Analysis of the Relationships between Waste Cooking Oil Qualities and Rejuvenated Asphalt Properties

Abstract

:1. Introduction

2. Experiment Materials

2.1. Asphalt

2.2. Waste Cooking Oil (WCO)

3. Research Methods

3.1. Preparation of Aged Asphalt Binder

3.2. Preparation of the Rejuvenated Asphalt Binder

3.3. Basic Properties Tests

3.4. Rheological Properties Tests

3.5. Chemical Properties Tests

3.6. Grey Correlation Analysis

- {X0(0)(r)} r = 1, 2, 3, ..., N0

- {X1(0)(r)}, r = 1, 2, 3, ..., N1

- {X2(0)(r)}, r = 1, 2, 3, ..., N2

- ... ...

- {Xk(0)(r)}, r = 1, 2, 3, ..., Nk

4. Results and Discussion

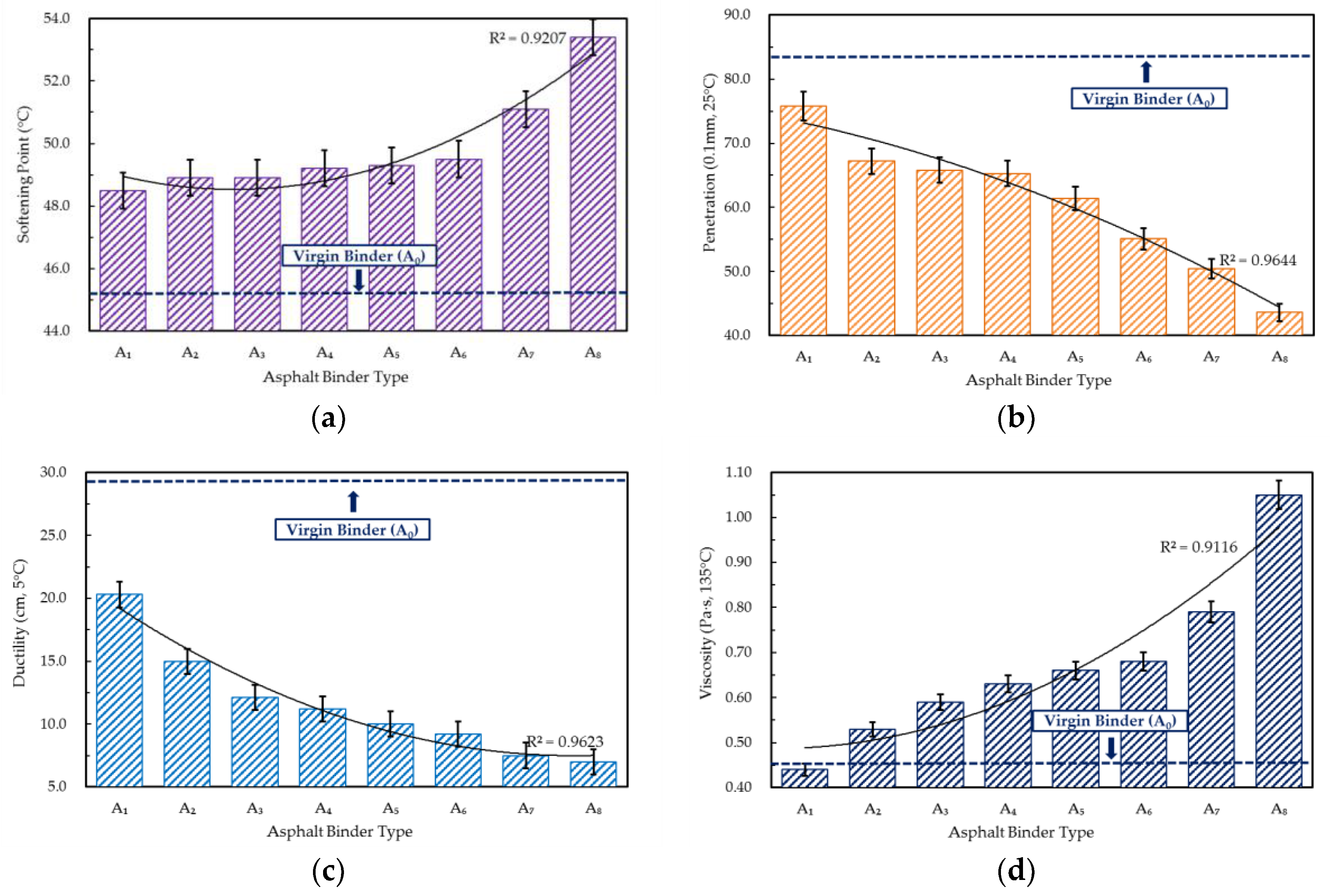

4.1. Basic Properties

4.2. Rheological Properties

4.2.1. Rotational Viscosity

4.2.2. Rutting Parameter

4.2.3. Critical High Temperature

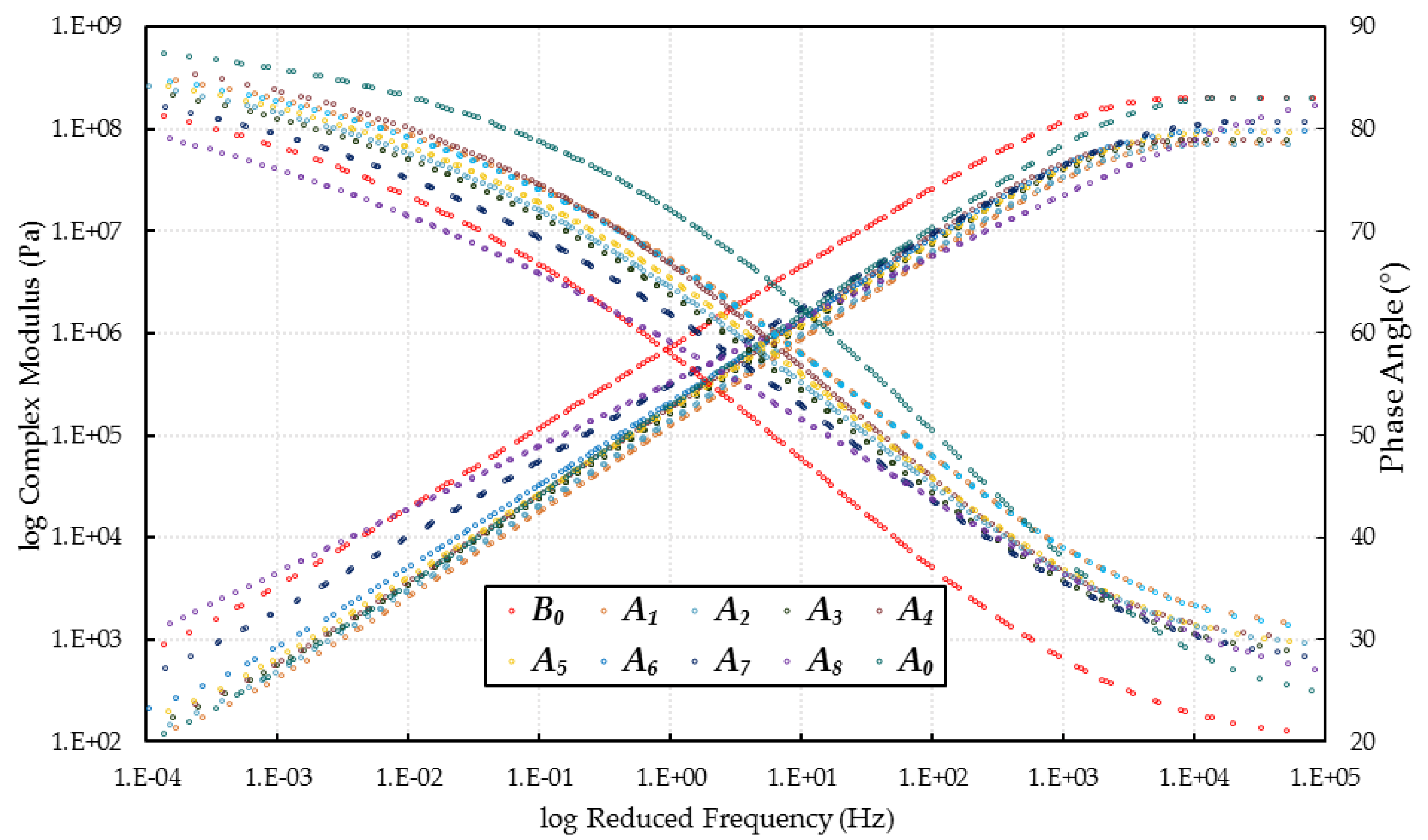

4.2.4. Complex Modulus and Phase Angle Master Curves

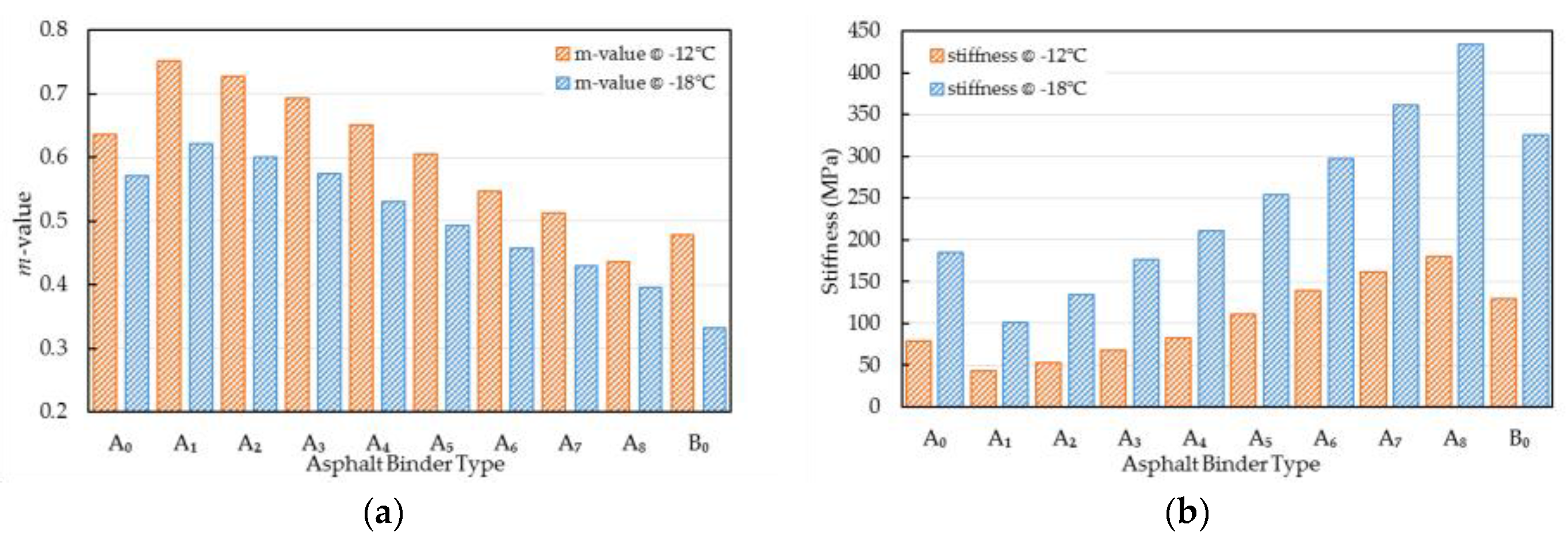

4.2.5. Stiffness and m-Value

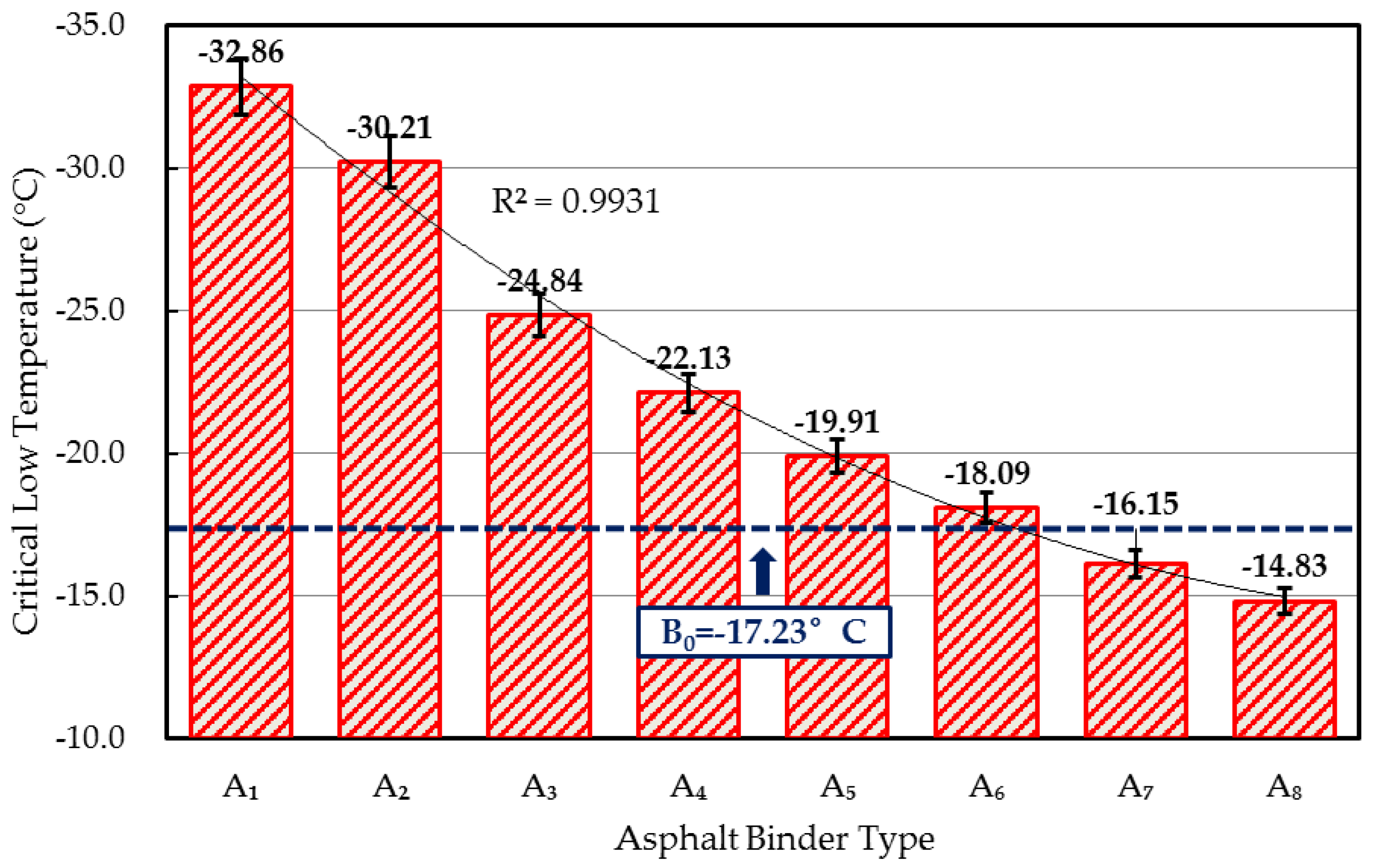

4.2.6. Critical Low Temperature

4.3. Chemical Properties

4.3.1. SARA Fractions

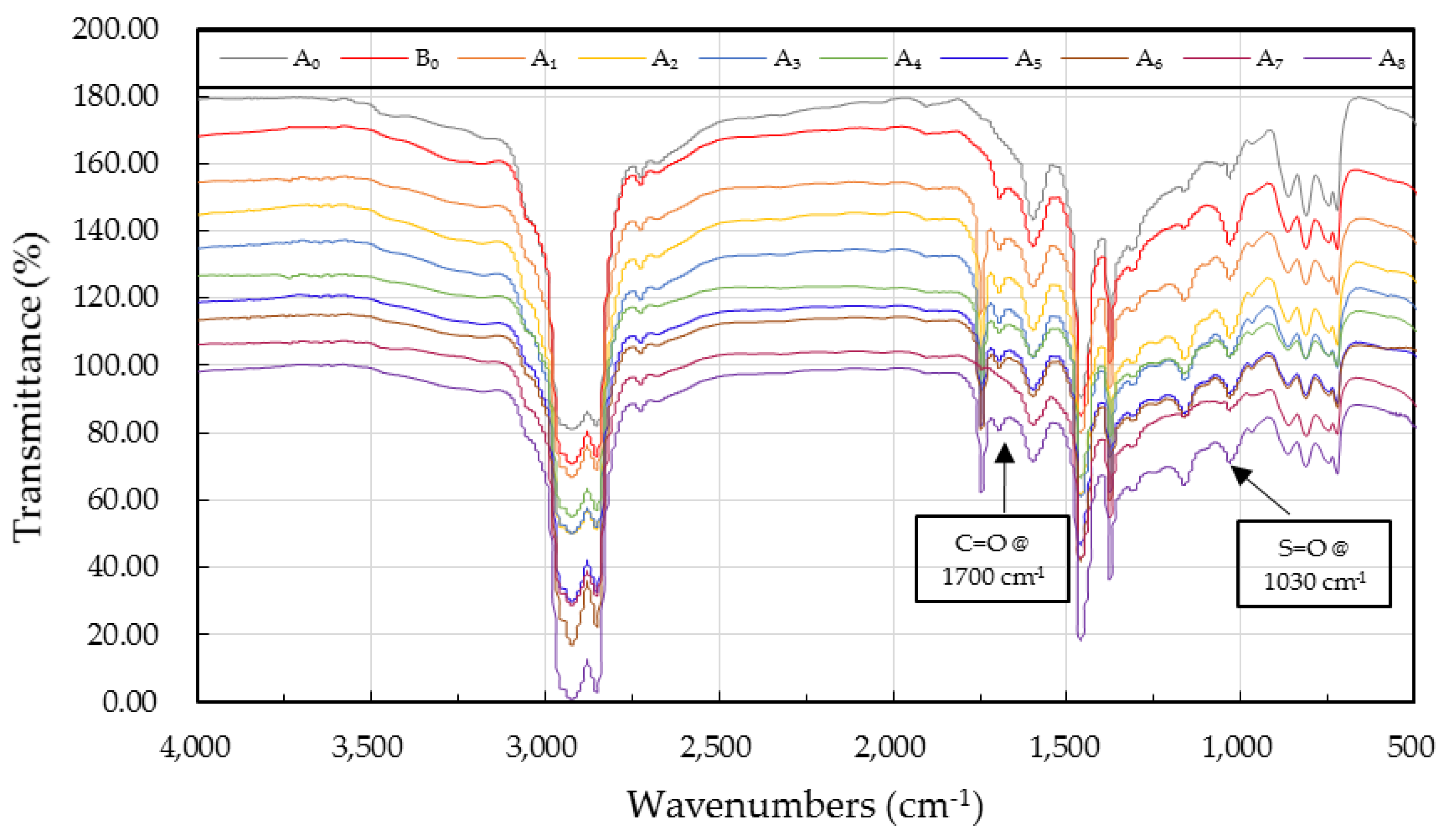

4.3.2. FTIR Spectra and Functional Group Index

4.4. Grey Correlation Analysis

5. Conclusions and Future Work

- WCO qualities influence the properties of the rejuvenated asphalt significantly, and the WCO with higher qualities (lower acid value and viscosity in this research) achieves superior rejuvenation effects of the aged asphalt.

- Grey correlation analyses indicate that both WCO acid value and WCO viscosity have a close relationship with the properties of the rejuvenated asphalt, especially for the aging degree and thermal cracking resistance. The WCO acid value is a better criterion than WCO viscosity to predict the performance of the WCO-rejuvenated asphalt.

- The rejuvenation thresholds of WCOs are varied with the property categories of the rejuvenated asphalts. For the high-temperature rheological properties, WCOs with acid values of 0.4–3.2 mg KOH/g or viscosities of 140–1140 mm2/s are preferable. For the low-temperature rheological properties and colloidal system stability, WCOs with acid values lower than 0.7 mg KOH/g or viscosities lower than 420 mm2/s are recommended. As for the chemical constituent recovery of an aged asphalt, WCO with acid values lower than 1.2 mg KOH/g or with viscosities lower than 540 mm2/s can achieve satisfactory results.

- Comprehensive results show that WCOs with acid and viscosity values in the ranges of 0.4–0.7 mg KOH/g and 140–540 mm2/s, respectively, can meet all of the requirements for asphalt rejuvenation based on the materials used in this research.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, L.; Tan, Y.Q.; Bahia, H. Relationship between glass transition temperature and low temperature properties of oil modified binders. Constr. Build. Mater. 2016, 104, 92–98. [Google Scholar]

- Chen, Z.; Wu, S.; Xiao, Y.; Zeng, W.; Yi, M.; Wan, J. Effect of hydration and silicone resin on basic oxygen furnace slag and its asphalt mixture. J. Clean. Prod. 2016, 112, 392–400. [Google Scholar] [CrossRef]

- Widyatmoko, I. Mechanistic-empirical mixture design for hot mix asphalt pavement recycling. Constr. Build. Mater. 2008, 22, 77–87. [Google Scholar] [CrossRef]

- Celauro, C.; Bernardo, C.; Gabriele, B. Production of innovative, recycled and high-performance asphalt for road pavements. Resour. Conserv. Recycl. 2010, 54, 337–347. [Google Scholar] [CrossRef]

- Mills-Beale, J.; You, Z. The mechanical properties of asphalt mixtures with recycled concrete aggregates. Constr. Build. Mater. 2010, 24, 230–235. [Google Scholar] [CrossRef]

- Taha, R.; Alharthy, A.; Alshamsi, K.; Alzubeidi, M. Cement stabilization of reclaimed asphalt pavement aggregate for road bases and subbases. J. Mater. Civ. Eng. 2002, 14, 239–245. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% recycled hot mix asphalt: A review and analysis. Resour. Conserv. Recycl. 2014, 92, 230–245. [Google Scholar] [CrossRef]

- You, Z.; Millsbeale, J.; Fini, E.; Shu, W.G.; Colbert, B. Evaluation of low-temperature binder properties of warm-mix asphalt, extracted and recovered rap and ras, and bioasphalt. J. Mater. Civ. Eng. 2011, 23, 1569–1574. [Google Scholar] [CrossRef]

- Mogawer, W.; Bennert, T.; Daniel, J.S.; Bonaquist, R.; Austerman, A.; Booshehrian, A. Performance characteristics of plant produced high rap mixtures. Road Mater. Pavement Des. 2012, 13, 183–208. [Google Scholar] [CrossRef]

- Mensching, D.J.; Daniel, J.S.; Bennert, T.; Jr, M.S.M.; Elwardany, M.D.; Mogawer, W.; Hajj, E.Y.; Alavi, M.Z. Low temperature properties of plant-produced rap mixtures in the northeast. Road Mater. Pavement Des. 2014, 15, 1–27. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.; Tang, B. Effects of rejuvenator on performance-based properties of rejuvenated asphalt binder and mixtures. Constr. Build. Mater. 2007, 21, 958–964. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. Determining optimum rejuvenator dose for asphalt recycling based on superpave performance grade specifications. Constr. Build. Mater. 2014, 69, 159–166. [Google Scholar] [CrossRef]

- Asli, H.; Ahmadinia, E.; Zargar, M.; Karim, M.R. Investigation on physical properties of waste cooking oil –rejuvenated bitumen binder. Constr. Build. Mater. 2012, 37, 398–405. [Google Scholar] [CrossRef]

- Zargar, M.; Ahmadinia, E.; Asli, H.; Karim, M.R. Investigation of the possibility of using waste cooking oil as a rejuvenating agent for aged bitumen. J. Hazard. Mater. 2012, 233–234, 254–258. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Leng, B.; Wu, S.; Sang, Y. Physical, chemical and rheological properties of waste edible vegetable oil rejuvenated asphalt binders. Constr. Build. Mater. 2014, 66, 286–298. [Google Scholar] [CrossRef]

- Chen, M.; Xiao, F.; Putman, B.; Leng, B.; Wu, S. High temperature properties of rejuvenating recovered binder with rejuvenator, waste cooking and cotton seed oils. Constr. Build. Mater. 2014, 59, 10–16. [Google Scholar] [CrossRef]

- Su, J.F.; Qiu, J.; Schlangen, E.; Wang, Y.Y. Investigation the possibility of a new approach of using microcapsules containing waste cooking oil: In situ rejuvenation for aged bitumen. Constr. Build. Mater. 2015, 74, 83–92. [Google Scholar] [CrossRef]

- Yu, X.; Zaumanis, M.; Santos, S.D.; Poulikakos, L.D. Rheological, microscopic, and chemical characterization of the rejuvenating effect on asphalt binders. Fuel 2014, 135, 162–171. [Google Scholar] [CrossRef]

- Wan, N.A.W.A.; Jaya, R.P.; Hainin, M.R.; Bujang, M.; Ngadi, N. Chemical modification of waste cooking oil to improve the physical and rheological properties of asphalt binder. Constr. Build. Mater. 2016, 126, 218–226. [Google Scholar]

- Deng, J.L. Control problems of grey systems. Syst. Control Lett. 1982, 1, 288–294. [Google Scholar]

- Deng, J.L. Introduction to grey system theory. J. Grey Syst. 1989, 1, 1–24. [Google Scholar]

- Wang, Z.; Wang, Q.; Ai, T. Comparative study on effects of binders and curing ages on properties of cement emulsified asphalt mixture using gray correlation entropy analysis. Constr. Build. Mater. 2014, 54, 615–622. [Google Scholar] [CrossRef]

- Shen, D.H.; Du, J.C. Application of gray relational analysis to evaluate hma with reclaimed building materials. J. Mater. Civ. Eng. 2005, 17, 400–406. [Google Scholar] [CrossRef]

- Romera, R.; Santamaría, A.; Peña, J.J.; Muñoz, M.E.; Barral, M.; García, E.; Jañez, V. Rheological aspects of the rejuvenation of aged bitumen. Rheol. Acta 2006, 45, 474–478. [Google Scholar] [CrossRef]

- Williams, M.L.; Landel, R.F.; Ferry, J.D. The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. J. Am. Chem. Soc. 1955, 77, 3701–3707. [Google Scholar] [CrossRef]

- Yusoff, N.I.M.; Shaw, M.T.; Airey, G.D. Modelling the linear viscoelastic rheological properties of bituminous binders. Constr. Build. Mater. 2012, 25, 2171–2189. [Google Scholar] [CrossRef]

- Siddiqui, M.N.; Ali, M.F. Studies on the aging behavior of the arabian asphalts. Fuel 1999, 78, 1005–1015. [Google Scholar] [CrossRef]

- Petersen, J.C. A Review of the Fundamentals of Asphalt Oxidation: Chemical, Physicochemical, Physical Property and Durability Relationships; Transportation Research Board: Washington, DC, USA, 2009. [Google Scholar] [CrossRef]

- Herrington, P.R.; Ball, G.F.A. Temperature dependence of asphalt oxidation mechanism. Fuel 1996, 75, 1129–1131. [Google Scholar] [CrossRef]

- Zeng, W.; Wu, S.; Wen, J.; Chen, Z. The temperature effects in aging index of asphalt during UV aging process. Constr. Build. Mater. 2015, 93, 1125–1131. [Google Scholar] [CrossRef]

| Asphalt Categories | Softening Point (°C) | Penetration (0.1 mm, 25 °C) | Ductility (cm, 15 °C) | Viscosity (Pa·s, 135 °C) |

|---|---|---|---|---|

| AH-90 (A0) | 45.1 | 83.7 | >100 | 0.45 |

| AH-90 RTFOT | 49.9 | 53.4 | 129 | 0.57 |

| AH-90 RTFOT+ PAV (B0) | 58.5 | 32.7 | 5 | 0.99 |

| Sample | W0 | W1 | W2 | W3 | W4 | W5 | W6 | W7 | W8 |

|---|---|---|---|---|---|---|---|---|---|

| Heating time (h) | 0 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 |

| Acid value (mg KOH/g) | 0.183 | 0.381 | 0.455 | 0.553 | 0.727 | 1.214 | 1.333 | 2.318 | 3.231 |

| Viscosity (mm2/s) | 55.31 | 144.27 | 208.56 | 300.22 | 420.20 | 540.95 | 693.05 | 866.10 | 1143.46 |

| Density (kg/L) | 0.904 | 0.908 | 0.911 | 0.916 | 0.921 | 0.928 | 0.935 | 0.941 | 0.955 |

| Sample | Saturates | Aromatics | Resins | Asphaltenes | IC |

|---|---|---|---|---|---|

| A0 | 13.23 | 41.84 | 34.80 | 10.13 | 0.3048 |

| B0 | 9.58 | 33.44 | 37.40 | 19.58 | 0.4116 |

| A1 | 13.71 | 45.23 | 32.03 | 9.03 | 0.2943 |

| A2 | 13.49 | 43.21 | 33.72 | 9.58 | 0.2999 |

| A3 | 13.03 | 42.89 | 33.24 | 10.84 | 0.3135 |

| A4 | 12.81 | 41.41 | 34.77 | 11.01 | 0.3127 |

| A5 | 12.44 | 40.02 | 34.20 | 13.34 | 0.3473 |

| A6 | 11.97 | 39.08 | 34.41 | 14.54 | 0.3607 |

| A7 | 10.06 | 38.68 | 36.23 | 15.03 | 0.3349 |

| A8 | 9.84 | 37.46 | 36.88 | 15.82 | 0.3452 |

| Asphalt | A0 | B0 | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 |

|---|---|---|---|---|---|---|---|---|---|---|

| Carbonyl index, IC=O | 0.000 | 0.031 | 0.008 | 0.013 | 0.018 | 0.023 | 0.030 | 0.035 | 0.040 | 0.053 |

| Sulfoxide index, IS=O | 0.079 | 0.118 | 0.037 | 0.051 | 0.062 | 0.070 | 0.074 | 0.081 | 0.089 | 0.074 |

| Properties Categories | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | Factor Analysis | |

|---|---|---|---|---|---|---|---|---|---|---|

| Acid Value (mg KOH/g) | Viscosity (60 °C, mm2/s) | |||||||||

| Penetration (25 °C, 0.1 mm) | 75.8 | 67.2 | 65.8 | 65.3 | 61.4 | 55.1 | 50.4 | 43.6 | 0.6513 | 0.5868 |

| Softening point (°C) | 48.5 | 48.9 | 48.9 | 49.2 | 49.3 | 49.5 | 51.1 | 53.4 | 0.6528 | 0.5883 |

| Ductility (15 °C, cm) | 20.3 | 15.0 | 12.1 | 11.2 | 10.0 | 9.2 | 7.5 | 7.0 | 0.6415 | 0.6522 |

| Viscosity (135 °C, Pa·s) | 0.44 | 0.53 | 0.59 | 0.63 | 0.66 | 0.68 | 0.79 | 1.05 | 0.6429 | 0.5465 |

| Critical high temperature (°C) | 72.89 | 73.46 | 74.60 | 75.29 | 75.61 | 75.87 | 77.08 | 80.66 | 0.6564 | 0.5808 |

| Carbonyl index | 0.008 | 0.013 | 0.018 | 0.023 | 0.030 | 0.035 | 0.040 | 0.053 | 0.6210 | 0.6424 |

| Sulfoxide index | 0.037 | 0.051 | 0.062 | 0.070 | 0.074 | 0.081 | 0.089 | 0.074 | 0.7777 | 0.7439 |

| Stiffness @−12 °C (MPa) | 43.1 | 53.2 | 67.4 | 82.3 | 110.5 | 138.8 | 161.2 | 179.6 | 0.8088 | 0.7245 |

| Stiffness @−18 °C (MPa) | 101.0 | 134.5 | 176.1 | 211.2 | 254.2 | 297.5 | 361.8 | 434.6 | 0.7532 | 0.6929 |

| m-value @−12 °C | 0.752 | 0.728 | 0.694 | 0.651 | 0.606 | 0.547 | 0.512 | 0.436 | 0.6314 | 0.5887 |

| m-value @−18 °C | 0.622 | 0.601 | 0.574 | 0.530 | 0.494 | 0.458 | 0.430 | 0.396 | 0.6173 | 0.5992 |

| Critical low temperature (°C) | −32.86 | −30.21 | −24.84 | −22.13 | −19.91 | −18.09 | −16.15 | −14.83 | 0.6300 | 0.6363 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Chen, M.; Wu, S.; Liu, J.; Amirkhanian, S. Analysis of the Relationships between Waste Cooking Oil Qualities and Rejuvenated Asphalt Properties. Materials 2017, 10, 508. https://doi.org/10.3390/ma10050508

Zhang D, Chen M, Wu S, Liu J, Amirkhanian S. Analysis of the Relationships between Waste Cooking Oil Qualities and Rejuvenated Asphalt Properties. Materials. 2017; 10(5):508. https://doi.org/10.3390/ma10050508

Chicago/Turabian StyleZhang, Dong, Meizhu Chen, Shaopeng Wu, Jingxiang Liu, and Serji Amirkhanian. 2017. "Analysis of the Relationships between Waste Cooking Oil Qualities and Rejuvenated Asphalt Properties" Materials 10, no. 5: 508. https://doi.org/10.3390/ma10050508