1. Introduction

With a wide range of applications of LED products in the lighting market, the reliability of the phosphor converted white LED (pc-white LED) has become a global spread hot research [

1,

2,

3]. A white LED with high reliability is expected to have a lower luminous flux degradation and color shift under a long-term operation time. Although some fundamental and advanced algorithms were developed to assist people to understand more about the essence of reliability of pc-white LEDs, unfortunately, the traditional reliability evaluation test methods still require a test time of at least 6000 h, which is definitely a too long time for LED manufacturers [

4,

5,

6,

7,

8,

9,

10,

11,

12,

13]. Therefore, fast and effective test methods are urgently needed with time and cost considerations [

14,

15].

In order to shorten the test duration, the constant stress accelerated degradation tests (CSADTs) under manifold uni/multi-environmental overstress conditions are developed for pc-white LEDs and the relevant products [

2,

16]. Through the deep investigation on the degradation characteristics of LEDs, the accelerated loadings could be anyone among high temperature [

17], high moisture [

18], and a hybrid combination of both [

19,

20,

21,

22]. However, the selection of practical accelerated loadings always meets a dilemma between accuracy and universality. Due to the diversity of the failures existing in LED products, a complex coupled stress might be a good accelerated test solution for some LED products but totally invalid for many others. Improvement of the universality is often achieved by reducing the complexity of the accelerated loadings. For a general application, C. Qian et al. developed a CSADT method to reduce the reliability test period from 6000 h to 2000 h for LED luminaires and lamps [

17]. Via a boundary curve theory, they proved that the qualification results obtained from the 6000 h test data under 25 °C and 1500 h test data under 55 °C are comparable to each other for a majority of LED lighting products.

Step stress accelerated degradation test (SSADT) is another commonly utilized test plan for lifetime evaluation of high reliability products [

23]. When combined with stochastic degradation models such as Gamma process and Wiener process, and statistical luminous flux distributions such as Gaussian distribution, Weibull distribution and Lognormal distribution, SSADT is capable to provide more efficient lifetime evaluation test plan with a smaller sample size and less test time for LED products, as compared to CSADT [

24,

25,

26]. This makes the optimization of the SSADT test strategy become a very hot research topic. Han proposed three different kinds of design criteria (i.e., C/D/A-optimal design criteria) for optimizing the increment step and test duration of each stress level in the SSADT with a constraint limit on the test cost [

25]. Among these three design plans, the C-optimal design was applied to minimize the lifetime variability, D-optimal design was applied maximize the joint precision of estimators of the lifetime model parameters, whereas A-optimal design was applied to minimize the variance of the lifetime model parameters. They argued the D-optimal design gives the best step stress loading scheme. Moreover, Hu et al. investigated the optimization plans for the step stress levels in SSADT with a Wiener degradation model, and argued that an optimal strategy for SSADT test can only be accomplished with no more than two step stress levels [

26].

Recently, there has been a couple of cases of using SSADT to estimate the lifetimes of LED products. Huang et al. built up a SSADT model by using a stochastic Wiener process to analyze the luminous flux data of pc-white LEDs collected from a k-step stress accelerated degradation test [

27]. With this model, a 2-step stress accelerated degradation test is proved to give similar lifetime estimation of the pc-white LEDs when compared to CSADT, but halve the sample size. Cai et al. developed a three-step stress accelerated test on the light source of a LED lamp. The test data were further used together with a fault tree and Monte Carlo algorithm to predict the degradation of luminous flux of the LED lamp [

28].

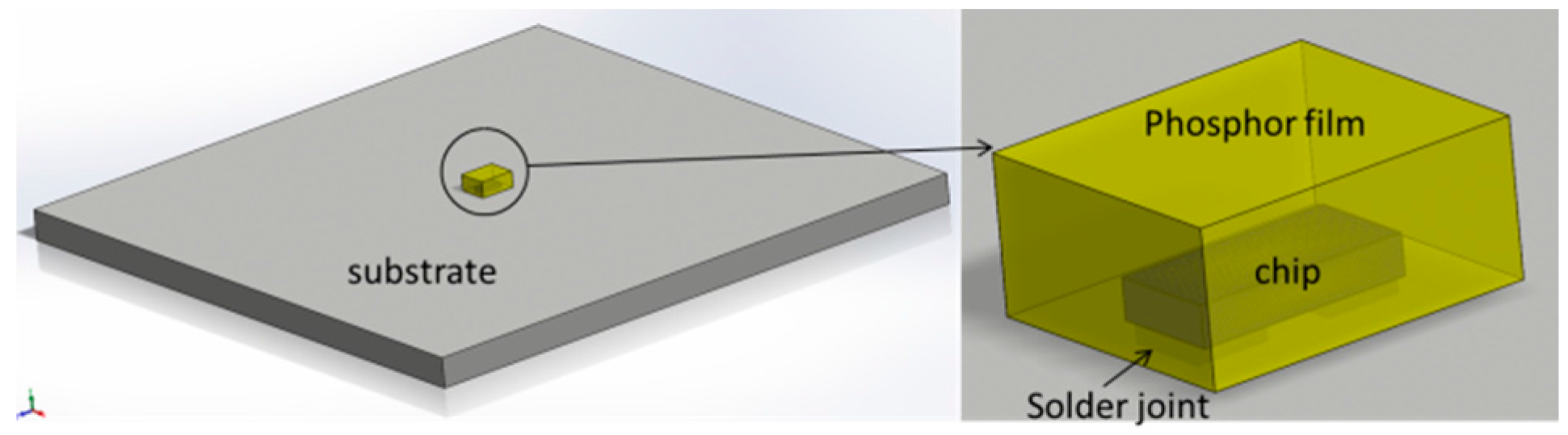

Although the above-mentioned SSADT models gained a successful use in literatures, it is noted that all of them are empirical models whose parameters were obtained by the curve fitting from experimental results. The physical failure mechanisms that occurred during the whole process of SSADT are unfortunately not fully investigated except for a rough assumption of no additional failure modes. Under such circumstances, the development of an optimum step stress strategy is always cumbersome and time-consuming as a huge amounts of experimental works need to be done. To enhance our understanding the failures existing in the SSADT for pc-white LEDs, a comprehensive study on the failure analysis during the ageing process of SSADT for CSP LEDs, one of the most promising white LED light sources with benefits of small size, high power, and high color quality, is carried on in this paper. The remainder of this paper is organized as follows:

Section 2 introduces the test samples used in this study and some conducted experiments.

Section 3 discusses the measurement results from experiments. Finally, the concluding remarks are presented in

Section 4.

4. Conclusions

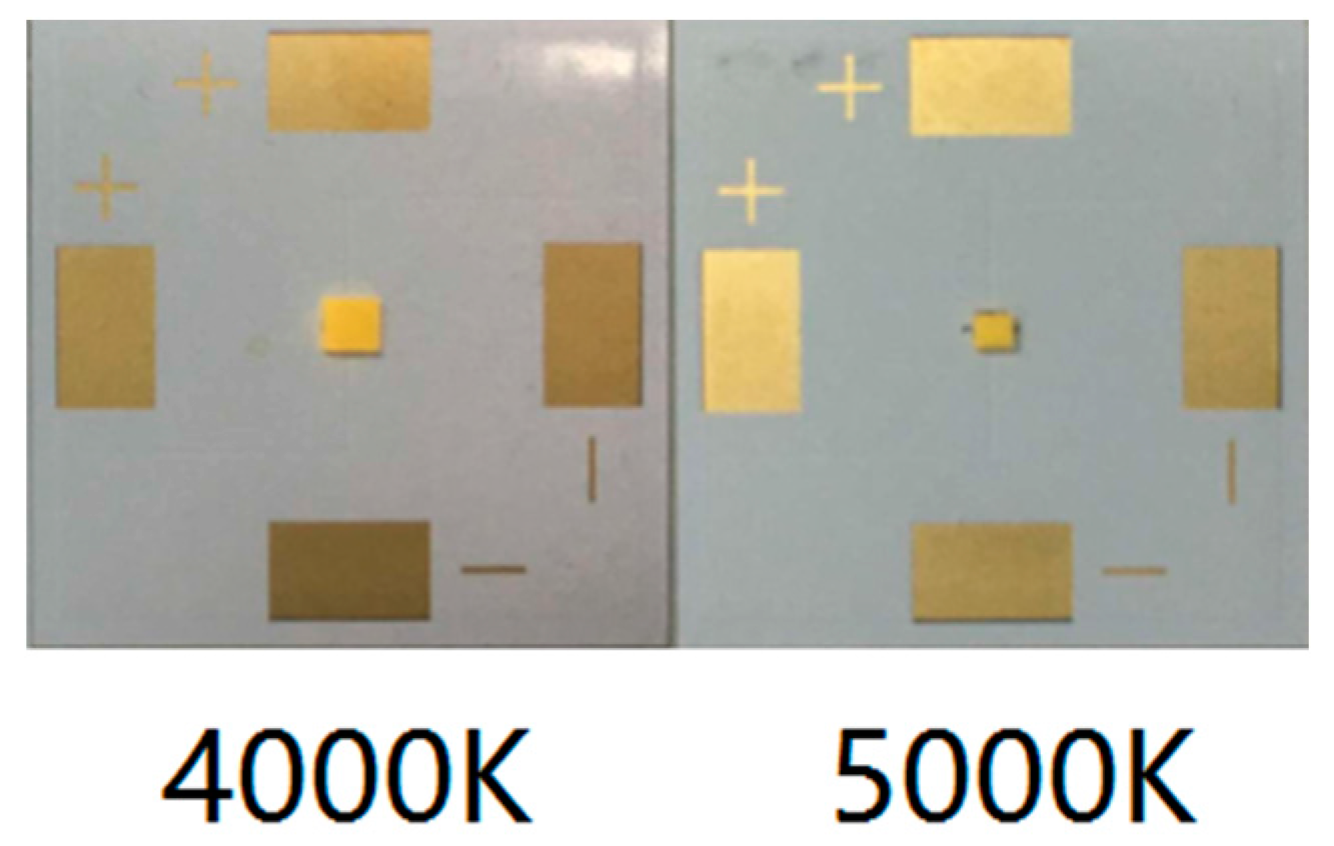

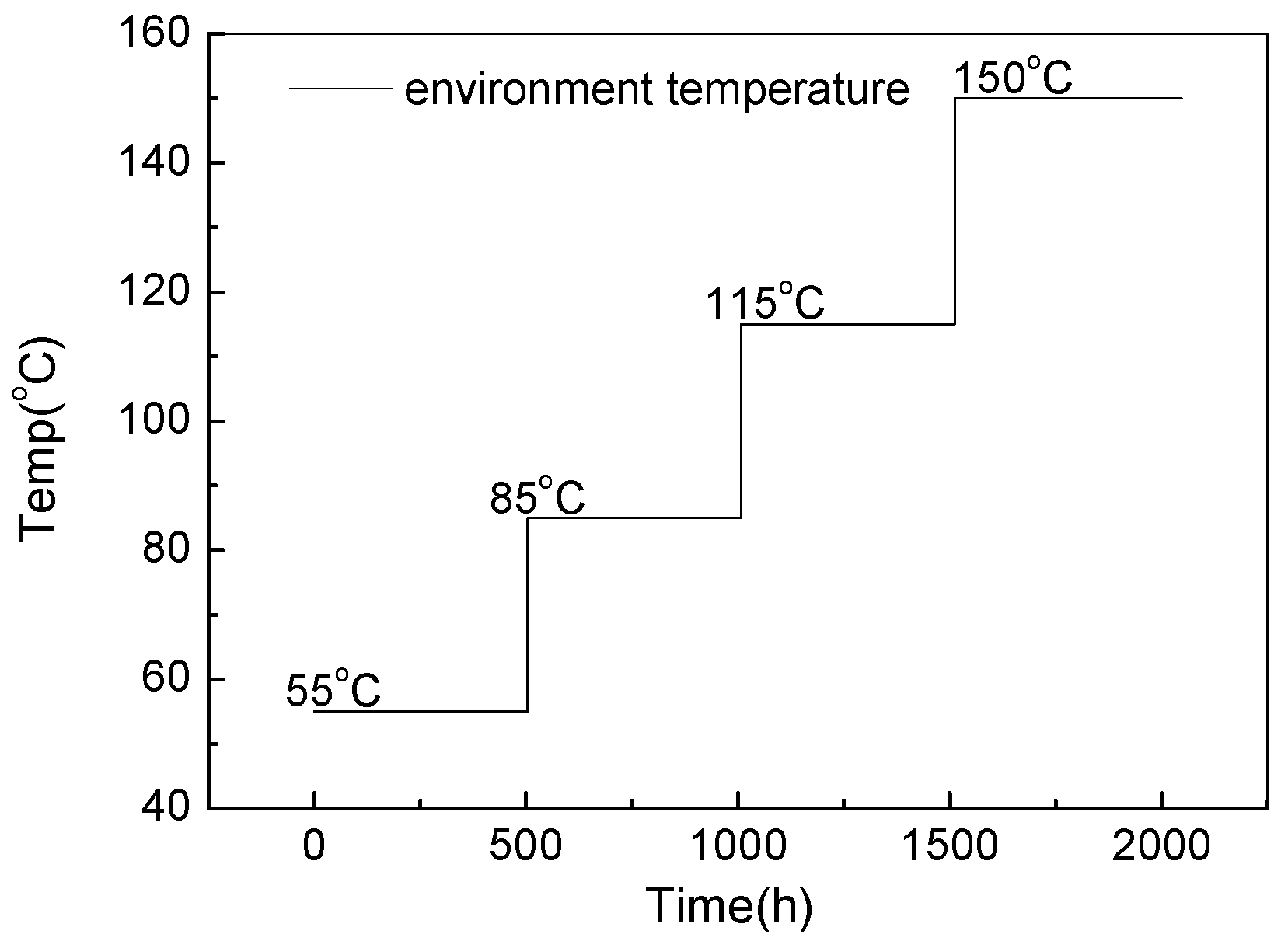

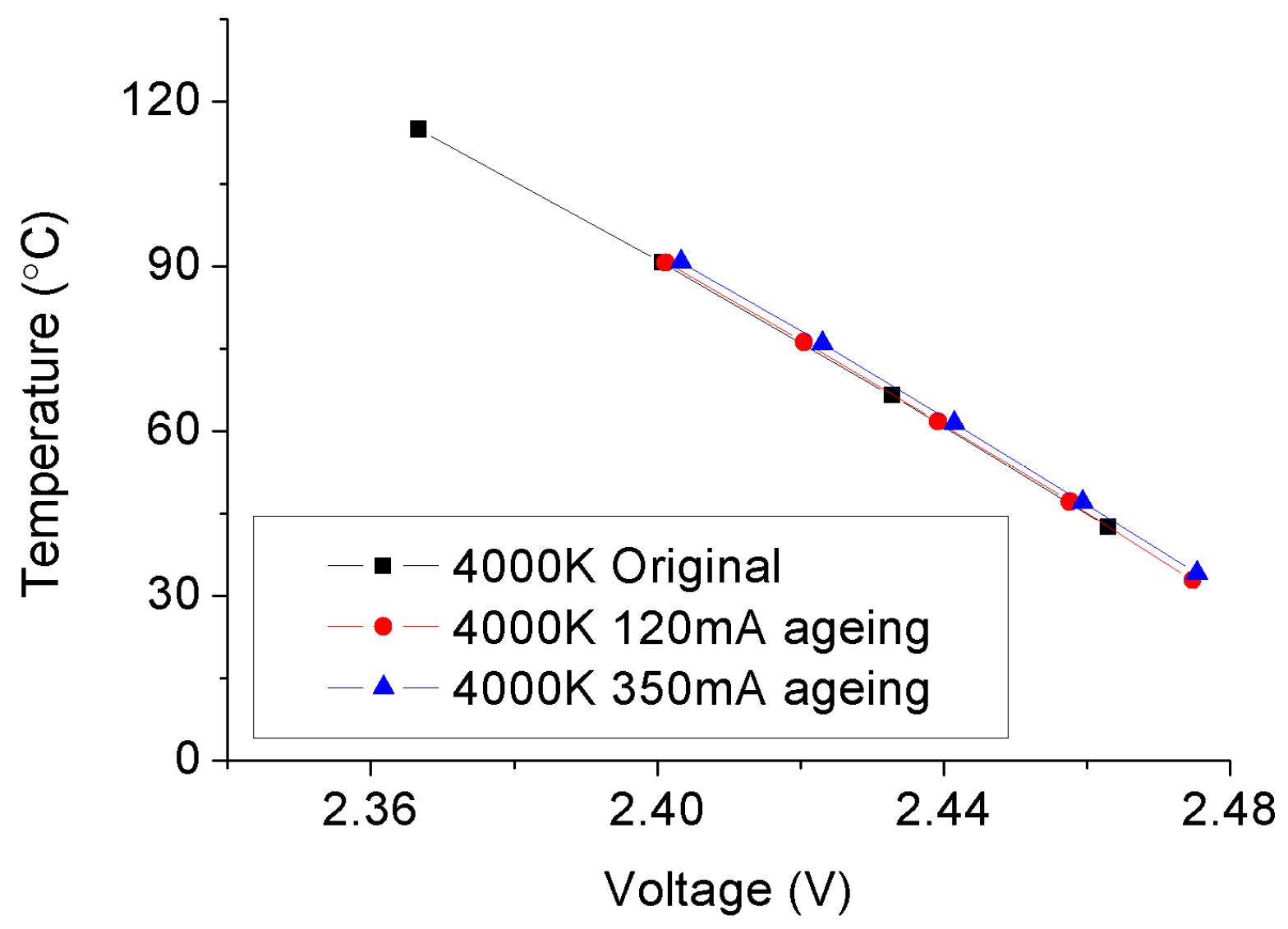

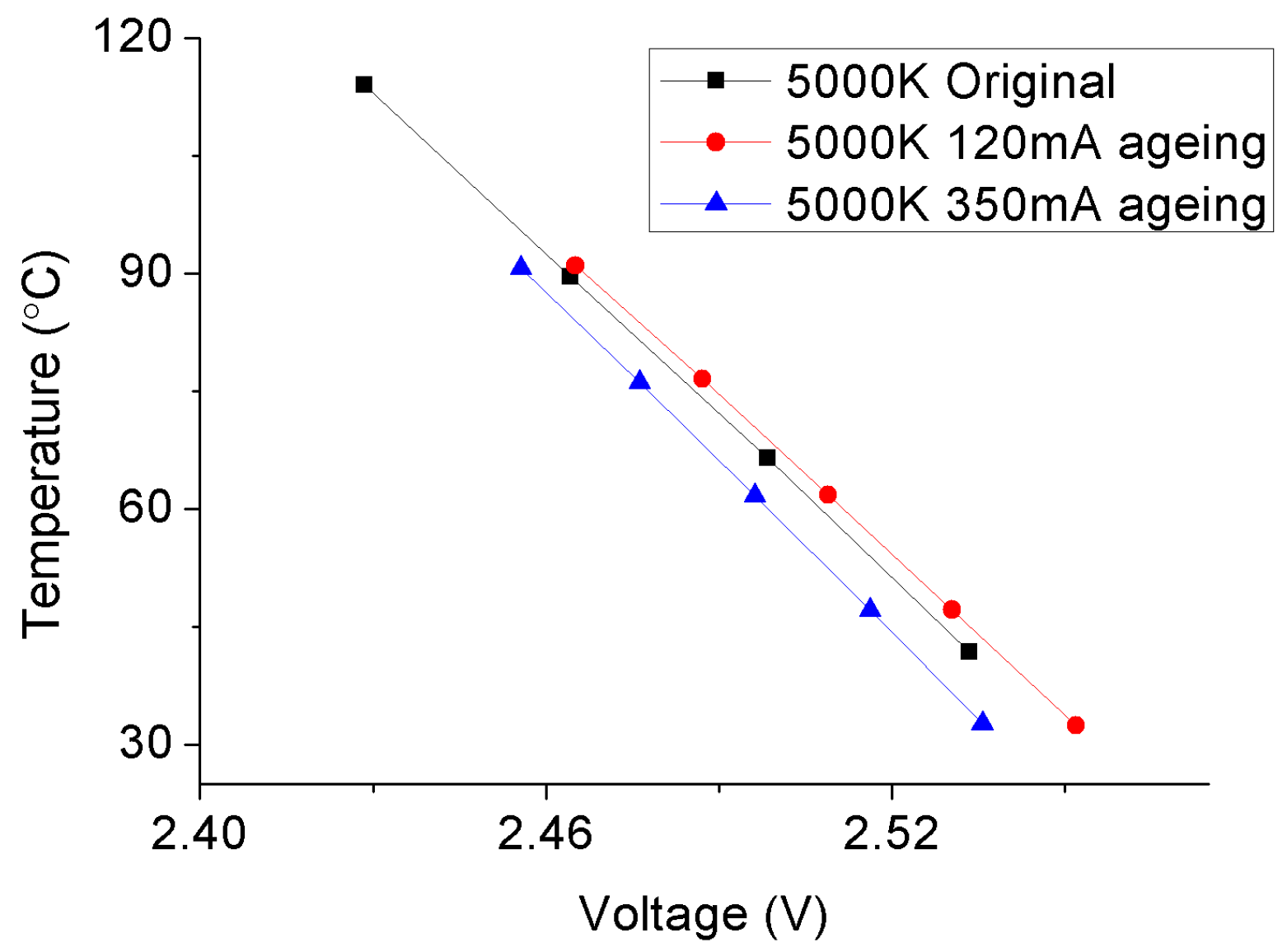

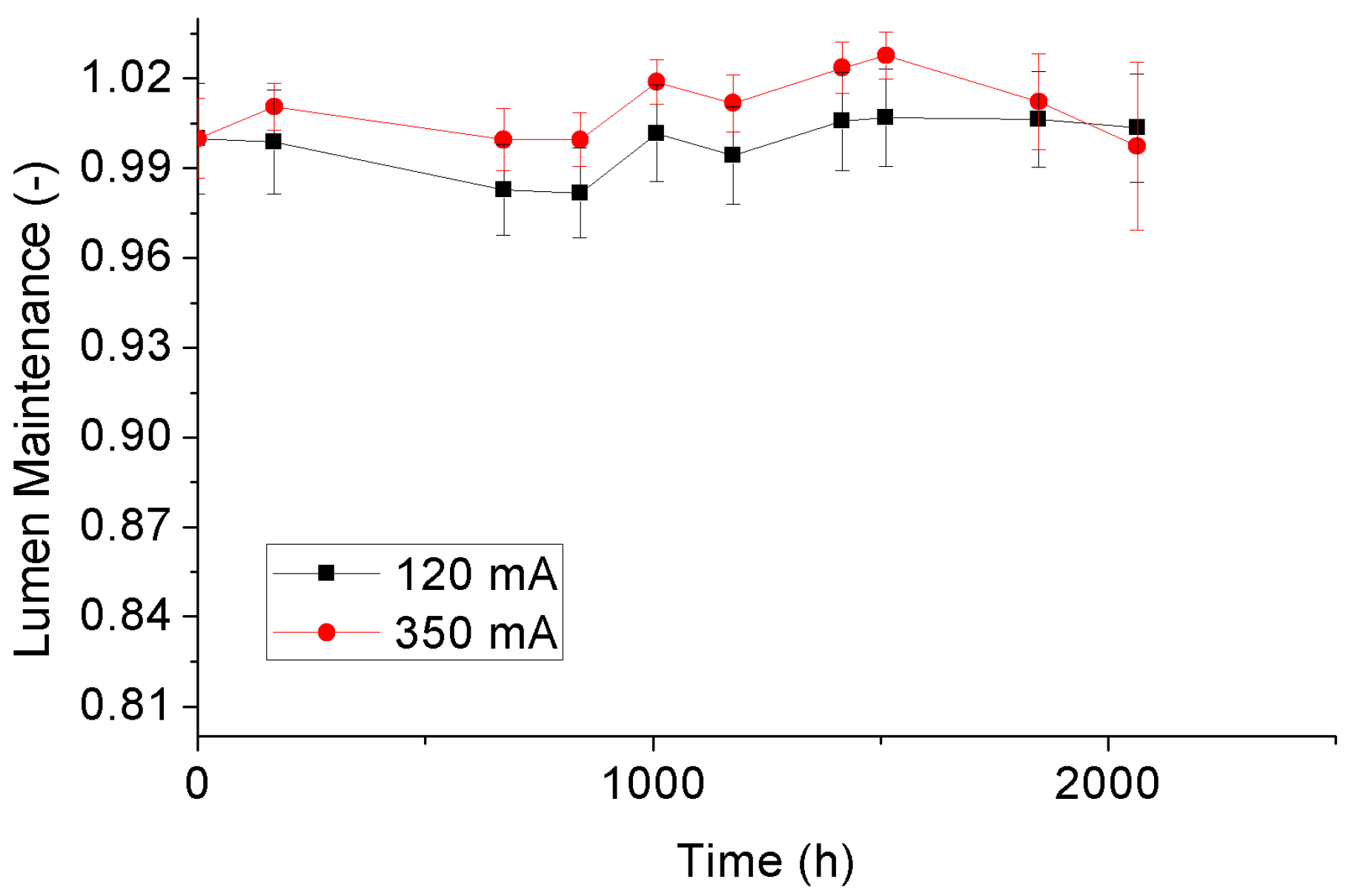

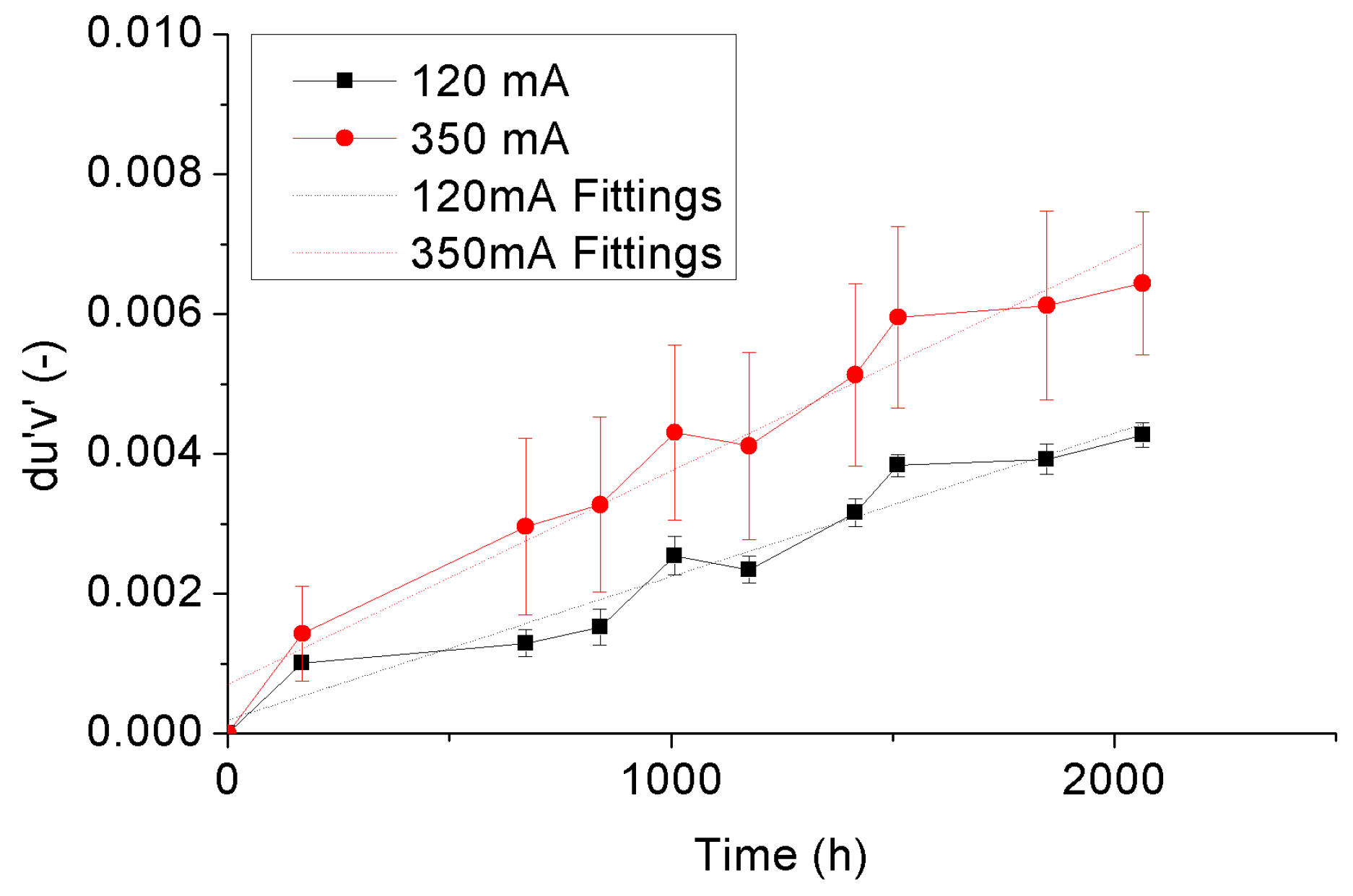

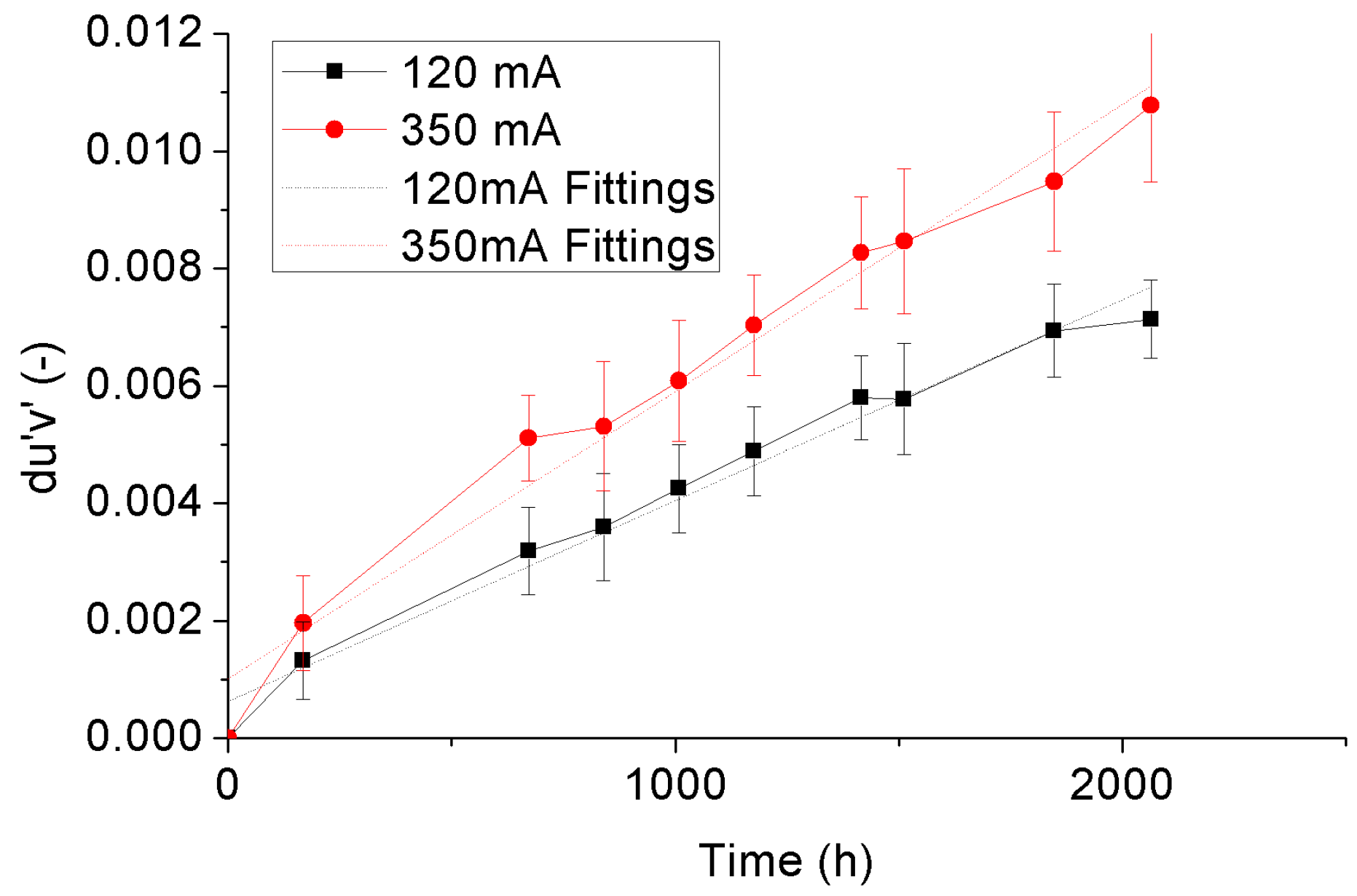

In this paper, the reliability issues, including thermal, photometric, and colorimetric properties, of LED chip scale packages during SSADT with driving currents of 120 mA and 350 mA were thoroughly investigated. The ageing process of SSADT is composed by four temperature stages from 55 °C to 150 °C, each step lasts 504 h. Two different types of LED chip scale packages were tested. The rate current is 350 mA for the 4000 °K samples, and 120 mA for the 5000 °K samples.

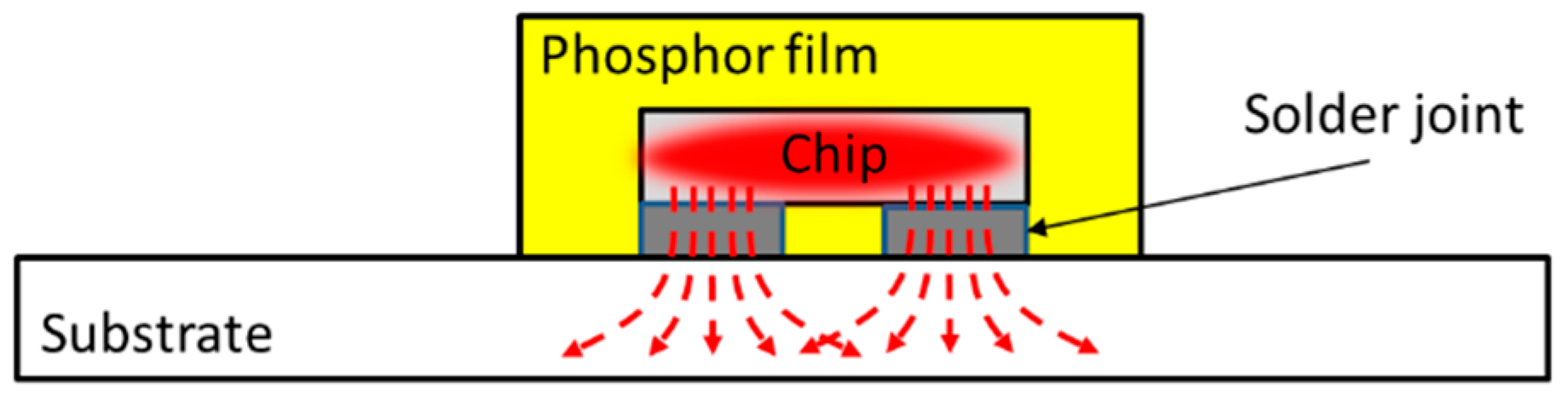

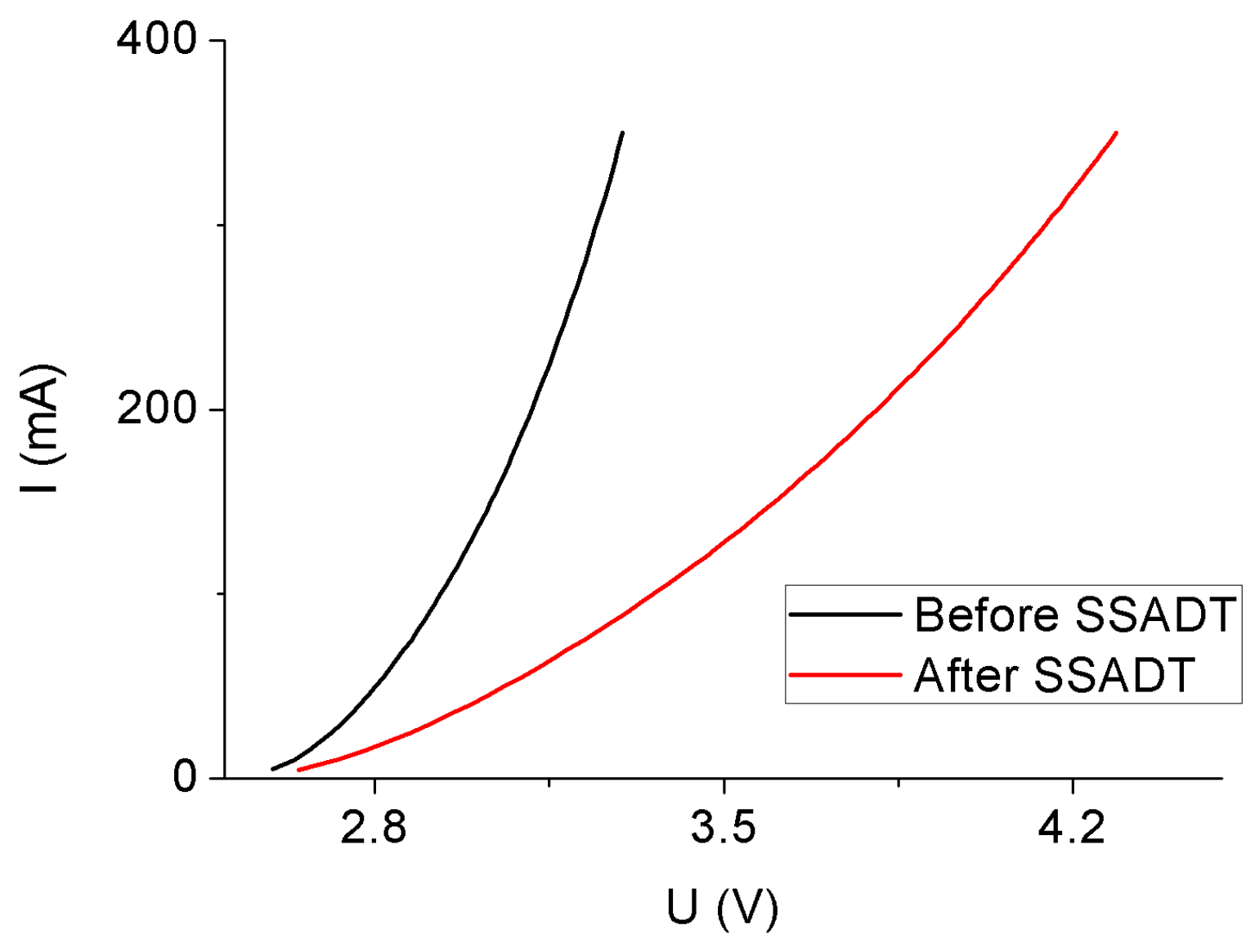

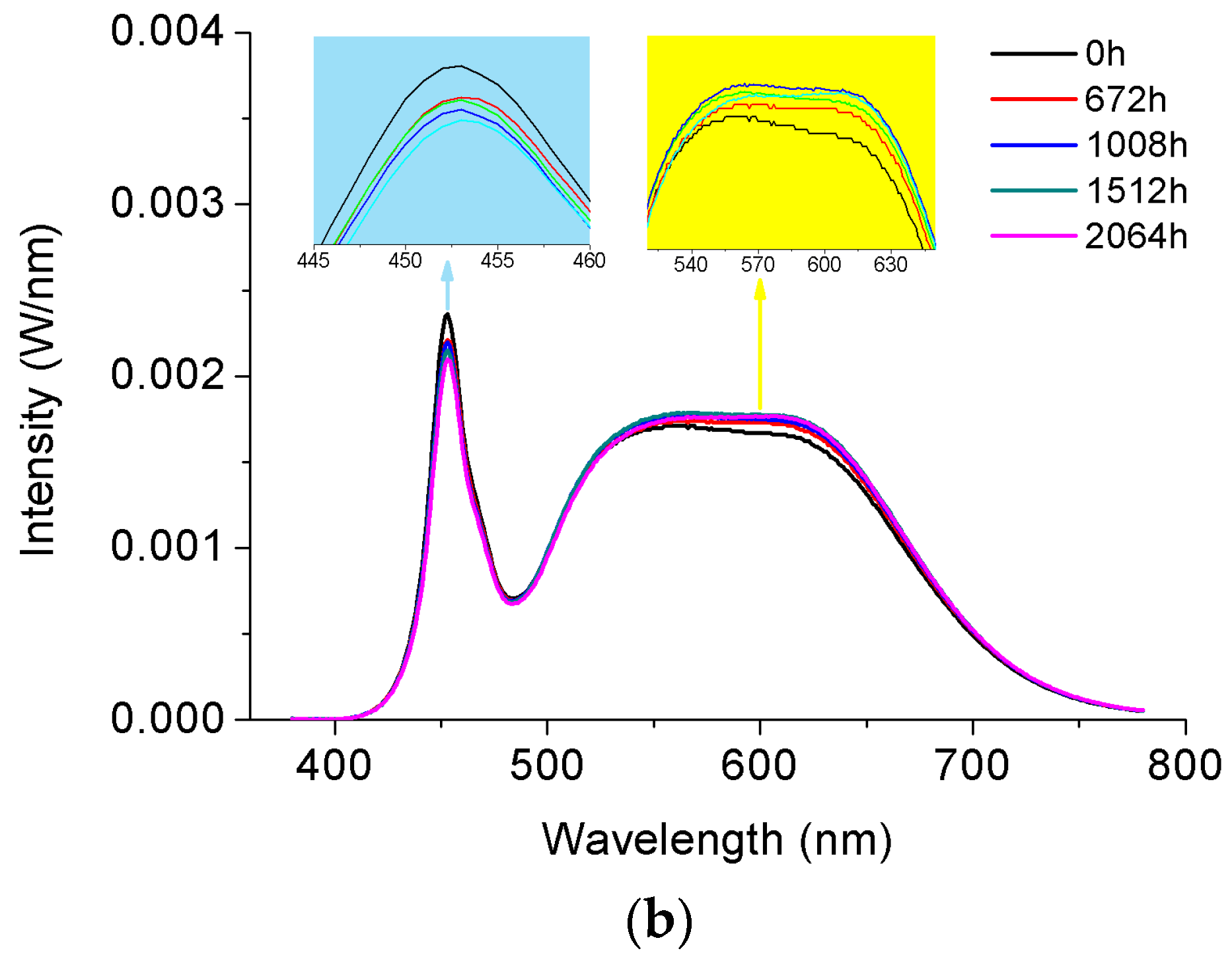

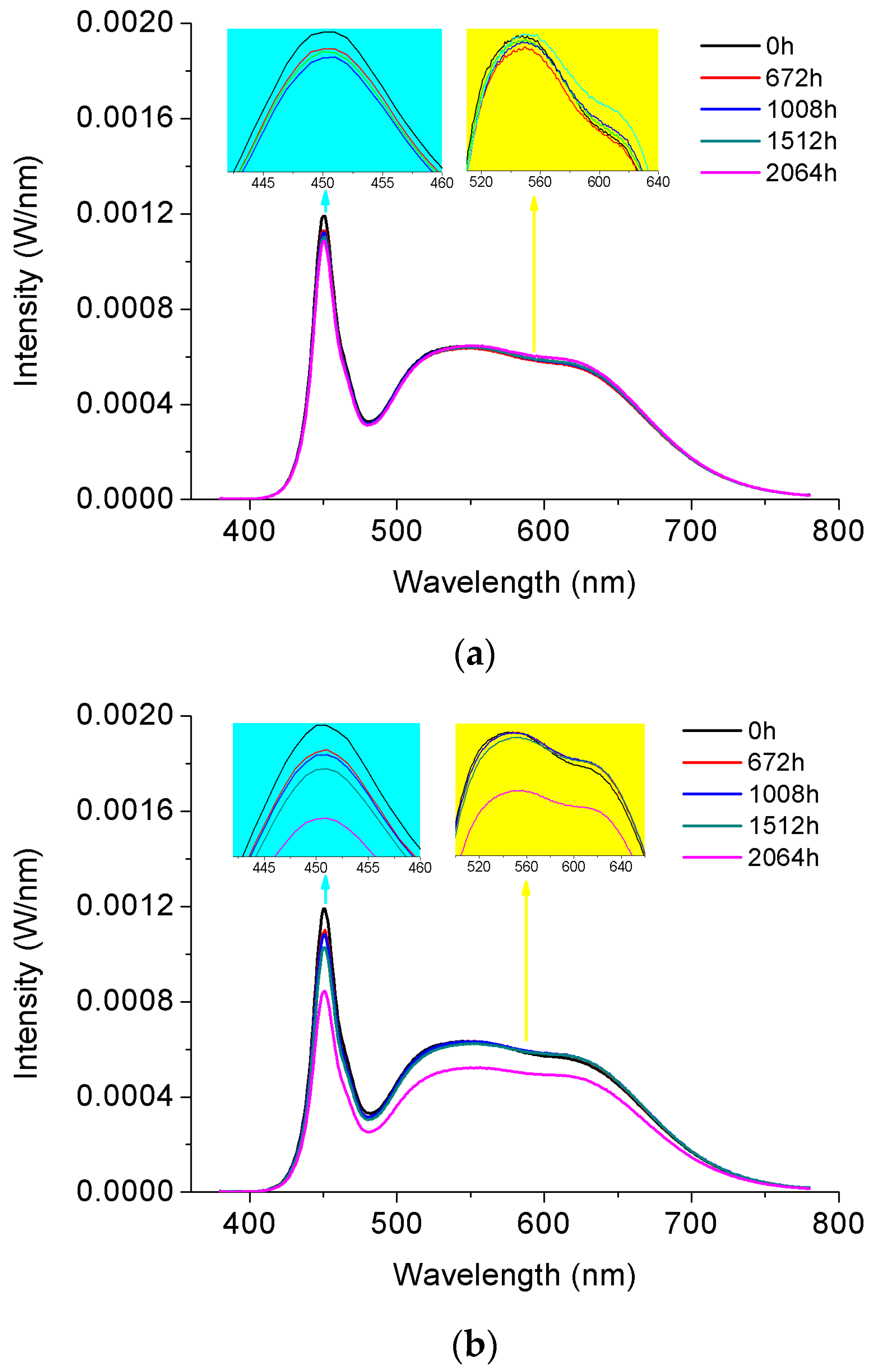

The thermal properties of the test samples were investigated via the comparison of junction temperatures and the temperature-voltage curves before and after SSADT. For a sample driving by a current below or equaling to the rated current, its junction temperature after SSADT was increased to a certain extent depending on the driving current. However, for the 5000 °K sample overdriven by a current of 350 mA, the junction temperature after SSADT was reduced, owing to a left shift of the temperature-voltage curve. This might be caused by partial damage in the active layer of the LED chip induced by a synergistic effect of the high temperature and overdrive current. The supporting evidence was obtained from two aspects: firstly, an obvious series resistance existed in the I-V curve of the 5000 °K sample after SSADT; secondly, a dramatic SPD attenuation of the 5000 °K sample was observed in the end of SSADT.

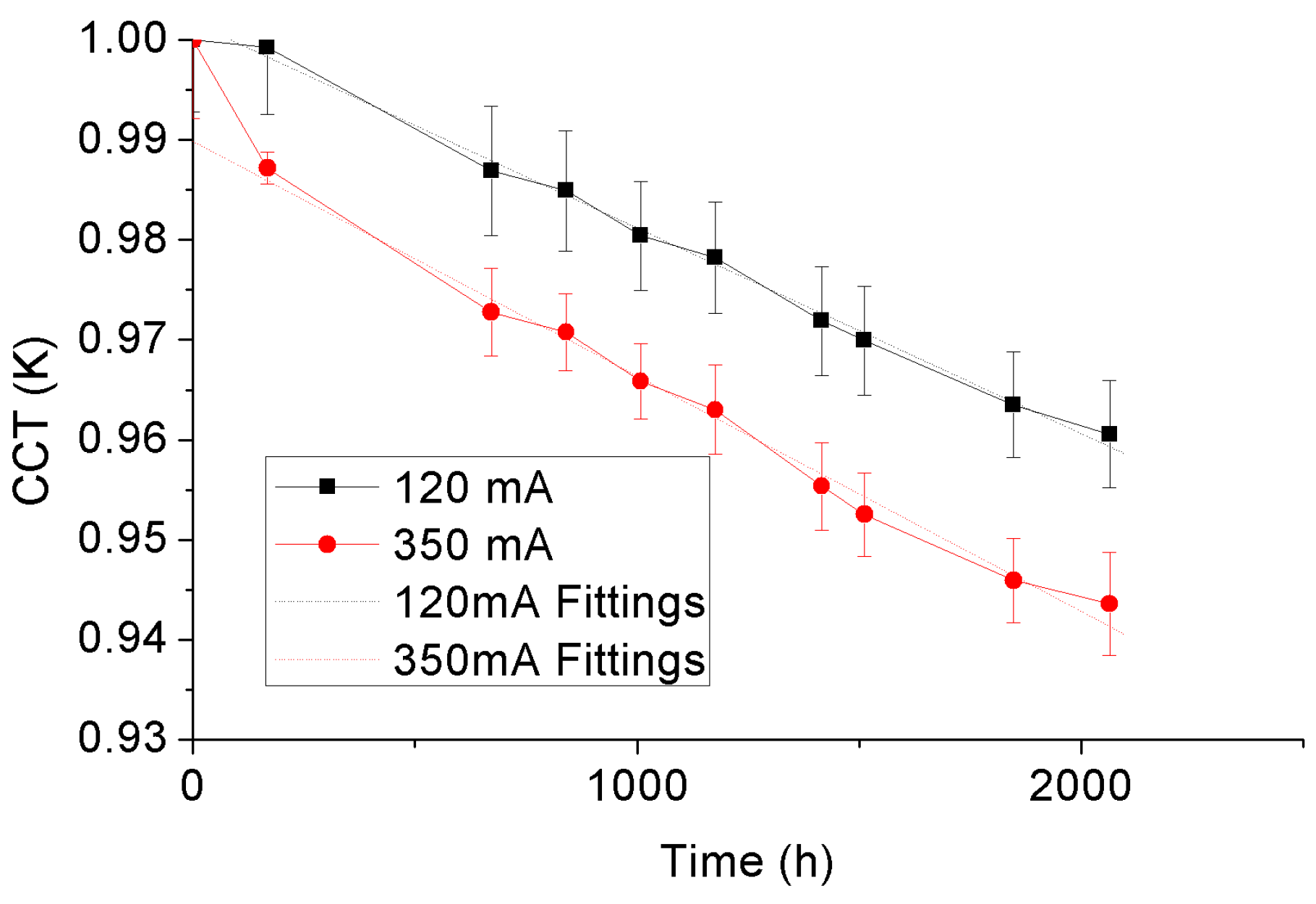

Finally, the time-dependent variances of lumen maintenance, color shift, and CCT of the test samples during SSADT, and the driving current effect on these results were studied in detail. The results suggest that failures, such as color shift and CCT depreciation of the LED chip scale packages, can be effectively aroused by SSADT. The varying rates of these two failures are further proved to have a positive relationship with the driving current.

At last, it is worth mentioning that similar time-varying trends of the photometric and colorimetric parameters observed in this study would be likely to occur in all types of phosphor converted LEDs, since the failure mechanisms among them are not significantly different. More case studies on other type of phosphor converted LEDs will be investigated in future studies to explore the applicability and usability of SSADT in fast evaluation of the reliability of LEDs.