1. Introduction

World energy demand is growing and it will continuously increase over the next 20 years. Due to the difficulties in addressing appropriate and shared energy policies, the world may not be able to face these issues with suitable supply and to meet its climate change goals [

1,

2]. It is well known that the growing energy demand is related to dangerous environmental impacts and the building sector is responsible of about 40% of the total energy use. Consequently, energy efficiency in buildings is the main goal [

3,

4,

5] and many systems and solutions have been proposed for measuring the impact on the environment, improving their energy efficiency and reduce the emissions [

6,

7]. Several countries have also developed energy certification procedures in order to assess buildings energy performance, according to the nearly zero-energy buildings (n-ZEB) perspective [

8,

9,

10]. Furthermore, in order to quantify and evaluate the level of “sustainability” in the building sector, the so-called green rating systems have been developed. These procedures allow one to evaluate a building by taking into account its energy consumption and efficiency as well as by analyzing its environmental impact (for instance during the operation phase) and the effects on human health. These assessment tools have been developed in different countries, according to their specific features, objectives and standards requirements [

11]. Many studies concerning the analysis and classification of different environmental rating systems have been carried out [

12,

13]. In particular, Ali and Al Nsairat [

14] identified two macro categories of tools: the protocols based on a multi-criteria approach and the ones based on a life cycle assessment (LCA) methodology. The first group of tools is based on a comprehensive environmental assessment scheme and point values are assigned to a selected number of parameters, on a scale ranging between “small” and ‘‘large’’ environmental impact. The second group is focused on building materials, energy supply, waste management and transport type during the design phase. They aim to show that the building construction phase too, as the operation phase, has a very remarkable impact on environmental sustainability. Among the multi-criteria-based tools, such as Building Research Establishment Environmental Assessment Method (BREEAM, UK) [

15], Istituto per l’innovazione e Trasparenza degli Appalti e la Compatibilità Ambientale (ITACA, in English: Institute for Transparency of Contracts and Environmental Compatibility, Italy) [

16], Deutsche Gesellschaft für Nachhaltiges Bauen (DGNB, Germany) [

17], Haute Qualité Environnementale (HQE, France) [

18], Green Star Rating Tools (Green Star, Australia) [

19], the most used and widely recognized environmental rating protocol is Leadership in Energy and Environmental Design (LEED, USA) [

20]. Despite the fact that apparently they all seem to adopt the same approach, these methods are actually quite different in terms of framework, weights and scores assignment, procedure for performance evaluations, and calculation of the final score [

21].

Many studies have been carried out in order to analyze and compare different methodological approaches of green rating systems [

22,

23,

24,

25]. More in detail, several studies focused on the analysis and comparison of specific macro-areas of green building rating systems, in order to evaluate the different weights assigned to the sub areas in each protocol. For example, Wu et al. [

26] performed a comparative analysis of waste management requirements among five green building rating systems for new residential buildings, highlighting that the construction waste management has to be considered as a fundamental aspect in the process of green building ranking even if it is not always fully taken into account. Dolezal and Spitzbart-Glasl [

27] showed that acoustic performance is considered a fundamental aspect in most of the green building labels, but big differences exist among the approaches both in the acoustic performance evaluation and impact on rating results. It was also shown that a higher number of layers in the structure helps to improve the building acoustic performance, but also increases the environmental impact. Wei et al. [

28] reviewed recent green building certifications and their schemes in order to identify how and to what extent indoor air quality (IAQ) is taken into account. They discovered that IAQ is taken into account in all the green building certifications considered, and equal emphasis is placed on the strategies to improve it.

Asdrubali et al. [

29] applied the ITACA and LEED protocols to two residential green buildings located in central Italy and developed a methodological approach based on the definition of five new common areas, in order to compare the two green rating systems. The evaluation parameters of the two point-based systems are organized in five different macro-areas. To make the two methods comparable new common macro-areas (site, water, energy, materials, and indoor environmental quality) were identified and new scores were established combining the parameters. To underline the differences and the analogies of the two protocols the scores were normalized on the basis of 100. The comparison shows that ITACA pays attention to energy and water management while LEED considers more the site choice and materials. The two methods in energy section are based on different simulation approaches but in general there are not important technical differences because both schemes are based on international standards and regulations.

Several studies analyzed the impact of building materials on green rating systems, but no one deals in particular with the influence of insulating materials change. As a matter of fact, materials impact in a very decisive way to sustainable building management since they can improve energy efficiency in the overall life cycle of buildings. In the design phase the use of locally produced natural, recyclable or recycled materials should be preferred in order to minimize consumed energy and emitted CO

2 for transportation. Furthermore, these low environmental impacting materials guarantee high level performances even in the operation phase, since building energy consumption can be strongly reduced. In their study, Giama and Papadopoulos [

30] compared and evaluated green certification building schemes through a LCA methodology, focusing on the role of environmental evaluation of construction materials on the final scores. Basnet [

31] compared the BREEAM and LEED approaches, analyzing how and to what extent the life cycle impacts of materials are considered and emphasized in these protocols. Finally, Dodo et al. [

32] evaluated the impact of three green products from Nippon Paint on the final score of Malaysian Green Building Index, by counting the total points that could be earned by the building that uses these products.

All the aforementioned studies put in light the differences among the most used and widely recognized green rating protocols, but it is worthy noticing that all the variables used in the assessment methods have also important similarities.

As previously mentioned, among the categories of variables, the ones related to materials have a big impact on the evaluation of the environmental performance and they have different weights in the various rating methods. In fact, as observed in [

29], where ITACA and LEED protocols were compared, the item “materials”, even if it has a similar weight, results in significantly contrasting scores, testifying strong differences between the two rating systems.

Within this framework, the aim of this research is to apply ITACA and LEED procedures to an Italian sustainable residential building in order to quantify the impact of different insulating materials on the certification results. These rating systems were selected because these are the two systems most widely used in Italy. The comparison between the two approaches was developed according to the procedure defined in [

29]. Moreover, one of the points of strength of this work is the validation of the methodological approach through the application on a real building. In fact, most of the previously described studies—which analyzed the weight of specific items on the environmental rating assessment—have evaluated and compared different protocols only from a theoretical point of view without considering real case studies. In particular, a case study building was chosen due to its specific characteristics: it was monitored from the design stage to the operational phase, it has very high sustainable performance (in fact it was built following a call for sustainable architecture in the Umbria region which planned to reach the highest energy class according to the ITACA protocol), all the construction details are known, it is a representative Italian new building in terms of walls stratigraphy and construction features and walls are characterized by an inside air gap which can be filled with different insulating materials. These materials were chosen with similar thermal conductivities but different environmental properties, in order to assess how the two different rating systems take into account the materials environmental impact.

2. Methodological Approach

The buildings sustainability assessment is correlated to different issues, one of them is the thermal insulating performance. Starting from the substantial differences between ITACA and LEED approaches [

29], this paper presents the comparison of these two different rating systems applied to a sustainable residential building located in the region of Umbria (central Italy), characterized by innovative solutions, according to the principles of bioclimatic architecture. The building sustainability rate was evaluated by simulating different configurations of the building envelope, characterized by a thermal insulation made of glass wool, replacing the original material with a synthetic one with high environmental impact (expanded polystyrene, EPS) and with two types of natural materials, wood fiber and kenaf.

This study shows how the materials characteristics can affect both the energy and environmental performance of the building and highlights the differences between the two green building rating methods. In particular, the research is divided in two steps: firstly, the effects of different types of insulating materials on the final and partial (referred to the single macro areas) scores for each protocol were investigated and then the two approaches were normalized and compared on the basis of the procedure described in [

29].

2.1. Leadership in Energy and Environmental Design and Istituto per l’innovazione e Trasparenza degli Appalti e la Compatibilità Ambientale: Systems Description

As mentioned, the two environmental sustainability-rating systems taken into account in this study are LEED and ITACA Protocols. LEED, which is managed by the US and Canada Green Building Councils (USGBC and CaGBC), is one of the most diffused and applied green building certification programs worldwide. Developed by the non-profit USGBC, LEED includes a set of rating systems for the design, construction, operation, and maintenance of green buildings, homes, and neighborhoods, aiming to drive building owners and operators in being more environmentally responsible and using resources efficiently. LEED approach is a point-based system, there are 100 possible base points distributed across six credit categories: sustainable sites, water efficiency, energy and atmosphere, materials and resources, indoor environmental quality, innovation in design. A reference building, which represents a standard sustainable building, is used for setting the performance during the design, construction and operation phases. The performance credit system final goal is to assign the credits starting from the potential environmental impacts and human benefits of each intervention and to assess the environmental performance of buildings from an overall point of view during their life cycle, design, construction and operation phases. Moreover, up to 10 additional points may be earned: four may be received for Regional Priority Credits and six for Innovation in Design. Considering the total number of credits, the project is classified in four different levels of certification: Certified, Silver, Gold and Platinum. A specific edition of LEED, the so-called LEED for homes, was developed in Italy in order to take into account the characteristics of the Italian context, both in terms of housing and surroundings. According to this, the manual “GBC HOME—Edifici residenziali”, which describes procedures and gives examples for calculating the building performance, was used. The latest version of GBC Home was developed in 2015 and some differences in the assignment of credits were introduced. Nevertheless, in this paper the 2011 version is adopted since the building was designed in 2008 and realized in 2014, when the previous version of the procedure was still in force. The categories and the final scores of LEED protocol are shown in

Figure 1 and

Table 1.

In Italy the nonprofit association Sustainable Building Council (SBC) developed the protocol ITACA, a national system of certification of environmental sustainability. This certification tool, as the previous one, allows to evaluate buildings of different destination of use in all the phases of the life cycle, from the design to the operation phase. The evaluation criteria are divided in different categories: quality of site, resources consumption, environmental loads, indoor comfort, quality of service, social and economic aspects. The value zero represents the minimum acceptable performance determined in reference to the Italian technical rules and the legislation in force or to the construction standard procedure. In the scale of the scores the number 3 represents the best available constructive practice and the number 5 excellence.

Many Italian regions have customized the basic protocol, adapting it to local features. In Umbria, the region where the case study is located, the Regional Law No. 17/08 [

33] defined the calculation methods for the buildings assessment based on the ITACA procedure. A tool called “ARPA” [

34], was developed by the region of Umbria for calculating the environmental performance. It is composed of 20 technical sheets, which deal with various environmental and energy aspects of the building to be certified, classified into the aforementioned five macro-areas. In particular, for each sheet a score is assigned from “poor” (−1) to excellent (+5). Each assigned mark is weighted according to a percentage value. For instance, the sheet “thermal transmittance of the building envelope”, counts for about 6% of the total: if the score assigned is 5 it will add to the total score a value of 6%, while if the score is 3, the contribution would be 3.70%. The weighted sum of the scores obtained in the five evaluation areas generates the final building score. There are five “classes” of certification: A+, A, B, C, D but a Class-D building does not get the Certificate of Environmental Sustainability.

As for the LEED protocol, a more recent version of ITACA was developed in 2015. This new version introduces a different framework for calculating building performance, including some new criteria and tools and standard limits. Nevertheless, since Umbria region has not yet customized this protocol and the building was realized in 2014, the ARPA tool based on the oldest version of the protocol was employed in this paper. The categories and the final scores of ITACA protocol are showed in

Figure 1 and

Table 1. The two different rating systems—LEED and ITACA—will be compared in the following for highlighting the main differences in the composition of the total score and in particular the influence of different insulating materials on the final certification in both methods will be assessed.

2.2. Leadership in Energy and Environmental Design and Istituto per l’innovazione e Trasparenza degli Appalti e la Compatibilità Ambientale: Comparison of Procedures

The two methods are different from many points of view: the number and typology of categories, the parameters associated to the different categories, the weights assigned to each parameter, the procedure for evaluating energy performance and the calculation and composition of the final scores. The analysis of the macro-areas topics and the normalization of the parameters distribution are required in order to highlight the differences between the two protocols and to compare the scores. According to this, the categories and credits influenced by the variation of building materials were analyzed for both protocols in order to evaluate the impacts on the partial (referred to the single categories) and final score.

In the LEED protocol, the categories related to building materials (

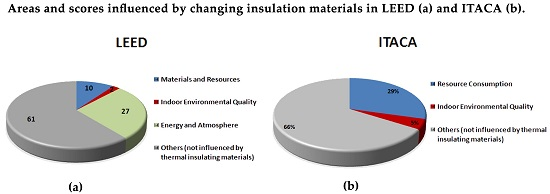

Figure 2) are: “energy and atmosphere”, “materials and resources”, and “indoor environmental quality”. The maximum score of 30 points, which can be obtained in “energy and atmosphere” category, is very high compared to the ones achievable in the other categories; this item includes two parameters: “optimization of energy performance”, which allows to get a maximum of 27 points, and “efficient domestic hot water production and distribution system”, in which a maximum of 3 points can be obtained. Only the first parameter is influenced by the change of thermal insulating materials but it strongly weights on the partial category score and on the final score. Most of the parameters included in “materials and resources” category are affected by the change of insulating material, which has a high impact on the partial score, counting up to 10 points over the total score equal to 15, and a relatively remarkable impact on the final score. Focusing on “indoor environmental quality” category, only the “acoustic” parameter is influenced by the variation of insulating materials. According to this the impact on the partial and final score is not significant, counting 2 points over 20.

In ITACA protocol, the categories influenced by the change of building materials are “resource consumption” and “indoor environmental quality” (

Figure 3). “Resource consumption” category includes parameter related both to the energy performance of the building and to the characteristics of materials (extraction, processing, and manufacturing phases). This category counts for the 53.60% on the final score, which is the highest weight compared to the ones assigned to the other categories. This parameters distribution differs from LEED categorization, in which the materials characteristics and the building energy performance are divided in two separated categories. The insulating materials variation influences five of the nine parameters, accounting for 29.40% of the total category weight. As for LEED protocol, the “indoor environmental quality” category is also affected by insulating material change, in fact it impacts on the partial score for a quarter of the total value (18.20%) through the “acoustic insulation of building envelope” parameter.

Consequently, it is noticeable that in LEED more importance is given to materials since a specific category has been assigned to this item. Furthermore, in this protocol a maximum of 39 points/100 can be achieved thanks to insulation material properties, while in ITACA they represent up to 33.95% of the total score (

Figure 4a,b).

In addition, it can be noticed that in both certification methods the “materials from renewable resources” and “local materials” parameters are considered; moreover, LEED pays particular attention to the use of recycled materials as a strategy for reducing waste and reusing existing buildings. This aspect is not considered in ITACA protocol.

Another substantial difference between ITACA and LEED lies in the method for calculating the energy performance. In fact, LEED proposes two calculation methods: the descriptive and the performance-based ones. The latter, which was used in this paper, requires a dynamic simulation. On the other side, the energy performance calculation in ITACA protocol is based on the procedure described by the Standard UNI/TS 11300 [

35], which involves the use of a semi-stationary code. This different approach can have a high impact on the score assignment. Furthermore, the ITACA tool-sheets energy results are obtained only through the simulation of the proposed building, while LEED requires the simulation of two models, one corresponding to the real building and one having the characteristics of the reference model defined in Appendix G of ASHRAE 90.1-2013 [

36]. This model called “GBC Reference Design Home” was slightly adapted to the Italian context.

Finally, in order to underline the main differences in the total score composition, the overall comparison between the two methods was developed on the basis of the procedure described in [

29]. In this procedure, the original categories described above for LEED and ITACA were taken into account, keeping out only “innovation in design” for LEED and “service quality” for ITACA because they do not have an environmental impact (

Figure 5). In this way, LEED allows scoring 100 points and ITACA allows racking up 93.3 points. It is worth noticing that ITACA is characterized by percentage points but they can be merely considered points, making the assignment of the score homogeneous.

In order to compare these two green building assessment methods, five new macro areas were defined based on the identification of the common items: site, water, materials, energy and indoor environmental quality.

Figure 6 shows the new distributions of the parameters in the new five macro areas, highlighting the differences between the scores achievable with LEED and ITACA. Moreover, the figure shows the maximum points equal to 100 for LEED and 93.3 for ITACA. After that, the new scores need to be normalized on the basis of 100 (

Table 2 and

Figure 7).

3. Case Study: Description and Modeling

A mixed use building located in the city of Terni in Umbria (Italy) was chosen as case study. The building is placed in a high density residential district, which is located next to Terni city center and it is equipped with a big variety of urban facilities. In addition, there are several public transportation systems (four bus lines, shuttles and trains) serving the area and connecting the site with the surroundings.

The nine-storey building (

Figure 8 and

Table 3) has a parallelepiped shape oriented along the east-west axis and it is composed by: an underground level where the garage, heating plant, video-surveillance system and rainwater tank are located; shops and residential entrances on the ground floor; seven residential floors (6 + 1 attic floor).

The two green building rating methods were applied only to the residential part of the building. A common staircase connects the underground floor and the seven residential floors. The total number of apartments is 38: six apartments for each floor and two bigger apartments on the attic floor. Flats’ surfaces range from 33 m2 to 140 m2.

The building lot is characterized by 811 m2 of green area and 750 m2 of paved one with self-locking concrete paving blocks, which ensure a high permeability index. Furthermore, suitable spaces for separate collection of rubbish were provided.

The structure of the building is a reinforced concrete frame with concrete and masonry flooring system; the walls and the roof are insulated by glass wool; the outer layer of external walls is composed of bricks and the pitched roof is covered by tiles.

The centralized heating plant is characterized by a condensing boiler with a separate accounting system for each flat; low temperature underfloor heating systems are installed in the apartments. Natural ventilation in the apartments is integrated with a mechanical air extraction system.

Particular attention has been paid to renewable energy production and water recycling, since an underground tank for rainwater recovery was installed, 164 photovoltaic panels (266 m2) were placed on the parking roofs and 25 solar water heating panels (50 m2) were located on the pitched roof. Furthermore, the use of natural sustainable and local building materials was preferred in order to limit the environmental impacts of building construction.

In order to assess the building energy behavior, four building configurations were simulated, according to the different typology of thermal insulating materials: EPS, glass wool, wood fiber and kenaf (

Table 4). The materials have similar thermal conductivities but different environmental properties: EPS has a higher embodied energy than the design solution (glass wool), while wood fiber and kenaf have a lower embodied energy [

37].

Figure 9a,b shows the schematic stratigraphy of walls and roofs employed in the four simulated configurations.

As described in

Section 2.2, the ITACA protocol, differently from LEED method, allows one to use a semi-stationary code for evaluating the building energy performance, in accordance with the Standard UNI/TS 11300 [

35]. However, the assessment of the real building energy performance, which is characterized by glass wool insulation, was performed in both cases by TRNSYS code which is more accurate [

38].

4. Results and Discussion

LEED and ITACA procedures were applied to the examined building by analyzing the effects of the four considered insulating materials on the partial and final scores.

Table 5 and

Table 6 show the results for both methods, taking into account the original macro-areas and credits; the real case characterized by glass wool insulating material is highlighted in grey. Observing the total scores, it can be seen that every building configuration obtained “Class A” certification for ITACA and “Gold” classification for LEED, except for the case with EPS which obtained “Silver” score. The impact of changing the insulating materials is very similar for both procedures and the effects are about the same: in fact, in both cases the EPS obtains the worst score and wood fiber the best one.

Regarding LEED protocol, changing insulating materials affects the results of two original categories: “energy and atmosphere” and “material and resources”, while in ITACA procedure only the "resource consumption" area is affected since it includes both energy aspects and materials sustainability. In particular, as far as LEED is concerned, in the “energy and atmosphere” macro-area the use of EPS and kenaf leads to a reduction of the partial score compared to the real case (orange color in

Table 5); on the contrary, considering the “material and resources” category, kenaf and wood fiber solutions increase the scores (green color in

Table 5). As far as ITACA is concerned, in “resource and consumption” area, EPS results to be the worst choice as in LEED (orange color in

Table 6), while both kenaf and wood fiber improve the partial score (green color in

Table 6).

Despite the previous considerations highlighted in

Section 2.2, the impact of the four different materials on the acoustic performance, taken into account in “indoor environmental quality” macro-area, is negligible for both protocols; in fact, the material change does not lead to a score variation, since the strongest contribute to acoustic insulation is given by the window frame characteristics.

After the normalization process and the definition of the new five macro-areas (according to

Table 2), the results of the two rating systems were compared category by category in

Figure 10 and

Figure 11, in order to better understand the assessment differences. The “total” values in figures refer to the maximum score achievable for each macro-area. The only two areas affected by the materials change are “materials” and “energy”. Focusing on the “energy” category, the energy demand for real building with glass wool is 20.74 kWh/m

2 calculated by TRNSYS, while in the configurations characterized by the employment of EPS, kenaf and wood fiber the energy demands are respectively 21.30, 21.28 and 20.47 kWh/m

2. In the LEED protocol, it leads to different scores achieved by the insulation materials in the “energy” item: compared to the actual employed material (glass wool), which obtained about 37% of the maximum achievable item score, the EPS and kenaf obtained a lower score (about 30%), while the wood fiber allows one to obtain the same score as the design solution (about 37%).

In the LEED protocol, as can be seen in

Figure 10, all the insulating materials in “site” category allowed one to achieve about 91%, in “water” about 83% and in “indoor environmental quality” 75% of the total achievable score for each item.

Differently, in the ITACA procedure, in “site” and “water” items all the building configurations, included the actual solution, obtained 100% of the maximum points; while in “indoor environmental quality” about 42% of the total score was achieved (

Figure 11).

Differently in the ITACA procedure, glass wool, EPS and kenaf have the same impact on the “energy” item score (about 88%), while the wood fiber results to be the best performing in this category (more than 91%).

LEED sensitivity for energy is associated to the energy assessment method, which consists in the construction of a reference building with the same shape of the real case, while ITACA assesses the energy performances through a general performances scale.

Observing the “materials” item, it can be seen that in LEED both the glass wool and the EPS achieve the lowest score, while in ITACA the worst performance corresponds to the use of EPS. The closeness of materials production to the building construction site is a very important aspect for both the procedures; it has a particular weight in ITACA protocol where it induces larger score variations (

Figure 10 and

Figure 11). For instance, wood fiber, which can be found locally, allows achieving a higher score compared to EPS, which is produced far from Terni.

Taking into account the LEED protocol, glass wool and EPS obtained the same score, which is about 13% of the maximum score achievable; kenaf achieved about 27% and wood fiber about 33%, resulting to be the best performing also in this category.

Considering the ITACA procedure, EPS obtained the worst score, which is about 26% of the maximum points; glass wool achieved about 45% and finally kenaf and wood fiber had the highest score, being 60% of the total achievable.

The scores obtained in “site”, “water” and “indoor environmental quality” items are not influenced by the change of materials, although the materials characteristics are involved also in the “indoor environmental quality” item, due to the acoustic buildings performance. Moreover, the “site”, “water” and “indoor environmental quality” items were analyzed in order to evaluate the building partial score related to these categories, compared to the maximum achievable score (called “total”), as shown in

Figure 10 and

Figure 11.

5. Conclusions

In this paper, a comparison between the ITACA and LEED procedures applied to an Italian real residential building has been carried out. These protocols are complex rating systems in which a plurality of elements (energy efficiency, site construction, management of water and waste, materials, comfort and indoor quality) are considered for evaluating buildings environmental impact. The environmental assessment tools were analyzed, underlining the main differences and analogies and were then normalized by subdividing and adding the credits (for LEED) and sheets (for ITACA) in order to create common macro-areas. Five new categories were finally defined (site, water, energy, materials, indoor environmental quality) for comparing the two methods and their scores. In particular, this research shows how and to what extent the insulating materials characteristics can affect both the building energy and environmental performance, highlighting the differences between the two methods in the partial and final scores. The sustainability rate of the building chosen as case study was evaluated by simulating different configurations of the building envelope, characterized by a thermal insulation made of glass wool, replacing the original material with a synthetic one with high environmental impact (EPS) and with two types of natural materials, wood fiber and kenaf. The final scores show that each configuration obtained “Class A” certification for ITACA and “Gold” classification for LEED, except for the case with EPS which obtained LEED “Silver” score. It demonstrates that the changing of insulating materials may have an impact on the final score. In particular, it can be observed that in ITACA approach all the four analyzed building configurations achieved a score which is fully included in “Class A”, which ranges from 70 points to 85 points (

Table 6). On the contrary, the results obtained in the different configurations through LEED procedure are on the boundary between “Silver” and “Gold” classes, which range respectively from 50 to 59 and from 60 to 79 (

Table 5). Considering that there is a certain degree of discretionality by the operator in assigning each score, the “Gold” certification for LEED might be not be as stable as the “Class A” certification for ITACA. These results show a substantial correspondence between the two green building assessment tools since there are no important technical differences between the two methods and a common scientific basis is applied in both cases. All the building configurations get a better and more stable score with ITACA method, probably since it is the most diffused in Italy and the designers were inspired by the guidelines of this method. In fact, it is worthy to notice that the ITACA protocol is based on the Italian Standard, which needs to be followed by the designers during the design phase. Moreover, the analyzed case study was built following a call for sustainable architecture in the Umbria region, aimed at getting the highest energy class according to the ITACA protocol.

Regarding the LEED protocol, changing insulating materials affects the results of two original categories: “energy and atmosphere” and “material and resources”, while in ITACA procedure only the “resource consumption” area is affected since it includes both energy aspects and materials sustainability. The influence on “indoor environmental quality” macro-area is negligible for both protocols, despite the fact the envelope acoustic properties included in this category are affected by the insulation characteristics.

After the normalization process, only “materials” and “energy” new macro-areas are affected by the insulating materials properties. In particular, it is worthy to notice that the score of each macro-area in LEED are the same as in the original credits distribution, while in ITACA there are several differences due to the fact that the energy and materials aspects are now analyzed separately. In LEED both the “materials” and “energy” categories are subject to changes when different insulating materials are employed (

Figure 10), while in ITACA the main variations occur in “materials” macro-area (

Figure 11). In particular, by analyzing the scores obtained by the different building configurations in “materials” and “energy” macro-areas compared to the maximum scores achievable, it is noticeable that for both protocols wood fiber resulted to be the best performing material. Furthermore, the points obtained in each category by the four building configurations are different in LEED and ITACA, due to the differences between the two assessment procedures.

In conclusion, the comparative analysis suggests that ITACA and LEED procedures could be optimized by taking into account in a more efficient way the effect of the insulating materials thermal and environmental properties. The insulation materials should be heavily considered in the green building rating systems: in particular, the embodied energy of the material, which affects the whole material life cycle, should be taken into account, in order to underline the environmental advantages of sustainable insulating materials. Green rating systems should involve in their evaluation procedure the materials’ life cycle analysis, which allows assessing the materials sustainable features along the overall life cycle (from cradle to grave). The choice of insulation material did not make much difference in the overall ratings, in terms of thermal behavior but it has a significantly different impact in terms of embodied energy and consequently in terms of environmental impact. Future developments of the study will include a more comprehensive analysis and comparison of other internationally recognized rating systems and more case studies.