Experimental Study on Mechanical Properties and Porosity of Organic Microcapsules Based Self-Healing Cementitious Composite

Abstract

:1. Introduction

2. Experimental Scheme

2.1. Materials and Specimens

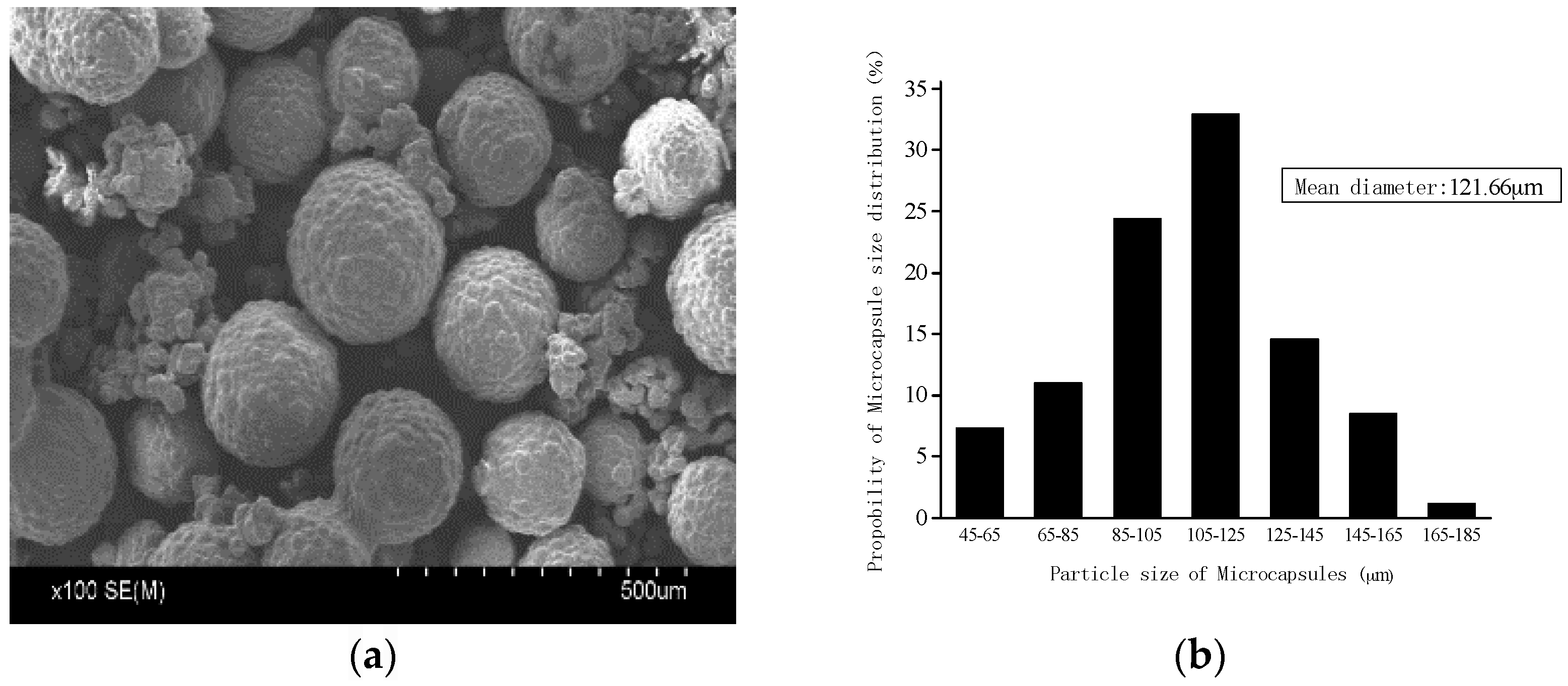

2.1.1. Preparation of Microcapsules

2.1.2. Preparation of the Microcapsule-Based Cementitious Materials and Specimens

2.2. Experimental Methods

2.2.1. Compressive Strength Test

2.2.2. Preparation of Specimens for Self-Healing Test

2.2.3. Dynamic Mechanical Analysis (DMA) Test

2.2.4. MIP Test

3. Results and Discussion

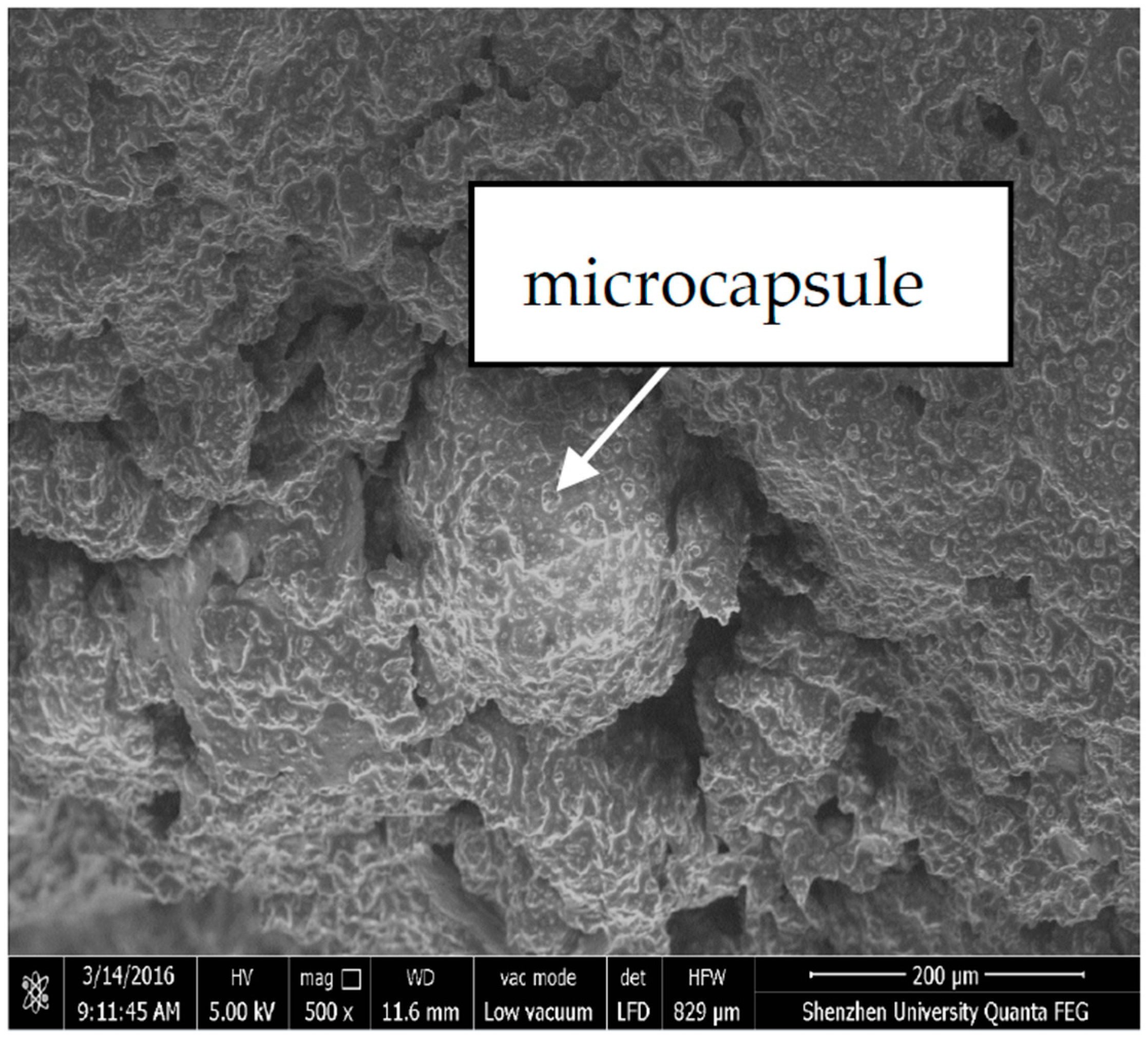

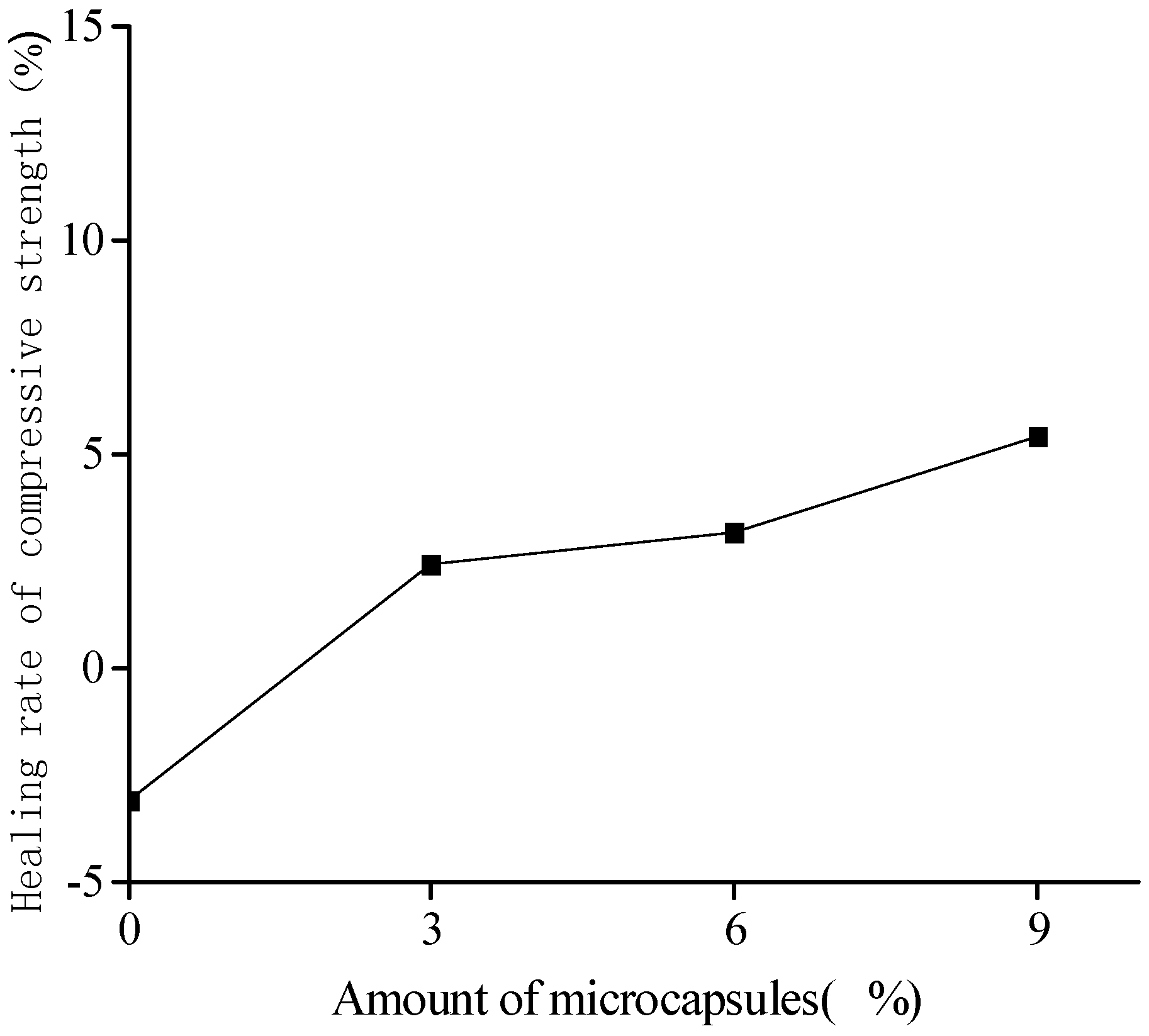

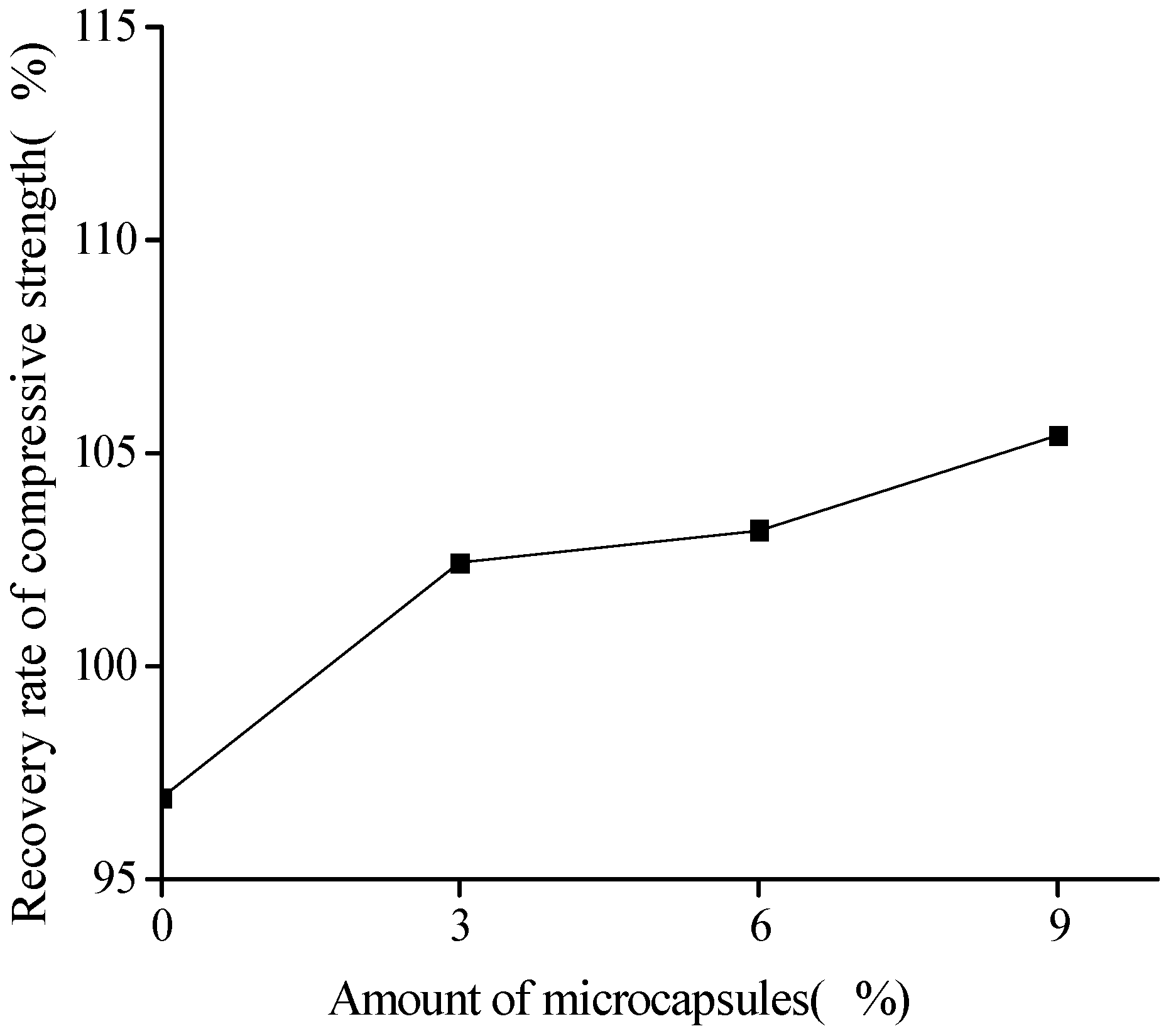

3.1. Compression Test Results and Discussions

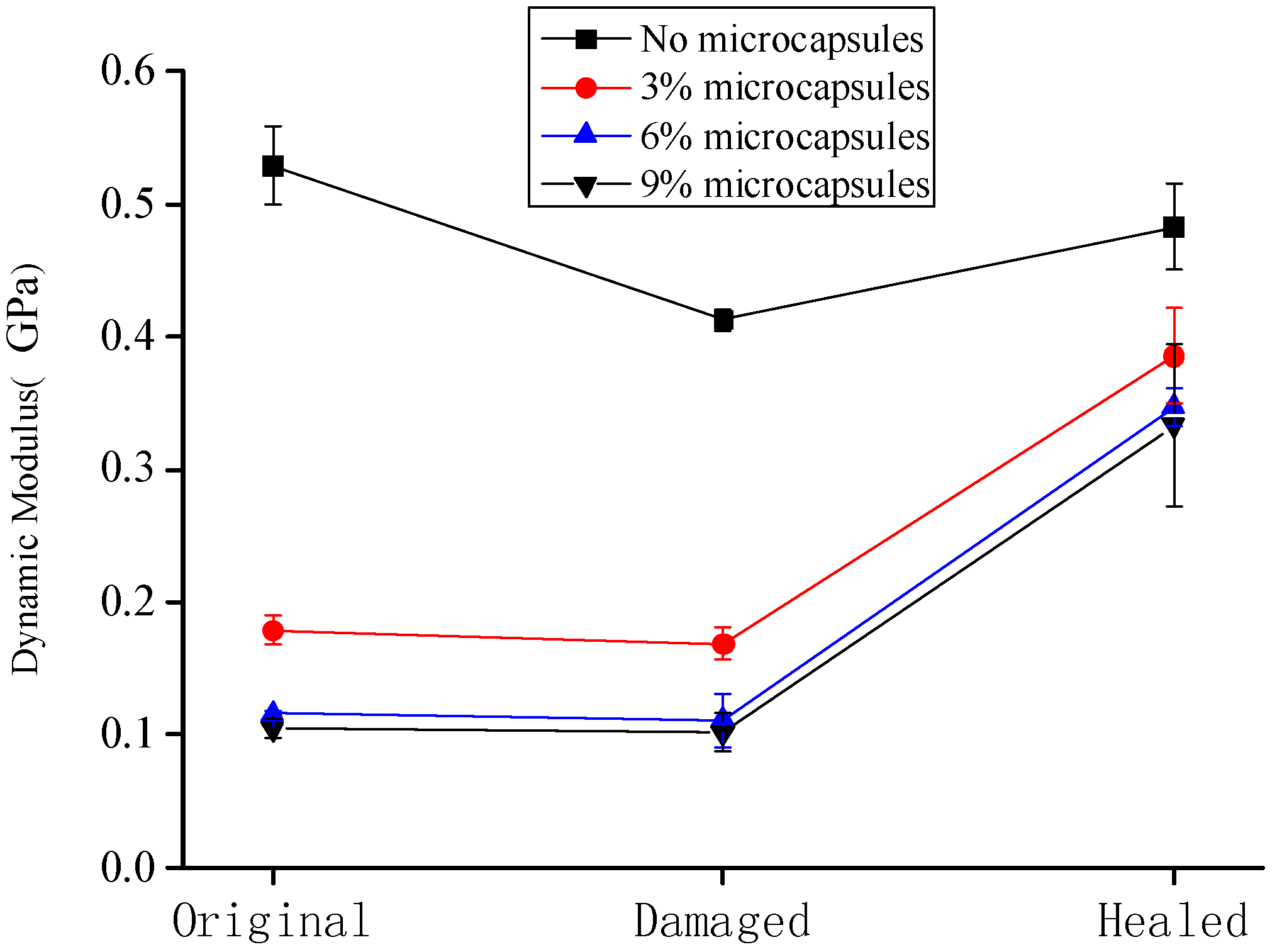

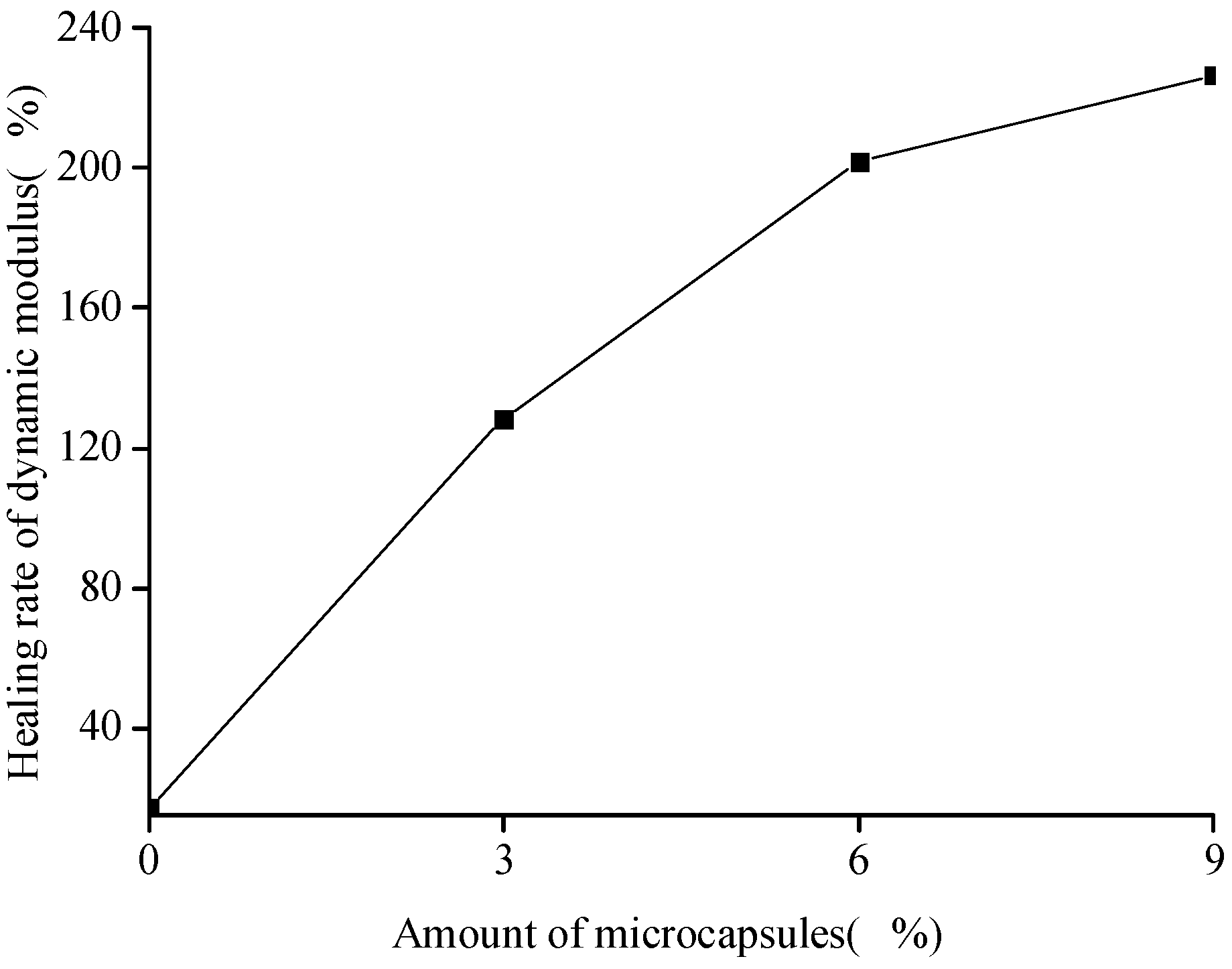

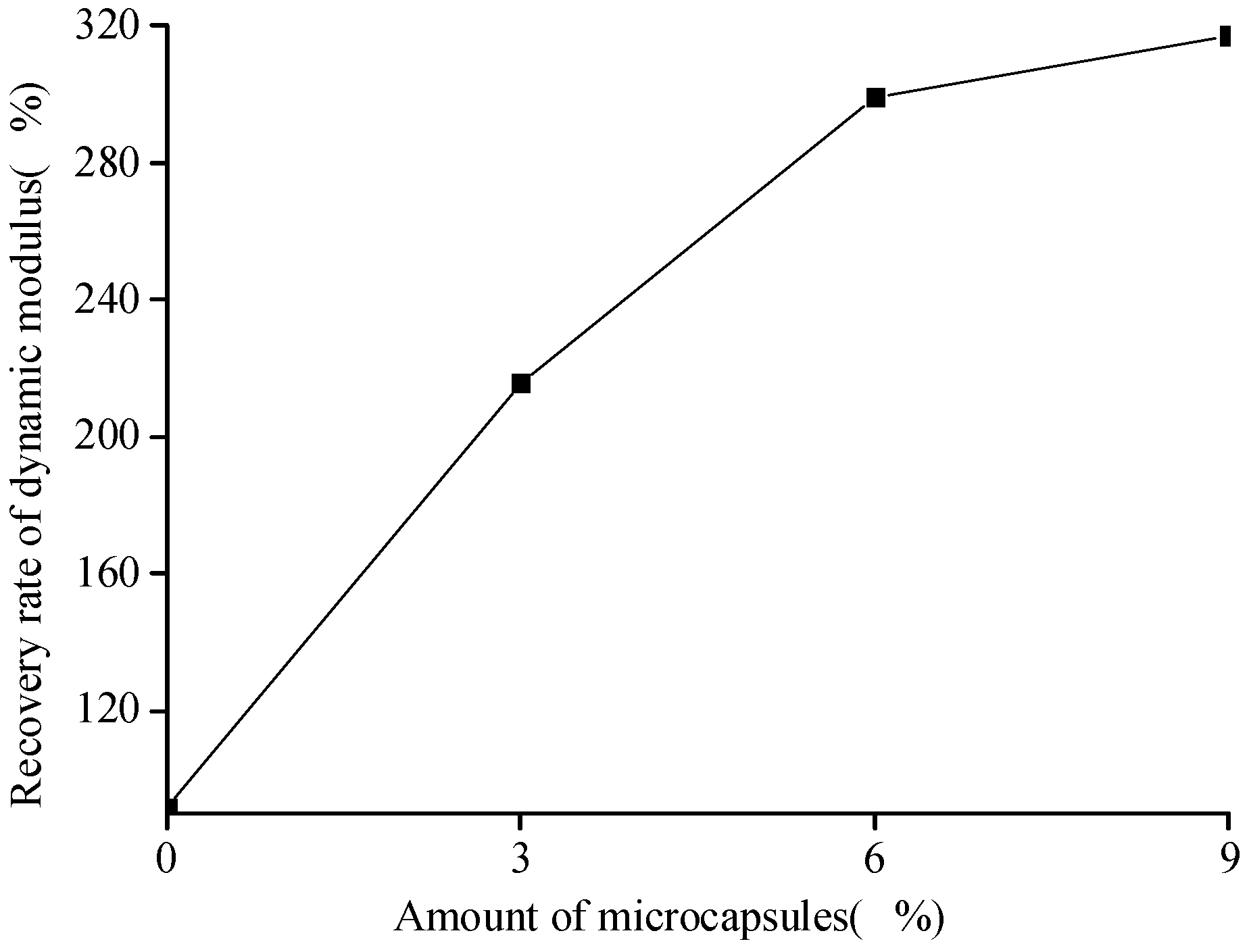

3.2. DMA Results and Discussions

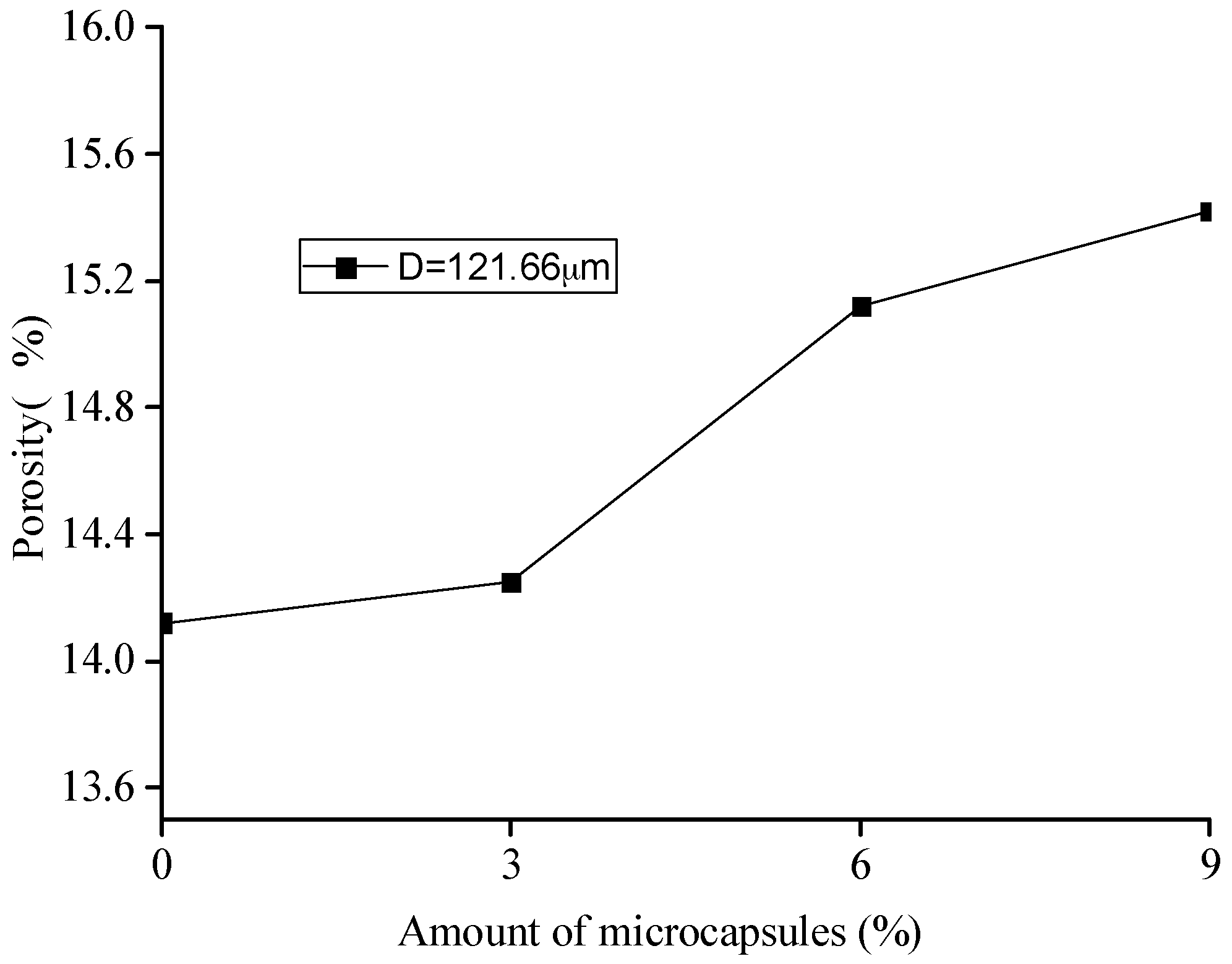

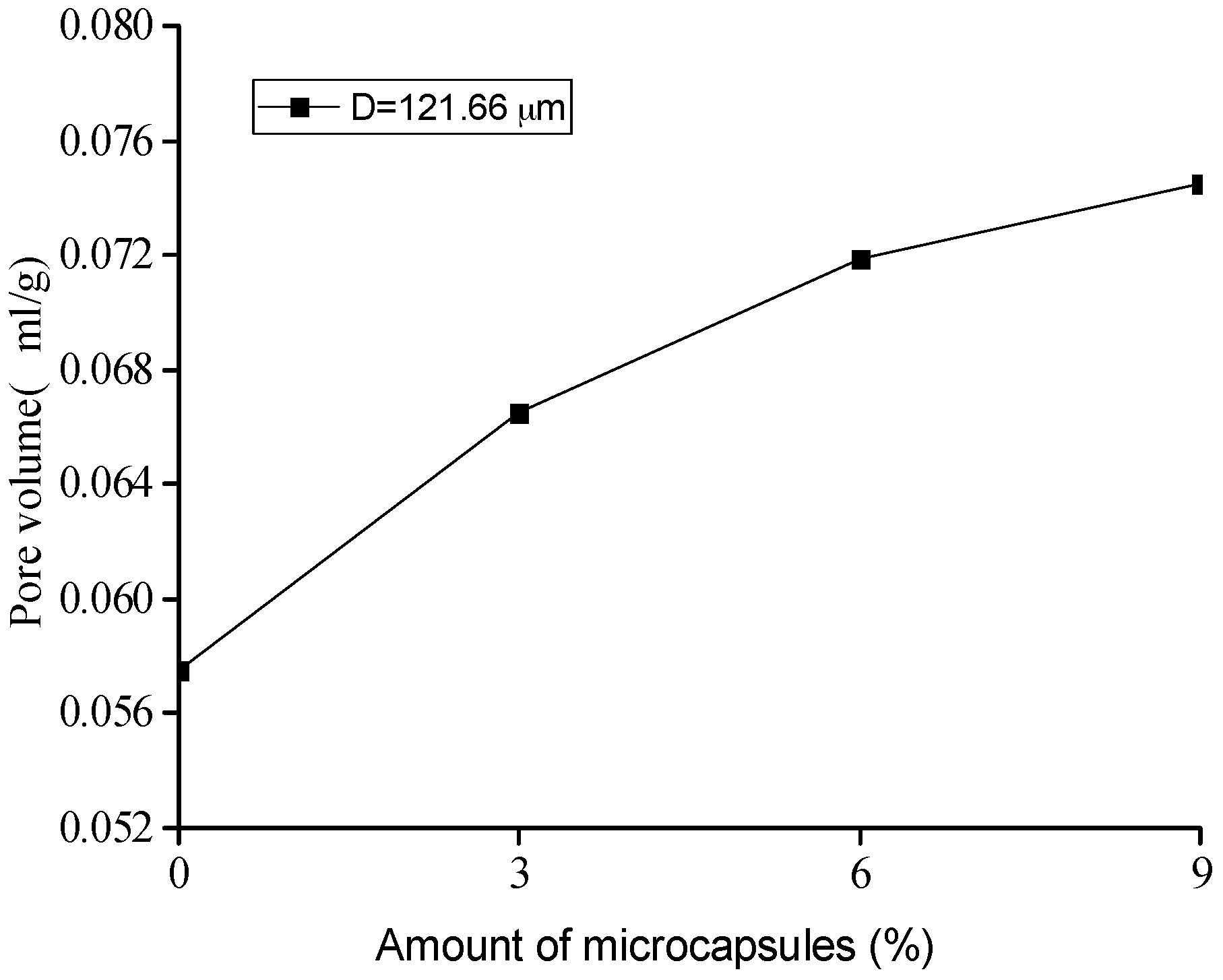

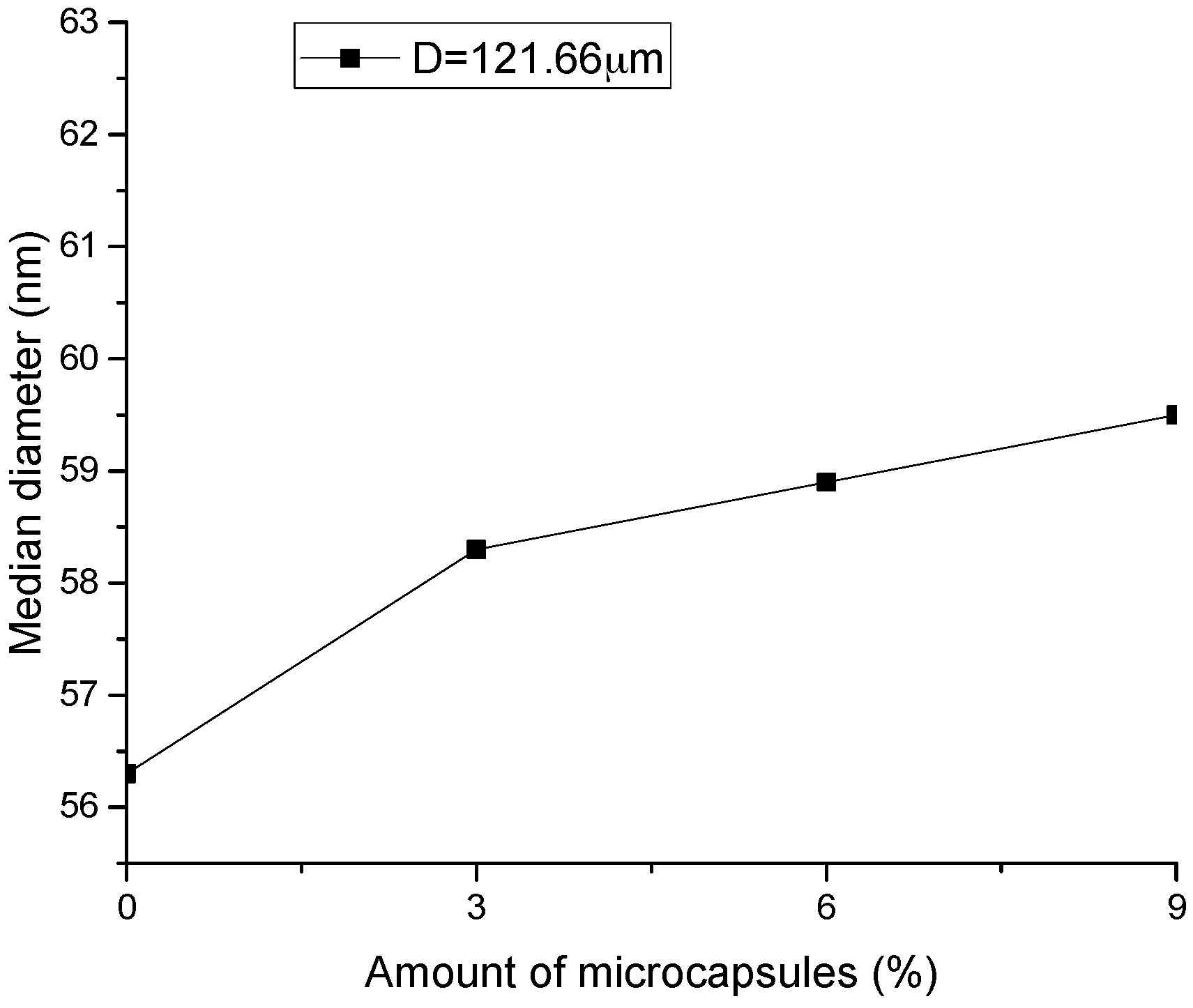

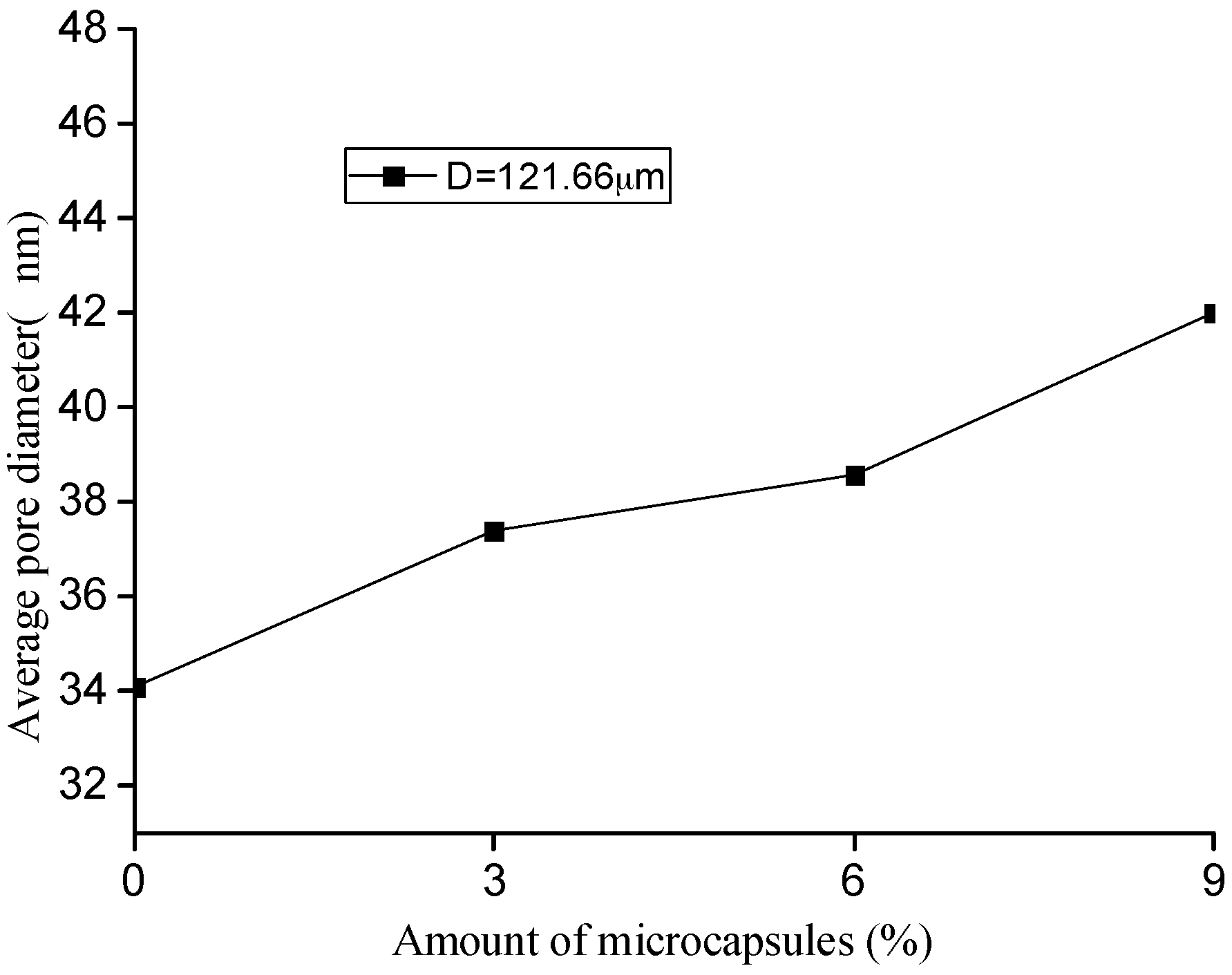

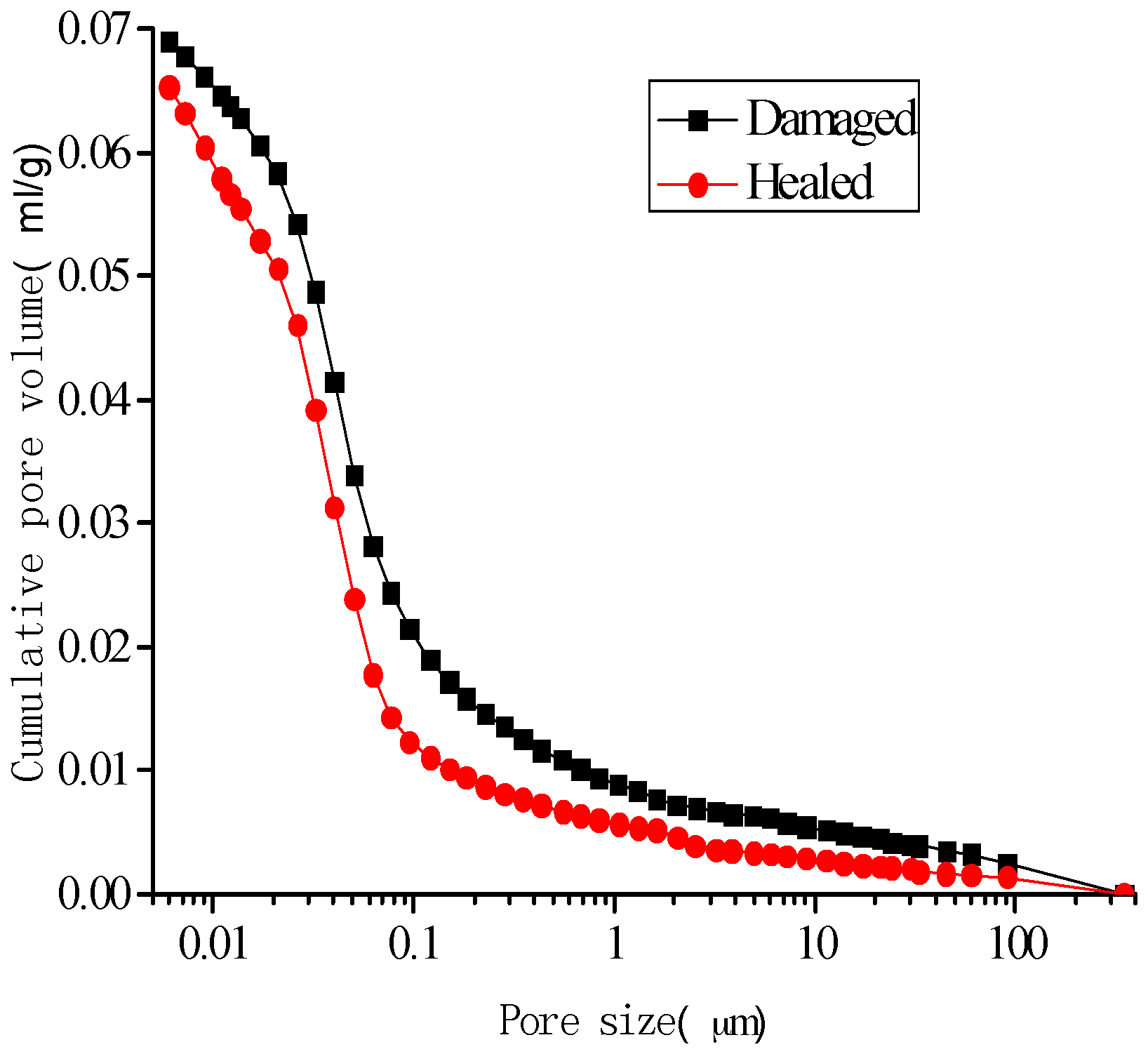

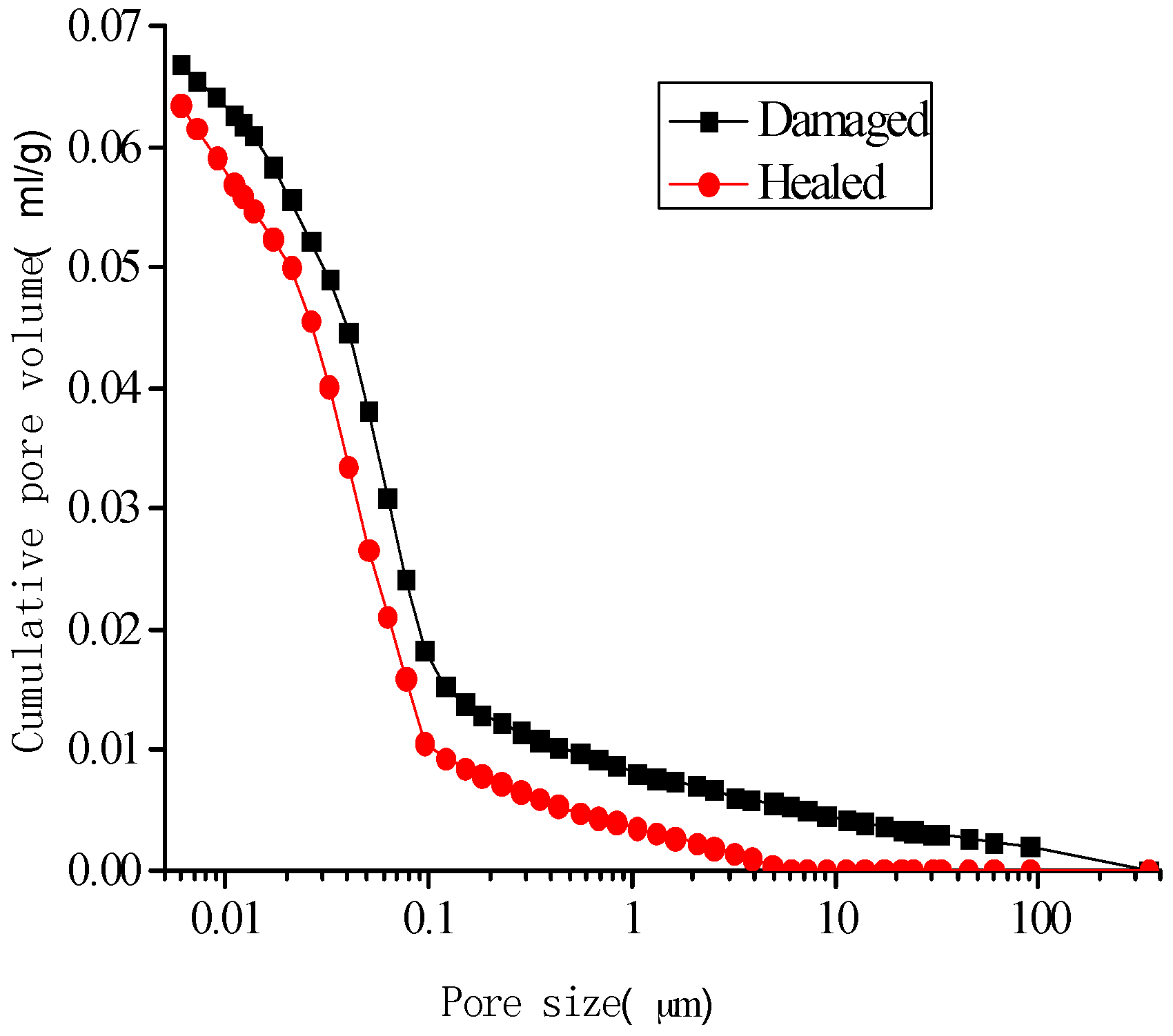

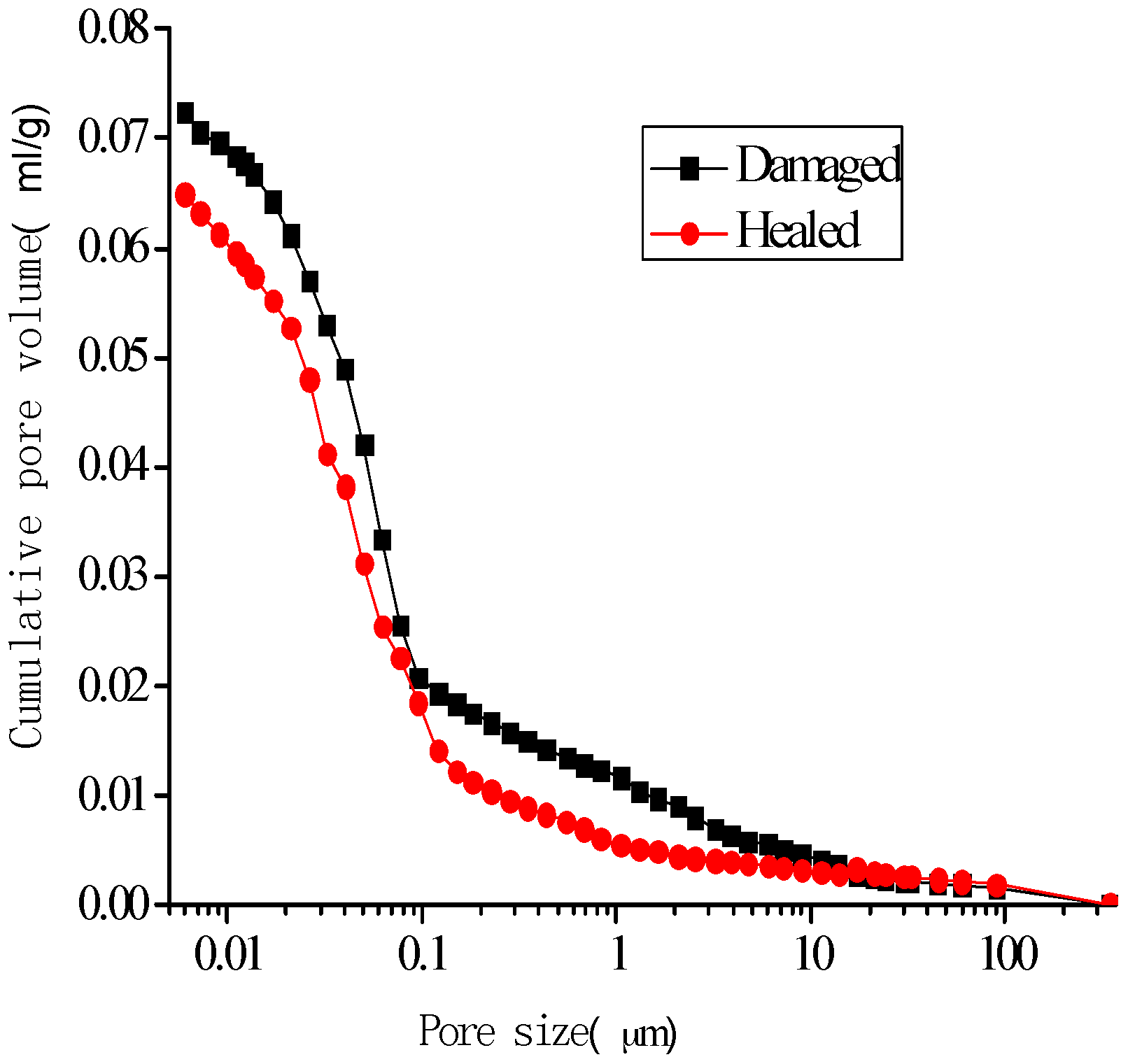

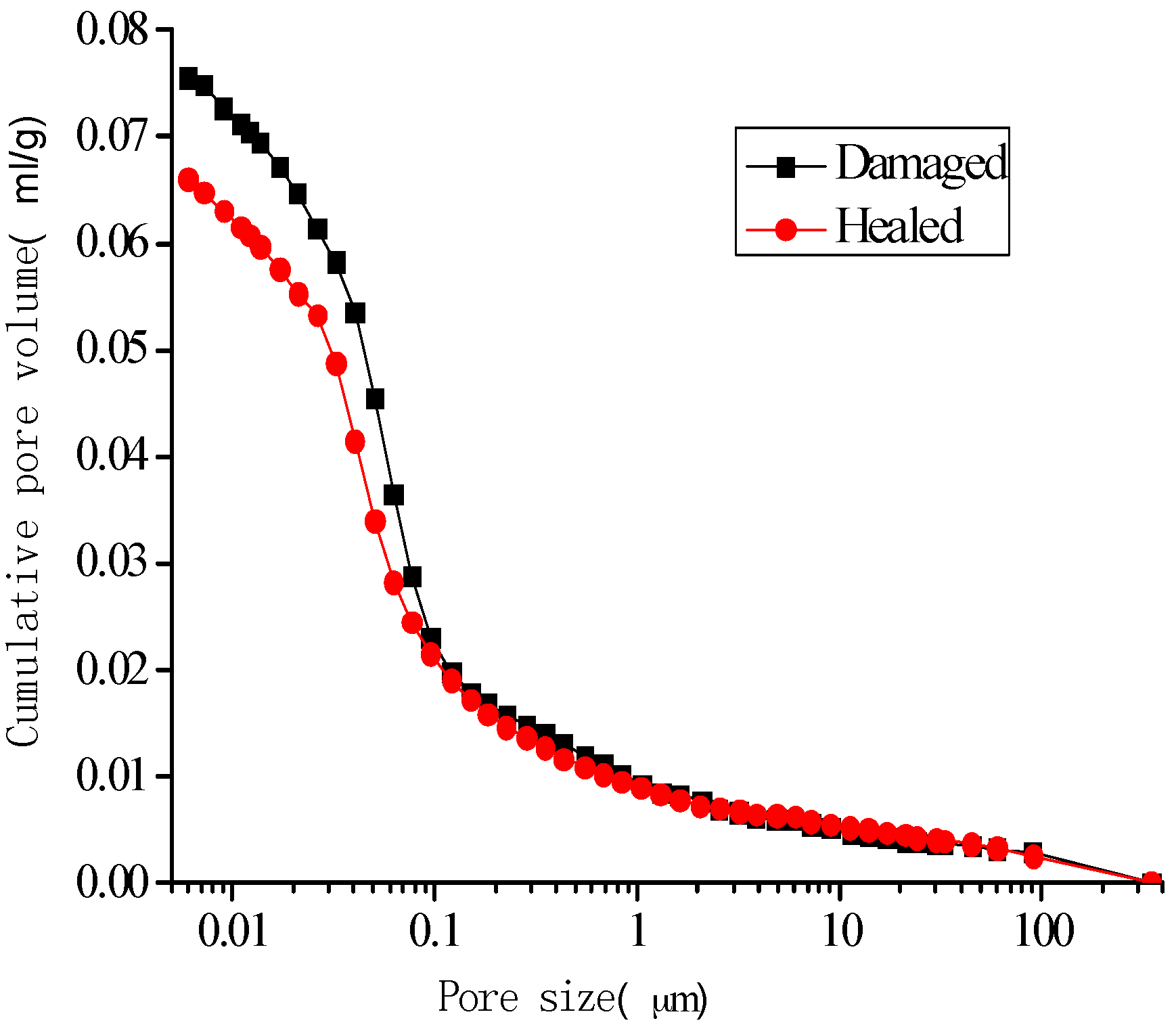

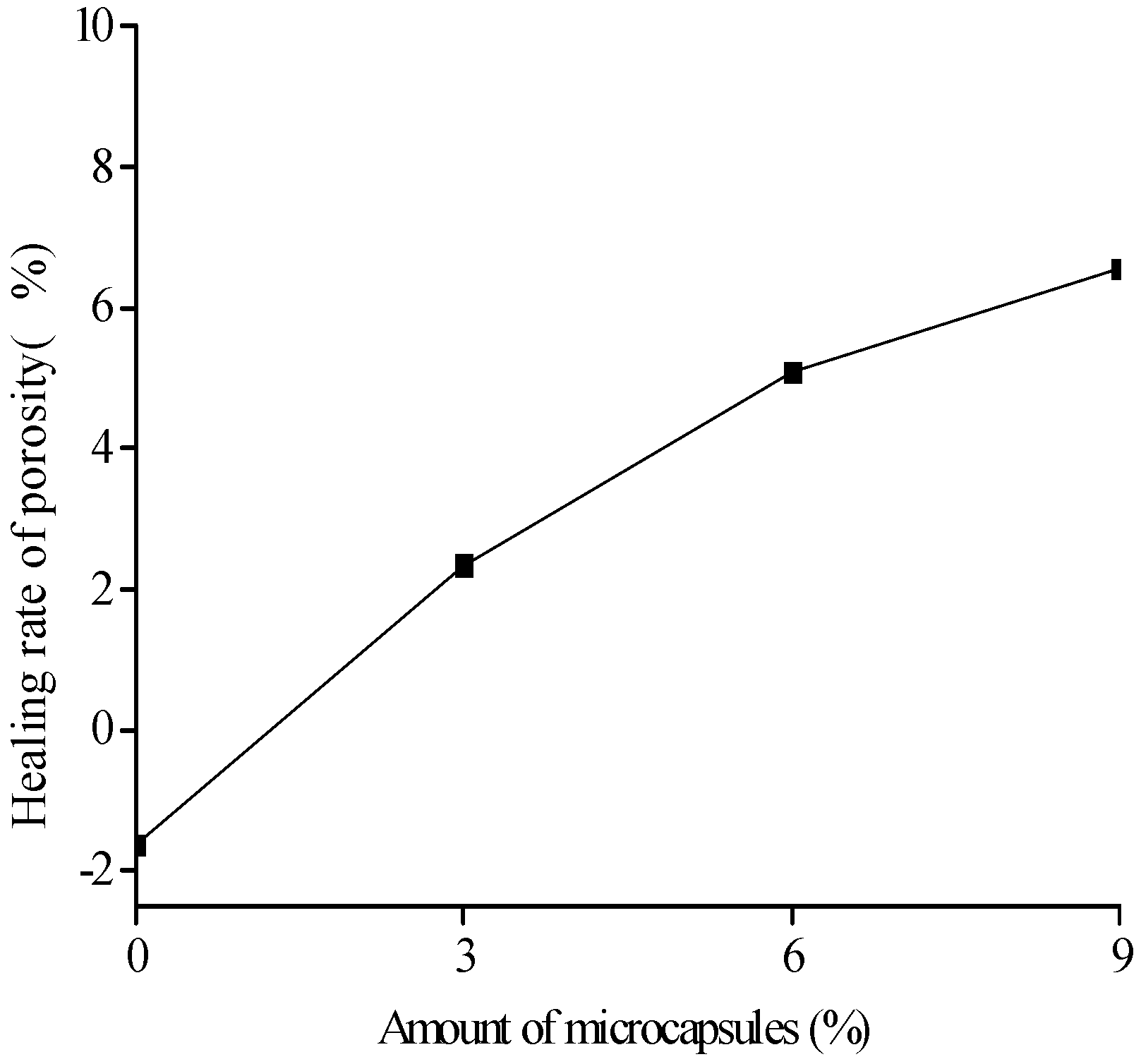

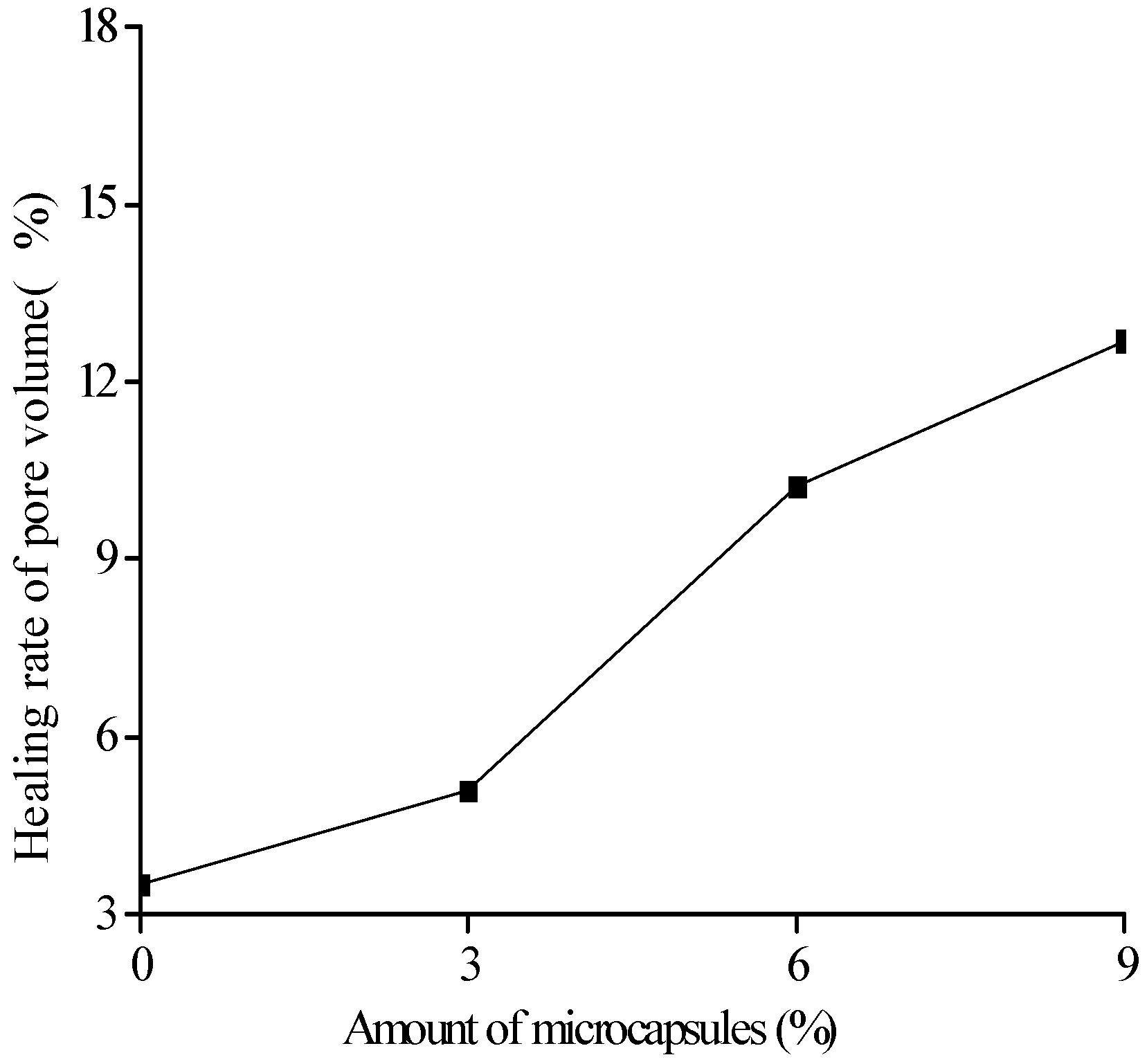

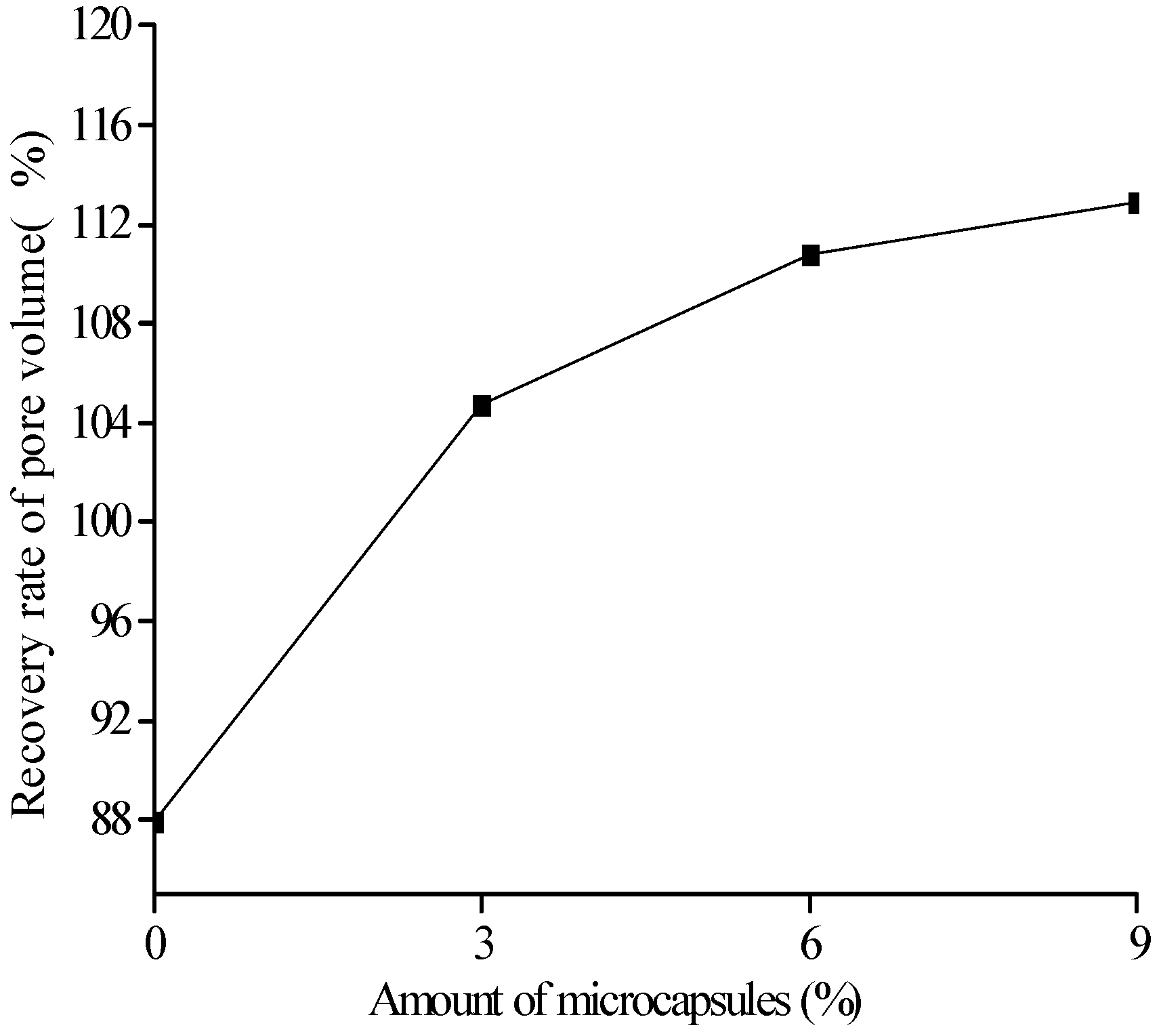

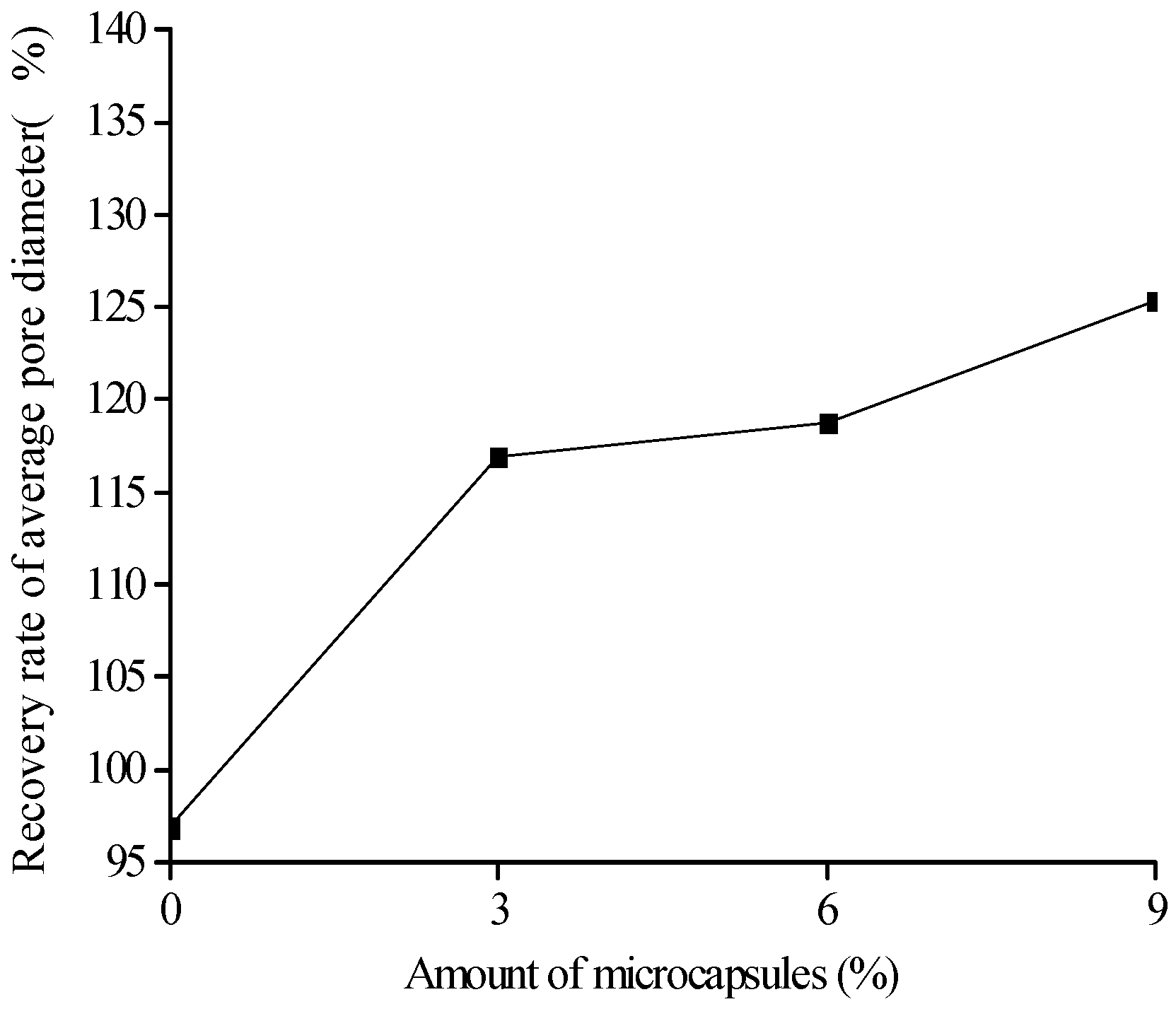

3.3. MIP Results and Discussions

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jonkers, H.M. Self healing concrete: A biological approach. In Self Healing Materials; Springer: Dordrecht, The Netherlands, 2007; Volume 100, pp. 195–204. [Google Scholar]

- Zhang, M. A Study on Microcapsule Based Self-Healing Method and Mechanism for Cementitious Composites. Ph.D. Thesis, Central South University, Changsha, China, June 2013. [Google Scholar]

- Xing, F.; Ni, Z.; Han, N.; Dong, B.; Du, X.; Huang, Z.; Zhang, M. Self-Healing Mechanism of a Novel Cementitious Composite Using Microcapsules. In Proceedings of the International Conference on Durability of Concrete Structures, Hangzhou, China, 26–27 November 2008.

- Victor, C.L.; Yun, M.L.; Yin, W.C. Feasibility study of a passive smart self-healing cementitious composite. Compos. Part B Eng. 1998, 29, 819–827. [Google Scholar]

- Xing, F.; Ni, Z. Self-Repairing Concrete Having Polyurethane Polymer Microcapsules and Method for Fabricating the Same. U.S. Patent No. 8362113 B2, 17 July 2012. [Google Scholar]

- Wang, X.F.; Xing, F.; Zhang, M. Experimental study on cementitious composites embedded with organic microcapsules. Materials 2013, 6, 4064–4081. [Google Scholar] [CrossRef]

- Xiong, W.; Tang, J.; Zhu, G.; Han, N.; Schlangen, E.; Dong, B.; Wang, X.F.; Xing, F. A novel capsule-based self-recovery system with a chloride ion trigger. Sci. Rep. UK 2015, 5, 10866. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.F.; Xing, F.; Xie, Q.; Han, N.X.; Kishi, T.; Ahn, T.H. Mechanical behavior of a capsule embedded in cementitious matrix-macro model and numerical simulation. J. Ceram. Process. Res. 2015, 16, 74s–82s. [Google Scholar]

- Han, N.; Xing, F. Intelligent resilience of cementitious materials for marine infrastructures. J. Ceram. Process. Res. 2015, 16, s14–s21. [Google Scholar]

- Su, J.-F.; Schlangen, E.; Qiu, J. Design and construction of microcapsules containing rejuvenator for asphalt. Powder Technol. 2013, 235, 563–571. [Google Scholar] [CrossRef]

- Su, J.-F.; Wang, Y.-Y.; Han, N.-X.; Yang, P.; Han, S. Experimental investigation and mechanism analysis of novel multi-self-healing behaviors of bitumen using microcapsules containing rejuvenator. Constr. Build. Mater. 2016, 106, 317–329. [Google Scholar] [CrossRef]

- Su, J.-F.; Yang, P.; Wang, Y.-Y.; Han, S.; Han, N.-X.; Li, W. Investigation of the Self-Healing Behaviors of Microcapsules/Bitumen Composites by a Repetitive Direct Tension Test. Materials 2016, 9, 600. [Google Scholar] [CrossRef]

- Dong, B.; Han, N.; Zhang, M.; Wang, X.; Cui, H.; Xing, F. A microcapsule technology based self-healing system for concrete structures. J. Earthq. Tsunami 2013, 7, 1350014. [Google Scholar] [CrossRef]

- Dong, B.; Fang, G.; Ding, W.; Liu, Y.; Zhang, J.; Han, N.; Xing, F. Self-healing features in cementitious material with urea–formaldehyde/epoxy microcapsules. Constr. Build. Mater. 2016, 106, 608–617. [Google Scholar] [CrossRef]

- Dong, B.; Wang, Y.; Fang, G.; Han, N.; Xing, F.; Lu, Y. Smart releasing behavior of a chemical self-healing microcapsule in the stimulated concrete pore solution. Cem. Concr. Compos. 2015, 56, 46–50. [Google Scholar] [CrossRef]

- Lv, L.; Yang, Z.; Chen, G.; Zhu, G.; Han, N.; Schlangen, E.; Xing, F. Synthesis and characterization of a new polymeric microcapsule and feasibility investigation in self-healing cementitious materials. Constr. Build. Mater. 2016, 105, 487–495. [Google Scholar] [CrossRef]

- Wang, J.Y.; Soens, H.; Verstraete, W.; De Belie, N. Self-healing concrete by use of microencapsulated bacterial spores. Cem. Concr. Res. 2014, 56, 139–152. [Google Scholar] [CrossRef]

- Van Stappen, J.; Bultreys, T.; Gilabert, F.A.; Hillewaere, X.K.D.; Gómez, D.G.; Van Tittelboom, K.; Dhaene, J.; De Belie, N.; Van Paepegem, W.; Du Prez, F.E.; et al. The microstructure of capsule containing self-healing materials: A micro-computed tomography study. Mater. Charact. 2016, 119, 99–109. [Google Scholar] [CrossRef]

- Van Breugel, K. Is there a market for self-healing cement-based materials? In Proceedings of the First International Conference on Self-Healing Materials, Noordwijk, The Netherlands, 18–20 April 2007.

- Wu, M.; Johannesson, B.; Geiker, M. A review: Self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Constr. Build. Mater. 2012, 28, 571–583. [Google Scholar] [CrossRef]

- Joseph, C.; Gardner, D.; Jefferson, T.; Isaacs, B.; Lark, B. Self-healing cementitious materials: A review of recent work. Proc. ICE Constr. Mater. 2010, 164, 29–41. [Google Scholar] [CrossRef]

- Mihashi, H.; Nishiwaki, T. Development of engineered self-healing and self-repairing concrete-state-of-the-art report. J. Adv. Concr. Technol. 2012, 10, 170–184. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N. Self-Healing in Cementitious Materials—A Review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef]

- Souradeep, G.; Kua, H. Encapsulation technology and techniques in self-healing concrete. J. Mater. Civ. Eng. 2016, 28. [Google Scholar] [CrossRef]

- Muhammad, N.Z.; Shafaghat, A.; Keyvanfar, A.; Majid, M.Z.A.; Ghoshal, S.K.; Yasouj, S.E.M.; Ganiyu, A.A.; Kouchaksaraei, M.S.; Kamyab, H.; Taheri, M.M.; et al. Tests and methods of evaluating the self-healing efficiency of concrete: A review. Constr. Build. Mater. 2016, 112, 1123–1132. [Google Scholar] [CrossRef]

- De Belie, N.; Van der Zwaag, S.; Gruyaert, E.; Van Tittelboom, K.; Debbaut, B. Self-Healing Materials. In Proceedings of the 4th International Conference on Self-Healing Materials, Ghent, Belgium, 16–20 June 2013.

- Reichert, M.; Craig, S.; Rubinstein, M.; Genzer, J.; Palmese, G.; White, S.; Li, V.; Van der Zwaag, S. Self-Healing Materials. In Proceedings of the 5th International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Guo, J.F. The Theoretical Research of Pore Structure and the Strength of Concrete. Master’s Thesis, Zhejiang University, Hangzhou, China, June 2004. [Google Scholar]

- Lian, H.Z. Building Materials Phase Research Foundation; Tsinghua University Press: Beijing, China, 1996. [Google Scholar]

- Abell, A.B.; Willis, K.L.; Lange, D.A. Mercury intrusion porosimetry and image analysis of cement-based materials. J. Colloid Interface Sci. 1999, 211, 39–44. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Liu, F.; Mu, W.; Han, Z.R. Factors Affecting Morphology and Encapsulation Ratio of Chlorpyrifos Microcapsules with UF-resin During Preparation. Chin. J. Appl. Chem. 2007, 24, 589–592. [Google Scholar]

- Standardization Administration of China. Common Portland Cement; GB 175-2007; SAC: Beijing, China, 2007. [Google Scholar]

- International Standard Organization (ISO). Method of Testing Cements—Determination of Strength ISO 679; ISO: Geneva, Switzerland, 1989. [Google Scholar]

- Sun, P. Study on Strength and Pore Structure of Microcapsules Based Self-Healing Cementitious Composites. Master’s Thesis, Shenzhen University, Shenzhen, China, May 2016. [Google Scholar]

| Rotation Velocity in Synthesis (r/min) | Mean Diameter (μm) | Wall Thickness (μm) | Capsule Core Content (%) |

|---|---|---|---|

| 600 | 121.66 | 5.46 | 67.8 |

| Sample No. | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Particle diameter (μm) | N/A | 121.66 | 121.66 | 121.66 |

| Microcapsule content (to cement mass) | 0% | 3% | 6% | 9% |

| Sample No. | 1 | 2 | 3 | 4 | Test Type | |

|---|---|---|---|---|---|---|

| No. | ||||||

| 1 | 1-1-1 | 2-1-1 | 3-1-1 | 4-1-1 | Compression test, | |

| 2 | 1-1-2 | 2-1-2 | 3-1-2 | 4-1-2 | DMA, MIP test | |

| 3 | 1-2-1 | 2-2-1 | 3-2-1 | 4-2-1 | DMA test | |

| 4 | 1-2-2 | 2-2-2 | 3-2-2 | 4-2-2 | MIP test to damaged sample | |

| 5 | 1-3-1 | 2-3-1 | 3-3-1 | 4-3-1 | Compression test to healed sample | |

| 6 | 1-3-2 | 2-3-2 | 3-3-2 | 4-3-2 | DMA, MIP test | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Sun, P.; Han, N.; Xing, F. Experimental Study on Mechanical Properties and Porosity of Organic Microcapsules Based Self-Healing Cementitious Composite. Materials 2017, 10, 20. https://doi.org/10.3390/ma10010020

Wang X, Sun P, Han N, Xing F. Experimental Study on Mechanical Properties and Porosity of Organic Microcapsules Based Self-Healing Cementitious Composite. Materials. 2017; 10(1):20. https://doi.org/10.3390/ma10010020

Chicago/Turabian StyleWang, Xianfeng, Peipei Sun, Ningxu Han, and Feng Xing. 2017. "Experimental Study on Mechanical Properties and Porosity of Organic Microcapsules Based Self-Healing Cementitious Composite" Materials 10, no. 1: 20. https://doi.org/10.3390/ma10010020