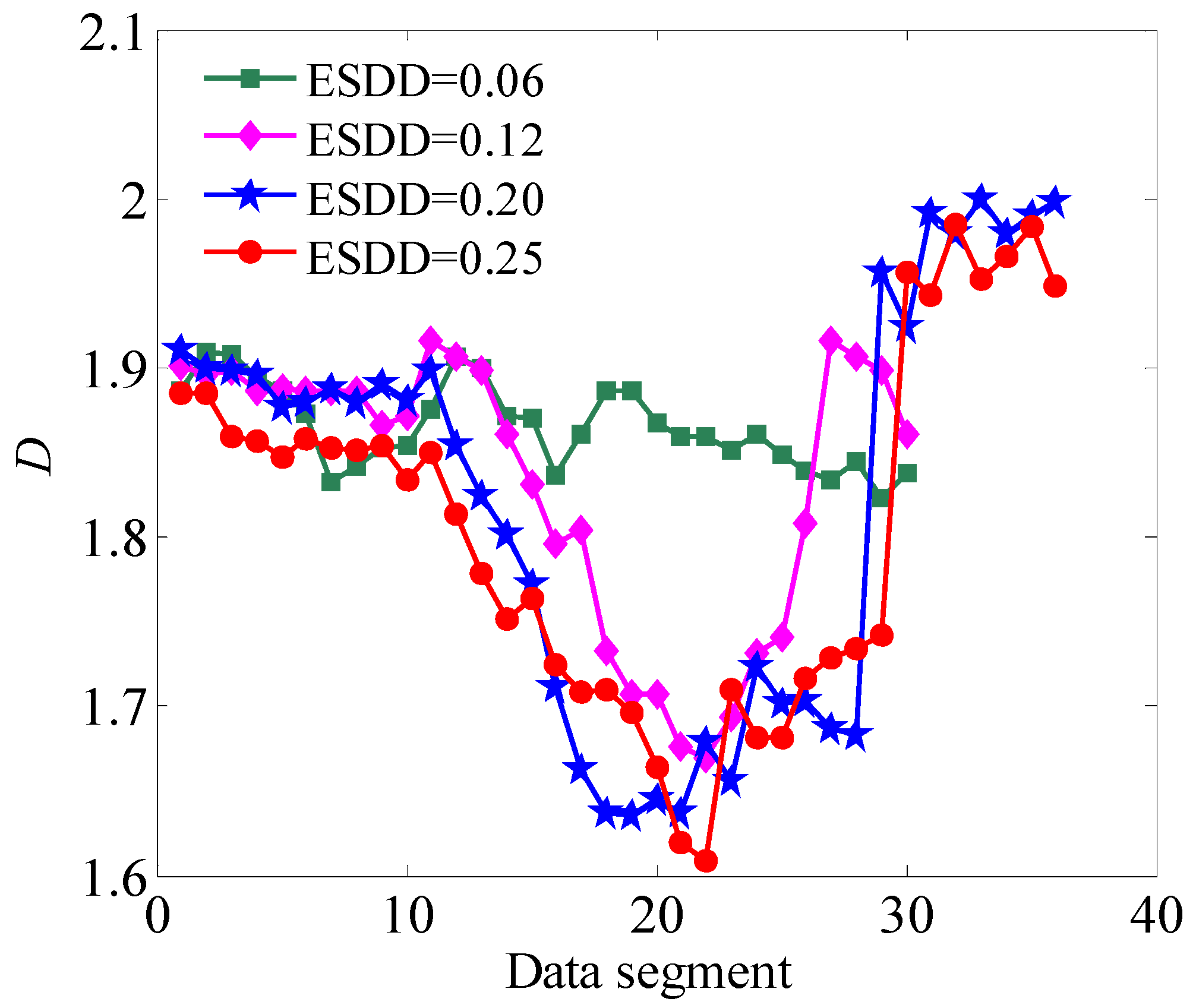

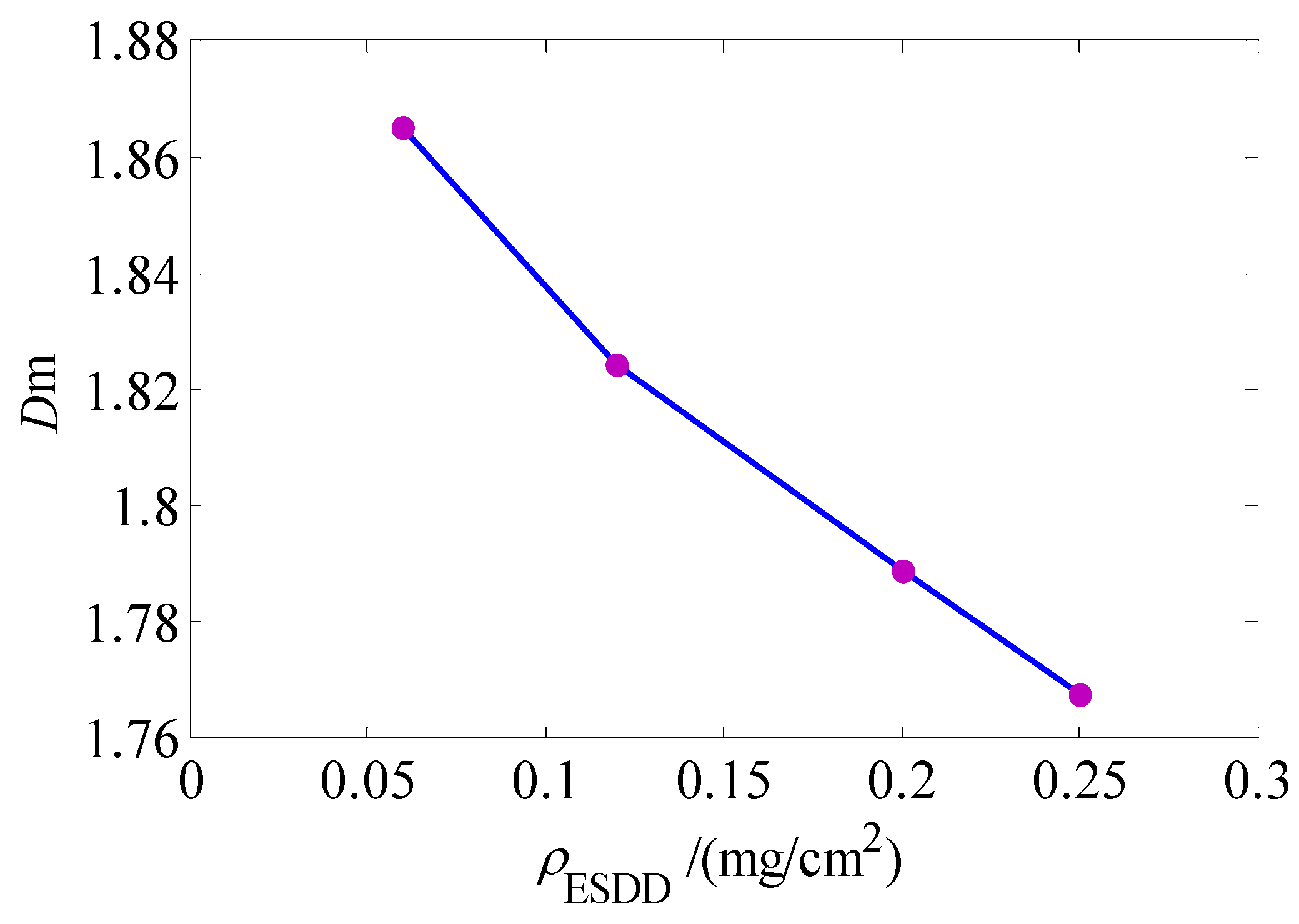

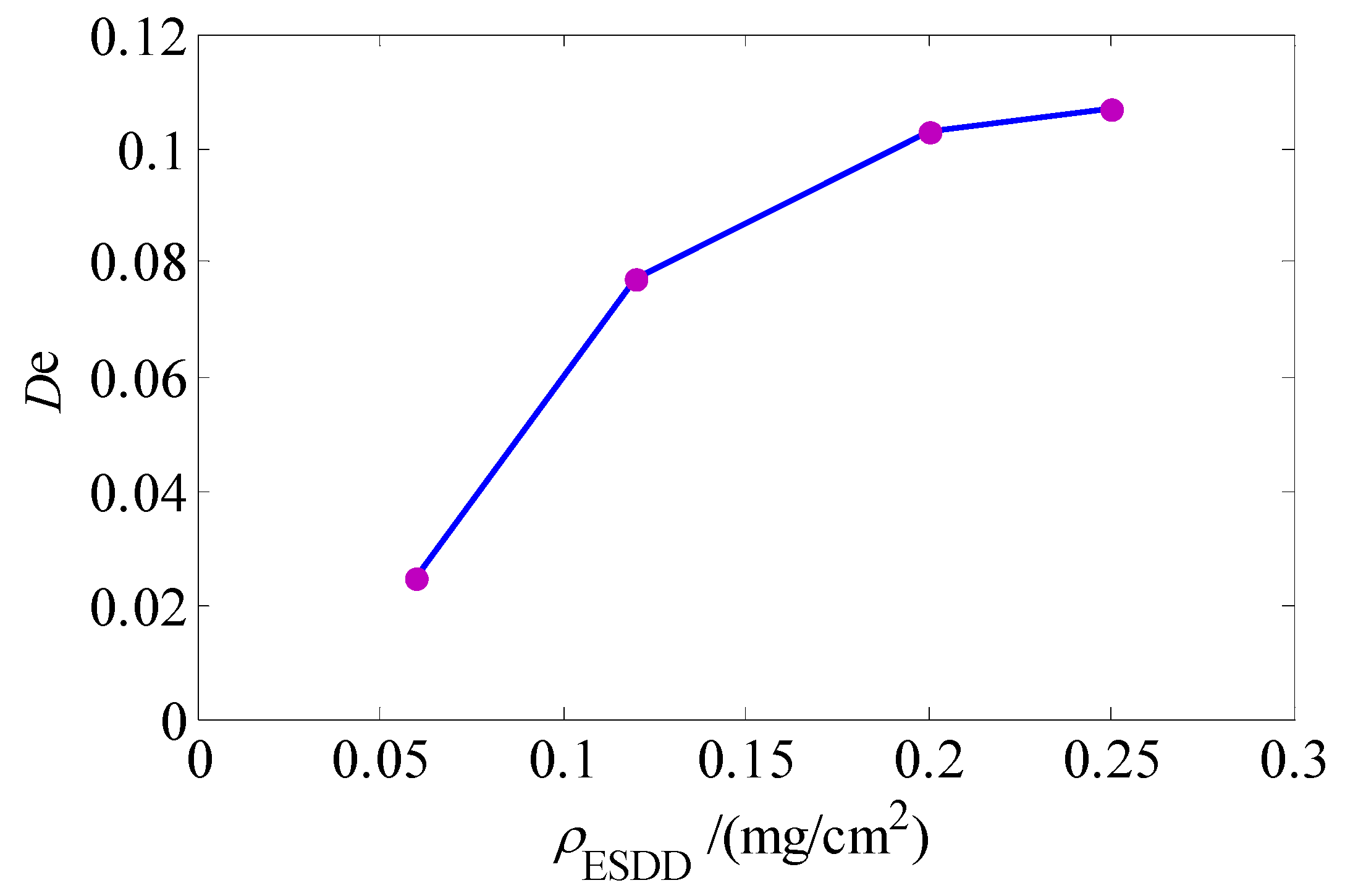

4.3. Relationship between the Fractal Dimension Characteristic Quantities and the Degrees of Contamination

5. Discussion and Conclusions

- (1)

- The fractal dimensions for insulator leakage current waveforms vary with uniformity. The fractal dimensions increase for waveforms with greater uniformity.

- (2)

- The leakage current waveform fractal dimensions are extracted in each of the three zones of contamination discharge: the security zone, the forecast zone and the danger zone. The variations in the characteristics of the fractal dimensions of the three zones are obvious, and the reference values of the fractal dimension variation for each of the three zones are provided.

- (3)

- Different magnitudes of the leakage current fractal dimension are observed for the different contamination levels. No partition of the three zones is evident for mild insulator contamination. However, the characteristics of the three zones are obvious for severe contamination. The fractal dimensions exhibit an overall decreasing trend as the degree of contamination increases.

- (4)

- Based on the extracted mean and standard deviation of the fractal dimension in the forecast zone, the more serious the contamination is, the smaller the mean and the greater the standard deviation.

Acknowledgments

References

- De La, A.; Gorur, R.S. Flashover of contaminated non-ceramic out-door insulators in a wet atmosphere. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 814–823. [Google Scholar] [CrossRef]

- Fontana, E.; Oliveira, S.C. Novel sensor system for leakage current detection on insulator strings of overhead transmission lines. IEEE Trans. Power Deliv. 2006, 21, 2064–2070. [Google Scholar] [CrossRef]

- An, L.; Jiang, X.; Han, Z. Measurements of equivalent salt deposit density (ESDD) on a suspension insulator. IEEE Trans. Dielectr. Electr. Insul. 2002, 9, 562–568. [Google Scholar] [CrossRef]

- Working Group C4.303, Part 1: General principles and the AC case. In Outdoor Insulation in Polluted Conditions: Guideline for Selection and Dimensioning; Cigré Press: Paris, France, 2008.

- Zhu, Y.; Otsubo, M.; Honda, C. Mechanism for change in leakage current waveform on a wet silicone rubber surface—a study using a dynamic 3-D model. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 556–565. [Google Scholar] [CrossRef]

- Akbar, M.; Zedan, F. Performances of HV transmission line insulators on desert conditions: Part 3: pollution measurement at a coastal site in the eastern region of Saudi Arabia. IEEE Trans. Power Deliv. 1991, 6, 429–438. [Google Scholar] [CrossRef]

- Tjokrodiponto, W.; Sebo, S.A. Leakage current magnitudes and wave shapes along polymer insulators. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Minneapolis, MN, USA, 19–22 October 1997; pp. 391–395.

- Ghosh, P.J.; Chatterjee, N. Polluted insulators flashover for AC voltage. IEEE Trans. Dielectr. Electr. Insul. 1995, 2, 128–136. [Google Scholar] [CrossRef]

- Sun, C.; Sima, W.; Yang, Q.; Hu, J. Contamination level prediction of insulators based on the characteristics of leakage current. IEEE Trans. Power Deliv. 2010, 25, 417–424. [Google Scholar]

- Richard, C.S.; Benner, C.L.; Butler-Purry, K.L. Electrical behavior of contaminated distribution insulators exposed to natural wetting. IEEE Trans. Power Deliv. 2003, 18, 551–558. [Google Scholar] [CrossRef]

- Li, J.; Sun, C.; Sima, W. Use of Leakage currents of insulators to determine the stage characteristics of the flashover process and contamination level prediction. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 490–501. [Google Scholar] [CrossRef]

- Dhahbi-Megriche, N.; Beroual, A. Flashover dynamic model of polluted insulators under AC voltage. IEEE Trans. Dielectr. Electr. Insul. 2000, 7, 283–289. [Google Scholar] [CrossRef]

- Suda, T. Frequency characteristics of leakage current waveforms of an artificially polluted suspension insulator. IEEE Trans. Dielectr. Electr. Insul. 2001, 8, 705–710. [Google Scholar] [CrossRef]

- Amarh, F.; Karady, G.G. Linear stochastic analysis of polluted insulator leakage current. IEEE Trans. Power Deliv. 2002, 17, 1063–1070. [Google Scholar] [CrossRef]

- Chandrasekar, S.; Kalaivanan, C. Investigations on leakage current and phase angle characteristics of porcelain and polymeric insulator under contaminated conditions. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 574–583. [Google Scholar] [CrossRef]

- Hui, A.; Zheng, J.; Lin, H.; He, B. Wavelet-fractal characteristics of leakage current on HV Insulators. In Proceedings of the 3rd International Conference on Electric Utility Deregulation and Restructuring and Power Technologies, Nanjing, China, 6–9 April 2008; pp. 732–736.

- Mandelbrot, B.B. The Fractal Geometry of Nature; W.H. Freeman Press: San Francisco, CA, USA, 1983. [Google Scholar]

- Pentland, A.P. Fractal-based description of nature scenes. IEEE Trans. Pattern Anal. 1984, 6, 661–674. [Google Scholar] [CrossRef]

- Sofuoglu, H.; Ozer, A. Thermo mechanical analysis of elastoplastic medium in sliding contact with fractal surface. Tribol. Int. 2008, 3, 783–796. [Google Scholar] [CrossRef]

- Zhao, J.; Lei, L.; Pu, X. Fractal Theory and Its Apply in Signal Processing; [In Chinese]; Tsinghua University Press: Beijing, China, 2008. [Google Scholar]

- IEC 60507. Artificial Pollution Tests on High Voltage Insulators to Be Used on AC Systems (a.c.), 2nd ed.; IEC: Geneva, Switzerland, 1997; Available online: http://webstore.iec.ch/webstore/webstore.nsf/mysearchajax?Openform&key=IEC%2060507&sorting=&start=1&onglet=1 (accessed on 27 June 2012).

- Chen, W.; Yao, C.; Sun, C. A new broadband micro-current transducer for insulator leakage current monitoring system. IEEE Trans. Power Deliv. 2008, 23, 355–361. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Chen, W.; Wang, W.; Xia, Q.; Luo, B.; Li, L. Insulator Contamination Forecasting Based on Fractal Analysis of Leakage Current. Energies 2012, 5, 2594-2607. https://doi.org/10.3390/en5072594

Chen W, Wang W, Xia Q, Luo B, Li L. Insulator Contamination Forecasting Based on Fractal Analysis of Leakage Current. Energies. 2012; 5(7):2594-2607. https://doi.org/10.3390/en5072594

Chicago/Turabian StyleChen, Weigen, Wanping Wang, Qing Xia, Bing Luo, and Licheng Li. 2012. "Insulator Contamination Forecasting Based on Fractal Analysis of Leakage Current" Energies 5, no. 7: 2594-2607. https://doi.org/10.3390/en5072594