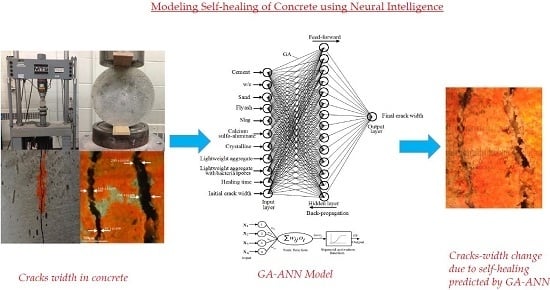

Modeling Self-Healing of Concrete Using Hybrid Genetic Algorithm–Artificial Neural Network

Abstract

:1. Introduction

2. Research Significance

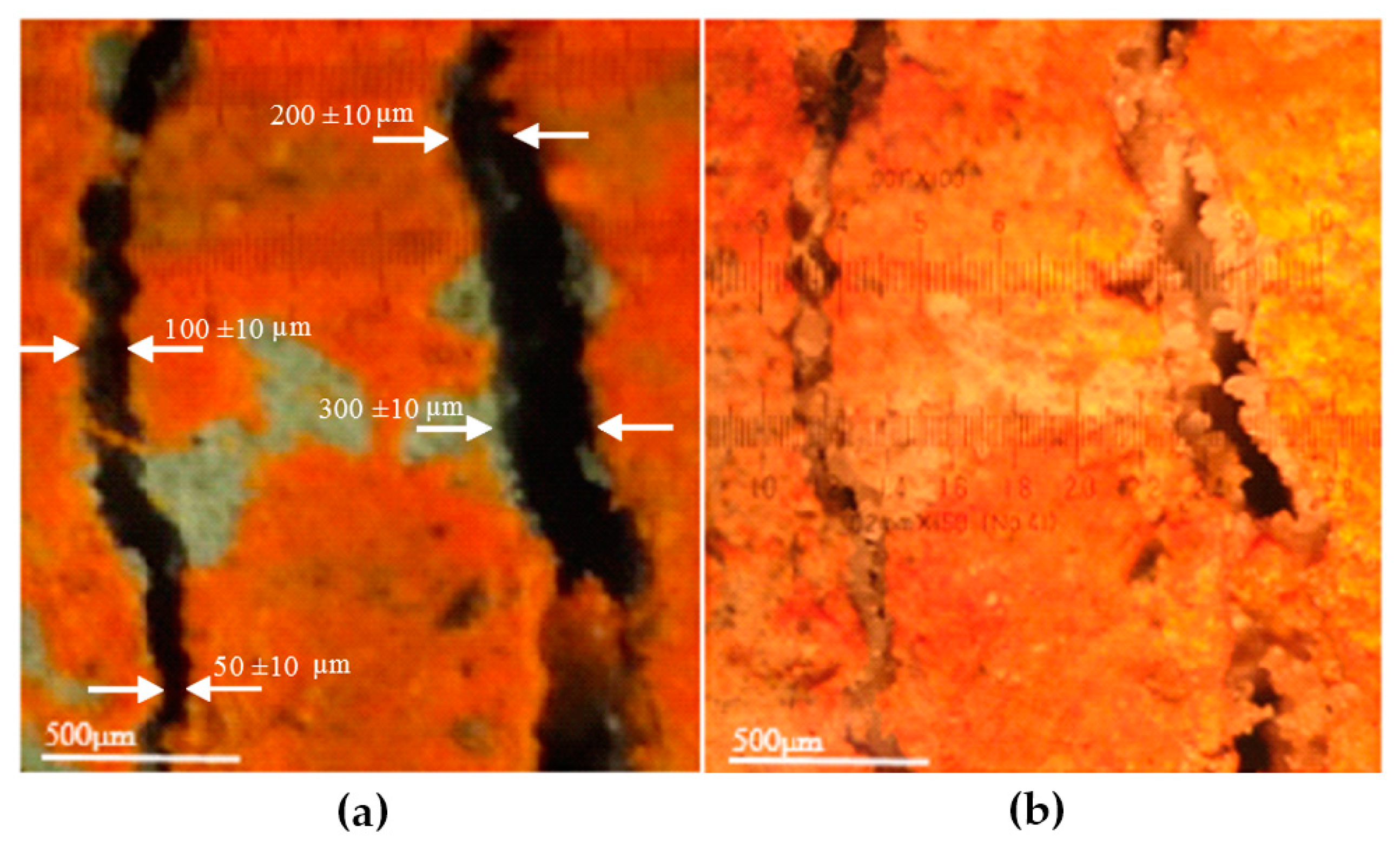

3. Concept of Neural Network Prediction of Self-Healing in Concrete

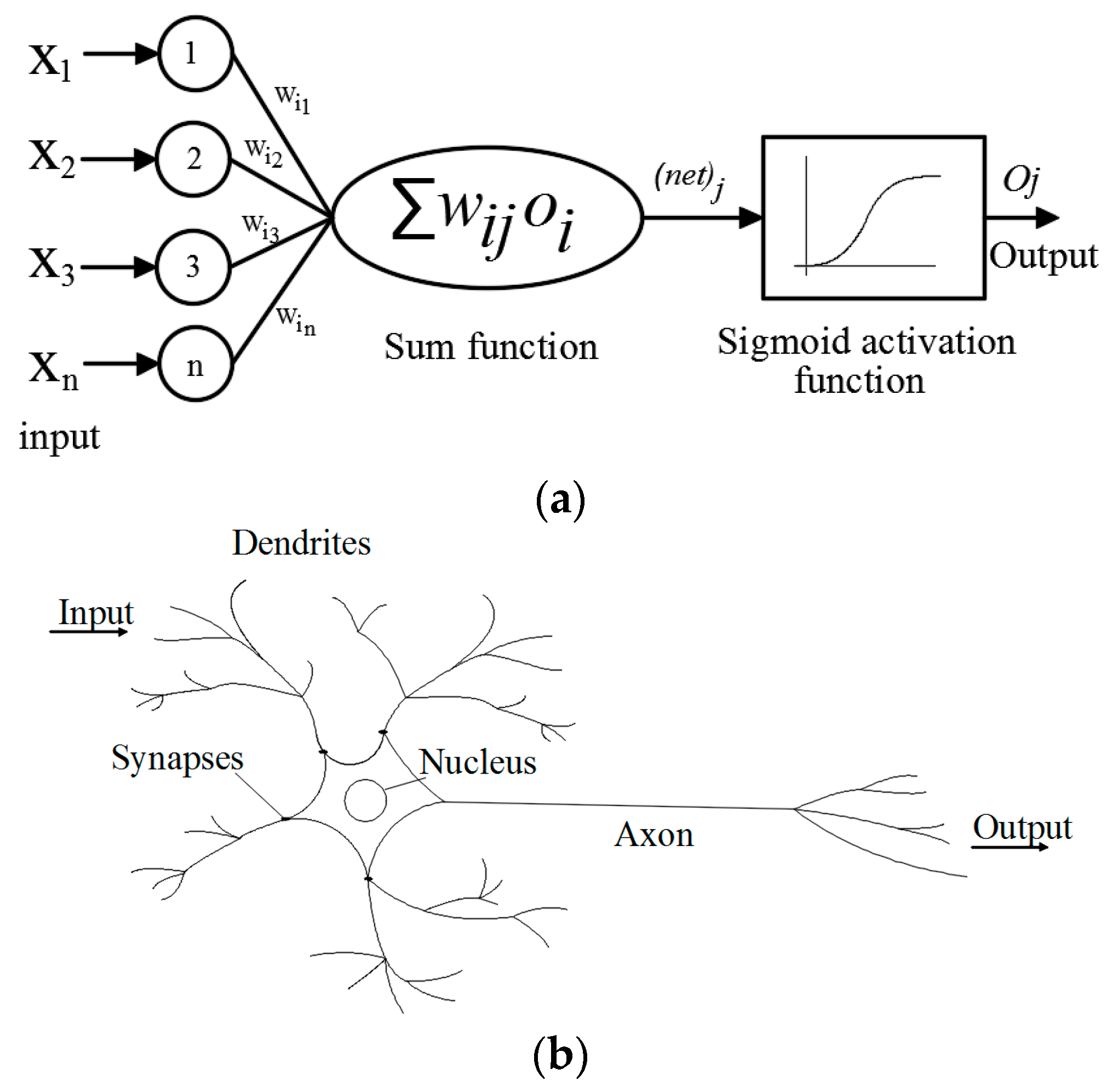

4. Artificial Neural Network (ANN)

4.1. Neural Network Approach

4.2. Neural Network Architectures and Parameters

4.3. Hybrid Genetic Algorithm–Artificial Neural Network (GA–ANN)

4.4. Database Sources and Range of Input and Output Variables

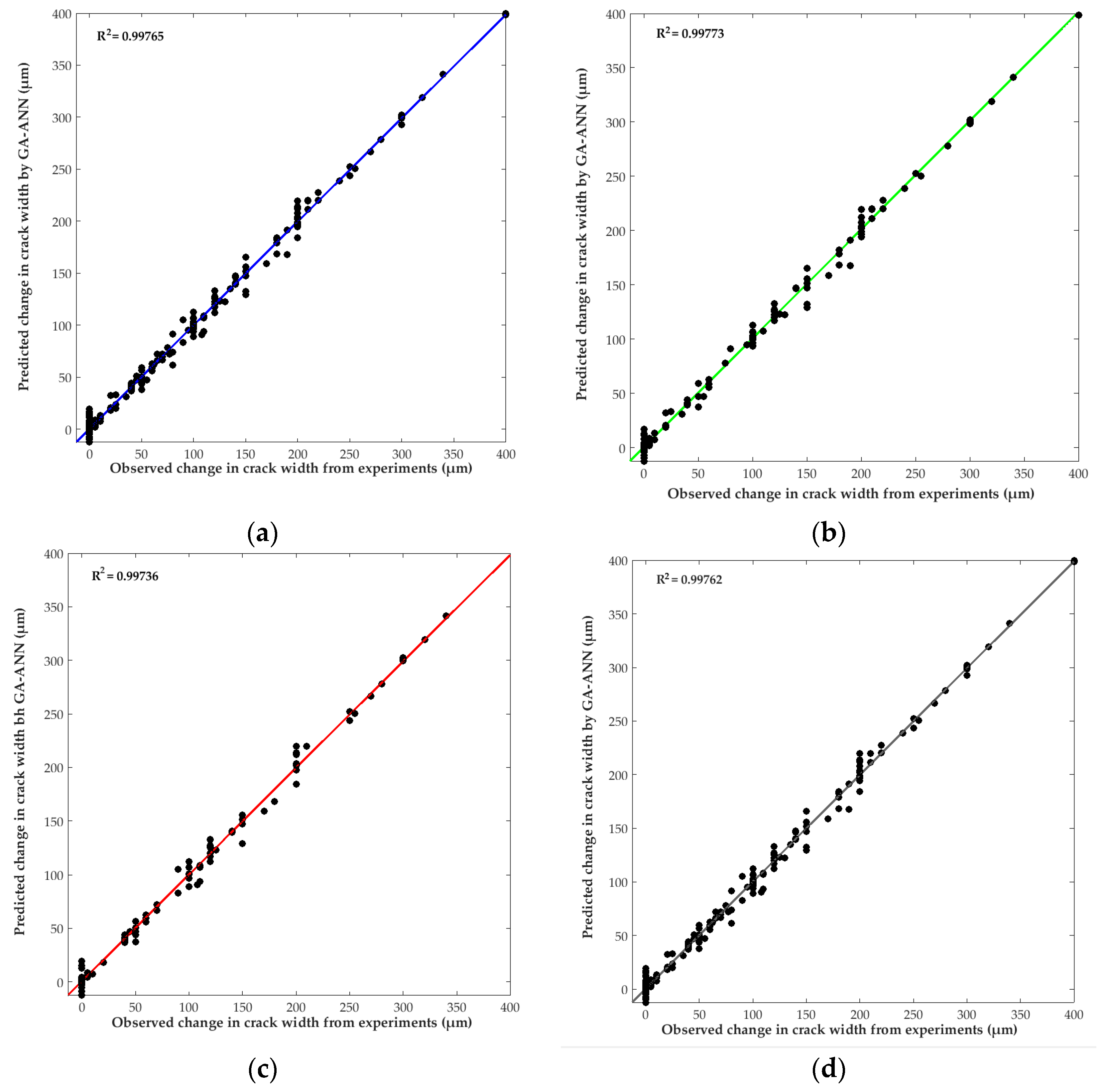

5. Performance of GA–ANN Model

6. Conclusions

- The developed GA–ANN model represents a powerful computational tool with high efficiency providing an alternative solution for the modeling procedure of the highly complex self-healing phenomenon in cement-based materials.

- A genetic algorithm was effectively applied in the ANN model to determine the optimal weights and biases that govern the input–output relationship of the model.

- Training the GA–ANN multilayered feed-forward neural network with a back-propagation algorithm showed accurate prediction of the self-healing crack ability in cementitious materials, yielding predictions that were close to the actual experimental values.

- The proposed model was capable of providing accurate predictions for the self-healing ability of a cementitious material, which in return can be used to enhance the durability design of concrete, leading to more durable and sustainable structures.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Herbert, E.; Li, V. Self-healing of microcracks in engineered cementitious composites (ECC) under a natural environment. Materials 2013, 6, 2831–2845. [Google Scholar] [CrossRef]

- Blaiszik, B.J.; Kramer, S.L.B.; Olugebefola, S.C.; Moore, J.S.; Sottos, N.R.; White, S.R. Self-healing polymers and composites. Annu. Rev. Mater. Res. 2010, 40, 179–211. [Google Scholar] [CrossRef]

- Ghosh, S.K. Self-Healing Materials: Fundamentals, Design Strategies, and Applications; Wiley-VCH: Berlin, Germany, 2009; p. 291. [Google Scholar]

- Gagne, R.; Argouges, M.A. Study of the natural self-healing of mortars using air-flow measurements. Mater. Struct. 2012, 45, 1625–1638. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G. Self-healing of cracks in cement paste affected by additional Ca2+ ions in the healing agent. J. Intell. Mater. Syst. Struct. 2015, 26, 309–320. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, W.; Yuan, Z. Influence of mineral additives and environmental conditions on the self-healing capabilities of cementitious materials. Cem. Concr. Res. 2015, 57, 116–127. [Google Scholar] [CrossRef]

- Pang, B.; Zhou, Z.; Hou, P.; Du, P.; Zhang, L.; Xu, H. Autogenous and engineered healing mechanisms of carbonated steel slag aggregate in concrete. Constr. Build. Mater. 2016, 107, 191–202. [Google Scholar] [CrossRef]

- Rahmani, H.; Bazrgar, H. Effect of coarse cement particles on the self-healing of dense concretes. Mag. Concr. Res. 2015, 67, 476–486. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Moscato, S.; Serna, P.; Ferrara, L. Self-healing capability of concrete with crystalline admixtures in different environments. Constr. Build. Mater. 2015, 86, 1–11. [Google Scholar] [CrossRef]

- Snoeck, D.; De Belie, N. From straw in bricks to modern use of microfibers in cementitious composites for improved autogenous healing—A review. Constr. Build. Mater. 2015, 95, 774–787. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Self-healing of surface cracks in mortars with expansive additive and crystalline additive. Cem. Concr. Compos. 2012, 34, 566–574. [Google Scholar] [CrossRef]

- Yang, Y.; Lepech, M.D.; Yang, E.; Li, V. Autogenous healing of engineered cementitious composites under wet–dry cycles. Cem. Concr. Res. 2009, 39, 382–390. [Google Scholar] [CrossRef]

- Edvardsen, C. Water permeability and autogenous healing of cracks in concrete. ACI Mater. J. 1999, 96, 448–454. [Google Scholar]

- Hearn, N. Self-healing, autogenous healing and continued hydration: What is the difference? Mater. Struct. 1998, 31, 563–567. [Google Scholar] [CrossRef]

- Jacobsen, S.; Marchand, J.; Hornain, H. SEM observation of the microstructure of frost deteriorated and self-healed concretes. Cem. Concr. Res. 1995, 25, 1781–1790. [Google Scholar] [CrossRef]

- Ramm, W.; Biscoping, M. Autogenous Healing and reinforcement corrosion of water-penetrated separation cracks in reinforced concrete. Nucl. Eng. Des. 1998, 179, 191–200. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Gruyaert, E.; Rahier, H.; De Belie, N. Influence of mix composition on the extent of autogenous crack healing by continued hydration or calcium carbonate formation. Construct. Build. Mater. 2012, 37, 349–359. [Google Scholar] [CrossRef]

- Termkhajornkit, P.; Nawa, T.; Yamashiro, Y.; Saito, T. Self-healing ability of fly ash-cement systems. Cem. Concr. Compos. 2009, 31, 195–203. [Google Scholar] [CrossRef]

- Şahmaran, M.; Keskin, S.B.; Ozerkan, G.; Yaman, I.O. Self-healing of mechanically-loaded self-consolidating concretes with high volumes of fly ash. Cem. Concr. Compos. 2008, 30, 872–879. [Google Scholar] [CrossRef]

- Chahal, N.; Siddique, R.; Rajor, A. Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of fly ash concrete. Constr. Build. Mater. 2012, 28, 351–356. [Google Scholar] [CrossRef]

- Jonkers, H.M.; Thijssena, A.; Muyzerb, G.; Copuroglua, O.; Schlangena, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Khaliq, W.; Ehsan, M.B. Crack healing in concrete using various bio influenced self-healing techniques. Constr. Build. Mater. 2016, 102, 349–357. [Google Scholar] [CrossRef]

- Lou, M.; Qian, C.; Li, R. Factors affecting crack repairing capacity of bacteria-based self-healing concrete. Constr. Build. Mater. 2015, 87, 1–7. [Google Scholar]

- Van Tittlboom, K.; De Belie, N.; De Muynck, W.; Verstraete, W. Use of bacteria to repair cracks in concrete. Cem. Concr. Res. 2010, 40, 157–166. [Google Scholar] [CrossRef]

- Wang, J.Y.; De Belie, N.; Verstraete, W. Diatomaceous earth as a protective vehicle for bacteria applied for self-healing concrete. J. Ind. Microbiol. 2012, 39, 567–577. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.Y.; Soens, H.; Verstraete, W.; De Belie, N. Self-healing concrete by use of microencapsulated bacterial spores. Cem. Concr. Res. 2014, 56, 139–152. [Google Scholar] [CrossRef]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Xu, J.; Yao, W. Multiscale mechanical quantification of self-healing concrete incorporating non-ureolytic bacteria-based healing agent. Cem. Concr. Res. 2014, 64, 1–10. [Google Scholar] [CrossRef]

- Adeli, H. Neural networks in civil engineering: 1989−2000. Comp. Aided Civ. Inf. Eng. 2001, 16, 126–142. [Google Scholar] [CrossRef]

- Kartam, N.; Flood, I.; Garret, J.H.; Agrawal, G. Artificial Neural Networks for Civil Engineers: Fundamentals and Applications; American Society of Civil Engineers: New York, NY, USA, 1997; p. 216. [Google Scholar]

- Adeli, H.; Yeh, C. Perceptron learning in engineering design. Microcomp. Civ. Eng. 1989, 4, 247–256. [Google Scholar] [CrossRef]

- Bal, L.; Buyle-Bodin, F. Artificial neural network for predicting drying shrinkage of concrete. Constr. Build. Mater. 2013, 38, 248–254. [Google Scholar] [CrossRef]

- Duan, Z.H.; Kou, S.C.; Poon, C.S. Using artificial neural networks for predicting the elastic modulus of recycled aggregate concrete. Constr. Build. Mater. 2013, 44, 524–532. [Google Scholar] [CrossRef]

- Elbahy, Y.I.; Nehdi, M.L.; Youssef, M.A. Artificial neural network model for deflection analysis of super-elastic shape memory alloy RC beams. Can. J. Civ. Eng. 2010, 37, 855–865. [Google Scholar] [CrossRef]

- El Chabib, H.; Nehdi, M.L. Neural network modeling of properties of cement based materials demystified. Adv. Cem. Res. 2005, 17, 91–102. [Google Scholar] [CrossRef]

- Hegazy, T.; Tully, S.; Marzouk, H. A neural network approach for predicting the structural behavior of concrete slabs. Can. J. Civ. Eng. 1998, 25, 668–677. [Google Scholar] [CrossRef]

- Hossian, K.M.; Gladson, L.R.; Anwar, M.S. Modeling shear strength of medium- to ultra-high-strength steel fiber-reinforced concrete beams using artificial neural network. Neural Comp. Appl. 2016, 1–12. [Google Scholar] [CrossRef]

- Lee, S. Prediction of concrete strength using artificial neural networks. Eng. Struct. 2003, 25, 849–857. [Google Scholar] [CrossRef]

- Mashhadban, H.; Kutanaei, S.S.; Sayarinejad, M.A. Prediction and modeling of mechanical properties in fiber reinforced self-compacting concrete using particle swarm optimization algorithm and artificial neural network. Constr. Build. Mater. 2016, 119, 277–287. [Google Scholar] [CrossRef]

- Nehdi, L.M.; Soliman, A.M. Artificial intelligence model for early-age autogenous shrinkage of concrete. ACI Mater. J. 2012, 109, 353–361. [Google Scholar]

- Venkiteela, G.; Gregori, A.; Sun, Z.; Shah, S.P. Artificial neural network modeling of early-age dynamic young’s modulus of normal concrete. ACI Mater. J. 2010, 107, 282–290. [Google Scholar]

- Yeh, I.C. Modeling of Strength of high-performance concrete using artificial neural networks. Cem. Concr. Res. 1998, 28, 1797–1808. [Google Scholar] [CrossRef]

- Yeh, I. Modeling slump flow of concrete using second-order regressions and artificial neural networks. Cem. Concr. Compos. 2007, 29, 474–480. [Google Scholar] [CrossRef]

- Chandwani, V.; Agrawal, V.; Nagar, R. Modeling slump of ready mix concrete using genetic algorithms assisted training of artificial neural networks. Exp. Syst. Appl. 2015, 42, 885–893. [Google Scholar] [CrossRef]

- Huang, H.; Li, J.; Xiao, C. A proposed iteration optimization approach integrating backpropagation neural network with genetic algorithm. Exp. Syst. Appl. 2015, 42, 146–155. [Google Scholar] [CrossRef]

- Rahman, M.M.; Setu, T.A. An implementation for combining neural networks and genetic algorithms. Int. J. Comp. Sci. Technol. 2015, 6, 218–222. [Google Scholar]

- Vadood, M.; Johari, M.S.; Rahai, A. Developing a hybrid artificial neural network-genetic algorithm model to predict resilient modulus of polypropylene/polyester fiber-reinforced asphalt concrete. J. Text. Inst. 2015, 106, 1239–1250. [Google Scholar] [CrossRef]

- Yuan, Z.; Wang, L.; Ji, X. Prediction of concrete compressive strength: Research on hybrid models genetic based algorithms and ANFIS. Adv. Eng. Softw. 2014, 67, 156–163. [Google Scholar] [CrossRef]

- Aldea, C.M.; Shah, S.P.; Karr, A. Permeability of cracked concrete. Mater. Struct. 1999, 32, 370–376. [Google Scholar] [CrossRef]

- Basheer, L.; Kropp, J.; Cleland, D.J. Assessment of the durability of concrete from its permeation properties: A review. Constr. Build. Mater. 2001, 15, 93–103. [Google Scholar] [CrossRef]

- Wang, K.; Jansen, D.C.; Shah, S.P. Permeability study of cracked concrete. Cem. Concr. Res. 1997, 27, 381–393. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N. Self-healing in cementitious materials—A review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef]

- Özbay, E.; Sahmaran, M.; Lachemi, M.; Yücel, H.E. Self-healing of microcracks in high-volume fly-ash-incorporated engineered cementitious composites. ACI Mater. J. 2013, 110, 33–43. [Google Scholar]

- Sahmaran, M.; Yildirim, G.; Erdem, T.K. Self-healing capability of cementitious composites incorporating different supplementary cementitious materials. Cem. Concr. Compos. 2013, 35, 89–101. [Google Scholar] [CrossRef]

- Haykin, S. Neural Networks: A Comprehensive Foundation; Macmillan College Publishing Company: New York, NY, USA, 1994; p. 696. [Google Scholar]

- Hewayde, E.; Nehdi, M.L.; Allouche, E.; Nakhla, G. Neural network prediction of concrete degradation by sulphuric acid attack. Struct. Inf. Eng. 2007, 3, 17–27. [Google Scholar] [CrossRef]

- Nehdi, M.L.; El Chabib, H.; Said, A. Evaluating shear capacity of FRP reinforced concrete beams using artificial neural networks. Smart Struct. Syst. 2007, 2, 81–100. [Google Scholar] [CrossRef]

- Shahriar, S.; Nehdi, M.L. Modelling rheological properties of oil well cement slurries using artificial neural networks. ASCE J. Mater. Civ. Eng. 2011, 23, 1703–1710. [Google Scholar] [CrossRef]

- Shahriar, S.; Nehdi, M.L. Modelling rheological properties of oil well cement slurries using multiple regression analysis and artificial neural networks. Int. J. Mater. Sci. 2013, 3, 26–37. [Google Scholar]

- Jiang, G.; Keller, J.; Bond, P.L.; Yuan, B.Z. Predicting concrete corrosion of sewers using artificial neural network. Water Res. 2016, 92, 52–60. [Google Scholar] [CrossRef] [PubMed]

- Sarıdemir, M. Predicting the compressive strength of mortars containing metakaolin by artificial neural networks and fuzzy logic. Adv. Eng. Softw. 2009, 40, 920–927. [Google Scholar] [CrossRef]

- Topcu, I.B.; Sarıdemir, M. Prediction of properties of waste AAC aggregate concrete using artificial neural network. Comp. Mater. Sci. 2007, 41, 117–125. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, J.; Yuan, Z.; Xu, H.; Yu, Q. Artificial neural network-genetic algorithm based optimization for the immobilization of cellulose on the smart polymer Eudragit L-100. Bioresour. Technol. 2010, 101, 3153–3158. [Google Scholar] [CrossRef] [PubMed]

- Yasin, Y.; Ahmad, F.B.; Ghaffari-Moghaddam, M.; Khajeh, M. Application of a hybrid artificial neural network–genetic algorithm approach to optimize the lead ions removal from aqueous solutions using intercalated tartrate-Mg–Al layered double hydroxides. Environ. Nanotechnol. Monitor. Manag. 2014, 1–2, 2–7. [Google Scholar] [CrossRef]

- Ho, W.; Chang, C. Genetic-algorithm-based artificial neural network modeling for platelet transfusion requirements on acute myeloblastic leukemia patients. Exp. Syst. Appl. 2011, 38, 6319–6323. [Google Scholar] [CrossRef]

- Nehdi, L.M.; El Chabib, H.; El Naggar, M.H. Predicting performance of self-compacting concrete mixtures using artificial neural networks. ACI Mater. J. 2001, 98, 349–401. [Google Scholar]

| Parameter | GA–ANN |

|---|---|

| Number of input layer neurons | 11 |

| Number of first hidden layer neurons | 14 |

| Number of output layer neurons | 1 |

| MSE goal | 13 × 10−5 |

| Source | No. of Data Points | |

| Wiktor and Jonkers [27] | 640 | |

| Sisomphon et al. [11] | 594 | |

| Sahmaran et al. [54] | 36 | |

| Van Tittelboom et al. [17] | 182 | |

| Özbay et al. [53] | 10 | |

| Database Parameter | Maximum | Minimum |

| Cement (mR %) | 100 | 15 |

| w/c (mR %) | 60 | 25 |

| Sand (mR %) | 309 | 200 |

| BFS (mR %) | 220 | 0 |

| FA (mR %) | 220 | 0 |

| Calcium sulfo-aluminate (mR %) | 10 | 0 |

| Crystalline additive (mR %) | 4 | 0 |

| LWA (mR %) | 76 | 0 |

| LWA with bacteria spores (mR %) | 76 | 0 |

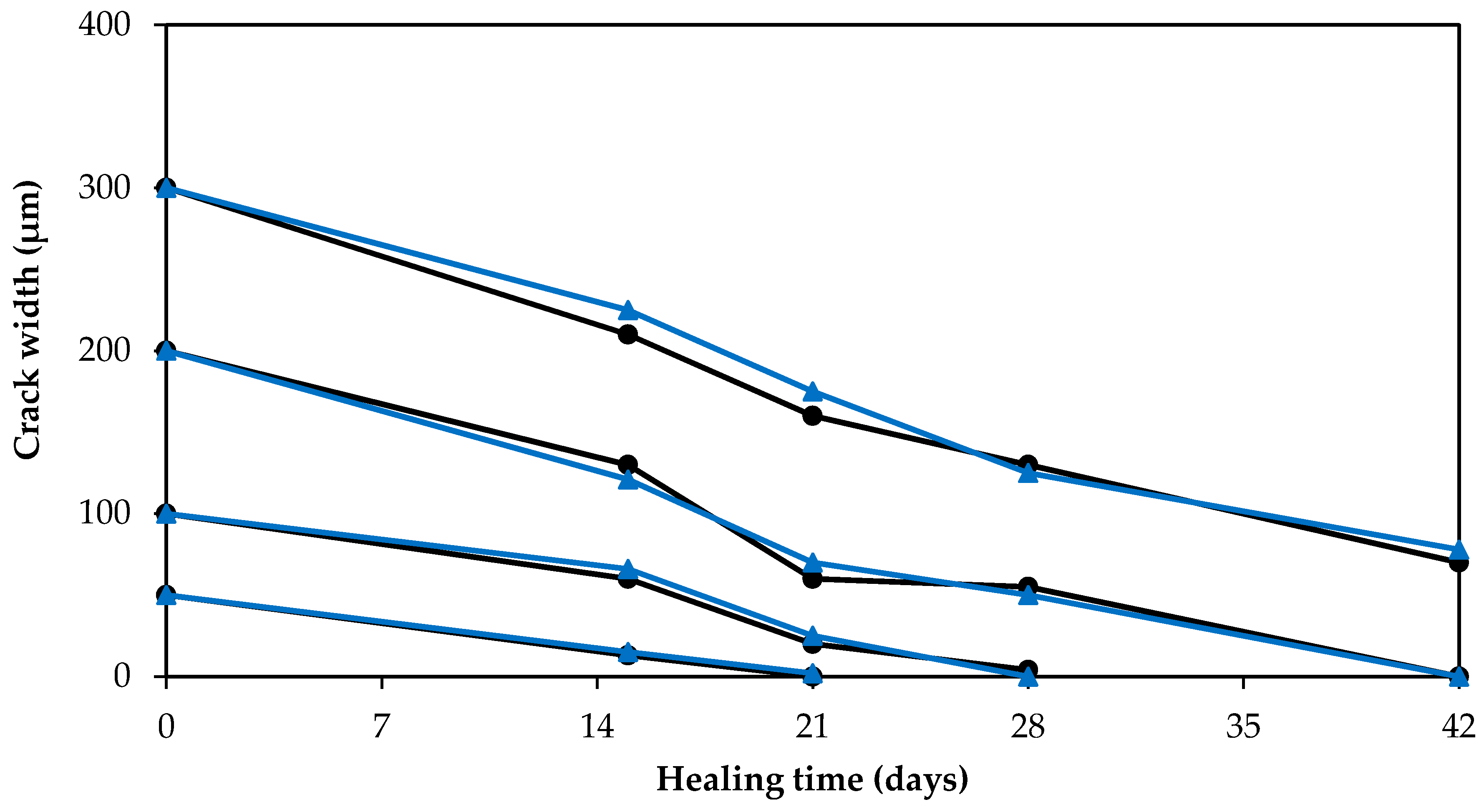

| Initial crack width (µm) | 400 | 40 |

| Healing time (days) | 150 | 0 |

| Final crack width (µm) * | 400 | 0 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramadan Suleiman, A.; Nehdi, M.L. Modeling Self-Healing of Concrete Using Hybrid Genetic Algorithm–Artificial Neural Network. Materials 2017, 10, 135. https://doi.org/10.3390/ma10020135

Ramadan Suleiman A, Nehdi ML. Modeling Self-Healing of Concrete Using Hybrid Genetic Algorithm–Artificial Neural Network. Materials. 2017; 10(2):135. https://doi.org/10.3390/ma10020135

Chicago/Turabian StyleRamadan Suleiman, Ahmed, and Moncef L. Nehdi. 2017. "Modeling Self-Healing of Concrete Using Hybrid Genetic Algorithm–Artificial Neural Network" Materials 10, no. 2: 135. https://doi.org/10.3390/ma10020135