Effects of Degree of Superheat on the Running Performance of an Organic Rankine Cycle (ORC) Waste Heat Recovery System for Diesel Engines under Various Operating Conditions

Abstract

: This study analyzed the variation law of engine exhaust energy under various operating conditions to improve the thermal efficiency and fuel economy of diesel engines. An organic Rankine cycle (ORC) waste heat recovery system with internal heat exchanger (IHE) was designed to recover waste heat from the diesel engine exhaust. The zeotropic mixture R416A was used as the working fluid for the ORC. Three evaluation indexes were presented as follows: waste heat recovery efficiency (WHRE), engine thermal efficiency increasing ratio (ETEIR), and output energy density of working fluid (OEDWF). In terms of various operating conditions of the diesel engine, this study investigated the variation tendencies of the running performances of the ORC waste heat recovery system and the effects of the degree of superheat on the running performance of the ORC waste heat recovery system through theoretical calculations. The research findings showed that the net power output, WHRE, and ETEIR of the ORC waste heat recovery system reach their maxima when the degree of superheat is 40 K, engine speed is 2200 r/min, and engine torque is 1200 N·m. OEDWF gradually increases with the increase in the degree of superheat, which indicates that the required mass flow rate of R416A decreases for a certain net power output, thereby significantly decreasing the risk of environmental pollution.1. Introduction

Waste heat recovery has recently become a more efficient and effective method by which to save energy and reduce emissions. The organic Rankine cycle (ORC) system is an effective and promising method for converting waste heat into useful work, and has been widely studied and applied in many domains [1–5]. Li et al. [6] analyzed the performance of ORC in recovering low-temperature waste heat from flue gas. Li et al. [7] proposed a supercritical ORC-driven seawater reverse osmosis system. Reverberi et al. [8] proposed an ORC system to generate electrical power at low temperatures. Wang et al. [9] found that ORC can effectively recover a low-grade heat source. Thus, the ORC system is suitable for waste heat recovery.

Different application areas require the appropriate configuration of the ORC system and the adoption of the optimal working fluid to take advantage of the available waste heat [10–17]. Liu et al. [18] discussed a subcritical ORC with 28 working fluids for waste heat recovery. Jin et al. [19] illustrated that zeotropic mixtures exhibit an obvious temperature glide during phase change. Wang et al. [20] compared the cycle performances of pure fluid and zeotropic mixtures based on an experimental prototype, and results showed that the collector efficiency and thermal efficiency (ηth) of the zeotropic mixtures are comparatively higher than that of the pure fluid under experimental conditions. Clemente et al. [21] defined an ORC system to recover heat from a commercial gas turbine with recuperator. Wang et al. [22] evaluated five different types of ORC, and their analysis indicated that the ORC with recuperator possesses the best thermodynamic performance. From the previously mentioned analysis, we can conclude that the running performance of the ORC system can be improved when a zeotropic mixture is used as working fluid or when an internal heat exchanger (IHE) is used.

Internal combustion (IC) engines consume a great deal of fuel; however, less than 40% of an IC engine's fuel combustion energy is converted into useful work, and the remaining combustion energy is released into the atmosphere in the form of waste heat through the exhaust and coolant system. This pollutes the environment and results in energy dissipation [23]. By recovering an IC engine's waste heat, the thermal efficiency of the IC engine can be effectively improved [24,25]. ORC waste heat recovery systems for IC engines have become a hot spot of research worldwide [26–30]. Katsanos et al. [31] studied the potential improvement in the overall efficiency of a truck engine equipped with an ORC, and results showed that the brake specific fuel consumption can be improved. Sprouse et al. [32] reviewed the history of IC engine exhaust waste heat recovery focusing on ORCs and demonstrated a potential fuel economy improvement of approximately 10% with modern refrigerants and advancements in expander technology.

From the aforementioned introduction, the use of ORC is an effective method by which to recover waste heat from IC engines and is helpful for improving the thermal efficiency of such engines. As a kind of power machinery, IC engines, especially those in vehicles, usually work under variable operating conditions. Therefore, the running performances of the ORC waste heat recovery system under various operating conditions should be comprehensively studied.

In this paper, an ORC waste heat recovery system with IHE has been designed to recover the exhaust energy from a diesel engine while considering the variation law of diesel engine exhaust energy under various operating conditions. The zeotropic mixture R416A was used as the working fluid. Three concepts, namely, waste heat recovery efficiency (WHRE), engine thermal efficiency increasing ratio (ETEIR), and output energy density of working fluid (OEDWF), have been defined. Based on the first and second laws of thermodynamics, in terms of various operating conditions of the diesel engine, the variation tendencies of the running performances of the ORC waste heat recovery system were studied, variation of occurrence position of the pinch point temperature difference (PPTD, ΔTpp) between diesel engine exhaust and zeotropic mixture R416A was investigated. Moreover, the effects of the degree of superheat (Tsup) on the running performances of the ORC waste heat recovery system were analyzed.

2. Description and Modeling of the ORC Waste Heat Recovery System

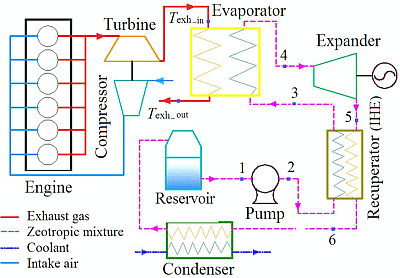

The working principle of the ORC waste heat recovery system is illustrated in Figure 1. The working fluid R416A is drawn from the reservoir and pressurized into a subcooled liquid state by the pump, which then absorbs the heat and is preheated in the recuperator (namely IHE). Subsequently, the working fluid is sent to the evaporator and heated by engine exhaust, and turns into a saturated vapor state or superheated vapor state. Then, the saturated or superheated vapor at high pressure and high temperature enters the expander to produce useful work, which can be used to generate electricity. After the expansion process, with a decrease in temperature and pressure, the superheated vapor exhausted from the expander flows into the recuperator and exchanges heat with the liquid working fluid exported from the pump. Afterwards, the cooled working fluid exhausted from the recuperator flows into the condenser, condenses into the liquid state in the condenser, and then flows into the reservoir. This completes the whole ORC process. In this paper, the engine exhaust acts as the high-temperature heat source of the ORC waste heat recovery system. The working fluid is heated by engine exhaust in the evaporator.

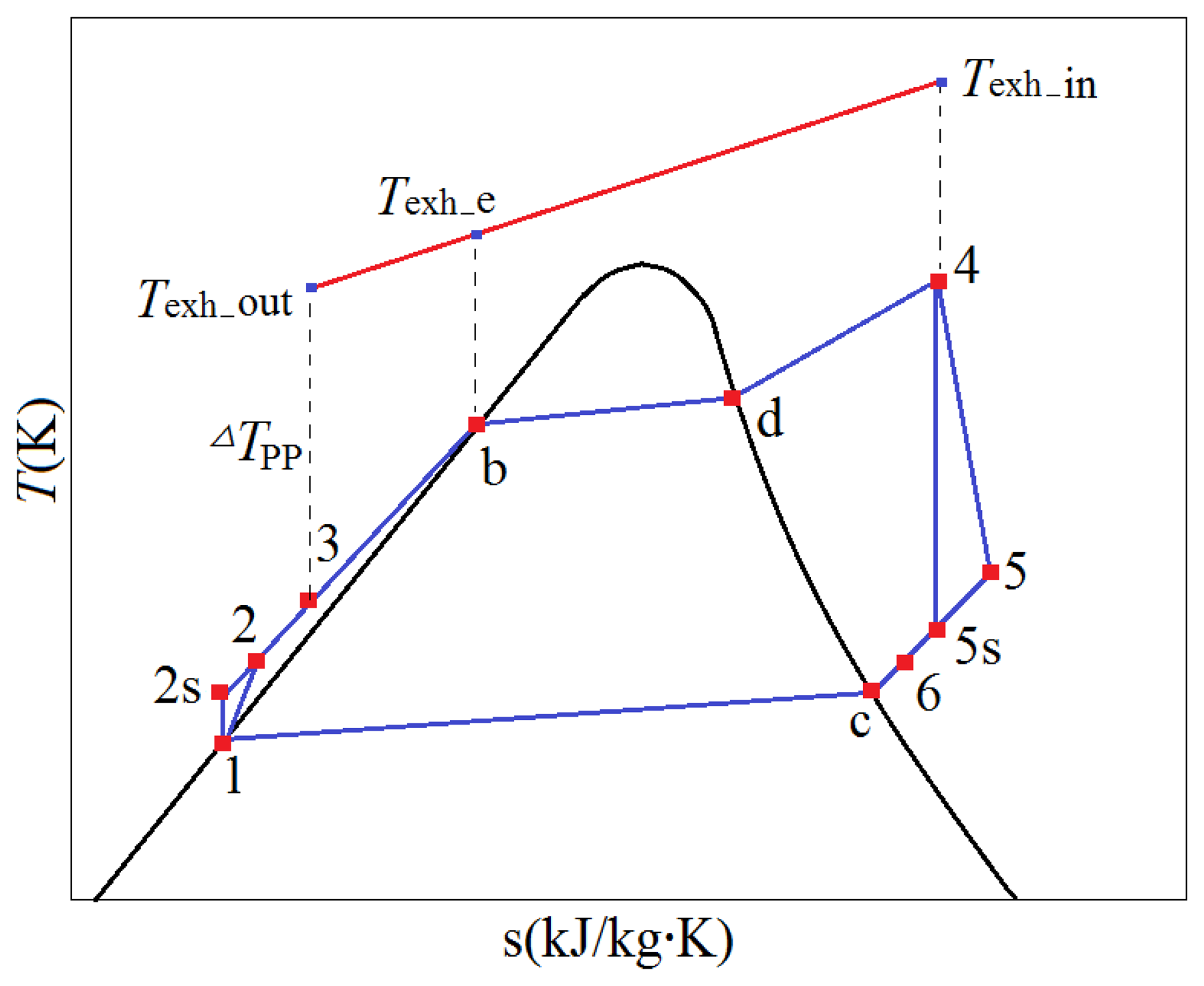

The T-s diagram of the ORC waste heat recovery system is shown in Figure 2, where Texh_in is the engine exhaust temperature at the inlet of the evaporator of the engine exhaust side, and Texh_out is the engine exhaust temperature at the outlet of the evaporator of the engine exhaust side. Process Texh_in-Texh_out is the heat rejection process of the engine exhaust in evaporator. Process 3-4 is the heat addition process of the working fluid R416A. In practice, a diesel engine generally runs under various operating conditions, both the exhaust temperature and amount of waste heat from the diesel engine vary with engine operating conditions, therefore, the occurrence position of PPTD between the diesel engine exhaust and the zeotropic mixture R416A may change, possibly appearing at the inlet of the evaporator of the zeotropic mixture side (State Point 3 in Figure 2), at the outlet of the evaporator of the zeotropic mixture side (State Point 4 in Figure 2), or at the saturated liquid state point of the zeotropic mixture (State Point b in Figure 2). In this paper, we analyzed the variation of the occurrence position of PPTD between diesel engine exhaust and zeotropic mixture R416A under engine various operating conditions. PPTD between the diesel engine exhaust and zeotropic mixture R416A is set to 10 K. The PPTD occurrence position is first assumed to appear at the inlet of the evaporator of the zeotropic mixture side (State Point 3 in Figure 2), which indicates that the difference between Texh_out and T3 is 10 K. T4 is the temperature of the zeotropic mixture R416A at the outlet of the evaporator of the zeotropic mixture side, Texh_in can be measured during the engine test, and T4 can be determined when the evaporating pressure and degree of superheat are certain (in this paper, “certain” means “be held constant”, the same as below), such that the difference between Texh_in and T4 can be calculated. Texh_e can be calculated using Equation (1), where Tb is the bubble temperature of the zeotropic mixture R416A in the saturated liquid state, such that the difference between Texh_e and Tb can be calculated. The occurrence position of PPTD between diesel engine exhaust and zeotropic mixture R416A can be determined by comparing the values of the above-mentioned three temperature difference:

The evaporator and condenser are mainly responsible for the exergy destruction rate ( İ ) of the ORC waste heat recovery system; exergy destruction rate is mainly caused by the temperature difference of the heat transfer between the hot and cold fluids. Zeotropic mixtures have a property called “temperature slip” in both the isobaric evaporating process and the isobaric condensing process. A certain difference exists between the bubble point temperature and the dew point temperature at the same pressure. The exergy destruction rate caused by the temperature difference of heat transfer can be decreased by selecting a suitable zeotropic mixture. The zeotropic mixture R416A was thus selected as the working fluid for the ORC waste heat recovery system through theoretical calculations and comprehensive comparison. The temperature difference between Td and Tb represents the slip temperature of the zeotropic mixture R416A at a certain evaporating pressure, whereas the temperature difference between Tc and T1 represents the slip temperature of the zeotropic mixture R416A at a certain condensing pressure (Figure 2). The zeotropic mixture R416A is a kind of wet fluid, at the end of the expansion process in the expander, phase state (such as superheated vapor, saturated vapor and unsaturated vapor) of the zeotropic mixture is related to the degree of superheat for the zeotropic mixture at the inlet of the expander. In this paper, according to various operating conditions of the diesel engine, we studied the effects of degree of superheat on the running performance of the ORC waste heat recovery system. The main properties of the zeotropic mixture R416A are listed in Table 1.

As shown in Figure 2, Process 1-2 is the actual compression process of the zeotropic mixture R416A in the pump, the power consumption and the exergy destruction rate of the pump are calculated using the following equations:

Process 2-3 is the isobaric endothermic process of the zeotropic mixture R416A in the recuperator (IHE), Process 5-6 is the isobaric exothermic process of the zeotropic mixture R416A in the recuperator (IHE), and ε is the effectiveness of the recuperator (IHE). The heat transfer rate (Q̇) between the hot and cold fluids, exergy destruction rate, and effectiveness of the recuperator (IHE; are calculated using the following equations:

Process 3-4 is the isobaric endothermic process of the zeotropic mixture R416A in the evaporator. The heat transfer rate between the hot and cold fluids, as well as the exergy destruction rate of the evaporator, is calculated using the following equations:

Process 4-5s is the isentropic expansion process, whereas Process 4-5 is the actual expansion process of the zeotropic mixture R416A in the expander. The power output and exergy destruction rate of the expander are calculated using the following equations:

Process 6-1 is the isobaric condensing process of the zeotropic mixture R416A in the condenser. The heat transfer rate between the hot and cold fluids, as well as the exergy destruction rate of the condenser, is calculated using the following equations:

The net power output (Ẇn), thermal efficiency, and exergy efficiency (ηex) are the main indexes for evaluating the running performances of the ORC waste heat recovery system.

The net power output of the ORC waste heat recovery system is calculated as follows:

The thermal efficiency of the ORC waste heat recovery system is calculated as follows:

The exergy efficiency of the ORC waste heat recovery system is calculated as follows:

Therein, TH is the average temperature of engine exhaust in the evaporator, and TH can be calculated using the following equation:

Three indexes have been proposed to evaluate the running performances of the ORC waste heat recovery system objectively. These indexes are WHRE, ETEIR, and OEDWF. WHRE is the ratio of the net power output of the ORC waste heat recovery system to the available exhaust energy rate (Q̇exh_id) of the IC engine. ETEIR is the ratio of the net power output of the ORC waste heat recovery system to the power output of the IC engine (Ẇeng). OEDWF is the ratio of the net power output of the ORC waste heat recovery system to the mass flow rate (ṁ) of the working fluid.

WHRE is calculated as follows:

ETEIR is calculated as follows:

OEDWF is calculated as follows:

The restricted conditions for the calculations are listed as follows:

- (1)

Pressure drop and heat loss of components and pipelines are neglected;

- (2)

The evaporating pressure is set to 3.5 MPa;

- (3)

The condensing temperature (at State Point 1 in Figure 2) is set to 308 K;

- (4)

Degree of superheat varies in the range of 10 K to 40 K and then set to 10, 20, 30, and 40 K;

- (5)

The temperature of the low-temperature heat source (TL) is set to 300 K, and the ambient temperature (T0) is set to 293 K;

- (6)

The working fluid turns into saturated liquid state after heat rejection in the condenser;

- (7)

The effectiveness of recuperator (ε) is set to 0.9;

- (8)

The isentropic efficiencies of both expander (ηs) and pump (ηp) are set to 0.8.

3. Engine Available Exhaust Energy

Exhaust energy varies according to the different operating conditions of the IC engine. The IC engine used in this research is a six-cylinder and four-stroke vehicle diesel engine. The main parameters of the diesel engine are listed in Table 2.

The operating parameters and performance parameters of the diesel engine can be obtained through the engine bench test, such as exhaust temperature (Texh_in), intake air flow rate, fuel consumption rate, engine speed, engine torque, and engine power output. The following equation is used to calculate the available exhaust energy rate of the diesel engine:

The variation law of available exhaust energy rate under various engine operating conditions is shown in Figure 3. When the engine torque is certain, engine available exhaust energy rate gradually increases with the increase of engine speed. When the engine speed is certain, engine available exhaust energy rate gradually increases with the increase of engine torque. When the engine speed is 2200 r/min and the engine torque is 1200 N·m, the engine available exhaust energy rate reaches its maximum of approximately 293 kW.

The power output of the diesel engine under various operating conditions is shown in Figure 4. When the engine speed is 2200 r/min and the engine torque is 1200 N·m, the engine power output reaches its maximum of 280 kW. Figures 3 and 4 show that the maximum value of engine available exhaust energy rate is higher than that of the engine power output. Therefore, thermal efficiency of the diesel engine can be effectively improved by recovering and utilizing the waste heat of the diesel engine exhaust.

4. Calculation

The variation tendency of the heat transfer temperature difference between Texh_in and T4 with engine operating conditions and degree of superheat is shown in Figure 5.

The red dashed line indicates that the heat transfer temperature difference is 10 K. When the heat transfer temperature difference between Texh_in and T4 is higher than 10 K, the PPTD occurrence position between engine exhaust and zeotropic mixture scarcely appears at State Point 4 in Figure 2 (the outlet of the evaporator of the zeotropic mixture side). When the heat transfer temperature difference between Texh_in and T4 is less than 10 K, the PPTD occurrence position between the engine exhaust and zeotropic mixture probably appears at State Point 4 in Figure 2. When the degree of superheat is certain, the heat transfer temperature difference between Texh_in and T4 varies according to the different operating conditions of the diesel engine, as shown in Figure 5. The main reason for this difference is the fact that the exhaust temperature of the diesel engine varies with the engine operating conditions. When the engine operating condition is determined, the heat transfer temperature difference between Texh_in and T4 decreases with the increase of degree of superheat, which means that the probability of PPTD occurrence position between the engine exhaust and zeotropic mixture being at State Point 4 in Figure 2 increases with the increase of degree of superheat. The main reason for this finding is that the temperature of the zeotropic mixture R416A at the outlet of the evaporator (T4) increases with the increase of degree of superheat, and the engine exhaust temperature at the inlet of the evaporator of the engine exhaust side (Texh_in) is certain, then the heat transfer temperature difference between Texh_in and T4 gradually decreases with the increase of degree of superheat. For the majority of the engine operating conditions, the heat transfer temperature difference between Texh_in and T4 is higher than 10 K.

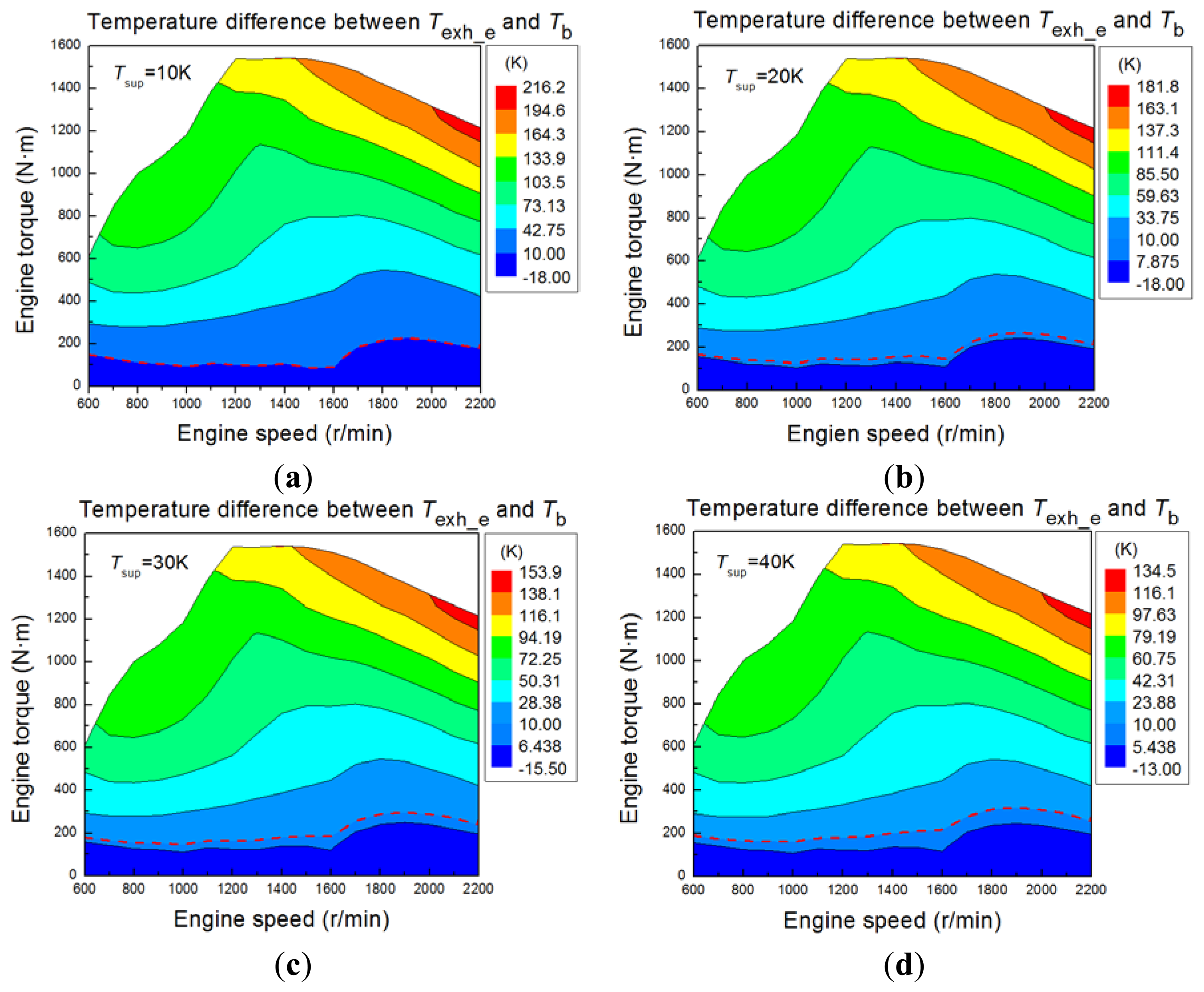

Figure 6 shows the variation tendency of heat-transfer temperature difference between Texh_e and Tb with engine operating condition and degree of superheat. The red dashed line indicates that the heat transfer temperature difference is 10 K. When the degree of superheat is certain, the heat transfer temperature difference between Texh_e and Tb varies according to different operating conditions of the diesel engine, which is mainly influenced by the engine exhaust temperature, as shown in Figure 6. When the engine operating condition is determined, the heat transfer temperature difference between Texh_e and Tb gradually decreases with the increase of degree of superheat, which means the probability of the change that PPTD occurrence position between engine exhaust and zeotropic mixture increases with the increase of degree of superheat. According to Figures 5 and 6, when the engine torque is higher than 300 N·m, the heat transfer temperature difference between Texh_in and T4 is certainly higher than 10 K, similar to the heat transfer temperature difference between Texh_e and Tb. The PPTD occurrence position between engine exhaust and zeotropic mixture certainly appears at State Point 3 in Figure 2 (the inlet of the evaporator of the zeotropic mixture side). When engine torque is less than 300 N·m, the PPTD occurrence position between the engine exhaust and zeotropic mixture may change. To decrease the influence of PPTD occurrence position variation on the running performances of the ORC waste heat recovery system, engine operating conditions with torque less than 300 N·m are excluded in the following discussion and analysis.

It can be concluded from the above analysis, that when the engine operating conditions and degree of superheat change, the occurrence position of PPTD between the engine exhaust and the zeotropic mixture R416A may change. Therefore, when we employ an ORC system to recover the waste heat from the engine exhaust, according to the various operating conditions of the engine, it should be taken into an overall consideration to design the running parameters of the ORC waste heat recovery system. In this paper, we put focus on degree of superheat.

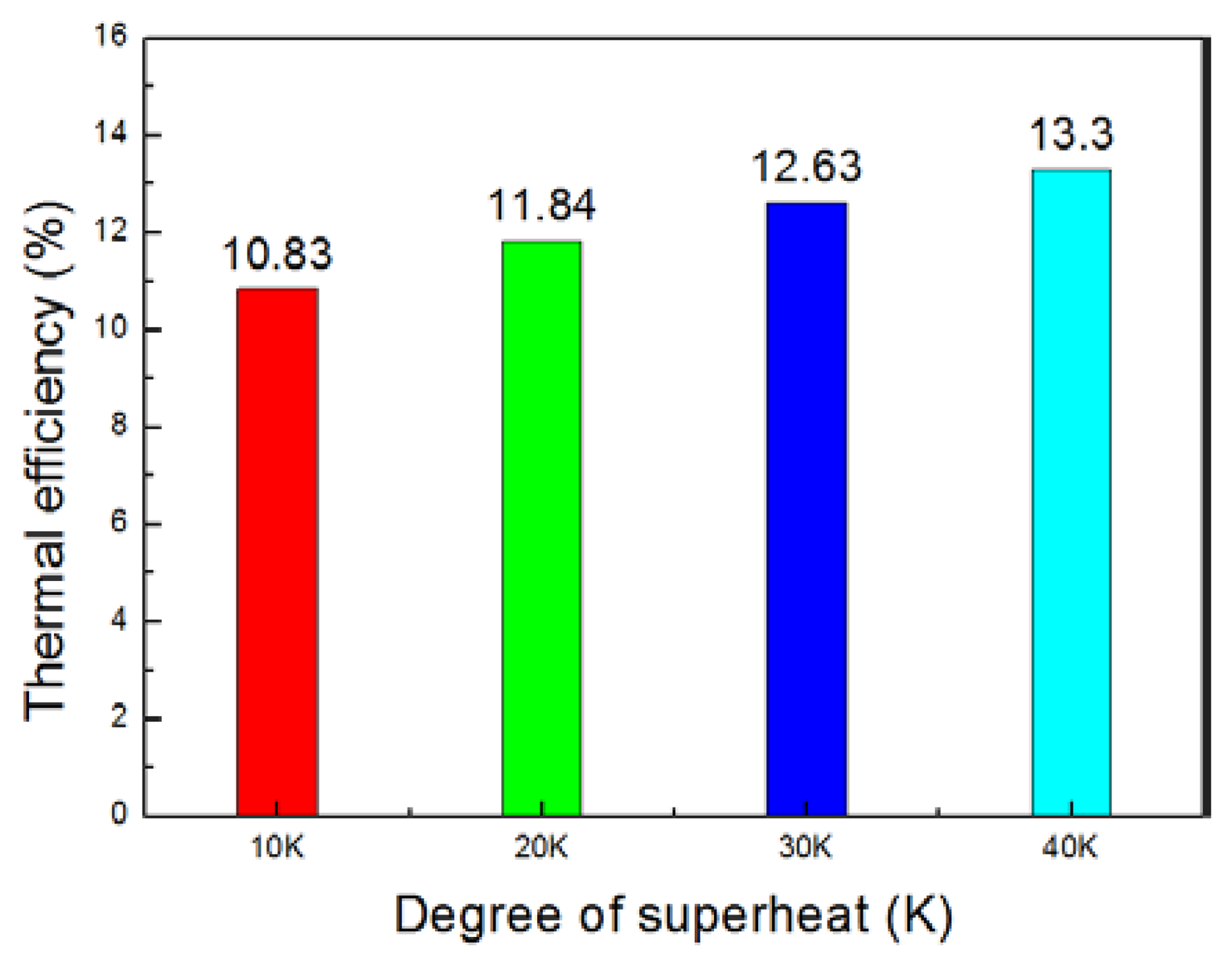

The effect of the degree of superheat on the thermal efficiency of the ORC waste heat recovery system is shown in Figure 7. Thermal efficiency gradually increases with the increase of degree of superheat. When degree of superheat is 40 K, the thermal efficiency reaches its maximum of 13.30%. The thermal efficiency of the ORC waste heat recovery system is mainly influenced by the enthalpy (h) value of each state point, and the enthalpy value is mainly dependent on the performances of each component and on the properties of the working fluid.

The enthalpy value of each state point for different degree of superheat is shown in Table 3. The enthalpy values of State Point 1 and State Point 2 do not vary with the increase of degree of superheat. The enthalpy values of State Point 3, State Point 4 and State Point 5 all increase with the increase of degree of superheat, both enthalpy difference between State Point 4 and State Point 5 and enthalpy difference between State Point 4 and State Point 3 increase with the increase of degree of superheat. Furthermore, compared with the increment of the enthalpy difference between State Point 4 and State Point 3, the increment of enthalpy difference between State Point 4 and State Point 5 is larger, and then thermal efficiency of the ORC waste heat recovery system gradually increases with the increase of degree of superheat.

Figure 8 indicates the variation of the net power output of the ORC waste heat recovery system with engine operating condition and degree of superheat. When the engine speed and degree of superheat are certain, the net power output of the ORC waste heat recovery system gradually increases with the increase of the engine torque; when the engine torque and degree of superheat are certain, the net power output of the ORC waste heat recovery system gradually increases with the increase of the engine speed. This is mainly because with the increase of engine speed and engine torque, the mass flow rate of the engine exhaust increases, and the heat transfer rate between the zeotropic mixture R416A and engine exhaust increases in the evaporator. Consequently, the net power output of the ORC waste heat recovery system increases. When the engine operating condition is certain, the net power output of the ORC waste heat recovery system gradually increases with the increase of degree of superheat, which is mainly dependent on the enthalpy difference of the zeotropic mixture between the inlet and outlet of the expander. As shown in Table 3, the enthalpy difference of the zeotropic mixture between inlet and outlet of the expander (enthalpy difference of the zeotropic mixture between State Point 4 and State Point 5) gradually increases with the increase of degree of superheat. Consequently, the net power output of the ORC waste heat recovery system gradually increases. When the degree of superheat is 40 K, the engine speed is 2200 r/min and the engine torque is 1200 N·m, the net power output of the ORC waste heat recovery system reaches its maximum of 35.66 kW. The analysis above shows when the diesel engine runs with high speed and high torque, net power output of the ORC waste heat recovery system is higher. Moreover, increasing degree of superheat is benefit for increasing the net power output of the ORC waste heat recovery system.

For exergy efficiency, its variation with engine operating condition and degree of superheat is shown in Figure 9. When the engine operating condition is certain, the exergy efficiency of the ORC waste heat recovery system gradually increases with the increase of degree of superheat. The main reason for this is, on one hand, the thermal efficiency of the ORC waste heat recovery system gradually increases with the increase of degree of superheat. On the other hand, engine exhaust temperature is definitely determined by the certain operating condition, then the temperature of the high-temperature heat source (TH) is also certain. When the engine speed and degree of superheat are certain, the exergy efficiency of the ORC waste heat recovery system gradually decreases with the increase of engine torque. When degree of superheat is certain and the engine torque is less than 1000 N·m, the exergy efficiency of the ORC waste heat recovery system initially decreases, increases, and then decreases again with the increase of engine speed. When degree of superheat is certain and the engine torque is in the range of 1000 N·m to 1300 N·m, the exergy efficiency of the ORC waste heat recovery system initially increases and then decreases with the increase of engine speed. When degree of superheat is certain and the engine torque is higher than 1300 N·m, the exergy efficiency of the ORC waste heat recovery system gradually decreases with the increase of engine speed, which is mainly dependent on the temperature of the engine exhaust. When degree of superheat is 40 K, engine torque is 300 N·m, and engine speed is 1900 r/min, the exergy efficiency of the ORC waste heat recovery system reaches its maximum of 54.60%. The study above shows that increasing the degree of superheat is beneficial for improving the exergy efficiency of the ORC waste heat recovery system. When the diesel engine runs with high speed and low torque, the exergy efficiency of the ORC waste heat recovery system is relatively better.

Available exhaust energy of the diesel engine varies with engine operating conditions. In order to recover the engine exhaust energy efficiently, some running parameters of the ORC waste heat recovery system (mainly the mass flow rate of the working fluid) should be actively regulated for the corresponding operating conditions of the diesel engine. In this paper, we studied the variation tendency of the zeotropic mixture mass flow rate of the ORC waste heat recovery system under various engine operating conditions. The variation trend of the mass flow rate of the zeotropic mixture R416A with engine operating condition and degree of superheat is depicted in Figure 10. When the engine operating conditions are certain, the mass flow rate of the zeotropic mixture R416A gradually decreases with the increase of degree of superheat. The principal reason is that with the increase of degree of superheat, the enthalpy difference of the zeotropic mixture R416A between the inlet and outlet of the evaporator increases, meanwhile engine available exhaust energy is certain, and then mass flow rate of the zeotropic mixture R416A decreases. When the degree of superheatins and engine torque are certain, the mass flow rate of the zeotropic mixture R416A gradually increases with the increase of engine speed. When the degree of superheat and engine speed are certain, the mass flow rate of the zeotropic mixture R416A gradually increases with the increase of engine torque. The main reason for this is, with the increase of engine speed and engine torque, engine available exhaust energy increases, then more working fluid R416A can be heated, evaporated, and superheated.

It can be concluded from the analysis above that the required mass flow rate of zeotropic mixture R416A varies with engine operating conditions, and the required mass flow rate of zeotropic mixture R416A is related to the available exhaust energy of the diesel engine. According to the available exhaust energy of the diesel engine, the mass flow rate of the zeotropic mixture R416A should be actively regulated to recover the engine exhaust energy efficiently.

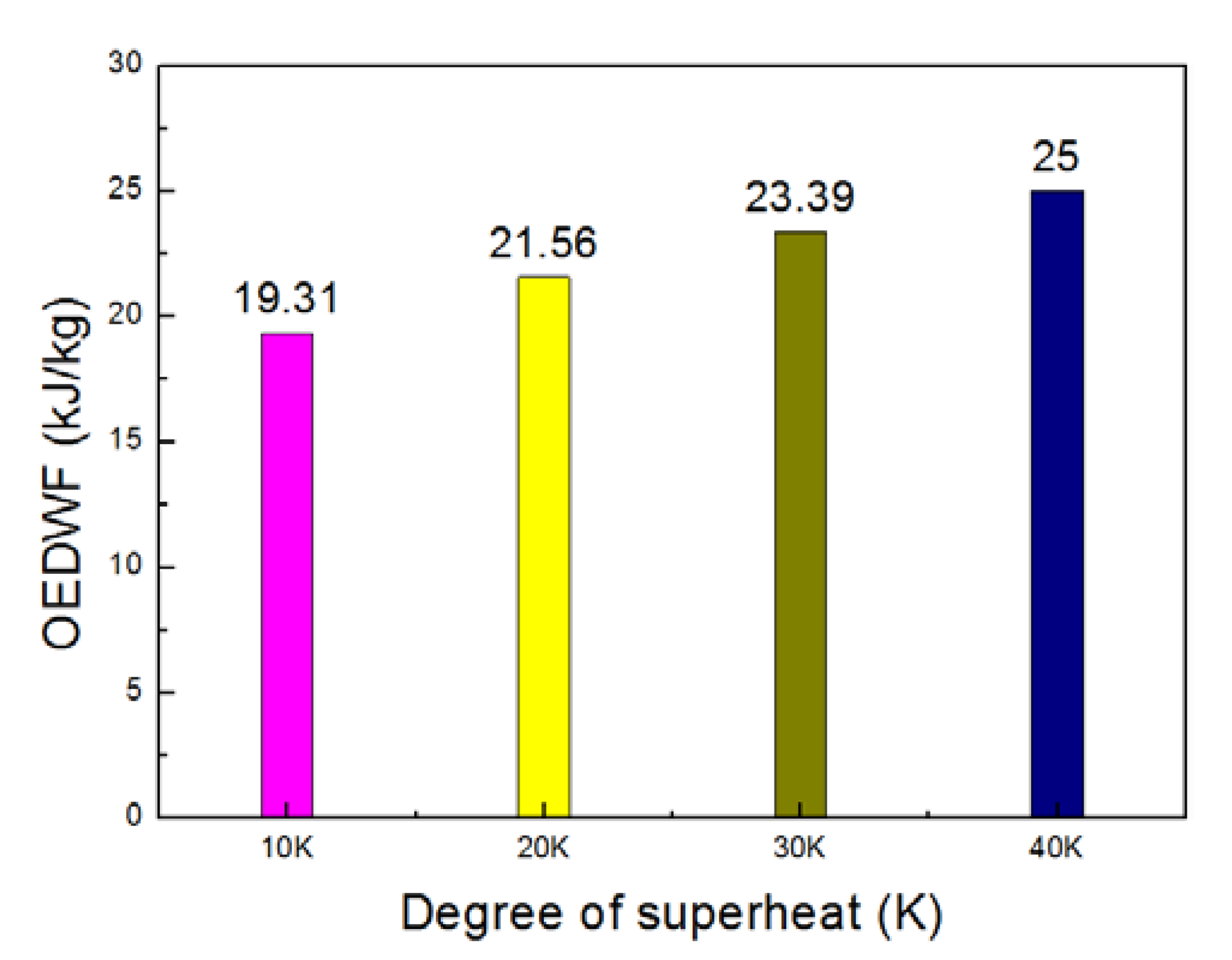

As shown in Figures 8 and 10, with the increase of degree of superheat, the net power output of the ORC waste heat recovery system gradually increases, and the required mass flow rate of the zeotropic mixture R416A gradually decreases. In this paper, OEDWF is defined to assess the capability to produce useful work for per unit of mass of working fluids. Figure 11 shows a comparison chart of the OEDWF for different degrees of superheat, OEDWF increases with the increase of degree of superheat. When the degree of superheat is 40 K, OEDWF reaches its maximum of 25.00 kJ/kg. Therefore, for the same net power output of ORC waste heat recovery system, the required mass flow rate of the zeotropic mixture R416A gradually decreases with the increase of degree of superheat, which can obviously reduce the R416A mass filled in the ORC waste heat recovery system. The total weight of the ORC waste heat recovery system can be reduced, and the risk of environmental pollution can be significantly decreased.

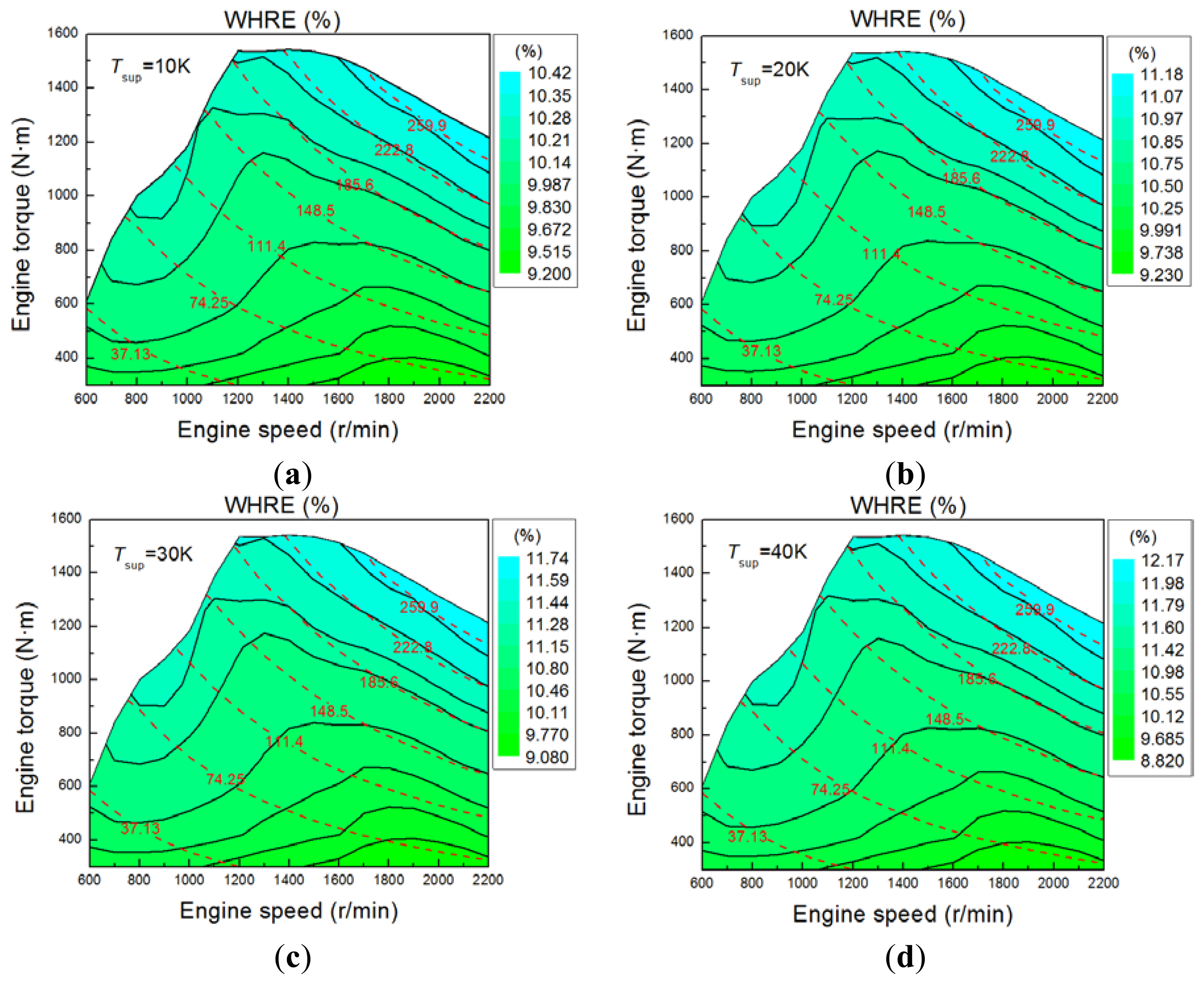

WHRE is defined to assess the utilization ratio of the engine available exhaust energy rate. The variation tendency of WHRE of the ORC waste heat recovery system with engine operating condition and degree of superheat is shown in Figure 12. The dashed lines are the contour lines of engine power output (unit: kW). When the engine operating conditions are certain, WHRE gradually increases with the increase of degree of superheat. The major reason of this is, on one hand, the net power output of the ORC waste heat recovery system increases with the increase of degree of superheat; on the other hand, when the engine operating conditions are certain, engine available exhaust energy rate is determined, therefore, WHRE gradually increases with the increase of degree of superheat. When degree of superheat and engine speed are certain, WHRE gradually increases with the increase of engine torque. When degree of superheat is certain and the engine torque is less than 1000 N·m. WHRE of the ORC waste heat recovery system initially increases, decreases, and then increases again with the increase of engine speed. When degree of superheat is certain and the engine torque is in the range of 1000 N·m to 1300 N·m, the WHRE of the ORC waste heat recovery system initially decreases and then increases with the increase of engine speed. When degree of superheat is certain and engine torque is higher than 1300 N·m, the WHRE of the ORC waste heat recovery system gradually increases with the increase of engine speed, which is mainly dependent on engine available exhaust energy rate and net power output of the ORC waste heat recovery system. When the degree of superheat is 40 K, the engine torque is 1200 N·m, and engine speed is 2200 r/min, the WHRE of the ORC waste heat recovery system reaches its maximum of 12.17%. It can be concluded from the analysis above that when the diesel engine runs with high speed and high torque, more exhaust energy can be recovered by the ORC waste heat recovery system. Moreover, increasing the degree of superheat is beneficial for recovering the waste heat from engine exhaust.

The concept of ETEIR is defined to assess the improvement in the thermal efficiency of the diesel engine. Figure 13 shows how the ETEIR of the ORC waste heat recovery system varies with engine operating conditions and degrees of superheat. The dashed lines are the contour lines of the engine power output (unit: kW). When the engine operating conditions are certain, ETEIR gradually increases with the increase of degree of superheat. This is chiefly because, on the one hand, when the engine operating conditions are certain, then engine power output is certain; on the other hand, the net power output of the ORC waste heat recovery system gradually increases with the increase of degree of superheat. When the degree of superheat is certain and the engine speed is less than 1100 r/min, ETEIR of the ORC waste heat recovery system gradually decreases with the increase of engine torque. When the degree of superheat is certain and the engine speed is higher than 1100 r/min, the ETEIR of the ORC waste heat recovery system initially decreases and then increases with the increase of engine torque. When degree of superheat is certain and the engine torque is higher than 1000 N·m, ETEIR gradually increases with the increase of engine speed. When the degree of superheat is 40 K, engine torque is 1200 N·m, and engine speed is 2200 r/min, the ETEIR of the ORC waste heat recovery system reaches its maximum of 12.74%. It can be concluded from the analysis above that increasing the degree of superheat is beneficial for improving the fuel economy of the diesel engine. When the diesel engine runs with high speed and high torque, the improvement in the fuel economy is higher.

5. Conclusions

In this paper, an ORC waste heat recovery system was designed to recover the exhaust energy from a diesel engine; IHE and ORC were adopted. According to the various operating conditions of the diesel engine, the variation tendencies of the running performances of the ORC waste heat recovery system were studied. The effects of the degree of superheat on the running performances of the ORC waste heat recovery system were analyzed. The variation of occurrence position of PPTD between the engine exhaust and zeotropic mixture were discussed. In order to recover the engine exhaust energy efficiently, we proposed that some running parameters of the ORC waste heat recovery system (mainly the mass flow rate of the working fluid) should be actively regulated for the corresponding operating conditions of the diesel engine:

- (1)

With the variation of degrees of superheat and engine operating conditions, the PPTD occurrence position between the engine exhaust and zeotropic mixture R416A may change. When the engine torque is higher than 300 N·m, the PPTD occurrence position between the engine exhaust and zeotropic mixture certainly appears at State Point 3 in Figure 2 (the inlet of the evaporator of the zeotropic mixture side). When the ORC system is employed to recover the waste heat from diesel engine exhaust, the PPTD occurrence position between engine exhaust and zeotropic mixture mainly appears at the inlet of the evaporator.

- (2)

With the increase of the degrees of superheat, the thermal efficiency, net power output, exergy efficiency, WHRE, and ETEIR of the ORC waste heat recovery system all increase gradually. With the increase of engine speed and engine torque, the net power output of the ORC waste heat recovery system gradually increases. Increasing the degrees of superheat is beneficial for improving the running performance and WHRE of the ORC waste heat recovery system.

- (3)

When the degree of superheat is 40 K, engine speed is 2200 r/min, and engine torque is 1200 N·m, the net power output, WHRE, and ETEIR of the ORC waste heat recovery system reach their maxima. The maximum net power output is approximately 35.66 kW, the maximum WHRE is about 12.17%, and the maximum ETEIR is around 12.74%. When the degree of superheat is 40 K, engine torque is 300 N·m, and engine speed is 1900 r/min, the exergy efficiency of the ORC waste heat recovery system reaches its maximum of 54.60%. When the degree of superheat is 40 K, the thermal efficiency of the ORC waste heat recovery system reaches its maximum of 13.30%. When the diesel engine runs with high speed and high torque, both the running performances of the ORC waste heat recovery system and fuel economy of the diesel engine are the best.

- (4)

The required mass flow rate of the zeotropic mixture R416A gradually increases with the increase of engine speed and engine torque. With the increase of the degrees of superheat, the required mass flow rate of the zeotropic mixture R416A gradually decreases, whereas the OEDWF for zeotropic mixture R416A gradually increases. For a certain net power output, a higher degree of superheat results in a lower mass flow rate of R416A required in the ORC system, therefore, the total weight of the ORC waste heat recovery system can be reduced, and the risk of environmental pollution can be significantly decreased.

- (5)

Available exhaust energy of the diesel engine varies with engine operating conditions. When the evaporating pressure and the degrees of superheat of the ORC waste heat recovery system are certain, the mass flow rate of the zeotropic mixture varies with engine operating conditions. In order to recover the engine exhaust energy efficiently, the mass flow rate of the working fluid should be actively regulated for the corresponding operating conditions of the diesel engine, and then the appropriate control strategy should be proposed, which will be the subject of further research work for us in the future.

Acknowledgments

This work was sponsored by the National Natural Science Foundation of China (Grant No. 51376011); Scientific Research Key Program of Beijing Municipal Commission of Education (Grant No. KZ201410005003); The National Basic Research Program of China (973 Program) (Grant No. 2011CB707202); and Research Fund for the Doctoral Program of Higher Education of China (Grant No. 3C005015201301).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, J.H.; Feng, J.C.; Zhou, Y.L.; Fang, F.; Yue, H. Linear active disturbance rejection control of waste heat recovery systems with organic Rankine cycles. Energies 2012, 5, 5111–5125. [Google Scholar]

- Lukowicz, H.; Kochaniewicz, A. Analysis of the use of waste heat obtained from coal-fired units in Organic Rankine Cycles and for brown coal drying. Energy 2012, 45, 203–212. [Google Scholar]

- Algieri, A.; Morrone, P. Comparative energetic analysis of high-temperature subcritical and transcritical Organic Rankine Cycle (ORC). A biomass application in the Sibari district. Appl. Therm. Eng. 2012, 36, 236–244. [Google Scholar]

- He, Y.L.; Mei, D.H.; Tao, W.Q.; Yang, W.W.; Liu, H.L. Simulation of the parabolic trough solar energy generation system with Organic Rankine Cycle. Appl. Energy 2012, 97, 630–641. [Google Scholar]

- Mago, P.J.; Luck, R. Evaluation of the potential use of a combined micro-turbine organic Rankine cycle for different geographic locations. Appl. Energy 2013, 102, 1324–1333. [Google Scholar]

- Li, Y.R.; Wang, J.N.; Du, M.T. Influence of coupled pinch point temperature difference and evaporation temperature on performance of organic Rankine cycle. Energy 2012, 42, 503–509. [Google Scholar]

- Li, C.N.; Besarati, S.; Goswami, Y.; Stefanakos, E.; Chen, H.J. Reverse osmosis desalination driven by low temperature supercritical organic rankine cycle. Appl. Energy 2013, 102, 1071–1081. [Google Scholar]

- Reverberi, A.; Borghi, A.D.; Dovì, V. Optimal design of cogeneration systems in industrial plants combined with district heating/cooling and underground thermal energy storage. Energies 2011, 4, 2151–2165. [Google Scholar]

- Wang, J.F.; Yan, Z.Q.; Wang, M.; Ma, S.L.; Dai, Y.P. Thermodynamic analysis and optimization of an (organic Rankine cycle) ORC using low grade heat source. Energy 2013, 49, 356–365. [Google Scholar]

- Gao, H.; Liu, C.; He, C.; Xu, X.X.; Wu, S.Y.; Li, Y.R. Performance analysis and working fluid selection of a supercritical organic Rankine cycle for low grade waste heat recovery. Energies 2012, 5, 3233–3247. [Google Scholar]

- Anowar Hossain, M.; Onaka, Y.J.; Afroz, H.M.M.; Miyara, A. Heat transfer during evaporation of R1234ze(E), R32, R410A and a mixture of R1234ze(E) and R32 inside a horizontal smooth tube. Int. J. Refrig. 2013, 36, 465–477. [Google Scholar]

- Aghahosseini, S.; Dincer, I. Comparative performance analysis of low-temperature Organic Rankine Cycle (ORC) using pure and zeotropic working fluids. Appl. Therm. Eng. 2013, 54, 35–42. [Google Scholar]

- Heberle, F.; Preißinger, M.; Brüggemann, D. Zeotropic mixtures as working fluids in Organic Rankine Cycles for low-enthalpy geothermal resources. Renew. Energy 2012, 37, 364–370. [Google Scholar]

- Roy, J.P.; Misra, A. Parametric optimization and performance analysis of a regenerative Organic Rankine Cycle using R-123 for waste heat recovery. Energy 2012, 39, 227–235. [Google Scholar]

- Khennich, M.; Galanis, N. Optimal design of ORC Systems with a low-temperature heat source. Entropy 2012, 14, 370–389. [Google Scholar]

- Xi, H.; Li, M.J.; Xu, C.; He, Y.L. Parametric optimization of regenerative organic Rankine cycle (ORC) for low grade waste heat recovery using genetic algorithm. Energy 2013, 58, 473–482. [Google Scholar]

- Kosmadakis, G.; Manolakos, D.; Kyritsis, S.; Papadakis, G. Design of a two stage Organic Rankine Cycle system for reverse osmosis desalination supplied from a steady thermal source. Desalination 2010, 250, 323–328. [Google Scholar]

- Liu, C.; He, C.; Gao, H.; Xu, X.X.; Xu, J.L. The optimal evaporation temperature of subcritical ORC based on second law efficiency for waste heat recovery. Entropy 2012, 14, 491–504. [Google Scholar]

- Jin, X.; Zhang, X.S. A new evaluation method for zeotropic refrigerant mixtures based on the variance of the temperature difference between the refrigerant and heat transfer fluid. Energy Convers. Manag. 2011, 52, 243–249. [Google Scholar]

- Wang, J.L.; Zhao, L.; Wang, X.D. A comparative study of pure and zeotropic mixtures in low-temperature solar Rankine cycle. Appl. Energy 2010, 87, 3366–3373. [Google Scholar]

- Clemente, S.; Micheli, D.; Reini, M.; Taccani, R. Bottoming organic Rankine cycle for a small scale gas turbine: A comparison of different solutions. Appl. Energy 2013, 106, 355–364. [Google Scholar]

- Wang, E.H.; Zhang, H.G.; Fan, B.Y.; Wu, Y.T. Optimized performances comparison of organic Rankine cycles for low grade waste heat recovery. J. Mech. Sci. Technol. 2012, 26, 2301–2312. [Google Scholar]

- Ou, X.M.; Yan, X.Y.; Zhang, X.; Zhang, X.L. Life-cycle energy use and greenhouse gas emissions analysis for bio-liquid jet fuel from open pond-based micro-algae under China conditions. Energies 2013, 6, 4897–4923. [Google Scholar]

- Fu, J.Q.; Liu, J.P.; Ren, C.Q.; Wang, L.J.; Deng, B.L.; Xu, Z.X. An open steam power cycle used for IC engine exhaust gas energy recovery. Energy 2012, 44, 544–554. [Google Scholar]

- Macián, V.; Serrano, J.R.; Dolz, V.; Sánchez, J. Methodology to design a bottoming Rankine cycle, as a waste energy recovering system in vehicles. Study in a HDD engine. Appl. Energy 2013, 104, 758–771. [Google Scholar]

- Yu, G.P.; Shu, G.Q.; Tian, H.; Wei, H.Q.; Liu, L. Simulation and thermodynamic analysis of a bottoming Organic Rankine Cycle (ORC) of diesel engine (DE). Energy 2013, 51, 281–290. [Google Scholar]

- Glavatskaya, Y.L.; Podevin, P.; Lemort, V.; Shonda, O.; Descombes, G. Reciprocating expander for an exhaust heat recovery rankine cycle for a passenger car application. Energies 2012, 5, 1751–1765. [Google Scholar]

- Boretti, A. Recovery of exhaust and coolant heat with R245fa organic Rankine cycles in a hybrid passenger car with a naturally aspirated gasoline engine. Appl. Therm. Eng. 2012, 36, 73–77. [Google Scholar]

- He, M.G.; Zhang, X.X.; Zeng, K.; Gao, K. A combined thermodynamic cycle used for waste heat recovery of internal combustion engine. Energy 2011, 36, 6821–6829. [Google Scholar]

- Wei, M.S.; Fang, J.L.; Ma, C.C.; Danish Syed, N. Waste heat recovery from heavy-duty diesel engine exhaust gases by medium temperature ORC system. Sci. China Technol. Sci. 2011, 54, 2746–2753. [Google Scholar]

- Katsanos, C.O.; Hountalas, D.T.; Pariotis, E.G. Thermodynamic analysis of a Rankine cycle applied on a diesel truck engine using steam and organic medium. Energy Convers. Manag. 2012, 60, 68–76. [Google Scholar]

- Sprouse, C., III.; Depcik, C. Review of organic Rankine cycles for internal combustion engine exhaust waste heat recovery. Appl. Therm. Eng. 2013, 51, 711–722. [Google Scholar]

Nomenclature

| Q̇exh_id | available exhaust energy rate (kW) |

| Ẇeng | power output of the IC engine (kW) |

| Ẇn | net power output (kW) |

| İ | exergy destruction rate (kW) |

| ΔTpp | pinch point temperature difference (K) |

| Texh in | exhaust temperature at evaporator inlet (K) |

| Texh out | exhaust temperature at evaporator outlet (K) |

| Texh_e | exhaust temperature corresponding to the saturated liquid state zeotropic mixtures in evaporator (K) |

| TL | temperature of the low-temperature heat source (K) |

| TH | temperature of the high-temperature heat source (K) |

| Ẇ | power (kW) |

| Q̇ | heat transfer rate (kW) |

| T | temperature (K) |

| s | entropy (kJ/kg·K) |

| P | pressure (MPa) |

| h | enthalpy (kJ/kg) |

| ṁ | mass flow rate (kgs) |

| T0 | ambient temperature (K) |

| ṁexh | exhaust mass flow rate (kg/s) |

| Tsup | degree of superheat (K) |

| Acronyms | |

|---|---|

| ORC | organic Rankine cycle |

| ETEIR | engine thermal efficiency increasing ratio |

| IC | internal combustion |

| IHE | internal heat exchanger |

| WHRE | waste heat recovery efficiency |

| PPTD | pinch point temperature difference |

| OEDWF | output energy density of working fluid |

| ODP | ozone depletion potential |

| GWP | global warming potential |

| Greek Letters | |

|---|---|

| cp | exhaust specific heat (kJ/kg·K) |

| ηp | isentropic efficiency of pump (%) |

| ηs | isentropic efficiency of expander (%) |

| ε | effectiveness of recuperator (IHE) |

| η | efficiency (%) |

| ηth | thermal efficiency (%) |

| ηex | exergy efficiency (%) |

| subscripts | |

|---|---|

| 1, 2, 2s, 3, b, d, 4, 5, 5s, 6, c | state points in cycle (see Figure 2) |

| r | recuperator (IHE) |

| s | expander |

| L | low-temperature heat source |

| H | high-temperature heat source |

| p | pump |

| e | evaporator |

| n | net |

| c | condenser |

| exh | exhaust |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Components | R134a/R124/R600 | Tcritical (K) | 380.23 |

| Composition (mass fraction) | 0.59/0.395/0.015 | Pcritical (MPa) | 3.98 |

| Molar mass (kg/kmol) | 111.92 | ρcritical (kg/m3) | 514.37 |

| ODP | 0.010 | GWP (100 years) | 1000 |

| Item | Parameter | Unit |

|---|---|---|

| Displacement | 9.726 | L |

| Maximum torque | 1500 | N·m |

| Rated power | 280 | kW |

| Rated speed | 2200 | r/min |

| Stroke | 130 | mm |

| Cylinder diameter | 126 | mm |

| Compression ratio | 17 | - |

| Degree of superheat | Enthalpy of State Point 1 (kJ/kg) | Enthalpy of State Point 2 (kJ/kg) | Enthalpy of State Point 3 (kJ/kg) | Enthalpy of State Point 4 (kJ/kg) | Enthalpy of State Point 5 (kJ/kg) |

|---|---|---|---|---|---|

| 10 K | 248.76 | 251.58 | 261.26 | 439.62 | 417.48 |

| 20 K | 248.76 | 251.58 | 273.87 | 455.95 | 431.56 |

| 30 K | 248.76 | 251.58 | 285.00 | 470.19 | 443.97 |

| 40 K | 248.76 | 251.58 | 295.46 | 483.47 | 455.64 |

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Yang, K.; Zhang, H.; Song, S.; Yang, F.; Liu, H.; Zhao, G.; Zhang, J.; Yao, B. Effects of Degree of Superheat on the Running Performance of an Organic Rankine Cycle (ORC) Waste Heat Recovery System for Diesel Engines under Various Operating Conditions. Energies 2014, 7, 2123-2145. https://doi.org/10.3390/en7042123

Yang K, Zhang H, Song S, Yang F, Liu H, Zhao G, Zhang J, Yao B. Effects of Degree of Superheat on the Running Performance of an Organic Rankine Cycle (ORC) Waste Heat Recovery System for Diesel Engines under Various Operating Conditions. Energies. 2014; 7(4):2123-2145. https://doi.org/10.3390/en7042123

Chicago/Turabian StyleYang, Kai, Hongguang Zhang, Songsong Song, Fubin Yang, Hao Liu, Guangyao Zhao, Jian Zhang, and Baofeng Yao. 2014. "Effects of Degree of Superheat on the Running Performance of an Organic Rankine Cycle (ORC) Waste Heat Recovery System for Diesel Engines under Various Operating Conditions" Energies 7, no. 4: 2123-2145. https://doi.org/10.3390/en7042123