1. Introduction

Taiwan is a small island country (about 36,000 km

2) in Asia with limited natural resources and densely populated (over 23 million). In the past two decades, Taiwan has been confronting several energy issues, which are summarized below [

1,

2,

3]:

- •

High dependence on energy imports: The dependence on imported energy is on an increasing trend, from 95.84% in 1990 to 99.39% in 2010. Meanwhile, the energy supply totaled 145.6 million kiloliters of oil equivalent (KLOE; 1 KLOE = 3.77 × 1010 J) in 2010, in contrast to 58.7 KLOE in 1990. Furthermore, a considerable portion of the energy consumption was used in the industrial sector for the purpose of heating and manufacturing, increasing from 45.4% in 1990 to 53.8% in 2010. This meant that the largest source of CO2 emissions was from the energy sector (combustion of fossil fuels) while the next important source was from the industrial sector.

- •

Increase in the total of carbon dioxide (CO2) emissions: The CO2 emission in 2010 was 2.54 × 10 8 t (1 t = 1000 kg) in comparison with 1.11 × 108 t in 1990. On average, the annual growth rate from 1990 to 2010 was 4.16%, which could be separated into two significant stages: 6.65% from year 1990 to 2000, and 1.48% from 2000 to 2010. This trend reflected the effects in the past decade as compared to the 1990s of the implementation in January 2002 of a policy of promoting energy savings and renewable energy development through the “Renewable Energy Development Plan” by the Executive Yuan of Taiwan.

Regarding the development of stationary biomass energy systems in Taiwan, currently a total installed capacity of 814.5 megawatts (MW) of power generation has been achieved through biomass energy utilization, which is primarily based on municipal solid waste (MSW) incineration generation (622.5 MW), biogas power generation (24.5 MW), and the utilization of agricultural and industrial wastes such as paper mill waste, bagasse and rice straw (167.5 MW). It was apparent that more than 75% of this biopower was substantially supplied by 24 operational large incineration plants consuming MSW, agricultural wastes and general industrial wastes.

In early 1990s, the central competent authority Taiwan adopted a strategy promoting the treatment of MSW incineration [

4]. The energy utilization from MSW and various other types of agricultural and industrial waste, also called waste-to-energy (WTE), received much attention during the 1990s mainly due to the advances in WTE technologies, the increasing energy price and the global warming issues [

5,

6]. More importantly, the energy from domestic waste resources not only enhances fuel diversification, but also possesses environmental benefits in terms of greenhouse gas (GHG) emissions, land use and cost savings as compared with land-filling [

4]. In this regard, biomass such as agricultural residues and biosolids are increasingly being recognized as valuable bioresources because they are renewable and rich carbon sources. The organic carbon can be further reused as a green energy source. Moreover, electricity and heat generated from bioresidues through the combined heat and power (CHP) systems are offsetting those generated from fossil fuels with GHG emission reduction credits. As a result, there is an increasing interest in co-firing non-hazardous biomass with coal in the coal-fired power plants and/or large-scale mass-burn MSW incineration plants, which have been designed with the best available control technology for toxic air pollutants emitted from flue stack [

7].

The elimination of biodegradable pollutants from effluents using the activated sludge process has been considered the most suitable method for lowering their negative discharges into the receiving water body. The removal of biochemical oxygen demand is the objective of secondary treatment in the allied plants such as food processing, wine brewing and swine raising, while wastewater sludge was further treated to achieve stabilization and dewatering (<75 wt%) before its utilization. Meanwhile, an increasing issue associated with the use of sewage sludge was concerned with its impacts on the environment and human health because of the unavoidable by-products which may contain toxic pollutants (e.g., heavy metals) along with a large fraction of pathogens due to the concentration of the sludge during the wastewater treatment [

8,

9]. The waste-activated sludge or biosludge may be the most difficult biosolid to dewater because initially it contains so much water (99%), which is tightly attached by chemical and physical means to the surface area provided by the minute micro-organisms. In the past decades, the biosludge was mainly applied to soils for agricultural purposes [

9,

10], but it was not considered an energy source. Due to the high cost of sludge treatment process (e.g., anaerobic digestion) and the strict regulations regarding sludge usage in agriculture, it’s utilization of biosludge as a biomass resource for the production of energy has gradually spread in recent years [

8].

In a previous paper [

4], only a comprehensive description of governmental regulations and policies for promoting industrial waste (

i.e., pulp sludge, scrap wood, sugarcane bagasse, textile sludge, and scrap plastics) as energy sources was presented. Environmental regulations on the emissions of hazardous air pollutants as well as benefit analysis from industrial waste-to-energy (IWTE) were also discussed. In this study, the open-access documents officially published by the Taiwan central government were used to provide a systemic and analytical description about the energy utilization of biosludge, including food processing sludge, wine brewery sludge and agricultural sludge. The main subjects of this paper cover the following key elements:

- (1)

Thermochemical characteristics of biosludge and its environmental implications;

- (2)

Analysis of biosludge generation and its current utilization;

- (3)

Concepts of biosludge-to-energy systems;

- (4)

Analysis of environmental benefits from the utilization of dried biosludge as fuels.

2. Thermochemical Characteristics of Biosludge and Its Environmental Implications

In this study, the target biomass was biosludge, which is produced from the biological decomposition of the organic discharges from food processing (milk-derivative), wine (beer) brewery and livestock (swine) farms in the secondary wastewater treatment system. The swine sludge (manure solid) was obtained from a solid-liquid separation unit in the three-step wastewater treatment plant [

11]. The data in

Table 1 indicate the results of ultimate analysis and calorific values for the above-mentioned bioresources [

11,

12]. It can be seen that the analyses revealed higher contents of carbon (C), hydrogen (H) and oxygen (O) in the food processing sludge and swine raising sludge on a dry basis, respectively, supporting that the dried biosludge had abundant in lignocellulosics, lipids, proteins, ash, and other components. The results were reasonable due to the fact that beer brewing sludge should contain lots of diatomaceous earth (approximately composed of 91.5 wt % SiO

2 and 4.0 wt % Al

2O

3) [

13], which are widely used as filtration medium for removal of insoluble residues from fermented beer before bottling, and its resulting wastes (also called spent diatomaceous earth) are generally utilized as a biosorbent and/or coagulant in the wastewater treatment system. As a consequence, the biosludge had lower carbon, hydrogen, and heating content. Compared to values of 75.3% C, 5.4% H and 15.6% O for coal [

14], these biosolids have much higher oxygen contents and lower carbon contents than those of coal, while the hydrogen contents in both biomass and coal are comparable. However, their calorific values are relatively higher, ranging from 13.4 to 19.4 MJ/kg on a dry basis. These data were consistent with the elemental analyses as described above.

Table 1.

Thermochemical characterization of dried sludge a.

Table 1.

Thermochemical characterization of dried sludge a.

Thermochemical

property | Values |

|---|

| Food processing sludge | Wine brewing sludge | Swine raising sludge | Coal |

|---|

| Ultimate analysis b | | | | |

| Carbon (wt %) | 42.3 ± 0.1 d | 31.6 ± 0.1 | 42.2 ± 0.1 | 75.3 |

| Hydrogen (wt %) | 6.3 ± 0.1 | 4.9 ± 0.1 | 6.6 ± 0.1 | 5.4 |

| Oxygen (wt %) | 31.8 ± 0.0 | 31.9 ± 0.2 | 36.4 ± 0.1 | 15.6 |

| Nitrogen (wt %) | 6.6 ± 0.1 | 5.5 ± 0.0 | 4.0 ± 0.1 | 1.8 |

| Sulfur (wt %) | 0.8 ± 0.0 | 0.6 ± 0.1 | 0.0 ± 0.0 | 0.4 |

| HHV b,c (MJ/kg) | 16.8 ± 0.1 | 13.4 ± 0.1 | 19.4 ± 0.5 | 30.1 |

With respect to the environmental implications from the standpoint of conversion of biosludge to energy, nitrogen oxides (NO

x) belong to the most important gaseous pollutants from combustion processes because NO

x may cause ground-level photochemical smog, ozone formation and acid rain. Concerning the acidic elements in the biosludge listed in

Table 1, the nitrogen concentration (

i.e., over 4.0% by mass) is relatively higher than those from forestry and crop residues (

i.e., <1.0% by mass) [

15]. The food processing sludge had higher nitrogen content because it might contain a higher protein content as a result of its origin from a milk-derivative factory. As a result, both thermal way and fuel-bound nitrogen will contribute to the emissions of nitrogen oxides (NO

x) and traces of N

2O from biomass combustion facilities where they could have a need for installing NO

x control systems such as combustion modification and selective catalytic/noncatalytic reduction [

16]. On the other hand, their sulfur contents are low compared with those of coal. Therefore it should be expected that sulfur oxides (SO

x) in the biosludge (especially in swine raising sludge) would not be emitted to a large extent.

3. Analysis of Biosludge Generation and Its Current Utilization

According to the Waste Management Act in Taiwan [

4], waste is classified into general waste (municipal waste) and industrial waste. Furthermore, industrial waste includes general industrial waste and hazardous industrial waste. In 2000, the Taiwan’s Environmental Protection Administrations (EPA) established an on-line reporting system that tracks the complete life cycle (cradle-to-grave) of industrial waste from generation source to disposal site. Meanwhile, industrial generators have adopted waste reuse and pollution prevention as top strategies for their industrial waste management under the regulatory promotion.

The treatment, disposal or reuse of sewage sludge or biosolids in Taiwan is regulated under the Waste Management Act.

Table 2 shows the annual statistics during the years of 2004–2010 based on the on-line reported amounts of food processing sludge, wine brewing sludge, and agricultural sludge. Herein, the food processing sludge, wine brewing sludge and agricultural sludge are officially defined by generating from secondary biological treatment facilities or manufacturing (formulating) processes in the food/drink, wine/beer and agricultural/livestock industries, respectively. From the data in

Table 2, it can be seen that these waste activated biosolids in Taiwan in recent years have remained relatively steady at about 43,300, 10,500 and 12,200 t per year on average for food processing sludge, wine brewing sludge, and agricultural sludge, respectively. Out of these volumes, the food processing sludge accounts for about two thirds. On the other hand, the food, drink and livestock markets in Taiwan may be considered mature with flat to declining overall volumes. The declining on-line reported amounts for these biosolids could also be due to the current financial crisis at this period.

Table 2.

Statistics on the reported amounts of dewatered biosludge for reuse in Taiwan a.

Table 2.

Statistics on the reported amounts of dewatered biosludge for reuse in Taiwan a.

| Year | Food Processing Sludge | Wine Brewery Sludge | Agricultural Sludge |

|---|

| 2004 | 43,497 | 8,210 | 7,656 |

| 2005 | 42,829 | 9,682 | 10,179 |

| 2006 | 37,804 | 11,519 | 13,696 |

| 2007 | 54,318 | 10,304 | 13,988 |

| 2008 | 39,096 | 11,461 | 14,352 |

| 2009 | 42,813 | 11,387 | 11,640 |

| 2010 | 42,801 | 10,934 | 13,659 |

In Taiwan, the law governing the reuse/recycling of industrial waste is the Waste Management Act. Under the authorization of Article 39 of the Act, the Responsible Agencies at the central government level (i.e., the Ministry of Economics Affairs and the Council of Agriculture) after consultation with the EPA have promulgated the “Regulations Governing the Permission of Industrial Waste Reuse” and “Regulations Governing the Permission of Agricultural Waste Reuse” relating to the reuse of industrial waste and agricultural waste since 2002. Presently, the target biosolids discussed in this study were legally designated to be reused as raw material for organic fertilizers and/or raw material for plant cultivation mediums. This directive also encourages the generators to reuse their resulting waste that is not previously announced subject for reuse (e.g., auxiliary fuel for cement kiln, industrial boiler and so on.), but the generator may submit a reuse plan to the EPA for review and approval.

4. Concepts of Biosludge-to-Energy Systems

From the standpoint of energy use of dried biosludge as a replacement for coal, its heating value is the most important fuel property. From the data in

Table 1, it can be seen that the calorific values (around 16 MJ/kg) of these biosolids is about 60% of the heating value (

i.e., about 28 MJ/kg) of fossil coal. Due to the high organic content, abundance, and associated environmental concerns with current management methods (

i.e., biological wastewater treatment system), these biosolids can be considered as available energy sources in the direct combustion systems such as industrial boiler, MSW incinerator and coal-fired power plants [

17].

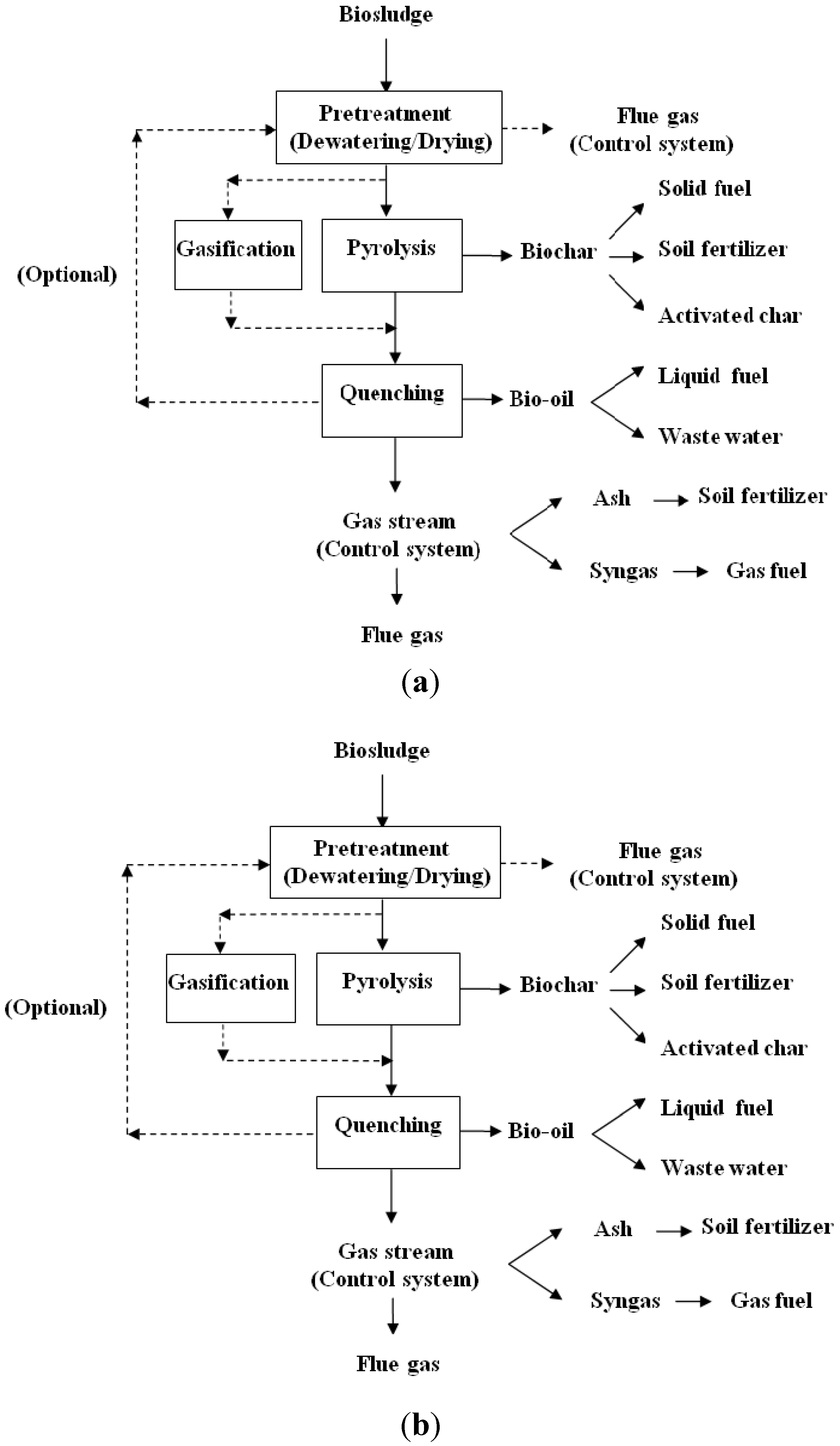

In this research, the biosludge-to-energy treatment concepts were addressed with considerations to thermochemical technologies for the production of heat, power, bio-oil and biochar. The process system can have more efficient nutrient recovery in recycling the plant nutrients into the residual ash.

Figure 1 shows the conceptual flow diagrams of direct combustion and pyrolysis/gasification, including pretreatment, thermochemical conversion, and energy recovery (combined heat and power) units. The dried biosludge-to-energy treatment system (

Figure 1a) can be simply described as follows:

Figure 1.

Conceptual flowchart of biosludge utilization using thermochemical processes. (a) direct combustion; (b) pyrolysis/gasification.

Figure 1.

Conceptual flowchart of biosludge utilization using thermochemical processes. (a) direct combustion; (b) pyrolysis/gasification.

- (1)

Pretreatment unit is intended to lower the moisture content of the collected biosludge using solar heating or recycled heat from combined heat and power (CHP) unit.

- (2)

Combustion unit may be an industrial boiler, or a municipal solid waste incinerator via co-fired operation. This means that the dried biosolid is reused as an auxiliary solid fuel. The combustion system using the biomass feedstock produces high-temperature flue gas that is further pumped into a CHP system for recovering process waste heat.

- (3)

Energy recovery (

i.e., CHP) unit refers to the simultaneous production of electricity and heat in one single process for dual output streams so as to maximize its thermal efficiency of up to 70% or more. The flue gas from the CHP system will be further treated by the advanced air pollution control systems for removing chlorinated pollutants, heavy metals, acidic gases (e.g., nitrogen oxides) and particles [

4,

18].

On the other hand, another biosludge-to-energy concept is depicted in

Figure 1b). This system focuses on the pyrolysis and gasification for converting biosolid into biochar, and syngas respectively. However, it should be noted that tar formation is one of the major problems to deal with during biomass gasification because it condenses at reduced temperature, thus blocking and fouling process equipment such as engines and turbines. Regarding the tar removal and syngas cleaning approach for gasification, several technologies have been successfully developed in recent years [

19]. For example, catalytic cracking is a preferred removal method because the cracking of tars inside the gasifier can significantly improve the heating value of the produced gas. The resulting fuel products can be further utilized as energy sources in the following cases [

10,

20,

21]:

- (1)

Biochar and bio-oil can be used as an auxiliary feedstock for existing CHP plants such as coal combustion power plant and MSW incineration plant.

- (2)

Syngas is a gas mixture that contains varying amounts of carbon monoxide (CO) and hydrogen (H

2). As a result, it can be used as an intermediate in producing synthetic petroleum for use as a fuel or lubricant via the Fischer–Tropsch process. Due to its high energy capacity, it is often used as a fuel for internal combustion engines (e.g., Stirling engine) for generating electricity. More recently, the combustion of hard coal with sewage sludge-derived syngas has been proposed in a reburning process to reduce NO

x emissions [

20,

21].

5. Analysis of Environmental Benefits from the Utilization of Dried Biosludge as Fuels

According to the Taiwanese regulations and the thermochemical properties (

Table 1), the dried biosolids (

i.e., food processing sludge, wine brewing sludge, and agricultural sludge) can also be also reused as auxiliary solid fuel for utilizing their heat contents in the industrial utilities. It should be noted that the main advantage of reusing biosludge as an alternative energy not only lies in the diversification of fuel sources but also in the mitigation of environmental pollution and global warming. Besides, combined heat and power (CHP) systems have been successfully applied to the generation of steam and electricity from the industrial boilers then used as auxiliary fuel sources by the generators themselves or sold to the market (as valuable fuels) for nearby plants (considering the transportation cost). To address opposition because of fears of dioxins and toxic heavy metal emissions, the concept of maximum available control technology (MACT) must be adopted in the air pollution control systems for these waste-to-energy (WTE) facilities and other allied processes under the regulatory authorization.

From the average reported quantities (

Table 2), the food processing sludge, wine brewing sludge, and agricultural sludge amounted to about 43.3, 10.5 and 12.2 × 10

3 tones, respectively. As listed in

Table 1, their corresponding heating values have been measured to be about 16.8, 13.4 and 19.4 MJ/kg, respectively. The energy potential was thus estimated to be the product of the average reported volume for that biosludge and its heating value. Therefore, the total energy potential of reusing those types of biosludge as energy source in Taiwan were calculated to be about 1,100 TJ per year, which is almost equal to 1.9 × 10

5 barrels oil equivalent.

Concerning the benefits of mitigating GHG emissions to the environment, a simple method (Tier 1 method) adopted by the Inter-governmental Panel on Climate Change (IPCC) was used to estimate equivalent CO

2 emissions mitigation from the combustible sludge as energy source for electricity generation (assumed in the present work) [

22]. The IPCC methodology is based on consumed quantities of waste fuels and average default emission factor. Therefore, the anthropogenic CO

2 emissions from the combustion of waste for electricity generation were calculated by multiplying levels of activity (power generation in kWh) with default emission factor (DEF in kg CO

2/kWh). Based on the statistical calculation by the state-owned company in Taiwan (Taipower Co.), the default value in terms of the equivalent amount of CO

2 produced per kWh, which ranges from 0.5 kg CO

2/kWh for combined cycle gas turbine to 1.1 kg CO

2/kWh for modern coal plant [

23], is about 0.62 kg CO

2/kWh. Using the following data:

- (1)

Power generation efficiency (assumed): 0.3 [

24];

- (2)

Total energy potential of reusing those types of biosludge as energy source: 1,100 TJ/yr;

- (3)

Equivalent amount of CO2 produced per kWh: 0.62 kg CO2/kWh.

The equivalent mitigation of CO

2 (Gg) from the reuse of biosludge as fuel was thus calculated as given below:

6. Conclusions

In response to the problem of sustainable waste management in Taiwan, the waste-to-energy system has been established through a regulatory framework under the “joint-venture” of the ministry-level departments in the past decade. Taking into account the alternative energy utilized and GHG emissions avoided, the reuse of some types of designated waste in the industrial and agricultural sectors as auxiliary fuels was encouraged. According to the online reported quantities of major sewage biosolids (i.e., food processing sludge, wine brewing sludge sludge and agricultural sludge) collected by the Taiwan EPA, the total energy potential and the environmental benefit of mitigating CO2 emissions were preliminarily calculated to be around 1100 TJ/year and 57 Gg/year, respectively. However, the emissions of toxic and hazardous pollutants like dioxins and mercury should be in compliance with the regulatory limits thus protecting public health. Furthermore, Taiwan’s cabinet (Executive Yuan) approved the Renewable Energy Development Act in June 2009, suggesting that the Act could further promote these combustible biosolids with fossil fuels in the industrial and private power plants with some economic incentives. This is due to the fact that the surplus electricity shall be sold to the state-owned company (Taipower Company) at an officially designated rate.