1. Introduction

Two-thirds of the oil consumption in the world is currently used in the transportation sector and half of that goes to passenger cars and light trucks [

1]. Prevalent consumption of the petroleum-based fuels leads to high greenhouse gas (GHG) emissions. The transportation sector in the U.S. and Europe accounts for around 25% of the total GHG emissions. In the U.S., the goal is to decrease the transportation GHG by 35% by 2025 [

2] and in Europe the goal is to cut the transportation GHG by 67% by 2050 [

3]. In this context, automakers must reduce the GHG emissions by introducing advanced fuel-efficient technologies and also by using alternative fuels. low temperature combustion (LTC) engines include a family of internal combustion engines (ICEs) technologies, including premixed charge compression ignition (PCCI), Homogeneous Charge compression ignition (HCCI), and reactivity controlled compression ignition (RCCI) engines, which offer low engine-out

and low soot emissions [

4], and peak net indicated thermal efficiency as high as 53% [

5]. Moreover, improvement in ICE fuel efficiency has the largest potential in improving hybrid electric vehicle (HEV) fuel economy improvement and reducing GHG emissions, compared to enhancement in other HEV component efficiency [

6]. Thus, integrating fuel-efficient LTC engines in HEVs has the potential to improve the vehicle fuel economy and decrease the GHG emissions.

However, utilizing the LTC engines in vehicles faces two major challenges: (i) limited engine operating range; and (ii) control complexity in mode transitions (e.g., SI ↔ LTC, CI ↔ LTC). To tackle these two challenges, this paper investigates the integration of an LTC engine with a series hybrid electric vehicle (HEV) by taking advantage of decoupling the ICE from the drivetrain. This allows the LTC engine to operate in a narrow operating range, removes the engine mode transients, and simplifies the LTC engine control. In addition, SHEVs are already available on the market, such as the Chevrolet Volt, Fisker Karma, and BMWi3.

Another important factor in improving the fuel economy of HEV powertrains is developing optimal energy management control (EMC) strategies to maximize fuel saving.

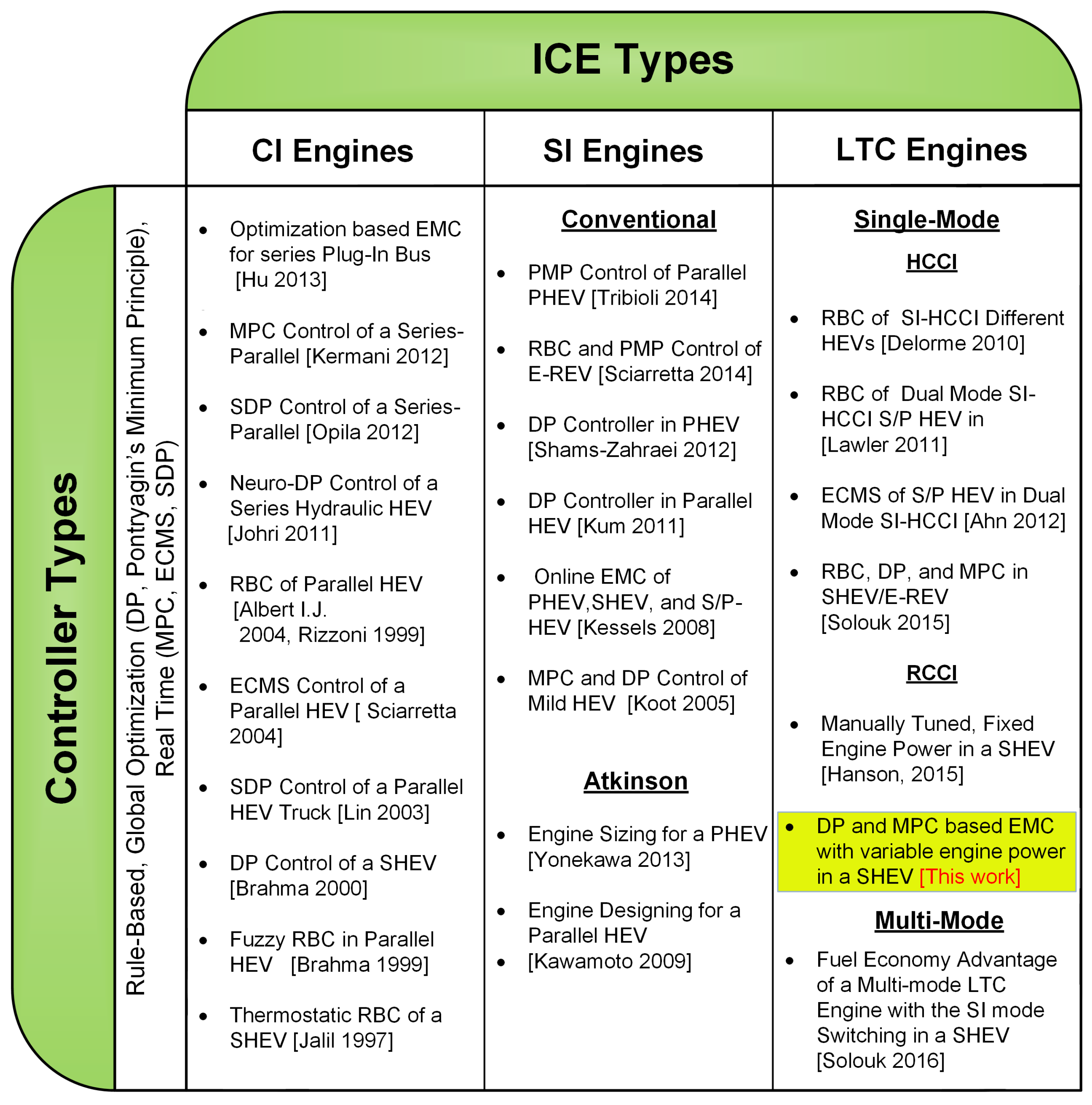

Figure 1 lists the major EMC approaches in HEVs. These include (1) a rule-based controller (RBC) such as fuzzy [

7] and on–off [

8] strategies. These strategies are implementable in real-time applications due to their robustness and low computational cost. However, the RBC strategies do not offer the best HEV fuel saving [

9,

10] due to their offline design; (2) Global optimization strategies such as pontryagin minimum principle (PMP) [

11,

12,

13] and dynamic programming (DP) [

14,

15,

16,

17]. These strategies require the complete information of the driving cycle to determine the optimum EMC. While these global optimization strategies cannot be applied in real-time, the solution from these strategies can be used as a platform to find the ultimate fuel saving for evaluating other EMC strategies [

9]; (3) Real-time optimization controllers such as stochastic dynamic programming (SDP) [

18,

19], equivalent consumption minimization strategy (ECMS) [

20,

21,

22], and model predictive controllers (MPC) [

23,

24,

25]. These sub-optimal EMC strategies can be implemented in real-time.

Prior HEV studies are divided into three groups according to the ICE type (

Figure 1). In the first group, CI engines have been used in different HEV architectures [

8,

14,

18,

20,

23,

26,

27,

28]. The CI engines have been mostly used in sport utility vehicles (SUVs), trucks, and buses [

7,

18,

27,

28,

29]. In the second group, SI engines have been used in HEV [

11,

12,

30,

31]. Recently, SI engines with Atkinson cycle have become more popular in the market (e.g., Ford C-Max, Honda Accord PHEV, Lexus RX 450h, and Toyota Prius). In [

32], an Atkinson cycle SI engine was used by Toyota R&D group to increase the fuel economy benefit of HEVs. In another study [

33], a Honda Accord PHEV was redesigned based on the Atkinson cycle and 10% lower fuel consumption was reported compared to the SI engine.

Few studies are found in the literature that investigated integrating LTC engines with HEVs. Among different types of LTC engines, HCCI was the first type explored in hybrid electric powertrains. In the first study at Argonne National Laboratory in U.S., the effects of using a dual mode SI-HCCI engine in different vehicle electrification levels were analyzed [

34]. Their simulation results predicted from 6% to 15% fuel consumption reduction, depending on powertrain configurations and driving cycles. In another study [

35], fuel economy improvement of a HCCI engine versus a SI engine for both mild and medium parallel HEVs was investigated. The authors reported a range from 17% to 35% fuel economy improvement with using a dual-mode SI-HCCI in comparison to a conventional SI non-hybrid powertrain. In both studies [

34,

35], a dual mode (SI-HCCI) engine was used with a rule-based EMC. Another study [

21] was conducted to investigate the effect of utilizing a dual mode SI-HCCI engine on a power-split HEV acceleration performance. The authors quantified the trade-off between the vehicle fuel economy and the vehicle performance. In [

36], we carried out the first study on utilizing a pure HCCI mode engine in a series hybrid powertrain and we found a 12.6% improvement in fuel economy in comparison with a SHEV running with a SI engine. In our next study [

37], we investigated the impact of engine startup fuel penalty on SHEV HCCI-based powertrains. Our results show that the HCCI fuel economy improvement compared to the SI engine is independent of the engine start/up fuel penalty amount.

RCCI is the second type of LTC engine that has been recently investigated for HEVs. The study in [

38] is the only study available in the literature for an RCCI-based HEV. In [

38], researchers at the University of Wisconsin-Madison and Oak Ridge National Laboratory in U.S. used an RCCI engine in a series hybrid electric powertrain. The authors tested the vehicle for the US environmental protection agency (EPA) highway fuel economy test (HWFET) procedure to measure the vehicle fuel economy and emissions. Based on simulation results, the authors predicted that a series-parallel RCCI-HEV configuration will lead to a 12% fuel economy improvement for the Chevrolet Volt, which currently uses a SI engine. The study in [

38] included preliminary results and no model-based EMC strategy was used for optimizing the energy balance between the battery and ICE energy sources. In addition, the results were presented only for the HWFET driving cycle. The EMC type and driving cycles will affect the RCCI-HEV performance and fuel saving results, as will be shown in this paper.

Moreover, in [

39] we carried out the first study on integrating a multi-mode LTC engine with a SHEV architecture. The multi-mode LTC engine was able to switch between the HCCI, RCCI and conventional SI modes by incorporating a fuel penalty. Our results show a 9% to 13.1% fuel economy improvement, compared to an identical SHEV platform running with a single-mode SI engine.

To the best of the authors’ knowledge, this is the first study undertaken to investigate the fuel economy benefit of integrating an RCCI engine in SHEV with advanced EMCs. The contribution from this study is threefold. First, it investigates the ultimate fuel saving of a dedicated RCCI-mode engine in SHEV configuration. Second, it investigates the effect of EMCs on the potential of fuel economy improvement for SHEV using an RCCI engine. Third, it studies the impact of driving cycle and also the battery initial SOC on the fuel economy of the RCCI-based SHEV.

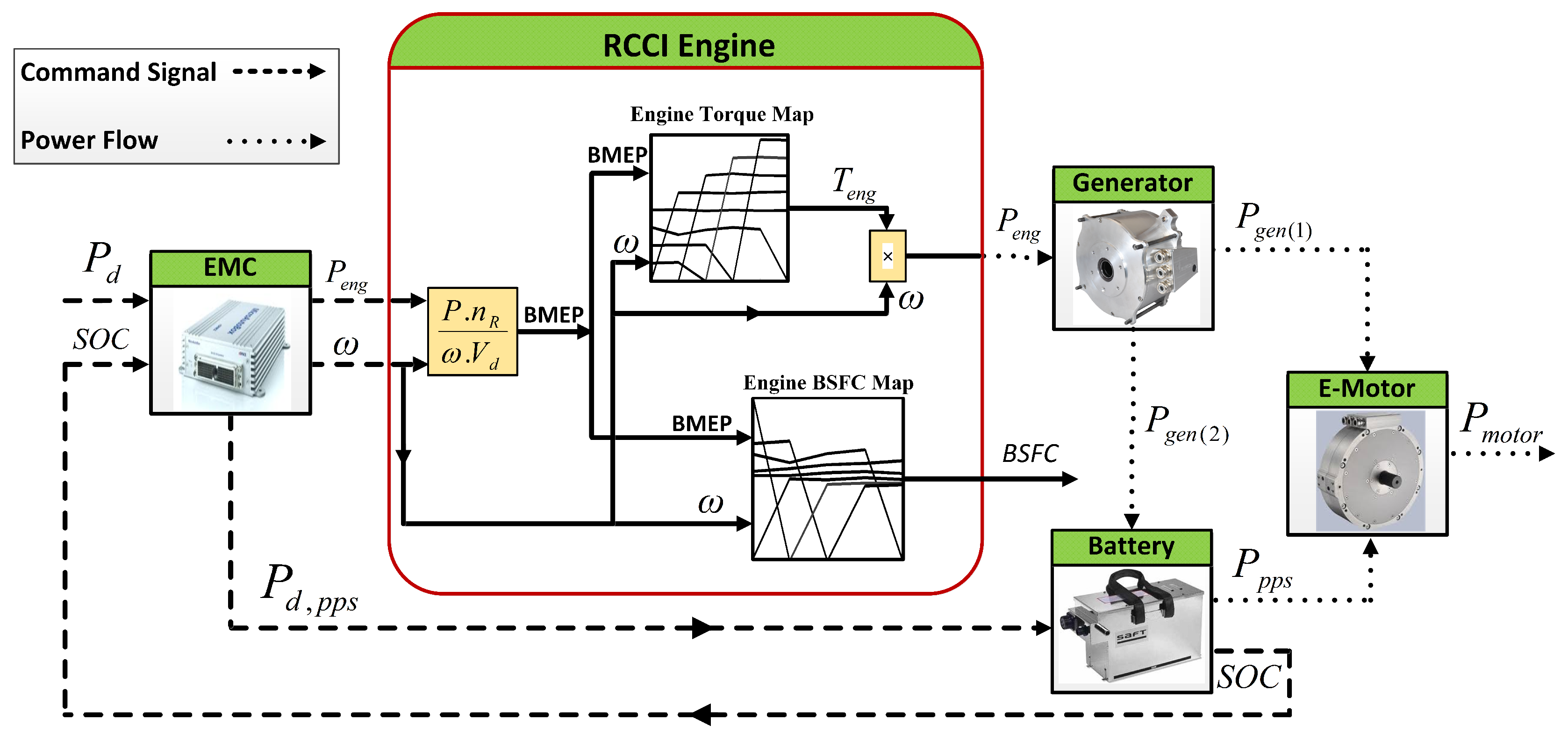

This paper is organized as follows. In

Section 2, the developed HEV model is presented and the main components of the HEV model are described.

Section 3 explains three different EMC strategies, including on–off RBC, global optimization DP and MPC. In

Section 4, the optimum number of engine operating points are selected with regards to the fuel economy. The SHEV results are presented in

Section 5. Finally,

Section 6 summarizes all findings from this paper.

4. Selection of Engine Operating Points

In SHEVs, the engine can operate independently of the vehicle speed and the wheel torque. Thus, the engine has the opportunity to work most of the time at high efficiency operating points and low engine-out emission region. In this section, the engine operating points are selected for three different constant power levels as low, mid, and high to fulfill the vehicle power requirements and also to guarantee low engine BSFC and low engine-out emissions. The low BSFC and low engine-out emission constraints are discussed in subsections A and B.

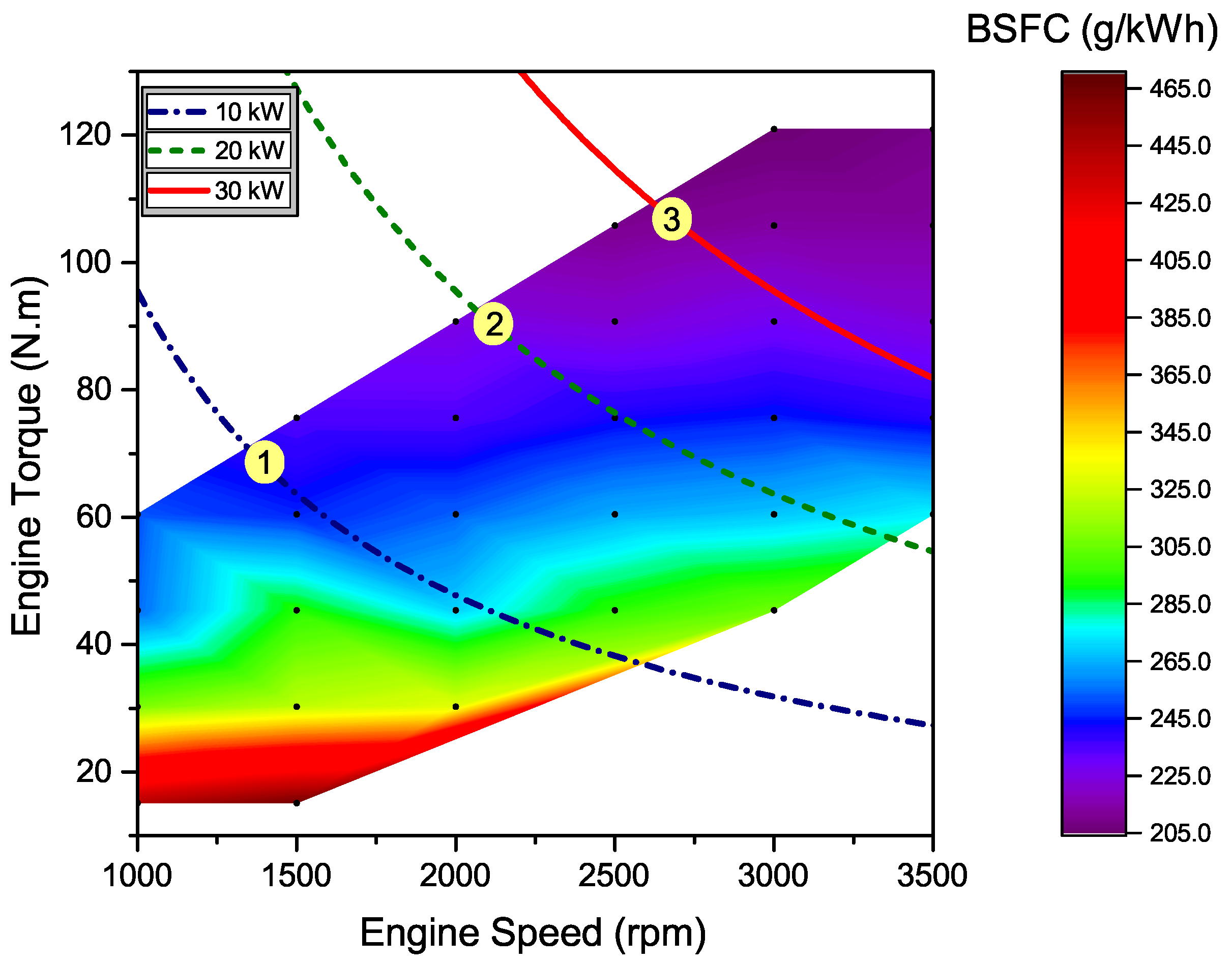

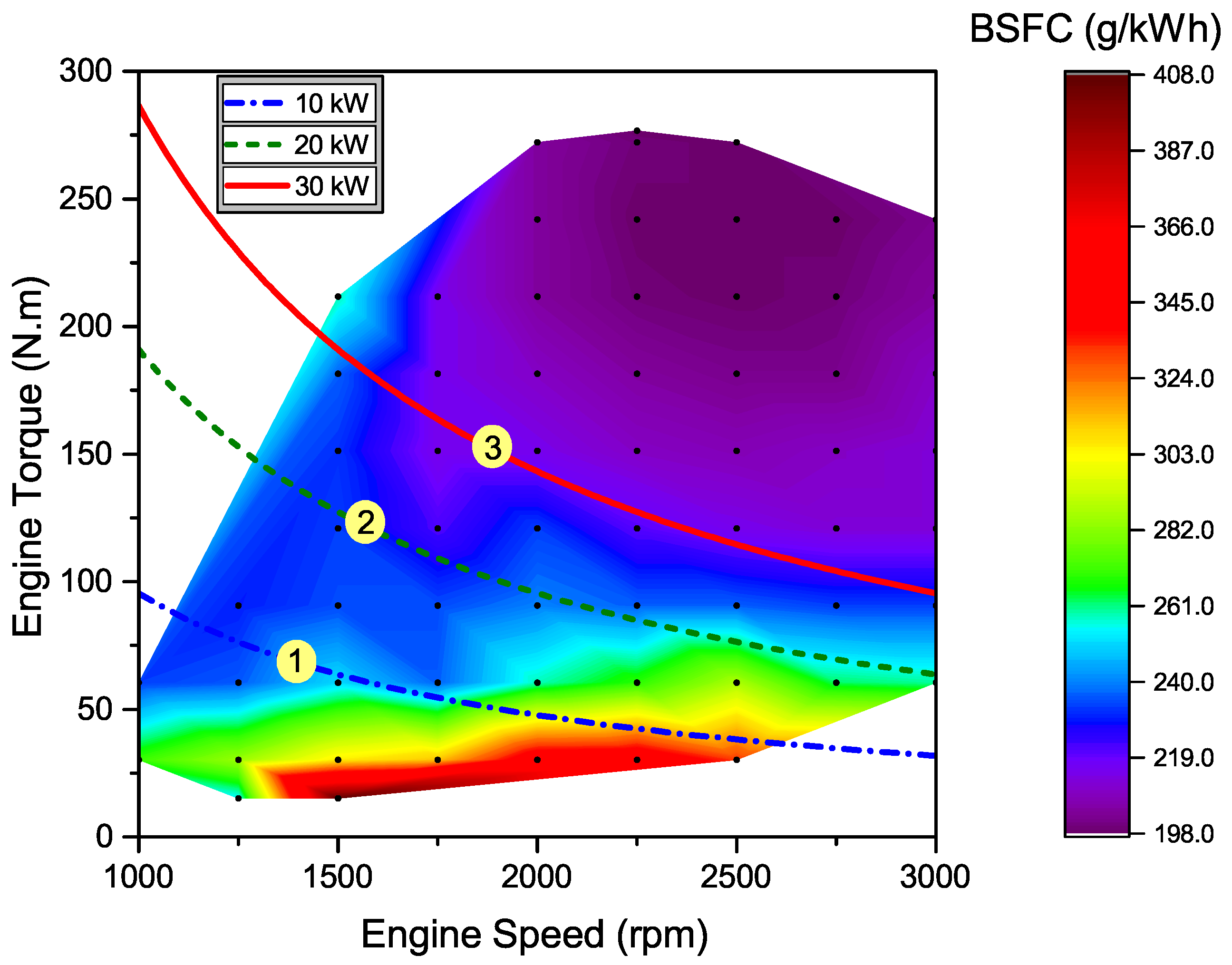

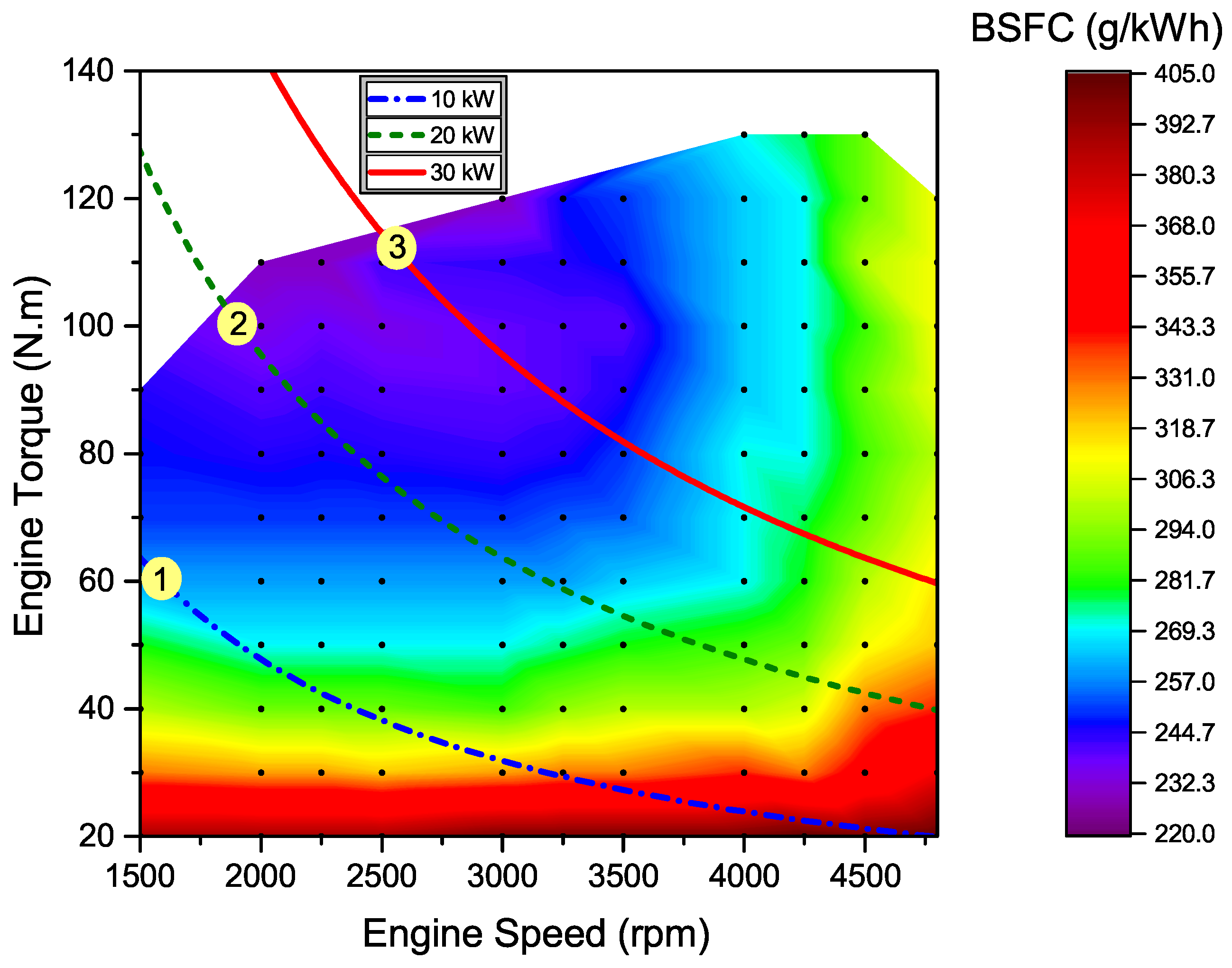

A. Engine BSFC Constraint: The selected operating points are at three power levels designated as 10 kW, 20 kW, and 30 kW. Within a range of 10 percent for each power level, a search is done to find the lowest BSFC value.

Figure 3 shows the three final selected operating points for the RCCI engine. In the single operating mode, the mid power level (i.e., point no. 2 in

Figure 3) is selected since the engine can provide the mean power requirement for the vehicle at this operating point. For the 2-mode operation, a low level power and a mid level power are selected for the engine operating points (i.e., points no. 1 and 2 in

Figure 3), and for the 3-mode operation all the three selected points are considered.

B. Engine Emissions Constraint: The engine HC, CO, and

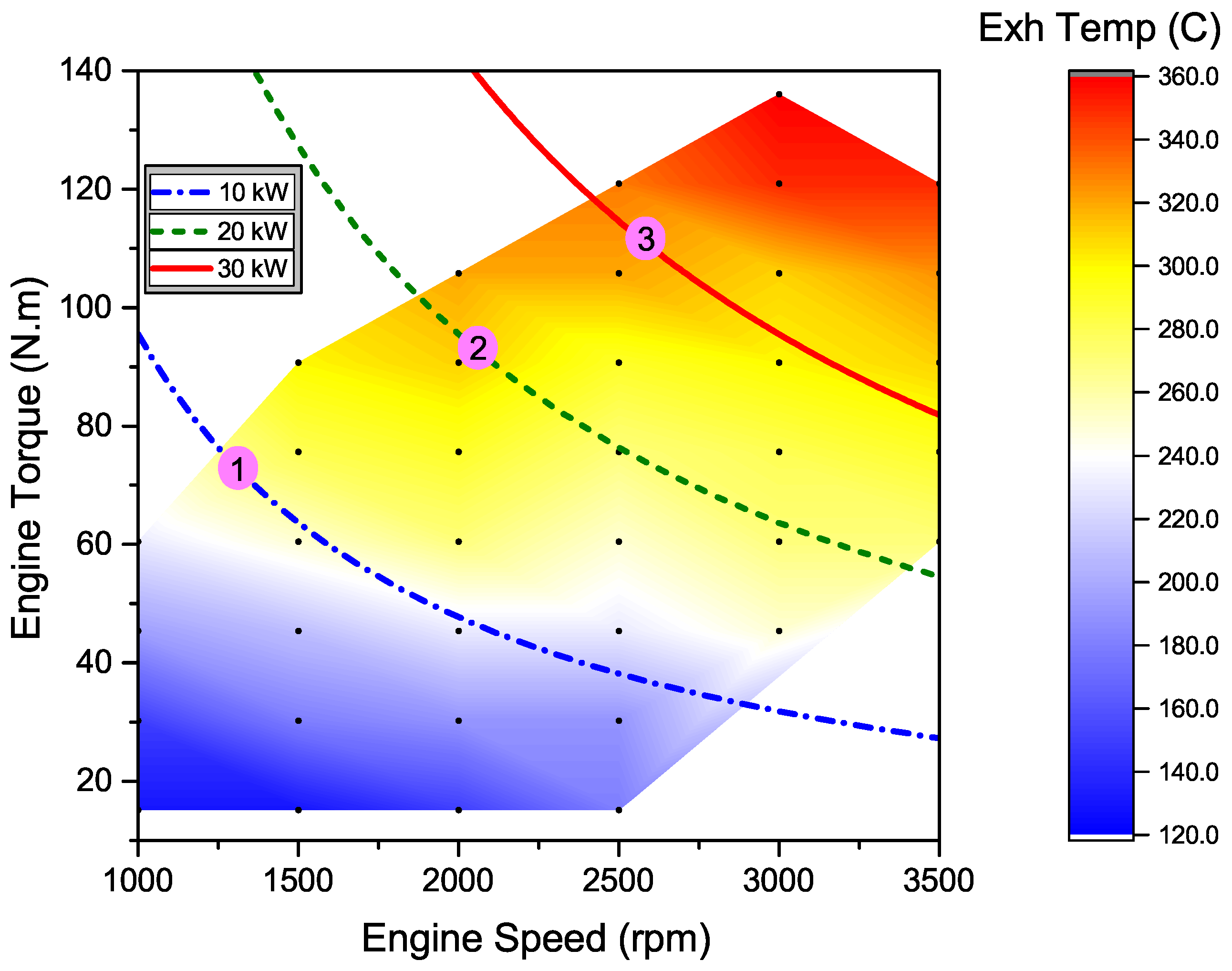

emissions are considered in selecting the engine operating points. CO and HC conversions in diesel oxidation catalysts (DOC) are a function of the exhaust gas temperature. Thus, the engine operating points are selected to meet the minimum DOC light-off temperature. The RCCI engine exhaust gas temperature for different engine speeds and torques are shown in

Figure 6 based on the data from [

40] along with the selected operating points. It is shown in

Figure 6 that the exhaust gas temperature for all of the three engine operating points are above 290 °C. Moreover, in reference [

50], it is shown that the DOC for the same RCCI engine achieved 90% and 100% HC and CO conversions, respectively, when the exhaust gas temperature in the RCCI engine was higher than 290 °C. Thus, the selected RCCI engine operating points meet the DOC light-off temperature to achieve low HC and CO emissions, similar to those in the CI and SI engines.

In addition to the HC and CO emissions, the

emission is also taken into account for selecting the engine operating points.

Table 3 lists the

emission associated with the selected operating points in both RCCI and CI engines. The table shows that the selected engine operating points in RCCI produce much less

compared to the selected operating points in the CI engine. This is a well-recognized fact in literature [

5,

40,

51] and considered as one of the main advantages of RCCI engines. Thus, a smaller

after-treatment system is required in RCCI engines, compared to CI engines.

Given that the SI and CI engines are production engines, the engines and exhaust after-treatment systems are optimized to meet HC, CO, and constraint for the emission standard. In addition, the discussions above demonstrate that the RCCI engine produces low HC, CO, and emissions in the three selected operating points. Thus, all the three engine operating points in the SI, CI, and RCCI engines have both low BSFC and low emissions advantages over the other engine operating regions at the designated power levels.

In this section, the effect of the number of the engine operating points on the HEV fuel economy is also discussed.

Table 4 shows the effect of number of engine operating points and the engine start-up fuel penalty on the RCCI-SHEV fuel economy.

The simulation results in

Table 4 show that the RCCI fuel economy increases by increasing the number of engine operating points. This can be explained by improved overall ICE efficiency when three modes are utilized in RCCI for different driver power request levels. Given better fuel economy results by using the 3-mode EMC, the rest of the results in this paper are presented for the 3-mode EMC.

5. Results and Discussion

In this section, the results for the SHEV with the RCCI, CI, and SI engines are discussed. In

Section 5.1, sensitivity of the driving cycle’s prediction time horizon on the vehicle’s fuel economy is studied. Moreover, the initial battery SOC effect on the vehicle’s fuel economy is investigated in

Section 5.2. Lastly, the effect of the type of the driving cycle is presented in

Section 5.3.

In this work, a combined driving cycle (

Figure 7) consisting of three standard driving cycles including UDDS (urban dynamometer driving schedule), HWFET (highway fuel economy test), and US06 is used to test the EMC strategies. The combined driving cycle is the base driving cycle for all the analyses in this paper except for

Section 5.3, where different driving cycles are compared.

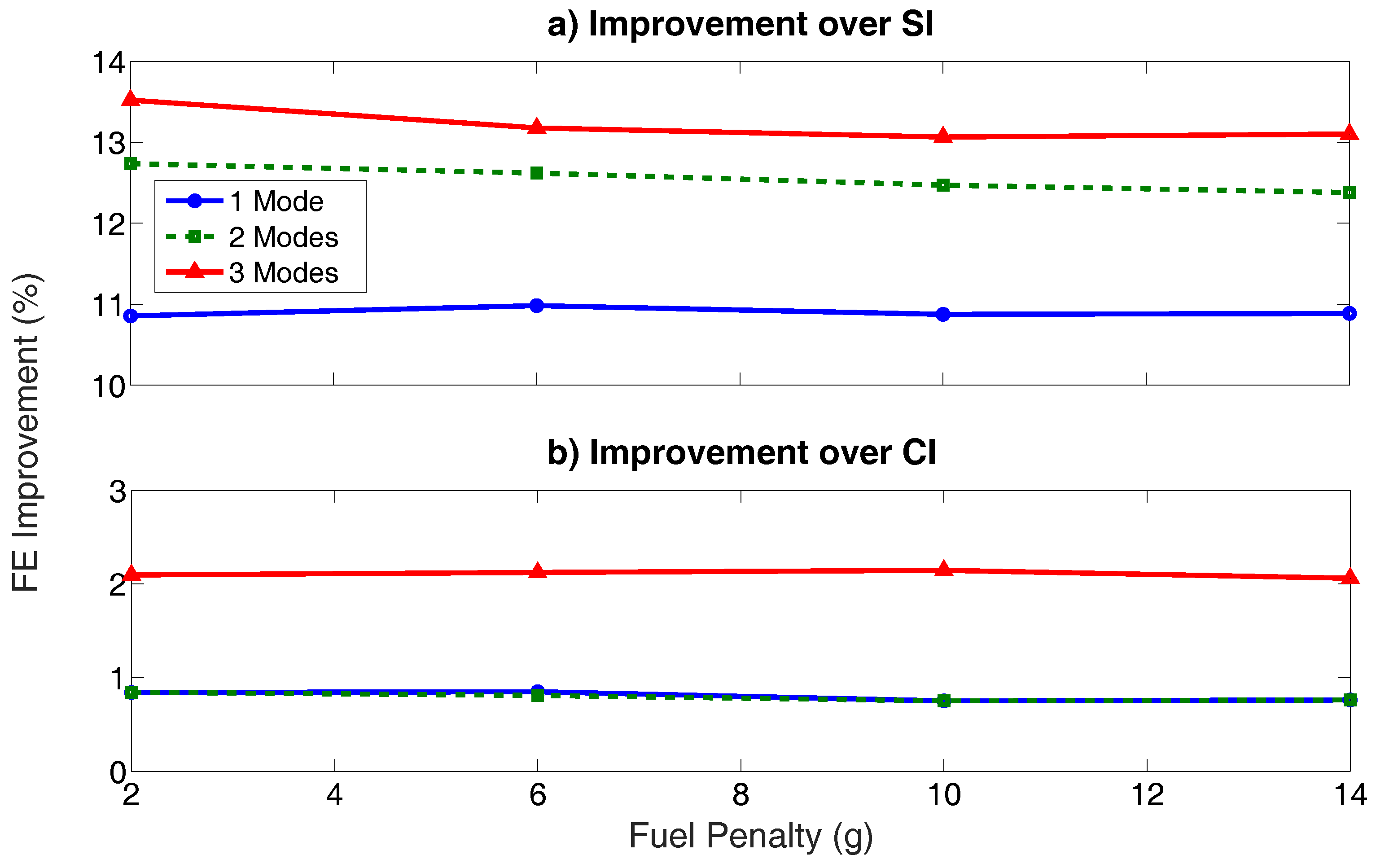

Figure 8 describes the effect of the engine start-up fuel penalty (

) on the fuel saving. The RCCI fuel economy improvement is constant versus the amount of

. This is because the power levels for each engine are similar; thus, the number of engine on/off switching will remain constant. This makes the RCCI fuel economy improvement independent of the

value.

Figure 8 also shows the same trend for the RCCI fuel saving over the number of engine operating points and the fuel economy improves with increasing number of the engine operating points.

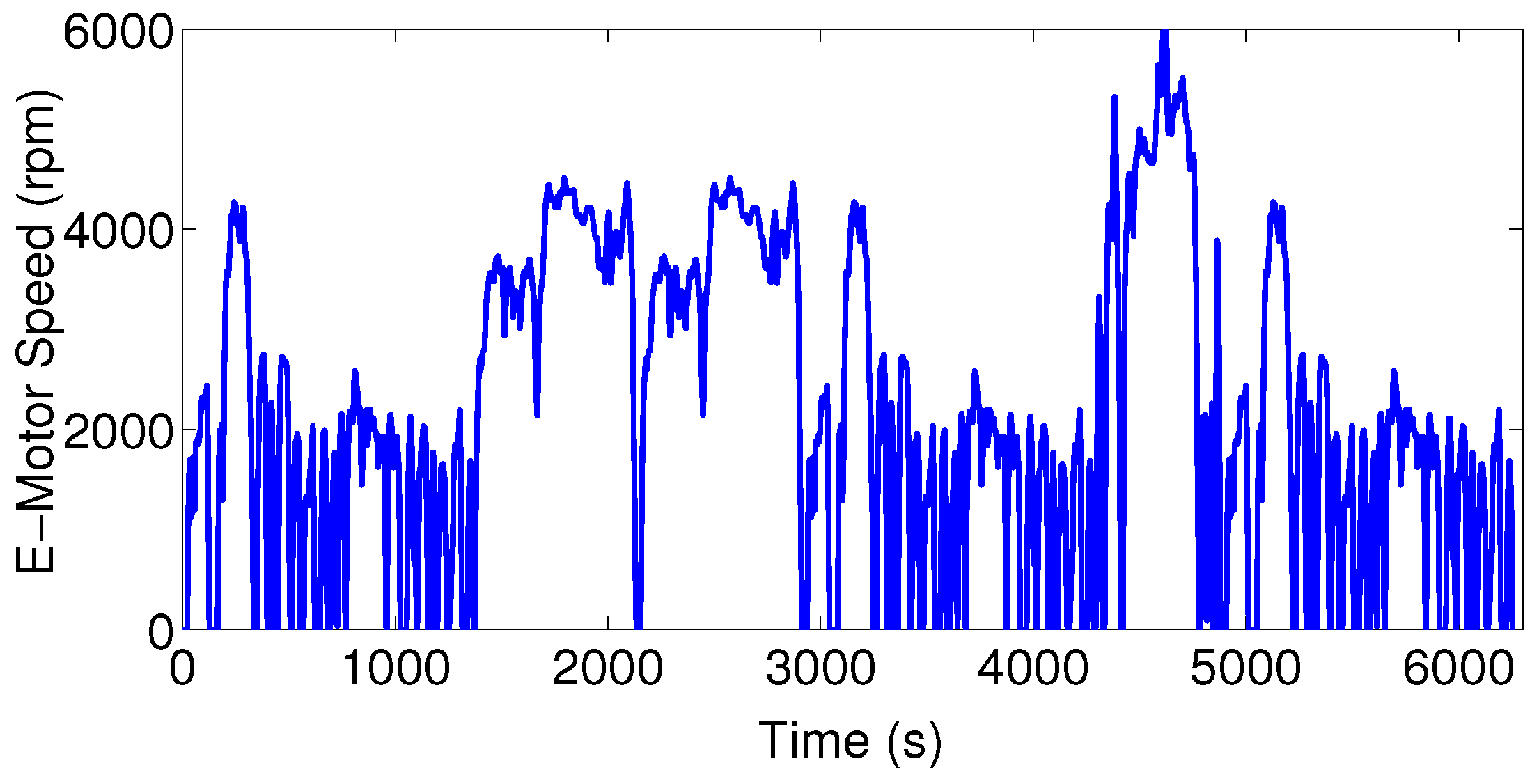

Figure 9 illustrates the E-motor speed variation for the combined driving cycle. A single gear is designed to synchronize the E-motor and vehicle maximum speeds in order to expand the E-motor operating points to the whole E-motor operating region. In

Figure 9, for the portion of the US06 driving cycle that the vehicle speed reaches to 80 mph, the E-motor speed is 6000 rpm.

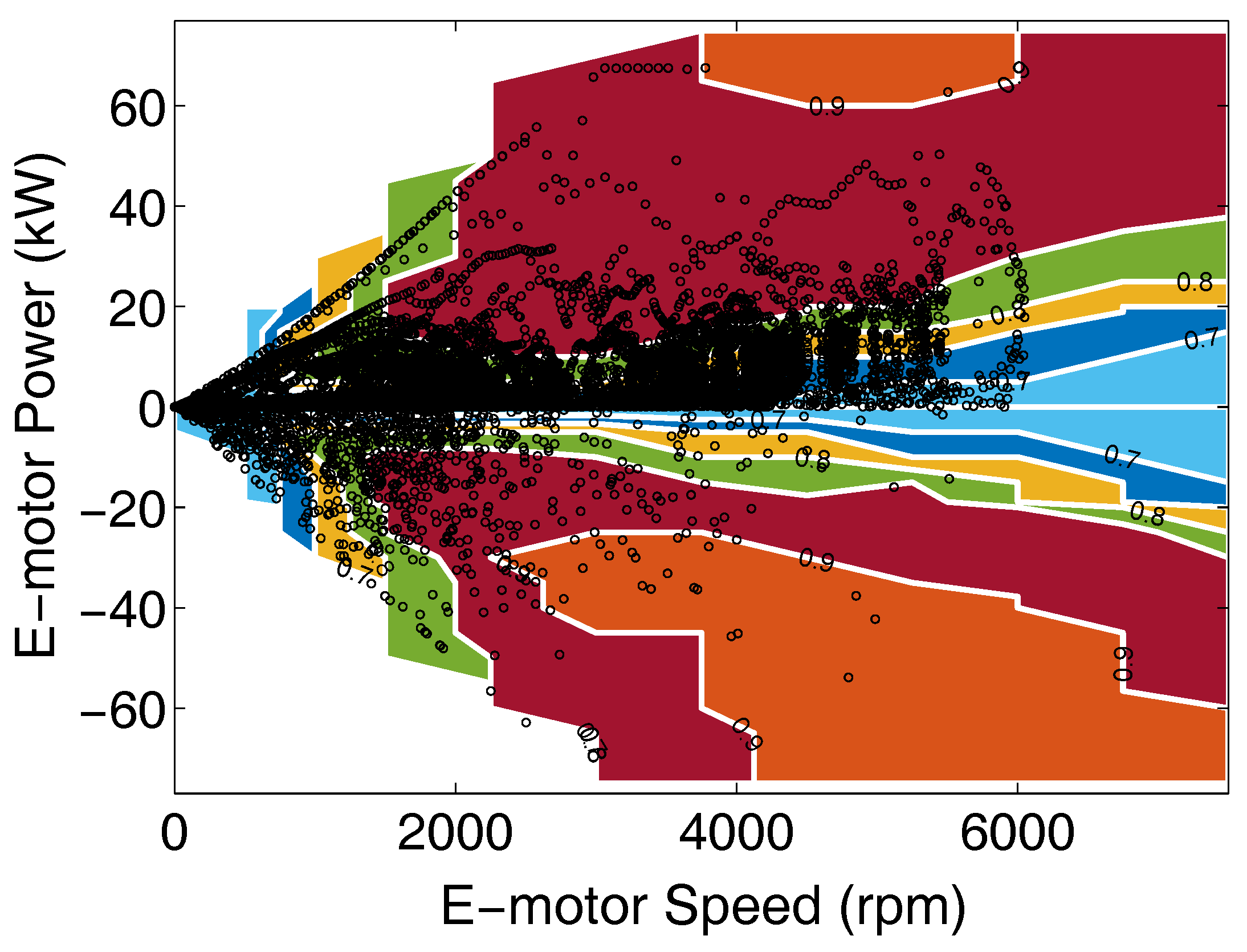

The E-motor operating points during the combined driving cycle are depicted in

Figure 10. The E-motor efficiency points range from 70% to 90% in the traction and regenerative braking modes. The E-motor efficiency is higher at higher E-motor power (i.e.,

40 kW) and the E-motor efficiency improves with increasing the E-motor power.

Figure 11 shows the vehicle tracking performance. The vehicle is able to follow the reference driving cycle with a root mean square error (RMSE) of 0.8 mph. This result also confirms that the HEV components’ sizing meets the performance requirements during the driving cycle. Thus, the HEV model can be used as a testbed for evaluation of EMCs.

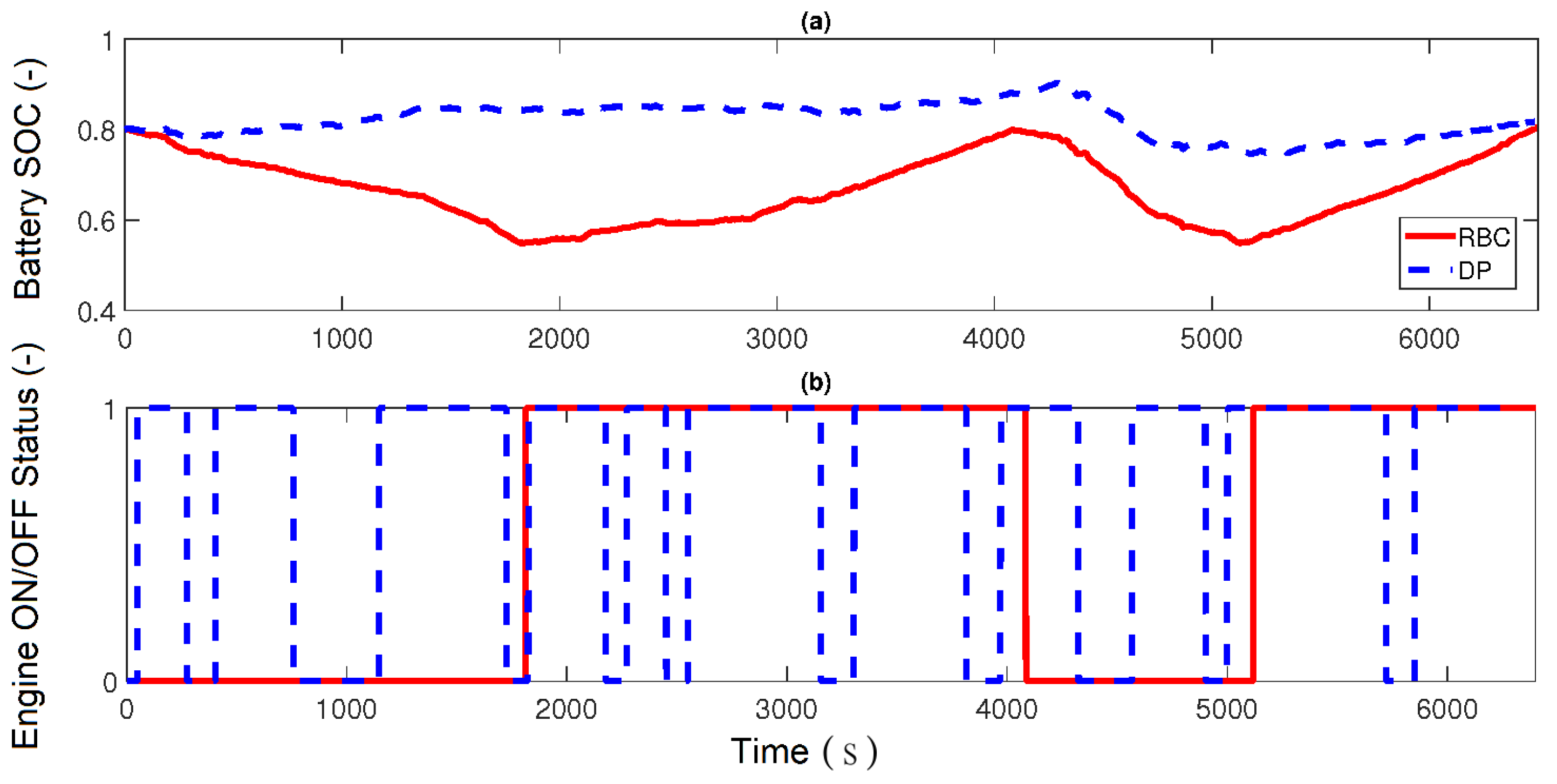

Figure 12 compares the engine on/off status and the battery SOC variation for both RBC and DP EMCs. The RBC strategy regulates the engine status command based on the SOC value. The RBC switches the engine on when the SOC reaches to its lowest allowed value (i.e.,

). In the DP controller, the SOC variation is much less than that of the RBC. This allows the EMC to choose the most optimal control strategy over the driving cycle at each time. However, in the DP strategy, the engine switches on and off more frequently (

Figure 12b).

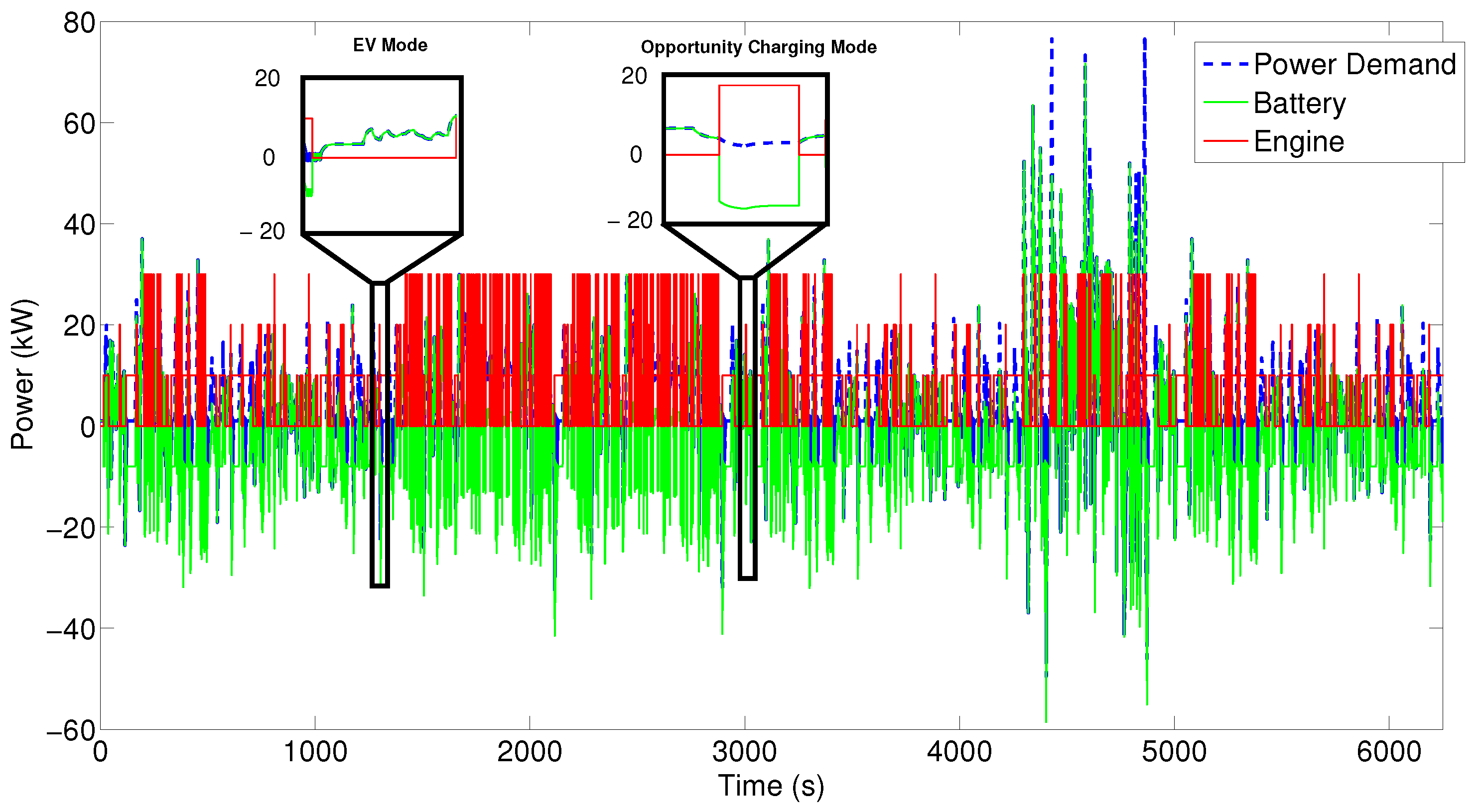

Figure 13 indicates the power distribution of the battery and the engine during the driving cycle for the DP control strategy. There are different operating modes, such as fully electric mode and opportunity charging mode based on

Figure 13. For instance, the battery only supplies the driver power demand at

s and runs the vehicle on the fully electric mode. For low power demands, at

s, the vehicle runs in the opportunity charging mode, in which the engine/generator supplies the power demand and charges the battery simultaneously. In RBC, the engine is turned off during the braking, but in the DP strategy, the engine can either be on or off to minimize the cost function. In addition, at the low vehicle speeds, the mechanical braking assists the regenerating braking to supply the braking torque, however, at the high vehicle speeds, all the braking torque is supplied by the regenerative braking.

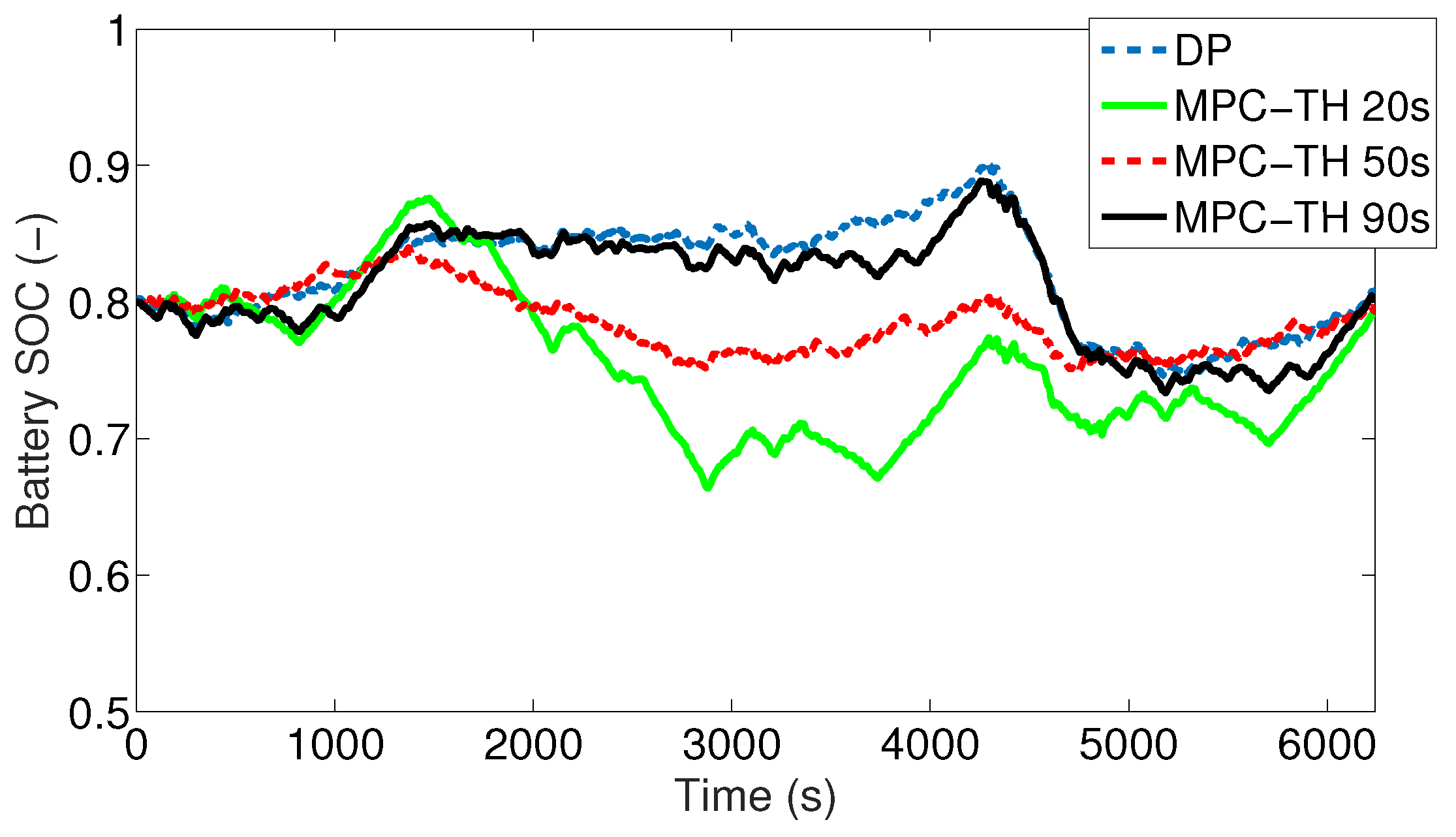

The SOC variations over the driving cycle for the DP and MPC controllers are illustrated in

Figure 14. The EMC is in the charge-sustaining mode and the EMC strategy is tuned to enforce the final SOC value to match the initial SOC value at the end of the driving cycle. Moreover,

Figure 14 compares the SOC profile for each EMC. The SOC variation for different prediction TH is also shown. The results in

Figure 14 show that all the designed EMCs can sustain SOC at the initial SOC by the end of the driving cycle. The designed DP EMC algorithm in this work is computationally efficient. The simulation processing time on a 2.20 GHz Intel processor is about 72.6 s for the whole combined driving cycle (i.e., 11.5 ms per one second of the driving cycle).

5.1. Prediction Time Horizon Sensitivity

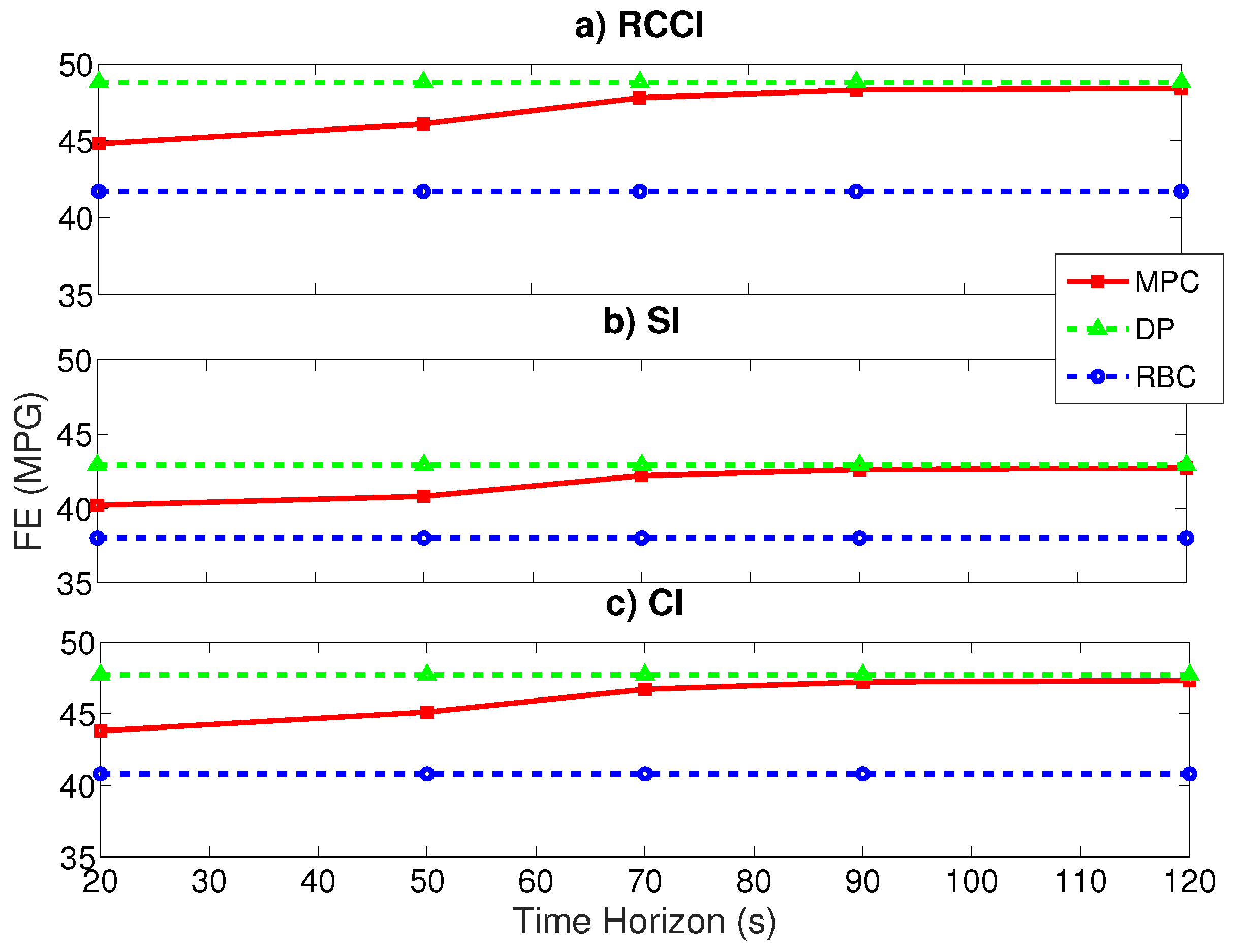

Figure 15 demonstrates the HEV fuel economy sensitivity with the driving cycle prediction TH for different engines. It is observed that the fuel economy increases by knowing more driving cycle information (i.e., larger TH) and it reaches a plateau, in which at

s the HEV fuel economy merges to the DP results. There is a trade-off between the computational cost and fuel saving by the MPC strategy. Higher TH improves the HEV fuel economy at the cost of needing more computation time. In these simulations,

s offers a good compromise between computation load and fuel economy improvement. These results show that by knowing a short time horizon information of the vehicle’s speed profile (i.e.,

s), 95% of the global optimal fuel economy (i.e., DP) is achieved. This figure also compares different engines’ fuel economy variations with the EMC types. The RCCI engine offers the highest fuel economy compared to SI and CI engines. In the DP EMC, the RCCI engine has 5.9 and 1.1 MPG greater fuel economy than the SI and CI engines, respectively.

5.2. Initial SOC Sensitivity

In this section, the effect of running the RCCI engine in a lower initial SOC on the fuel economy is studied. The low SOC can represent operation in an extended range electric vehicle (E-REV). It is assumed the battery is operating at a lower initial SOC value (i.e.,

) during the charge-sustaining mode. Fuel economy of the HEV integrated with RCCI, SI, and CI engines for different EMCs are shown in

Table 5.

Comparing

Figure 15 and

Table 5 shows that the fuel economy is greater when the

is higher. In the lower

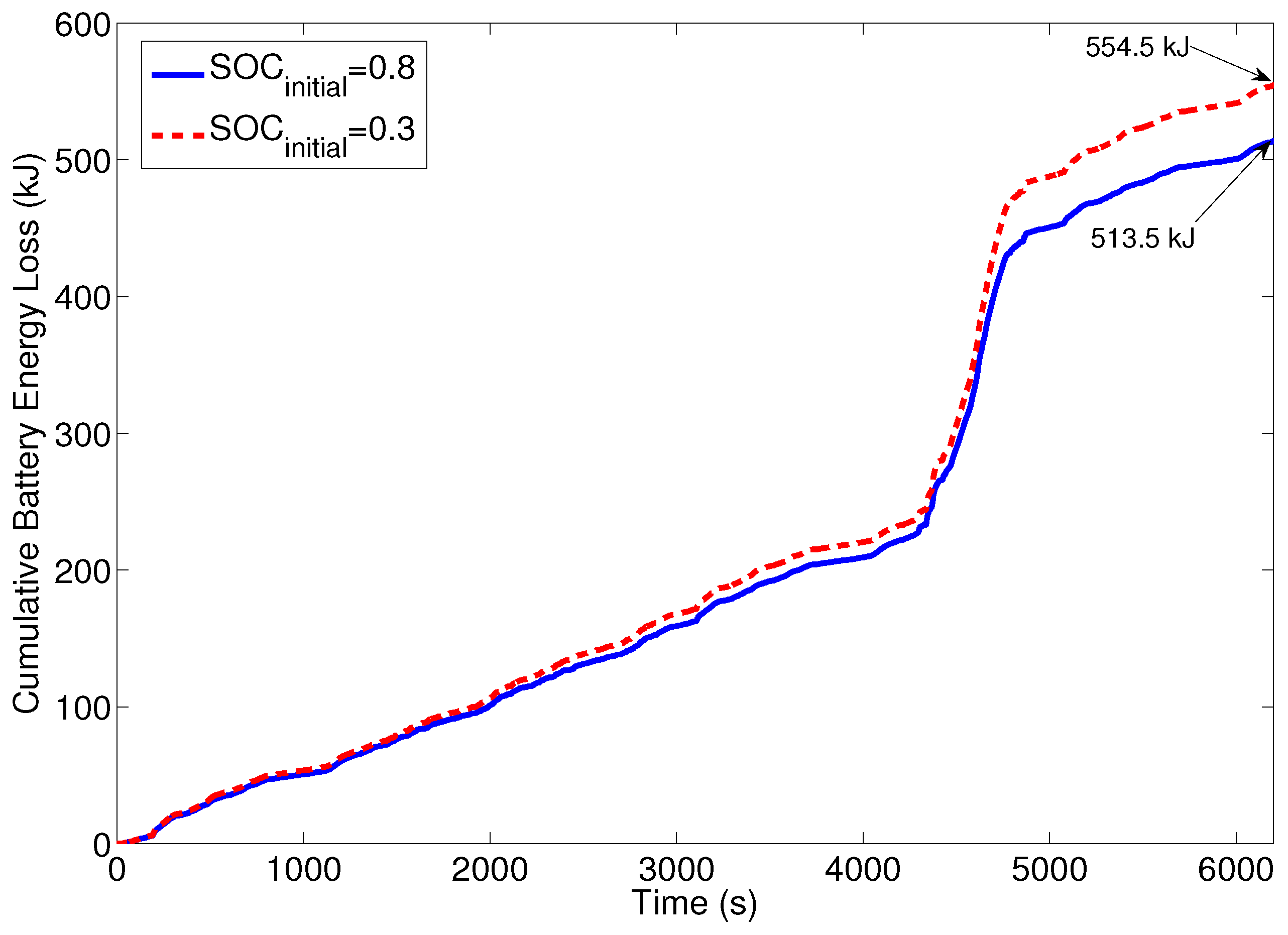

scenario, the battery has greater losses than that in higher initial SOC since the battery loss is greater in the low SOC region.

Figure 16 shows the battery energy losses in both the scenarios. It can be seen that the SHEV with lower initial SOC has 31 kJ more battery energy losses than the larger SOC case in the combined driving cycle. The battery energy losses should be compensated by running the ICE for a longer time, which leads to lower fuel economy in the low

scenario.

Figure 17 shows the engine produced power profile in both low

SOC and high

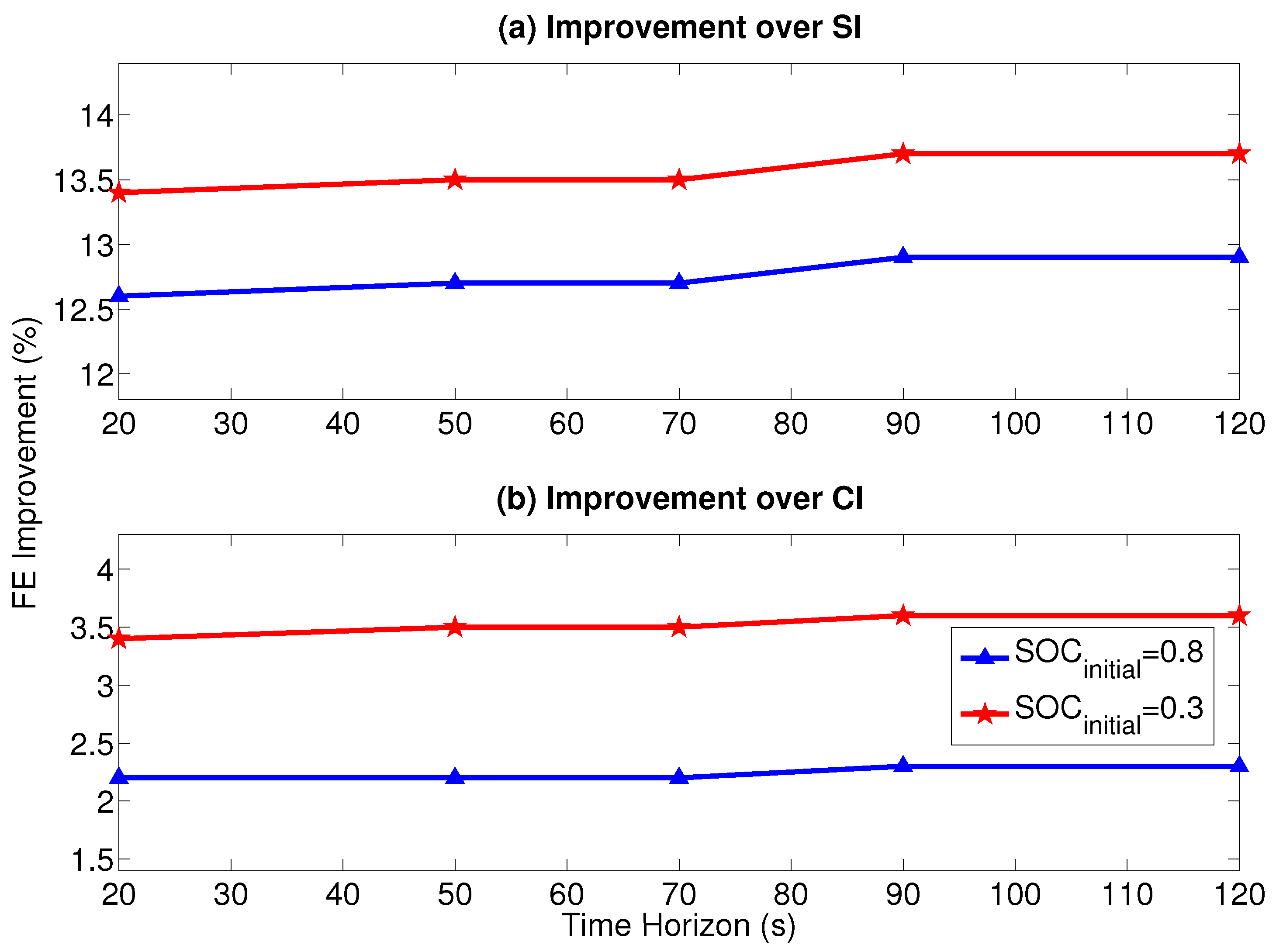

scenarios. The number of ICE on/off switching is identical in the two cases, but the engine runs for a longer time in the low initial SOC case. Therefore, the RCCI engine in this condition has more opportunity to work and consequently more fuel saving is achieved compared to the SI and CI engines. This is shown in

Figure 18, where the SHEV with low

has higher fuel economy improvement (Fuel economy improvement is calculated by

where

is the fuel economy for the RCCI-HEV powertrain, and

is the fuel economy for SI-HEV or CI-HEV powertrain) compared to the high

scenario.

5.3. Driving Cycle Effect

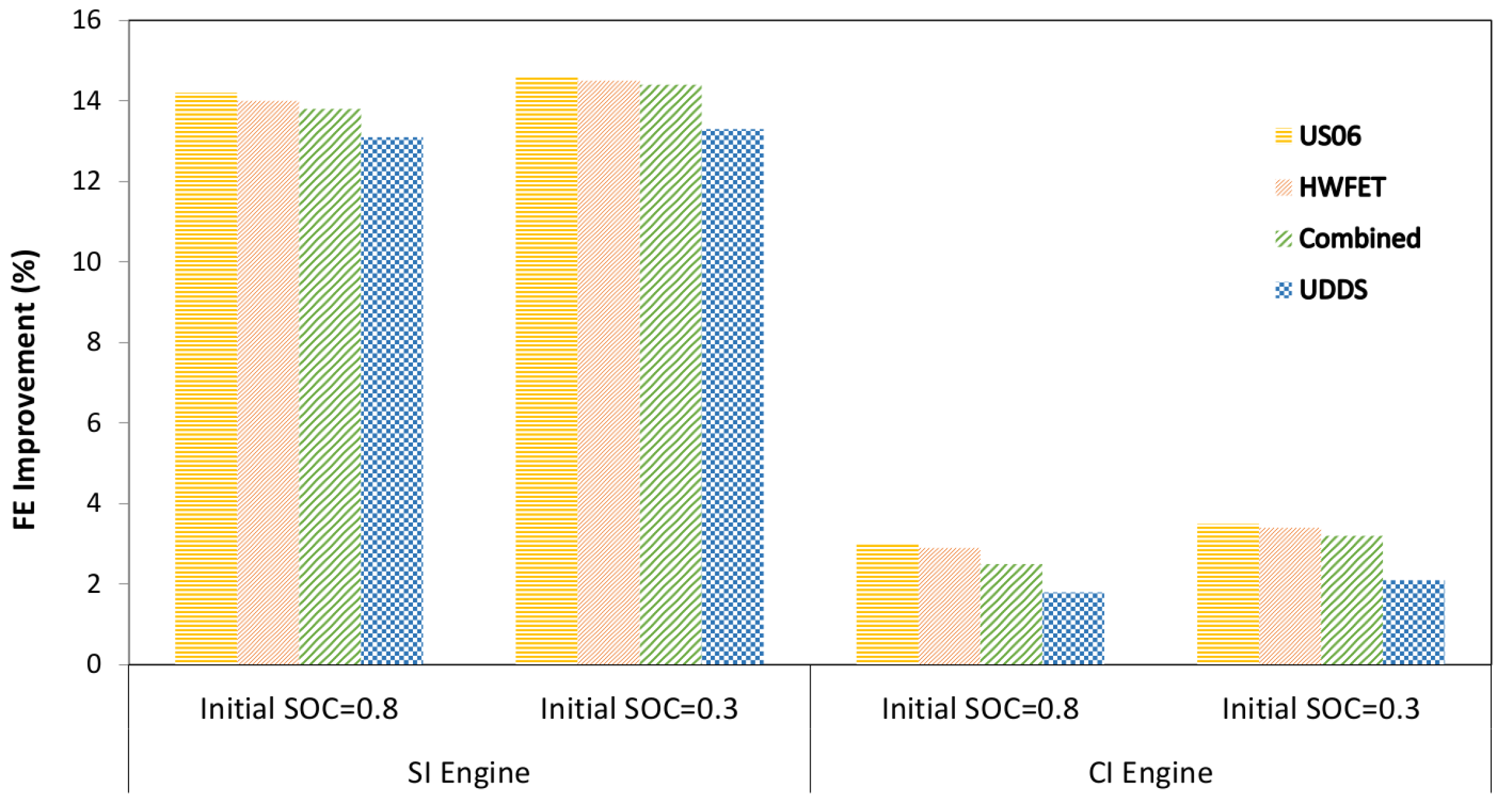

Here, the effect of using various driving cycles is investigated for the RCCI fuel economy improvement for both SHEVs with low initial SOC and high initial SOC scenarios. Four different driving cycles including US06, HWFET, UDDS, and the combined driving cycle are studied.

Figure 19 shows the effect of the various driving cycles on the HEV fuel economy improvement by incorporating the RCCI engine versus conventional SI and CI engines. The fuel economy improvement of the RCCI engine versus the SI engine varies from 13.1% to 14.2% depending on driving cycles. Moreover, the fuel economy improvement versus the CI engine varies from 1.8% to 3.0%.

Table 6 lists the required average power of the HEVs in each of the studied driving cycles. By comparing

Table 6 and

Figure 19, it becomes clear that the average power of a driving cycle has a direct effect on the RCCI fuel economy saving over the SI and CI engines. In high power demand driving cycles (e.g., US06), the engine needs to run longer to charge the battery and compensate for the higher power demand. This gives the RCCI engine more opportunities to save more fuel since it is generally more fuel-efficient than conventional SI and CI engines. In addition, the initial SOC effect in

Figure 19 is related to the difference in the length of the engine runtime, as previously mentioned in

Section 5.2.