Nitrogen-Polar (000 1 ¯ ) GaN Grown on c-Plane Sapphire with a High-Temperature AlN Buffer

Abstract

:1. Introduction

2. Experiment

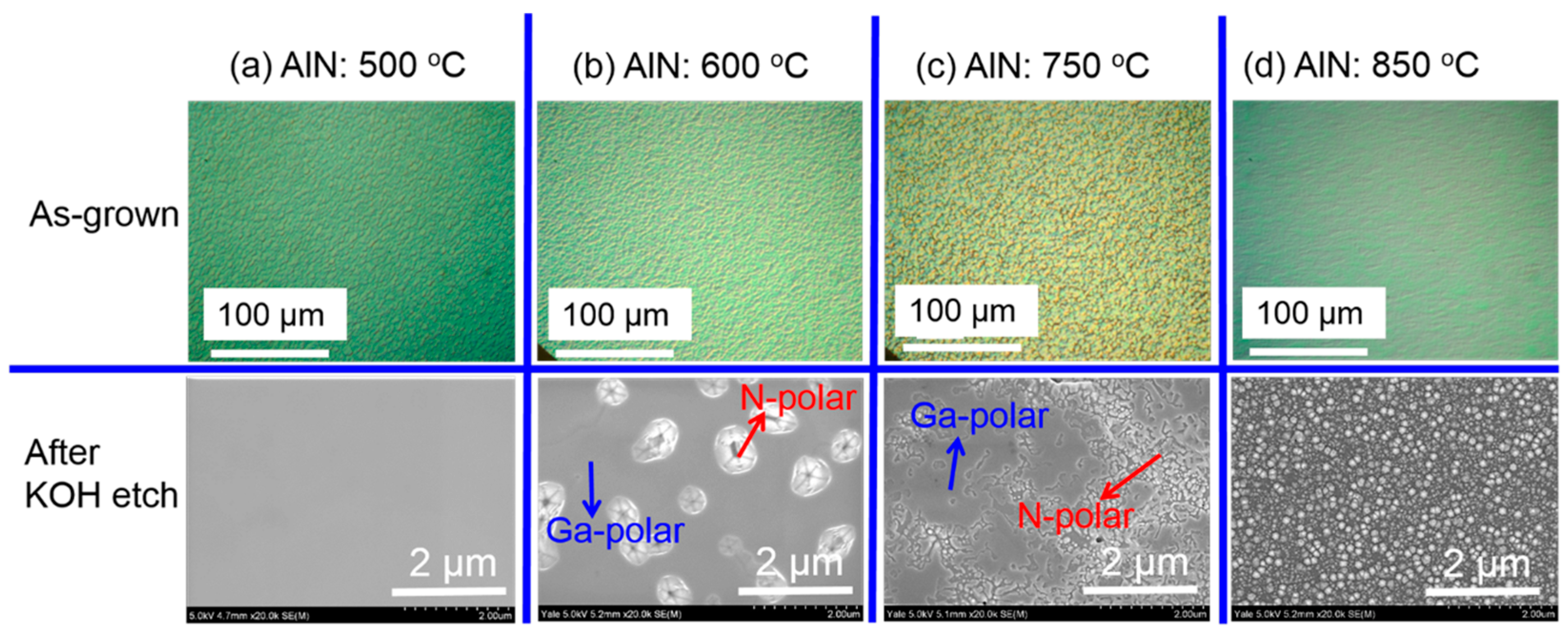

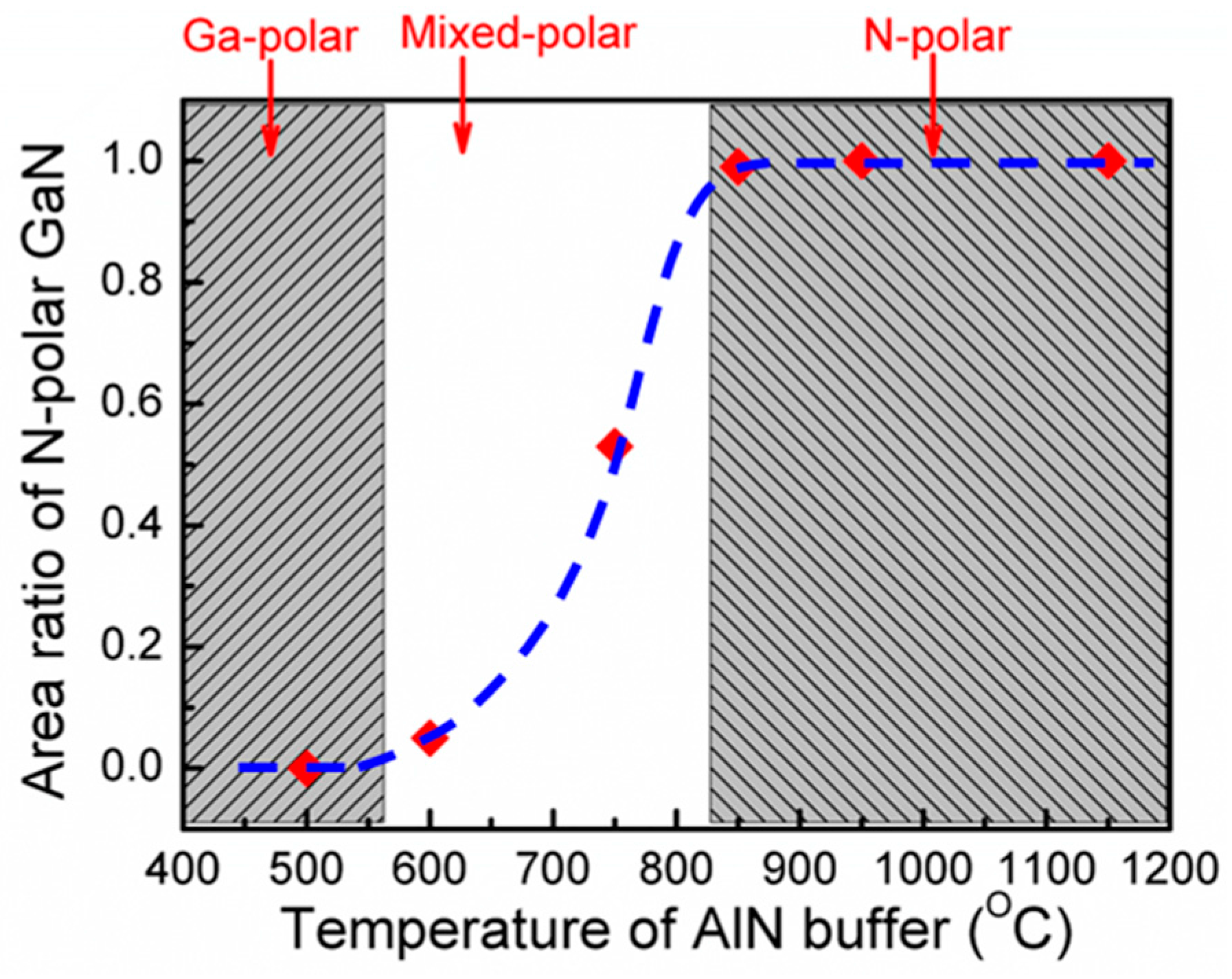

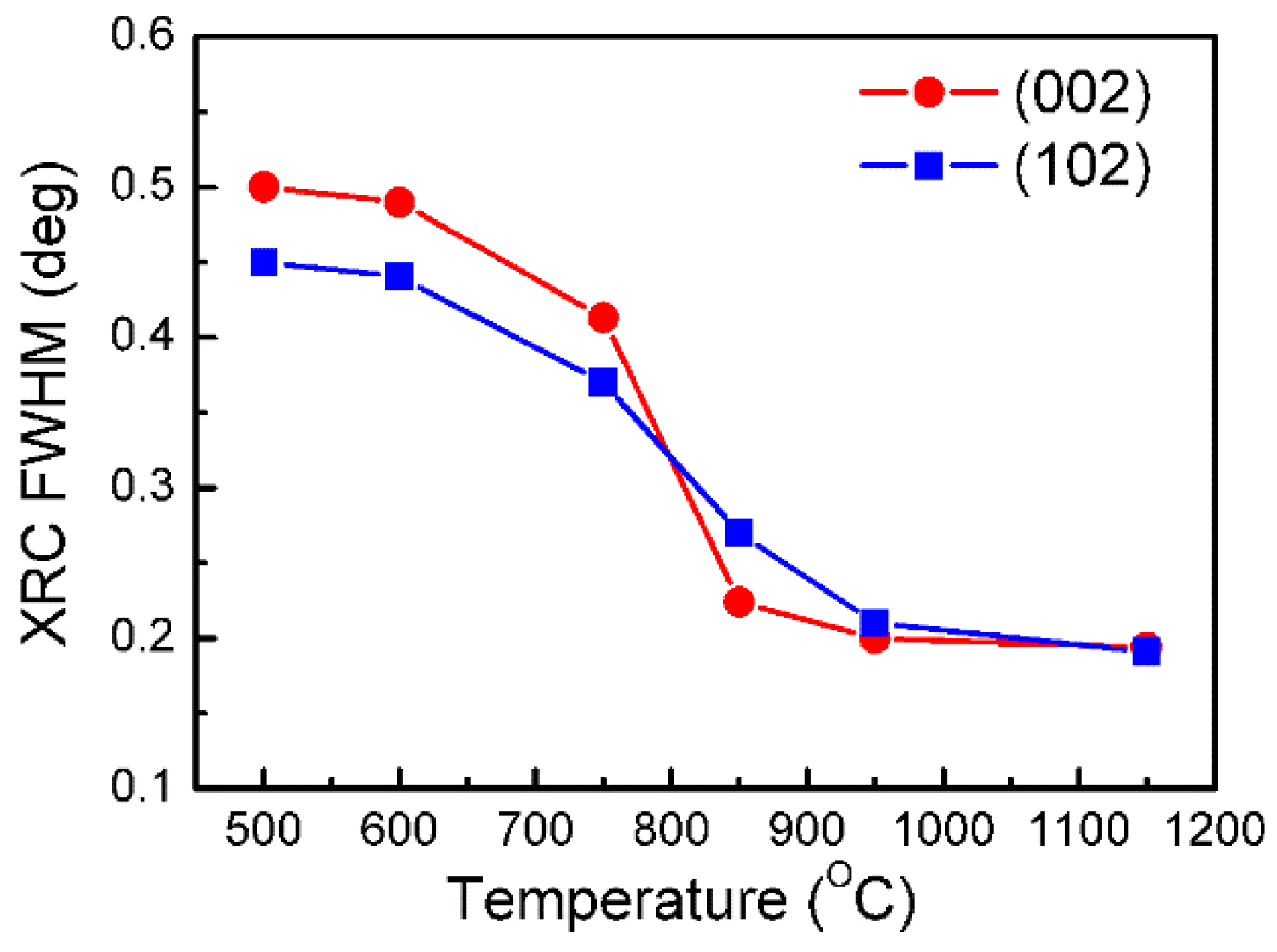

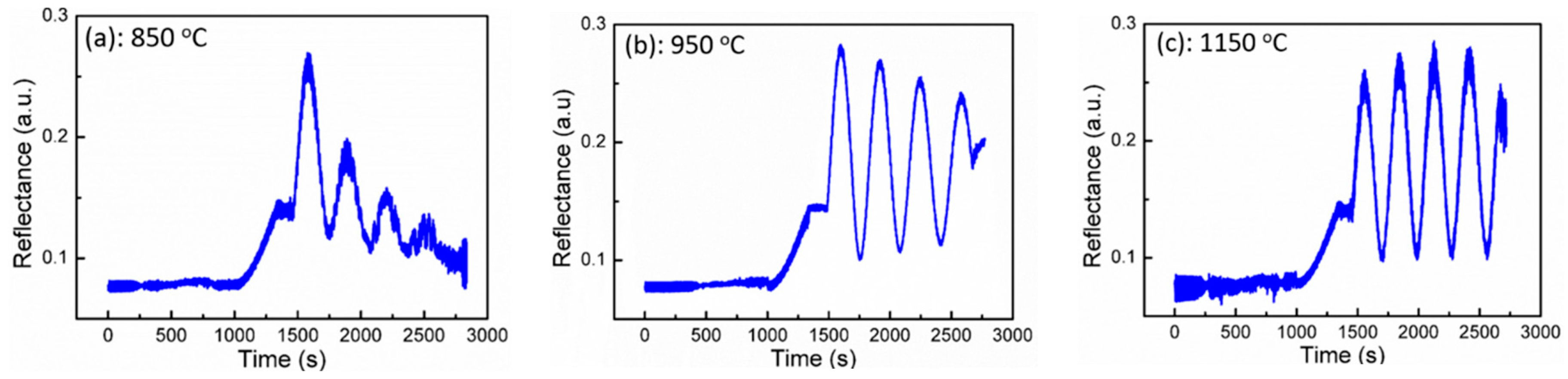

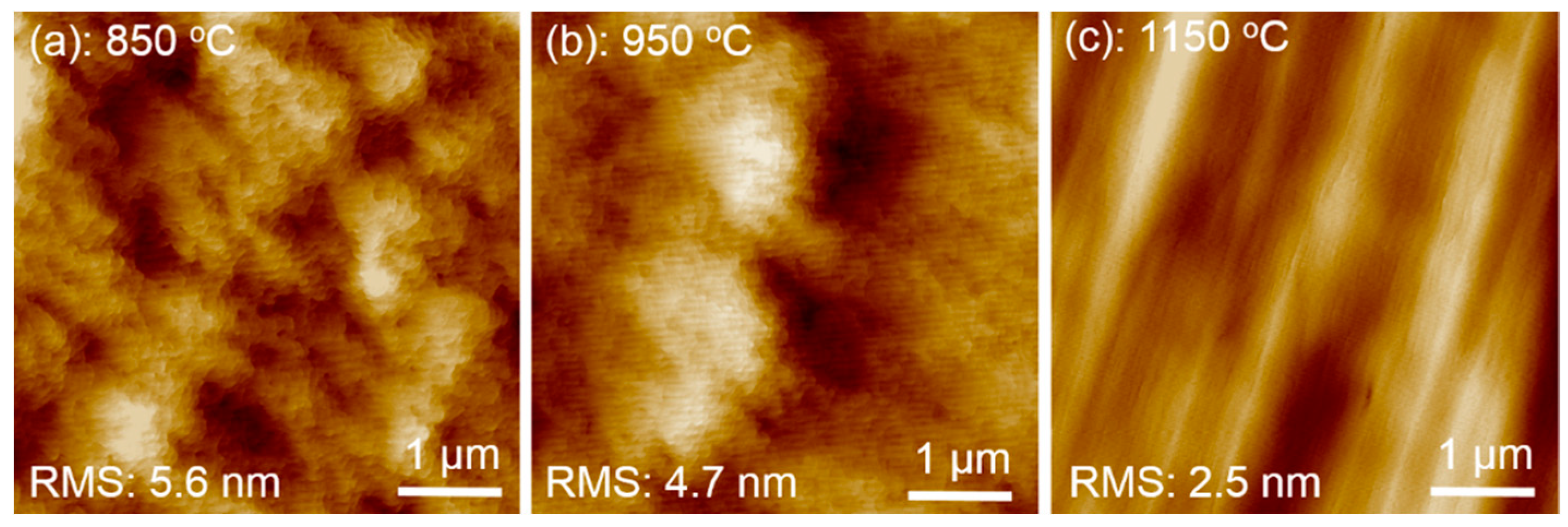

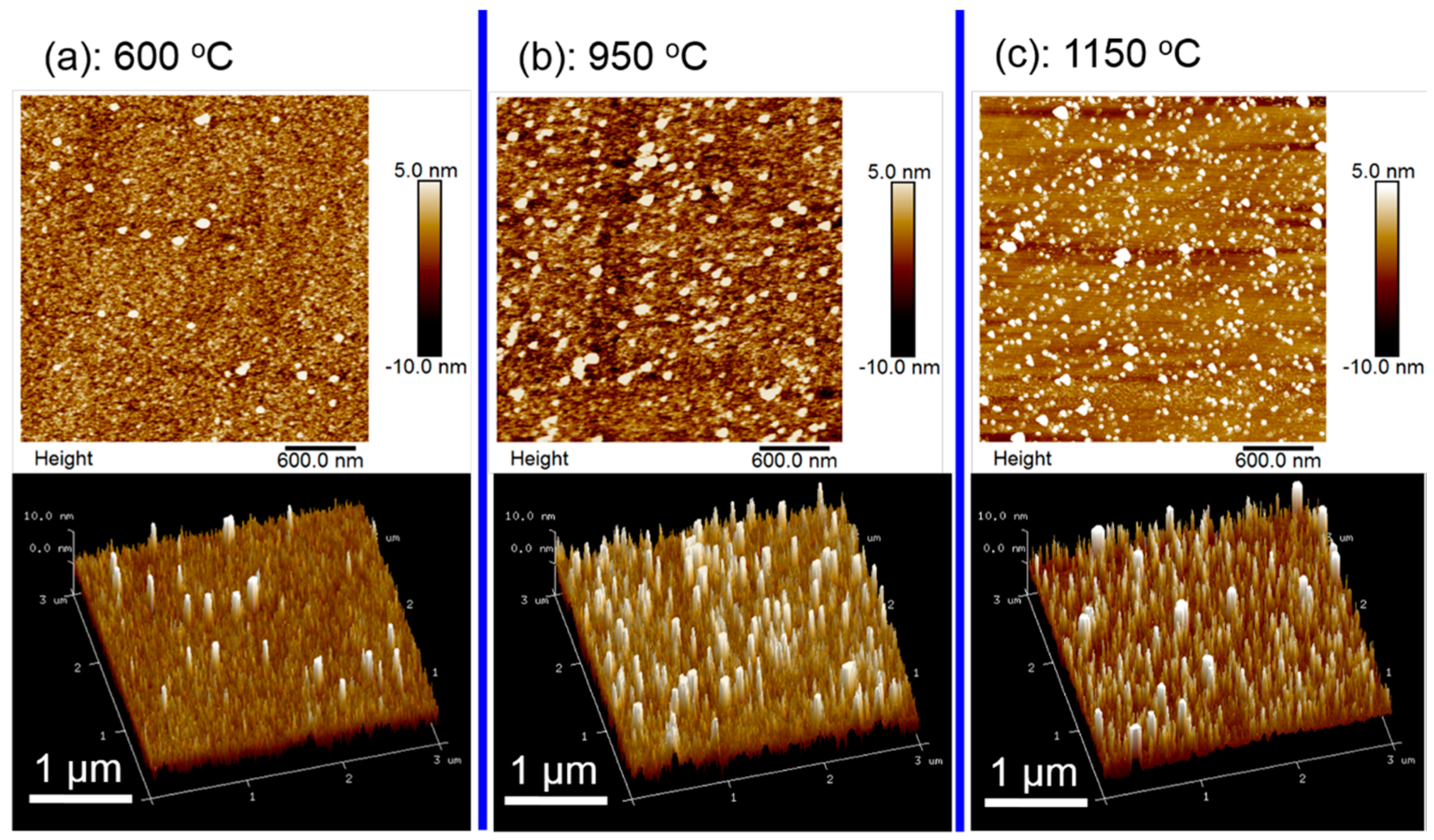

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yen, S.-H.; Kuo, Y.-K. Polarization-dependent optical characteristics of violet InGaN laser diodes. J. Appl. Phys. 2008, 103, 103115. [Google Scholar] [CrossRef]

- Akyol, F.; Nath, D.N.; Krishnamoorthy, S.; Park, P.S.; Rajan, S. Suppression of electron overflow and efficiency droop in N-polar GaN green light emitting diodes. Appl. Phys. Lett. 2012, 100, 111118. [Google Scholar] [CrossRef]

- Keller, S.; Fichtenbaum, N.A.; Furukawa, M.; Speck, J.S.; Denbaars, S.P.; Mishra, U.K. Growth and characterization of N-polar InGaN/GaN multiquantum wells. Appl. Phys. Lett. 2007, 90, 191908. [Google Scholar] [CrossRef]

- Masui, H.; Keller, S.; Fellows, N.; Fichtenbaum, N.A.; Furukawa, M.; Nakamura, S.; Mishra, U.K.; DenBaars, S.P. Luminescence characteristics of N-Polar GaN and InGaN films grown by metal organic chemical vapor deposition. Jpn. J. Appl. Phys. 2009, 48, 071003. [Google Scholar] [CrossRef]

- Shojiki, K.; Tanikawa, T.; Choi, J.-H.; Kuboya, S.; Hanada, T.; Katayama, R.; Matsuoka, T. Red to blue wavelength emission of N-polar InGaN light-emitting diodes grown by metalorganic vapor phase epitaxy. Appl. Phys. Express 2015, 8, 061005. [Google Scholar] [CrossRef]

- Keller, S.; Suh, C.S.; Chen, Z.; Chu, R.; Rajan, S.; Fichtenbaum, N.A.; Furukawa, M.; DenBaars, S.P.; Speck, J.S.; Mishra, U.K. Properties of N-polar AlGaN/GaN heterostructures and field effect transistors grown by metalorganic chemical vapor deposition. J. Appl. Phys. 2008, 103, 033708. [Google Scholar] [CrossRef]

- Wong, M.H.; Pei, Y.; Palacios, T.; Shen, L.; Chakraborty, A.; McCarthy, L.S.; Keller, S.; DenBaars, S.P.; Speck, J.S.; Mishra, U.K. Low nonalloyed Ohmic contact resistance to nitride high electron mobility transistors using N-face growth. Appl. Phys. Lett. 2007, 91, 232103. [Google Scholar] [CrossRef]

- Chowdhury, A.; Ng, H.M.; Bhardwaj, M.; Weimann, N.G. Second-harmonic generation in periodically poled GaN. Appl. Phys. Lett. 2003, 83, 1077–1079. [Google Scholar] [CrossRef]

- Aleksov, A.; Collazo, R.; Mita, S.; Schlesser, R.; Sitar, Z. Current-voltage characteristics of n/n lateral polarity junctions in GaN. Appl. Phys. Lett. 2006, 89, 052117. [Google Scholar] [CrossRef]

- Ng, H.M.; Parz, W.; Weimann, N.G.; Chowdhury, A. Patterning GaN microstructures by polarity-selective chemical etching. Jpn. J. Appl. Phys. 2003, 42, L1405. [Google Scholar] [CrossRef]

- Liu, F.; Collazo, R.; Mita, S.; Sitar, Z.; Duscher, G.; Pennycook, S.J. The mechanism for polarity inversion of GaN via a thin AlN layer: Direct experimental evidence. Appl. Phys. Lett. 2007, 91, 203115. [Google Scholar] [CrossRef]

- Keller, S.; Fichtenbaum, N.A.; Wu, F.; Brown, D.; Rosales, A.; DenBaars, S.P.; Speck, J.S.; Mishra, U.K. Influence of the substrate misorientation on the properties of N-polar GaN films grown by metal organic chemical vapor deposition. J. Appl. Phys. 2007, 102, 083546. [Google Scholar] [CrossRef]

- Sun, Q.; Cho, Y.S.; Lee, I.-H.; Han, J.; Kong, B.H.; Cho, H.K. Nitrogen-polar GaN growth evolution on c-plane sapphire. Appl. Phys. Lett. 2008, 93, 131912. [Google Scholar] [CrossRef]

- Sun, Q.; Suk Cho, Y.; Kong, B.H.; Koun Cho, H.; Shine Ko, T.; Yerino, C.D.; Lee, I.-H.; Han, J. N-face GaN growth on c-plane sapphire by metalorganic chemical vapor deposition. J. Cryst. Growth 2009, 311, 2948–2952. [Google Scholar] [CrossRef]

- Ito, T.; Ohtsuka, K.; Kuwahara, K.; Sumiya, M.; Takano, Y.; Fuke, S. Effect of AlN buffer layer deposition conditions on the properties of GaN layer. J. Cryst. Growth 1999, 205, 20–24. [Google Scholar] [CrossRef]

- Jasinski, J.; Liliental-Weber, Z.; Paduano, Q.S.; Weyburne, D.W. Inversion domains in AlN grown on (0001) sapphire. Appl. Phys. Lett. 2003, 83, 2811–2813. [Google Scholar] [CrossRef]

- Paduano, Q.; Weyburne, D. Two-step process for the metalorganic chemical vapor deposition growth of high quality AlN films on sapphire. Jpn. J. Appl. Phys. 2003, 42, 1590–1591. [Google Scholar] [CrossRef]

- Wu, Y.; Hanlon, A.; Kaeding, J.F.; Sharma, R.; Fini, P.T.; Nakamura, S.; Speck, J.S. Effect of nitridation on polarity, microstructure, and morphology of AlN films. Appl. Phys. Lett. 2004, 84, 912–914. [Google Scholar] [CrossRef]

- Kirste, R.; Mita, S.; Hussey, L.; Hoffmann, M.P.; Guo, W.; Bryan, I.; Bryan, Z.; Tweedie, J.; Xie, J.; Gerhold, M.; et al. Polarity control and growth of lateral polarity structures in AlN. Appl. Phys. Lett. 2013, 102, 181913. [Google Scholar] [CrossRef]

- Hussey, L.; White, R.M.; Kirste, R.; Mita, S.; Bryan, I.; Guo, W.; Osterman, K.; Haidet, B.; Bryan, Z.; Bobea, M.; et al. Sapphire decomposition and inversion domains in N-polar aluminum nitride. Appl. Phys. Lett. 2014, 104, 032104. [Google Scholar] [CrossRef]

- Uchida, K.; Watanabe, A.; Yano, F.; Kouguchi, M.; Tanaka, T.; Minagawa, S. Nitridation process of sapphire substrate surface and its effect on the growth of GaN. J. Appl. Phys. 1996, 79, 3487–3491. [Google Scholar] [CrossRef]

- Mohn, S.; Stolyarchuk, N.; Markurt, T.; Kirste, R.; Hoffmann, M.P.; Collazo, R.; Courville, A.; Di Felice, R.; Sitar, Z.; Vennéguès, P.; et al. Polarity control in group-III nitrides beyond pragmatism. Phys. Rev. Appl. 2016, 5, 054004. [Google Scholar] [CrossRef]

- Han, J.; Ng, T.-B.; Biefeld, R.M.; Crawford, M.H.; Follstaedt, D.M. The effect of H2 on morphology evolution during GaN metalorganic chemical vapor deposition. Appl. Phys. Lett. 1997, 71, 3114–3116. [Google Scholar] [CrossRef]

- Zhao, D.G.; Zhu, J.J.; Liu, Z.S.; Zhang, S.M.; Yang, H.; Jiang, D.S. Surface morphology of AlN buffer layer and its effect on GaN growthby metalorganic chemical vapor deposition. Appl. Phys. Lett. 2004, 85, 1499–1501. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, J.; Han, J. Nitrogen-Polar (000 1 ¯ ) GaN Grown on c-Plane Sapphire with a High-Temperature AlN Buffer. Materials 2017, 10, 252. https://doi.org/10.3390/ma10030252

Song J, Han J. Nitrogen-Polar (000 1 ¯ ) GaN Grown on c-Plane Sapphire with a High-Temperature AlN Buffer. Materials. 2017; 10(3):252. https://doi.org/10.3390/ma10030252

Chicago/Turabian StyleSong, Jie, and Jung Han. 2017. "Nitrogen-Polar (000 1 ¯ ) GaN Grown on c-Plane Sapphire with a High-Temperature AlN Buffer" Materials 10, no. 3: 252. https://doi.org/10.3390/ma10030252