Composite Materials Based on Hemp and Flax for Low-Energy Buildings

Abstract

:1. Introduction

2. Materials and Methods

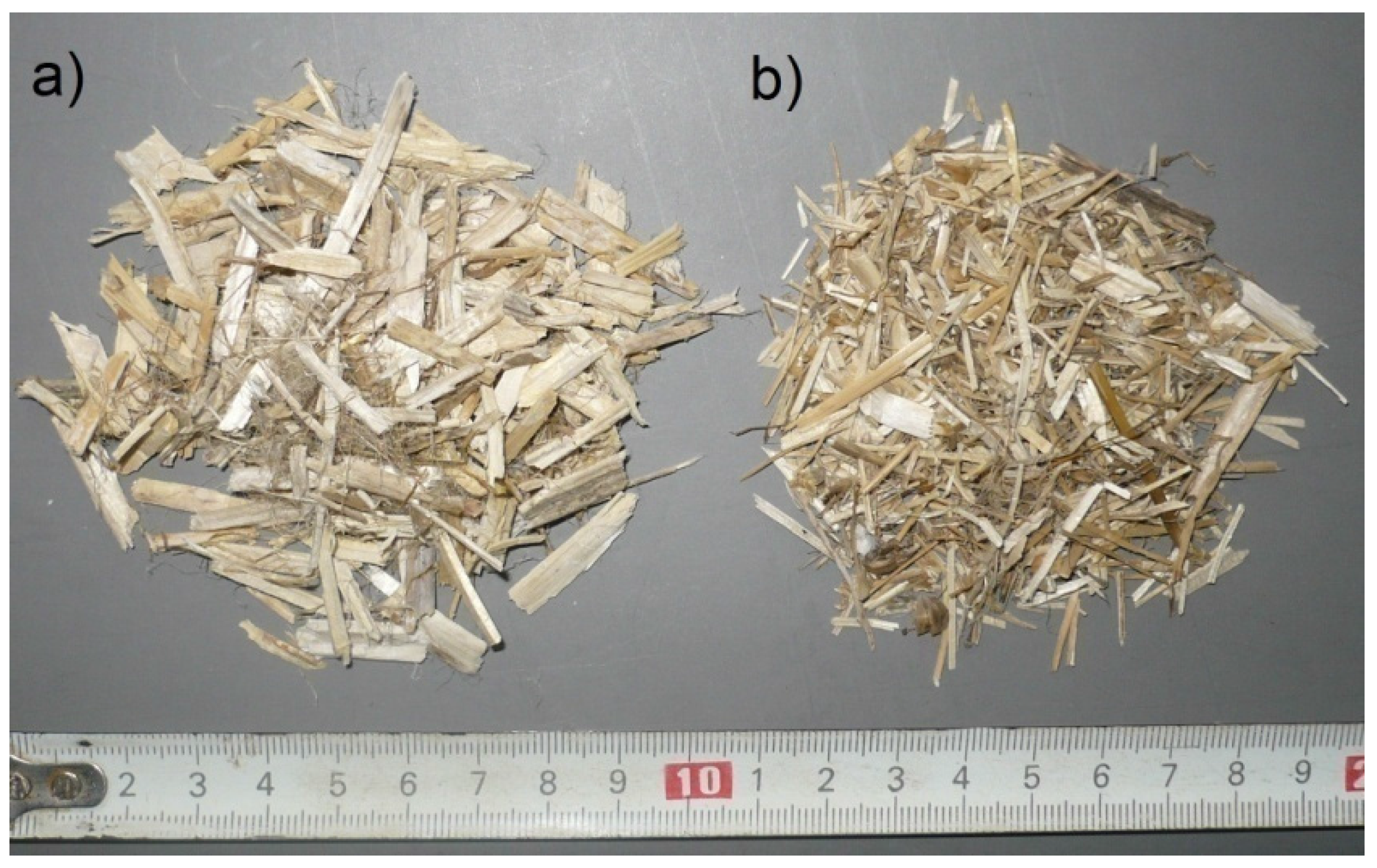

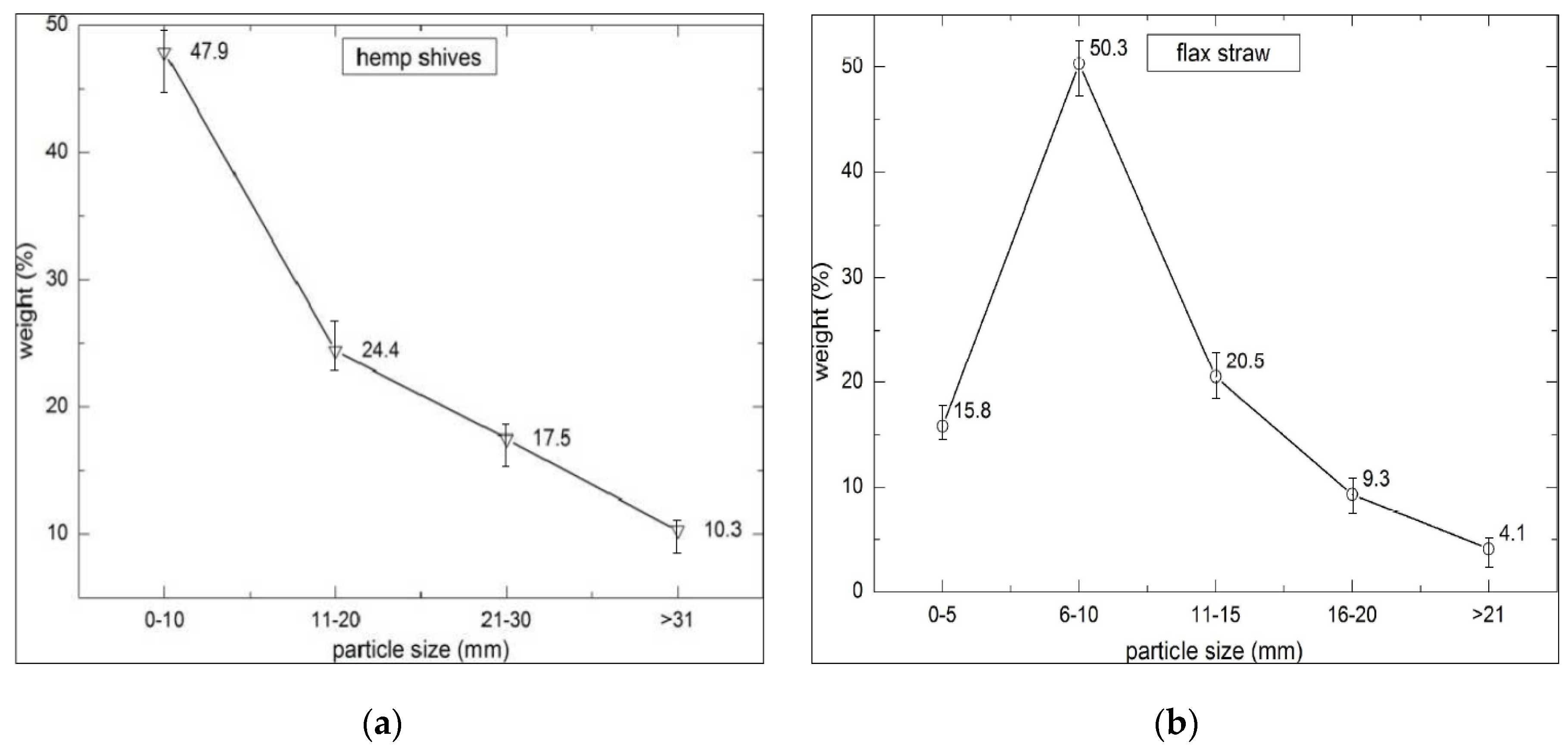

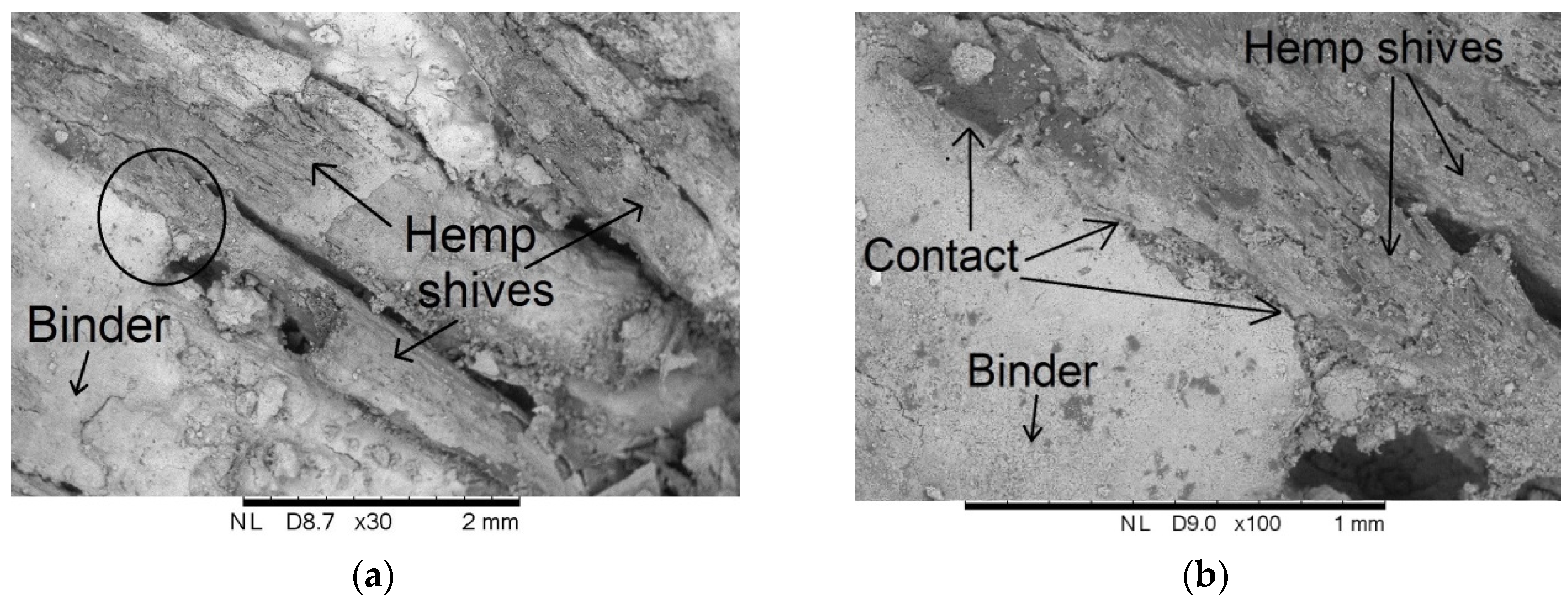

2.1 Manufacturing of the Composite Materials

2.2. Preparation of Mixture and Specimen

2.3. Methods

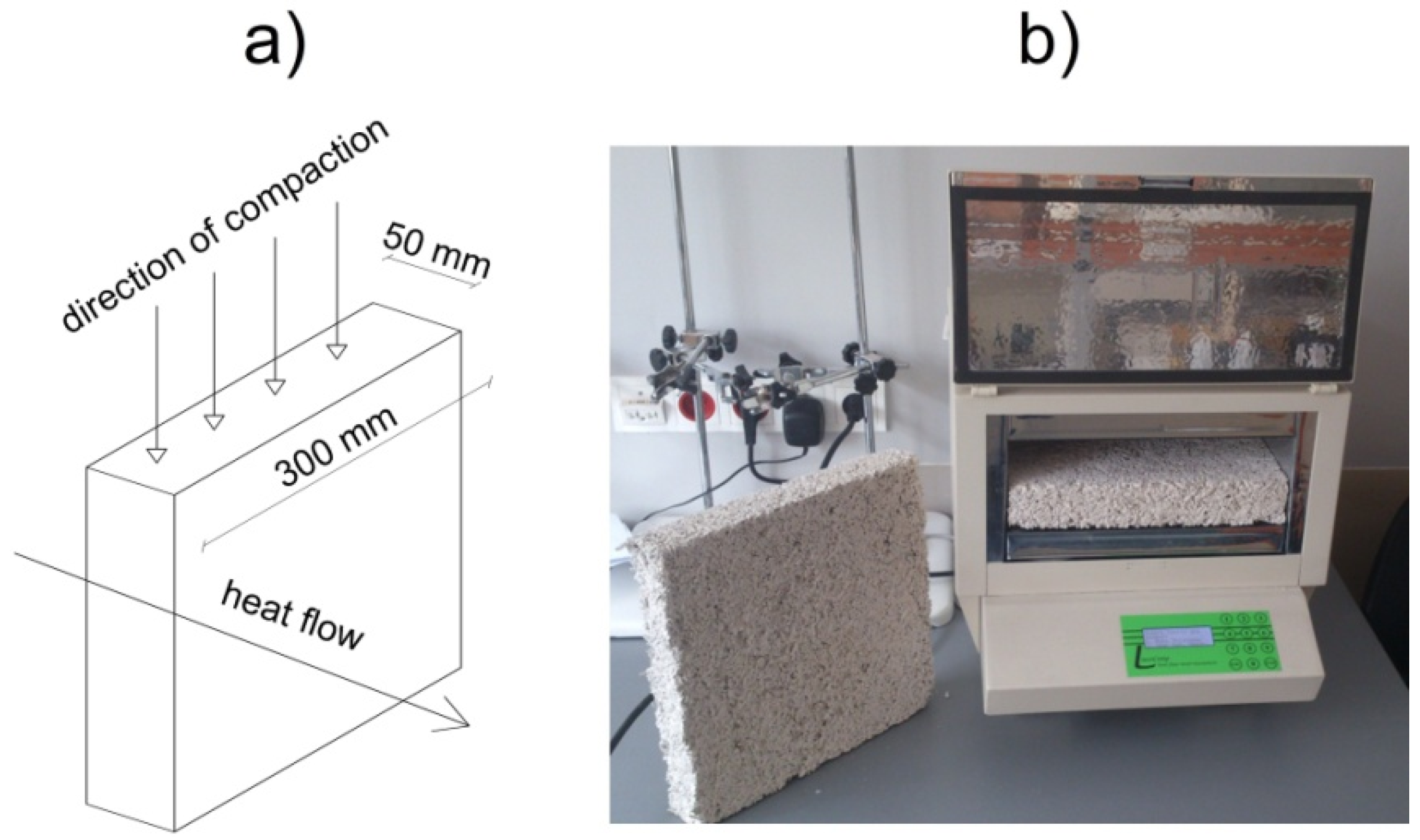

2.3.1. Determination of Physical and Mechanical Properties of the Composites

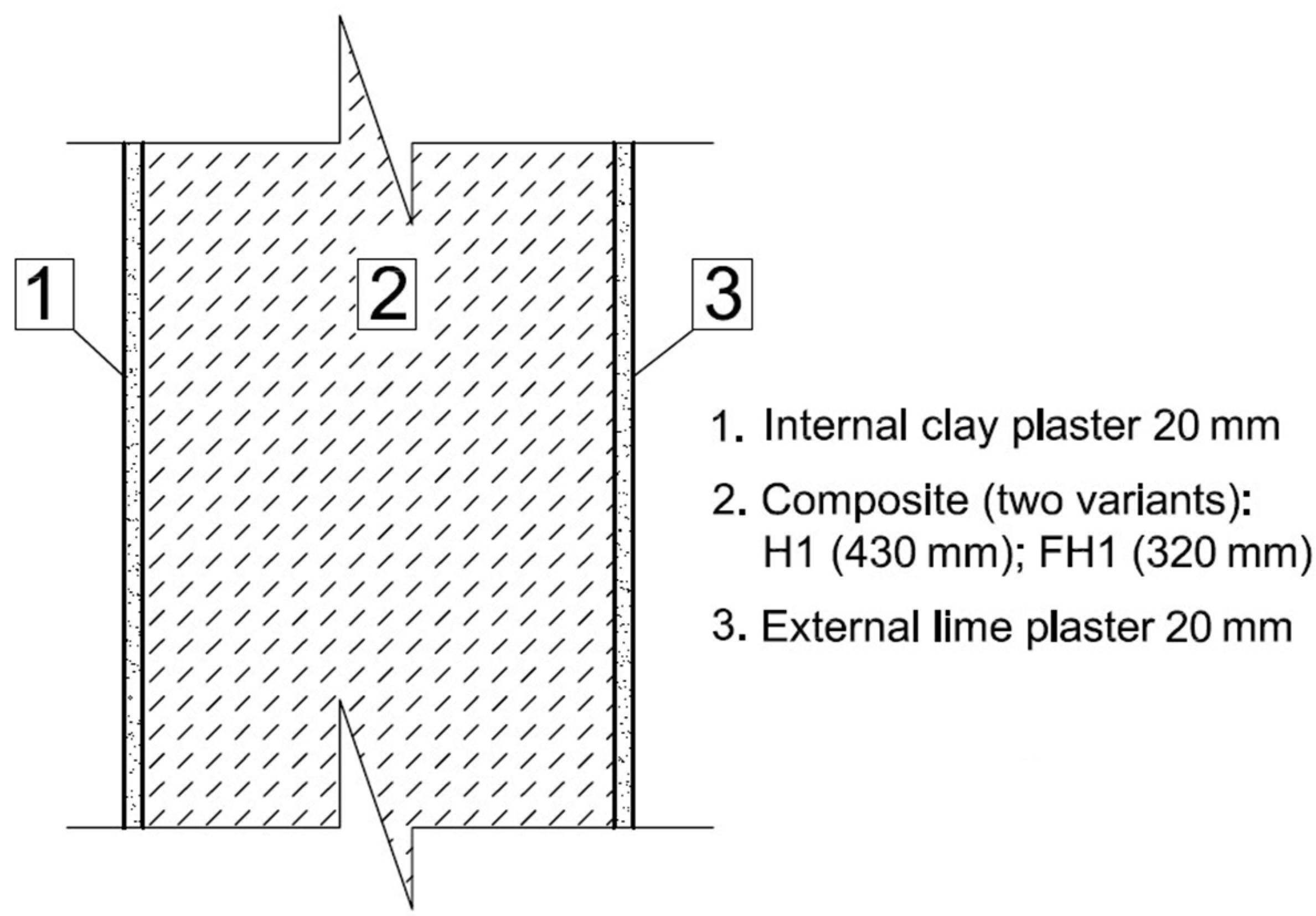

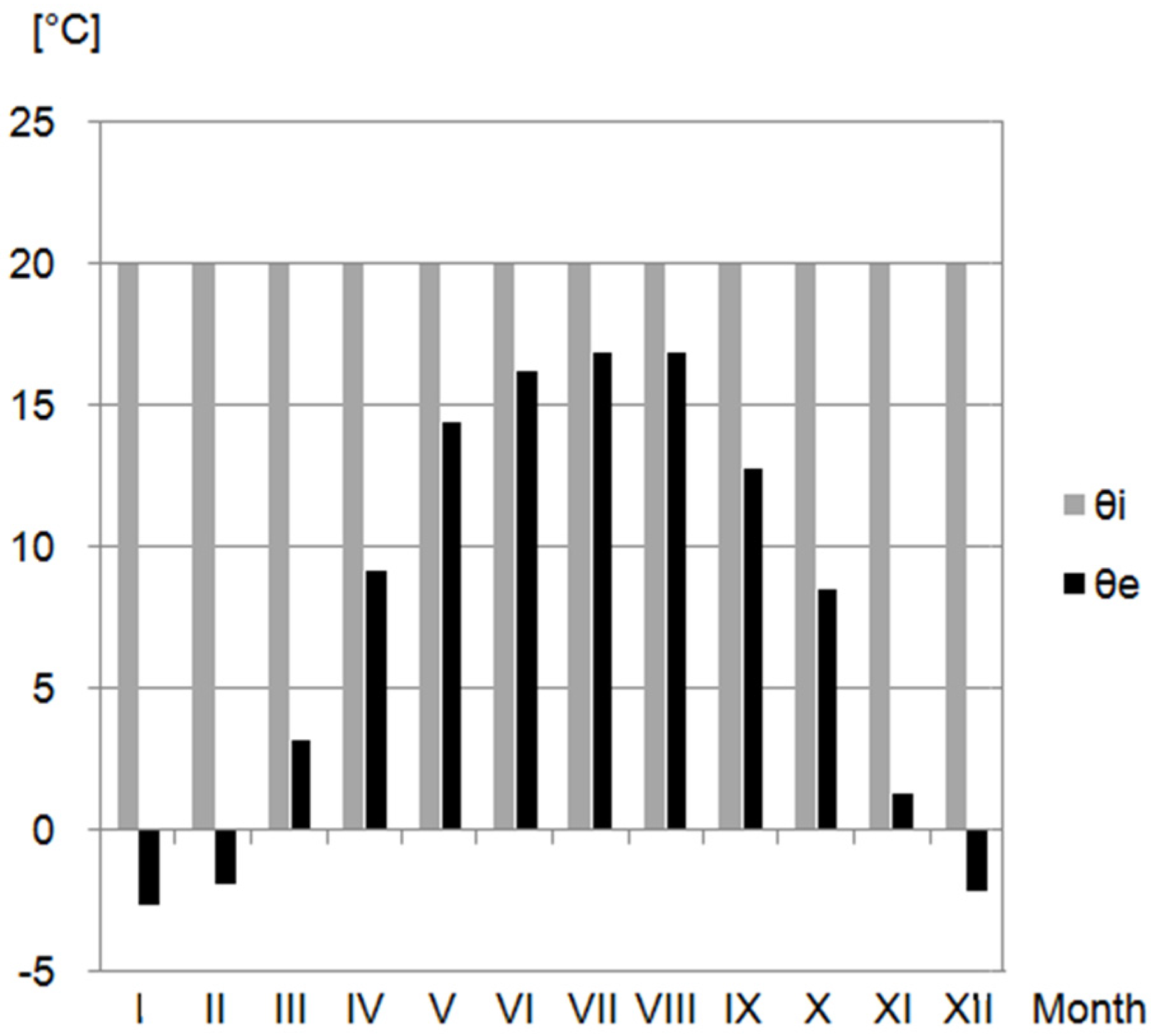

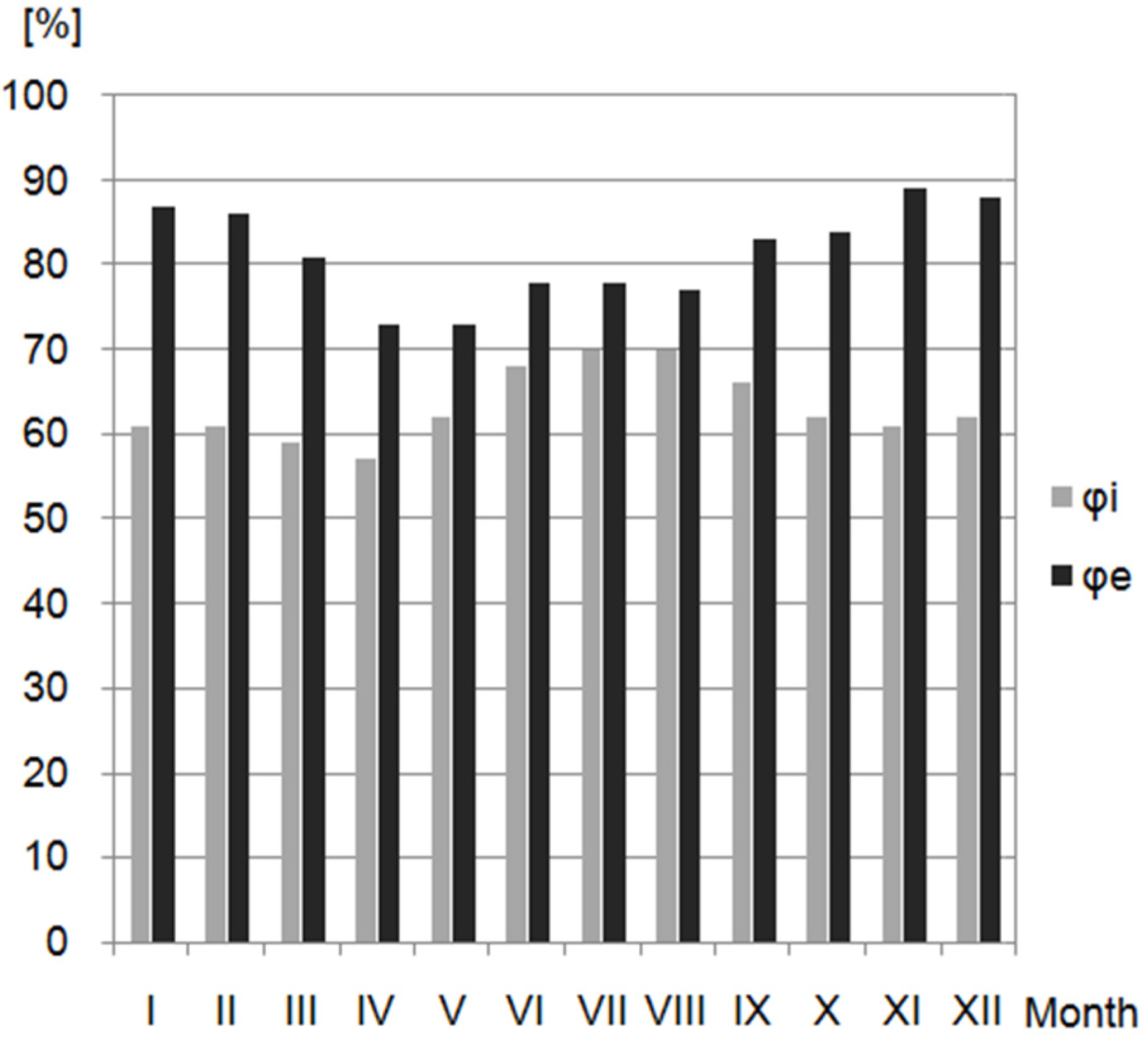

2.3.2. Water Vapor Condensation

3. Results

3.1. Physical Parameters of the Composites

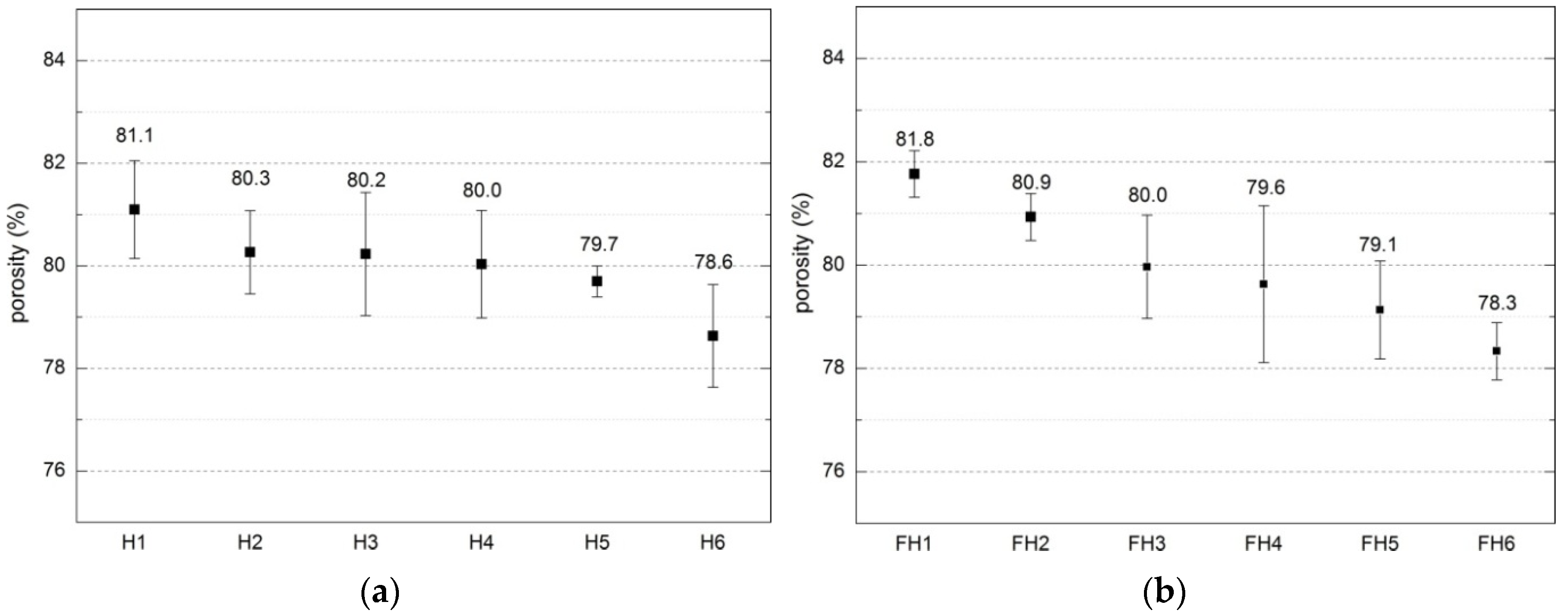

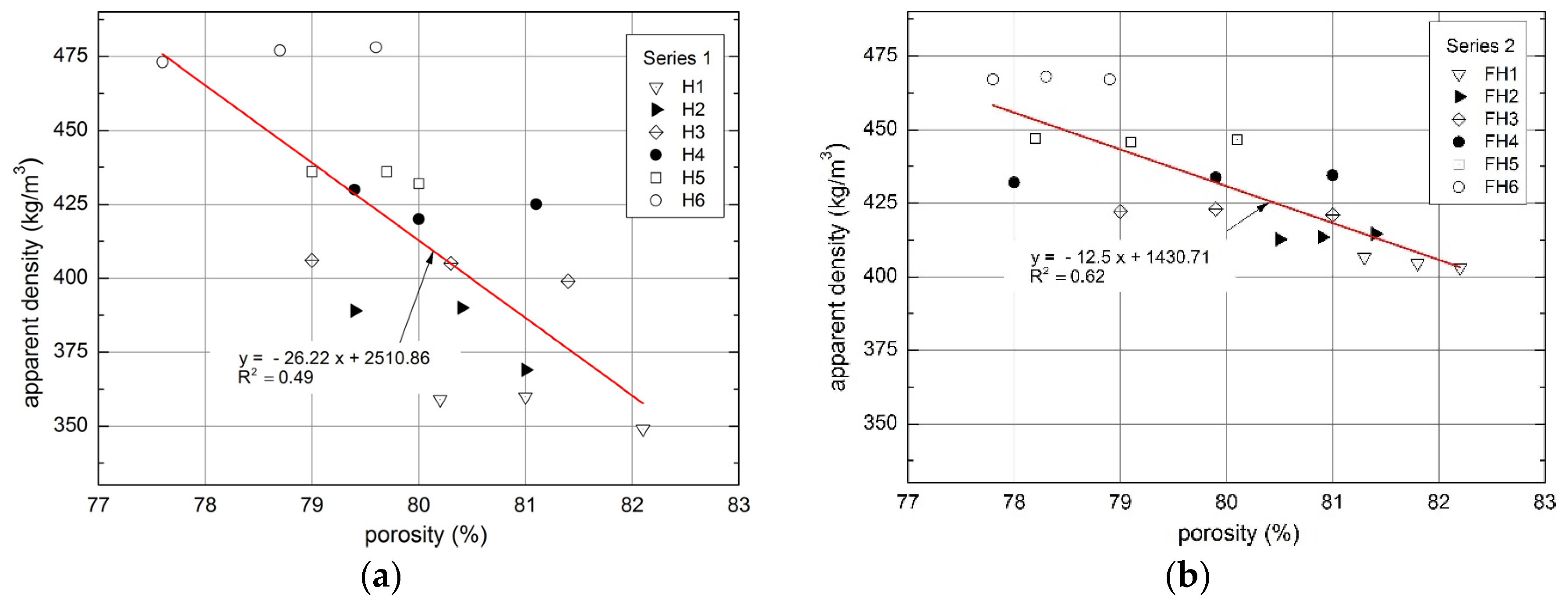

3.1.1. Density and Porosity

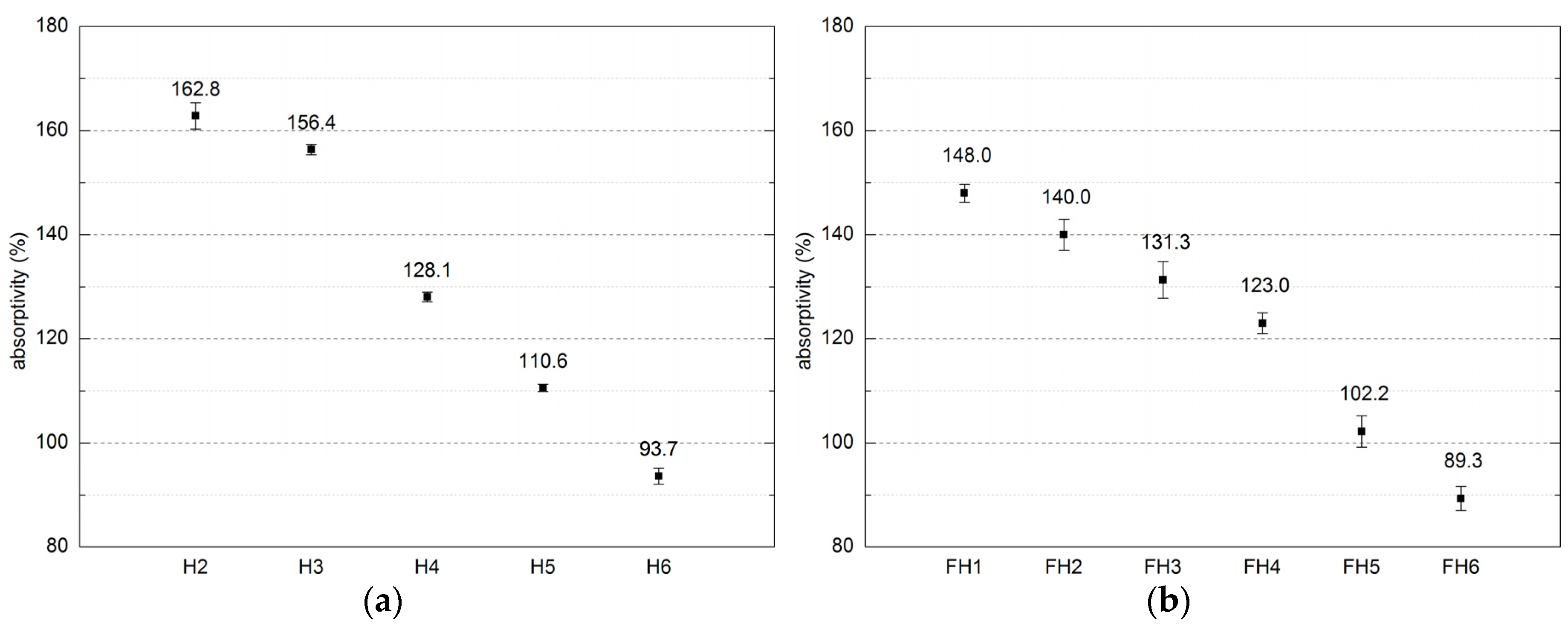

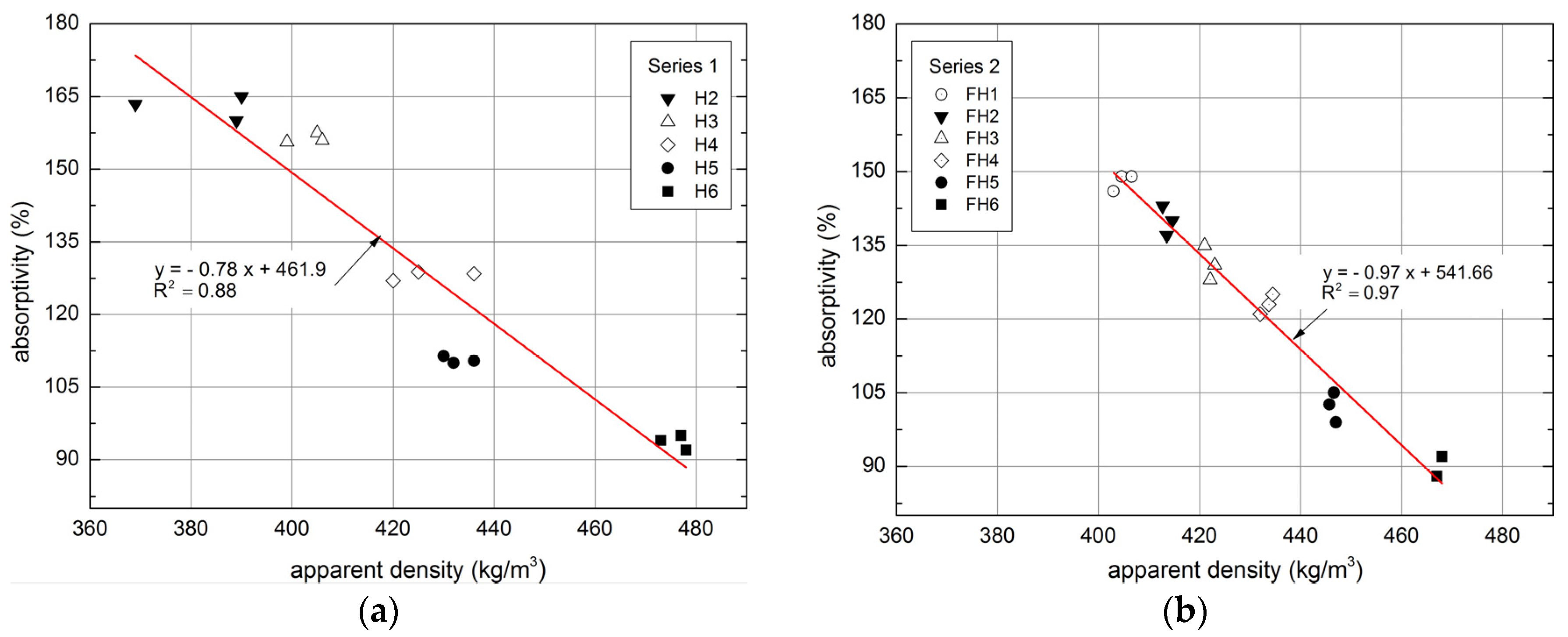

3.1.2. Composites Absorptivity

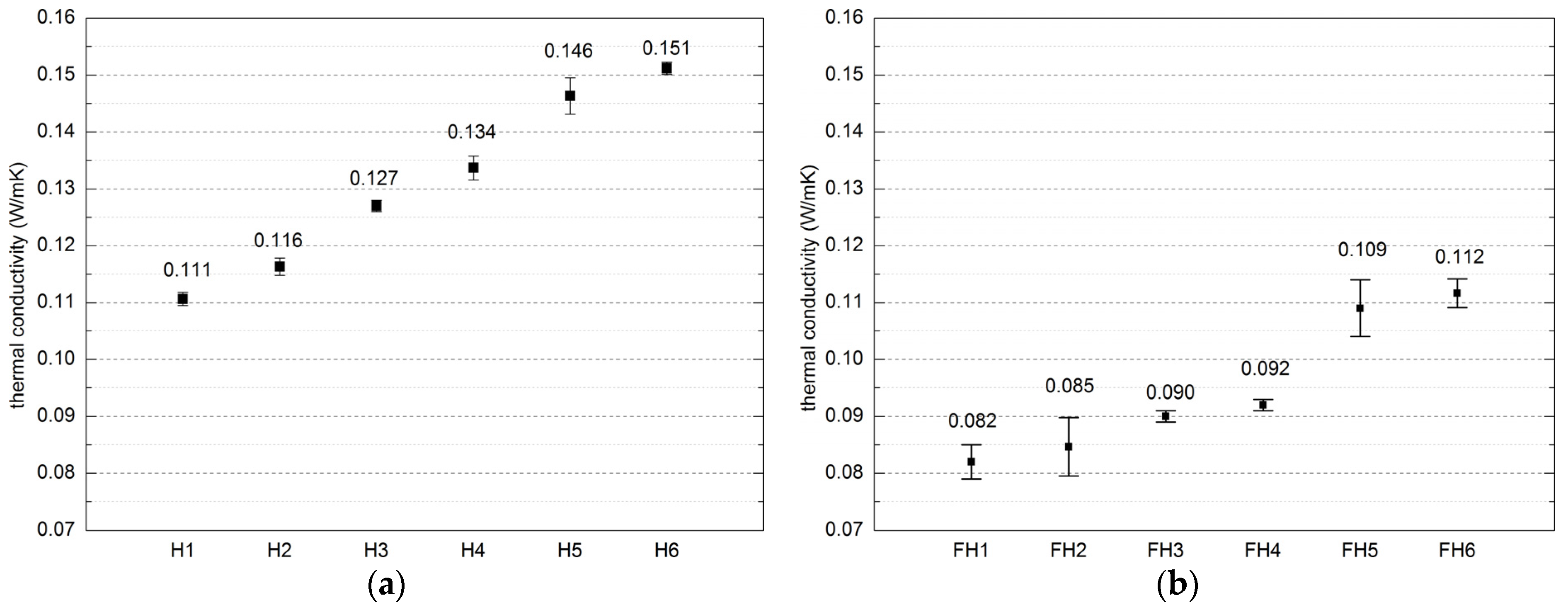

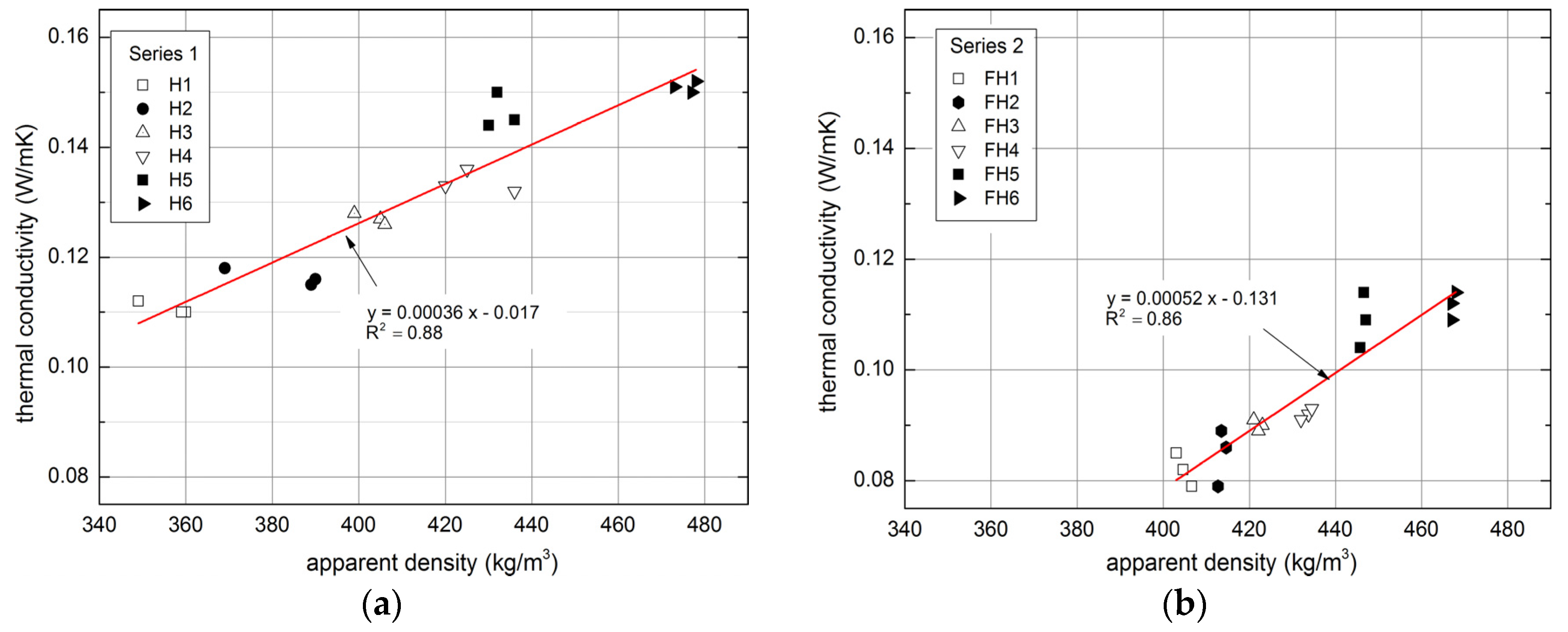

3.1.3. Thermal Conductivity Coefficient

3.1.4. Water Vapor Permeability Coefficient and Diffusion Resistance Factor

3.2. Mechanical Properties of the Material

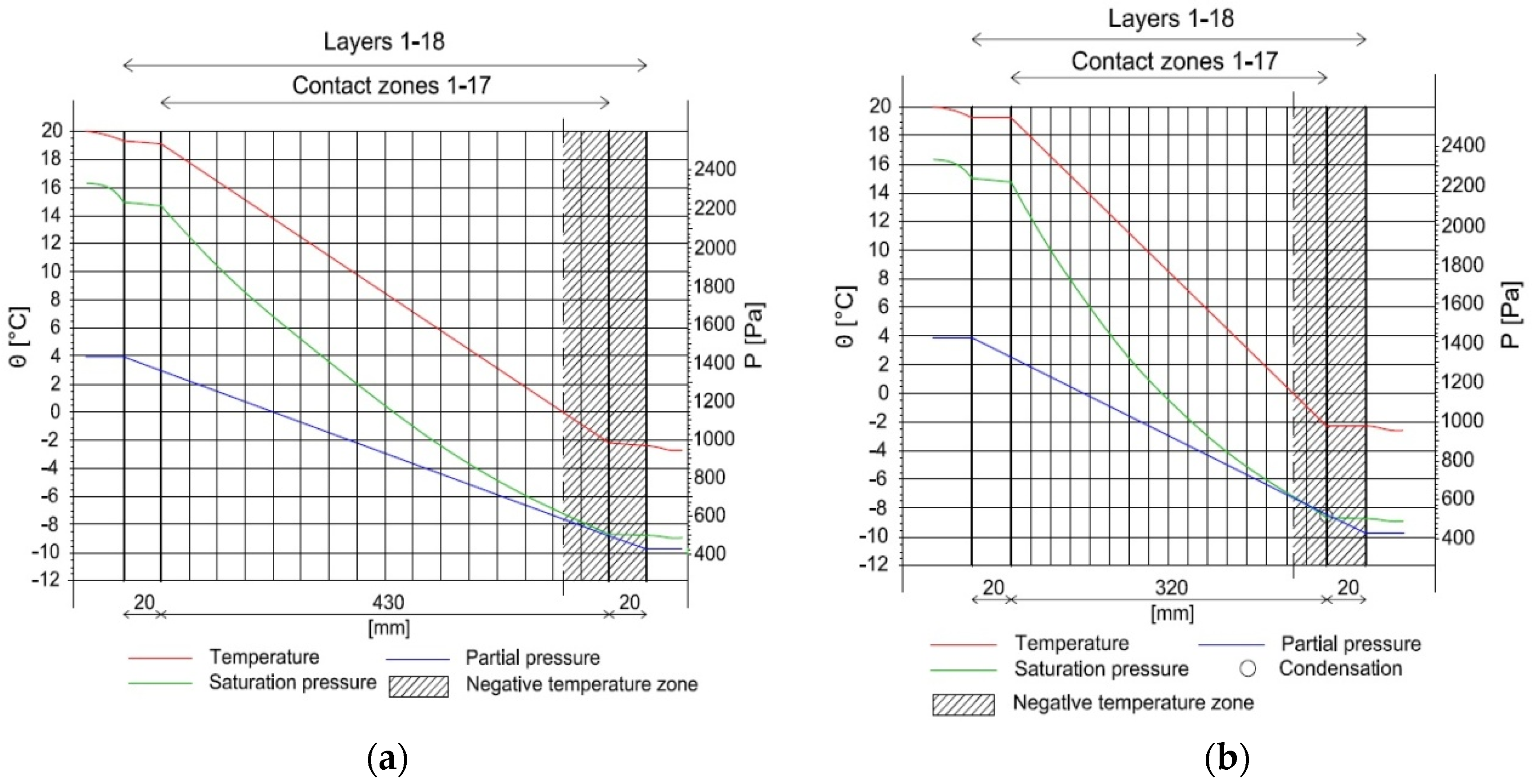

3.3. Calculation of Condensation Process

3.3.1. Internal Surface Temperature to Avoid Critical Surface Humidity

3.3.2. Determination of the Possibility of Interstitial Condensation

4. Discussion

4.1. Physical Parameters of the Composites

4.1.1. Density and Porosity

4.1.2. Composites Absorptivity

4.1.3. Thermal Conductivity Coefficient

4.1.4. Water Vapor Permeability Coefficient and Diffusion Resistance Factor

4.2. Discussion on Mechanical Properties of the Examined Composites

4.2.1. Compressive Strength of the Composites

4.2.2. Flexural Strength

4.3. Discussion on Condensation Phenomenon

4.3.1. Internal Surface Temperature to Avoid Critical Surface Humidity

4.3.2. Determination of the Possibility of Interstitial Condensation

5. Conclusions

- Biological composites based on hemp and flax are characterized by low strength parameters, which prevent them from being applied as bearing materials. The compressive strength of the tested composites was below 1 MPa, which makes them inferior to the lightest autoclaved aerated concretes.

- Thermal properties of the tested composites are promising for the application as an insulating material. In the case of the lightest mixtures, thermal conductivity coefficient values are below 0.1 W/(m·K), which makes them superior to autoclaved aerated concretes.

- Composites based on flax straw and hemp shives fillers exhibit better thermal properties than the composites containing only hemp shives as filler.

- Good thermal properties and poor durability makes lime–hemp and lime–flax–hemp composites an appropriate filling material for timber frame constructions of the external walls, even without additional insulation.

- Manufactured composites are characterized by low apparent density, ranging 356–476 kg/m3. This value is similar to lightweight autoclaved aerated concrete and should therefore ensure a relatively low weight of the constructed building.

- The density of the composite and the related thermal conductivity are both determined by the content of flax and hemp fillers. The increase of filler content simultaneously lowers the apparent density and decreases thermal conductivity coefficient.

- The composite produced from hemp and flax is characterized by high absorptivity, in most cases exceeding 100% by weight. It value may be lowered by the increase of binder content.

- Lime–flax–hemp composite can be used for the construction of external walls, preventing the growth of mold and mitigating the negative impact of interstitial condensation that occurs in the wall to a limited degree, and can be quickly evaporated during the first spring days.

- Lime–hemp composites, due to high water vapor permeability (μ = 5.28 and 5.53), are appropriate materials for the external walls, when using the suitable external and internal plasters providing diffusive openness of the whole barrier.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Adamczyk, J.; Dylewski, R. Recycling of Construction Waste in Terms of Sustainable Building. Probl. Sustain. Dev. 2010, 5, 125–131. [Google Scholar]

- Żelazna, A.; Pawlowski, A. The environmental analysis of insulation materials in the context of sustainable buildings. In Proceedings of the 8th International Conference Environmental Engineering, Vilnius, Lithuania, 19–20 May 2011; pp. 825–829. [Google Scholar]

- Halicka, A.; Ogrodnik, P.; Zegardlo, B. Using ceramic sanitary ware waste as concrete aggregate. Constr. Build. Mater. 2013, 48, 295–305. [Google Scholar] [CrossRef]

- Pavlik, Z.; Fort, J.; Zaleska, M.; Pavlikova, M.; Trnik, A.; Medved, I.; Keppert, M.; Koutsoukos, P.G.; Cerny, R. Energy-efficient thermal treatment of sewage sludge for its application in blended cements. J. Clean. Prod. 2016, 112, 409–419. [Google Scholar] [CrossRef]

- Oh, D.Y.; Noguchi, T.; Kitagaki, R.; Park, W.J. CO2 emission reduction by reuse of building material waste in the Japanese cement industry. Renew. Sustain. Energy Rev. 2014, 38, 796–810. [Google Scholar] [CrossRef]

- Arrigoni, A.; Pelosato, R.; Melià, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Life cycle assessment of natural building materials: The role of carbonation, mixture components and transport in the environmental impacts of hempcrete blocks. J. Clean. Prod. 2017, 149, 1051–1061. [Google Scholar] [CrossRef]

- Dembovska, L.; Bajare, D.; Ducman, V.; Korat, L.; Bumanis, G. The use of different by-products in the production of lightweight alkali activated building materials. Constr. Build. Mater. 2017, 135, 315–322. [Google Scholar] [CrossRef]

- Hroudova, J.; Zach, J. Acoustic and Thermal Insulating Materials Based On Natural Fibres Used in Floor Construction. World Acad. Sci. Eng. Technol. Int. J. Civ. Environ. Eng. 2014, 8, 1152–1155. [Google Scholar]

- Binici, H.; Eken, M.; Dolaz, M.; Aksogan, O.; Kara, M. An environmentally friendly thermal insulation material from sunflower stalk, textile waste and stubble fibres. Constr. Build. Mater. 2014, 51, 24–33. [Google Scholar] [CrossRef]

- Allin, S. Building with Hemp; Seed Press: Kenmare, Ireland, 2012. [Google Scholar]

- Minke, G.; Mahlke, F. Building with Straw; Birkhäuser Architecture: Berlin, Germany, 2015. [Google Scholar]

- Cripps, A.; Handyside, A.; Dewar, L.; Fovargue, J. Crops in Construction Handbook; CIRIA: London, UK, 2004. [Google Scholar]

- Sodagar, B.; Rai, D.; Jones, B.; Wihan, J.; Fieldson, R. The carbon-reduction potential of straw–bale housing. Build. Res. Inform. 2011, 39, 51–65. [Google Scholar] [CrossRef]

- Arnaud, L.; Gourlay, E. Experimental study of parameters influencing mechanical properties of hemp concrete. Constr. Build. Mater. 2012, 28, 50–56. [Google Scholar] [CrossRef]

- Arizzi, A.; Cultrone, G.; Brummer, M.; Viles, H.A. A chemical, morphological and mineralogical study on the interaction between hemp hurds and aerial and natural hydraulic lime particles: Implications for mortar manufacturing. Constr. Build. Mater. 2015, 75, 375–384. [Google Scholar] [CrossRef]

- Boutin, M.P.; Flamin, C.; Quinton, S.; Gosse, G.; Inra, L. Étude: Des Caracteristiquesenvironnementales du Chanvre par L’analyse de Son Cycle de vie; Ministère de l’Agricultureet de la Pêche: Paris, France, 2006. [Google Scholar]

- Bevan, R.; Wooley, T. Hemp Lime Construction—A Guide to Building with Hemp Lime Composites; IHS BRE: Bracknell, UK, 2008. [Google Scholar]

- Stevulova, N.; Kidalova, L.; Cigasova, J.; Junak, J.; Sicakova, A.; Terpakova, E. Lightweight Composites Containing Hemp Hurds. Proced. Eng. 2013, 65, 69–74. [Google Scholar] [CrossRef]

- Elfordy, S.; Lucas, F. Mechanical and thermal properties of lime and hemp concrete (“hempcrete”) manufactured by a projection process. Constr. Build. Mater. 2008, 22, 2116–2123. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Smarzewski, P.; Fic, S. Mechanicaland thermal properties of hemp-lime composites. Compos. Theory Pract. 2015, 15, 21–27. [Google Scholar]

- Evrard, A.; De Herde, A. Hygrothermal performance of lime-hemp wall assemblies. J. Build. Phys. 2010, 34, 5–25. [Google Scholar] [CrossRef]

- Van-der-Werf, H. Life cycle analysis of field production of fibre hemp, the effect of production practices on environmental impacts. Euphytica 2004, 140, 13–23. [Google Scholar] [CrossRef]

- Suchorab, Z.; Jedut, A.; Sobczuk, H. Water content measurement in building barriers and materials using surface TDR probe. Proc. ECOpole 2008, 2, 123–127. [Google Scholar]

- Gomes, G.; Flores-Colen, I.; Manga, L.M.; Soares, A.; de Brito, J. The influence of moisture content on the thermal conductivity of external thermal mortars. Orig. Res. Artic. Constr. Build. Mater. 2017, 135, 279–286. [Google Scholar] [CrossRef]

- Randazzo, L.; Montana, G.; Hein, A.; Castiglia, A.; Rodonò, G.; Donato, D.I. Moisture absorption, thermal conductivity and noise mitigation of clay based plasters: The influence of mineralogical and textural characteristics. Orig. Res. Artic. Appl. Clay Sci. 2016, 132–133, 498–507. [Google Scholar] [CrossRef]

- Polednik, B.; Dudzinska, M. Ventilation control based on the CO2 and aerosol concentration and the perceived air quality measurements—A case study. Arch. Environ. Prot. 2010, 36, 67–80. [Google Scholar]

- Von Mackensen, S.; Bullinger, M.; Morfeld, M. The sick building syndrome as a subjective perception-theoretical approach and assessment methods. Zent. Hyg. Umweltmed. 1999, 202, 243–248. [Google Scholar]

- Hansen, L. Monitoring of symptoms in estimating the effect of intervention in the sick building syndrome: A field study. Environ. Int. 1989, 15, 159–162. [Google Scholar] [CrossRef]

- De Bruijn, P.B.; Jeppsson, K.H.; Sandin, K.; Nilsson, C. Mechanical properties of lime–hemp concrete containing shives and fibres. Biosyst. Eng. 2009, 103, 474–479. [Google Scholar] [CrossRef]

- Kinnane, O.; Reilly, A.; Grimes, J.; Pavia, S.; Walker, R. Acoustic absorption of hemp-lime construction. Constr. Build. Mater. 2016, 122, 674–682. [Google Scholar] [CrossRef]

- Stevulova, N.; Kidalova, L.; Junak, J.; Cigasova, J.; Terpakova, E. Effect of hemp shive sizes on mechanical properties of lightweight fibrous composites. Proc. Eng. 2012, 42, 496–500. [Google Scholar] [CrossRef]

- Stikute, A.; Kukle, S.; Shakhmenko, G. Ecological Materials for Frame Housing. Sci. J. Riga Tech. Univ. 2011, 6, 43–48. [Google Scholar]

- Cerezo, V. Propriétésmécaniques, Thermiquesetacoustiques d’un Matériau à base de Particulesvégétales: Approcheéxpérimentale et Modélisationthéorique; L’Institut National des Sciences Appliquées de Lyon: Saint Valérien, France, 2005. [Google Scholar]

- Nguyen, T. Contribution à L’étude de la Formulation et du Procédé de Fabrication D’éléments de Construction Enbéton de Chanvre. Ph.D. Thesis, Université de Bretagne Sud, Morbihan, France, 2010. [Google Scholar]

- Hirst, E.; Walker, P.; Paine, K.; Yates, T. Characterisation of low density hemp-lime composite building materials under compression loading. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010. [Google Scholar]

- Gourlay, E.; Arnaud, L. Comportementhygrothermique des murs de béton de chanvre. In Proceedings of the Actes du Congrès SFT, Le Touquet, France, 25–28 May 2010. [Google Scholar]

- Walker, R.; Pavía, S.; Mitchell, R. Mechanical properties and durability of hemp-lime concretes. Constr. Build. Mater. 2014, 61, 340–348. [Google Scholar] [CrossRef]

- Stanwix, W.; Sparrow, A. The hempcrete book. Designing and Building with Hemp-Lime; Green Books: Cambridge, UK, 2014. [Google Scholar]

- Benfratello, S.; Capitano, C.; Peri, G.; Rizzo, G.; Scaccianoce, G.; Sorrentino, G. Thermal and structural properties of a hemp–lime biocomposite. Constr. Build. Mater. 2013, 48, 745–754. [Google Scholar] [CrossRef]

- Tierrafino Home Page. Available online: http://www.tierrafino.com (accessed on 15 March 2017).

- Brzyski, P. Risk assesment of water vapor condensation in wall made of hemp-lime composite. Arch. Civ. Eng. Environ. 2016, 2, 47–56. [Google Scholar]

- Ministerstwo Infrastruktury i Budownictwa. Available online: http://www.mib.gov.pl (accessed on 15 March 2017).

- Collet, F.; Pretot, S. Thermal conductivity of hemp concretes: Variation with formulation, density and water content. Constr. Build. Mater. 2014, 65, 612–619. [Google Scholar] [CrossRef]

- Barclay, M.; Holcroft, N.; Shea, A.D. Methods to determine whole building hygrothermal performance of hempelime buildings. Build. Environ. 2014, 80, 204–212. [Google Scholar] [CrossRef]

- Labat, M.; Magniont, C.; Oudhof, N.; Aubert, J.E. From the experimental characterization of the hygrothermal properties of straw-clay mixtures to the numerical assessment of their buffering potential. Build. Environ. 2016, 97, 69–81. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Smarzewski, P.; Brzyski, P. Properties of Hemp-Flax Composites for Use in the Building Industry. J. Nat. Fibers 2017, 14, 410–425. [Google Scholar] [CrossRef]

- Rahim, M.; Douzane, O.; Le, A.D.T.; Promis, G.; Laidoudi, B.; Crigny, A.; Dupre, B.; Langlet, T. Characterization of flax lime and hemp lime concretes: Hygricproperties and moisture buffer capacity. Energy Build. 2015, 88, 91–99. [Google Scholar] [CrossRef]

- Suchorab, Z.; Barnat–Hunek, D.; Sobczuk, H. Influence of moisture on heat conductivity coefficient of aerated concrete. Ecol. Chem. Eng. 2011, 18, 111–120. [Google Scholar]

- Walker, R.; Pavía, S. Moisture transfer and thermal properties of hemp–lime concretes. Constr. Build. Mater. 2014, 64, 270–276. [Google Scholar] [CrossRef]

- Sassoni, E.; Manzi, S.; Motori, A.; Montecchi, M.; Canti, M. Novel sustainable hemp-based composites for application in the building industry: Physical, thermal and mechanical characterization. Energy Build. 2014, 77, 219–226. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Smarzewski, P. Analysis of the physical properties of hydrophobised lightweight-aggregate mortars. Compos. Theory Pract. 2016, 15, 96–102. [Google Scholar]

- Yusuf, I.T.; Jimoh, Y.A.; Salami, W.A. An appropriate relationship between flexural strength and compressive strength of palm kernel shell concrete. Alex. Eng. J. 2016, 55, 1553–1562. [Google Scholar] [CrossRef]

- Ahmed, M.; Hadi, K.M.E.; Hasan, M.A.; Mallick, J.; Ahmed, A. Evaluating the co-relationship between concrete flexural tensile strength and compressive strength. Int. J. Struct. Eng. 2014, 5. [Google Scholar] [CrossRef]

| Material | Unit | Series 1 | Series 2 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H1 | H2 | H3 | H4 | H5 | H6 | FH1 | FH2 | FH3 | FH4 | FH5 | FH6 | ||

| Lime | (%) | 23.8 | 20.8 | 21.0 | 21.3 | 22.2 | 23.8 | 18.9 | 18.9 | 18.9 | 11.8 | 18.9 | 18.9 |

| Cement | (%) | 2.5 | 3.9 | 4.6 | 5.3 | 5.6 | 5.2 | 6.2 | 6.2 | 6.2 | 11.8 | 6.2 | 6.2 |

| Clay | (%) | - | - | - | - | - | - | 1.9 | 1.9 | 1.9 | 2.3 | 1.9 | 1.9 |

| Hemp shives | (%) | 23.8 | 17.4 | 15.4 | 13.3 | 11.1 | 8.7 | 18.9 | 13.5 | 9.5 | 11.3 | 5.4 | - |

| Flax straw | (%) | - | - | - | - | - | - | - | 5.4 | 9.5 | 11.3 | 13.5 | 18.9 |

| Sand | (%) | 11.4 | 8.6 | 7.7 | 6.7 | 5.6 | 4.3 | - | - | - | - | - | - |

| Water | (%) | 39.5 | 49.3 | 51.2 | 53.3 | 55.6 | 58.0 | 54.1 | 54.1 | 54.1 | 51.6 | 54.1 | 54.1 |

| Composite | Water Vapor Permeability Coefficient (kg/(m∙s∙Pa)) | Water Vapor Diffusion Resistance Factor (-) |

|---|---|---|

| H1 | 3.79 × 10−11 ± 4.3 × 10−13 | 5.28 ± 0.06 |

| FH1 | 3.62 × 10−11 ± 5.2 ×10−13 | 5.53 ± 0.08 |

| Property | Series 1 | Series 2 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H1 | H2 | H3 | H4 | H5 | H6 | FH1 | FH2 | FH3 | FH4 | FH5 | FH6 | |

| Compressive strength (MPa) | 0.41 ± 0.023 | 0.45 ± 0.021 | 0.54 ± 0.027 | 0.65 ± 0.031 | 0.67 ± 0.029 | 0.70 ± 0.032 | 0.51 ± 0.028 | 0.53 ± 0.026 | 0.64 ± 0.029 | 0.70 ± 0.030 | 0.80 ± 0.032 | 0.85 ± 0.033 |

| Flexural Strength (MPa) | 0.05 ± 0.002 | 0.06 ± 0.002 | 0.1 ± 0.004 | 0.14 ± 0.005 | 0.19 ± 0.005 | 0.24 ± 0.007 | 0.09 ± 0.003 | 0.1 ± 0.002 | 0.13 ± 0.003 | 0.17 ± 0.005 | 0.21 ± 0.007 | 0.24 ± 0.008 |

| Month | pe (Pa) | Δp (Pa) | pi (Pa) | psat(θsi,min) (Pa) | θsi,min (°C) | fRsi,min | fRsi |

|---|---|---|---|---|---|---|---|

| I | 428 | 915 | 1435 | 1794 | 15.8 | 0.814 | 0.939 |

| II | 449 | 887 | 1424 | 1780 | 15.7 | 0.803 | |

| III | 624 | 680 | 1373 | 1716 | 15.1 | 0.709 | |

| IV | 844 | 437 | 1326 | 1657 | 14.6 | 0.496 | |

| V | 1205 | 227 | 1454 | 1818 | 16.0 | 0.287 | |

| VI | 1430 | 154 | 1599 | 1999 | 17.5 | 0.343 | |

| VII | 1495 | 126 | 1633 | 2041 | 17.8 | 0.301 | |

| VIII | 1487 | 126 | 1625 | 2032 | 17.8 | 0.277 | |

| IX | 1221 | 292 | 1542 | 1927 | 16.9 | 0.572 | |

| X | 928 | 466 | 1440 | 1800 | 15.8 | 0.639 | |

| XI | 598 | 757 | 1431 | 1789 | 15.8 | 0.773 | |

| XII | 453 | 895 | 1438 | 1797 | 15.8 | 0.811 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brzyski, P.; Barnat-Hunek, D.; Suchorab, Z.; Łagód, G. Composite Materials Based on Hemp and Flax for Low-Energy Buildings. Materials 2017, 10, 510. https://doi.org/10.3390/ma10050510

Brzyski P, Barnat-Hunek D, Suchorab Z, Łagód G. Composite Materials Based on Hemp and Flax for Low-Energy Buildings. Materials. 2017; 10(5):510. https://doi.org/10.3390/ma10050510

Chicago/Turabian StyleBrzyski, Przemysław, Danuta Barnat-Hunek, Zbigniew Suchorab, and Grzegorz Łagód. 2017. "Composite Materials Based on Hemp and Flax for Low-Energy Buildings" Materials 10, no. 5: 510. https://doi.org/10.3390/ma10050510