On the Effect of Hydrogen on the Low-Temperature Elastic and Anelastic Properties of Ni-Ti-Based Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results

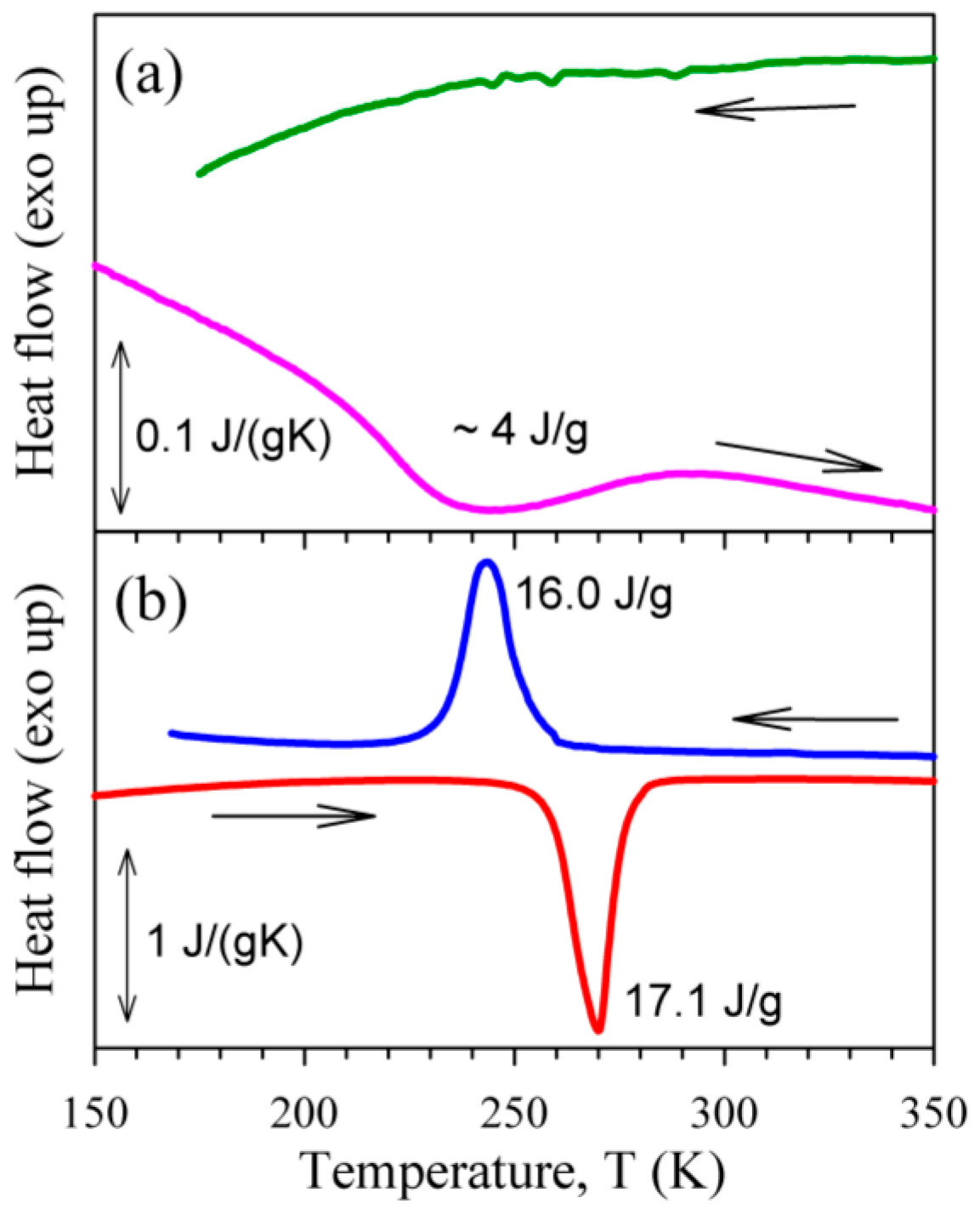

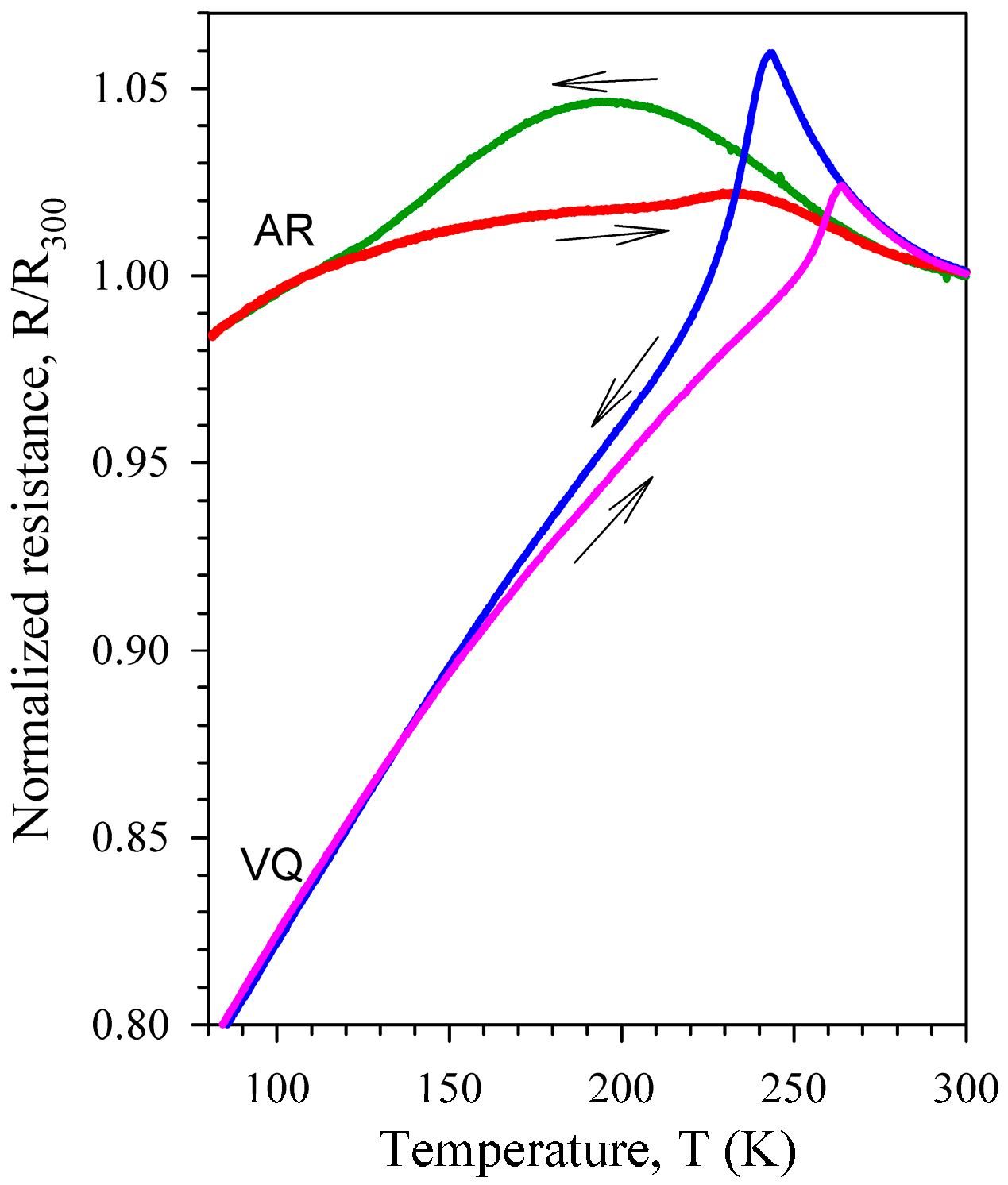

3.1. Characterization of Martensitic Transformations Using Calorimetry and Resistance Data

3.2. Hydrogen Content Evaluation

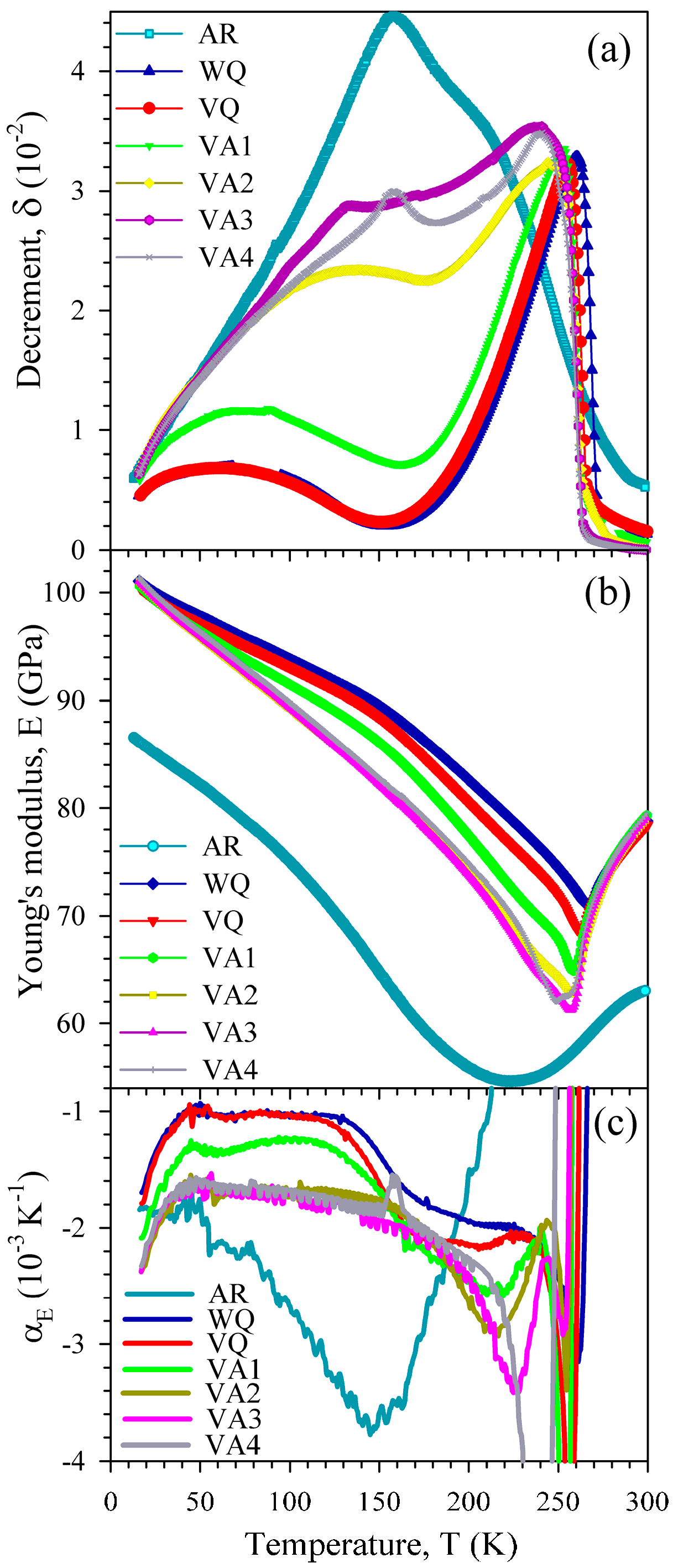

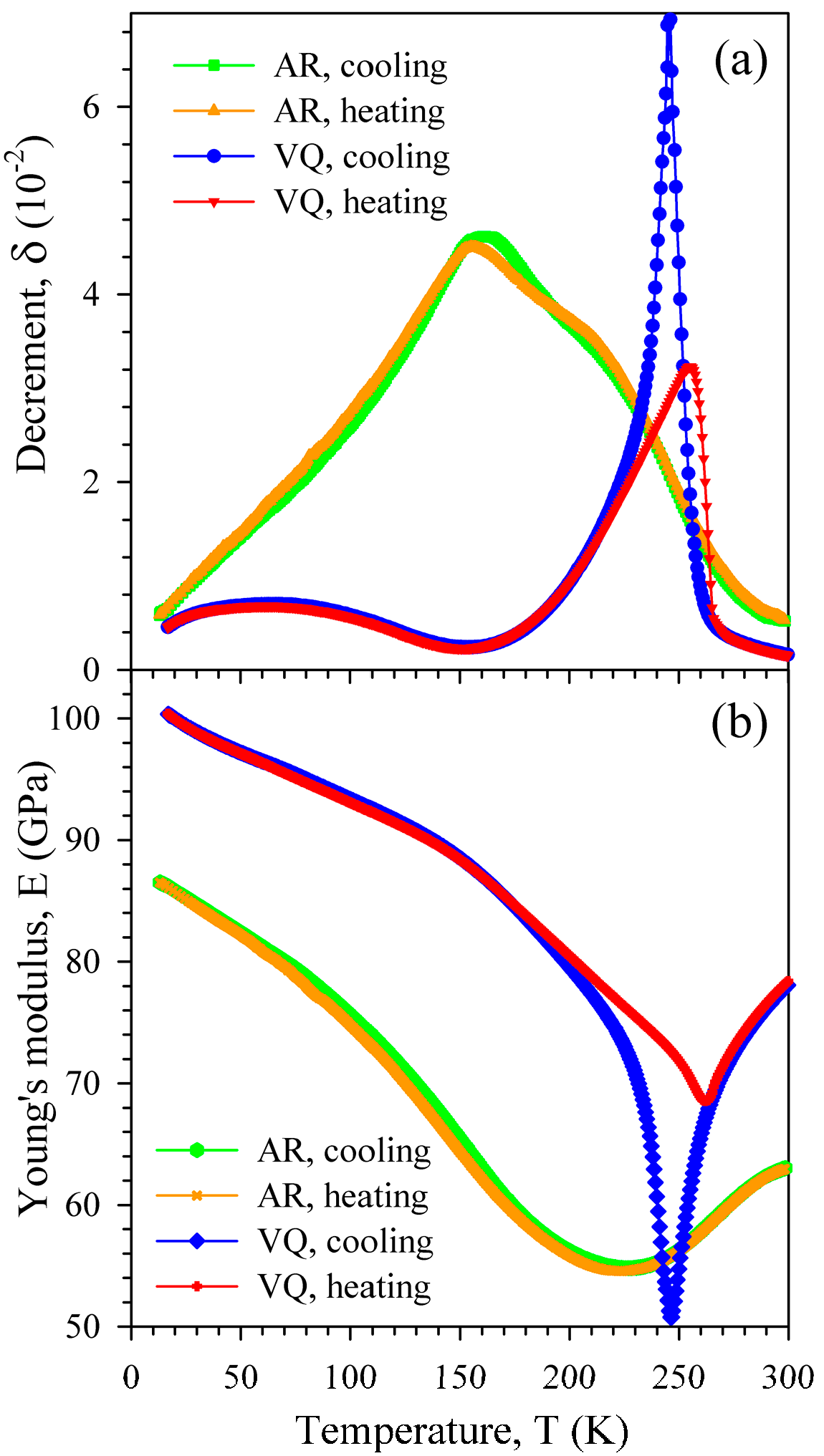

3.3. Temperature Dependence of the Internal Friction and Young’s Modulus

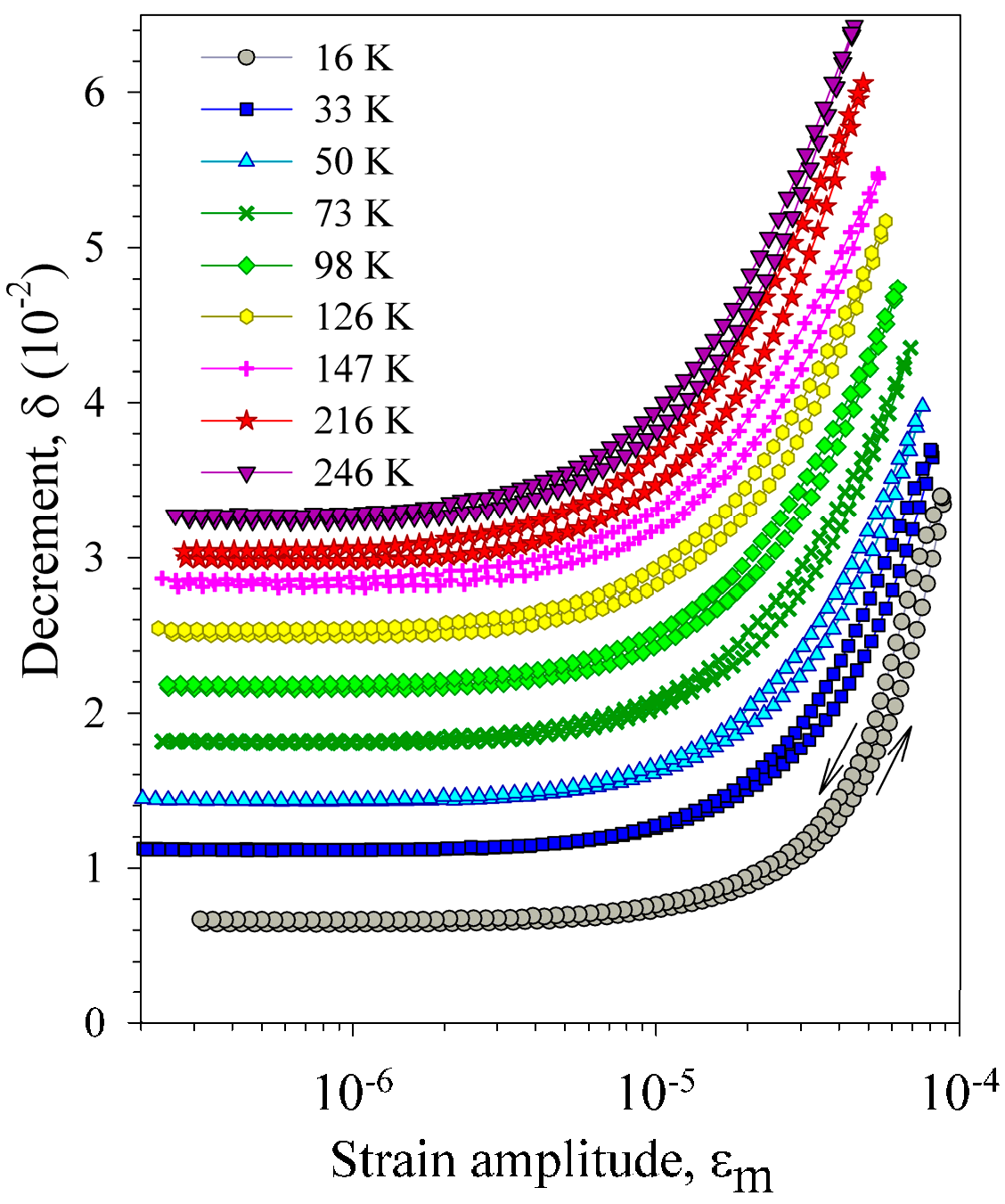

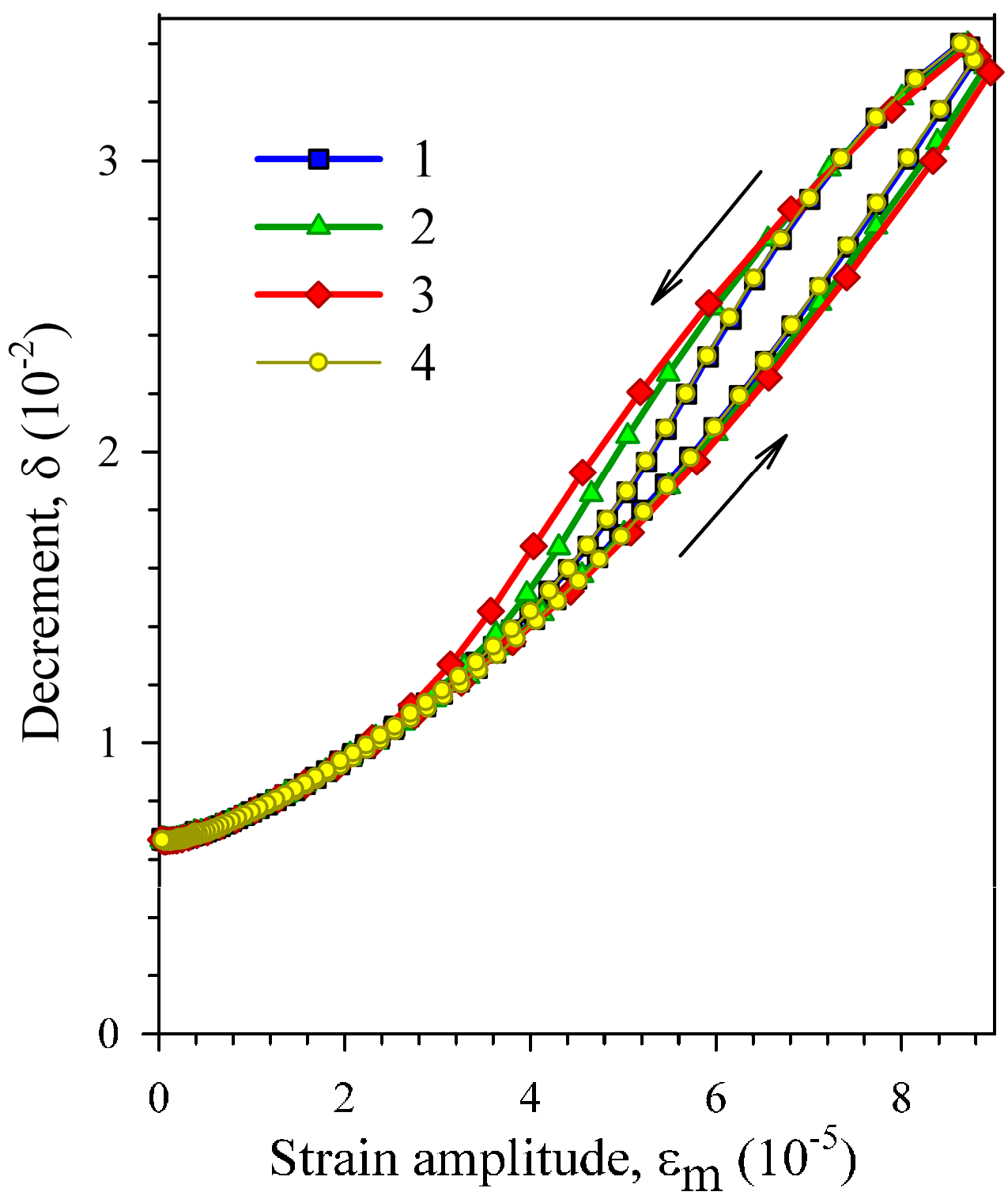

3.4. Strain Amplitude Dependence of the Internal Friction

4. Discussion

5. Conclusions

- (1)

- The martensitic transformation in the cold-worked (strain of about 40%) Ni50.8Ti49.2 alloy is only partial and very diffuse. High amplitude-independent IF in the cold-worked state is due to grain boundaries and/or bulk dislocations, rather than to twin boundaries, as is the case for heat-treated states of the alloy.

- (2)

- Contamination of the Ni50.8Ti49.2 alloy by hydrogen strongly affects the IF and Young’s modulus of the martensitic phase.

- (3)

- Presence of hydrogen gives rise to a non-relaxation IF maximum, whose temperature and height depend strongly on the hydrogen content.

- (4)

- The observed non-relaxation IF maximum is formed due to a competition of two different temperature-dependent processes affecting the hydrogen concentration in the core regions of twin boundaries (after heat treatments) or grain boundaries/bulk dislocations (after cold-working).

- (5)

- Many of the low-temperature IF peaks (Tirbonod-Koshimizu peak, Pd, PTWM, P150K, P200K’, P50K, PH’), reported earlier for differently treated Ni-Ti-based alloys, have actually the same origin as the present maximum.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Blanter, M.S.; Golovin, I.S.; Neuhäuser, H.; Sinning, H.-R. Internal Friction in Metallic Materials. A Handbook; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Hasiguti, R.R.; Iwasaki, K. Internal friction and related properties of the TiNi intermetallic compound. J. Appl. Phys. 1968, 39, 2182–2186. [Google Scholar] [CrossRef]

- Fan, G.; Zhou, Y.; Otsuka, K.; Ren, X.; Nakamura, K.; Ohba, T.; Suzuki, T.; Yoshida, I.; Yin, F. Effects of frequency, composition, hydrogen and twin boundary density on the internal friction of Ti50Ni50-xCux shape memory alloys. Acta Mater. 2006, 54, 5221–5229. [Google Scholar] [CrossRef]

- Fan, G.; Otsuka, K.; Ren, X.; Yin, F. Twofold role of dislocations in the relaxation behavior of Ti-Ni martensite. Acta Mater. 2008, 56, 632–641. [Google Scholar] [CrossRef]

- Tirbonod, B.; Koshimizu, S. Dislocation relaxation in the martensitic phase of the thermoelastic NiTi and NiTiCu alloys. J. Phys. 1981, 42, C5-1043–C5-1047. [Google Scholar] [CrossRef]

- Coluzzi, B.; Biscarini, A.; Campanella, R.; Trotta, L.; Mazzolai, G.; Tuissi, A.; Mazzolai, F.M. Mechanical spectroscopy and twin boundary properties in a Ni50.8Ti49.2 alloy. Acta Mater. 1999, 47, 1965–1976. [Google Scholar] [CrossRef]

- Coluzzi, B.; Biscarini, A.; Campanella, R.; Mazzolai, G.; Trotta, L.; Mazzolai, F.M. Effect of thermal cycling through the martensitic transition on the internal friction and Young’s modulus of a Ni50.8Ti49.2 alloy. J. Alloys Compd. 2000, 310, 300–305. [Google Scholar] [CrossRef]

- Mazzolai, F.M.; Coluzzi, B.; Mazzolai, G.; Biscarini, A. Hydrogen diffusion and interpretation of the 200K anelastic relaxation in NiTi alloys. Appl. Phys. Lett. 2004, 85, 2756–2758. [Google Scholar] [CrossRef]

- Coluzzi, B.; Biscarini, A.; Mazzolai, G.; Mazzolai, F.M.; Tuissi, A. Damping spectrum of H-free and H-doped shape memory alloys NiTiHfCu at kHz frequencies. Scr. Mater. 2004, 51, 199–202. [Google Scholar] [CrossRef]

- Villa, E.; Tuissi, A.; Coluzzi, B.; Biscarini, A.; Mazzolai, G.; Mazzolai, F.M. Dependence on composition of the internal friction of Ni100-xTix alloys containing hydrogen. Mater. Sci. Eng. A 2009, 521–522, 175–177. [Google Scholar] [CrossRef]

- Coluzzi, B.; Biscarini, A.; Mazzolai, G.; Mazzolai, F.M. A new low-temperature internal friction peak in NiTi based alloys. Mater. Sci. Eng. A 2006, 442, 414–417. [Google Scholar] [CrossRef]

- Mazzolai, F.M.; Biscarini, A.; Coluzzi, B.; Mazzolai, G.; Villa, E.; Tuissi, A. Low-frequency internal friction of hydrogen-free and hydrogen-doped NiTi alloys. Acta Mater. 2007, 55, 4243–4252. [Google Scholar] [CrossRef]

- Mazzolai, G. Recent progresses in the understanding of the elastic and anelastic properties of H-free, H-doped and H-contaminated NiTi based alloys. AIP Adv. 2011, 1, 040701-1–040701-24. [Google Scholar] [CrossRef]

- Biscarini, A.; Campanella, R.; Coluzzi, B.; Mazzolai, G.; Trotta, L.; Tuissi, A.; Mazzolai, F.M. Martensitic transitions and mechanical spectroscopy of Ni50.8Ti49.2 alloy containing hydrogen. Acta Mater. 1999, 47, 4525–4533. [Google Scholar] [CrossRef]

- Biscarini, A.; Coluzzi, B.; Mazzolai, G.; Mazzolai, F.M.; Tuissi, A. Mechanical spectroscopy of the H-free and H-doped Ni30Ti50Cu20 shape memory alloy. J. Alloys Compd. 2003, 356–357, 669–672. [Google Scholar] [CrossRef]

- Sakaguchi, T.; Uehara, T.; Kogo, Y.; Takeuchi, S.; Igata, N. Effect of hydrogen on damping capacity of Ti50Ni25Cu25 alloy. Mater. Trans. 2005, 46, 1306–1310. [Google Scholar] [CrossRef]

- Yokoyama, K.; Tomita, M.; Sakai, J. Hydrogen embrittlement behavior induced by dynamic martensite transformation of Ni-Ti superelastic alloy. Acta Mater. 2009, 57, 1875–1885. [Google Scholar] [CrossRef]

- Saito, T.; Yokoyama, T.; Takasaki, A. Hydrogenation of TiNi shape memory alloy produced by mechanical alloying. J. Alloy. Compd. 2011, 509 (Suppl. 2), S779–S781. [Google Scholar] [CrossRef]

- Ribeiro, R.M.; Lemus, L.F.; dos Santos, D.S. Hydrogen absorption study of Ti-based alloys performed by melt-spinning. Mater. Res. 2013, 16, 679–682. [Google Scholar] [CrossRef]

- Robinson, W.H.; Edgar, A. The piezoelectric method of determining mechanical damping at frequencies of 30 to 200 kHz. IEEE Trans. Sonics Ultrason. 1974, 21, 98–105. [Google Scholar] [CrossRef]

- Kustov, S.; Golyandin, S.; Ichino, A.; Gremaud, G. A new design of automated piezoelectric composite oscillator technique. Mater. Sci. Eng. A 2006, 442, 532–537. [Google Scholar] [CrossRef]

- Polyanskiy, A.M.; Polyanskiy, V.A.; Yakovlev, Yu.A. Experimental determination of parameters of multichannel hydrogen diffusion in solid probe. Int. J. Hydrogen Energy 2014, 39, 17381–17390. [Google Scholar] [CrossRef]

- Golyandin, S.; Kustov, S.; Sapozhnikov, K.; Parlinska, M.; Gotthardt, R.; Van Humbeeck, J.; De Batist, R. Structural anelasticity of NiTi during two-stage martensitic transformation. J. Alloys Compd. 2000, 310, 312–317. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Schryvers, D.; Van Humbeeck, J. Grain growth and precipitation in an annealed cold-rolled Ni50.2Ti49.8 alloy. Intermetallics 2007, 15, 1538–1547. [Google Scholar] [CrossRef]

- Mulyukov, R.R.; Pshenichnyuk, A.I. Structure and damping of nanocrystalline metals and alloys prepared by high plastic deformation techniques. J. Alloys Compd. 2003, 355, 26–30. [Google Scholar] [CrossRef]

- Koizumi, Y.; Ueyama, M.; Tsuji, N.; Minamoto, Y.; Ota, K. High damping capacity of ultra-fine grained aluminum produced by accumulative roll bonding. J. Alloys Compd. 2003, 355, 47–51. [Google Scholar] [CrossRef]

- Trojanova, Z.; Lukac, P.; Ferkel, H.; Riehemann, W. Internal friction in microcrystalline and nanocrystalline Mg. Mater. Sci. Eng. A 2004, 370, 154–157. [Google Scholar] [CrossRef]

- Thompson, D.O.; Pare, V.K. Effect of fast neutron bombardment at various temperatures upon the Young’s modulus and internal friction of copper. J. Appl. Phys. 1960, 31, 528–535. [Google Scholar] [CrossRef]

- Magalas, L.B.; Moser, P. Internal friction in cold worked iron. J. Phys. 1981, 42, C5-97–C5-102. [Google Scholar] [CrossRef]

- Takamura, S.; Kobiyama, M. Dislocation pinning in Al and Ag alloys after low-temperature deformation. Phys. Status Solidi A 1986, 95, 165–172. [Google Scholar] [CrossRef]

- Chambers, R.H.; Smoluchowski, R. Time-dependent internal friction in aluminium and magnesium single crystals. Phys. Rev. 1960, 117, 725–731. [Google Scholar] [CrossRef]

- Baturin, A.; Lotkov, A.; Grishkov, V.; Lider, A. Formation of vacancy-type defects in titanium nickelide. MATEC Web Conf. 2015, 33, 03017-1–03017-6. [Google Scholar]

- Wu, S.K.; Wayman, C.M. Interstitial ordering of hydrogen and oxygen in TiNi alloys. Acta Metall. 1988, 36, 1005–1013. [Google Scholar] [CrossRef]

- Fiore, N.F.; Bauer, C.L. The binding of solute atoms to dislocations. Prog. Mater. Sci. 1968, 13, 87–134. [Google Scholar] [CrossRef]

- Hirth, J.P.; Lothe, J. Theory of Dislocations; McGraw-Hill: New York, NY, USA, 1968. [Google Scholar]

- Myers, S.M.; Baskes, M.I.; Birnbaum, H.K.; Corbett, J.W.; DeLeo, G.G.; Estreicher, S.K.; Haller, E.E.; Jena, P.; Johnson, N.M.; Kirchheim, R.; et al. Hydrogen interactions with defects in crystalline solids. Rev. Mod. Phys. 1992, 64, 559–617. [Google Scholar] [CrossRef]

| Sample | Hydrogen Content, At. ppm | ||

|---|---|---|---|

| Extracted at 803 K | Extracted at 1073 K | Total Content | |

| AR | 11 | 62 | 73 |

| WQ | 195 | 102 | 297 |

| VA4 | 9 | 24 | 33 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sapozhnikov, K.; Torrens-Serra, J.; Cesari, E.; Van Humbeeck, J.; Kustov, S. On the Effect of Hydrogen on the Low-Temperature Elastic and Anelastic Properties of Ni-Ti-Based Alloys. Materials 2017, 10, 1174. https://doi.org/10.3390/ma10101174

Sapozhnikov K, Torrens-Serra J, Cesari E, Van Humbeeck J, Kustov S. On the Effect of Hydrogen on the Low-Temperature Elastic and Anelastic Properties of Ni-Ti-Based Alloys. Materials. 2017; 10(10):1174. https://doi.org/10.3390/ma10101174

Chicago/Turabian StyleSapozhnikov, Konstantin, Joan Torrens-Serra, Eduard Cesari, Jan Van Humbeeck, and Sergey Kustov. 2017. "On the Effect of Hydrogen on the Low-Temperature Elastic and Anelastic Properties of Ni-Ti-Based Alloys" Materials 10, no. 10: 1174. https://doi.org/10.3390/ma10101174