Impedance Spectroscopy Study of the Effect of Environmental Conditions on the Microstructure Development of Sustainable Fly Ash Cement Mortars

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Environmental Conditions

2.3. Mercury Intrusion Porosimetry (MIP)

2.4. Impedance Spectroscopy (IS)

3. Results and Discussion

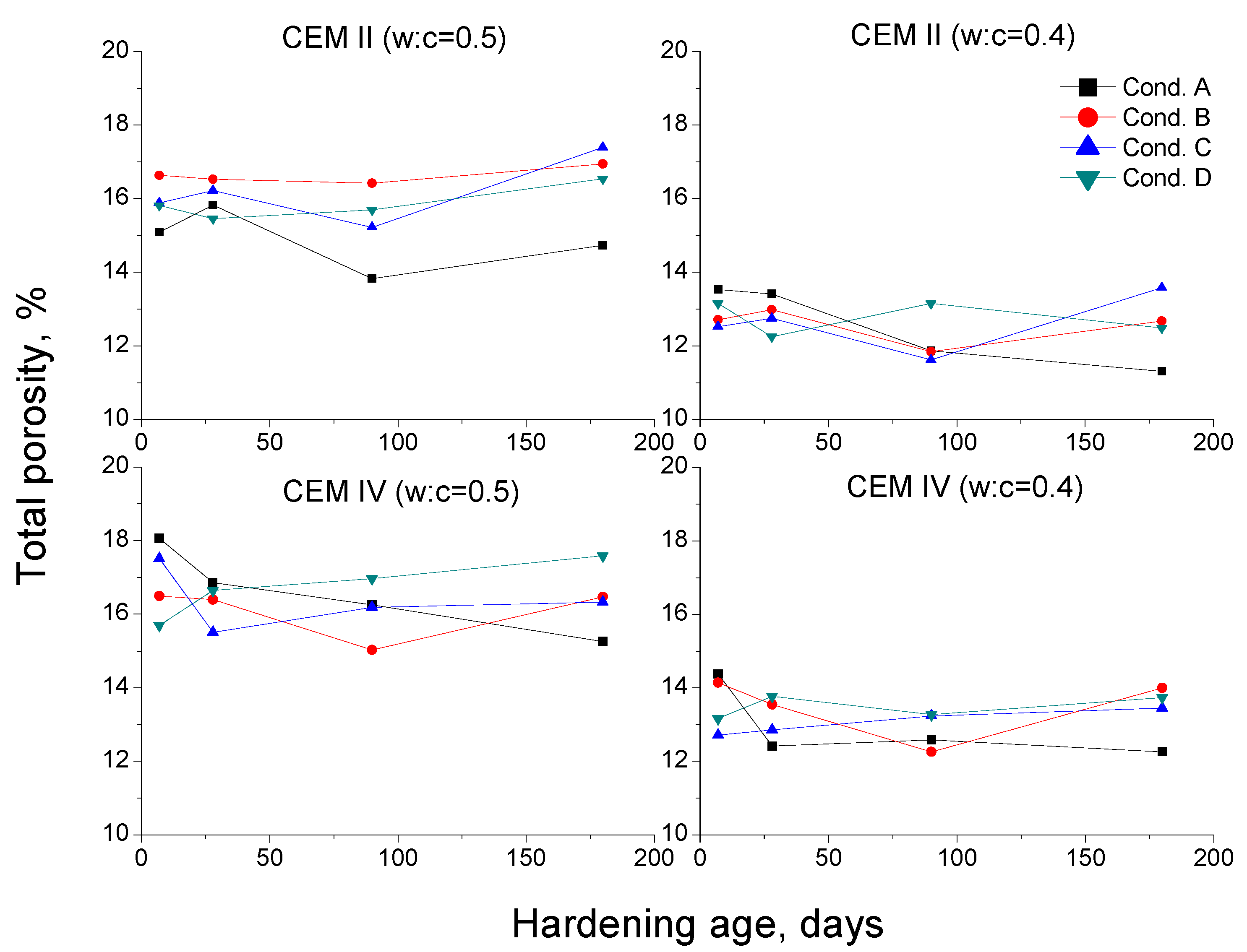

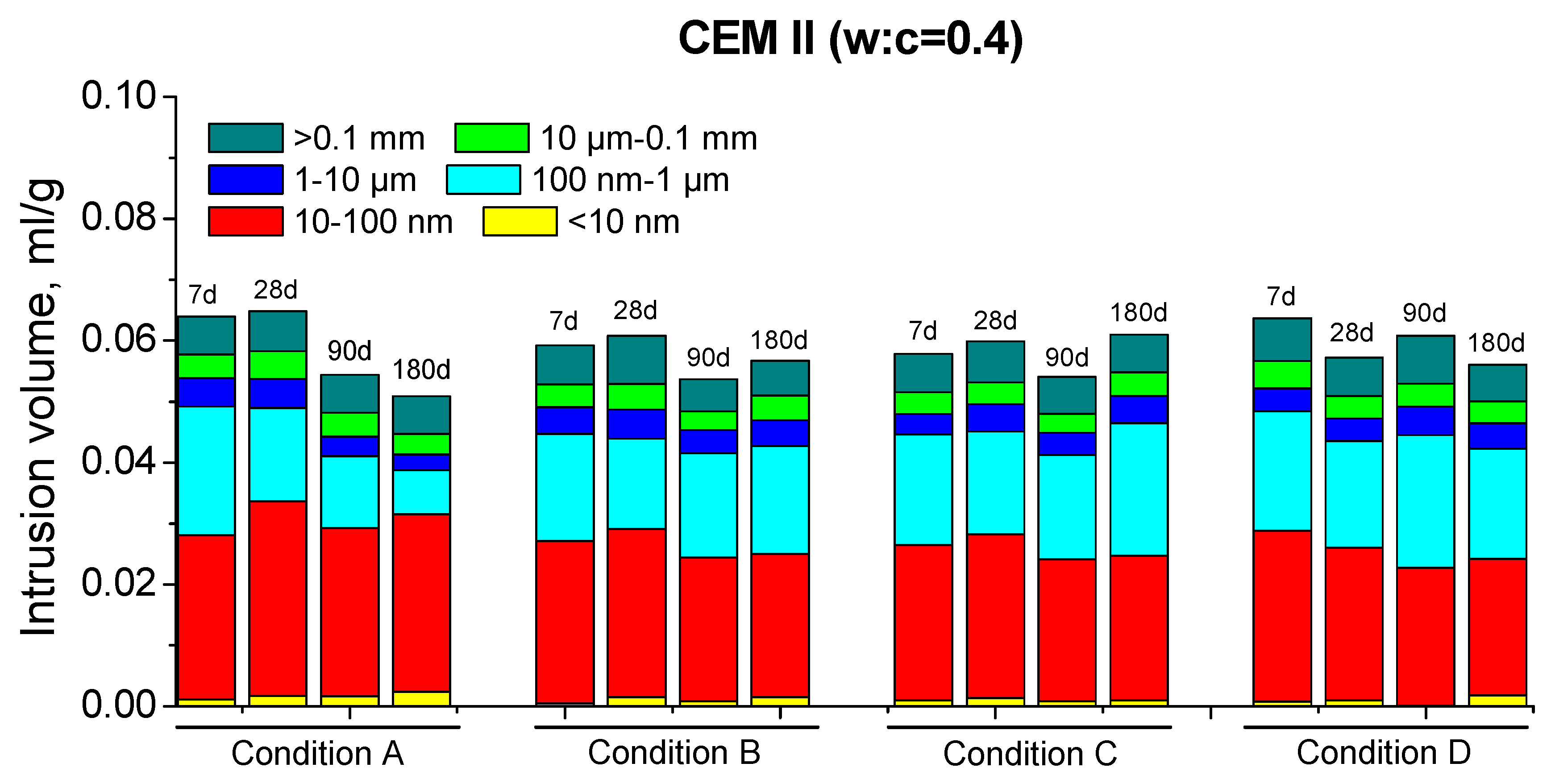

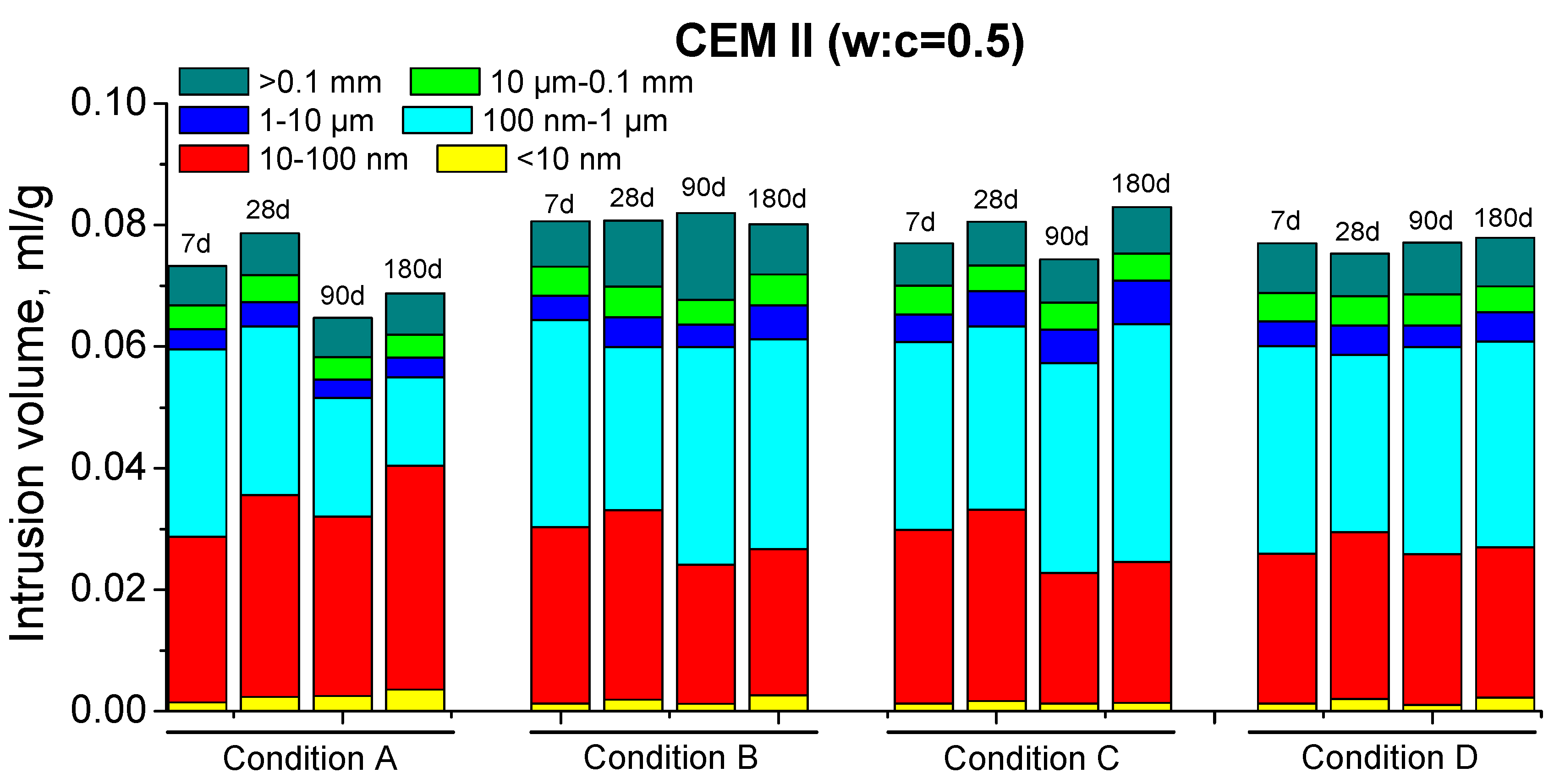

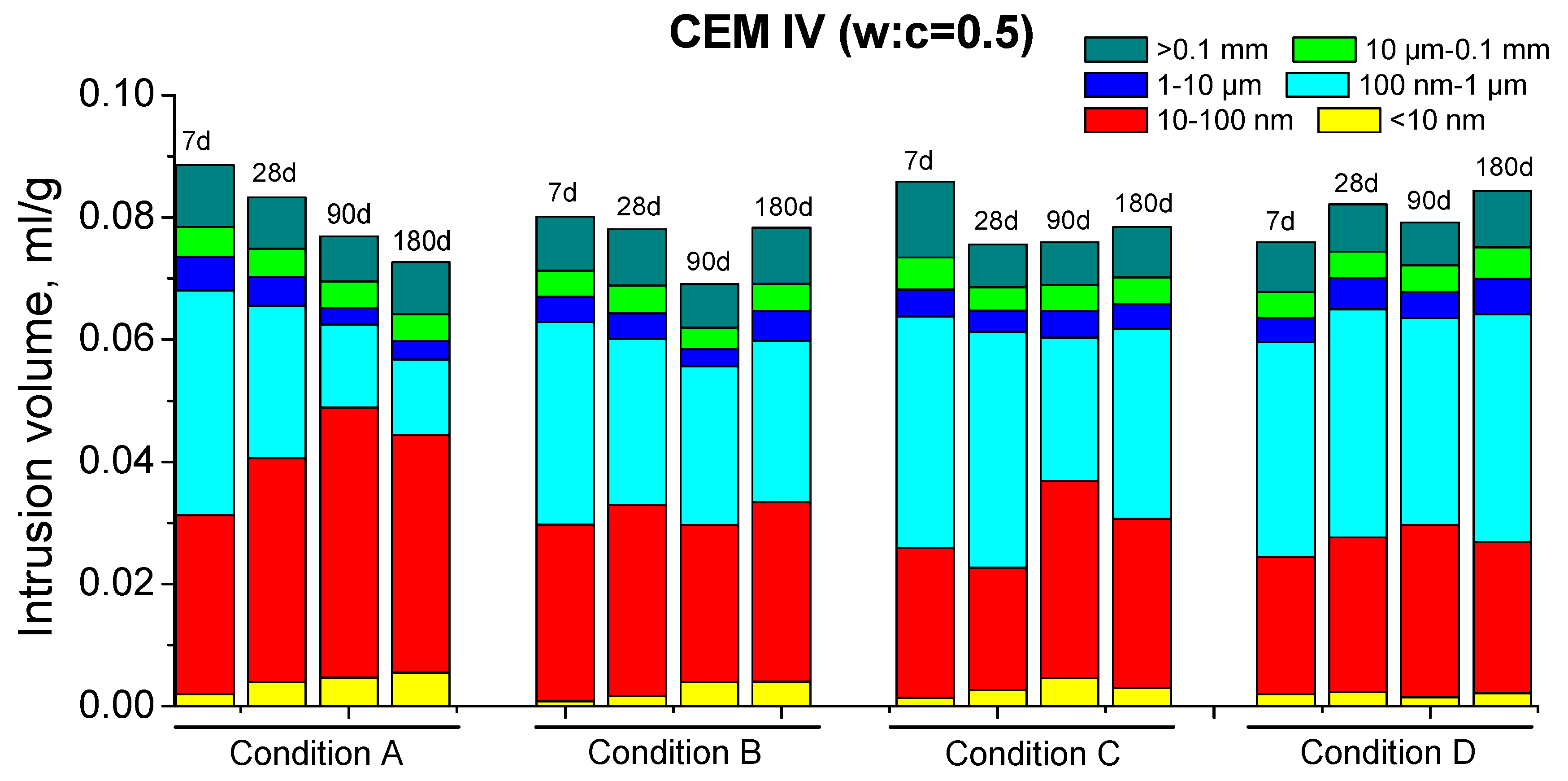

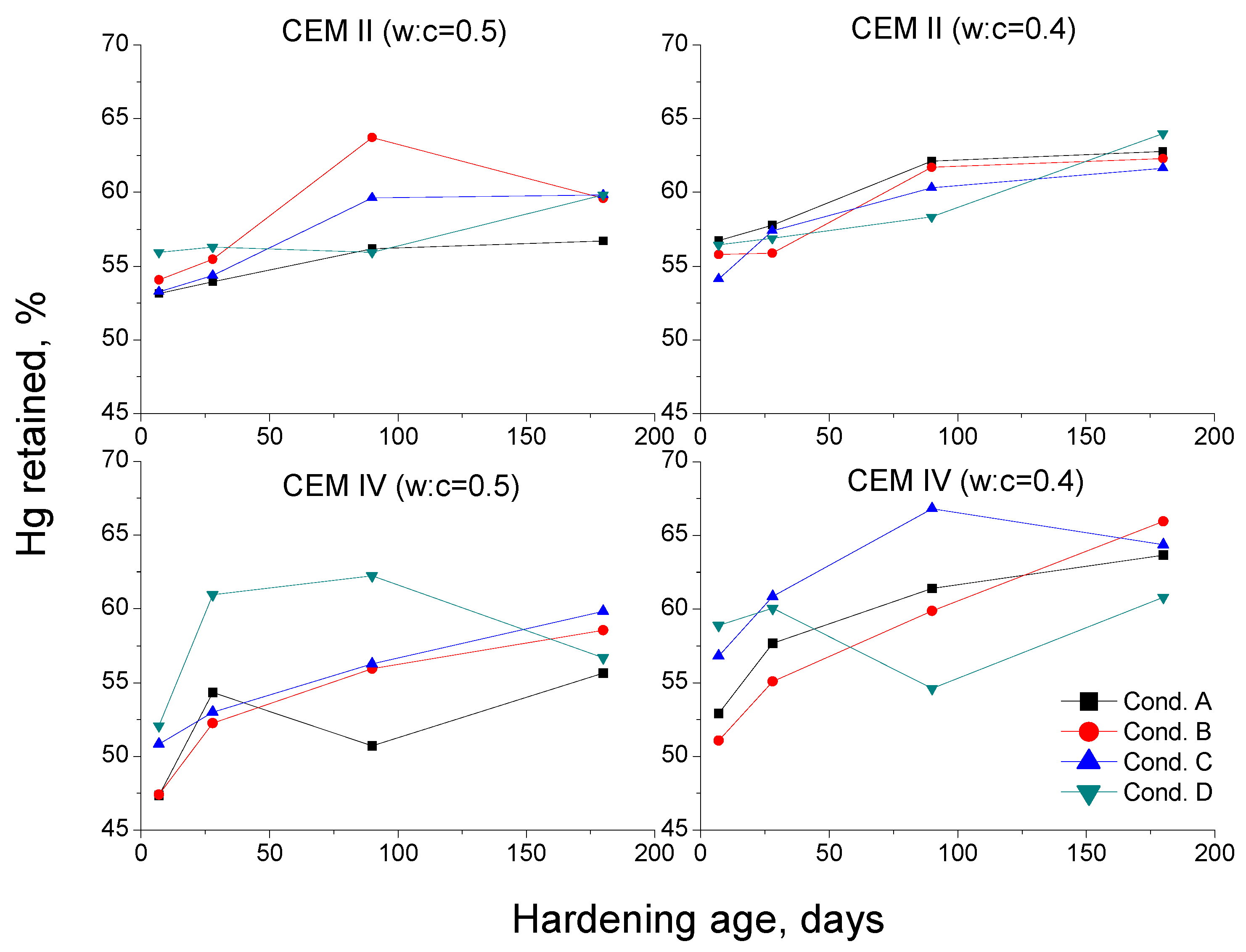

3.1. Mercury Intrusion Porosimetry

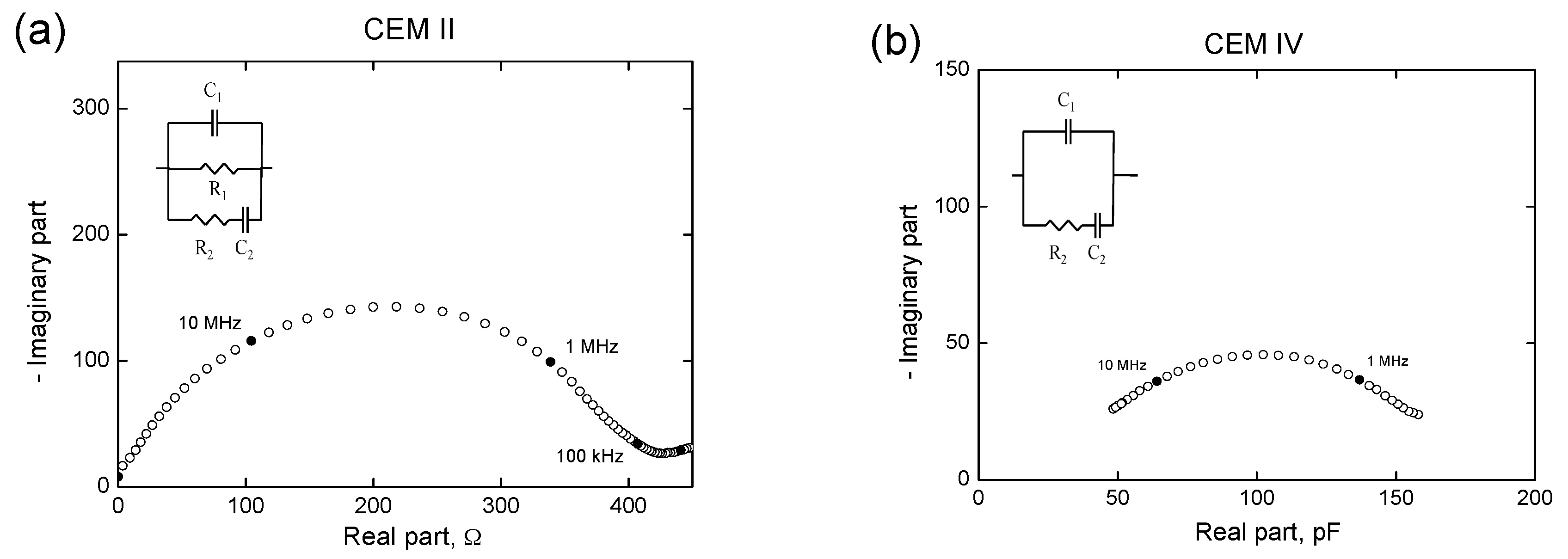

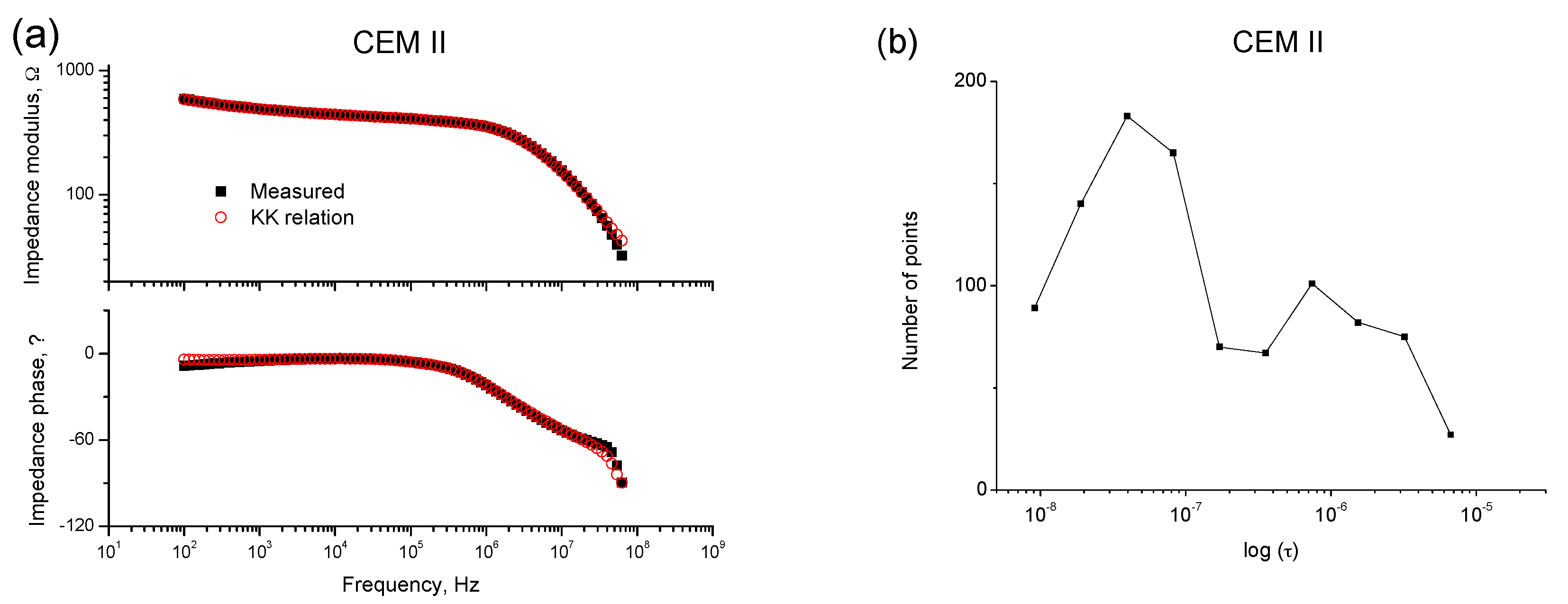

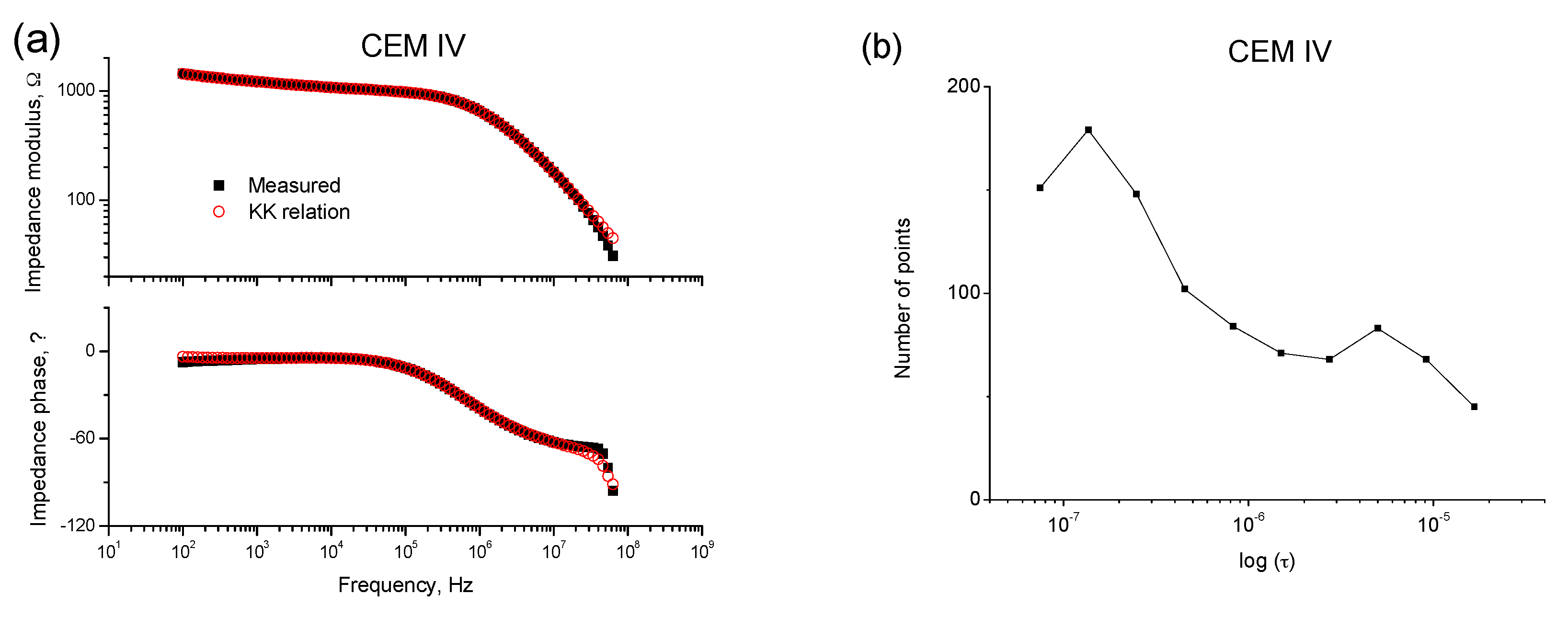

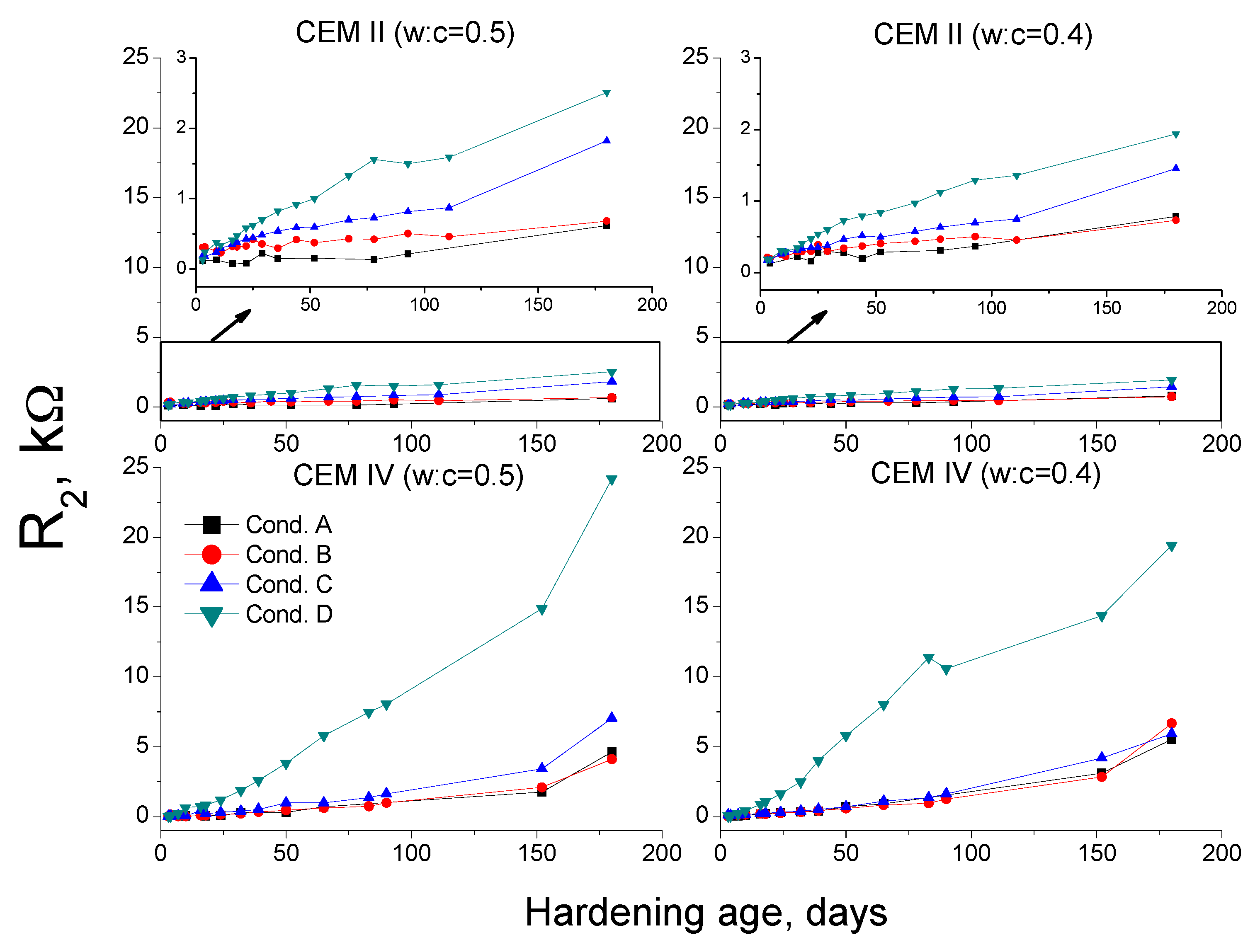

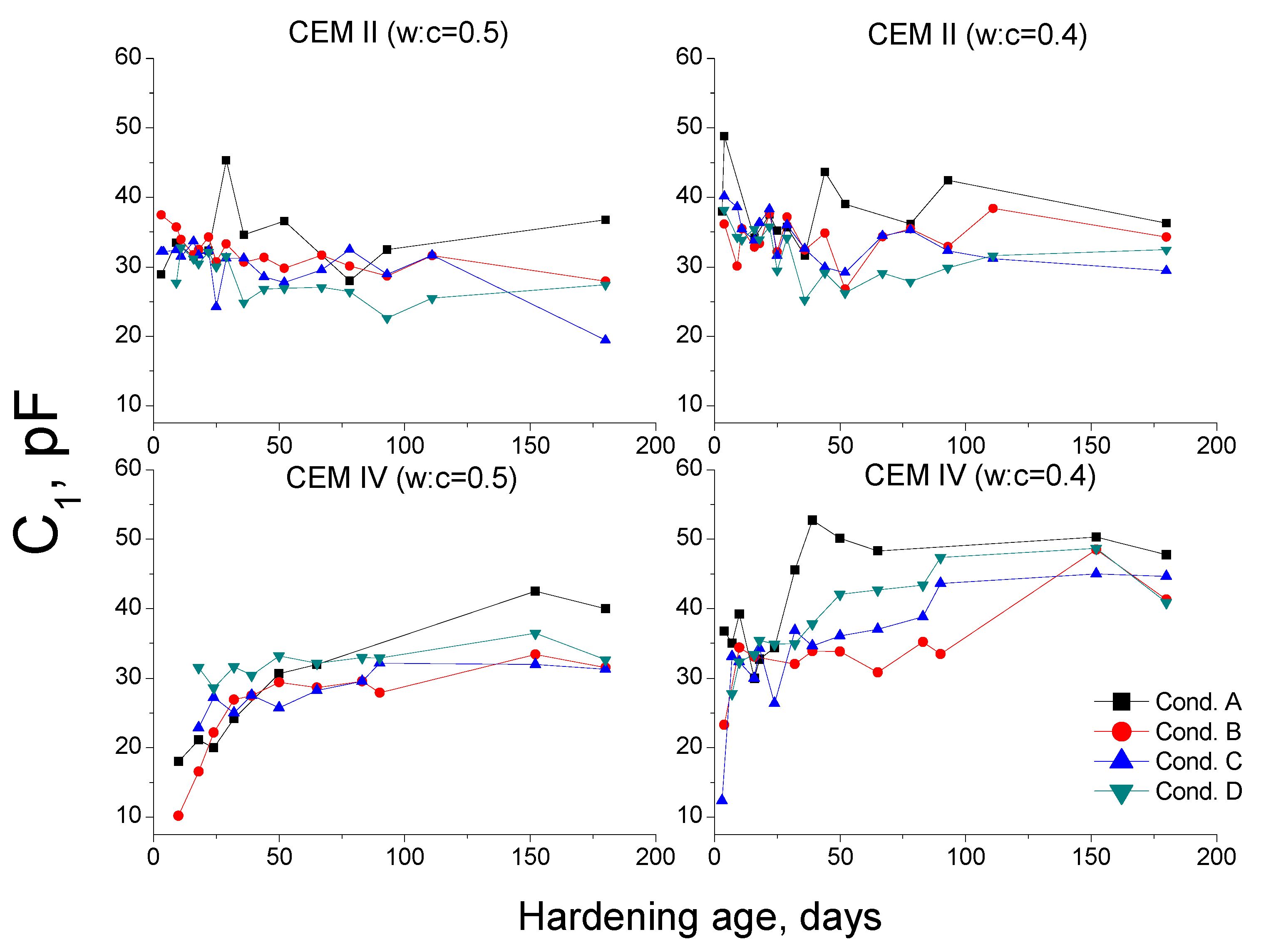

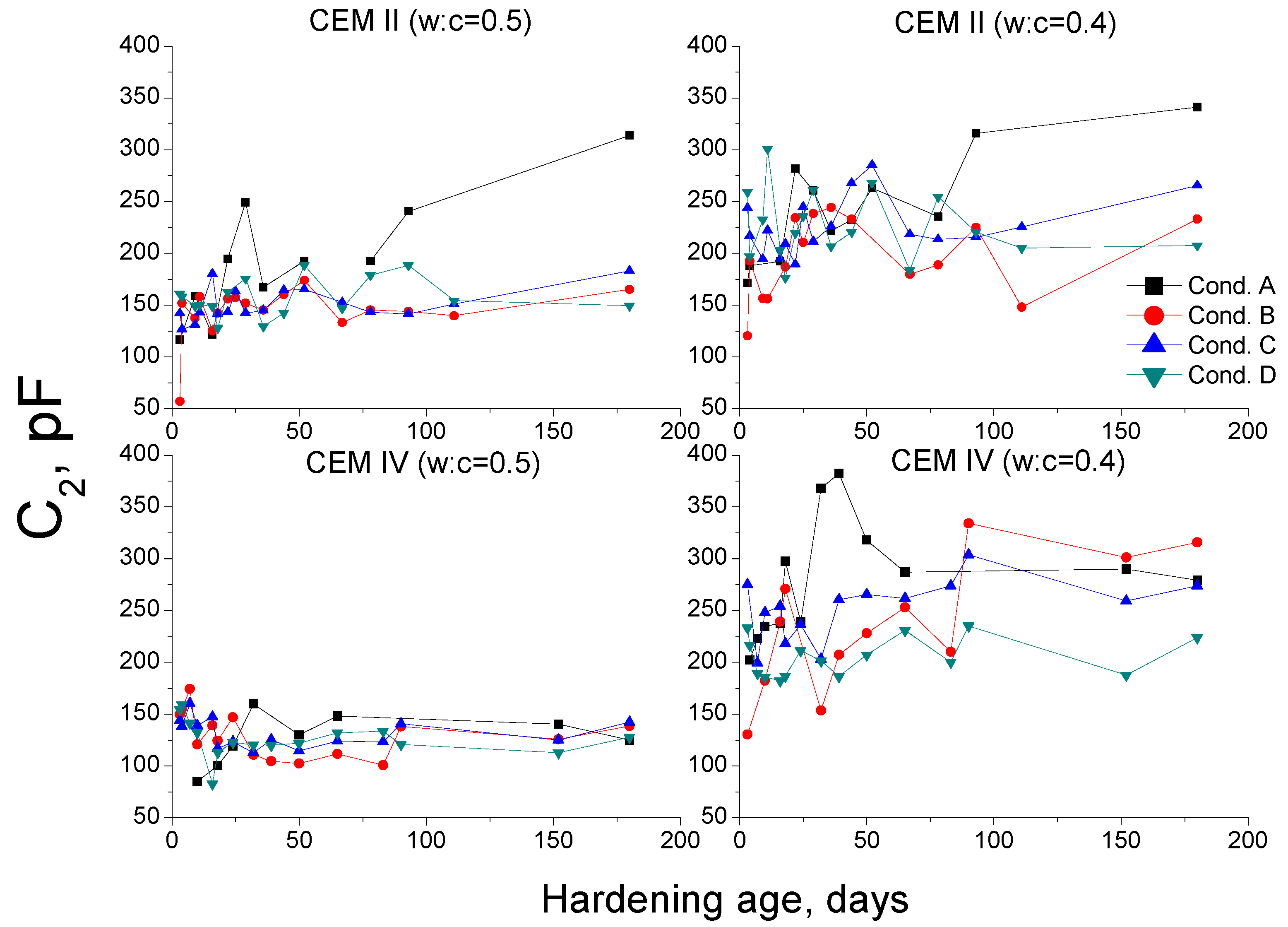

3.2. Impedance Spectroscopy

4. Conclusions

- The influence of the environmental condition on microstructure of fly ash cement mortars can be studied with impedance spectroscopy, using the equivalent circuits already defined for ordinary Portland cement.

- A high environmental relative humidity entails a more refined microstructure of CEM II and IV mortars, because the high availability of water facilitates the clinker hydration, producing a quicker formation of portlandite, which permits an earlier beginning of fly ash pozzolanic reactions.

- Conditions with high temperature bring a more refined microstructure and a lower porosity of CEM II and IV mortars in the short-term, because the clinker hydration is accelerated, causing the subsequent earlier development of fly ash pozzolanic reactions.

- The impedance spectroscopy resistances R1 and R2 obtained for fly ash mortars hardened in conditions with relative humidities lower than 100% are more affected by the drying of the materials than by the microstructure development. This result coincided with those obtained in a previous research for OPC and slag cement mortars exposed to the same conditions, so they would confirm that impedance resistances R1 and R2 are not suitable for following the microstructural evolution of cement-based materials hardened under non-optimum conditions.

- The impedance capacitances C1 and C2 allow following the microstructure development of fly ash cement mortars, and their results are in accordance with MIP ones for all conditions studied in this research.

- The rise of total porosity and the pore refinement loss observed in the long-term for the mortars exposed to drier conditions could be due to the appearance of shrinkage microcracks as a consequence of the low environmental relative humidity.

- The combined analysis of capacitances C1 and C2 evolution could justify the abovementioned formation of shrinkage microcracks for CEM II and IV mortars exposed to the drier environments. This result is also in agreement with that obtained in a previous research for OPC and slag cement mortars exposed to the same conditions, which would corroborate the usefulness of both capacitances for studying shrinkage processes in cement-based materials.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Demirboğa, R. Thermal conductivity and compressive strength of concrete incorporation with mineral admixtures. Build. Environ. 2007, 42, 2467–2471. [Google Scholar] [CrossRef]

- Ganjian, E.; Pouya, H.S. The effect of Persian Gulf tidal zone exposure on durability of mixes containing silica fume and blast furnace slag. Constr. Build. Mater. 2009, 23, 644–652. [Google Scholar] [CrossRef]

- Ponikiewski, T.; Gołaszewski, J. The effect of high-calcium fly ash on selected properties of self-compacting concrete. Arch. Civ. Mech. Eng. 2014, 14, 455–465. [Google Scholar] [CrossRef]

- Glinicki, M.; Jóźwiak-Niedźwiedzka, D.; Gibas, K.; Dąbrowski, M. Influence of Blended Cements with Calcareous Fly Ash on Chloride Ion Migration and Carbonation Resistance of Concrete for Durable Structures. Materials 2016, 9, 18. [Google Scholar] [CrossRef] [PubMed]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Durability related transport properties of OPC and slag cement mortars hardened under different environmental conditions. Constr. Build. Mater. 2012, 27, 176–183. [Google Scholar] [CrossRef]

- Williams, M.; Ortega, J.M.; Sánchez, I.; Cabeza, M.; Climent, M.A. Non-Destructive Study of the Microstructural Effects of Sodium and Magnesium Sulphate Attack on Mortars Containing Silica Fume Using Impedance Spectroscopy. Appl. Sci. 2017, 7, 648. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Cabeza, M.; Climent, M.A. Short-Term Behavior of Slag Concretes Exposed to a Real In Situ Mediterranean Climate Environment. Materials 2017, 10, 915. [Google Scholar] [CrossRef] [PubMed]

- Ortega, J.M.; Esteban, M.D.; Rodríguez, R.R.; Pastor, J.L.; Ibanco, F.J.; Sánchez, I.; Climent, M.A. Influence of Silica Fume Addition in the Long-Term Performance of Sustainable Cement Grouts for Micropiles Exposed to a Sulphate Aggressive Medium. Materials 2017, 10, 890. [Google Scholar] [CrossRef] [PubMed]

- Ortega, J.M.; Sánchez, I.; Climent, M.Á. Influence of different curing conditions on the pore structure and the early age properties of mortars with fly ash and blast-furnace slag. Mater. Constr. 2013, 63, 219–234. [Google Scholar] [CrossRef]

- Ortega, J.M.; Pastor, J.L.; Albaladejo, A.; Sánchez, I.; Climent, M.A. Durability and compressive strength of blast furnace slag-based cement grout for special geotechnical applications. Mater. Constr. 2014, 64. [Google Scholar] [CrossRef] [Green Version]

- Bijen, J. Benefits of slag and fly ash. Constr. Build. Mater. 1996, 10, 309–314. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of fly ash on Portland cement systems. Cem. Concr. Res. 1999, 29, 1727–1736. [Google Scholar] [CrossRef]

- Wang, A.; Zhang, C.; Sun, W. Fly ash effects. Cem. Concr. Res. 2004, 34, 2057–2060. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Homwuttiwong, S.; Sirivivatnanon, V. Influence of fly ash fineness on strength, drying shrinkage and sulfate resistance of blended cement mortar. Cem. Concr. Res. 2004, 34, 1087–1092. [Google Scholar] [CrossRef]

- Nochaiya, T.; Wongkeo, W.; Chaipanich, A. Utilization of fly ash with silica fume and properties of Portland cement–fly ash–silica fume concrete. Fuel 2010, 89, 768–774. [Google Scholar] [CrossRef]

- Ortega, J.M.; Esteban, M.D.; Rodríguez, R.R.; Pastor, J.L.; Sánchez, I. Microstructural Effects of Sulphate Attack in Sustainable Grouts for Micropiles. Materials 2016, 9, 905. [Google Scholar] [CrossRef] [PubMed]

- Ortega, J.M.; Esteban, M.D.; Rodríguez, R.R.; Pastor, J.L.; Ibanco, F.J.; Sánchez, I.; Climent, M.A. Long-Term Behaviour of Fly Ash and Slag Cement Grouts for Micropiles Exposed to a Sulphate Aggressive Medium. Materials 2017, 10, 598. [Google Scholar] [CrossRef] [PubMed]

- Sánchez, I.; López, M.P.; Ortega, J.M.; Climent, M.Á. Impedance spectroscopy: An efficient tool to determine the non-steady-state chloride diffusion coefficient in building materials. Mater. Corros. 2011, 62, 139–145. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on microstructure of blended cement paste. Constr. Build. Mater. 2007, 21, 1534–1541. [Google Scholar] [CrossRef]

- Leng, F.; Feng, N.; Lu, X. An experimental study on the properties of resistance to diffusion of chloride ions of fly ash and blast furnace slag concrete. Cem. Concr. Res. 2000, 30, 989–992. [Google Scholar] [CrossRef]

- Chalee, W.; Ausapanit, P.; Jaturapitakkul, C. Utilization of fly ash concrete in marine environment for long term design life analysis. Mater. Des. 2010, 31, 1242–1249. [Google Scholar] [CrossRef]

- Pastor, J.L.; Ortega, J.M.; Flor, M.; López, M.P.; Sánchez, I.; Climent, M.A. Microstructure and durability of fly ash cement grouts for micropiles. Constr. Build. Mater. 2016, 117, 47–57. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Antón, C.; De Vera, G.; Climent, M.A. Influence of environment on durability of fly ash cement mortars. ACI Mater. J. 2012, 109, 647–656. [Google Scholar]

- Wedding, P.; Manmohan, D.; Mehta, P. Influence of Pozzolanic, Slag, and Chemical Admixtures on Pore Size Distribution and Permeability of Hardened Cement Pastes. Cem. Concr. Aggreg. 1981, 3, 63. [Google Scholar] [CrossRef]

- Ouellet, S.; Bussière, B.; Aubertin, M.; Benzaazoua, M. Microstructural evolution of cemented paste backfill: Mercury intrusion porosimetry test results. Cem. Concr. Res. 2007, 37, 1654–1665. [Google Scholar] [CrossRef]

- Baroghel-Bouny, V. Water vapour sorption experiments on hardened cementitious materials. Cem. Concr. Res. 2007, 37, 414–437. [Google Scholar] [CrossRef]

- Popovics, J.S.; Subramaniam, K.V.L. Review of Ultrasonic Wave Reflection Applied to Early-Age Concrete and Cementitious Materials. J. Nondestruct. Eval. 2014, 34, 267. [Google Scholar] [CrossRef]

- Kogbara, R.B.; Iyengar, S.R.; Grasley, Z.C.; Masad, E.A.; Zollinger, D.G. Non-destructive evaluation of concrete mixtures for direct LNG containment. Mater. Des. 2015, 82, 260–272. [Google Scholar] [CrossRef]

- Henry, M.; Darma, I.S.; Sugiyama, T. Analysis of the effect of heating and re-curing on the microstructure of high-strength concrete using X-ray CT. Constr. Build. Mater. 2014, 67, 37–46. [Google Scholar] [CrossRef]

- Demčenko, A.; Visser, H.A.; Akkerman, R. Ultrasonic measurements of undamaged concrete layer thickness in a deteriorated concrete structure. NDT E Int. 2016, 77, 63–72. [Google Scholar] [CrossRef]

- Kang, X.; Ge, L. Enhanced series-parallel model for estimating the time-dependent thermal conductivity of fly ash soil mixtures. Granul. Matter 2015, 17, 579–592. [Google Scholar] [CrossRef]

- Kim, K.-H.; Jeon, S.-E.; Kim, J.-K.; Yang, S. An experimental study on thermal conductivity of concrete. Cem. Concr. Res. 2003, 33, 363–371. [Google Scholar] [CrossRef]

- Kang, X.; Ge, L.; Kang, G.-C.; Mathews, C. Laboratory investigation of the strength, stiffness, and thermal conductivity of fly ash and lime kiln dust stabilised clay subgrade materials. Road Mater. Pavement Des. 2015, 16, 928–945. [Google Scholar] [CrossRef]

- McCarter, W.J.; Brousseau, R. The A.C. response of hardened cement paste. Cem. Concr. Res. 1990, 20, 891–900. [Google Scholar] [CrossRef]

- Havriliak, S., Jr.; Havriliak, S.J. Dielectrical and Mechanical Relaxation in Materials; Hanser Publishers: Munich, Germany, 1997. [Google Scholar]

- Cabeza, M.; Merino, P.; Miranda, A.; Nóvoa, X.R.; Sanchez, I. Impedance spectroscopy study of hardened Portland cement paste. Cem. Concr. Res. 2002, 32, 881–891. [Google Scholar] [CrossRef]

- Sánchez, I.; Antón, C.; de Vera, G.; Ortega, J.M.; Climent, M.A. Moisture Distribution in Partially Saturated Concrete Studied by Impedance Spectroscopy. J. Nondestruct. Eval. 2013, 32, 362–371. [Google Scholar] [CrossRef] [Green Version]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Impedance spectroscopy study of the effect of environmental conditions in the microstructure development of OPC and slag cement mortars. Arch. Civ. Mech. Eng. 2015, 15, 569–583. [Google Scholar] [CrossRef]

- Ortega, J.M.; Albaladejo, A.; Pastor, J.L.; Sánchez, I.; Climent, M.A. Influence of using slag cement on the microstructure and durability related properties of cement grouts for micropiles. Constr. Build. Mater. 2013, 38, 84–93. [Google Scholar] [CrossRef]

- Maltais, Y.; Marchand, J. Influence of curing temperature on cement hydration and mechanical strength development of fly ash mortars. Cem. Concr. Res. 1997, 27, 1009–1020. [Google Scholar] [CrossRef]

- Escalante-García, J.I.; Sharp, J.H. Effect of temperature on the hydration of the main clinker phases in Portland cements: Part I, neat cements. Cem. Concr. Res. 1998, 28, 1245–1257. [Google Scholar] [CrossRef]

- Escalante-García, J.I.; Sharp, J.H. Effect of temperature on the hydration of the main clinker phasesin Portland cements: Part II, blended cements. Cem. Concr. Res. 1998, 28, 1259–1274. [Google Scholar] [CrossRef]

- Hanehara, S.; Tomosawa, F.; Kobayakawa, M.; Hwang, K. Effects of water/powder ratio, mixing ratio of fly ash, and curing temperature on pozzolanic reaction of fly ash in cement paste. Cem. Concr. Res. 2001, 31, 31–39. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Malhotra, V.M. Effect of curing on the compressive strength, resistance to chloride-ion penetration and porosity of concretes incorporating slag, fly ash or silica fume. Cem. Concr. Compos. 1995, 17, 125–133. [Google Scholar] [CrossRef]

- Shafiq, N.; Cabrera, J.G. Effects of initial curing condition on the fluid transport properties in OPC and fly ash blended cement concrete. Cem. Concr. Compos. 2004, 26, 381–387. [Google Scholar] [CrossRef]

- AENOR. Composición, Especificaciones y Criterios de Conformidad de los Cementos Comunes; UNE-EN 197-1:2011; AENOR: Madrid, Spain, 2011; p. 30. [Google Scholar]

- Deutsches Institut für Normung e.V. Deutsche Norm DIN 50008 Part 1; DIN: Berlin, Germany, 1981. [Google Scholar]

- Diamond, S. Aspects of concrete porosity revisited. Cem. Concr. Res. 1999, 29, 1181–1188. [Google Scholar] [CrossRef]

- Diamond, S. Mercury porosimetry. Cem. Concr. Res. 2000, 30, 1517–1525. [Google Scholar] [CrossRef]

- Sánchez, I.; Albertos, T.S.; Ortega, J.M.; Climent, M.A. Influence of environmental conditions on durability properties of fly ash cement mortars. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; Zachar, J., Claisse, P., Naik, T.R., Ganjian, E., Eds.; pp. 655–666. [Google Scholar]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Influence of environmental conditions on durability of slag cement mortars. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; Zachar, J., Claisse, P., Naik, T.R., Ganjian, E., Eds.; pp. 277–287. [Google Scholar]

- Ortega, J.M.; Ferrandiz, V.; Antón, C.; Climent, M.A.; Sánchez, I. Influence of curing conditions on the mechanical properties and durability of cement mortars. In Materials Characterisation IV: Computational Methods and Experiments; Mammoli, A.A., Brebbia, C.A., Eds.; WIT Press: Southampton, UK, 2009; pp. 381–392. [Google Scholar]

- Barsoukov, E.; Macdonald, J.R. Impedance Spectroscopy; Barsoukov, E., Macdonald, J.R., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Neville, A.M. Properties of Concrete, 4th ed.; Pearson Education Limited: Harlow, UK, 1995. [Google Scholar]

- Climent, M.A.; Ortega, J.M.; Sánchez, I. Cement mortars with fly ash and slag—Study of their microstructure and resistance to salt ingress in different environmental conditions. In Concrete Repair, Rehabilitation and Retrofitting III, Proceedings of the 3rd International Conference on Concrete Repair, Rehabilitation and Retrofitting, ICCRRR 2012, Cape Town, South Africa, 3–5 September 2012; Taylor & Francis Group: London, UK, 2012; pp. 345–350. [Google Scholar]

- Kanna, V.; Olson, R.A.; Jennings, H.M. Effect of shrinkage and moisture content on the physical characteristics of blended cement mortars. Cem. Concr. Res. 1998, 28, 1467–1477. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on compressive strength and pore size of blended cement paste. Cem. Concr. Compos. 2005, 27, 425–428. [Google Scholar] [CrossRef]

- Cabeza, M.; Keddam, M.; Nóvoa, X.R.; Sánchez, I.; Takenouti, H. Impedance spectroscopy to characterize the pore structure during the hardening process of Portland cement paste. Electrochim. Acta 2006, 51, 1831–1841. [Google Scholar] [CrossRef]

| Condition | Temperature | Relative Humidity | Represented Climate |

|---|---|---|---|

| Condition A | 20 °C | 100% | Laboratory condition |

| Condition B | 15 °C | 85% | Atlantic climate |

| Condition C | 20 °C | 65% | Mediterranean climate |

| Condition D | 30 °C | 40% | Extreme condition |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortega, J.M.; Sánchez, I.; Climent, M.Á. Impedance Spectroscopy Study of the Effect of Environmental Conditions on the Microstructure Development of Sustainable Fly Ash Cement Mortars. Materials 2017, 10, 1130. https://doi.org/10.3390/ma10101130

Ortega JM, Sánchez I, Climent MÁ. Impedance Spectroscopy Study of the Effect of Environmental Conditions on the Microstructure Development of Sustainable Fly Ash Cement Mortars. Materials. 2017; 10(10):1130. https://doi.org/10.3390/ma10101130

Chicago/Turabian StyleOrtega, José Marcos, Isidro Sánchez, and Miguel Ángel Climent. 2017. "Impedance Spectroscopy Study of the Effect of Environmental Conditions on the Microstructure Development of Sustainable Fly Ash Cement Mortars" Materials 10, no. 10: 1130. https://doi.org/10.3390/ma10101130