Thermo-Mechanical Fatigue Crack Growth of RR1000

Abstract

:1. Introduction

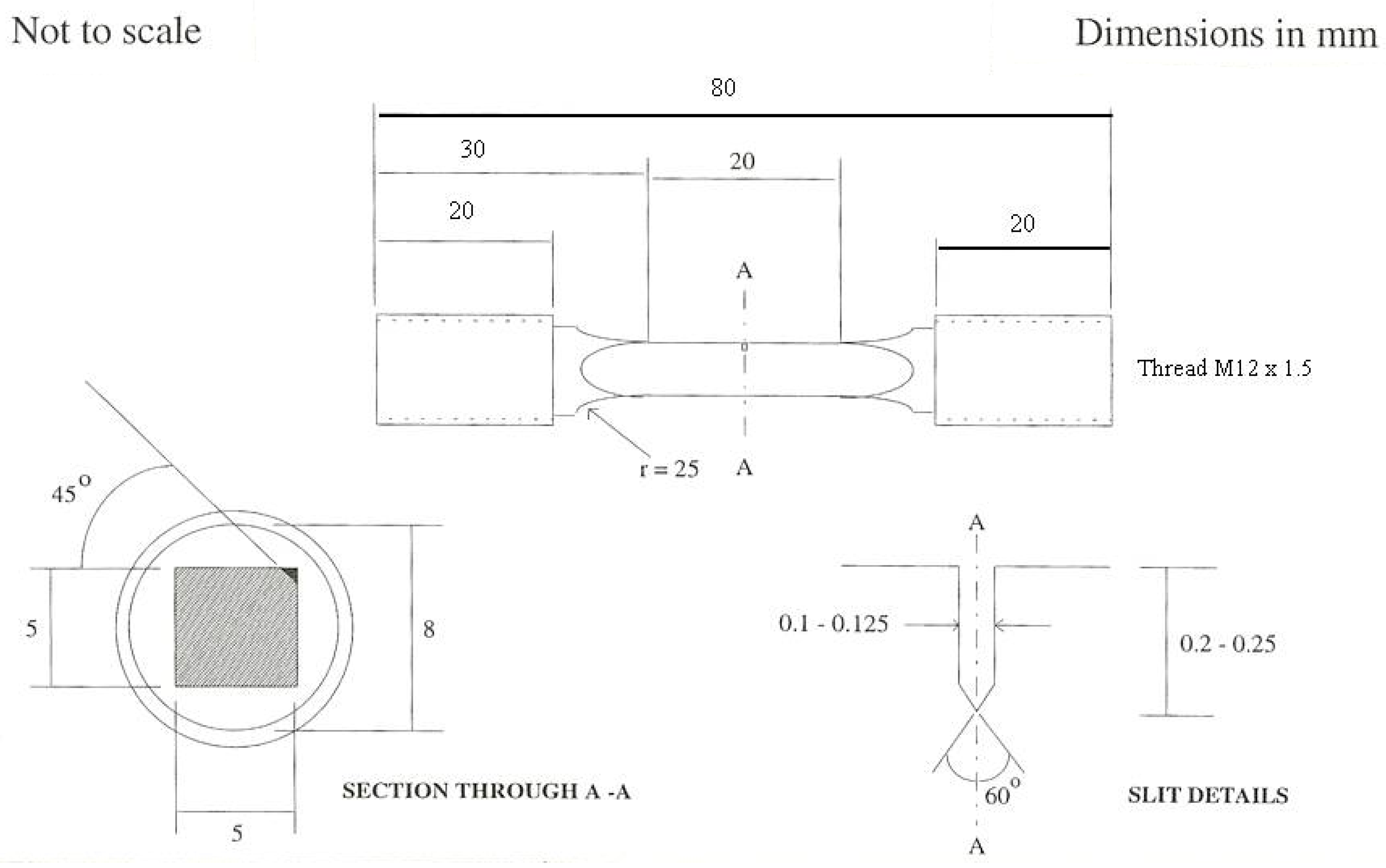

2. Experimental Procedure

3. Results and Discussion

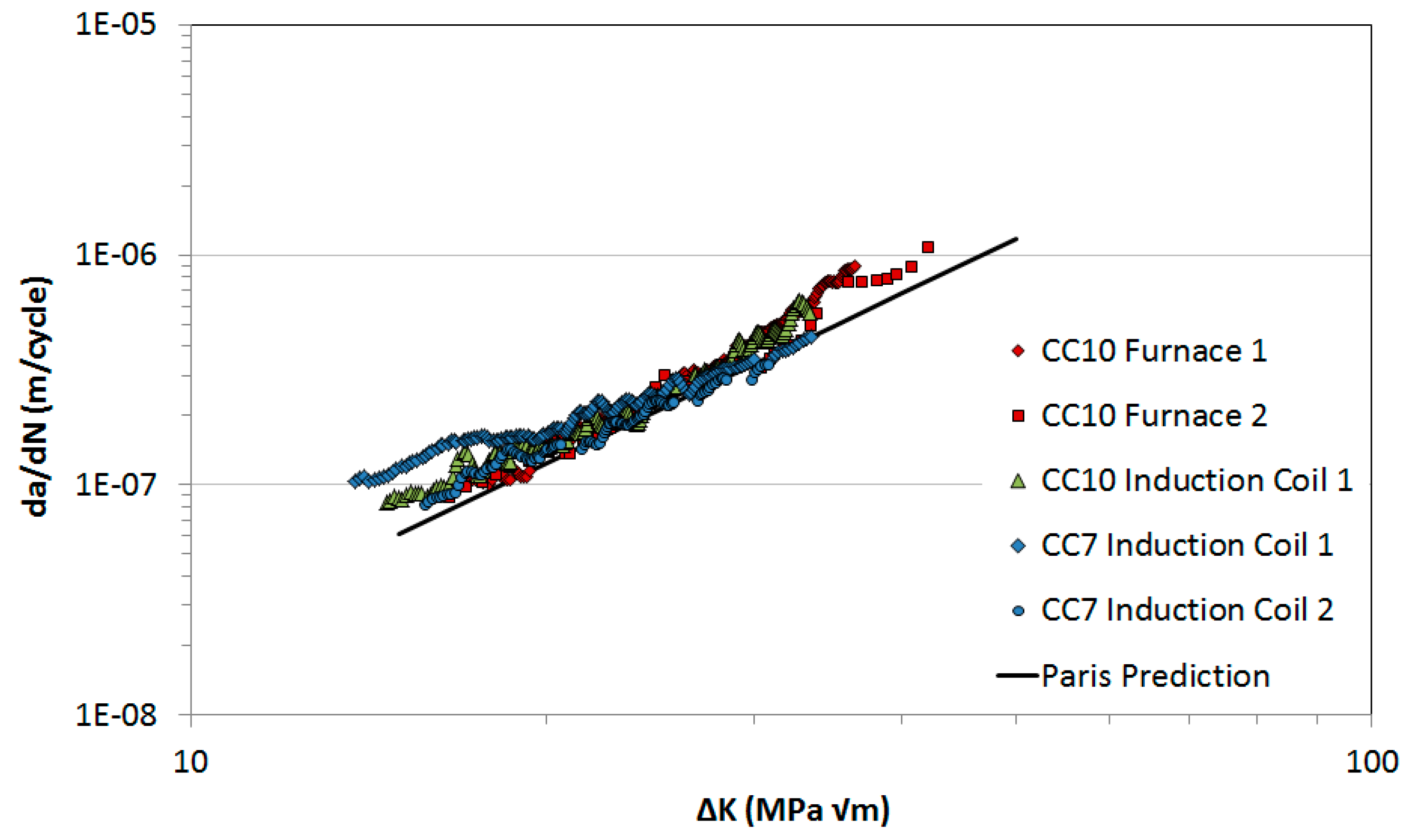

3.1. Preliminary Waspaloy Isothermal Tests

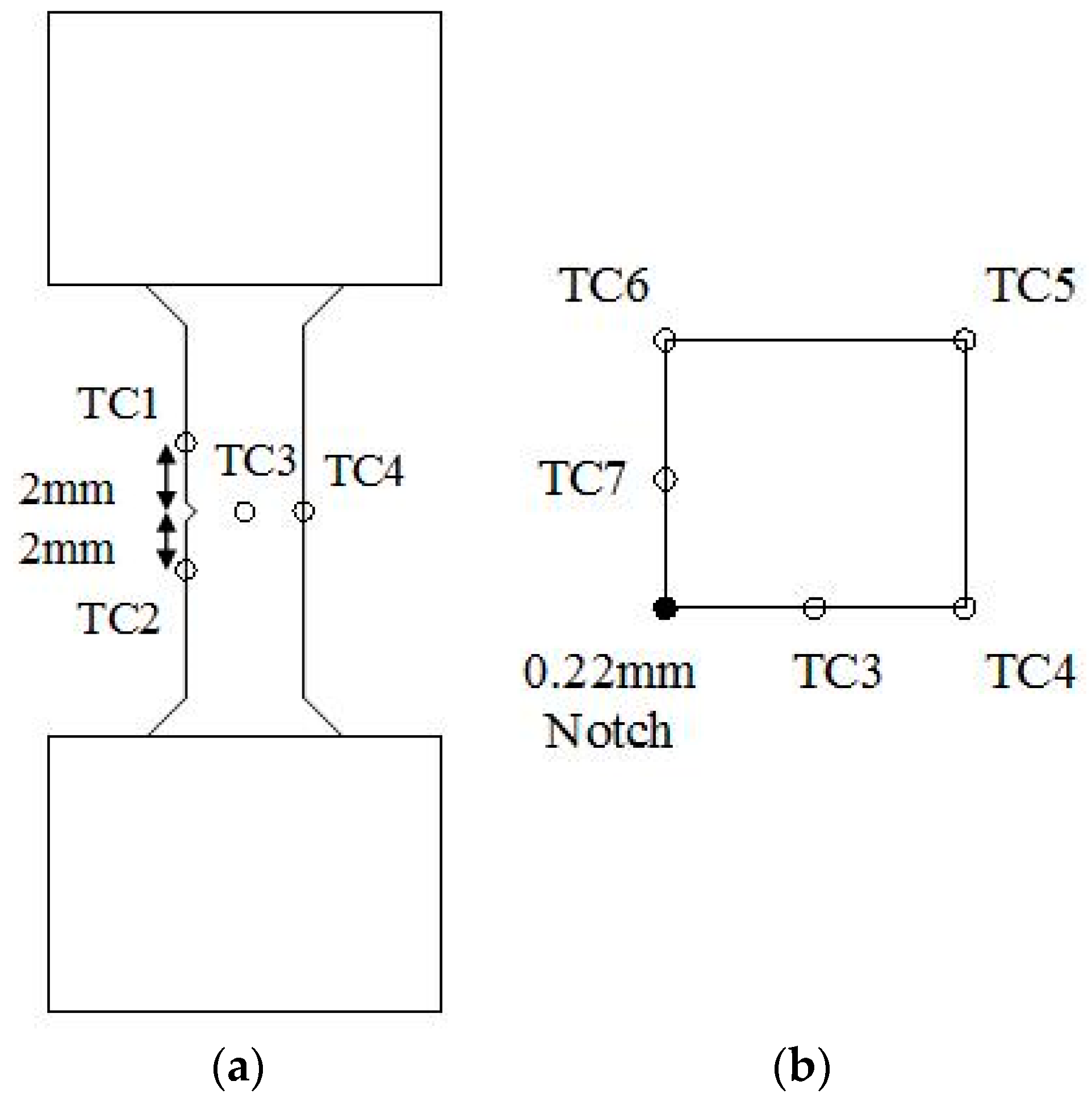

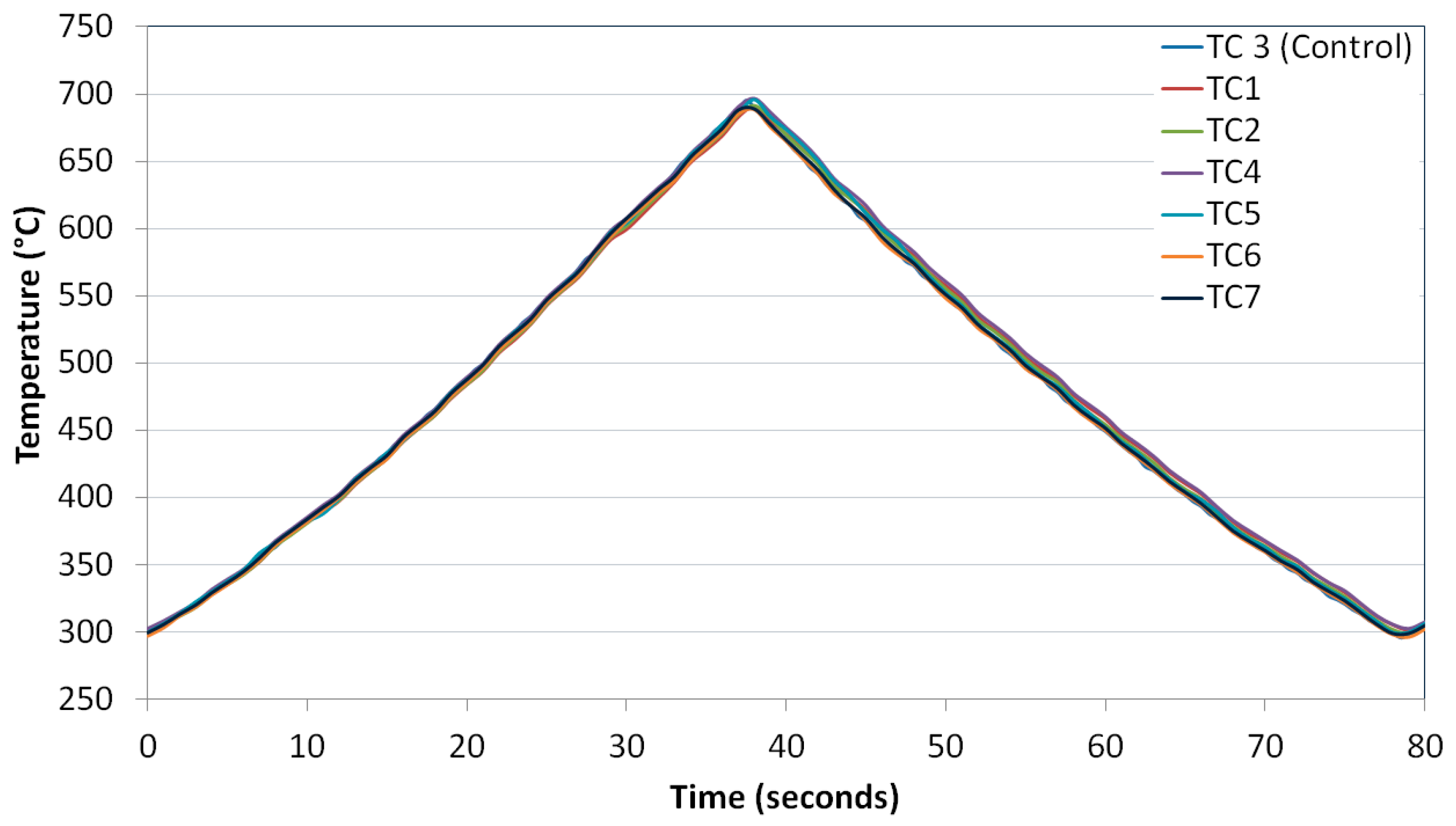

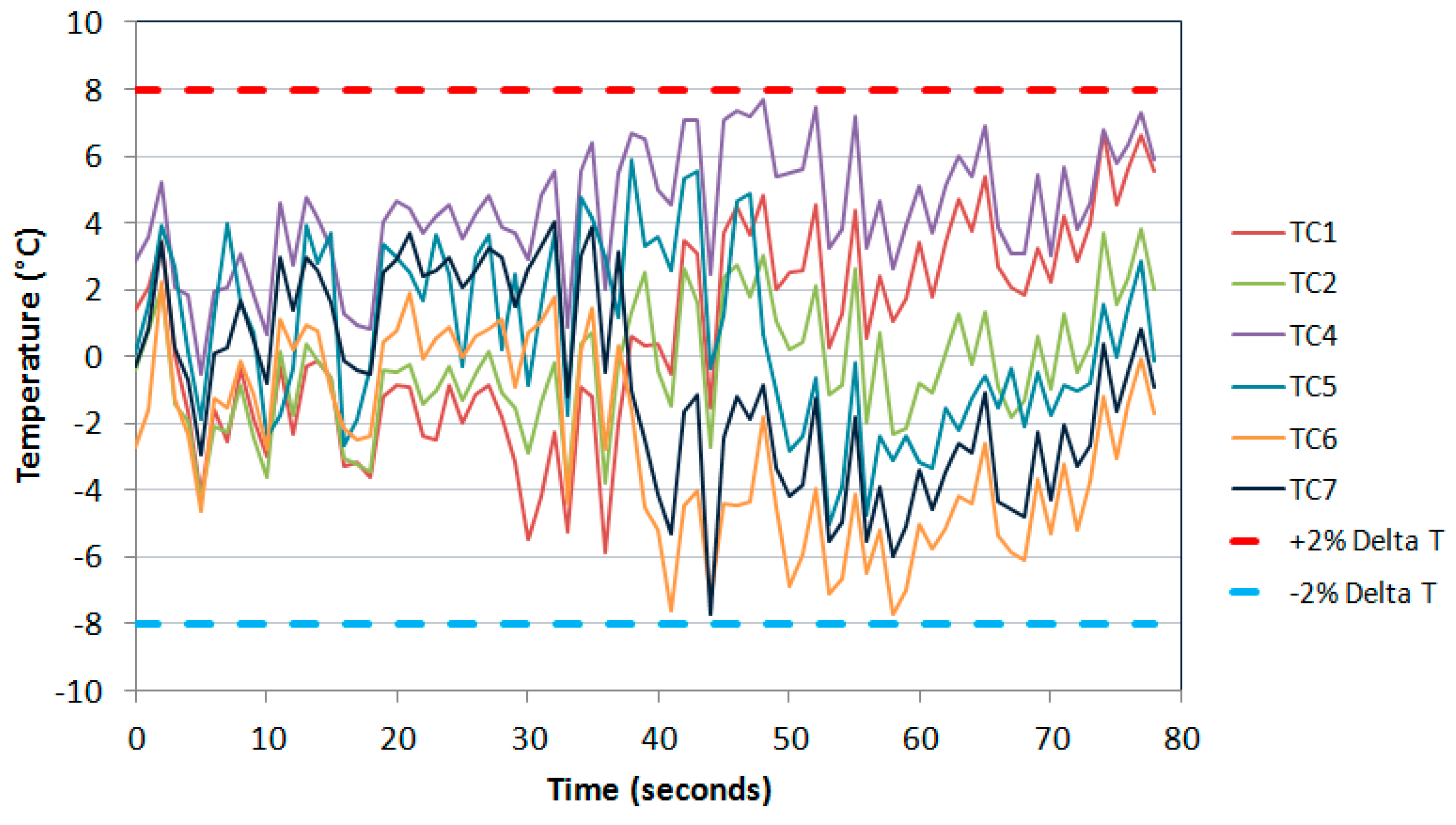

3.2. Thermal Profiling

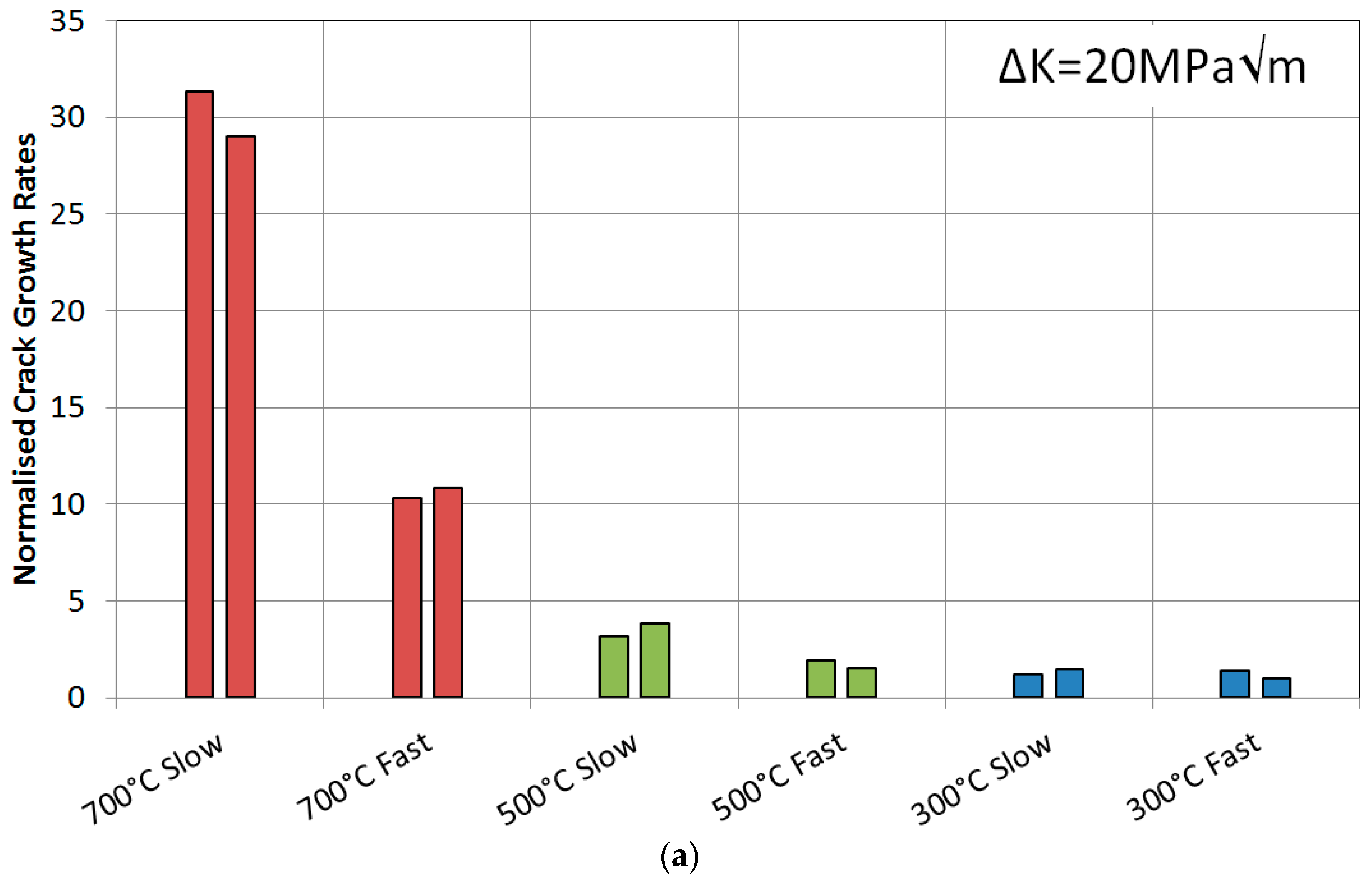

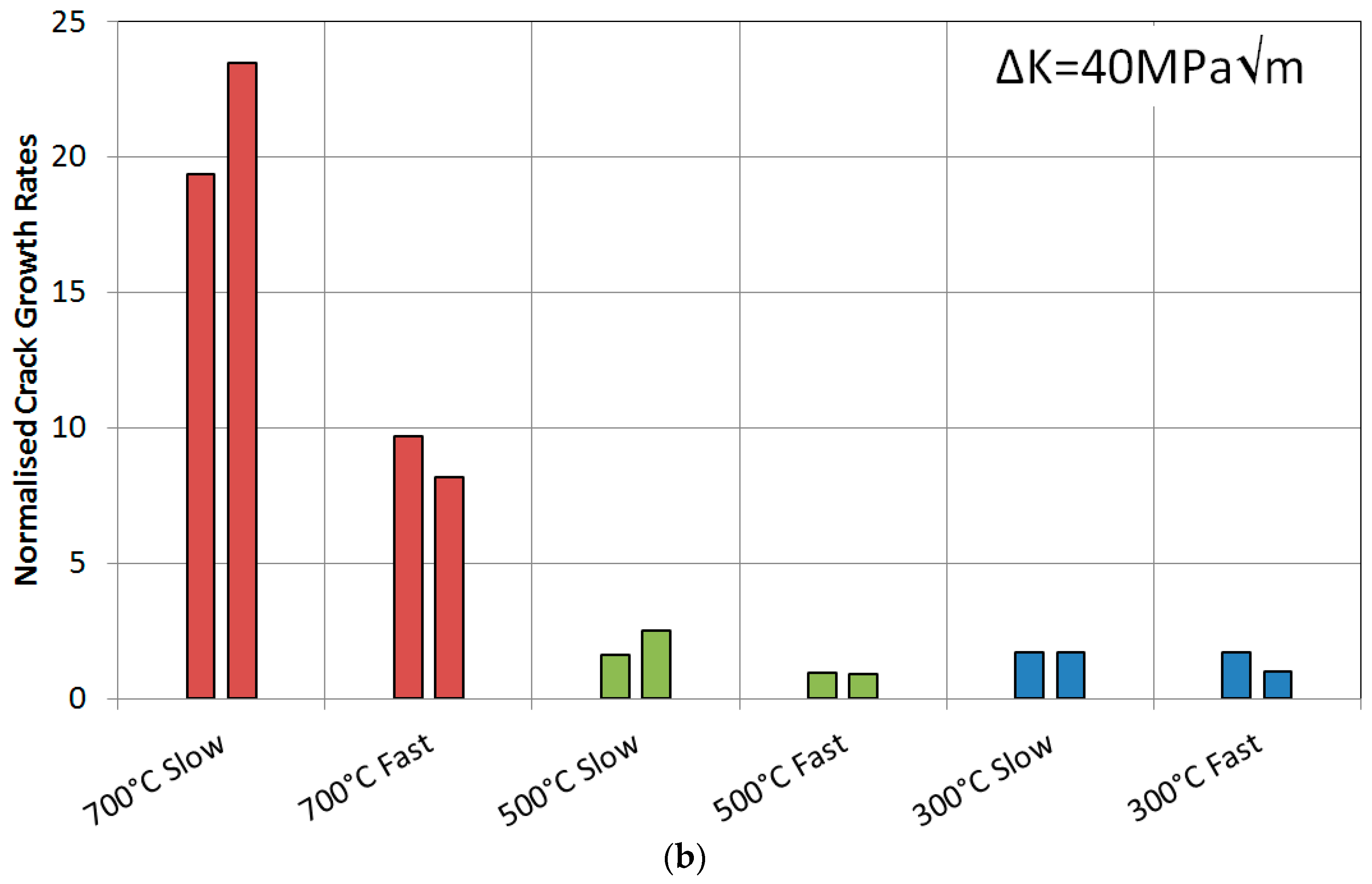

3.3. RR1000 Isothermal Testing

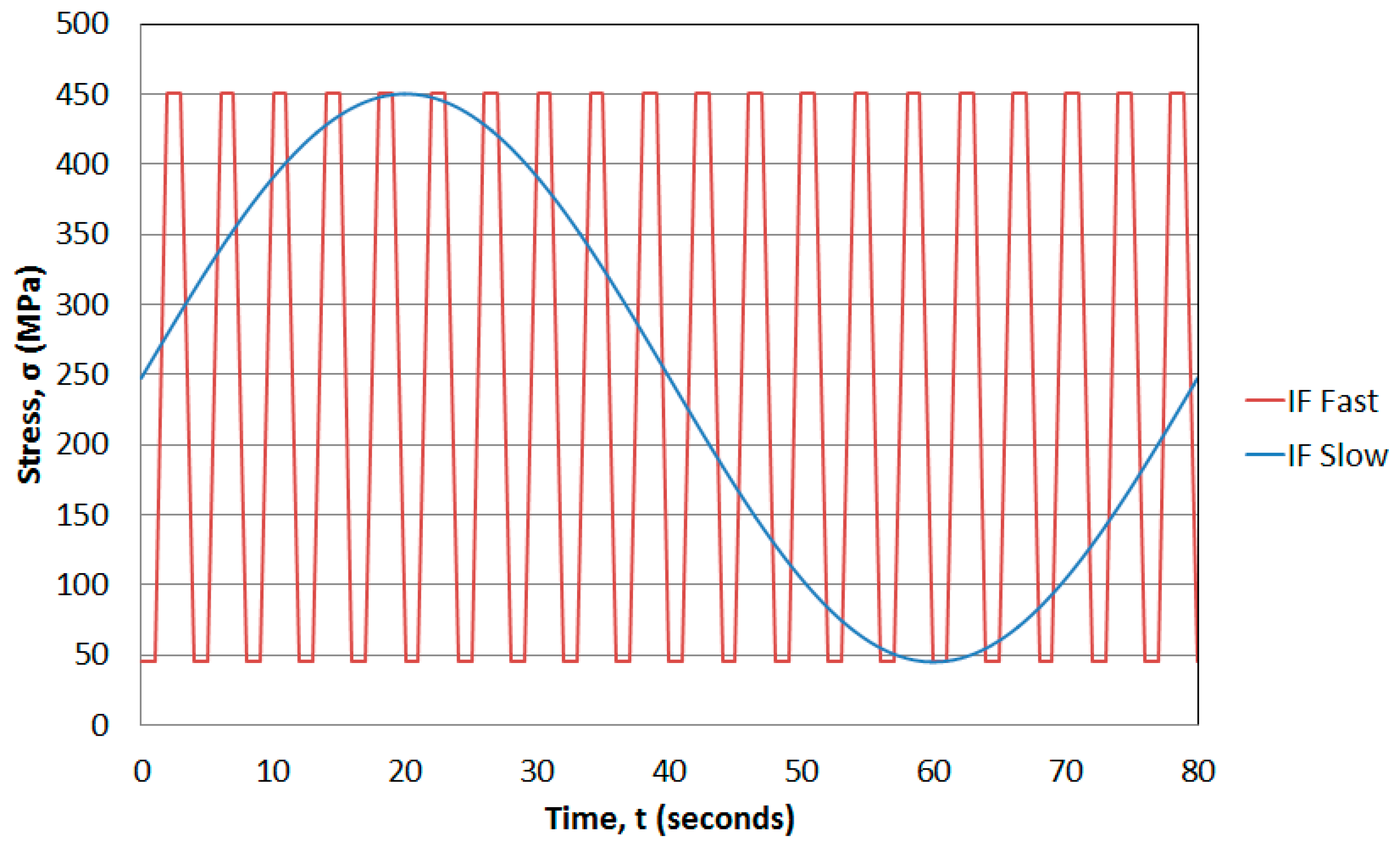

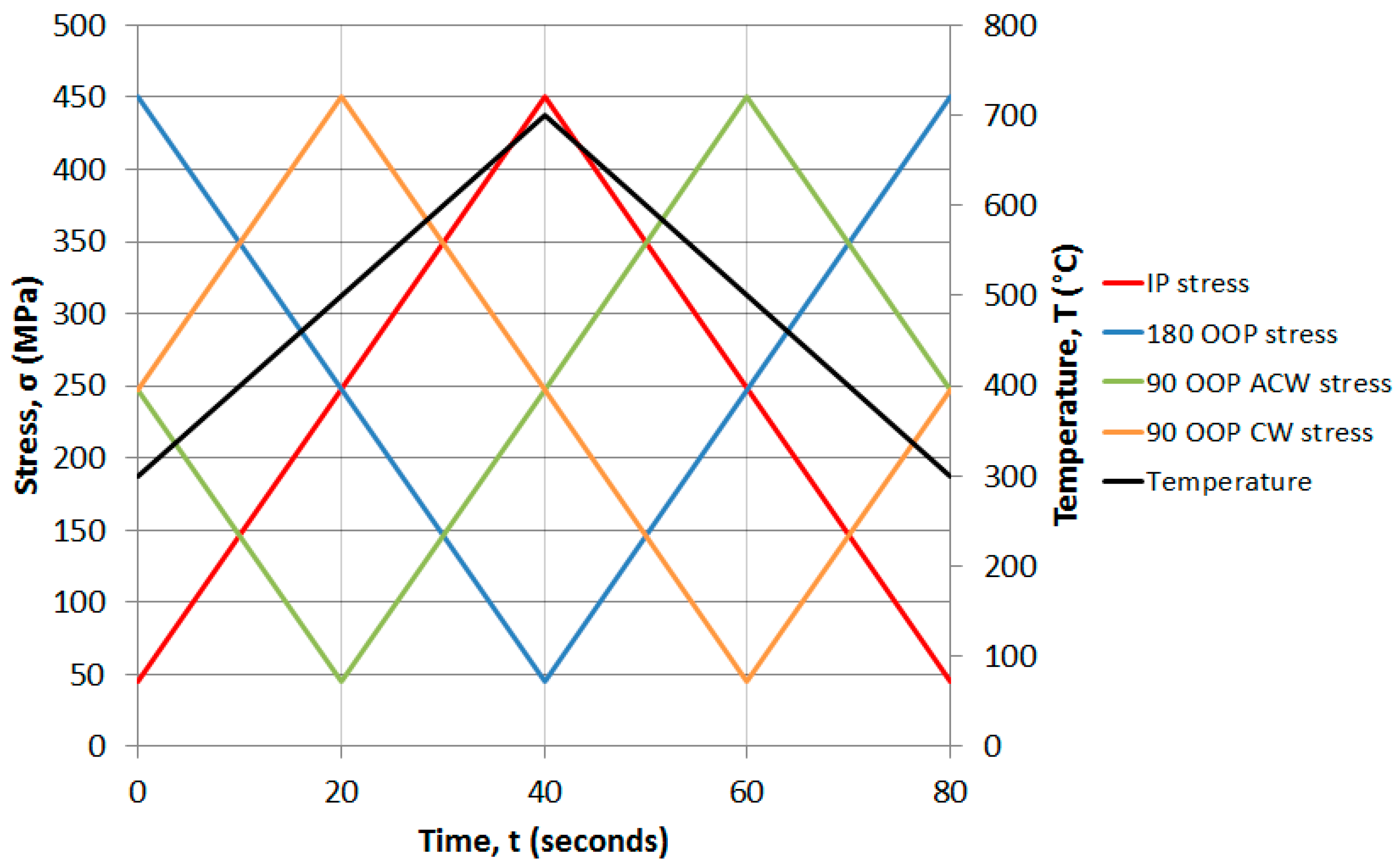

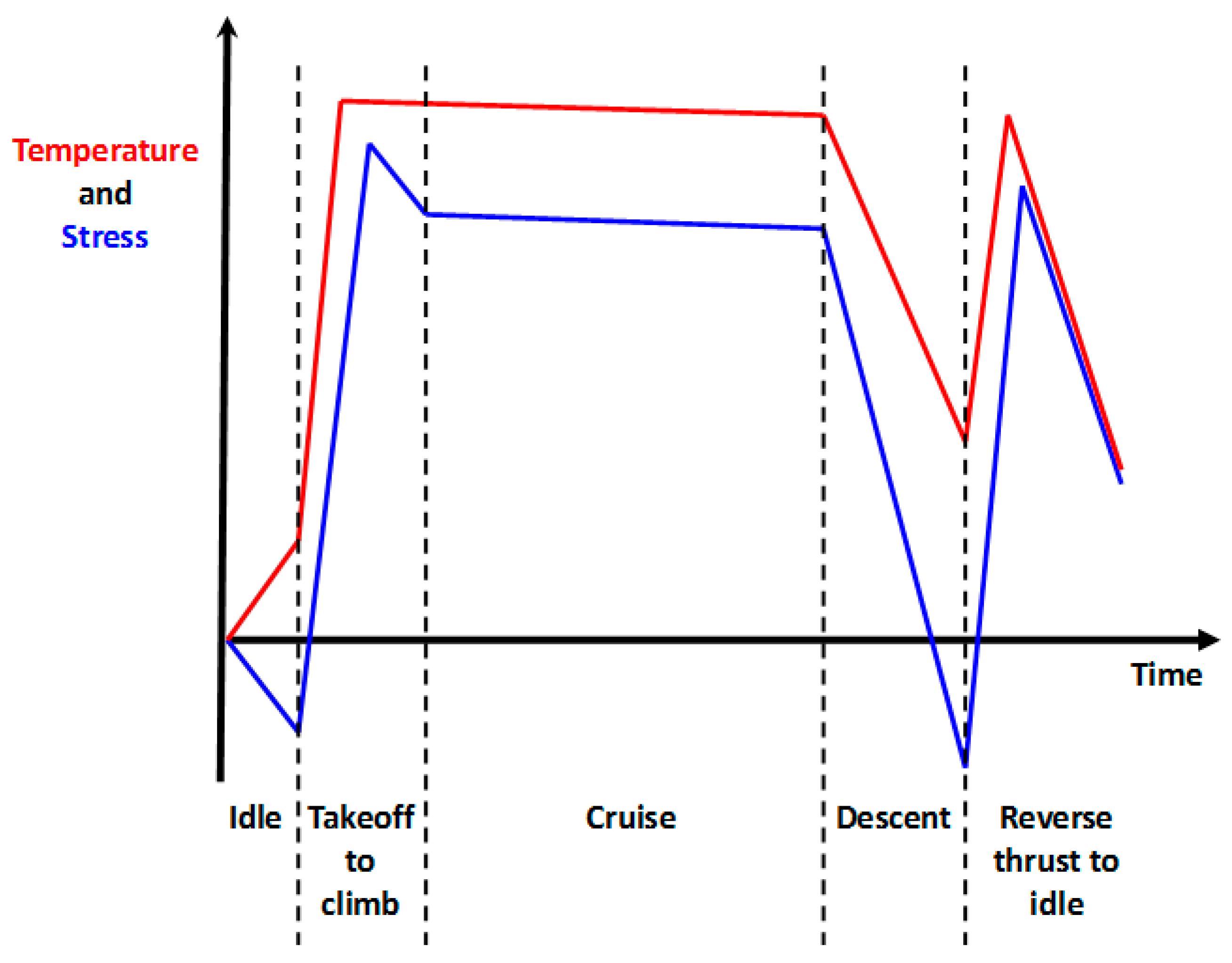

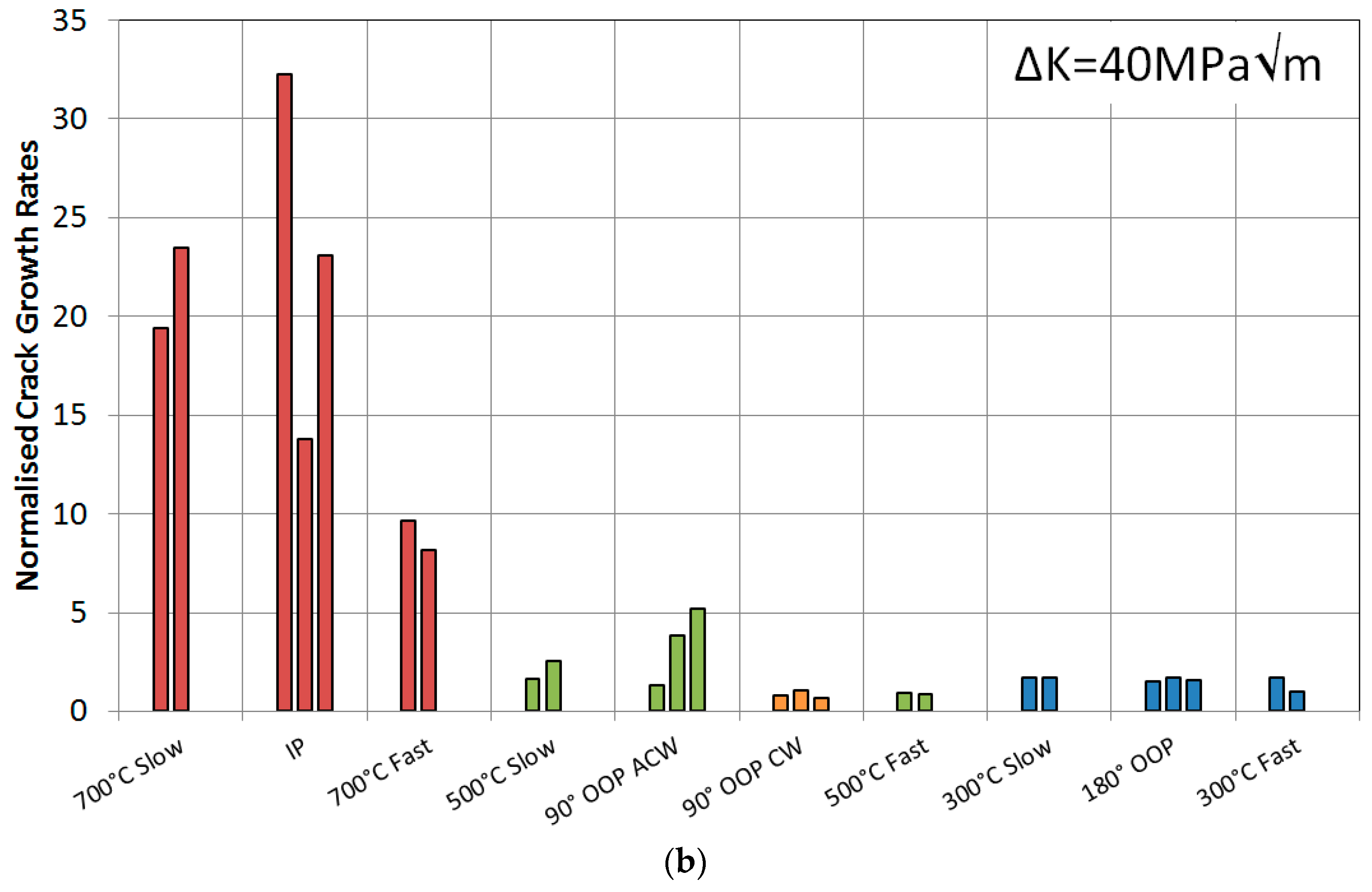

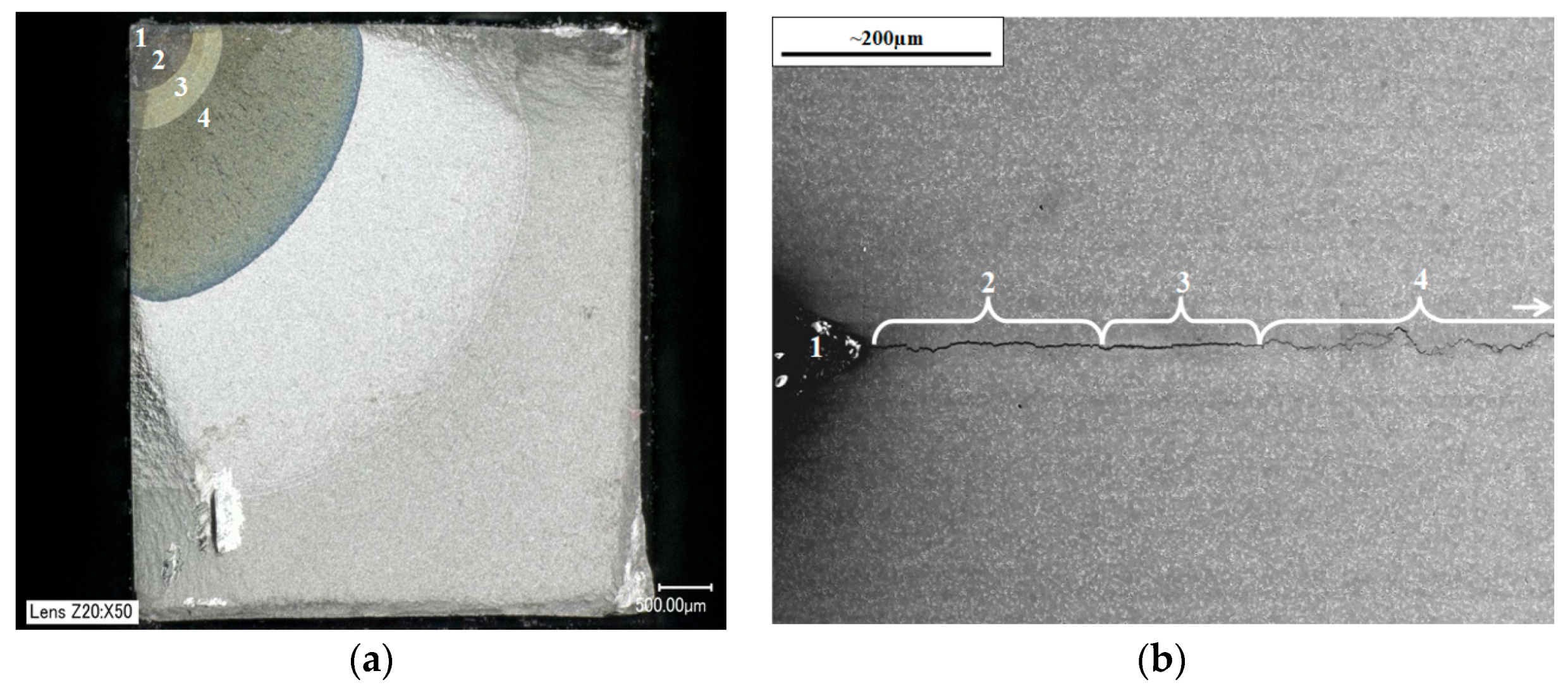

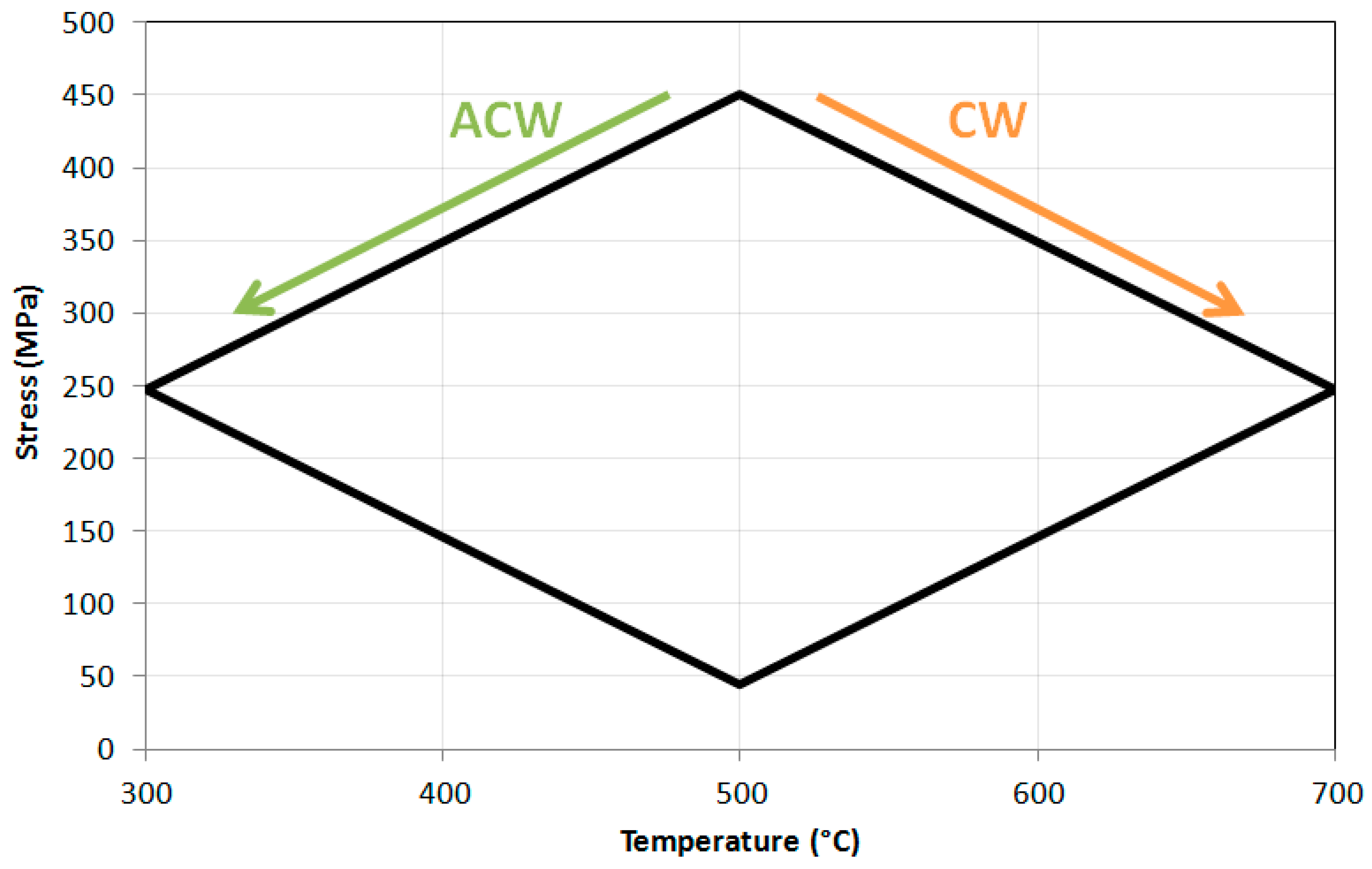

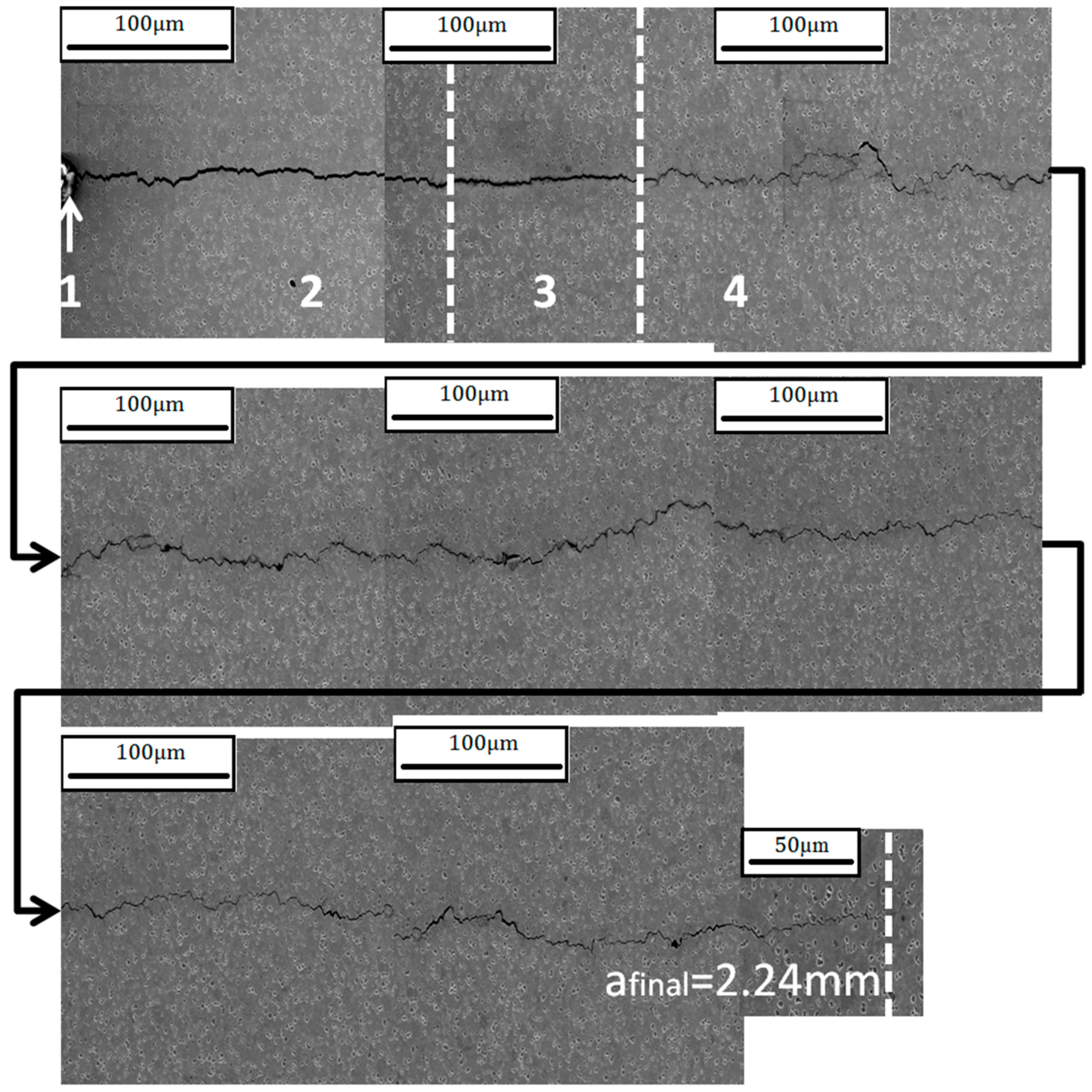

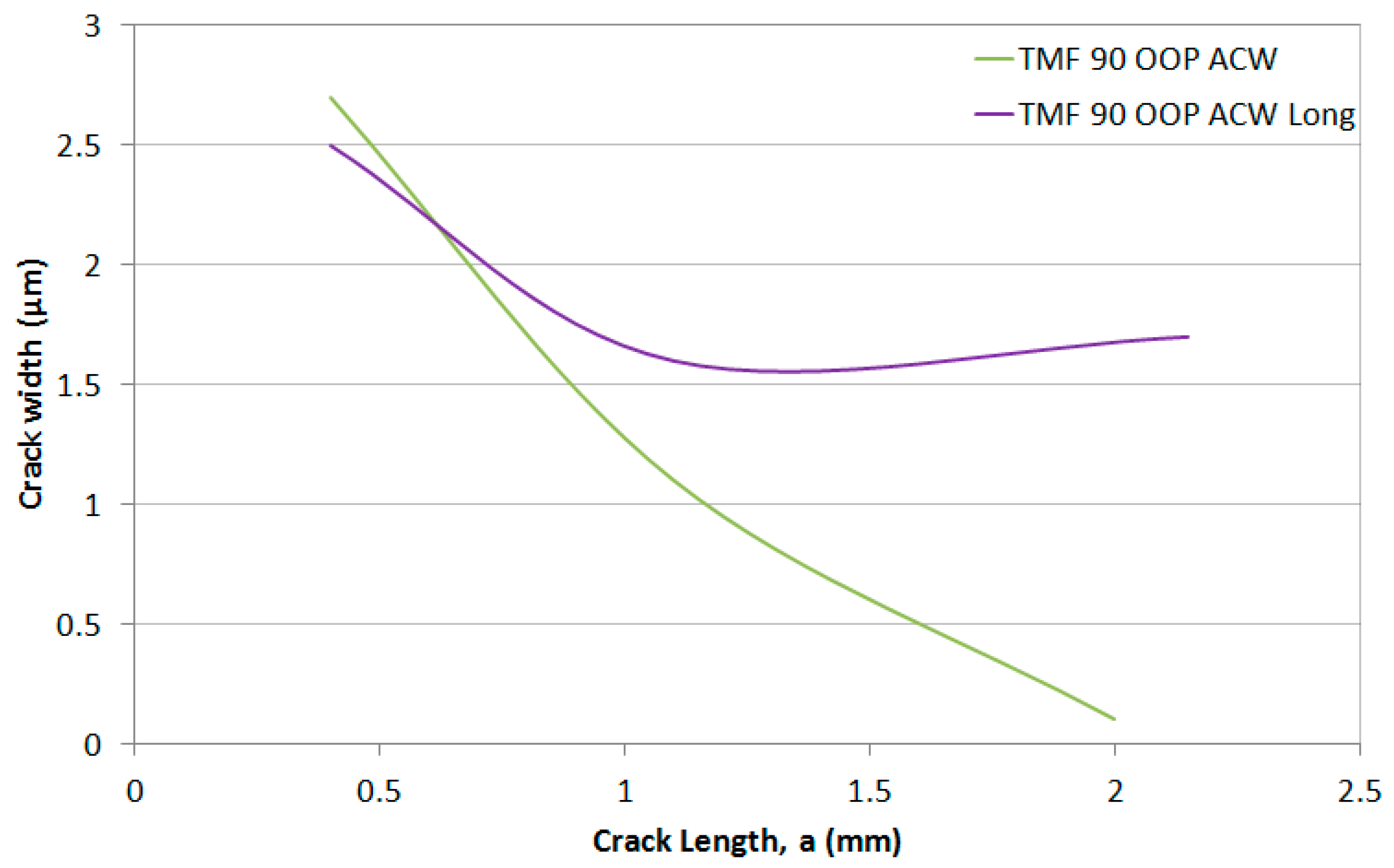

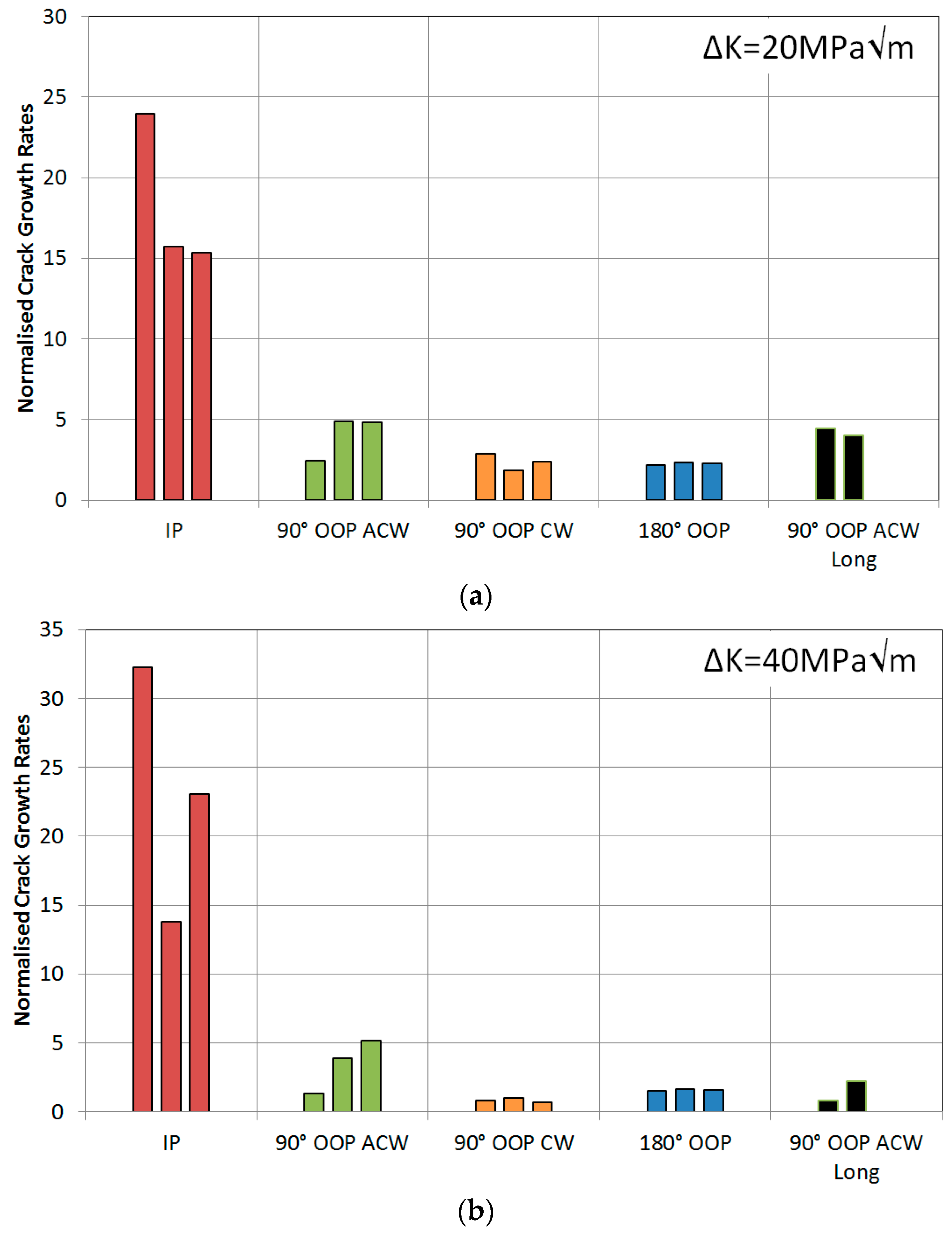

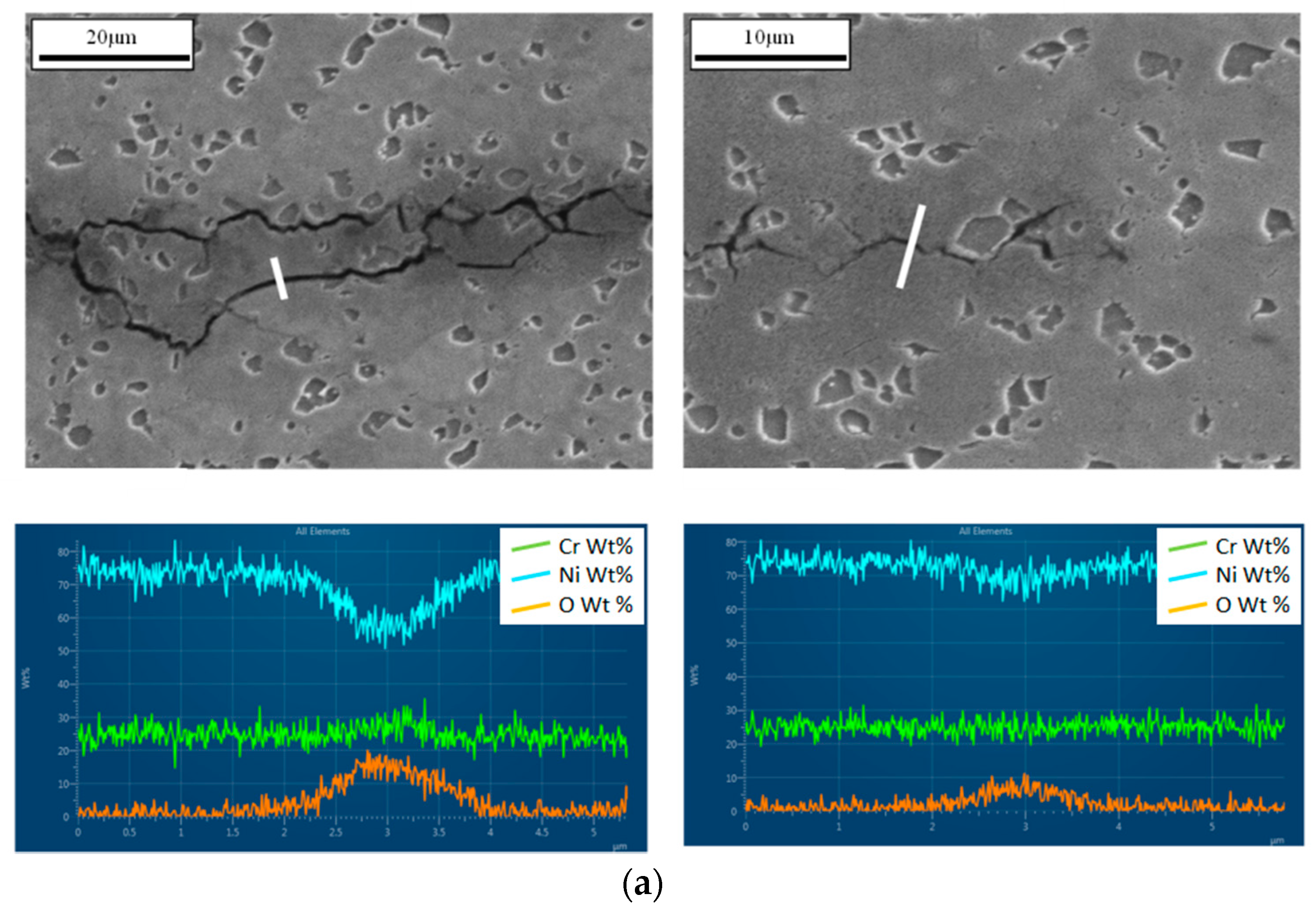

3.4. TMFCG Testing

- Pre-machined notch region;

- Room temperature pre-cracking;

- Test temperature (IF) or temperature at which maximum stress is experienced (TMF) pre-cracking;

- IF or TMF test where the crack is grown to about 2 mm.

4. Conclusions

- Induction heating appears to have no effect in terms of crack tip heating or interference with DCPD crack monitoring techniques, and the combination of the two therefore appears satisfactory both for IF crack growth and TMFCG load control tests.

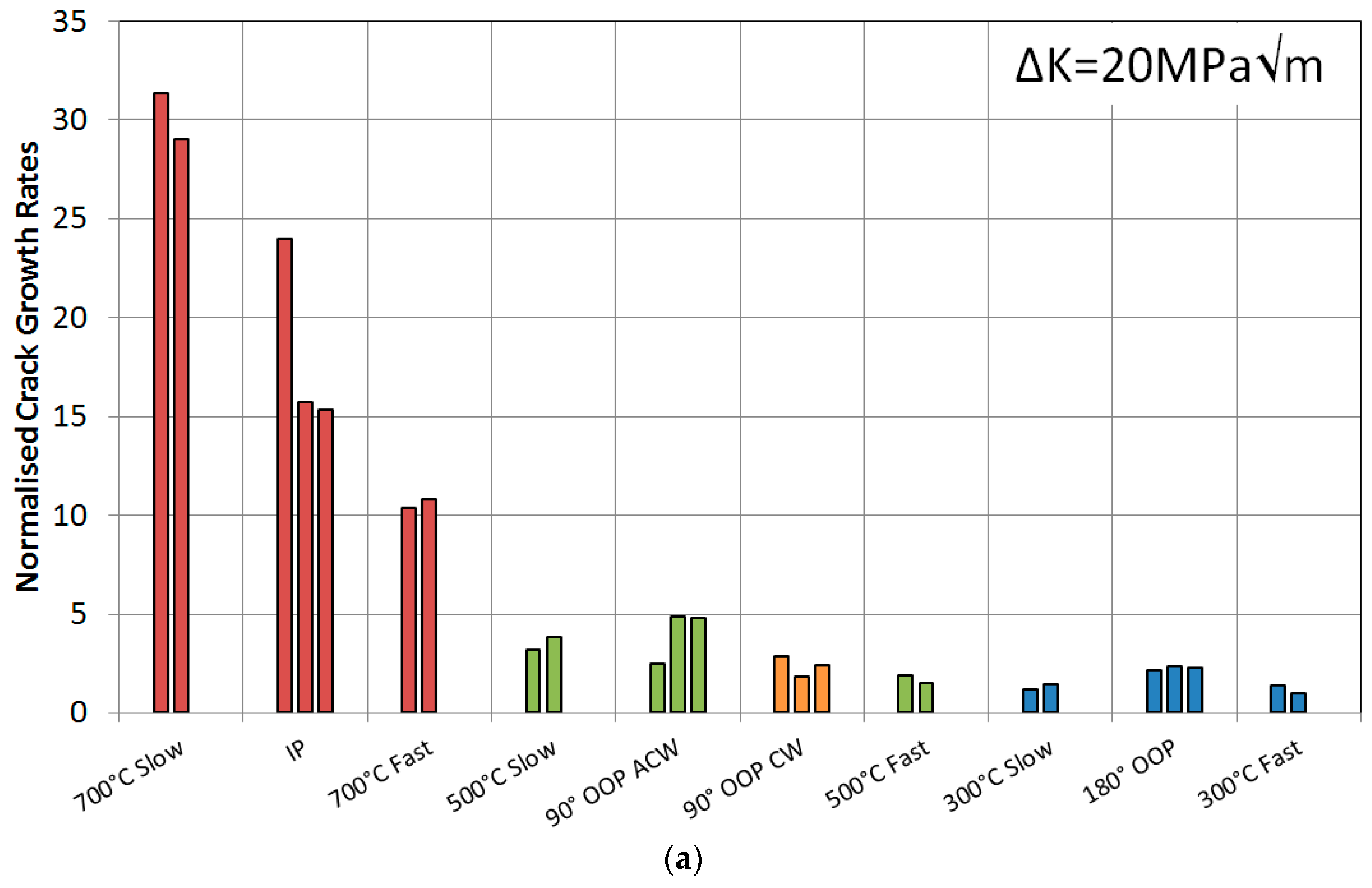

- Time dependence plays a significant role when comparing ‘fast’ and ‘slow’ cycle IF tests at temperatures higher than 500 °C.

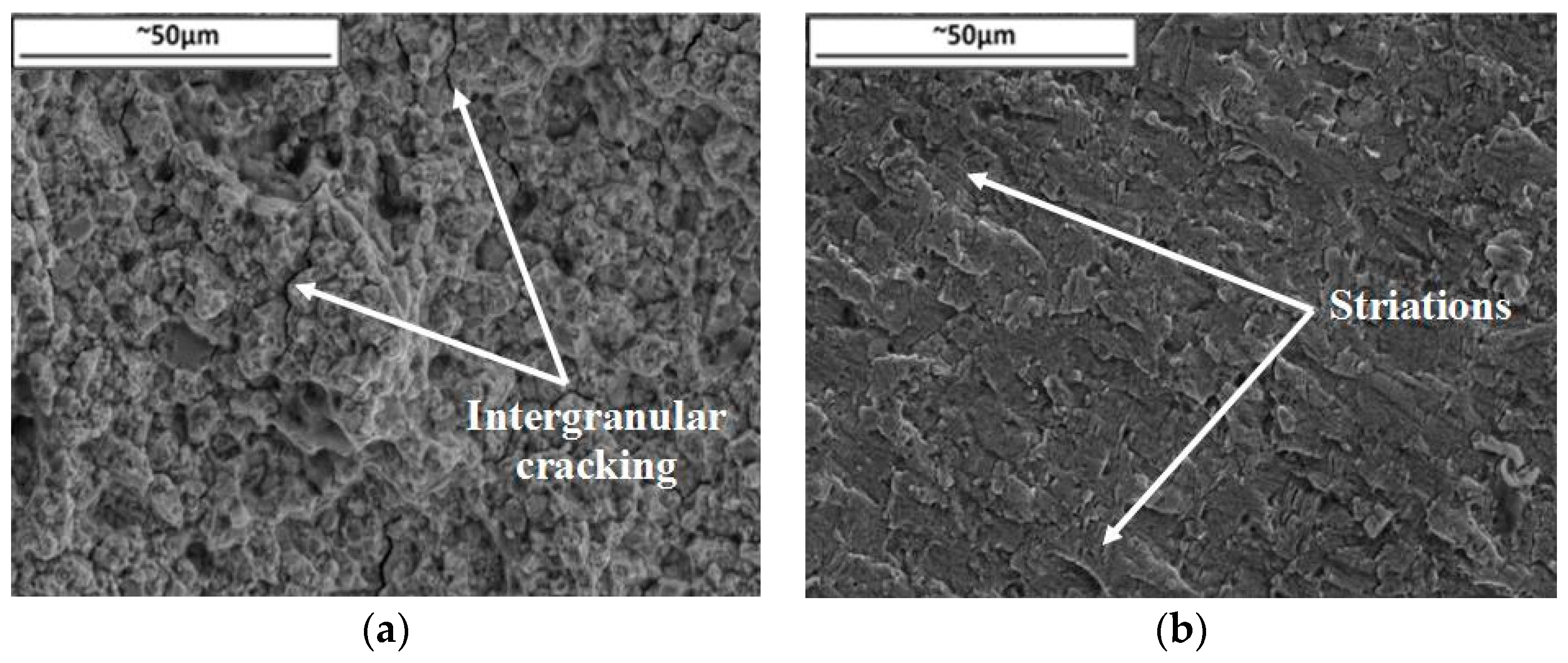

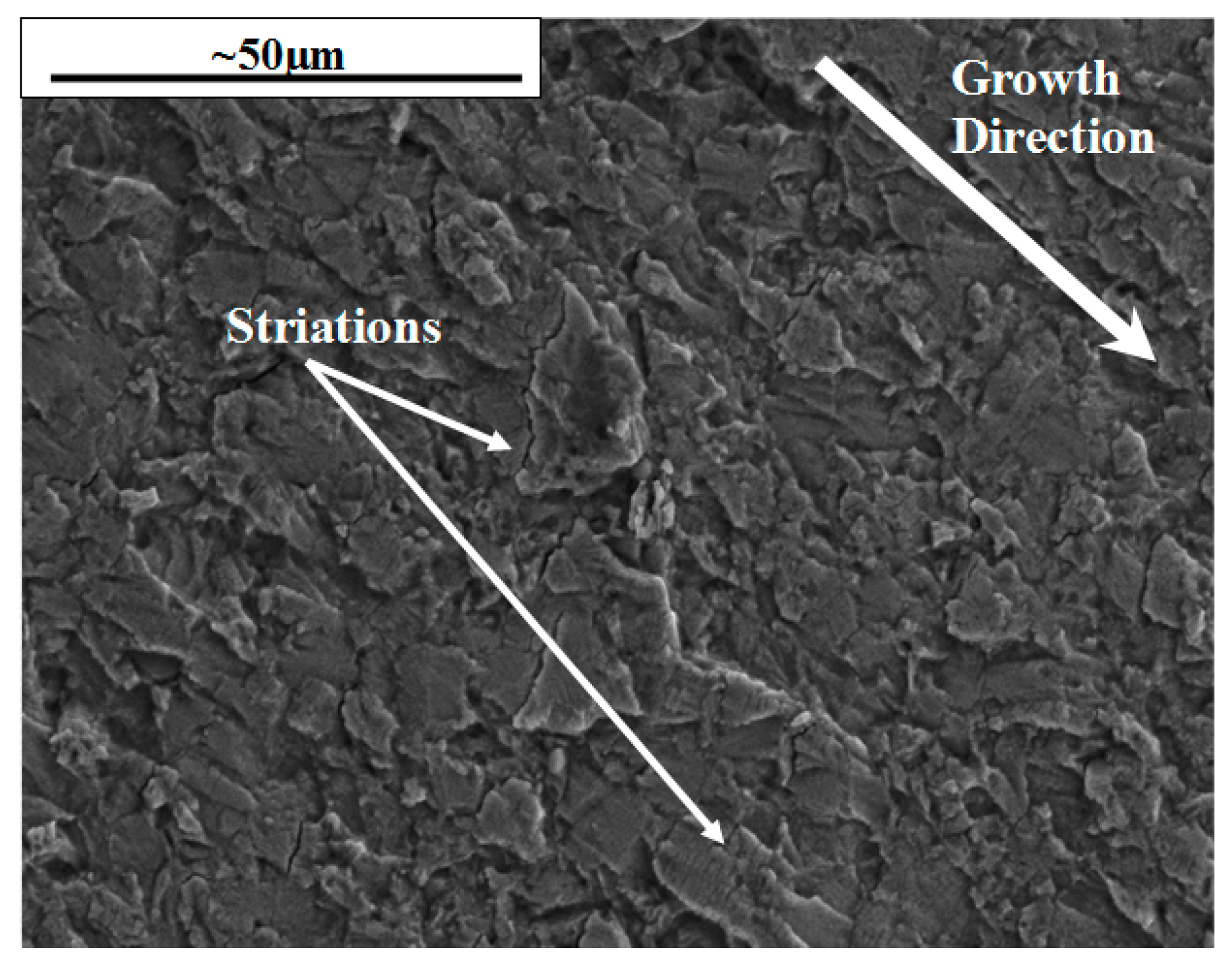

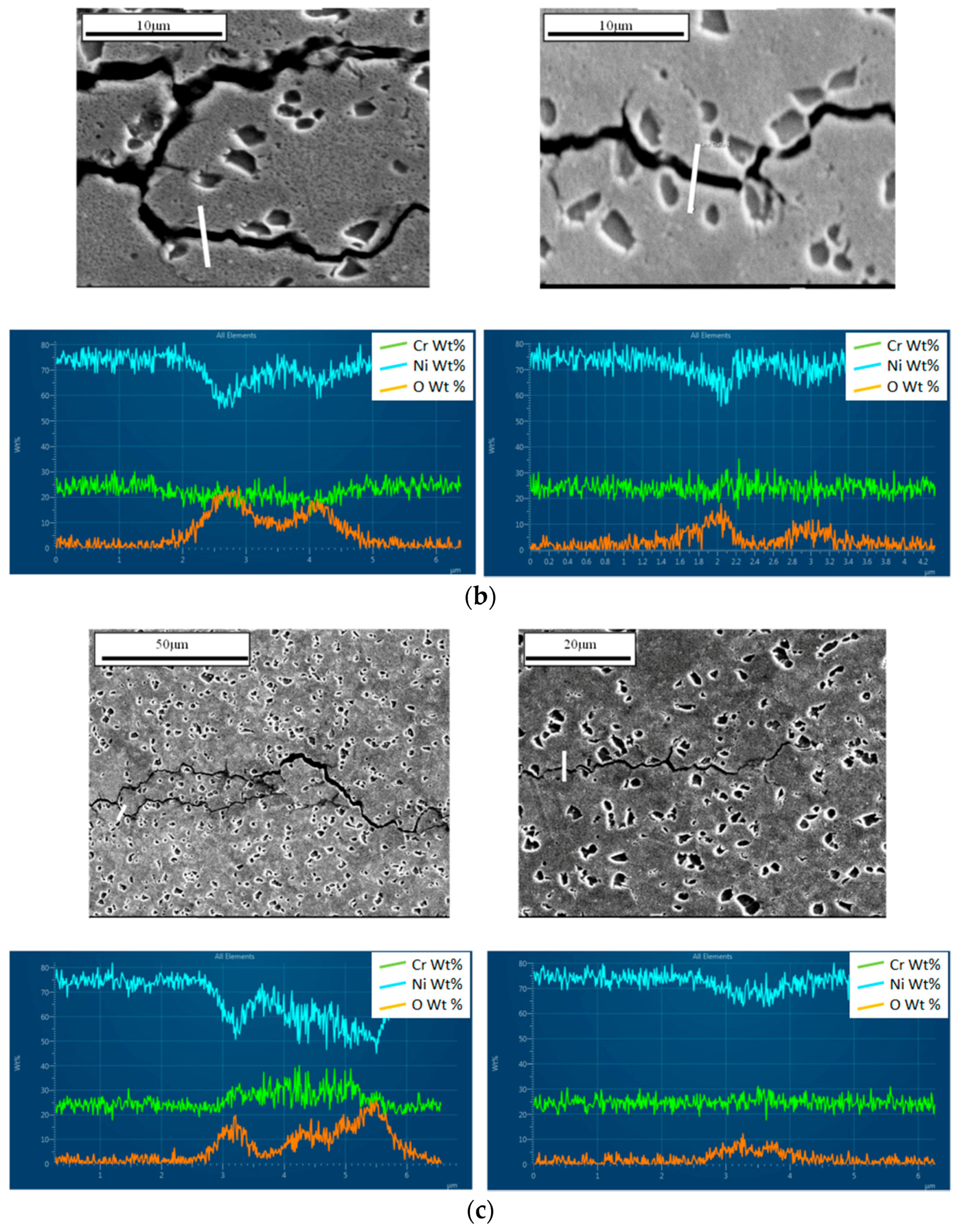

- IP conditions result in faster crack growth rates than OOP, due to the high stress and high temperature regime being more damaging in terms of creep and oxidation, giving rise to intergranular failure compared to the more transgranular-dominated failure with OOP.

- Diamond cycles are sensitive to loading direction, as shown by the 90° OOP, with slightly increased growth rates resulting from the ACW cycles.

- A theory has been tested to determine if oxidation rates are responsible for the change in damage mechanism between the two. Early signs suggest that this theory holds such that a fast moving crack at high temperatures oxidises less than a dormant crack in the same temperature range (right hand side of Figure 16) which results in transgranular failure in the former and a more brittle intergranular dominated failure in the latter.

- Oxygen films have been found to build up on the upper and lower surfaces of the crack, particularly during the highly oxidising CW and 500 s ACW cycles, resulting in crack tip blunting and thus retarded crack growth rates.

- Further work is required to confirm the effect of oxygen under these test conditions. Vacuum tests and dwell tests would be useful to identify and confirm if oxidation is the main factor involved in the intergranular aspect of failure in the diamond cycles.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Marchionni, M.; Klingelhöffer, H.; Kühn, H.J.; Ranucci, T.; Matzak, K. Thermo-Mechanical Fatigue of the Nickel–Base Superalloy Nimonic 90. Key Eng. Mater. 2007, 345–346, 347–350. [Google Scholar] [CrossRef]

- Pahlavanyali, S.; Drew, G.; Rayment, A.; Rae, C. Thermo-mechanical fatigue of a polycrystalline superalloy: The effect of phase angle on TMF life and failure. Int. J. Fatigue 2008, 30, 330–338. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, Z.; Zhu, S.; Yuan, F.; Wang, F. Thermomechanical fatigue behavior and life prediction of a cast nickel-based superalloy. Mater. Sci. Eng. A 2006, 432, 308–316. [Google Scholar] [CrossRef]

- Hyde, C.J.; Sun, W.; Hyde, T.H. An investigation of the failure mechanisms in high temperature materials subjected to isothermal and anisothermal fatigue and creep conditions. Engineering 2011, 10, 1157–1162. [Google Scholar] [CrossRef]

- Hyde, C.J.; Sun, W.; Hyde, T.H.; Becker, A.A. The Effect of a Starter Notch on the Isothermal and Thermomechanical Fatigue Life of a Nickel-Based Superalloy. In Proceedings of the ASME 2010 Pressure Vessells & Piping Division/K-PVP Conference, Washington, DC, USA, 18–22 July 2010; pp. 1–10.

- Rau, C., Jr.; Gemma, A.; Leverant, G. Thermal-Mechanical Fatigue Crack Propagation in Nickel and Cobalt-Base Superalloys under Various Strain-Temperature Cycles; Fatigue at Elevated Temperatures, ASTM STP 520; ASTM International: West Conshohocken, PA, USA, 1973; pp. 166–178. [Google Scholar]

- Gemma, A.; Langer, B.; Leverant, G. Thermomechanical Fatigue Crack Propagation in an Anistropic (Directionally Solidified) Nickel-Base Superalloy; Thermal Fatigue of Materials and Components, ASTM STP 612; ASTM International: West Conshohocken, PA, USA, 1976; pp. 199–213. [Google Scholar]

- Okazaki, M.; Koizumi, T. Crack propagation of steels during low cycle thermal-mechanical and isothermal fatigue at elevated temperatures. Metall. Trans. A 1983, 14, 1641–1648. [Google Scholar] [CrossRef]

- Pelloux, R.M.; Marchand, N. Thermal-Mechanical Fatigue Behavior of Nickel-Base Superalloys; NASA-CR-175048; NASA Technical Report; NASA: Hampton, VA, USA, 1986.

- Kim, K.S.; van Stone, R.H. Crack growth under thermo-mechanical and temperature gradient loads. Eng. Fract. Mech. 1997, 58, 133–147. [Google Scholar] [CrossRef]

- Ljustell, P. Fatigue Crack Growth Experiments and Analyses—From Small Scale to Large Scale Yielding at Constant and Variable Amplitude Loading. Ph.D. Thesis, KTH School of Engineering Sciences, Stockholm, Sweden, 2013. [Google Scholar]

- Elber, W. The Significance of Fatigue Crack Closure; Damage Tolerance in Aircraft Structures, ASTM STP 486; ASTM International: West Conshohocken, PA, USA, 1971; pp. 230–242. [Google Scholar]

- Pernot, J.J. Crack Growth Rate Modelling of a Titanium Aluminide Alloy under Thermal Mechanical Cycling. Ph.D. Dissertation, Air Force Institute of Technology, Wright-Patterson AFB, OH, USA, 1991. [Google Scholar]

- Jacobsson, L.; Persson, C.; Melin, S. Experimental methods for thermomechanical fatigue in gas turbine materials. In Proceedings of the 15th European Conference of Fracture, Stockholm, Sweden, 11–13 August 2004.

- Jacobsson, L.; Persson, C.; Melin, S. In-situ ESEM study of thermo-mechanical fatigue crack propagation. Mater. Sci. Eng. A 2008, 496, 200–208. [Google Scholar] [CrossRef]

- Jacobsson, L.; Persson, C.; Melin, S. Thermo-mechanical fatigue crack propagation experiments in Inconel 718. Int. J. Fatigue 2009, 31, 1318–1326. [Google Scholar] [CrossRef]

- Evans, W.; Screech, J.; Williams, S. Thermo-mechanical fatigue and fracture of INCO718. Int. J. Fatigue 2009, 30, 257–267. [Google Scholar] [CrossRef]

- Beck, T.; Hähner, P.; Kühn, H.-J.; Rae, C.; Affeldt, E.E.; Andersson, H.; Köster, A.; Marchionni, M. Thermo-mechanical fatigue—The route to standardisation (‘TMF-standard’ project). Mater. Corros. 2006, 57, 53–59. [Google Scholar] [CrossRef]

- Davis, J.R. Heat-Resistant Materials; ASM International: West Conshohocken, PA, USA, 1997. [Google Scholar]

- Hardy, M.; Zirbel, B.; Shen, G.; Shankar, R. Developing Damage Tolerance and Creep Resistance in a High Strength Nickel Alloy for Disc Applications. In Proceedings of the TMS (The Minerals, Metals and Materials Society), Charlotte, NC, USA, 14–18 March 2004.

- Andersson, M.; Persson, C.; Melin, S. An In-Situ SEM Study of Crack Propagation. In Proceedings of the 15th European Conference of Fracture, Stockholm, Sweden, 11–13 August 2004.

- Pahlavanyali, S.; Drew, G.; Rayment, A.; Rae, C.M.F. Oxidation assisted thermomechanical fatigue failure of polycrystalline superalloys. Mater. Sci. Technol. 2007, 23, 1454–1460. [Google Scholar] [CrossRef]

- Hähner, P.; Affeldt, E.; Beck, T.; Klingelhöffer, H.; Loveday, M.; Rinaldi, C. Validated Code-of-Practice for Thermo-Mechanical Fatigue Testing; Joint Research Centre: Brussels, Belgium, 2006. [Google Scholar]

- Suresh, S. Fatigue of material. Mater. Sci. Eng. A 1991, 154, 221. [Google Scholar]

- Jacques, S.; Lynch, M.; Wisbey, A.; Stekovic, S.; Williams, S. Development of Fatigue Crack Growth Testing under Thermo-Mechanical Fatigue Conditions; Serco: Hampshire, UK, 2011. [Google Scholar]

- Tong, J.; Dalby, S.; Byrne, J.; Hardy, M.C. Creep, fatigue and oxidation in crack growth in advanced nickel base superalloys. Int. J. Fatigue 2001, 23, 897–902. [Google Scholar] [CrossRef]

- Marchand, N.; Pelloux, R.M. A computerized test system for thermal-mechanical fatigue crack growth. J. Test. Eval. 1986, 14, 303–311. [Google Scholar]

- Pahlavanyali, S.; Rayment, A.; Roebuck, B.; Drew, G.; Rae, C. Thermo-mechanical fatigue testing of superalloys using miniature specimens. Int. J. Fatigue 2008, 30, 397–403. [Google Scholar] [CrossRef]

- De Yedra, A.G.; Martín, R.R.; Pedrejón, J.L. Thermo-mechanical fatigue behaviour and life prediction of C-1023 nickel based superalloy. Int. J. Eng. Sci. Technol. 2011, 3, 88–101. [Google Scholar]

- Li, H.Y.; Sun, J.F.; Hardy, M.C.; Evans, H.E.; Williams, S.J.; Doel, T.J.; Bowen, P. Effects of microstructure on high temperature dwell fatigue crack growth in a coarse grain PM nickel based superalloy. Acta Mater. 2015, 90, 355–369. [Google Scholar] [CrossRef]

| Alloy | Ni | Cr | Co | Mo | Ta | Al | Ti | Hf | C | B | Zr |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Waspaloy | bal | 19.5 | 13.5 | 4.3 | – | 1.3 | 3.0 | – | 0.08 | 0.006 | – |

| RR1000 | bal | 15.0 | 18.5 | 5.0 | 2.0 | 3.0 | 3.6 | 0.5 | 0.03 | 0.02 | 0.06 |

| Isothermal/TMF | Cycle | Mean No. of Cycles to 2 mm | Mean Time to 2 mm (Hours) |

|---|---|---|---|

| IF | 700 °C Slow | 1180 | 26 |

| 700 °C Fast | 2450 | 3 | |

| 500 °C Slow | 8700 | 193 | |

| 500 °C Fast | 19,500 | 22 | |

| 300 °C Slow | 36,000 | 800 | |

| 300 °C Fast | 45,000 | 50 | |

| TMF | IP | 2800 | 62 |

| 90° OOP CW | 9300 | 207 | |

| 90° OOP ACW | 8000 | 178 | |

| 90° OOP ACW Long | 6700 | 931 | |

| 180° OOP | 14,600 | 324 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pretty, C.J.; Whitaker, M.T.; Williams, S.J. Thermo-Mechanical Fatigue Crack Growth of RR1000. Materials 2017, 10, 34. https://doi.org/10.3390/ma10010034

Pretty CJ, Whitaker MT, Williams SJ. Thermo-Mechanical Fatigue Crack Growth of RR1000. Materials. 2017; 10(1):34. https://doi.org/10.3390/ma10010034

Chicago/Turabian StylePretty, Christopher John, Mark Thomas Whitaker, and Steve John Williams. 2017. "Thermo-Mechanical Fatigue Crack Growth of RR1000" Materials 10, no. 1: 34. https://doi.org/10.3390/ma10010034