Research on a Household Dual Heat Source Heat Pump Water Heater with Preheater Based on ASPEN PLUS

Abstract

:1. Introduction

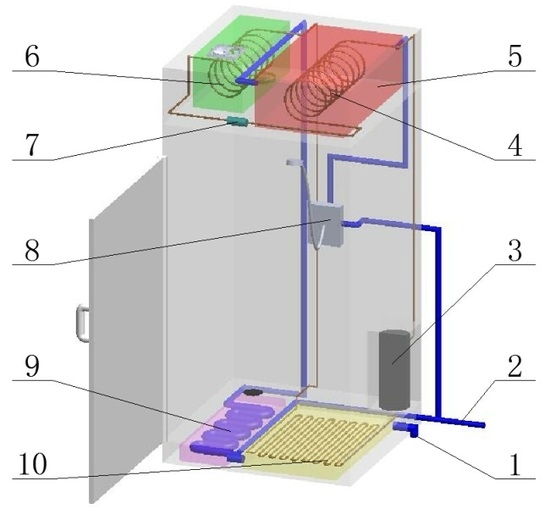

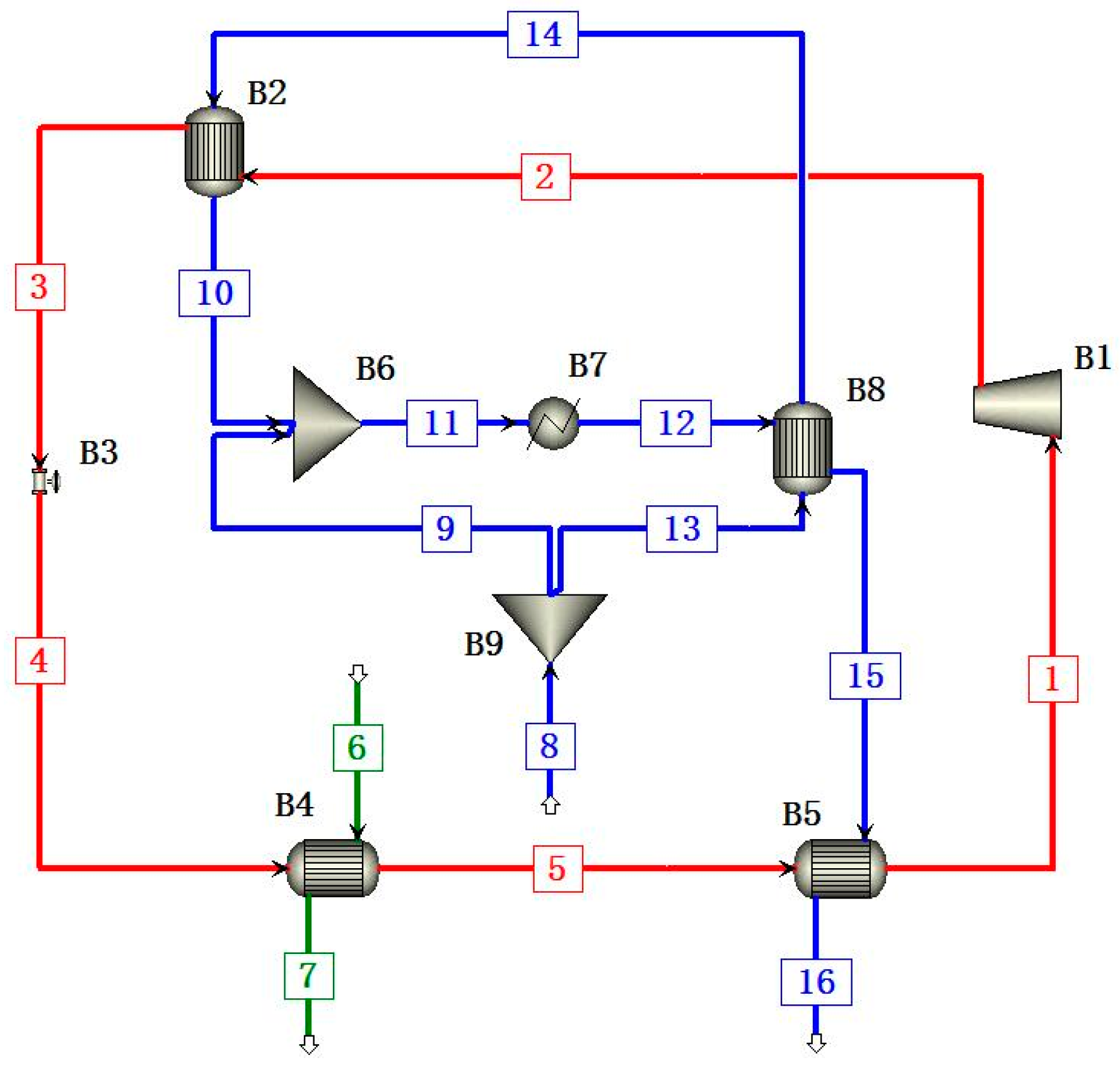

2. Characteristics of the System

3. Establishment of the Simulation Process

3.1. The State and Property of the Matter in the Simulation Process

3.1.1. The Peng-Robinson Property Method

3.1.2. The IDEAL Property Method

3.1.3. STEAM-TA Property Method

3.1.4. The Fluid Transfer Modules

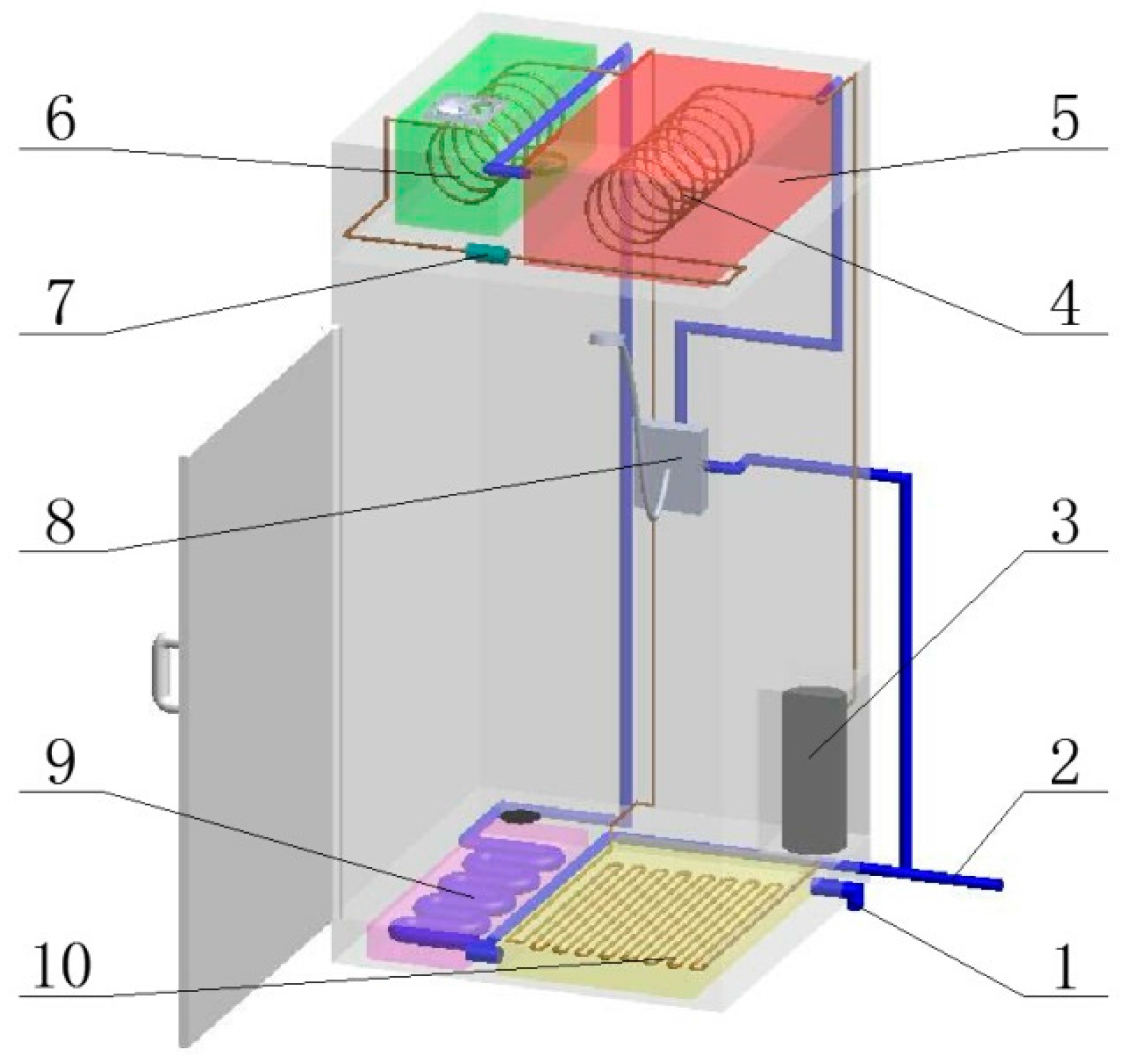

3.2. Establishment of the Simulation Process

3.3. Cases of the Steady State Simulation with ASPEN PLUS

4. Simulation Results and Analyses

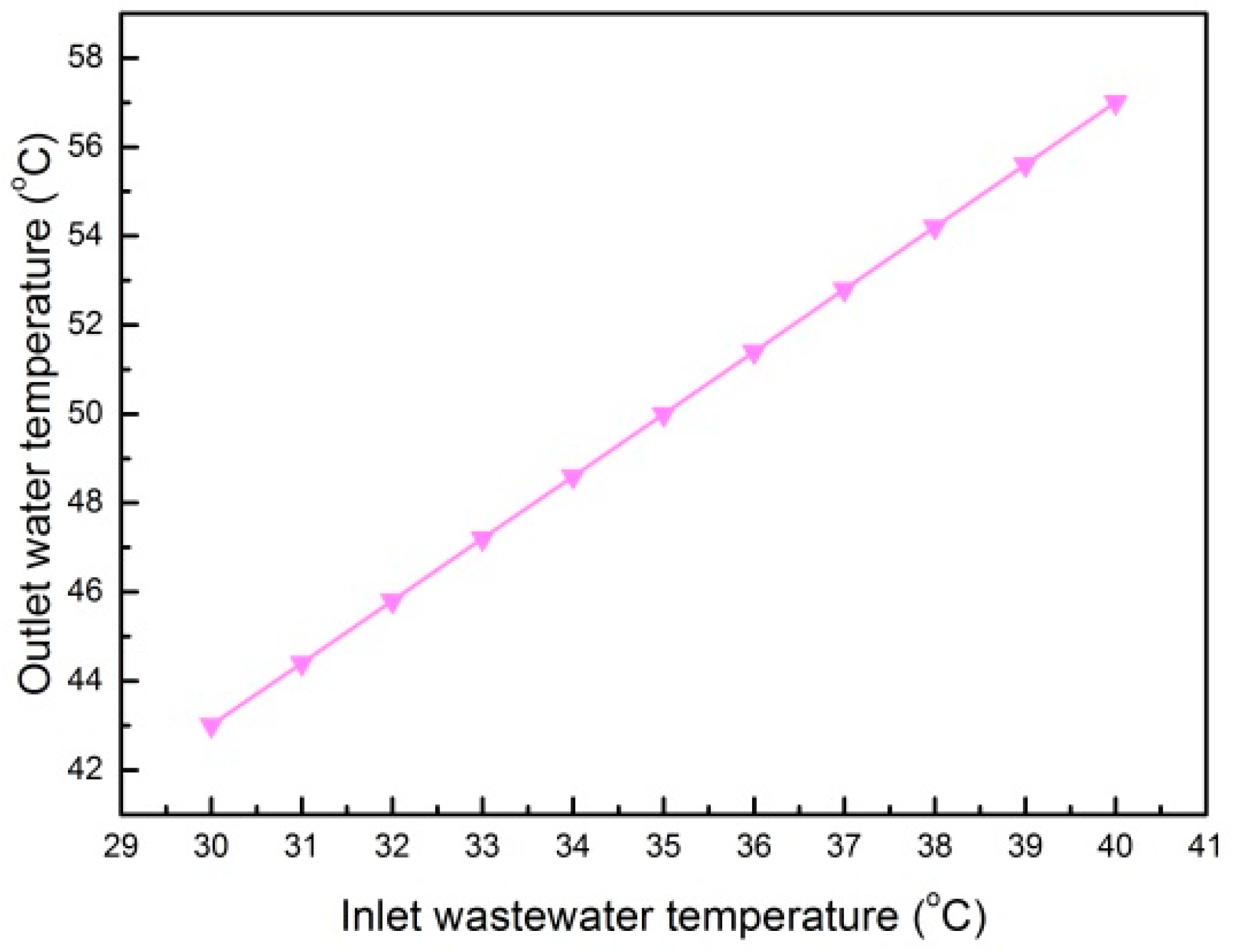

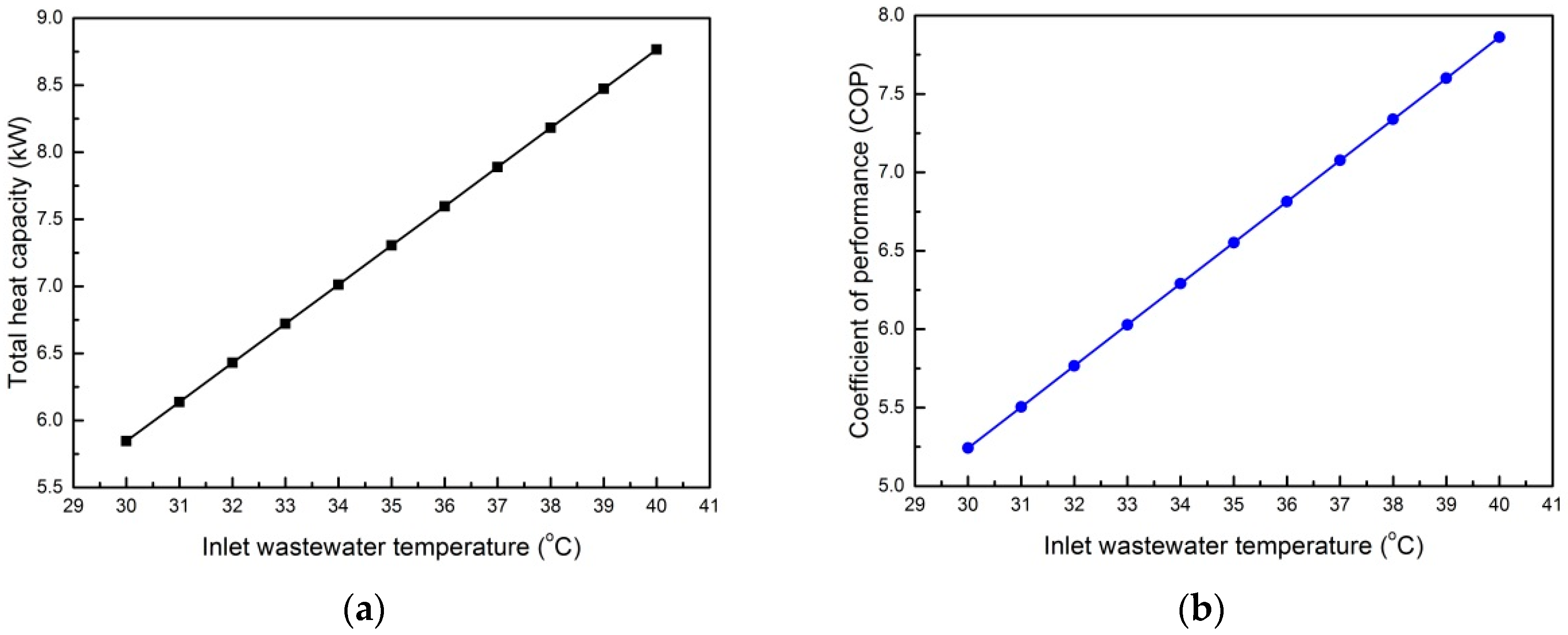

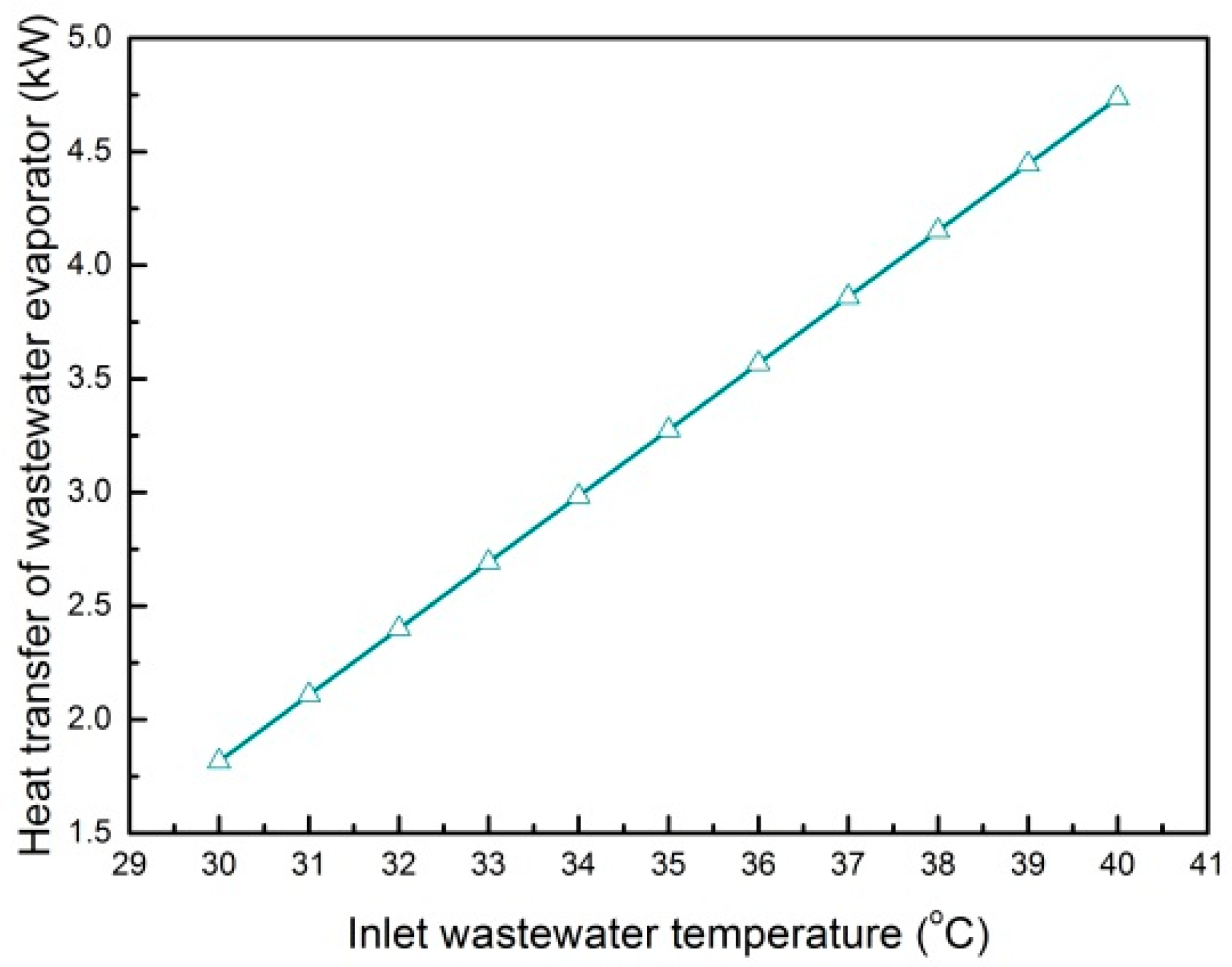

4.1. Influence of Inlet Wastewater Temperature on the System

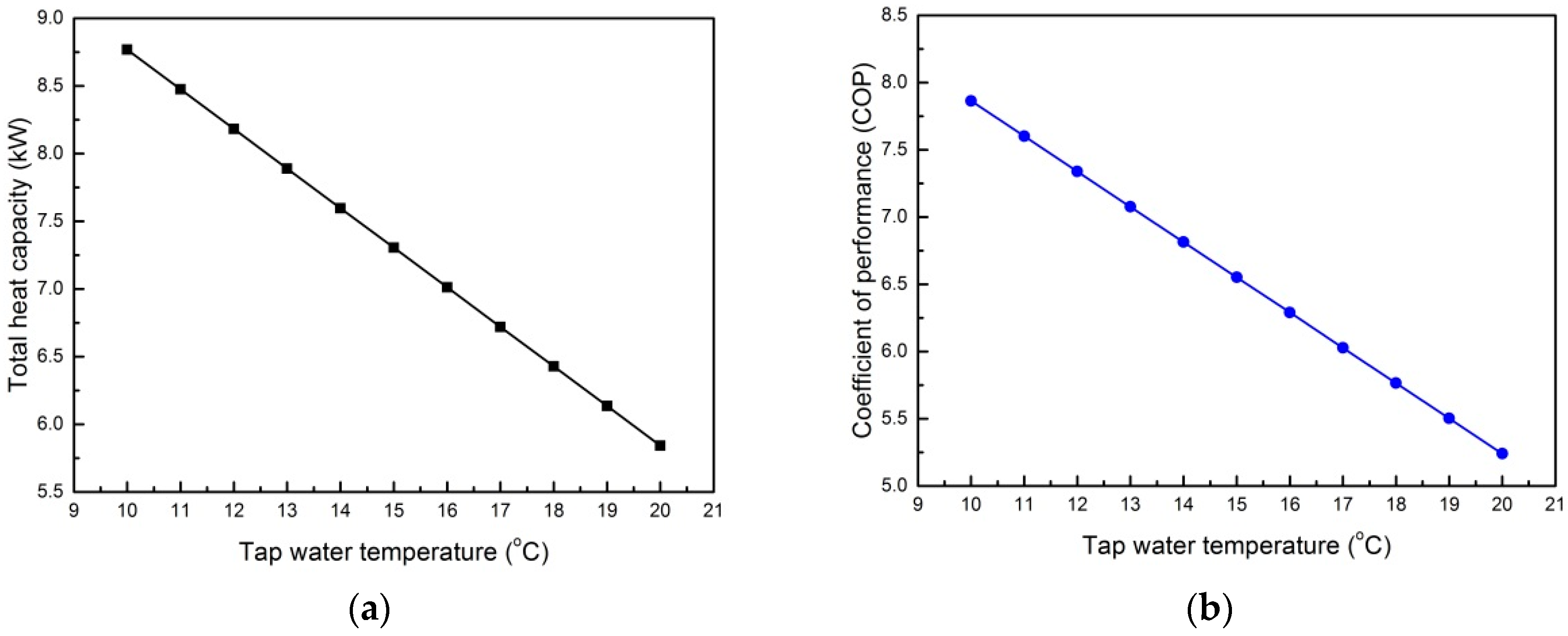

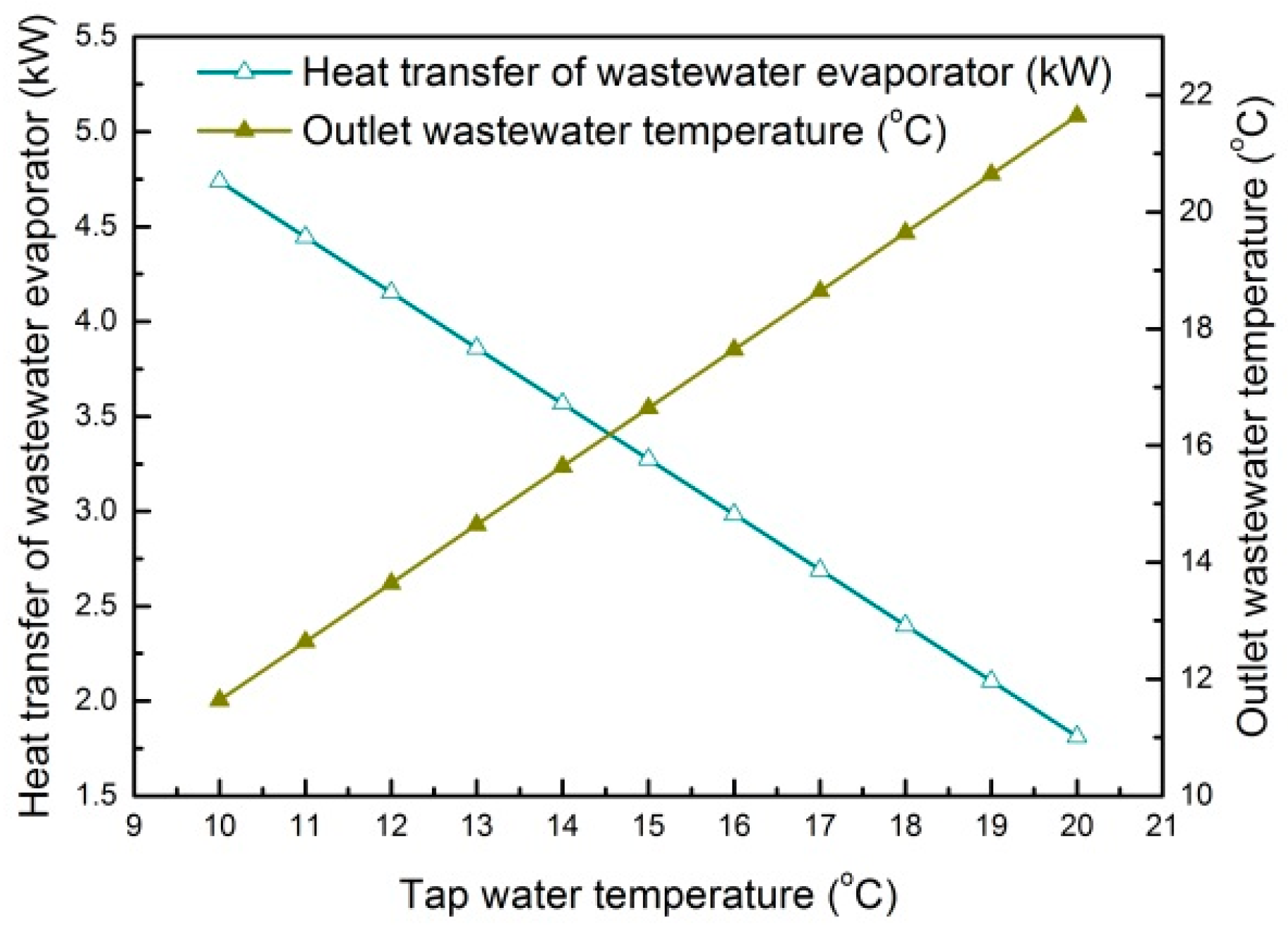

4.2. Influence of Tap Water Temperature on the System

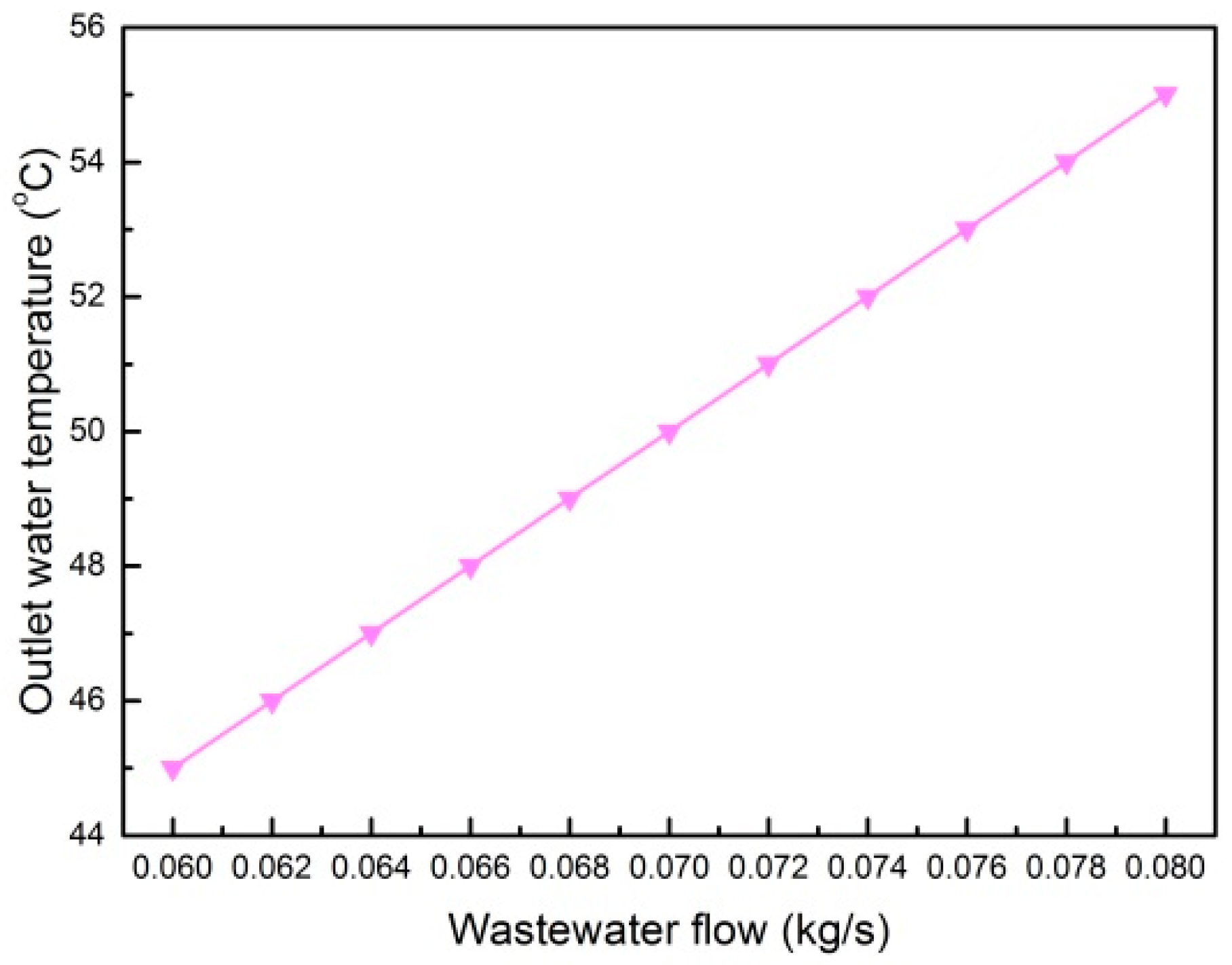

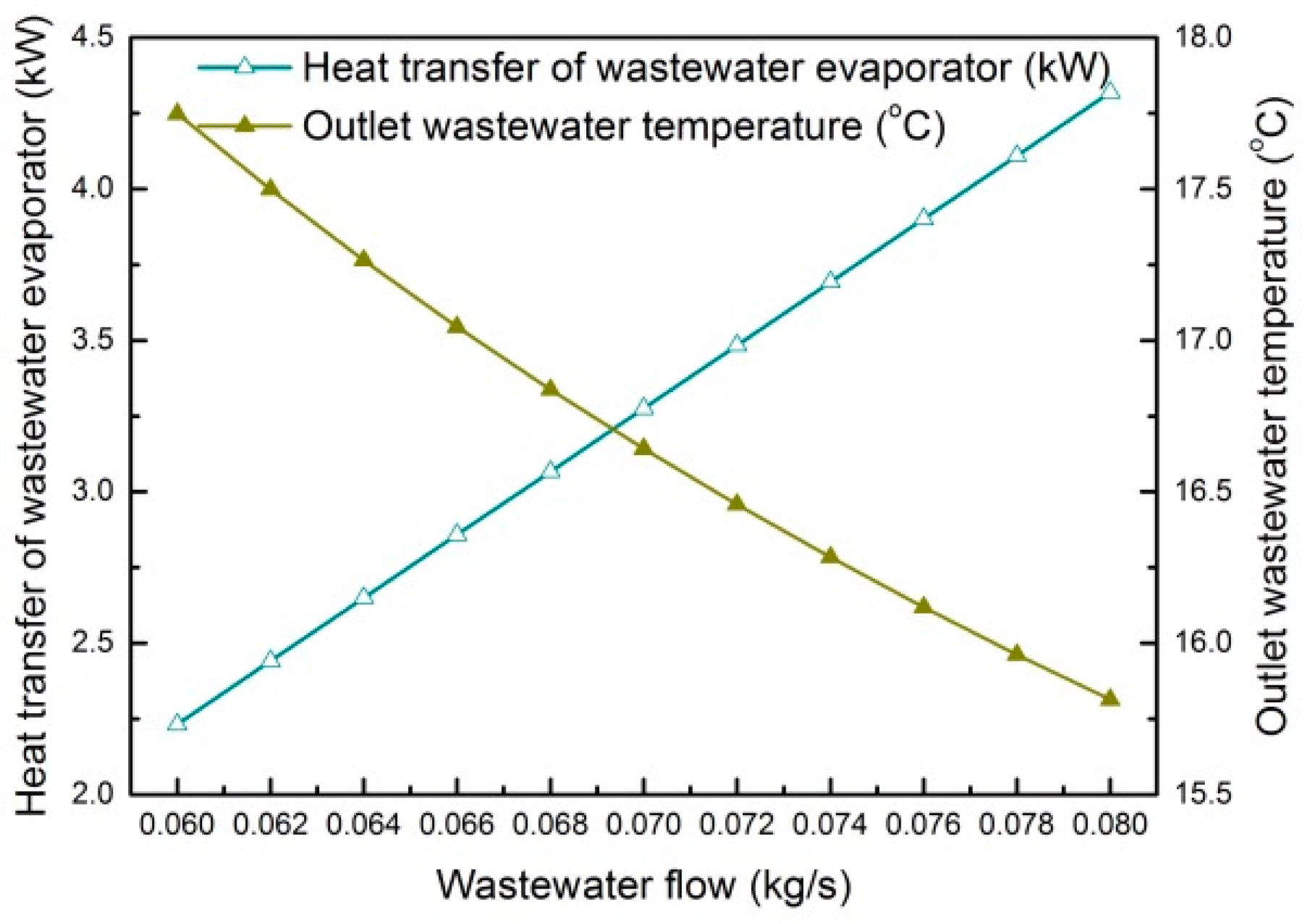

4.3. Influence of Wastewater Flow on the System

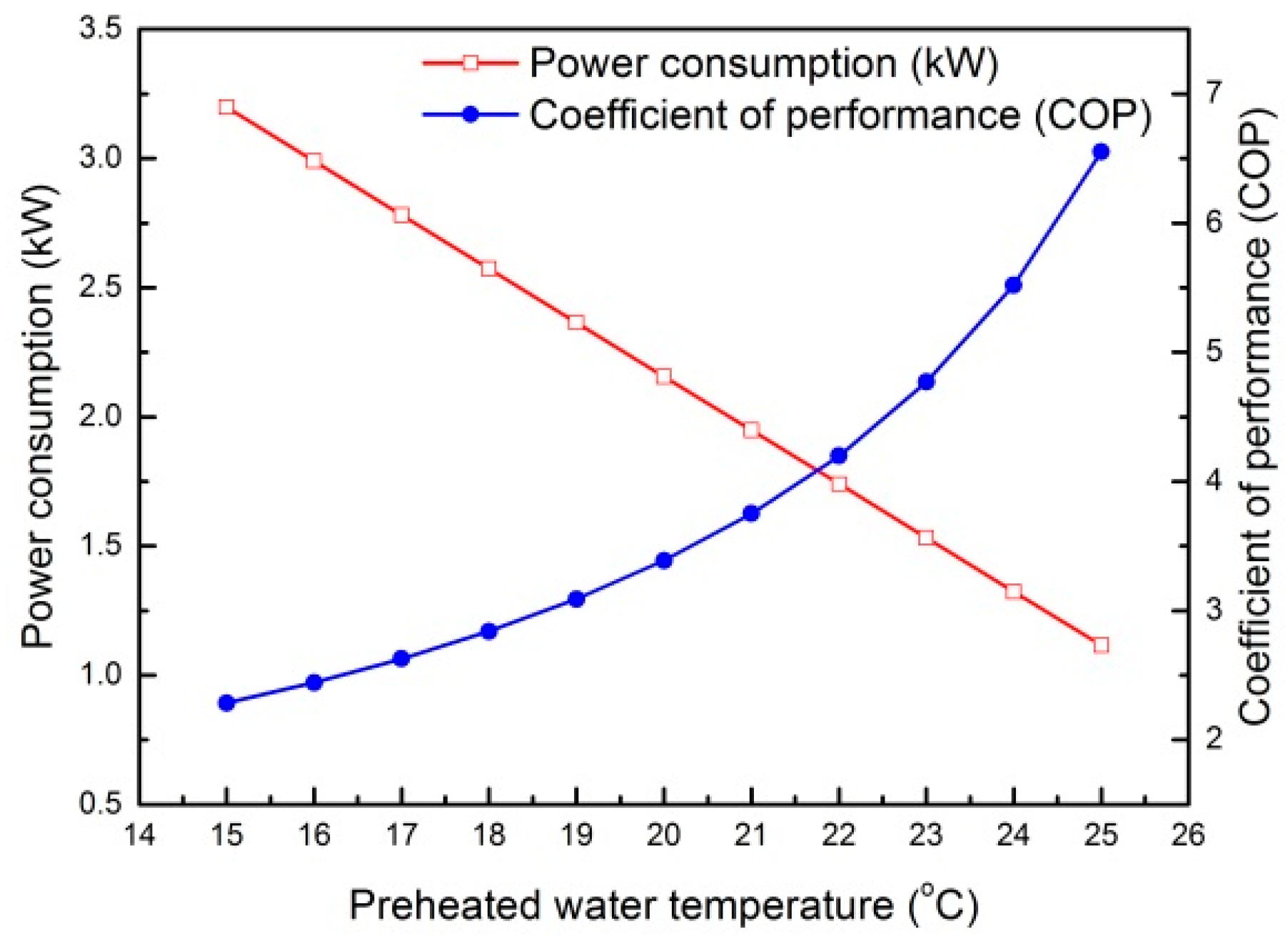

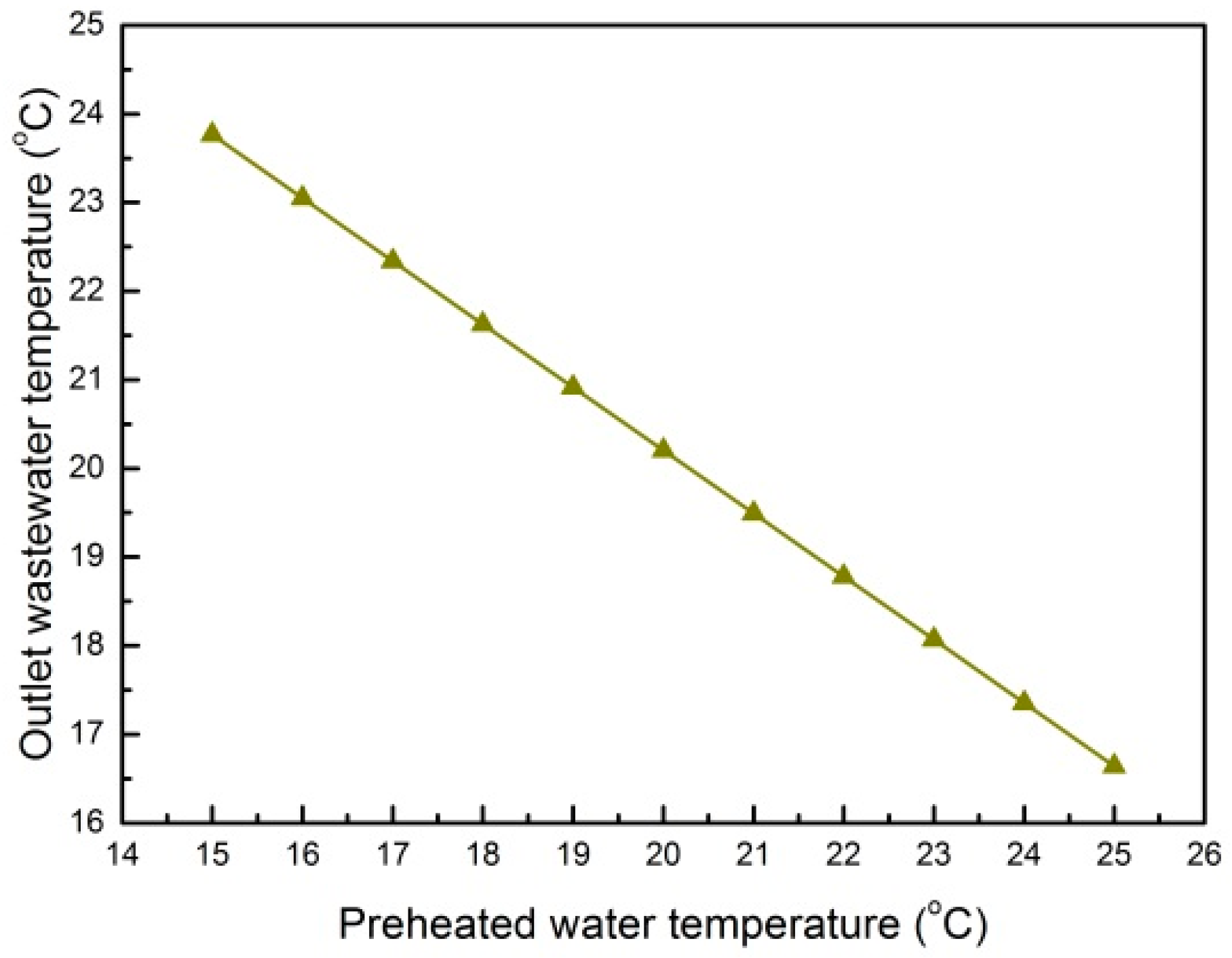

4.4. Influence of Preheated Water Temperature on the System

5. Optimization and Analysis of the System Energy Savings

6. Conclusions

- (1)

- Different cases of the system are simulated. The energy saving effect and the heat recovery of the wastewater increase as inlet wastewater temperature increases, tap water temperature decreases, or wastewater flow increases;

- (2)

- The system with or without preheater is simulated. The system energy saving effect increases when the system is coupled with preheater and the preheated water temperature or the preheater heat exchange area are kept in a proper range;

- (3)

- Based on the optimization and analysis, under the standard conditions of air at 25 °C, relative humidity of 70%, wastewater at 35 °C, wastewater flow rate of 0.07 kg/s, tap water at 15 °C, and condenser outlet water temperature at 50 °C, the theoretical COP of the system can reach 9.784 at the evaporating temperature of 14.96 °C, the condensing temperature of 48.74 °C, and the preheated water temperature of 27.19 °C.

- (4)

- The COPs of the system of a household dual heat source heat pump water heater with and without preheater are 6.588 and 4.677, respectively. The energy saving effect of the system of household dual heat source heat pump water heater with preheater is better than that without a preheater.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| A | heat exchange area of heat exchanger, (m2) |

| c | specific heat, J/(kg·K) |

| COP | coefficient of the system performance |

| Duty | duty, (W) |

| F | correction factor of Log mean temperature difference (LMTD) |

| h | enthalpy, (J/kg) |

| HeatFlow | heat flow, (W) |

| M | mass flow, (kg/s) |

| p | pressure, (Pa) |

| Q | heat exchange capacity, (W) |

| Qtotal | total heat exchange capacity of system, (W) |

| Qloss, Qleak | heat loss of heat exchanger, (W) |

| R | gas constant, (J/(mol·K)) |

| S | velocity, (m/s) |

| T | temperature, (K) |

| △TLM | LMTD of heat exchanger, (K) |

| U | heat exchange coefficient of heat exchanger, (W/(m2·K)) |

| Vm | ideal gas molar volume, (m3/mol) |

| v | specific volume, (m3/mol) |

| W | power consumption, (W) |

| Z | compressibility factor |

| ω | acentric factor |

| Subscripts | |

| c | critical |

| re | reduced |

| prev | previous module |

| next | next module |

| out | outlet |

| in | inlet |

| hot | hot fluid |

| cold | cold fluid |

| r | circulating working fluid |

| cooler | cooler |

| heatx | heat exchanger |

| dis | compressor outlet |

| suc | compressor inlet |

| v | valve |

| air,evap | air source evaporator |

| wastewater,evap | wastewater source evaporator |

| cond | condenser |

| preheater | preheater |

References

- Zhang, D.L.; Huang, G.Q.; Xu, Y.M.; Gong, Q.H. Waste-to-Energy in China: Key Challenges and Opportunities. Energies 2015, 8, 14182–14196. [Google Scholar] [CrossRef]

- Qu, J.S.; Maraseni, T.; Liu, L.N.; Zhang, Z.Q.; Yusaf, T. A Comparison of Household Carbon Emission Patterns of Urban and Rural China over the 17 Year Period (1995–2011). Energies 2015, 8, 10537–10557. [Google Scholar] [CrossRef]

- Nam, Y.J.; Gao, X.Y.; Yoon, S.H.; Lee, K.H. Study on the Performance of a Ground Source Heat Pump System Assisted by Solar Thermal Storage. Energies 2015, 8, 13378–13394. [Google Scholar] [CrossRef]

- Kim, J.S.; Nam, Y.J. A Numerical Study on System Performance of Groundwater Heat Pumps. Energies 2016, 9, 4. [Google Scholar] [CrossRef]

- Hepbasli, A.; Kalinci, Y. A review of heat pump water heating systems. Renew. Sustain. Energy Rev. 2009, 13, 1211–1229. [Google Scholar] [CrossRef]

- Ni, L.; Dong, J.K.; Yao, S.; Shen, C.; Qv, D.H.; Zhang, X.D. A review of heat pump systems for heating and cooling of buildings in China in the last decade. Renew. Energy 2016, 84, 30–45. [Google Scholar] [CrossRef]

- Touchie, M.F.; Pressnail, K.D. Testing and simulation of a low-temperature air-source heat pump operating in a thermal buffer zone. Energy Build. 2014, 75, 149–159. [Google Scholar] [CrossRef]

- Ma, G.Y.; Zhao, H.X. Experimental study of a heat pump system with flash-tank coupled with scroll compressor. Energy Build. 2008, 40, 697–701. [Google Scholar] [CrossRef]

- Xu, S.X.; Ma, G.Y. Research on air-source heat pump coupled with economized vapor injection scroll compressor and ejector. Int. J. Refrig. 2011, 34, 1587–1595. [Google Scholar] [CrossRef]

- Safa, A.A.; Fung, A.S.; Kumar, R. Performance of two-stage variable capacity air source heat pump: Field performance results and TRNSYS simulation. Energy Build. 2015, 94, 80–90. [Google Scholar] [CrossRef]

- Wu, J.H.; Lin, J. Thermodynamic analysis of a novel heat pump water heater with two-stage heating for a great rise of water temperature. Energy Build. 2015, 91, 97–104. [Google Scholar] [CrossRef]

- Bhattacharyya, S.; Garai, A.; Sarkar, J. Thermodynamic analysis and optimization of a novel N2O–CO2 cascade system for refrigeration and heating. Int. J. Refrig. 2009, 32, 1077–1084. [Google Scholar] [CrossRef]

- Getu, H.M.; Bansal, P.K. Thermodynamic analysis of an R744–R717 cascade refrigeration system. Int. J. Refrig. 2008, 31, 45–54. [Google Scholar] [CrossRef]

- Fernandez, N.; Hwang, Y.; Radermacher, R. Comparison of CO2 heat pump water heater performance with baseline cycle and two high COP cycles. Int. J. Refrig. 2010, 33, 635–644. [Google Scholar] [CrossRef]

- Zhang, J.F.; Qin, Y.; Wang, C.C. Review on CO2 heat pump water heater for residential use in Japan. Renew. Sustain. Energy Rev. 2015, 50, 1383–1391. [Google Scholar] [CrossRef]

- Wu, H.G.; Shu, P.G.; Xing, Z.W. Experimental study on performance of air source heat pumps with alternative refrigerants. Heat. Vent. Air Cond. 2006, 36, 61–62. [Google Scholar]

- Dong, J.K.; Li, S.; Yao, Y.; Jiang, Y.Q.; Tian, Y.; Tian, H. Defrosting performances of a multi-split air source heat pump with phase change thermal storage. Int. J. Refrig. 2015, 55, 49–59. [Google Scholar] [CrossRef]

- Hu, W.J.; Jiang, Y.Q.; Qv, M.L.; Ni, L.; Yao, Y.; Deng, S.M. An experimental study on the operating performance of a novel reverse-cycle hot gas defrosting method for air source heat pumps. Appl. Therm. Eng. 2011, 31, 363–369. [Google Scholar]

- Seong, Y.B.; Lim, J.H. Energy saving potentials of phase change materials applied to lightweight building envelopes. Energies 2013, 6, 5219–5230. [Google Scholar] [CrossRef]

- Lazzarin, R.M. Dual source heat pump systems: Operation and performance. Energy Build. 2012, 52, 77–85. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, J.; Zhou, G.H.; Zhang, C.; Wan, W.L. Performance of a solar air composite heat source heat pump system. Renew. Energy 2016, 87, 1053–1058. [Google Scholar] [CrossRef]

- Tian, Y.; Shi, W.X.; Wang, B.L. A new ground-coupled heat pump system integrated with a multi-mode air-source heat compensator to eliminate thermal imbalance in cold regions. Energy Build. 2015, 107, 103–112. [Google Scholar]

- Congedo, P.M.; Lorusso, C.; Giorgi, M.G.D.; Laforgia, D. Computational fluid dynamic modeling of horizontal air-ground heat exchangers (HAGHE) for HVAC systems. Energies 2014, 7, 8465–8482. [Google Scholar] [CrossRef]

- Hepbasli, A.; Biyik, E.; Ekren, O.; Gunerhan, H.; Araz, M. A key review of wastewater source heat pump (WWSHP) systems. Energy Convers. Manag. 2014, 88, 700–722. [Google Scholar] [CrossRef]

- Tanha, K.; Fung, A.S.; Kuma, R. Performance of two domestic solar water heaters with drain water heat recovery units: Simulation and experimental investigation. Appl. Therm. Eng. 2015, 90, 444–459. [Google Scholar] [CrossRef]

- Liu, L.B.; Fu, L.; Jiang, Y. Application of an exhaust heat recovery system for domestic hot water. Energy 2010, 35, 1476–1481. [Google Scholar] [CrossRef]

- Kahraman, A.; Çelebi, A. Investigation of the Performance of a Heat Pump Using Waste Water as a Heat Source. Energies 2009, 2, 697–713. [Google Scholar] [CrossRef]

- Wong, L.T.; Mui, K.W.; Guan, Y. Shower water heat recovery in high-rise residential buildings of Hong Kong. Appl. Energy 2010, 87, 703–709. [Google Scholar] [CrossRef]

- Liu, L.B.; Fu, L.; Zhang, S.G. The design and analysis of two exhaust heat recovery systems for public shower facilities. Appl. Energy 2014, 132, 267–275. [Google Scholar] [CrossRef]

- Chen, W.; Liang, S.Q.; Guo, Y.X.; Cheng, K.Y.; Gui, X.H.; Tang, D.W. Investigation on the thermal performance and optimization of a heat pump water heater assisted wish shower waste water. Energy Build. 2013, 64, 172–181. [Google Scholar] [CrossRef]

- Dong, J.K.; Zhang, Z.; Yao, Y.; Jiang, Y.Q.; Lei, B. Experimental performance evaluation of a novel heat pump water heater assisted with shower drain water. Appl. Energy 2015, 154, 842–850. [Google Scholar] [CrossRef]

- Chen, Z.S.; Tao, W.Q.; Zhu, Y.W.; Hu, P. Performance analysis of air-water dual source heat pump water heater with heat recovery. Sci. China Technol. Sci. 2012, 55, 2148–2156. [Google Scholar] [CrossRef]

- Zhang, C.; Dong, J.Y.; Zhao, X.D.; Zhou, G.H. The influence factors of the compound heat-exchanging temperature difference of dual-source compound heat-exchanger. Cryog. Supercond. 2012, 40, 68–72. [Google Scholar]

- Zhang, C.; Dong, J.Y.; Zhao, X.D.; Zhou, G.H. Structure parameter optimization of air-water dual-source compound heat-exchanger. Fluid Mach. 2012, 40, 61–64. [Google Scholar]

- Mansouri, R.; Boukholda, I.; Bourouis, M.; Bellagi, A. Modelling and testing the performance of a commercial ammonia/water absorption chiller using Aspen-Plus platform. Energy 2015, 93, 2374–2383. [Google Scholar] [CrossRef]

- De Guido, G.; Langè, S.; Pellegrini, L.A. Refrigeration cycles in low-temperature distillation processes for the purification of natural gas. J. Nat. Gas Sci. Eng. 2015, 27, 887–900. [Google Scholar] [CrossRef] [Green Version]

- Somers, C.; Mortazavi, A.; Hwang, Y.; Radermacher, R.; Rodgers, P.; Al-Hashimi, S. Modeling water/lithium bromide absorption chillers in ASPEN Plus. Appl. Energy 2011, 88, 4197–4205. [Google Scholar] [CrossRef]

- Peng, D.Y.; Robinson, D.B. A New Two-Constant Equation of State. Ind. Eng. Chem. Fundam. 1976, 15, 59–64. [Google Scholar] [CrossRef]

- Soave, G. Equilibrium constants from a modified Redlich-Kwong equation of state. Chem. Eng. Sci. 1972, 27, 1197–1203. [Google Scholar] [CrossRef]

- Spencer, R.C.; Meyer, C.A. The 1967 ASME Steam tables. Nav. Eng. J. 1968, 80, 751–758. [Google Scholar]

| Case | Wastewater Temperature (°C) | Tap Water Temperature (°C) | Wastewater Mass Flow (kg/s) | Preheated Water Temperature (°C) |

|---|---|---|---|---|

| 1 | 30–40 | 15 | 0.07 | 25 |

| 2 | 35 | 10–20 | 0.07 | 20–30 |

| 3 | 35 | 15 | 0.06–0.08 | 25 |

| 4 | 35 | 15 | 0.07 | 15–25 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gou, X.; Fu, Y.; Shah, I.A.; Li, Y.; Xu, G.; Yang, Y.; Wang, E.; Liu, L.; Wu, J. Research on a Household Dual Heat Source Heat Pump Water Heater with Preheater Based on ASPEN PLUS. Energies 2016, 9, 1026. https://doi.org/10.3390/en9121026

Gou X, Fu Y, Shah IA, Li Y, Xu G, Yang Y, Wang E, Liu L, Wu J. Research on a Household Dual Heat Source Heat Pump Water Heater with Preheater Based on ASPEN PLUS. Energies. 2016; 9(12):1026. https://doi.org/10.3390/en9121026

Chicago/Turabian StyleGou, Xiang, Yang Fu, Imran Ali Shah, Yamei Li, Guoyou Xu, Yue Yang, Enyu Wang, Liansheng Liu, and Jinxiang Wu. 2016. "Research on a Household Dual Heat Source Heat Pump Water Heater with Preheater Based on ASPEN PLUS" Energies 9, no. 12: 1026. https://doi.org/10.3390/en9121026