Design of a Novel Experimental Facility for Testing of Tidal Arrays

Abstract

:1. Introduction

2. Tidal Devices and Arrays

2.1. Effects of Tidal Device Interaction

2.2. Experimental Facilities

3. Past Work in the Interaction of Units in an Array

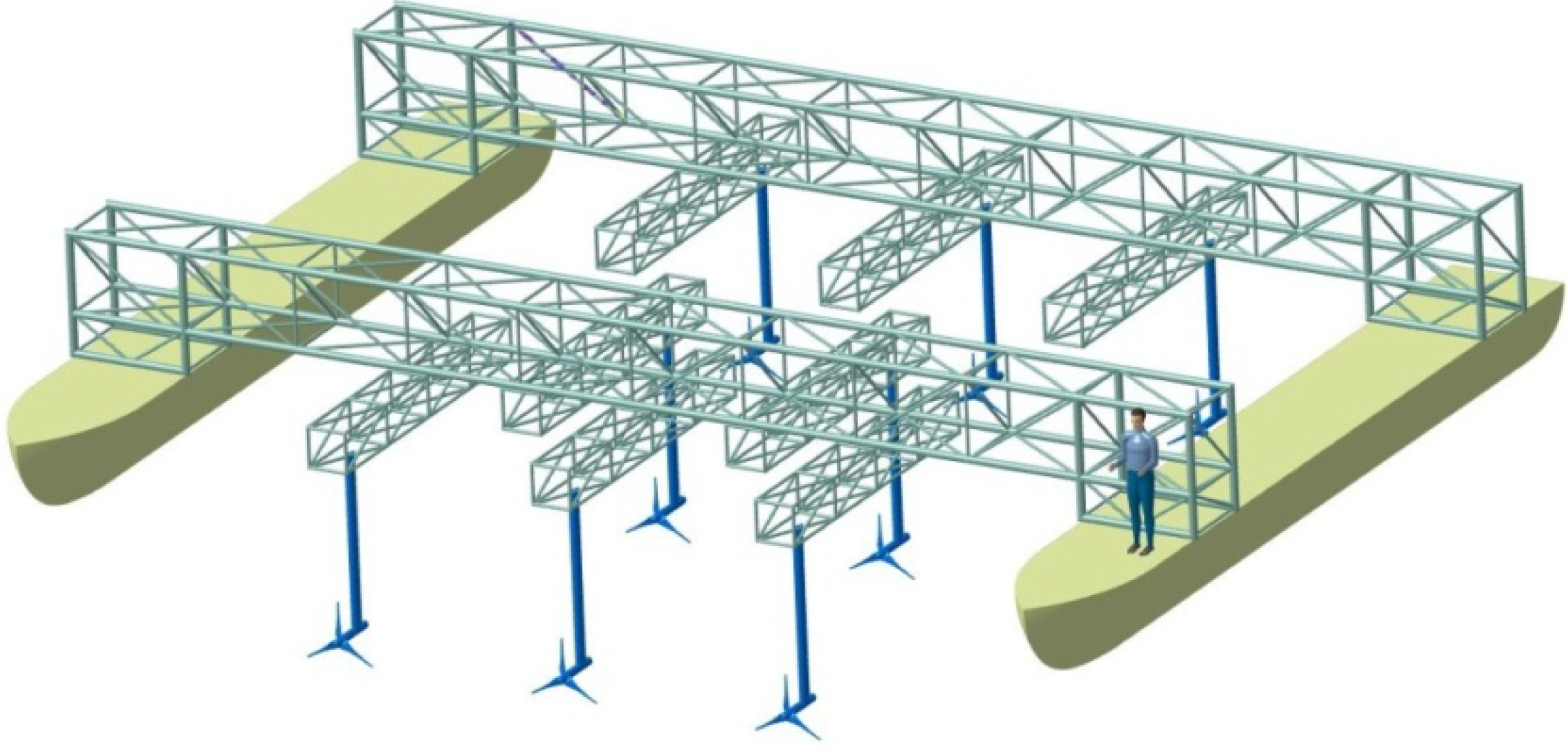

4. Novel Experimental Configuration

- Scalability. The vessel can accommodate prototypes of larger scale and larger turbine arrays, compared to the most of the towing tanks.

- Low CAPEX cost. The vessel will probably cost only a fraction of a comparable large towing tank. Facilities of different scales can be designed;

- Small size and modular design. Comparing the modular geometry and size of the vessel and the scale of prototypes that can accommodate the existing towing tanks around the world, the size of the new facility is considered very small.

5. Results of a Preliminary Study of the Concept

- Maximum diameter of tested turbines;

- Range of testing speeds of the vessel;

- Maximum number of turbines and shape of the array;

- Maximum distance between turbines.

5.1. Non-Dimensional Scaling

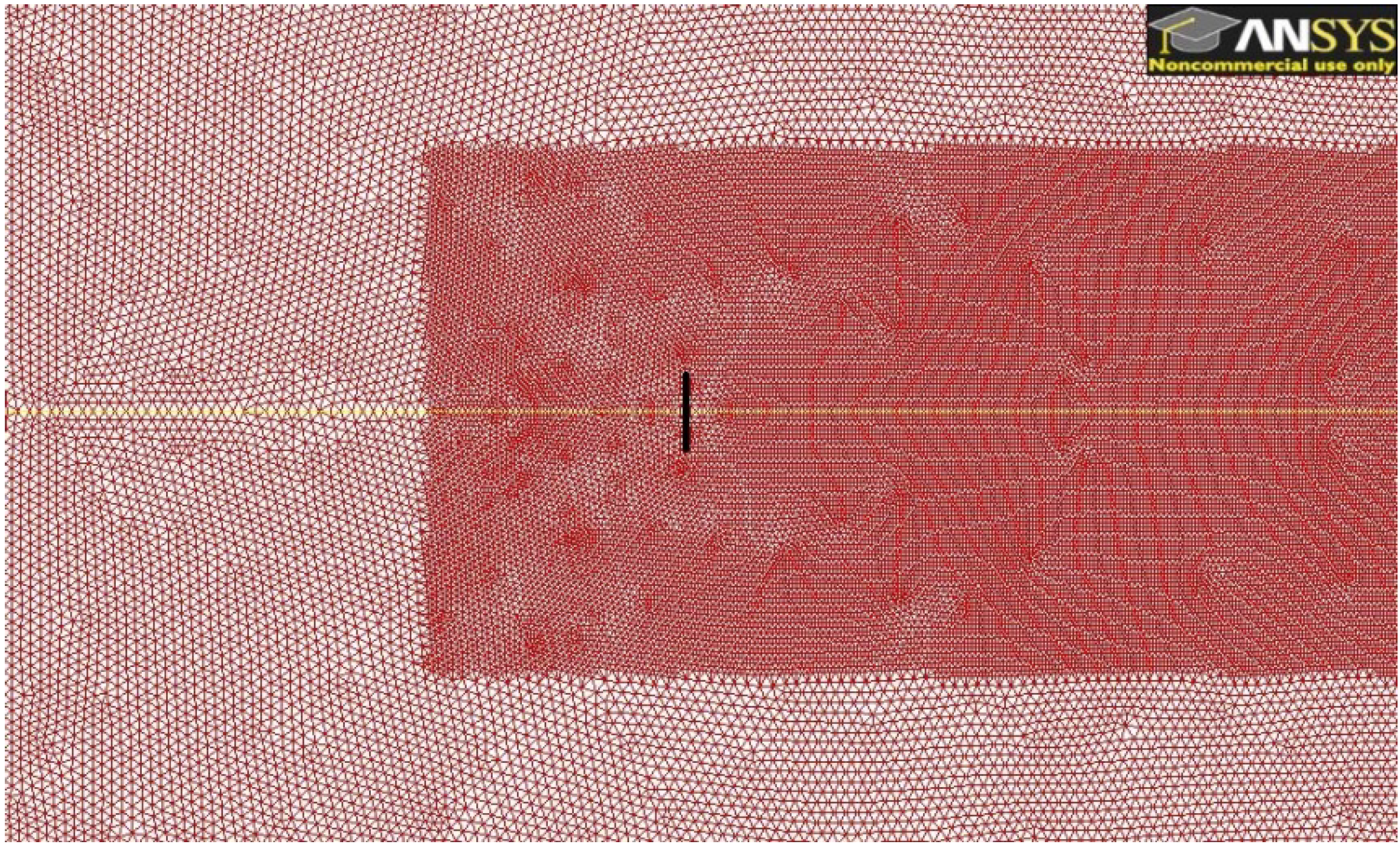

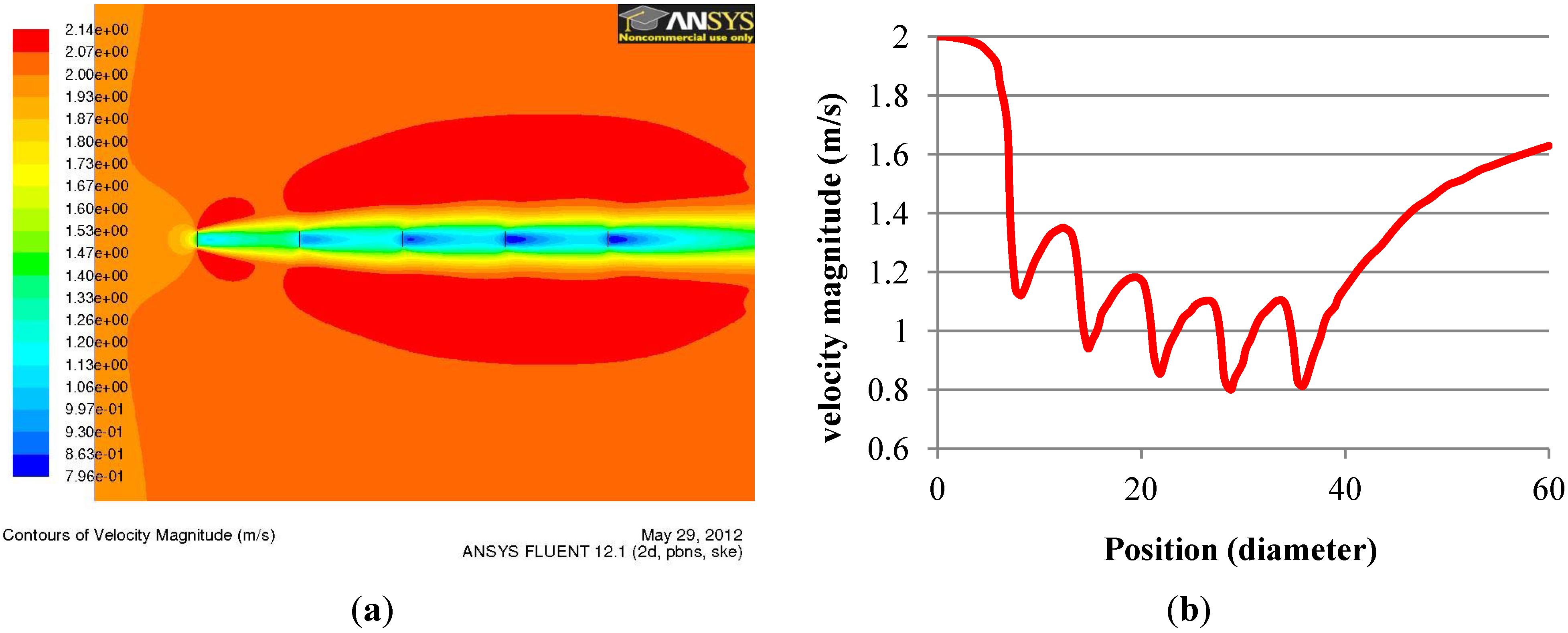

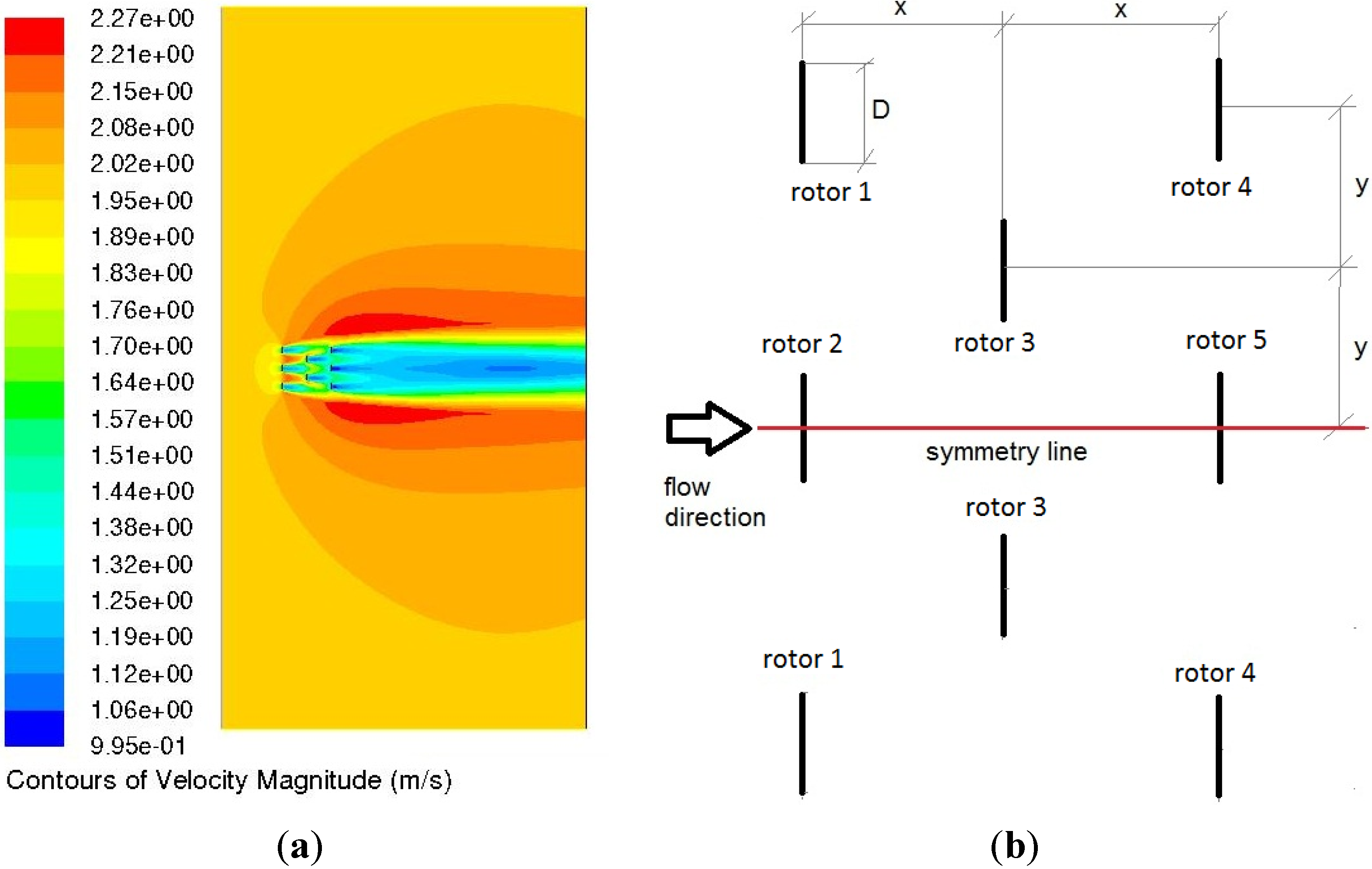

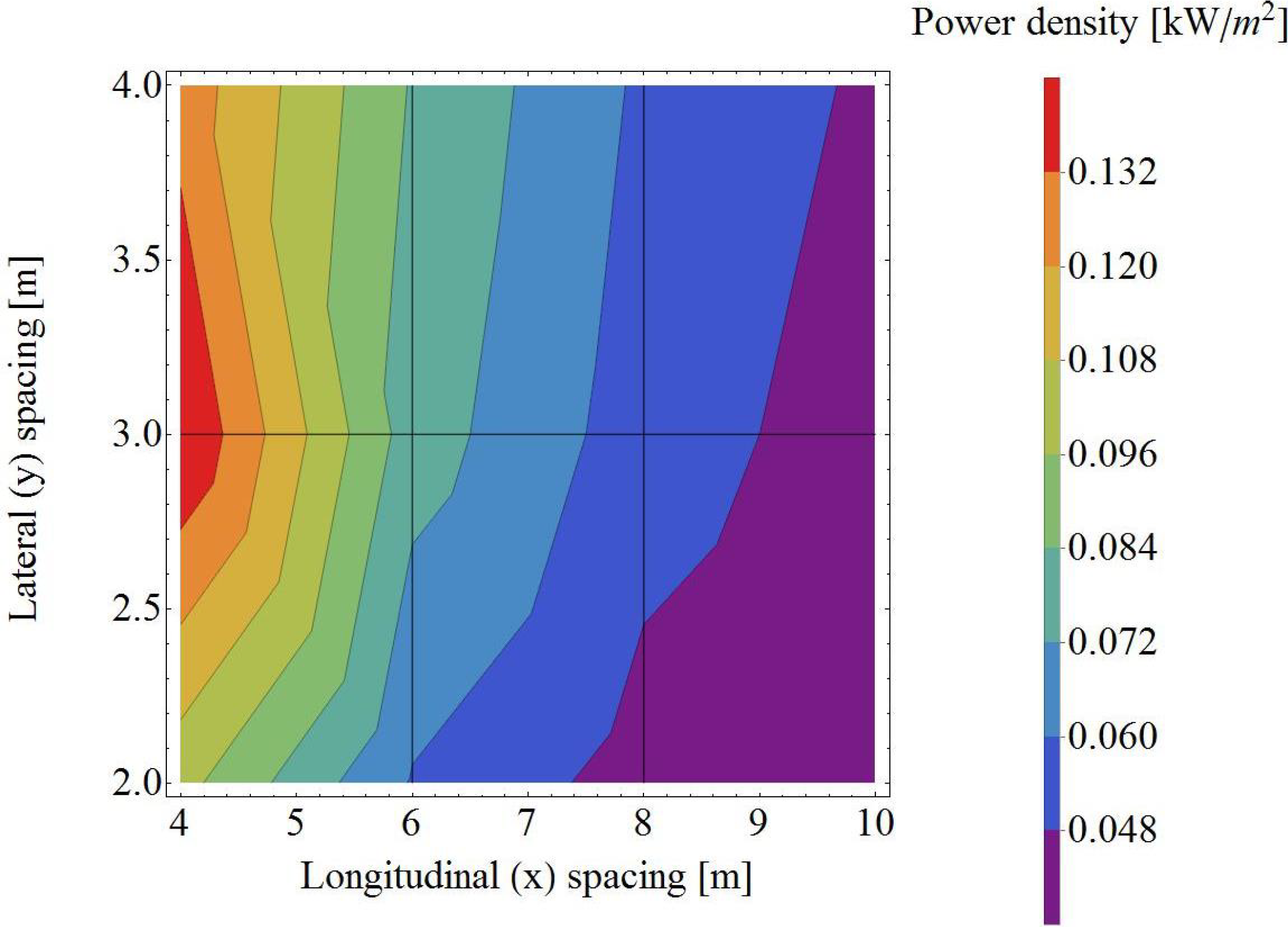

5.2. CFD of Tidal Turbine Array

| Zone | Name of Boundary Condition | Value of Parameter |

|---|---|---|

| Inlet | Velocity inlet | Magnitude (uniform): 2 m/s |

| Turbulence intensity: 1% | ||

| Turbulence length scale: 1 m | ||

| Outlet | Outflow | - |

| Side wall | Symmetry | - |

| Middle line | Symmetry | - |

| Turbine (rotor—actuator disc) | Pressure jump | Face permeability (α): 1010 m2 |

| Porous media thickness (∆m): 0.01 m | ||

| Pressure jump coefficient (C): 200 m−1 |

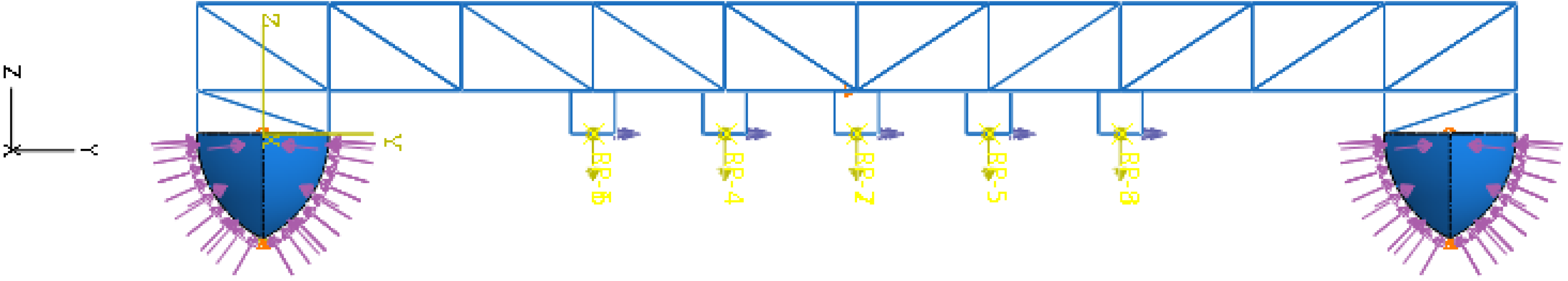

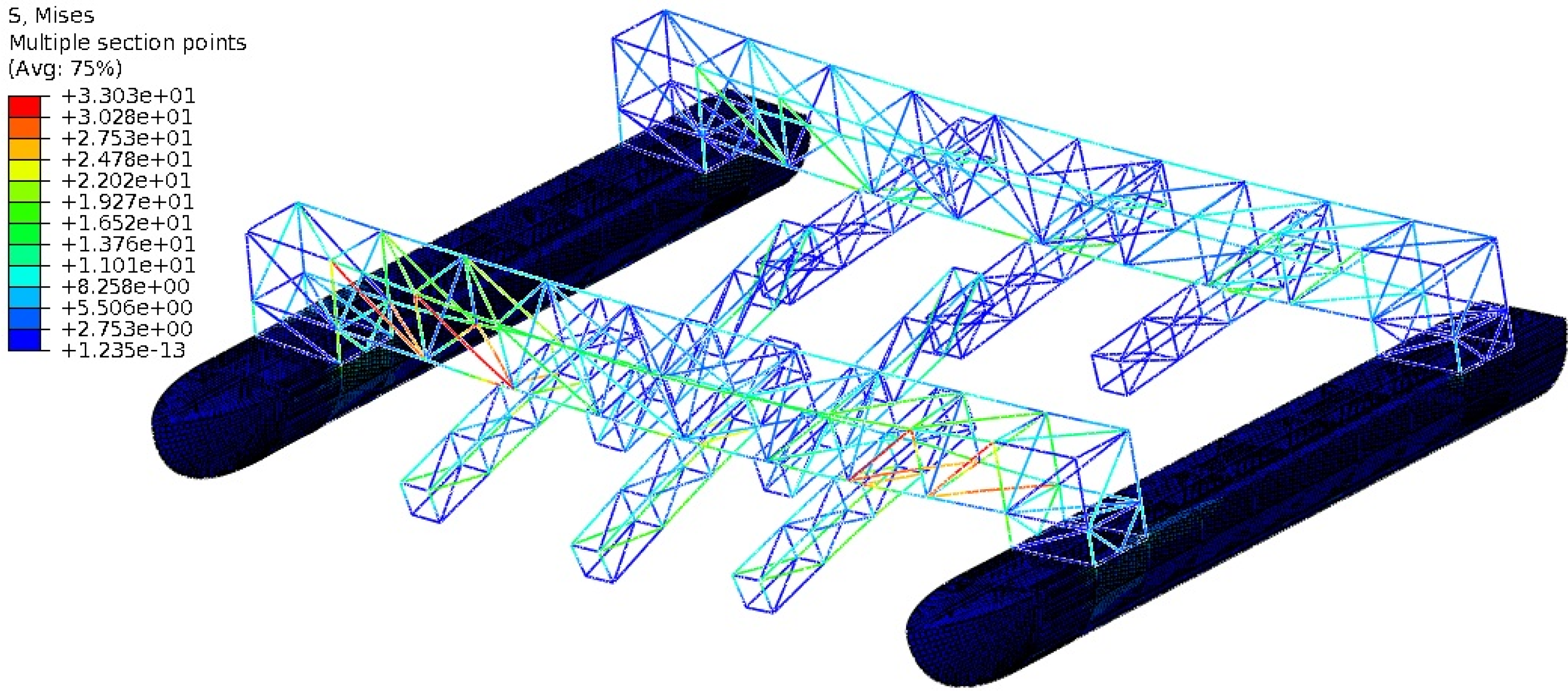

5.3. Structural Design and Analysis

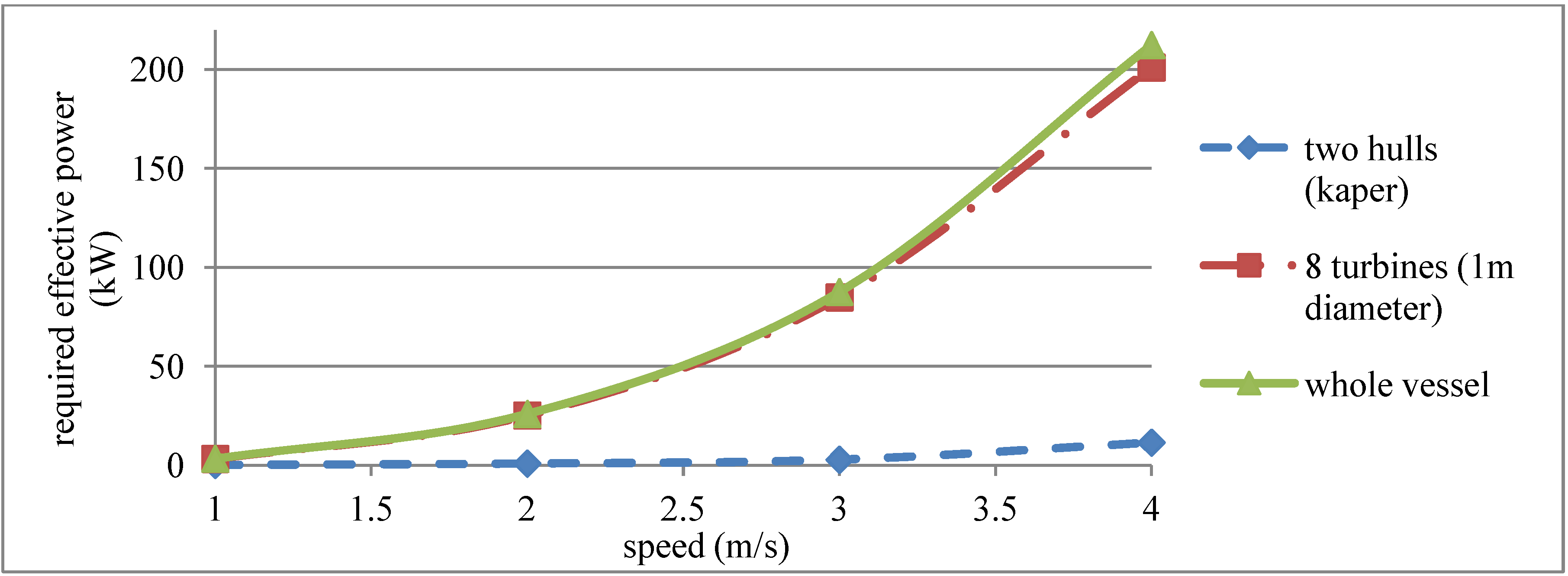

5.4. Resistance and Propulsion

| Main dimension of the hull | value | units |

|---|---|---|

| Volumetric displacement ∇ | 1.541 | m3 |

| Length of waterline LWL | 11.27 | m |

| Maximum beam of waterline BWL | 0.83 | m |

| Maximum draught T | 0.32 | m |

| Prismatic coefficient Cprism | 0.57 | / |

| Hull wetted area Awet | 11.57 | m2 |

| Longitudinal centre of buoyancy LCB | −5 | % |

| Method source | Total resistance force (N) | Calculated at speed (m/s) |

|---|---|---|

| Larsson and Eliasson | 92 | 2 |

| Schneekluth and Bertram | 77 | 2 |

| DelftShip (“Kaper”) | 200 | 2 |

| Vessel speed (m/s) | True power required (kW) | True power required (HP) |

|---|---|---|

| 1 | 6.7 | 9 |

| 2 | 52.2 | 70 |

| 3 | 176 | 236 |

| 4 | 425 | 570 |

6. Conclusions

- Repeat CFD simulation of the tidal turbine array in 3D, considering even more realistic simulation settings, including free surface effects, and determine the minimum distance between the hull and tested turbines in order to avoid unwanted interactions;

- Perform thorough structural dynamics and hydrodynamics analyses in order to produce an even more realistic design of the vessel and the interaction of its individual components;

- Instrumentation and other experimental equipment should be determined;

- Determination of possible testing locations (lake, sea or both), define relevant operational conditions and possible experiments that could be performed on the facility. Review relevant legislation and planning of the commissioning process;

- Perform a thorough techno-economic analysis deriving the optimum scale range of tidal devices that the facility can accommodate.

Conflict of Interest

References

- Carbon Thrust. In Accelerating Marine Energy: The Potential for Cost Reduction—Insights from the Carbon Trust Marine Energy Accelerator; Carbon Thrust: London, UK, 2011.

- Bahaj, A.S. Generating electricity from the oceans. Renew. Sustain. Energy Rev. 2011, 15, 3399–3416. [Google Scholar] [CrossRef]

- Delorm, T.M.; Zappala, D.; Tavner, P.J. Tidal stream device reliability comparison models. J. Risk Reliab. 2012, 226, 6–17. [Google Scholar]

- Bianchi, F.D.; Battista, H.; Mantz, R.J. Wind Turbine Control Systems: Principles, Modelling and Gain Scheduling Design; Springer: Berlin, Germany, 2007. [Google Scholar]

- Turnock, S.R.; Phillips, A.B.; Banks, J.; Nicholls-Lee, R. Modelling tidal current turbine wakes using a coupled RANS-BEMT approach as a tool for analysing power capture of arrays of turbines. Ocean Eng. 2011, 38, 1300–1307. [Google Scholar] [CrossRef]

- Mason-Jones, A.; O’Dohtery, D.M.; Morris, C.E.; O’Dohtery, T.; Byrne, C.B.; Prickett, P.W.; Grosvenor, R.I.; Owen, I.; Tedds, S.; Poole, R.J. Non-dimensional scaling of tidal stream turbines. Energy 2012, 44, 820–829. [Google Scholar] [CrossRef]

- International Towing Tank Conference: Catalogue of Facilities. Available online: http://ittc.sname.org/Catalogue%20of%20facilities/index.pdf (accessed on 20 August 2012).

- Kinsey, T.; Dumas, G.; Lalande, G.; Ruel, J.; Mehut, A.; Viarouge, P.; Lemay, J.; Jean, Y. Prototype testing of a hydrokinetic turbine based on oscillating hydrofoils. Renew. Energy 2011, 36, 1710–1718. [Google Scholar] [CrossRef]

- Kirke, B.K. Tests on ducted and bare helical and straight blade Darrieus hydrokinetic turbines. Renew. Energy 2011, 36, 3013–3022. [Google Scholar] [CrossRef]

- Rose, S.; Good, A.; Atcheson, M.; Hamill, G.; Johnstone, C.; MacKinnon, P.; Robinson, D.; Grant, A.; Whittaker, T. Investigating Experimental Techniques for Measurement of the Downstream Near Wake of a Tidal Turbine. In Proceedings of the 9th European Wave and Tidal Energy Conference, Southampton, UK, 4–9 September 2011.

- Coiro, D.P.; Scherillo, F.; Familio, R.; Maisto, U.; Troise, G. Experimental Test Campaign on an Innovative Device to Harness Clean Energy from Tidal and River Current. In Proceedings of the International Conference on Clean Electrical Power, Capri, Italy, 9–11 June 2009.

- Crespo, A.; Hernandez, J.; Frandsen, S. Survey of modelling methods for wind turbine wakes and wind farms. Wind Energy 1999, 2, 1–24. [Google Scholar] [CrossRef]

- Dabiri, J.O. Potential order-of-magnitude enhancement of wind farm power density via counter-rotating vertical-axis wind turbine arrays. J. Renew. Sustain. Energy 2011, 3, 1–12. [Google Scholar] [CrossRef]

- Sun, X.; Chick, J.P.; Bryden, I.G. Laboratory-scale simulation of energy extraction from tidal currents. Renew. Energy 2008, 33, 1267–1274. [Google Scholar] [CrossRef]

- Harrison, M.E.; Batten, W.M.J.; Myers, L.E.; Bahaj, A.S. Comparison between CFD simulations and experiments for predicting the far wake of horizontal axis tidal turbines. IET Renew. Power Gener. 2010, 4, 613–627. [Google Scholar] [CrossRef]

- Harrison, M.E.; Batten, W.M.J.; Bahaj, A.S. A Blade Element Actuator Disc Approach Applied to Tidal Stream Turbines. In Proceedings of the OCEANS 2010, Seattle, WA, USA, 20–23 September 2010.

- Bai, L.; Spence, R.R.G. Investigation of the Influence of Array Arrangement and Spacing on Tidal Energy Converter (TEC) Performance Using a 3-Dimensional CFD Model. In Proceedings of the 8th European Wave and Tidal Conference, Uppsala, Sweden, 7–10 September 2009.

- Churchfield, M.J.; Li, Y.; Moriarty, P.J. A Large-Eddy Simulation Study of Wake Propagation and Power Production in an Array of Tidal-Current Turbines. In Proceedings of the 9th European Wave and Tidal Energy Conference, Southampton, UK, 4–9 September 2011.

- Myers, L.E.; Bahaj, A.S. Experimental analysis of the flow field around horizontal axis tidal turbines by use of scale mesh disk rotor simulators. Ocean Eng. 2010, 37, 218–227. [Google Scholar] [CrossRef]

- Myers, L.E.; Bahaj, A.S. An experimental investigation simulating flow effects in first generation marine current energy converter arrays. Renew. Energy 2012, 37, 28–36. [Google Scholar] [CrossRef]

- Bahaj, A.S.; Molland, A.F.; Chaplin, J.R.; Batten, W.M.J. Power and thrust measurements of marine current turbines under various hydrodynamic flow conditions in a cavitation tunnel and a towing tank. Renew. Energy 2007, 32, 407–426. [Google Scholar] [CrossRef]

- Pintar, M. Design of Novel Experimental Configuration for Tidal Arrays. Master’s Thesis, Cranfield University, Cranfield, UK, 2012. [Google Scholar]

- Det Norske Veritas. Classification Notes: CSA-Direct Analysis of Ship Structures, 2013. Available online: http://exchange.dnv.com/publishing/cn/CN34-1.pdf (accessed on 7 August 2013).

- Larsson, L.; Eliasson, R. Principles of Yacht Design, 2nd ed.; McGraw-Hill: New York, NY, USA, 2000. [Google Scholar]

- Schneekluth, H.; Bertram, V. Ship Design for Efficiency and Economy; Butterworth-Heinemann: Oxford, UK, 1998. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Pintar, M.; Kolios, A.J. Design of a Novel Experimental Facility for Testing of Tidal Arrays. Energies 2013, 6, 4117-4133. https://doi.org/10.3390/en6084117

Pintar M, Kolios AJ. Design of a Novel Experimental Facility for Testing of Tidal Arrays. Energies. 2013; 6(8):4117-4133. https://doi.org/10.3390/en6084117

Chicago/Turabian StylePintar, Matevz, and Athanasios J. Kolios. 2013. "Design of a Novel Experimental Facility for Testing of Tidal Arrays" Energies 6, no. 8: 4117-4133. https://doi.org/10.3390/en6084117