Photovoltaic Performance Characterization of Textured Silicon Solar Cells Using Luminescent Down-Shifting Eu-Doped Phosphor Particles of Various Dimensions

Abstract

:1. Introduction

2. Experiment

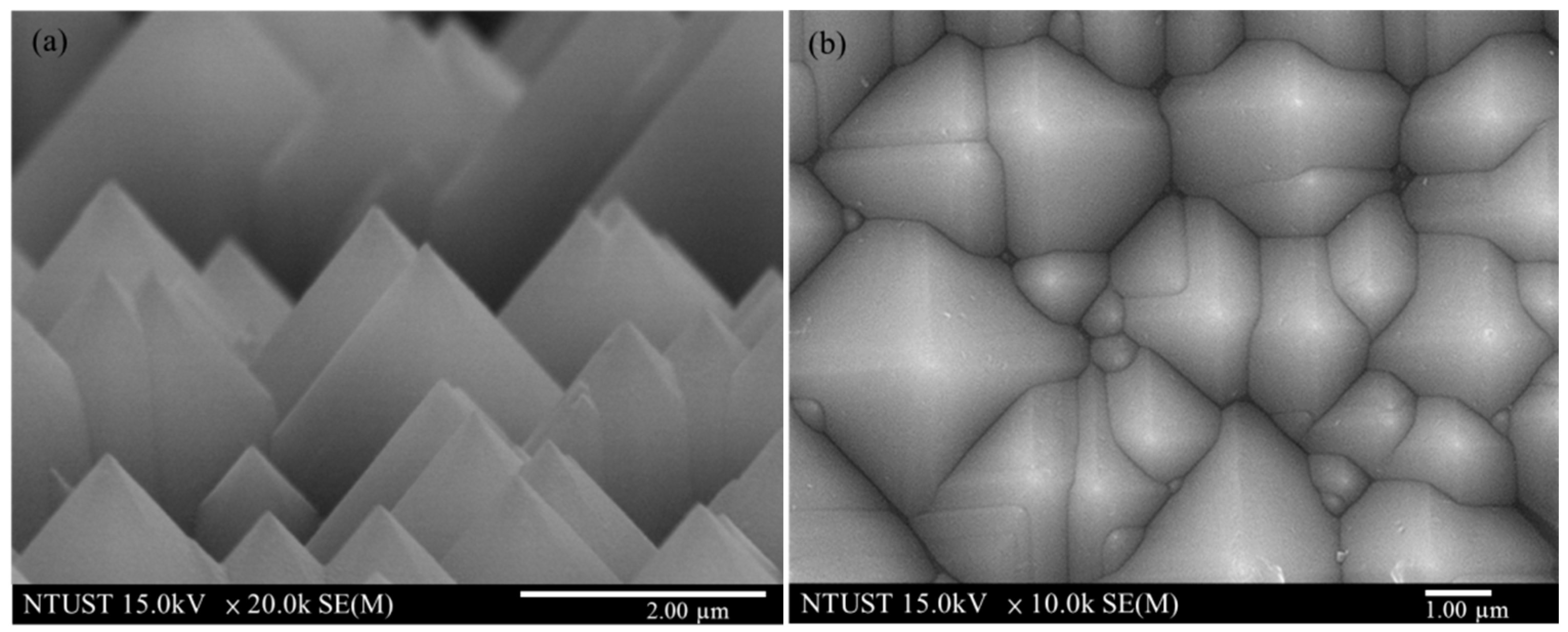

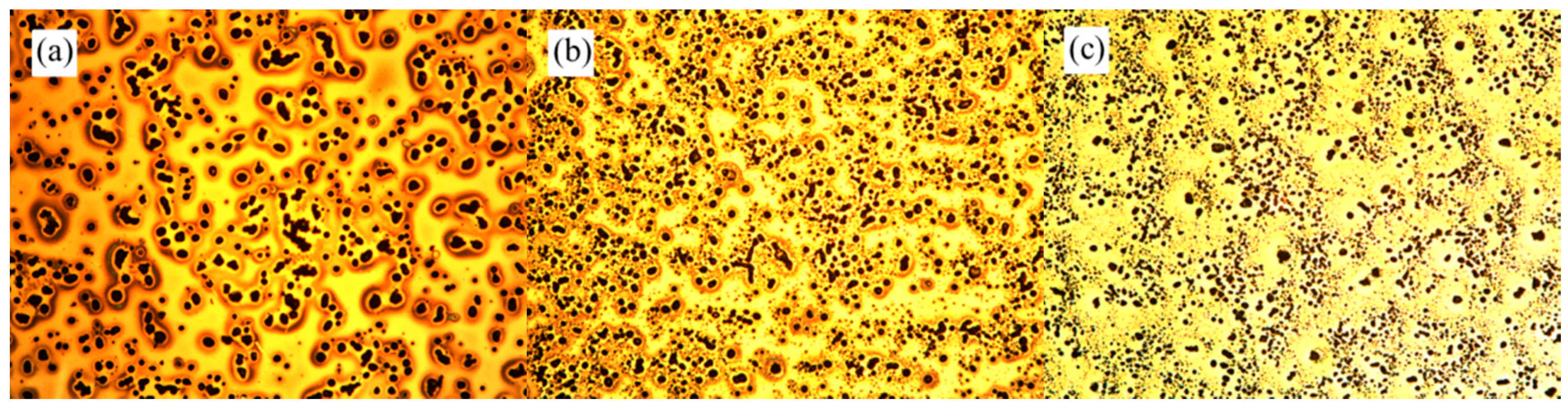

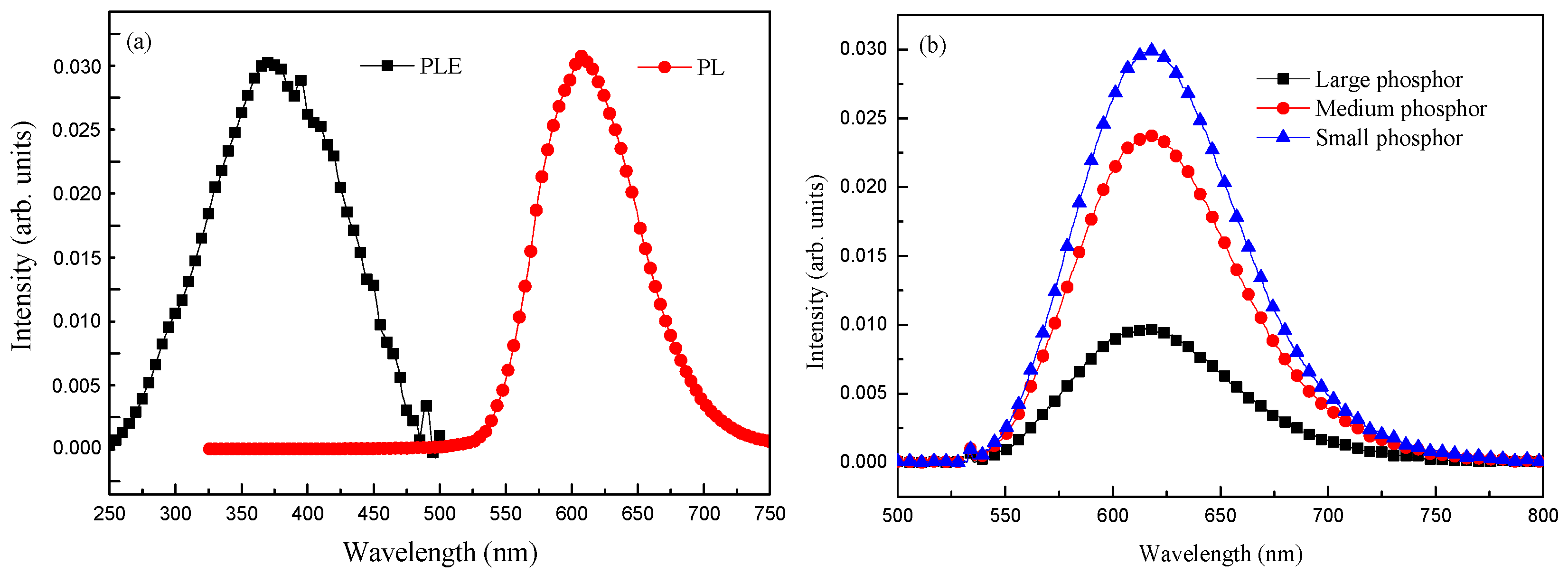

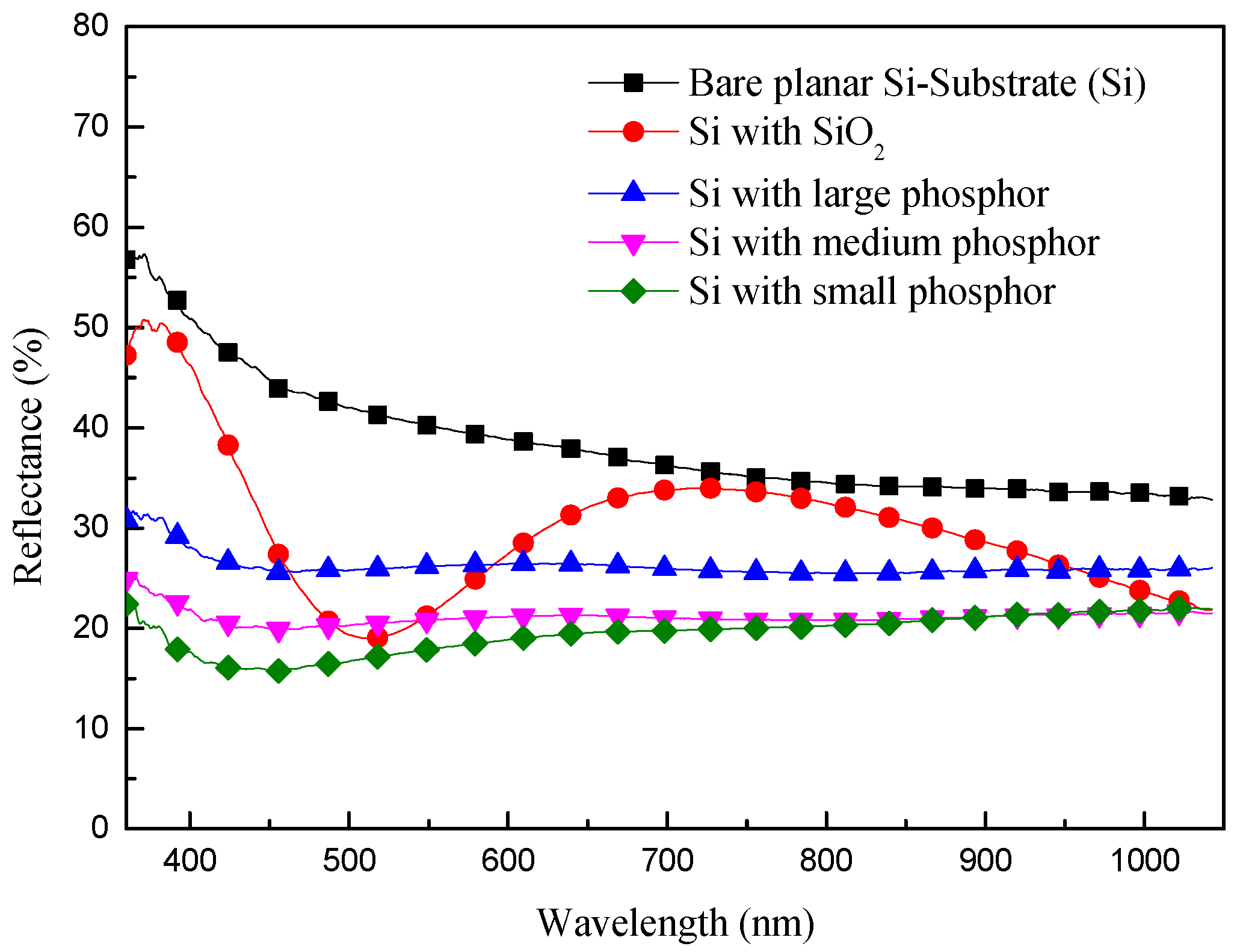

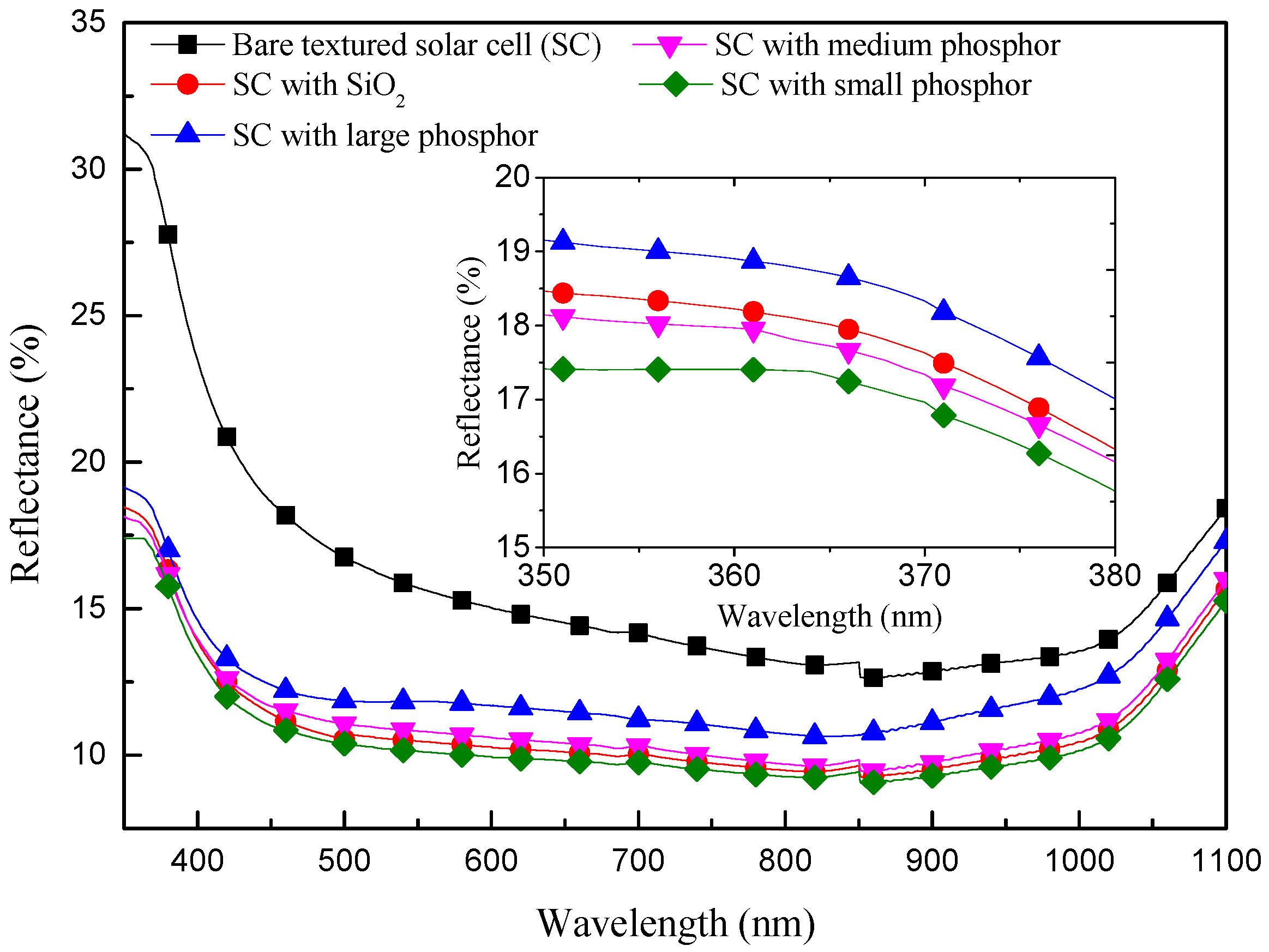

2.1. Characterization of Eu-Doped Silicate Phosphor Layer

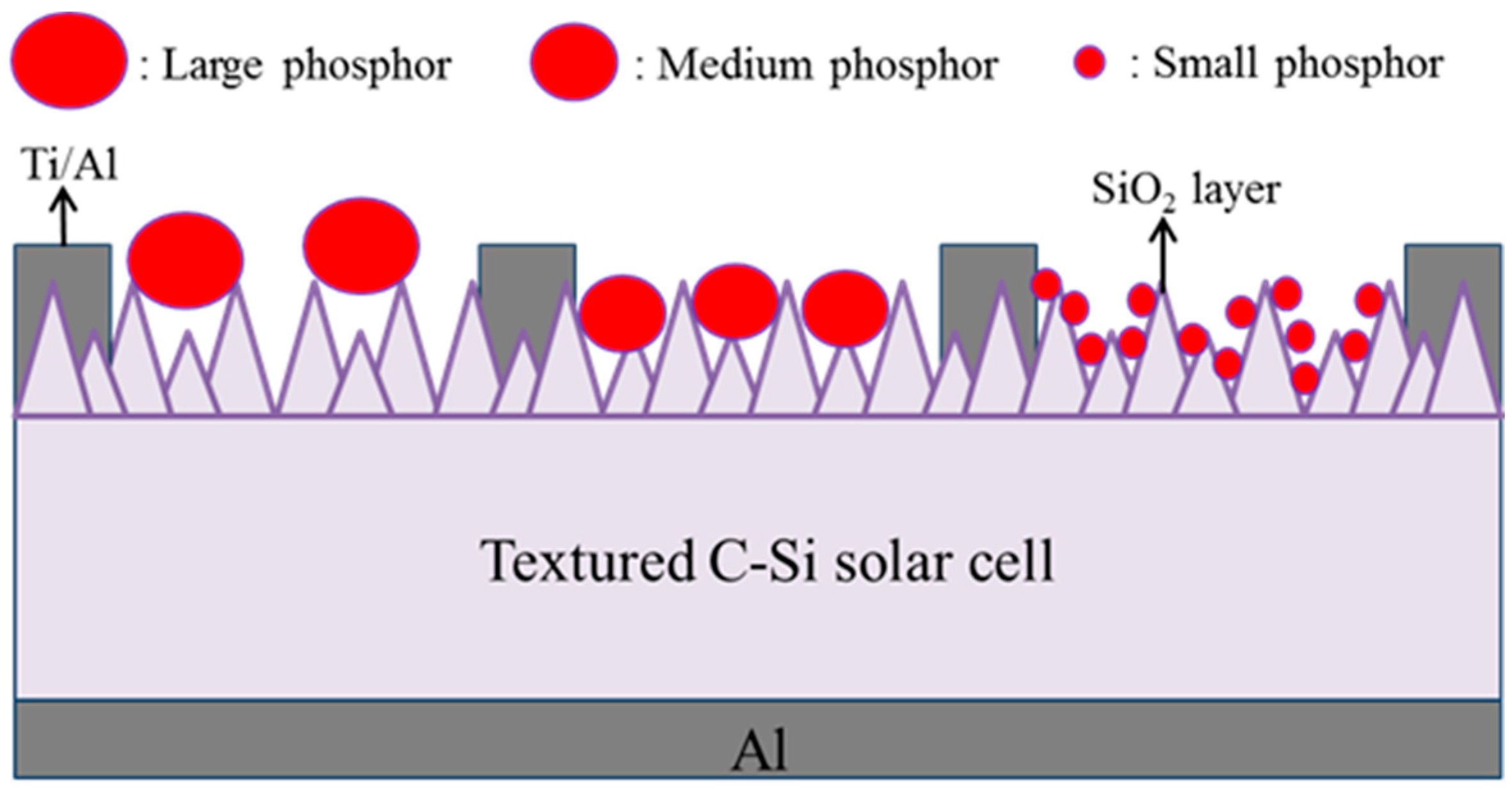

2.2. Fabrication and Characterization of Textured C-Si Solar Cells Coated with a Eu-Doped Phosphor Layer

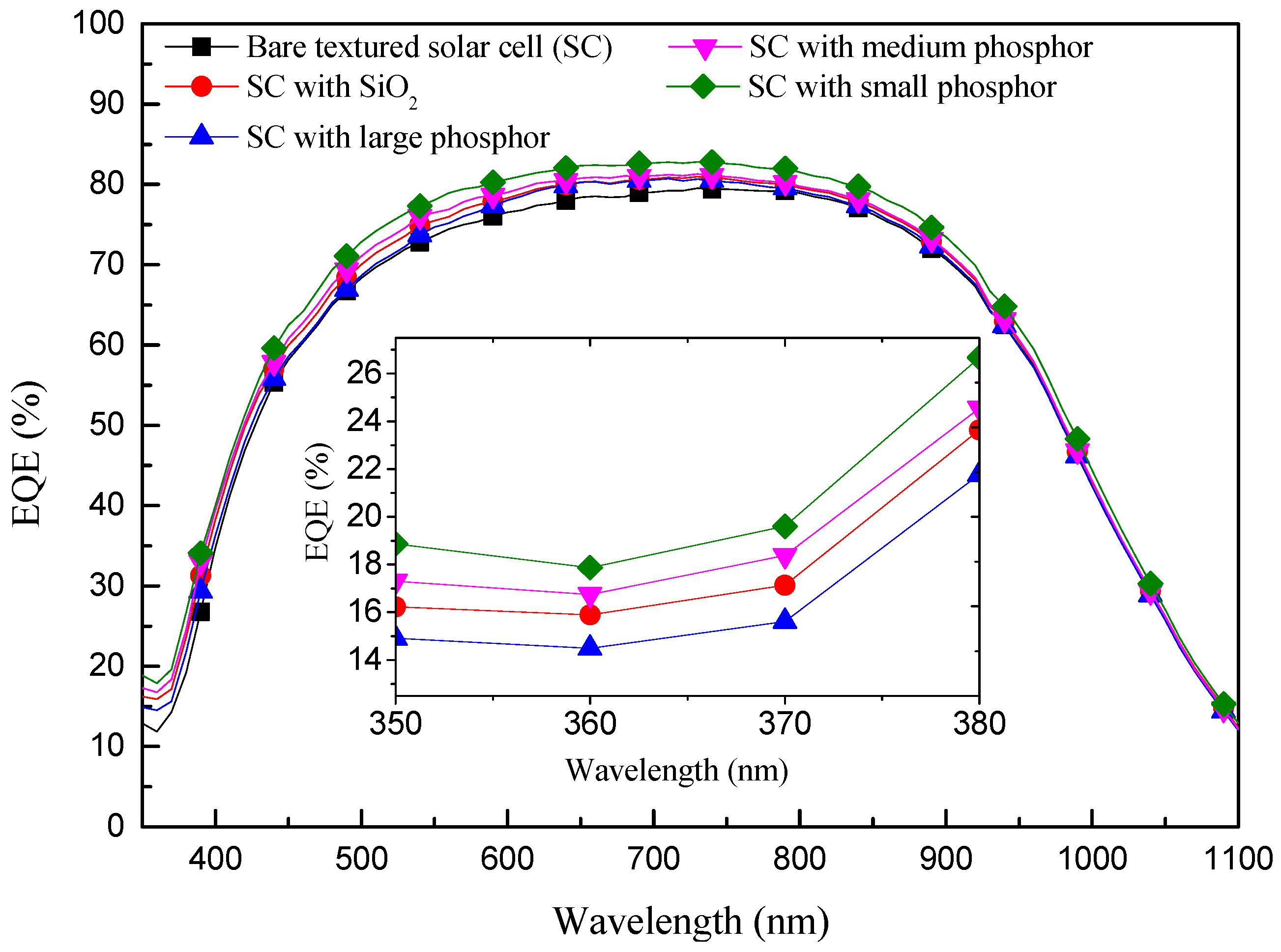

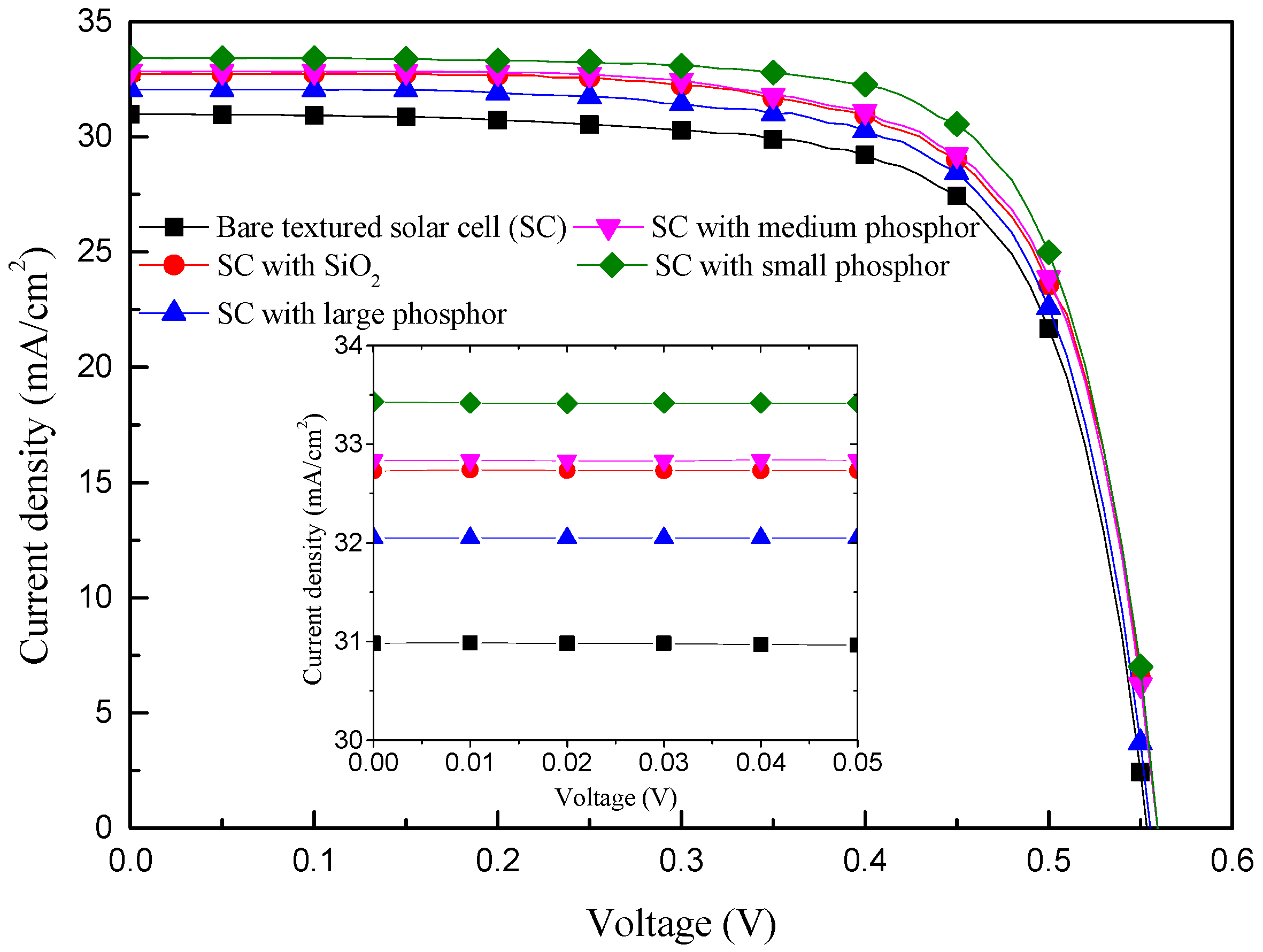

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shockley, W.; Queisser, H.J. Detailed balance limit of efficiency of p-n junction solar cells. J. Appl. Phys. 1961, 32, 510–519. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, A.; Green, M.A. 24.5% Efficiency silicon PERT cells on MCZ substrates and 24.7% efficiency PERL cells on FZ substrates. Prog. Photovolt. Res. Appl. 1999, 7, 471–474. [Google Scholar] [CrossRef]

- Wolf, M. New look at silicon solar cell performance. Energy Convers. 1971, 11, 63–73. [Google Scholar] [CrossRef]

- Huang, X.; Han, S.; Huang, W.; Liu, X. Enhancing solar cell efficiency: The search for luminescent materials as spectral converters. Chem. Soc. Rev. 2013, 42, 173–201. [Google Scholar] [CrossRef] [PubMed]

- Richards, B.S. Enhancing the performance of silicon solar cells via the application of passive luminescence conversion layers. Sol. Energy Mater. Sol. Cells 2006, 90, 2329–2337. [Google Scholar] [CrossRef]

- Liu, M.; Lei, F.; Jiang, N.; Zheng, Q.; Lin, D. Enhanced piezoelectricity, bright up-conversion and down-conversion photoluminescence in Er3+ doped 0.94(BiNa)0.5TiO3−0.06BaTiO3 multifunctional ceramics. Mater. Res. Bull. 2016, 74, 62–69. [Google Scholar] [CrossRef]

- Mahalingam, V.; Thirumalai, J.; Krishnan, R.; Mantha, S. Up/down conversion luminescence and charge compensation investigation of Ca0.5Y1−x(WO4)2:xLn3+ (Ln = Pr, Sm, Eu, Tb, Dy, Yb/Er) phosphors. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2016, 152, 172–180. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Sun, J.; Liu, J.; Li, X.; Zhang, J.; Tian, Y.; Fu, S.; Cheng, L.; Zhong, H.; Xia, H.; et al. Pumping-route-dependent concentration quenching and temperature effect of green up- and down-conversion luminescence in Er3+/Yb3+ co-doped Gd2(WO4)3 phosphors. Mater. Res. Bull. 2013, 48, 2159–2165. [Google Scholar] [CrossRef]

- Li, Y.; Wang, G.; Pan, K.; Qu, Y.; Liu, S.; Feng, L. Formation and down/up conversion luminescence of Ln3+ doped NaY(MoO4)2 microcrystals. Dalton Trans. 2013, 42, 3366–3372. [Google Scholar] [CrossRef] [PubMed]

- Ren, L.W.; Wang, G.F.; Cui, J.Y.; Li, Y.; Fan, N.Y.; Pan, K.; Liu, S.; Feng, L. Effect of pH value on synthesis of NaYW2O8:Ln3+ microcrystals with tunable up/down conversion luminescence. Chin. J. Inorg. Chem. 2013, 29, 2631–2636. [Google Scholar]

- Tamrakar, R.K.; Bisen, D.P.; Upadhyay, K.; Bramhe, N. Down-conversion luminescence property of Er3+ and Yb3+ co-doped Gd2O3 crystals prepared by combustion synthesis and solid state reaction method. Superlattices Microstruct. 2015, 81, 34–48. [Google Scholar] [CrossRef]

- Rakov, N.; Guimarães, R.B.; Maciel, G.S. Photon up-conversion production in Tb3+–Yb3+ co-doped CaF2 phosphors prepared by combustion synthesis. Mater. Res. Bull. 2016, 74, 103–108. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, N.; Xu, L.; Jiao, H. Color-tunable up-conversion emission from Yb3+/Er3+/Tm3+ tri-doped T-AgGd(W, Mo)2O8 phosphors. Mater. Res. Bull. 2016, 73, 171–178. [Google Scholar] [CrossRef]

- Chander, N.; Khan, A.F.; Chandrasekhar, P.S.; Thouti, E.; Swami, S.K.; Dutta, V.; Komarala, V.K. Reduced ultraviolet light induced degradation and enhanced light harvesting using YVO4:Eu3+ down-shifting nano-phosphor layer in organometal halide perovskite solar cells. Appl. Phys. Lett. 2014, 105, 033904-1–033904-5. [Google Scholar] [CrossRef]

- Shehata, N.; Clavel, M.; Meehan, K.; Samir, E.; Gaballah, S.; Salah, M. Enhanced erbium-doped ceria nanostructure coating to improve solar cell performance. Materials 2015, 8, 7663–7672. [Google Scholar] [CrossRef]

- Griffini, G.; Bella, F.; Nisic, F.; Dragonetti, C.; Roberto, D.; Levi, M.; Bongiovanni, R.; Turri, S. Multifunctional luminescent down-shifting fluoropolymer coatings: A straightforward strategy to improve the UV-light harvesting ability and long-term outdoor stability of organic dye-sensitized solar cells. Adv. Energy Mater. 2015, 5, 1041312. [Google Scholar] [CrossRef]

- Chander, N.; Sardana, S.K.; Parashar, P.K.; Khan, A.F.; Chawla, S.; Komarala, V.K. Improving the short-wavelength spectral response of silicon solar cells by spray deposition of YVO4:Eu3+ downshifting phosphor nanoparticles. IEEE J. Photovolt. 2015, 5, 1373–1379. [Google Scholar] [CrossRef]

- Han, H.V.; Lin, C.C.; Lin, W.Y.; Tsai, Y.L.; Shen, T.L.; Kuo, H.C.; Yu, P. Enhance current density and power conversion efficiency in solar cells by using luminescent downshifting phosphors. In Proceedings of the 40th IEEE Photovoltaic Specialist Conference, Denver, CO, USA, 8–13 June 2014; pp. 22–24.

- Huang, C.K.; Chen, Y.C.; Hung, W.B.; Chen, T.M.; Sun, K.W.; Chang, W.L. Enhanced light harvesting of Si solar cells via luminescent down-shifting using YVO4:Bi3+, Eu3+ nanophosphors. Prog. Photovolt. Res. Appl. 2013, 21, 1507–1513. [Google Scholar] [CrossRef]

- Hung, W.B.; Chen, J.Y.; Sung, K.W.; Chen, T.M. Enhanced conversion efficiency of crystalline Si solar cells via luminescent down-shifting using Ba2SiO4:Eu2+ phosphor. J. Ceram. Process. Res. 2014, 15, 157–161. [Google Scholar]

- Shao, G.; Lou, C.; Xiao, D. Enhancing the efficiency of solar cells by down shifting YAG:Ce3+ phosphors. J. Lumin. 2015, 157, 344–348. [Google Scholar] [CrossRef]

- Hodgson, S.D.; Brooks, W.S.M.; Clayton, A.J.; Kartopu, G.; Lamb, D.A.; Barrioz, V.; Irvine, S.J.C. Increased conversion efficiency in cadmium telluride photovoltaics by luminescent downshifting with quantum dot/poly(methyl methacrylate) films. Prog. Photovolt. Res. Appl. 2015, 23, 150–159. [Google Scholar] [CrossRef]

- Kennedy, M.; Ahmed, H.; Doran, J.; Norton, B.; Bosch-Jimenez, P.; Della Pirriera, M.; Torralba-Calleja, E.; Gutiérrez Tauste, D.; Aubouy, L.; Daren, S.; et al. Large Stokes shift downshifting Eu(III) films as efficiency enhancing UV blocking layers for dye sensitized solar cells. Phys. Status Solidi A 2015, 212, 203–210. [Google Scholar] [CrossRef] [Green Version]

- Sgrignuoli, F.; Ingenhoven, P.; Pucker, G.; Mihailetchi, V.D.; Froner, E.; Jestin, Y.; Moser, E.; Sànchez, G.; Pavesi, L. Purcell effect and luminescent downshifting in silicon nanocrystals coated back-contact solar cells. Sol. Energy Mater. Sol. Cells 2015, 132, 267–274. [Google Scholar] [CrossRef]

- Cheng, Z.; Pan, L.; Su, F.; Cao, M.; Sun, Z. Eu3+ doped silica film as luminescent down-shifting layer for crystalline Si solar cells. Surf. Rev. Lett. 2009, 16, 669–673. [Google Scholar] [CrossRef]

| Cell Type | EQEW (%) |

|---|---|

| Bare Textured Cell (SC) | 67.31 |

| SC with a SiO2 Layer | 68.83 |

| SC with Large Phosphor Particles | 68.53 |

| SC with Medium Phosphor Particles | 69.41 |

| SC with Small Phosphor Particles | 70.91 |

| Cell Type | Jsc (mA/cm2) | Voc (mV) | FF (%) | η (%) |

|---|---|---|---|---|

| Bare Textured Cell (SC) | 30.98 | 554.93 | 72.94 | 12.54 |

| SC with a SiO2 Layer | 32.73 | 559.40 | 72.75 | 13.32 |

| Bare Textured Cell (SC) | 30.67 | 554.51 | 72.74 | 12.37 |

| SC with Large Phosphor Particles | 32.05 | 556.67 | 72.70 | 12.98 |

| Bare Textured Cell (SC) | 30.75 | 556.98 | 72.51 | 12.43 |

| Cell with Medium Phosphor Particles | 32.83 | 559.34 | 72.75 | 13.36 |

| Bare Textured Cell (SC) | 30.62 | 557.07 | 73.61 | 12.56 |

| SC with Small Phosphor Particles | 33.43 | 560.77 | 73.94 | 13.86 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, W.-J.; Deng, Y.-J.; Liu, J.-J.; Feng, S.-K.; Lin, J.-C. Photovoltaic Performance Characterization of Textured Silicon Solar Cells Using Luminescent Down-Shifting Eu-Doped Phosphor Particles of Various Dimensions. Materials 2017, 10, 21. https://doi.org/10.3390/ma10010021

Ho W-J, Deng Y-J, Liu J-J, Feng S-K, Lin J-C. Photovoltaic Performance Characterization of Textured Silicon Solar Cells Using Luminescent Down-Shifting Eu-Doped Phosphor Particles of Various Dimensions. Materials. 2017; 10(1):21. https://doi.org/10.3390/ma10010021

Chicago/Turabian StyleHo, Wen-Jeng, Yu-Jie Deng, Jheng-Jie Liu, Sheng-Kai Feng, and Jian-Cheng Lin. 2017. "Photovoltaic Performance Characterization of Textured Silicon Solar Cells Using Luminescent Down-Shifting Eu-Doped Phosphor Particles of Various Dimensions" Materials 10, no. 1: 21. https://doi.org/10.3390/ma10010021