Mechanical Behavior of Recycled Aggregate Concrete-Filled Steel Tubular Columns before and after Fire

Abstract

:1. Introduction

2. Testing Program

2.1. Test Parameters

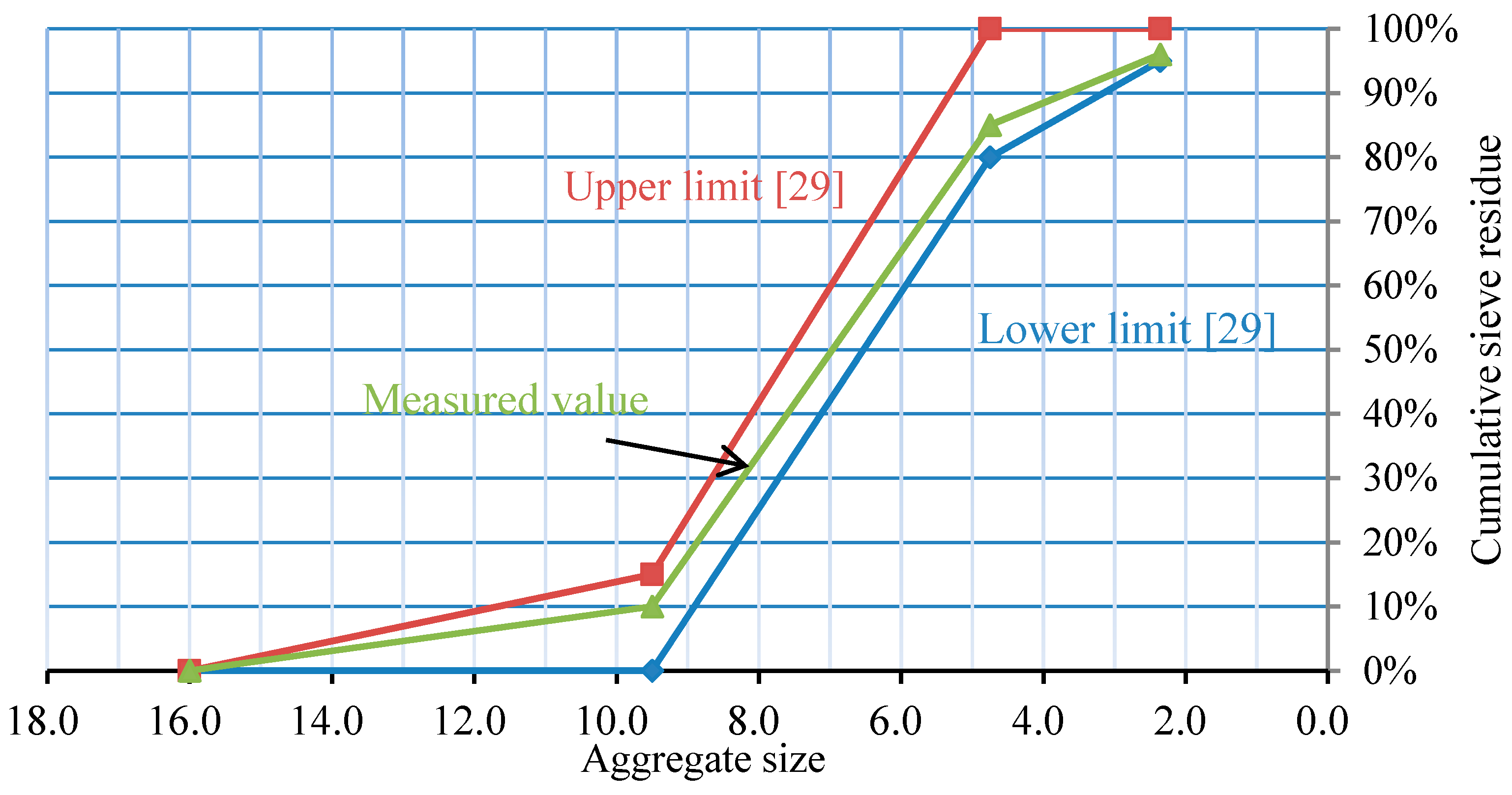

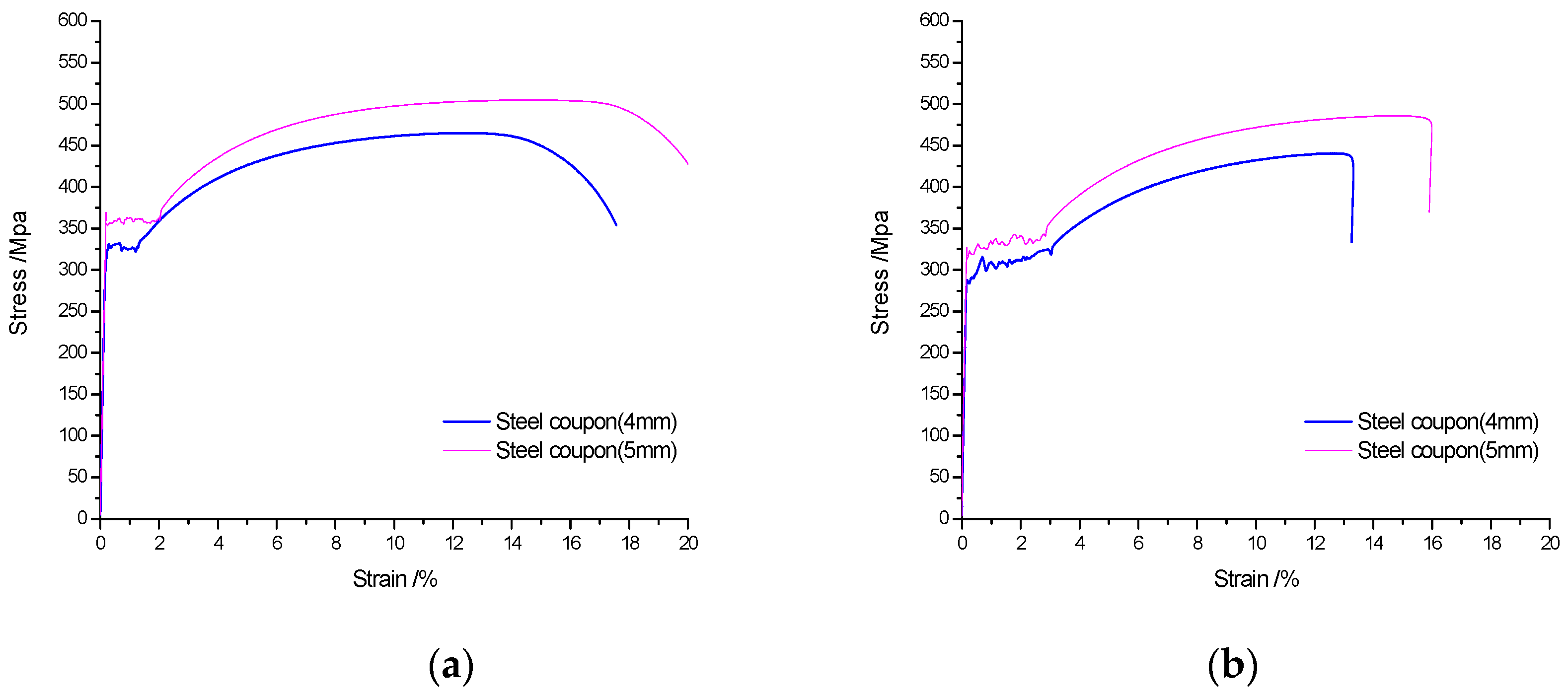

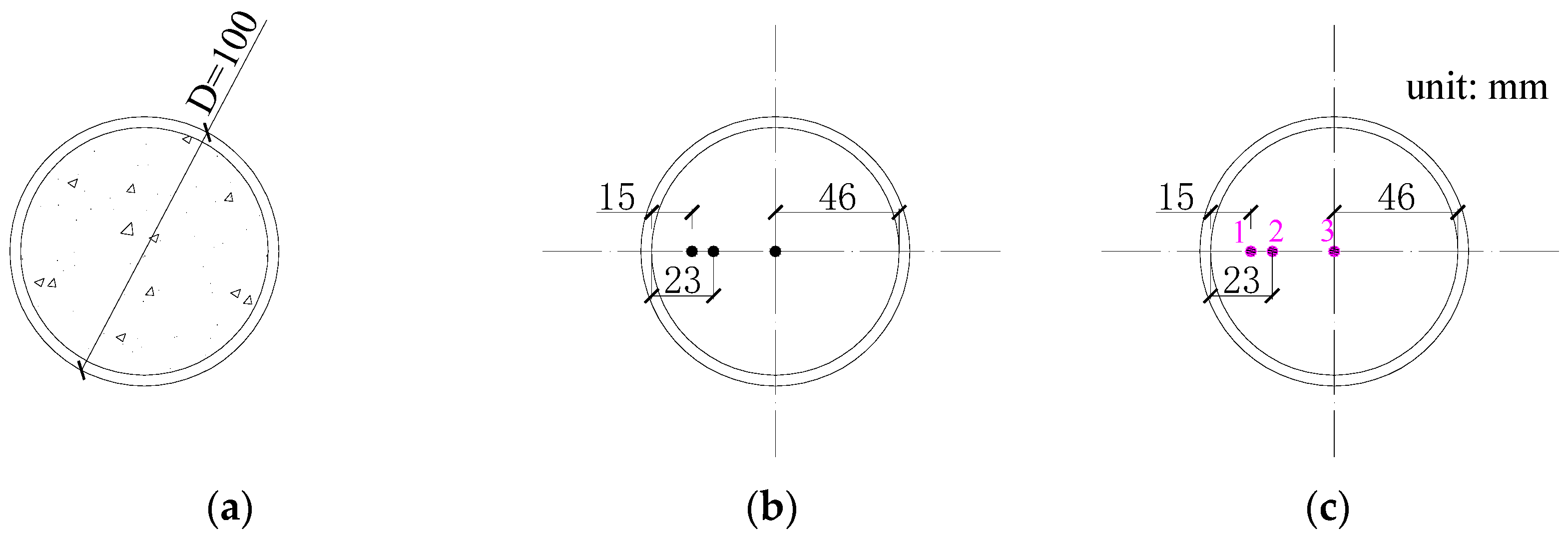

2.2. Material Properties

2.3. Construction of Test Specimens

3. Performance of RACFST under Axial Compression at Room Temperature

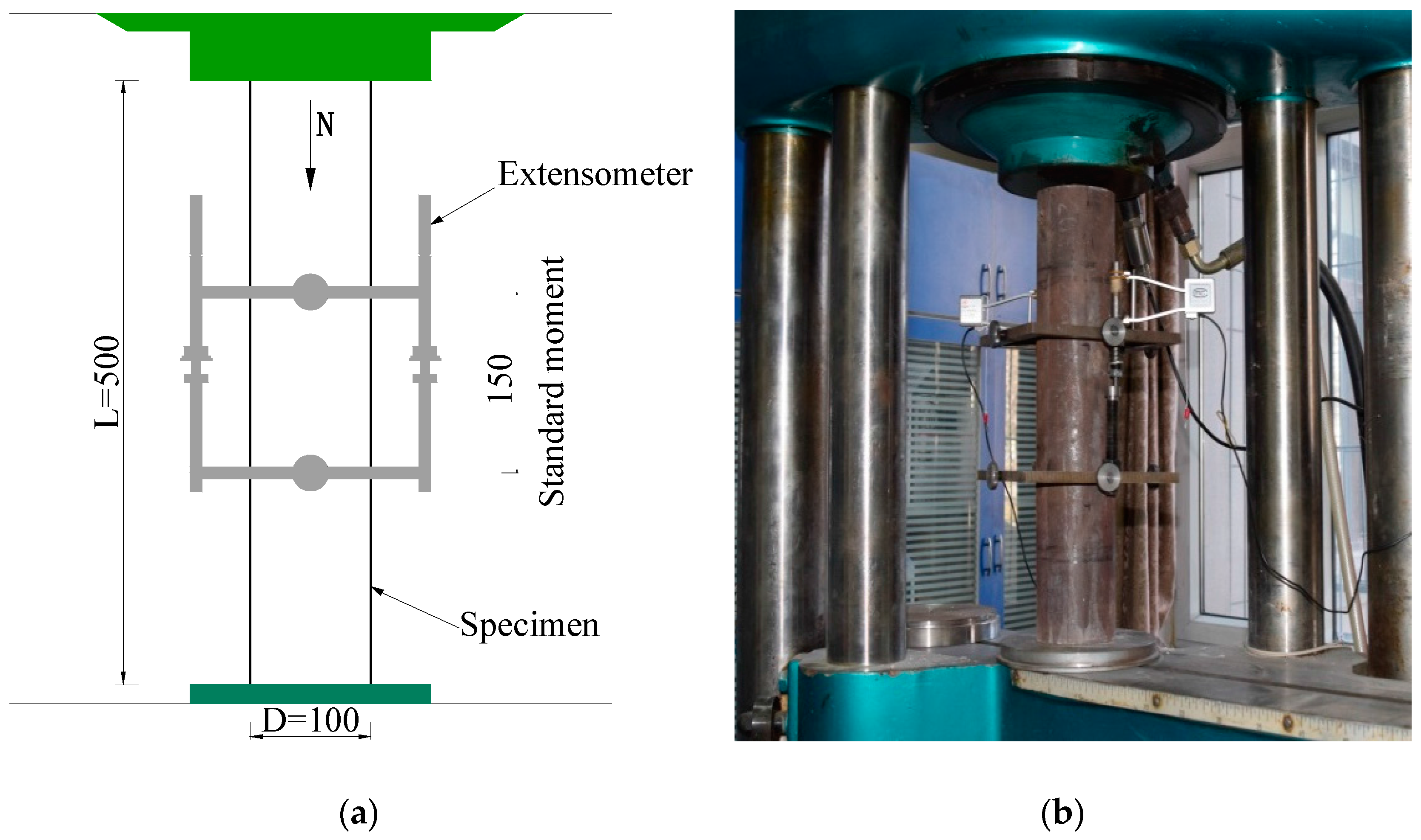

3.1. Test Set-Up and Loading Program

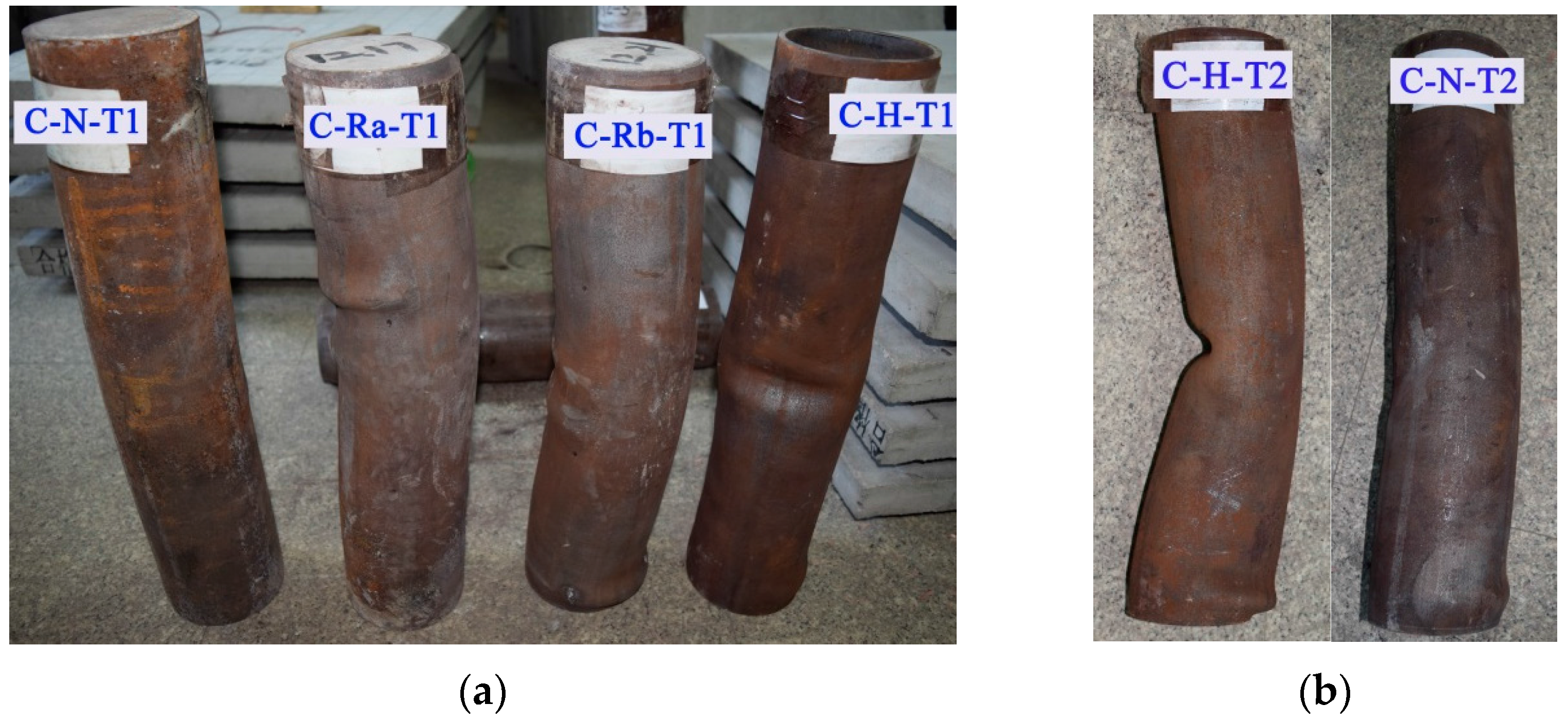

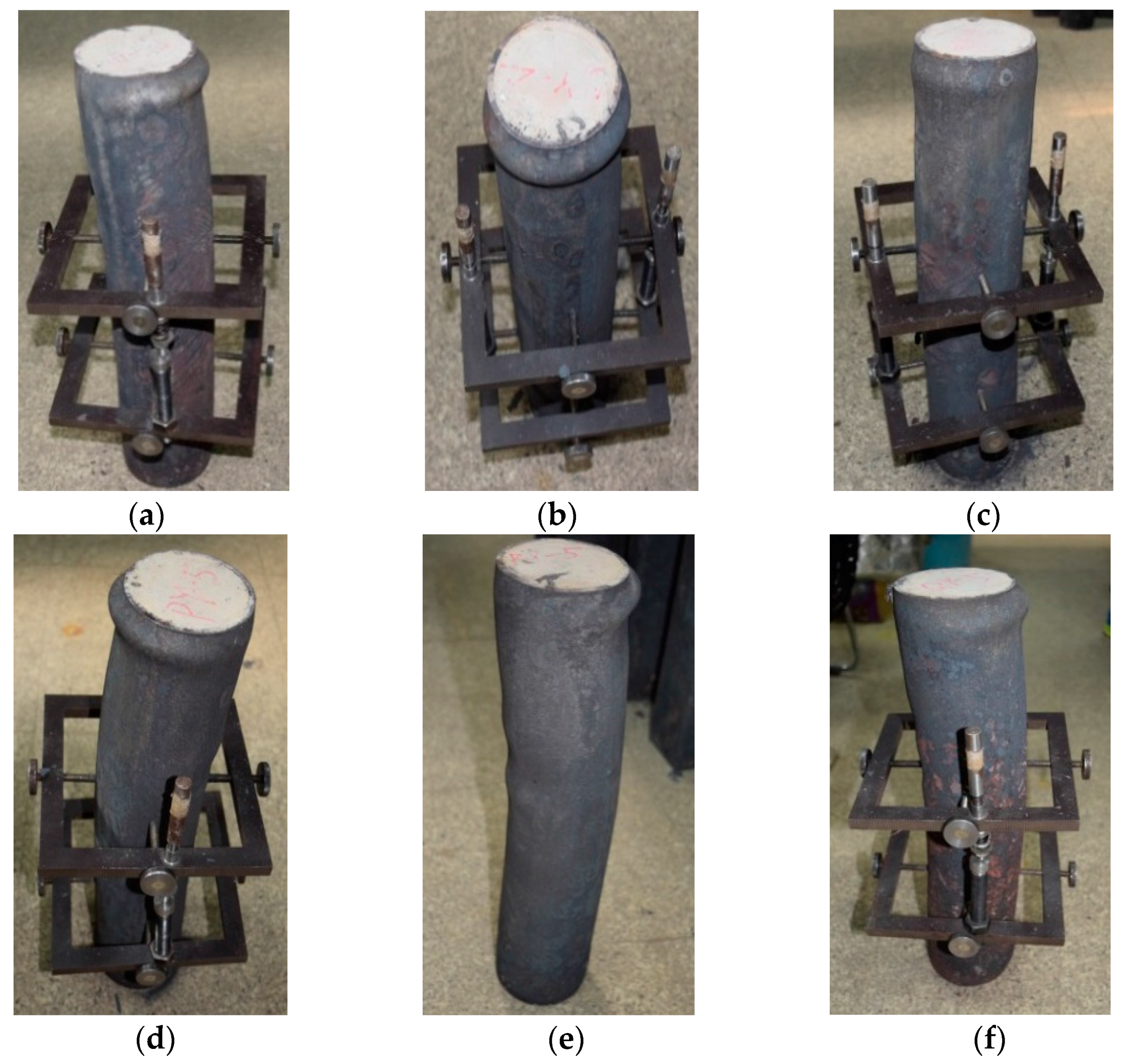

3.2. Failure Modes of Specimens at Room Temperature

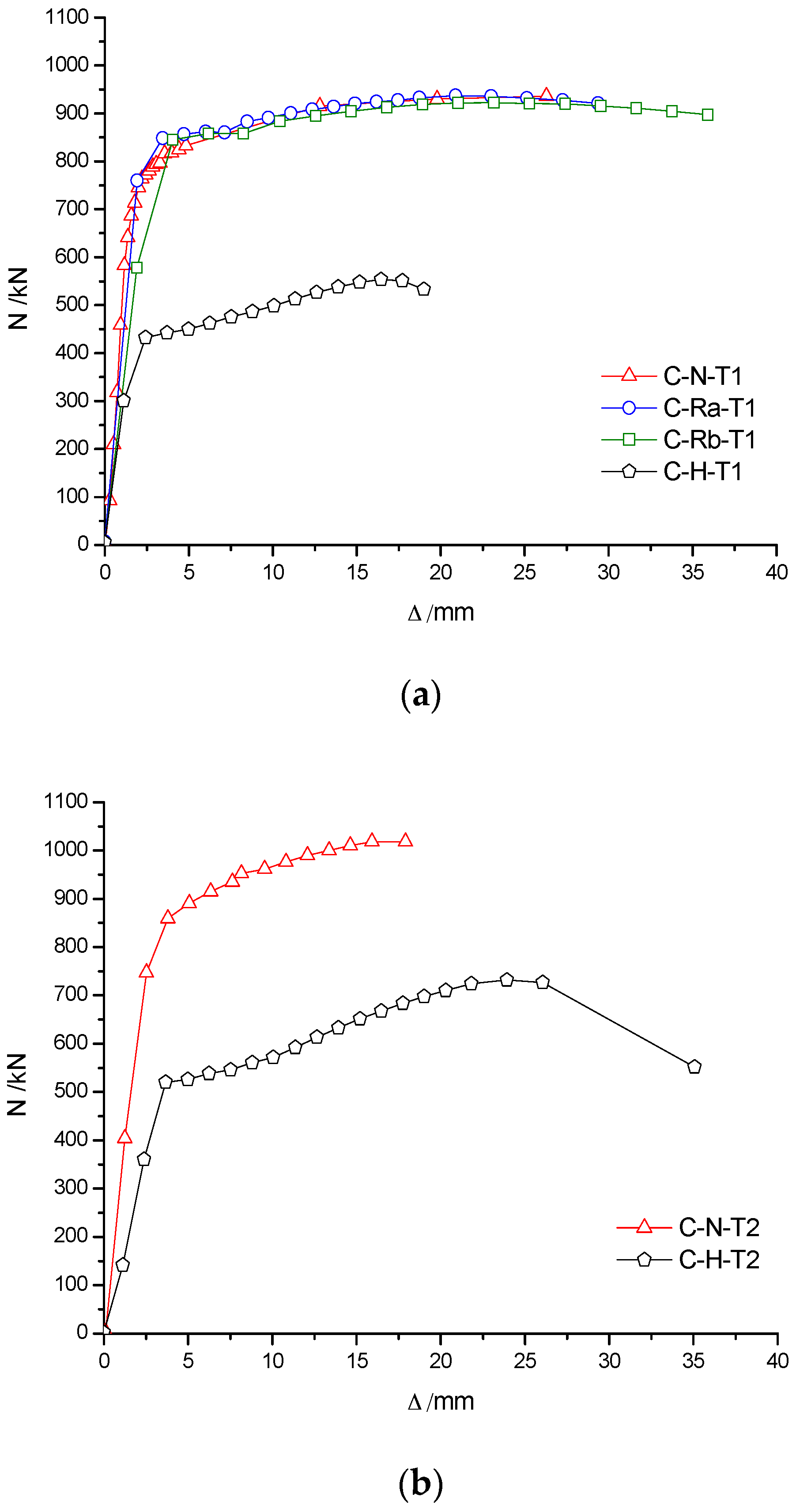

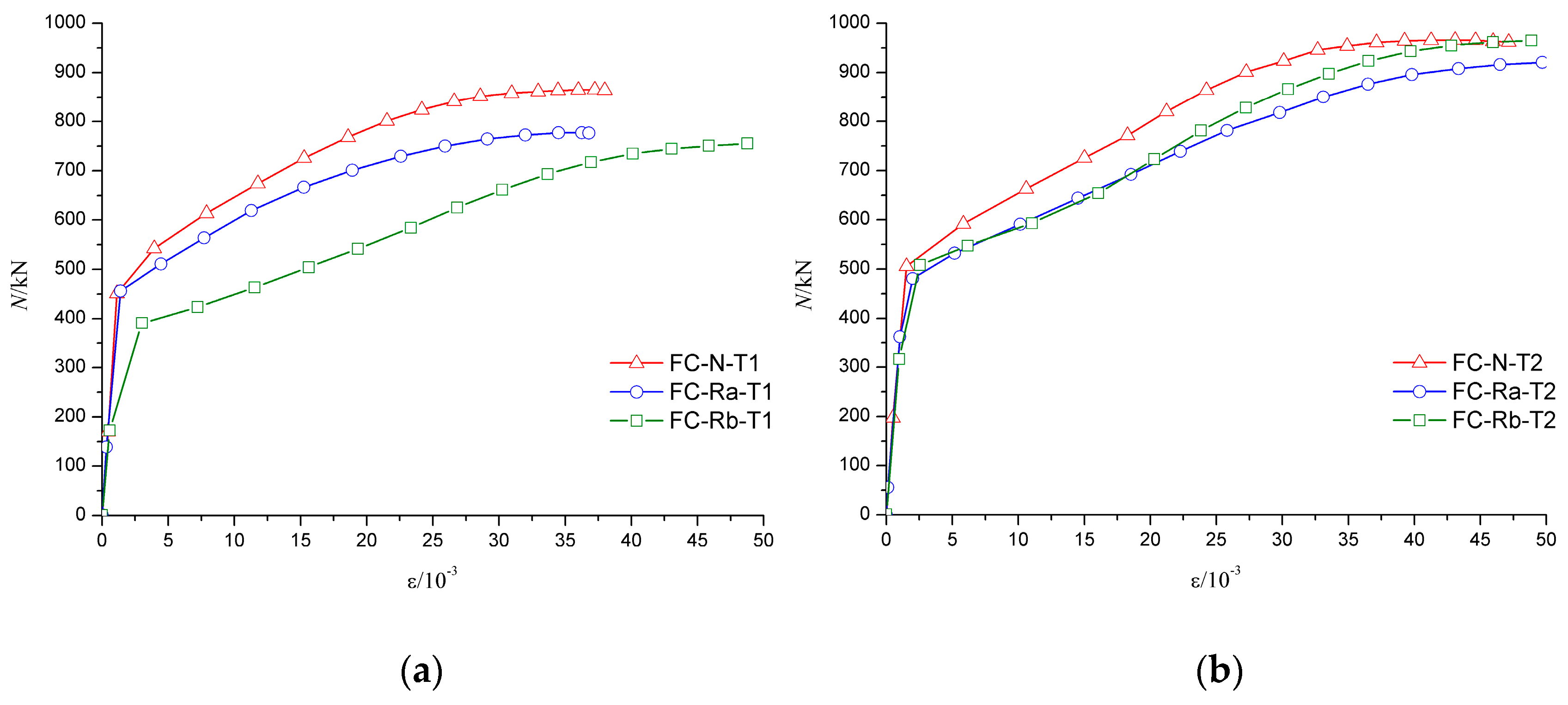

3.3. Load–Deformation Relationship of RACFST at Room Temperature

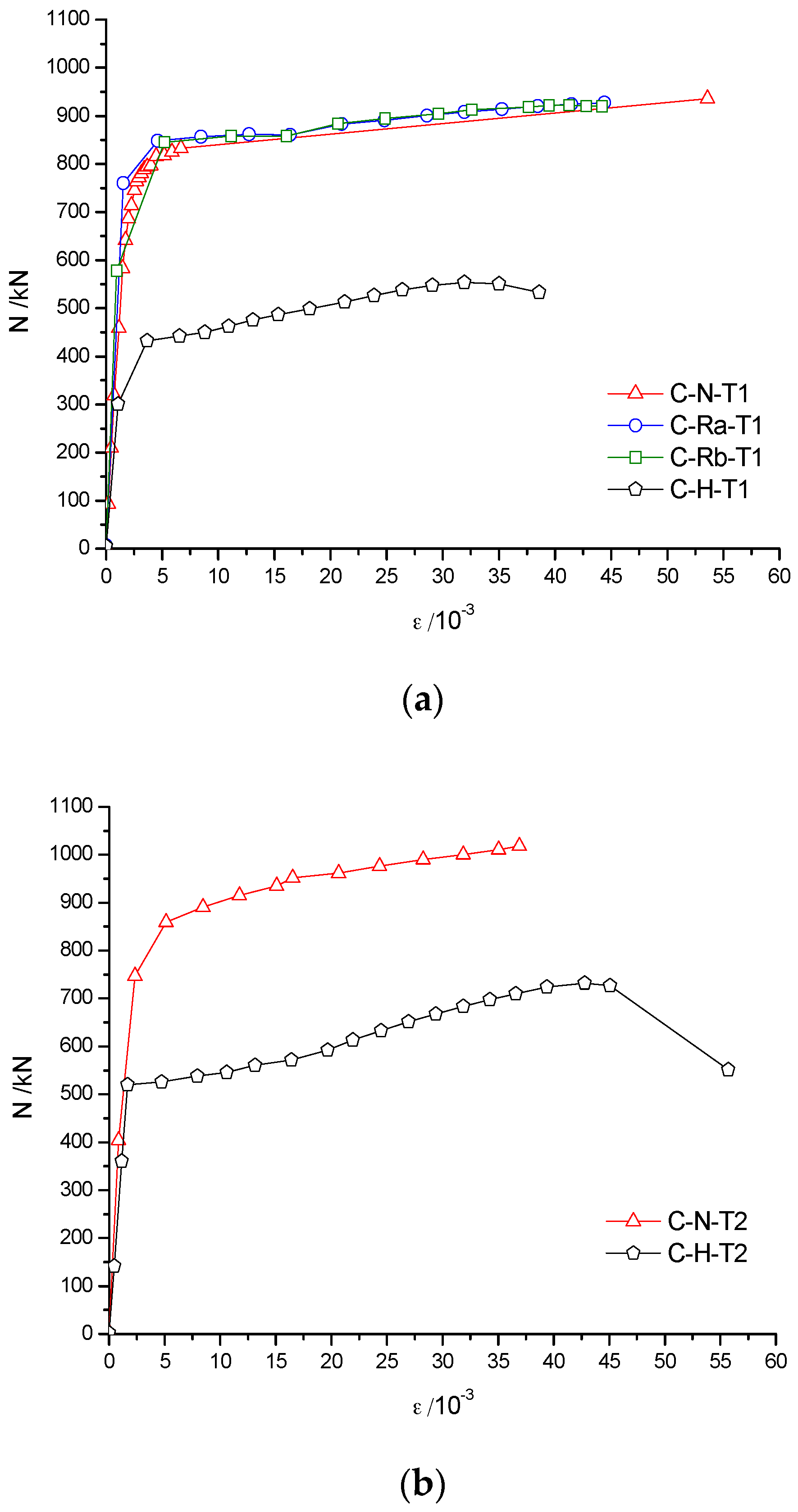

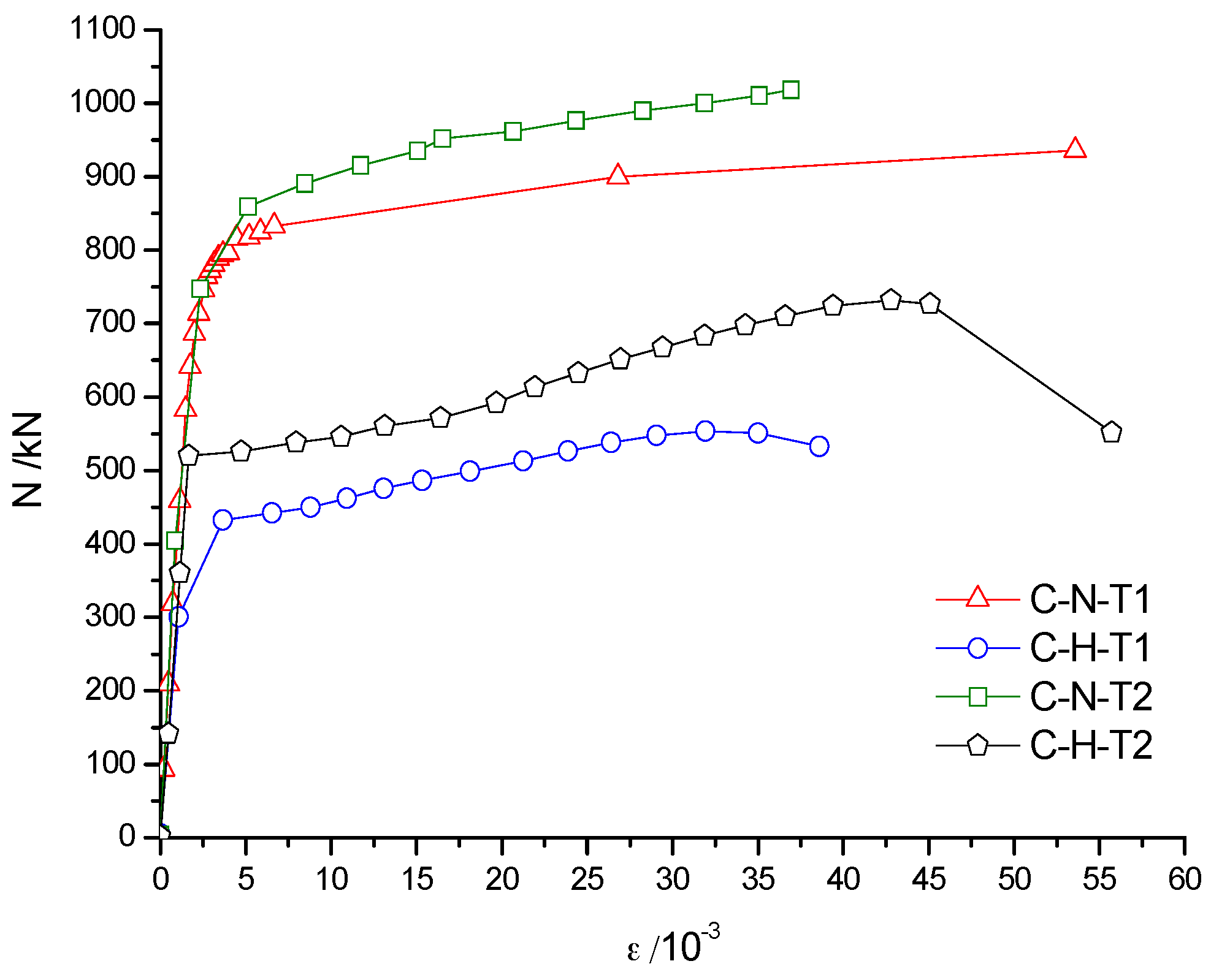

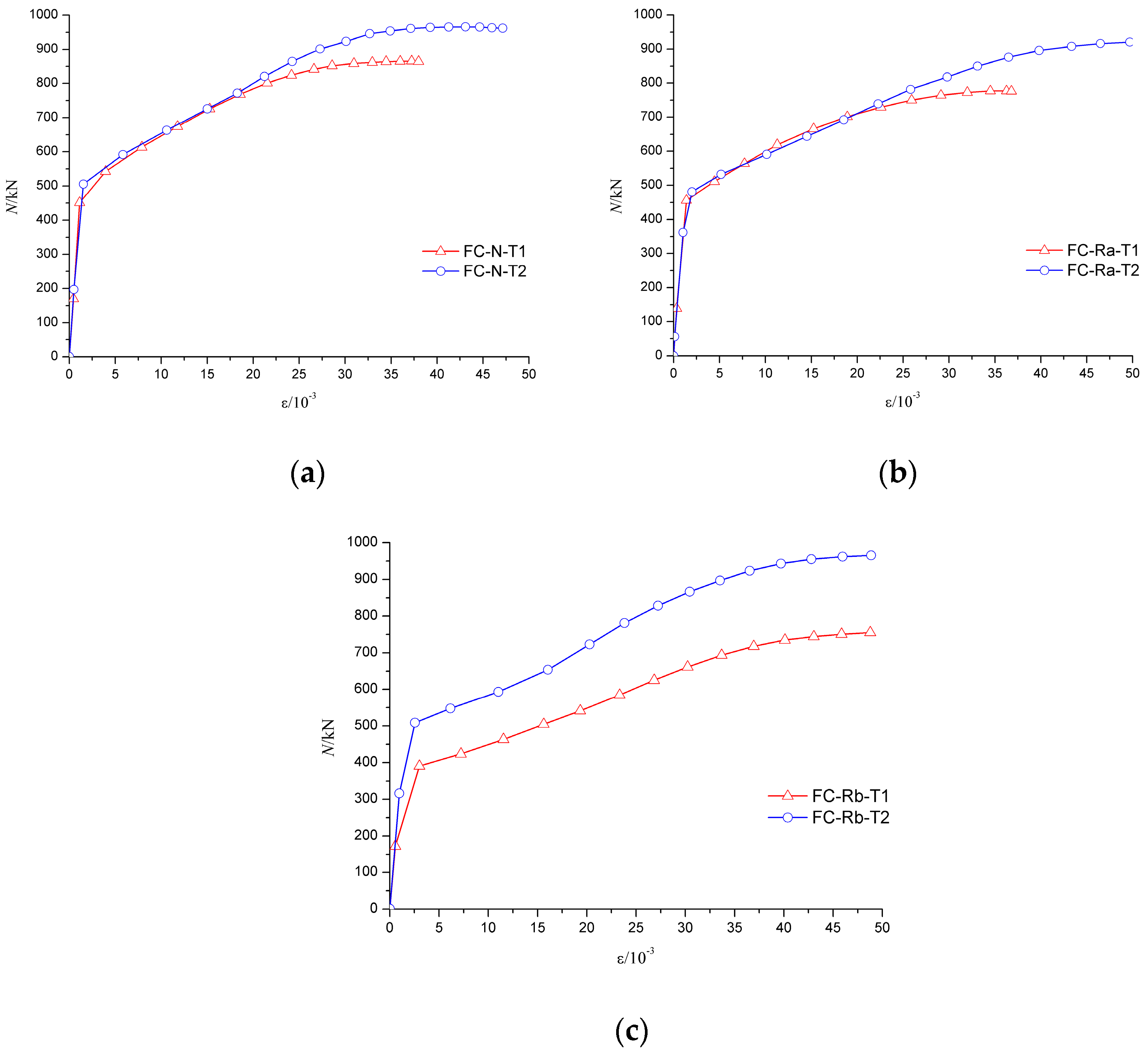

3.4. Load–Axial Strain Relationship of RACFST at Room Temperature

4. The Fire Test and the Post-Fire Axial Loading Test of RACFST

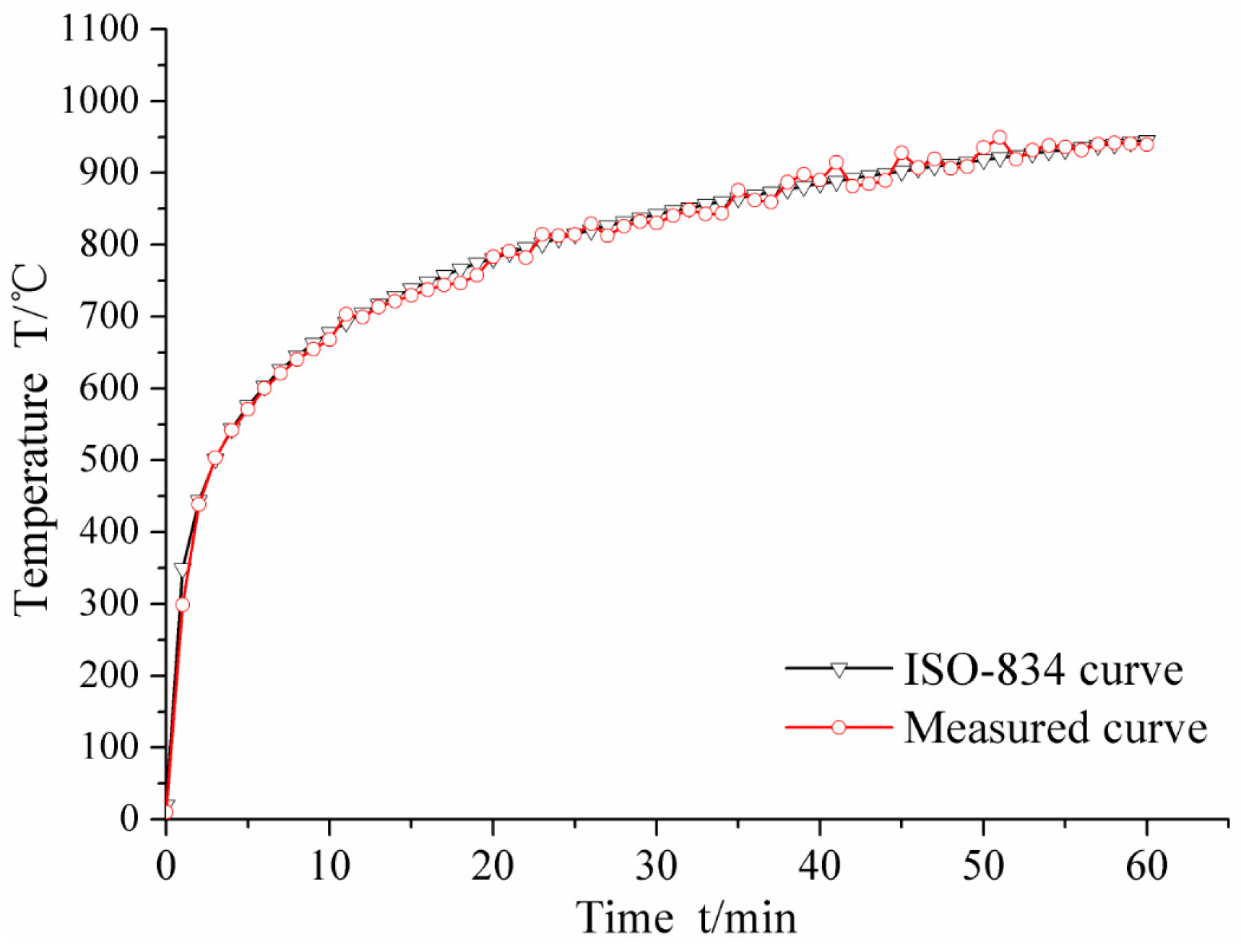

4.1. General Situation of the Fire Test

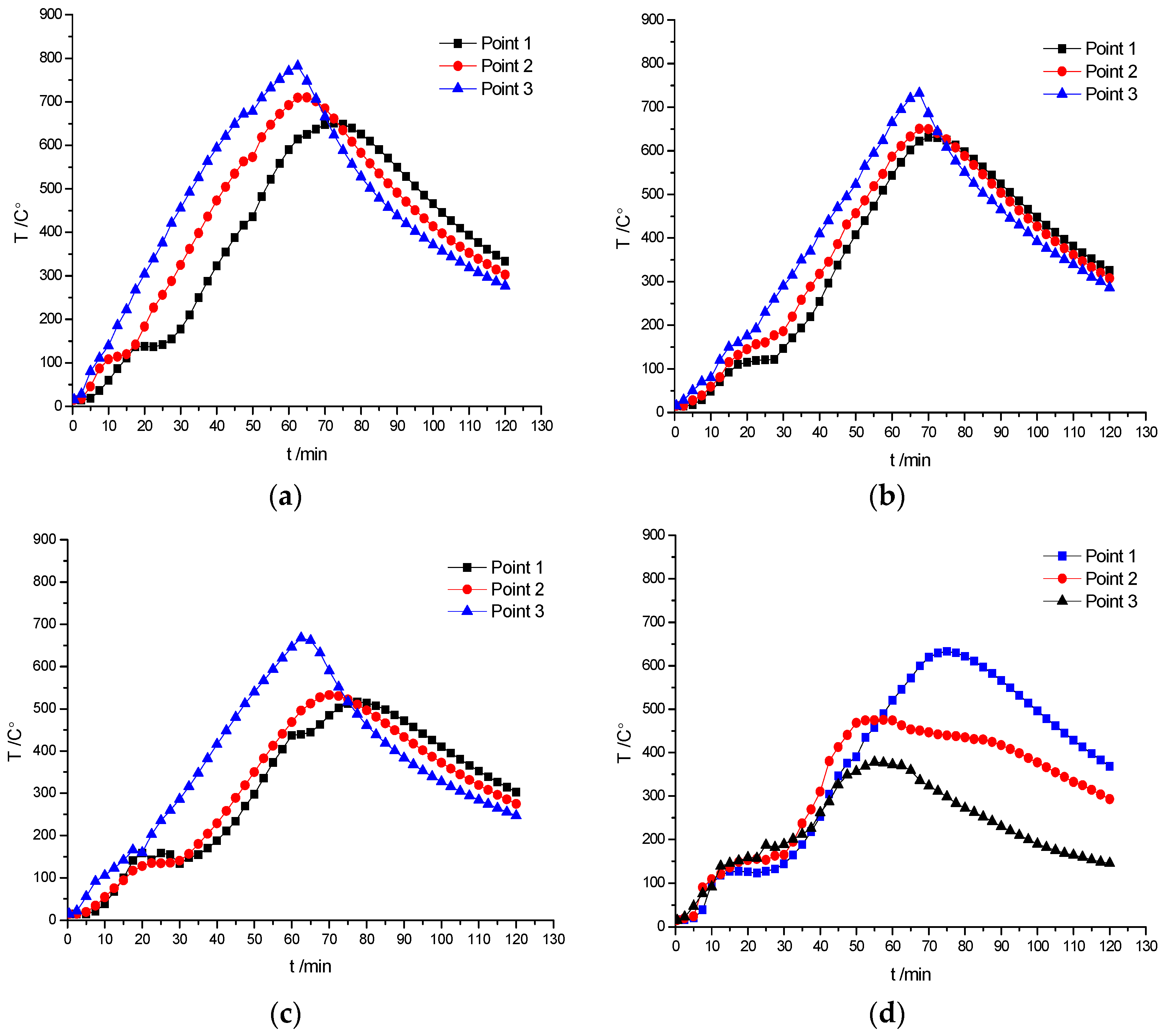

4.2. Monitoring of Internal Temperature of Specimen

4.3. Failure Modes of Specimen after Fire

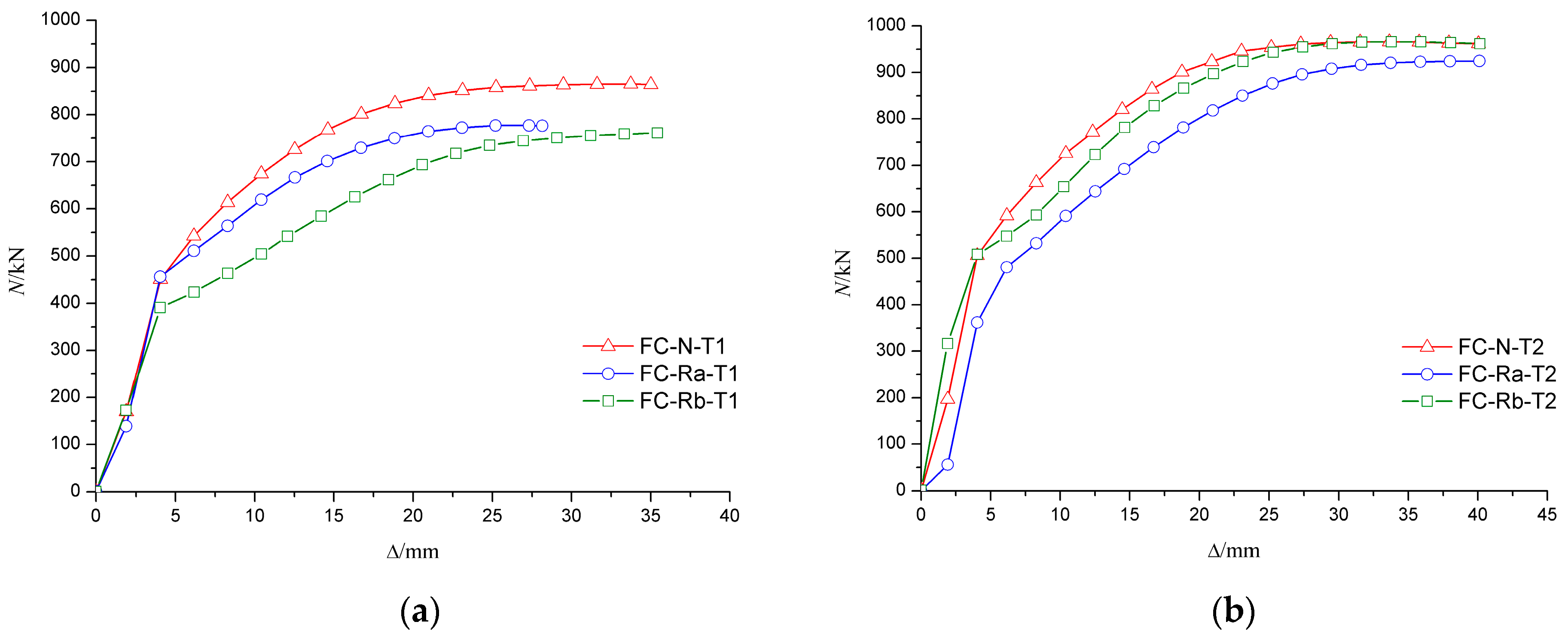

4.4. Load–Deformation Relationship of RACFST after Fire

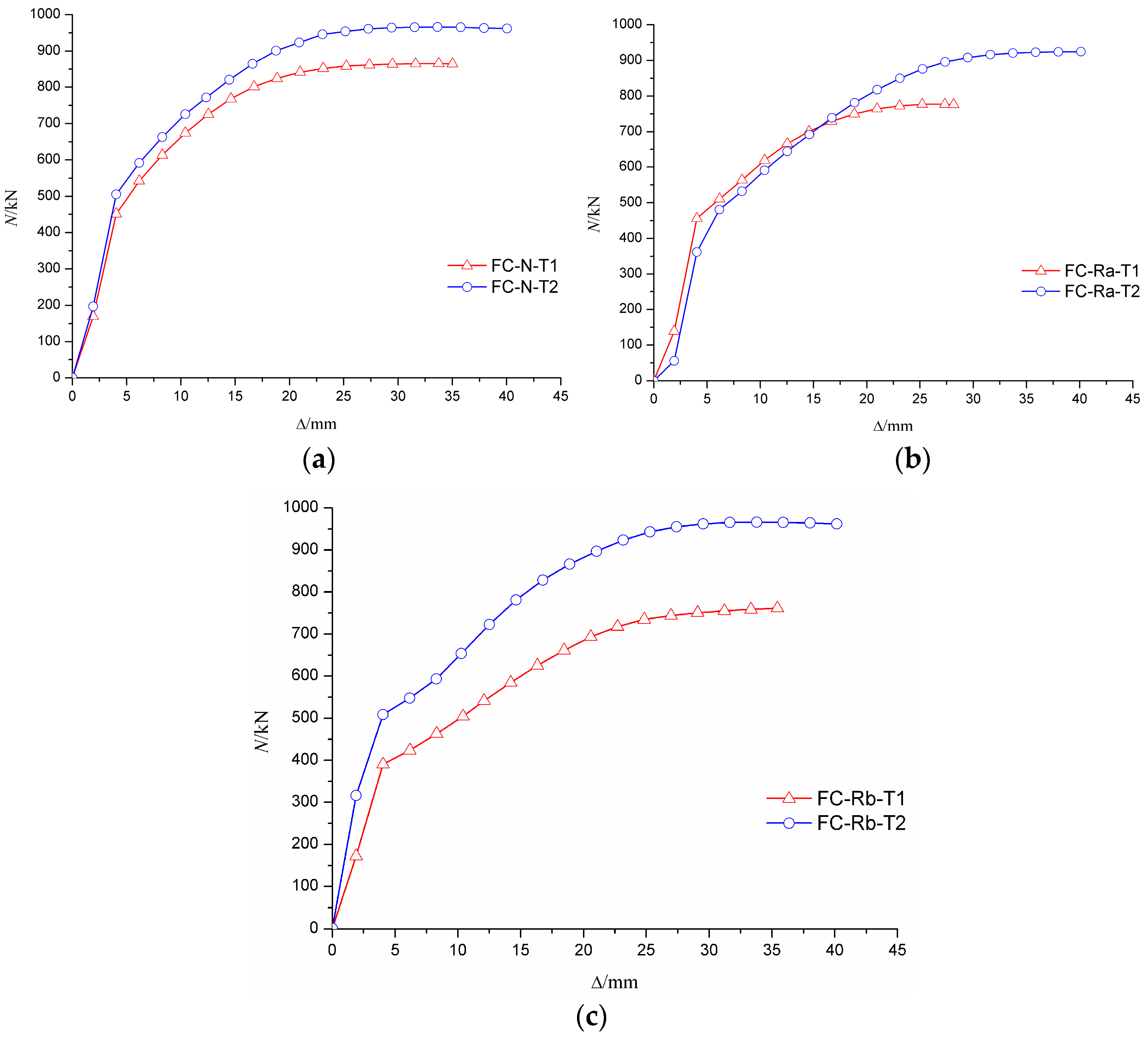

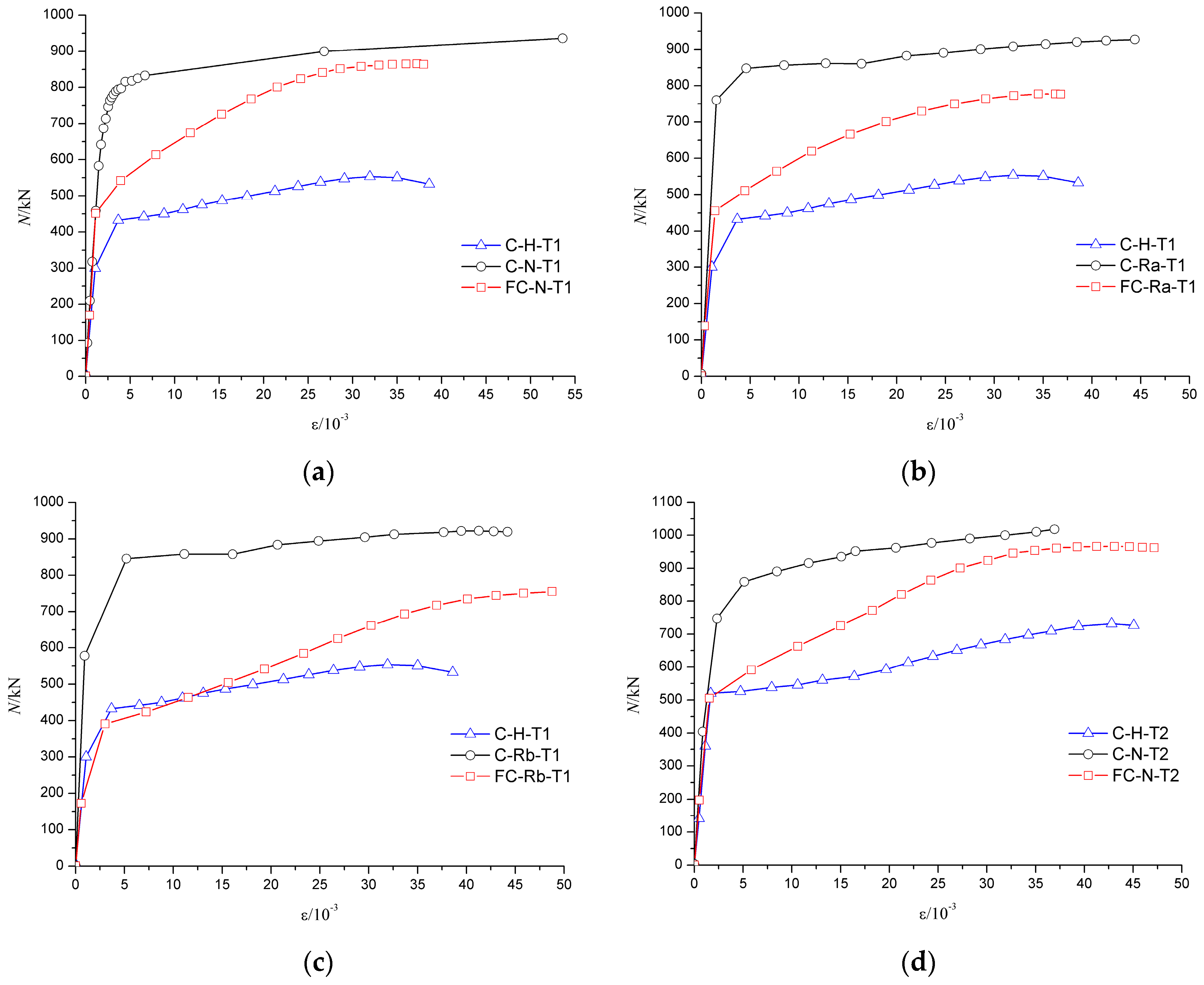

4.5. Load–Axial Strain Relationship of RACFST after Fire

5. Comparative Analysis of Bearing Capacity of RACFST Column before and after Fire

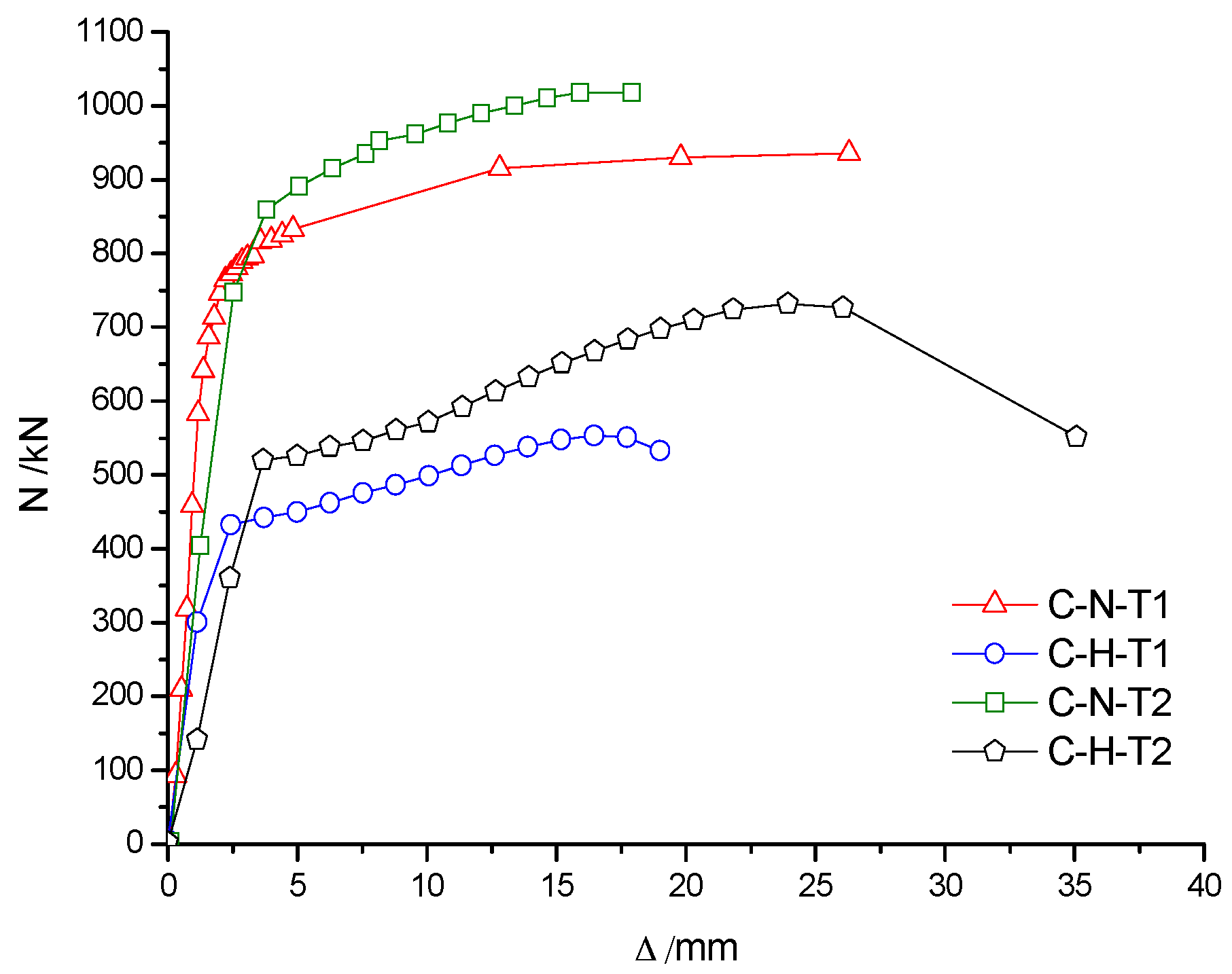

5.1. Analysis of the Load–Deformation Curve

5.2. Analysis of the Load–Strain Curve

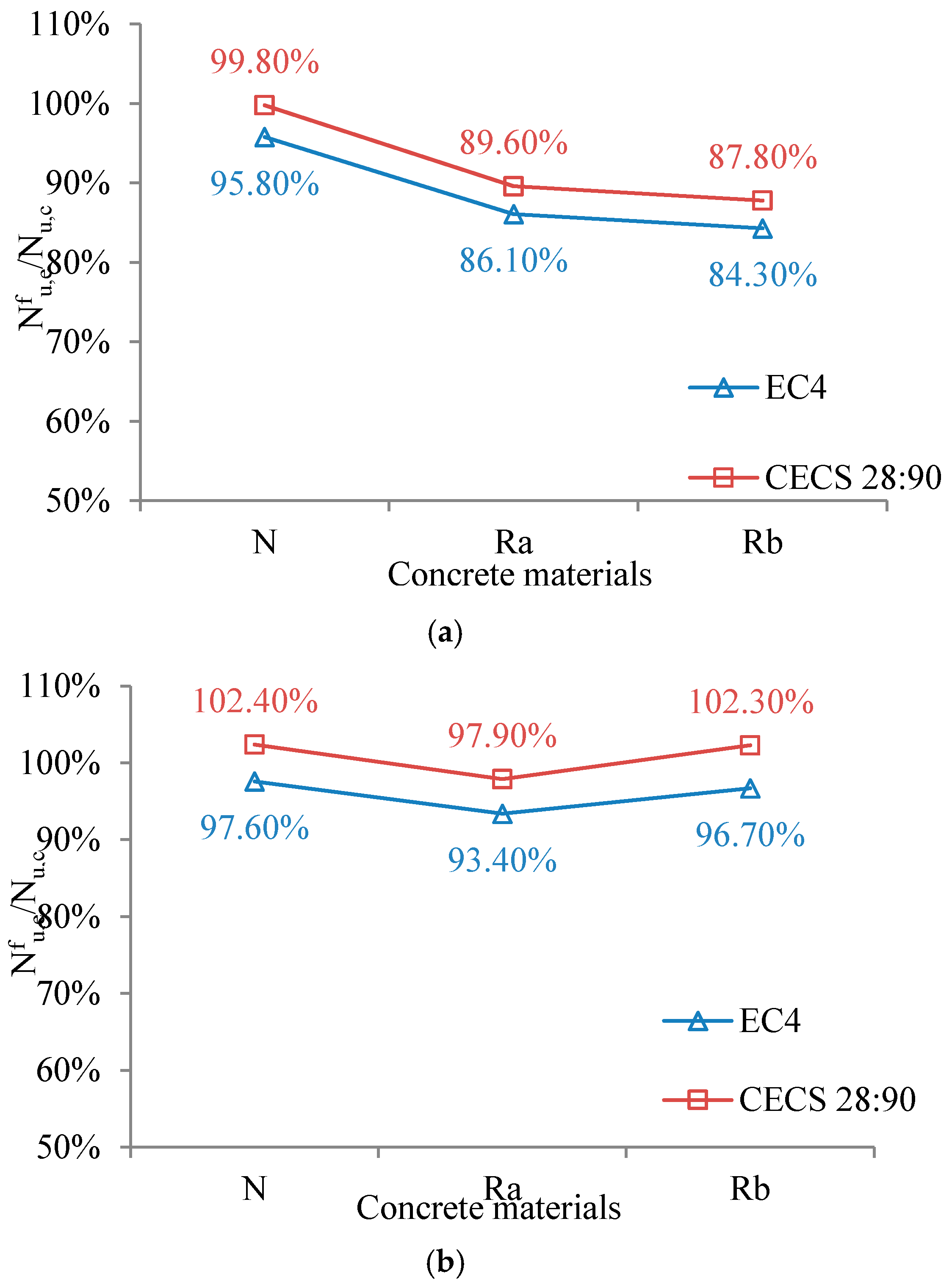

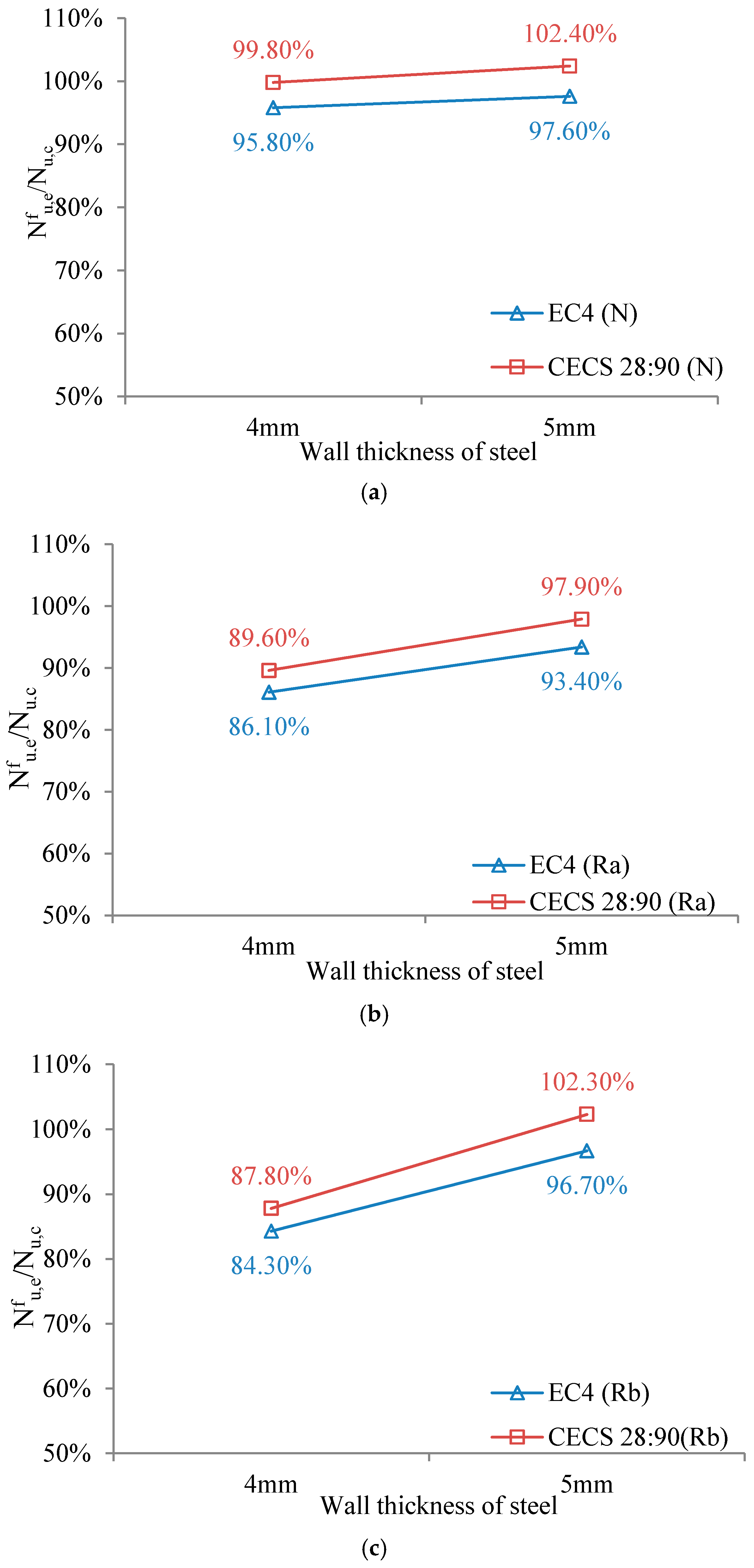

5.3. Analysis of Bearing Capacity before and after Fire

6. Conclusions

- (1)

- The specimen failure occurred finally in the form of buckling. The failure mode of a recycled concrete column specimen which experienced fire was similar to that without fire. The N-Δ curve changed linearly in the early stage and then the axial stiffness of the specimen decreased rapidly after yielding. It is worth noting that the bearing capacity and deformation ability of specimens were weakened after fire; the RACFST columns were damaged seriously, but the overall ductility of specimen was still good.

- (2)

- A temperature platform (the temperature is maintained at 100–150 °C) was observed in the temperature field of the interior of recycled concrete-filled steel tube columns and of ordinary concrete-filled steel tube columns. For concrete-filled steel tube column, the maximum temperature of FC-Rb-T1 was 14.7% lower than that of FC-N-T1, which indicates that the tendency of rise in internal temperature of RACFST column was low.

- (3)

- For the specimens which experienced fire, when the wall thickness of the steel pipe was relatively small, concrete material had a large influence on the bearing capacity. However, with an increase in wall thickness of the steel tube, the influence of concrete material was diminished. For identical concrete material, the ultimate bearing capacity of the steel tube with wall thickness of 5 mm was 11% higher than that of 4 mm thick wall (ordinary concrete N) [16% (when coarse aggregate was 100% replaced by recycled aggregate, Ra) and 21% (when coarse and fine aggregate were 100% replaced by recycled aggregate, Rb)]. The wall thickness of steel pipe was the main factor to determine the bearing capacity of RACFST column.

- (4)

- The axial compressive stiffness of specimens with 100% replacement of coarse and fine aggregates was severely damaged. Meanwhile, its elastic phase was relatively short, indicating that in the case of relatively smaller bearing capacity, the middle region of the steel tube showed large deformation, or even exhibited a drum package. Therefore, considering the safety of structures, it is not recommended to use recycled concrete material with 100% replacement of coarse and fine aggregate.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| CFST | Concrete filled steel tube |

| RAC | Recycled aggregate concrete |

| RCA | Recycled concrete aggregate |

| FAC | Fine aggregate concrete |

| RACFST | Recycled aggregate concrete-filled steel tube |

| RP | Replacement percentage |

| MV | Measured value |

| RV | Relative value |

References

- Xiao, J.Z.; Li, J.B.; Lan, Y. Research on recycled aggregate concrete—A review. Concrete 2003, 168, 17–57. (In Chinese) [Google Scholar]

- Liu, W.; Cao, W.; Zhang, J. Seismic Performance of Composite Shear Walls Constructed Using Recycled Aggregate Concrete and Different Expandable Polystyrene Configurations. Materials 2016, 9, 148. [Google Scholar] [CrossRef]

- Safiuddin, M.; Alengaram, U.J.; Rahman, M.M. Use of recycled concrete aggregate in concrete: A review. J. Civ. Eng. Manag. 2013, 19, 796–810. [Google Scholar] [CrossRef]

- Topçu, I.B. Physical and mechanical properties of concretes produced with waste concrete. Cem. Concr. Res. 1997, 27, 1817–1823. [Google Scholar] [CrossRef]

- Sagoe-Crentsil, K.K.; Brown, T.; Taylor, A.H. Performance of concrete made with commercially produced coarse recycled concrete aggregate. Cem. Concr. Res. 2001, 31, 707–712. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Li, J.B.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Durability performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Behnood, A.; Olek, J.; Glinicki, M.A. Predicting modulus elasticity of recycled aggregate concrete using M5′ model tree algorithm. Constr. Build. Mater. 2015, 94, 137–147. [Google Scholar] [CrossRef]

- Gales, J.; Parker, T.; Cree, D.; Green, M. Fire Performance of Sustainable Recycled Concrete Aggregates: Mechanical Properties at Elevated Temperatures and Current Research Needs. Fire Technol. 2016, 52, 817–845. [Google Scholar] [CrossRef]

- Li, L.; Xiao, J.Z.; Poon, C.S. Dynamic compressive behavior of recycled aggregate concrete. Mater. Struct. 2016, 49, 4451–4462. [Google Scholar] [CrossRef]

- Bendimerad, A.Z.; Roziere, E.; Loukili, A. Plastic shrinkage and cracking risk of recycled aggregates concrete. Constr. Build. Mater. 2016, 121, 733–745. [Google Scholar] [CrossRef]

- Dong, H.; Cao, W.; Bian, J.; Zhang, J. The Fire Resistance Performance of Recycled Aggregate Concrete Columns with Different Concrete Compressive Strengths. Materials 2014, 7, 7843–7860. [Google Scholar] [CrossRef]

- Sato, R.; Maruyama, I.; Sogabe, T.; Sog, M. Flexural behavior of reinforced recycled concrete beams. J. Adv. Concr. Technol. 2007, 5, 43–61. [Google Scholar] [CrossRef]

- Kang, T.H.-K.; Kim, W.; Kwak, Y.-K.; Hong, S.-G. Flexural Testing of Reinforced Concrete Beams with Recycled Concrete Aggregates. ACI Struct. J. 2014, 111, 607–616. [Google Scholar] [CrossRef]

- Cao, W.L.; Zhang, J.; Dong, H.Y. Experimental research on flexural performance of high strength recycled aggregate concrete slabs with steel bar truss. J. Build. Struct. 2014, 35, 31–38. [Google Scholar]

- Cao, W.L.; Liu, Q.; Zhang, J.W. Seismic Experiment and analysis of low-rise recycled concrete shear wall. J. Beijing Univ. Technol. 2011, 37, 409–417. (In Chinese) [Google Scholar]

- Cao, W.L.; Xu, T.G.; Liu, Q. Experimental study on seismic performance of high-rise recycled aggregate concrete shear wall. World Earthq. Eng. 2009, 25, 18–23. (In Chinese) [Google Scholar]

- Cao, W.L.; Cheng, J.; Zhang, Y.B. Experiment of seismic behavior of low-rise recycled aggregate concrete shear wall with insulation modules and single layer of reinforcement. J. Build. Struct. 2015, 36, 51–58. [Google Scholar]

- Zhang, J.W.; Cao, W.L.; Meng, S.B. Shaking table experimental study of recycled concrete frame-shear wall structures. Earthq. Eng. Eng. Vib. 2014, 13, 257–267. [Google Scholar] [CrossRef]

- Zhang, J.W.; Dong, H.Y.; Cao, W.L. Shaking Table Tests of Low-Rise Shear Walls Made of Recycled Aggregate Concrete. Struct. Eng. Int. 2016, 26, 62–73. [Google Scholar] [CrossRef]

- Konno, K.; Sato, Y.; Kakuta, Y. Property of recycled concrete column encased by steel tube subjected to axial compression. Trans. Jpn. Concr. Inst. 1997, 19, 231–238. [Google Scholar]

- Konno, K.; Sato, Y.; Kakuta, Y. Mechanical property of recycled concrete under lateral confinement. Trans. Jpn. Concr. Inst. 1998, 20, 287–292. [Google Scholar]

- Johansson, M.; Gylltoft, K. Mechanical Behavior of Circular Steel-Concrete Composite Stub Columns. J. Struct. Eng. 2002, 128, 1073–1081. [Google Scholar] [CrossRef]

- Hu, Y.M.; Yu, T.; Teng, J.G. FRP-Confined Circular Concrete-Filled Thin Steel Tubes under Axial Compression. J. Compos. Constr. 2011, 15, 850–860. [Google Scholar] [CrossRef]

- Karantzikis, M.; Papanicolaou, C.G.; Antonopoulos, C.P. Experimental investigation of nonconventional confinement for concrete using FRP. J. Compos. Constr. 2005, 9, 480–487. [Google Scholar] [CrossRef]

- Rousakis, T. Hybrid Confinement of Concrete by FRP Sheets and Fiber Ropes Under Cyclic Axial Compressive Loading. J. Compos. Constr. 2013, 17, 732–743. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Papanicolaou, C.G.; Zissimopoulos, P. Concrete confinement with textile-reinforced mortar jackets. ACI Struct. J. 2006, 103, 28–37. [Google Scholar]

- Choi, E.; Jeon, J.S.; Cho, B.S. External jacket of FRP wire for confining concrete and its advantages. Eng. Struct. 2013, 56, 555–566. [Google Scholar] [CrossRef]

- Rousakis, T. Elastic Fiber Ropes of Ultrahigh-Extension Capacity in Strengthening of Concrete through Confinement. J. Mater. Civ. Eng. 2014, 26, 34–44. [Google Scholar] [CrossRef]

- Anggawidjaja, D.; Ueda, T.; Dai, J. Deformation capacity of RC piers by new fiber-reinforced polymer with large fracture strain. Cem. Concr. Compos. 2006, 28, 914–927. [Google Scholar] [CrossRef]

- Rousakis, T.C.; Kouravelou, K.B.; Karachalios, T.K. Effects of Carbon Nanotube Enrichment of Epoxy Resins on Hybrid FRP-FR Confinement of Concrete. Compos. B Eng. 2014, 57, 210–218. [Google Scholar] [CrossRef]

- Dai, J.G.; Bai, Y.L.; Teng, J.G. Behavior and Modeling of Concrete Confined with FRP Composites of Large Deformability. J. Compos. Constr. 2011, 15, 963–973. [Google Scholar] [CrossRef]

- Yang, Y.F.; Han, L.H. Experimental behaviour of recycled aggregate concrete filled steel tubular columns. J. Constr. Steel Res. 2006, 62, 1310–1324. [Google Scholar] [CrossRef]

- Mohanraj, E.K.; Kandasamy, S.; Malathy, R. Behaviour of steel tubular stub and slender columns filled with concrete using recycled aggregates. J. S. Afr. Inst. Civ. Eng. 2011, 53, 31–38. [Google Scholar]

- Chen, Z.P.; Zhang, X.G.; Xue, J.Y. Analysis on aseismic performance and influence factors of recycled concrete filled circular steel-tube columns. Eng. Mech. 2016, 33, 129–136. [Google Scholar]

- Yang, Y.F.; Hou, R. Experimental study and theoretical analysis on mechanical behavior recycled aggregate concrete filled steel tubular short column after high temperature. J. Disaster Prev. Mitig. Eng. 2012, 32, 71–75. (In Chinese) [Google Scholar]

- Chen, Z.P.; Jing, C.G.; Xue, J.Y. Study of mechanical behavior recycled aggregate concrete filled circular steel tube columns under eccentric loading after high temperature. Ind. Constr. 2014, 44, 19–25. (In Chinese) [Google Scholar]

- Luo, C.N.; Zha, X.X. Research on fire resistance of recycled concrete filled steel tubular columns. J. Build. Struct. 2015, 36, 35–41. [Google Scholar]

- China Standards Publication. Recycled Coarse Aggregate for Concrete; GB/T25177-2010; Standard Press of China: Beijing, China, 2011. [Google Scholar]

- China Standards Publication. Code for Construction of Concrete Structures; GB 50010-2010; Standard Press of China: Beijing, China, 2011. [Google Scholar]

- China Standards Publication. Metallic Materials-Tensile Testing at Ambient Temperature; GB/T 228-2002; Standard Press of China: Beijing, China, 2003. [Google Scholar]

- Eurocodes. Design of Composite Steel and Concrete Structures, Part 1.1: General Rules and Rules for Buildings; Eurocode 4; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- Trade Standards of China. Design Regulation for the Fire Protection of Steel Structures; Chinese Planning Press: Beijing, China, 1992. [Google Scholar]

| Specimen | D/mm | t/mm | L/mm | L/D | RPRCA/% | RPRFA/% |

|---|---|---|---|---|---|---|

| C-H-T1 | 100 | 4 | 500 | 5 | - | - |

| C-H-T2 | 100 | 5 | 500 | 5 | - | - |

| C-N-T1 | 100 | 4 | 500 | 5 | 0 | 0 |

| C-N-T2 | 100 | 5 | 500 | 5 | 0 | 0 |

| C-Ra-T1 | 100 | 4 | 500 | 5 | 100 | 0 |

| C-Rb-T1 | 100 | 4 | 500 | 5 | 100 | 100 |

| Specimen | D/mm | t/mm | L/mm | L/D | RPRCA/% | RPRFA/% |

|---|---|---|---|---|---|---|

| FC-N-T1 | 100 | 4 | 500 | 5 | 0 | 0 |

| FC-N-T2 | 100 | 5 | 500 | 5 | 0 | 0 |

| FC-Ra-T1 | 100 | 4 | 500 | 5 | 100 | 0 |

| FC-Ra-T2 | 100 | 5 | 500 | 5 | 100 | 0 |

| FC-Rb-T1 | 100 | 4 | 500 | 5 | 100 | 100 |

| FC-Rb-T2 | 100 | 5 | 500 | 5 | 100 | 100 |

| Type of Concrete | Concrete Design Strength (MPa) | Cube Compressive Strength (MPa) | Elastic Modulus (MPa) |

|---|---|---|---|

| N | C40/40.00 | 40.10 | 32,958 |

| Ra | RC40/40.00 | 41.15 | 31,553 |

| Rb | RC40/40.00 | 38.81 | 29,865 |

| Type of Concrete | Cube Compressive Strength (MPa) |

|---|---|

| N-fire | 17.51 |

| Ra-fire | 16.32 |

| Rb-fire | 15.68 |

| Steel Coupons (mm) | fy (MPa) | fu (MPa) | δ (%) | fy-Fire (MPa) | fu-Fire (MPa) | δ-Fire (%) |

|---|---|---|---|---|---|---|

| 4 × 10 × 80 | 326 | 469 | 16.6 | 287 | 444 | 13.3 |

| 5 × 10 × 80 | 347 | 513 | 19.3 | 325 | 498 | 15.9 |

| Specimen | Fy: kN | Fu: kN | Δy | Δu | ||||

|---|---|---|---|---|---|---|---|---|

| MV | RV | MV | RV | MV | RV | MV | RV | |

| C-H-T1 | 455.53 | 1.000 | 553.48 | 1.000 | 5.53 | 1.000 | 16.44 | 1.000 |

| C-N-T1 | 818.93 | 1.798 | 935.89 | 1.691 | 3.37 | 0.609 | 23.30 | 1.417 |

| C-Ra-T1 | 832.09 | 1.827 | 936.91 | 1.693 | 3.44 | 0.622 | 20.89 | 1.271 |

| C-Rb-T1 | 820.41 | 1.801 | 922.61 | 1.667 | 4.05 | 0.732 | 24.16 | 1.470 |

| C-H-T2 | 525.75 | 1.154 | 731.98 | 1.322 | 4.99 | 0.902 | 23.93 | 1.445 |

| C-N-T2 | 859.07 | 1.886 | 1018.3 | 1.840 | 3.81 | 0.689 | 17.90 | 1.089 |

| No. | Test Results | Calculation Results-EC4 [44] | Calculation Results-CECS [45] | ||||

|---|---|---|---|---|---|---|---|

| /kN | /kN | / | /kN | / | /kN | / | |

| C-N-T1 | 936.9 | 865.4 | 0.923 | 903.2 | 0.958 | 867.5 | 0.998 |

| C-Ra-T1 | 935.6 | 777.3 | 0.831 | 903.2 | 0.861 | 867.5 | 0.896 |

| C-Rb-T1 | 922.3 | 761.6 | 0.826 | 903.2 | 0.843 | 867.5 | 0.878 |

| C-N-T2 | 1020.1 | 966.1 | 0.947 | 989.6 | 0.976 | 943.8 | 1.024 |

| C-Ra-T2 | - | 924.2 | - | 989.6 | 0.934 | 943.8 | 0.979 |

| C-Rb-T2 | - | 965.6 | - | 989.6 | 0.967 | 943.8 | 1.023 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Cao, W.; Zhang, J.; Wang, R.; Ren, L. Mechanical Behavior of Recycled Aggregate Concrete-Filled Steel Tubular Columns before and after Fire. Materials 2017, 10, 274. https://doi.org/10.3390/ma10030274

Liu W, Cao W, Zhang J, Wang R, Ren L. Mechanical Behavior of Recycled Aggregate Concrete-Filled Steel Tubular Columns before and after Fire. Materials. 2017; 10(3):274. https://doi.org/10.3390/ma10030274

Chicago/Turabian StyleLiu, Wenchao, Wanlin Cao, Jianwei Zhang, Ruwei Wang, and Lele Ren. 2017. "Mechanical Behavior of Recycled Aggregate Concrete-Filled Steel Tubular Columns before and after Fire" Materials 10, no. 3: 274. https://doi.org/10.3390/ma10030274