Effects of Cold-Rolling/Aging Treatments on the Shape Memory Properties of Ti49.3Ni50.7 Shape Memory Alloy

Abstract

:1. Introduction

2. Results

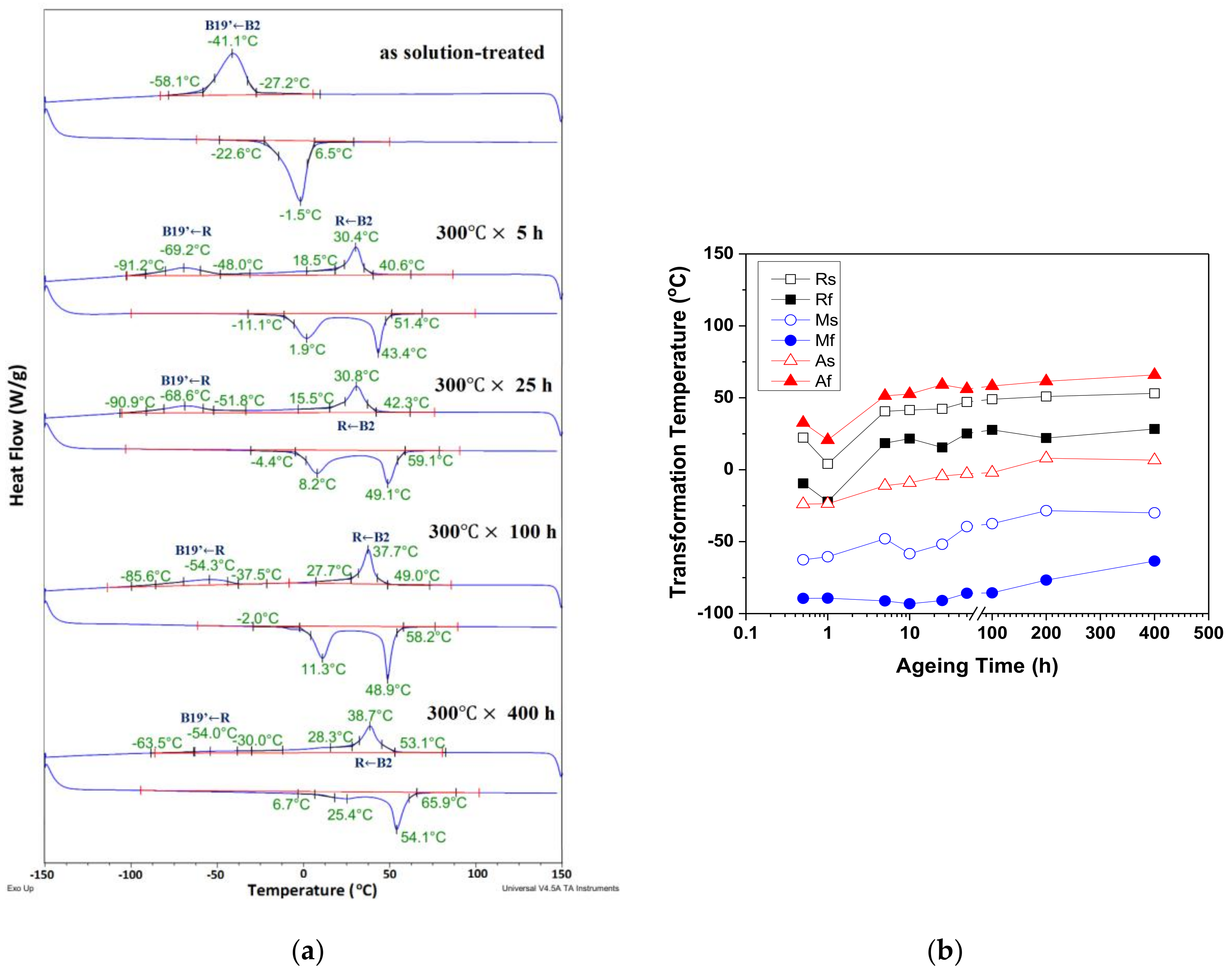

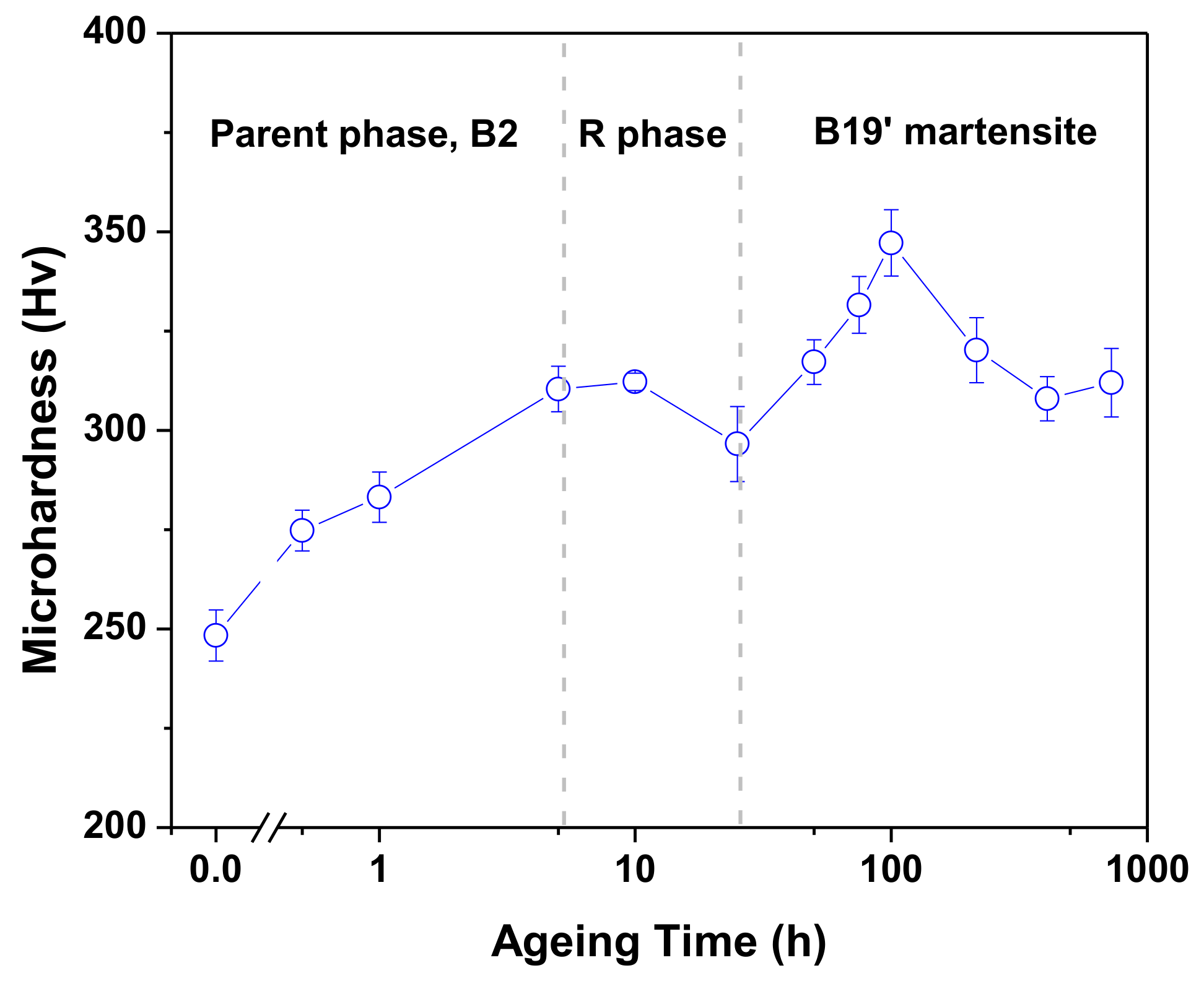

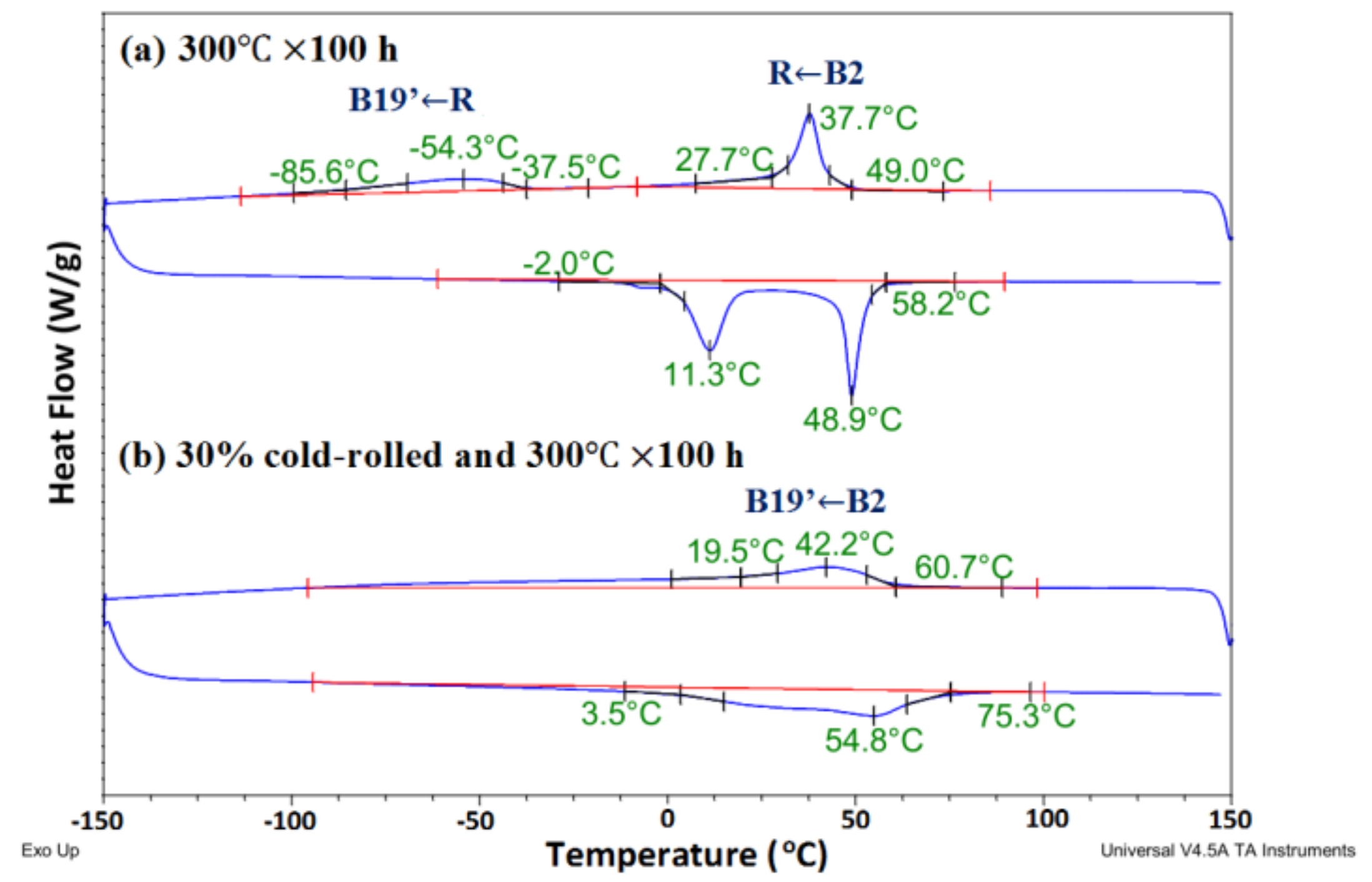

2.1. DSC and Microhardness Results

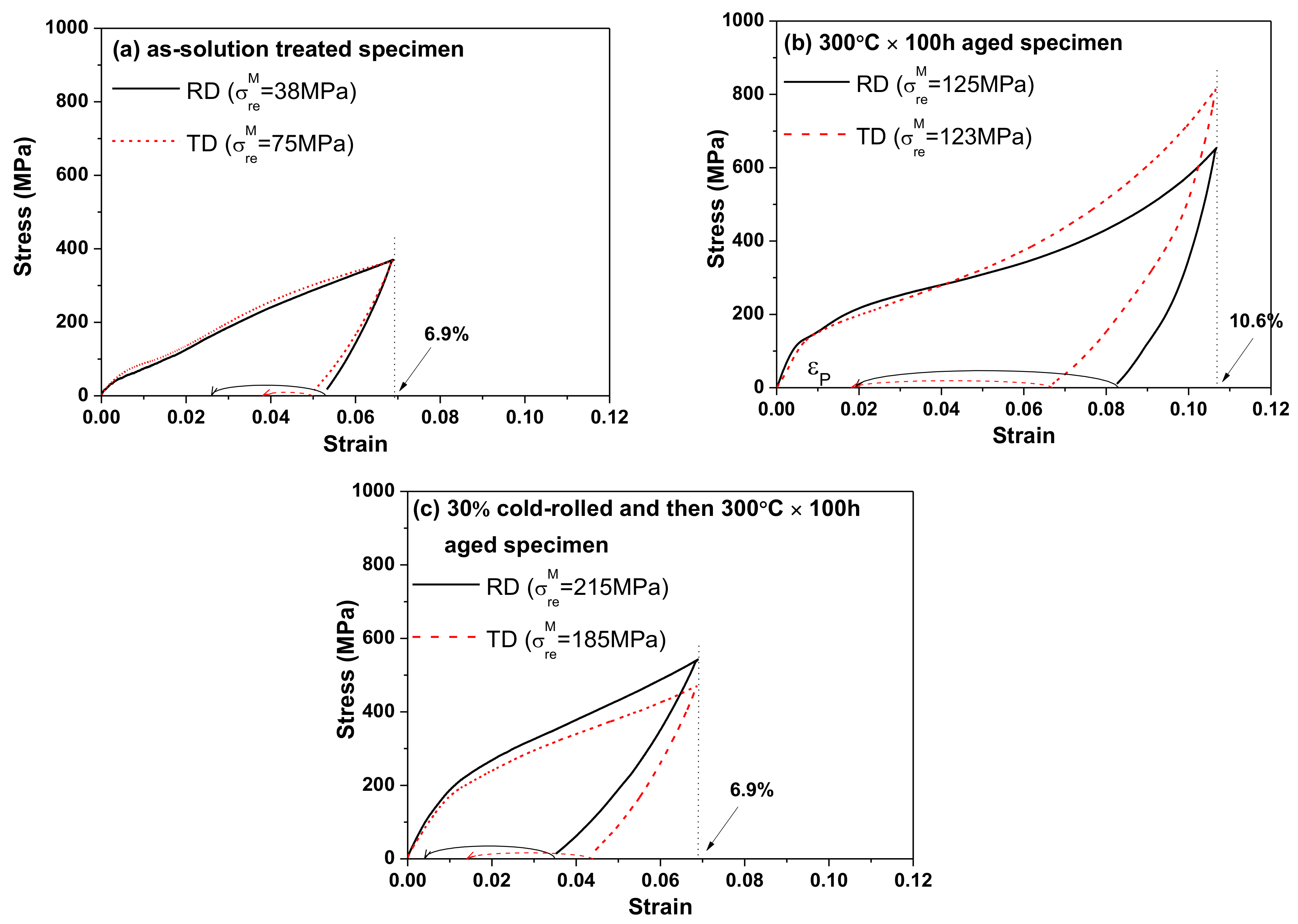

2.2. Shape Memory Effect Measurements

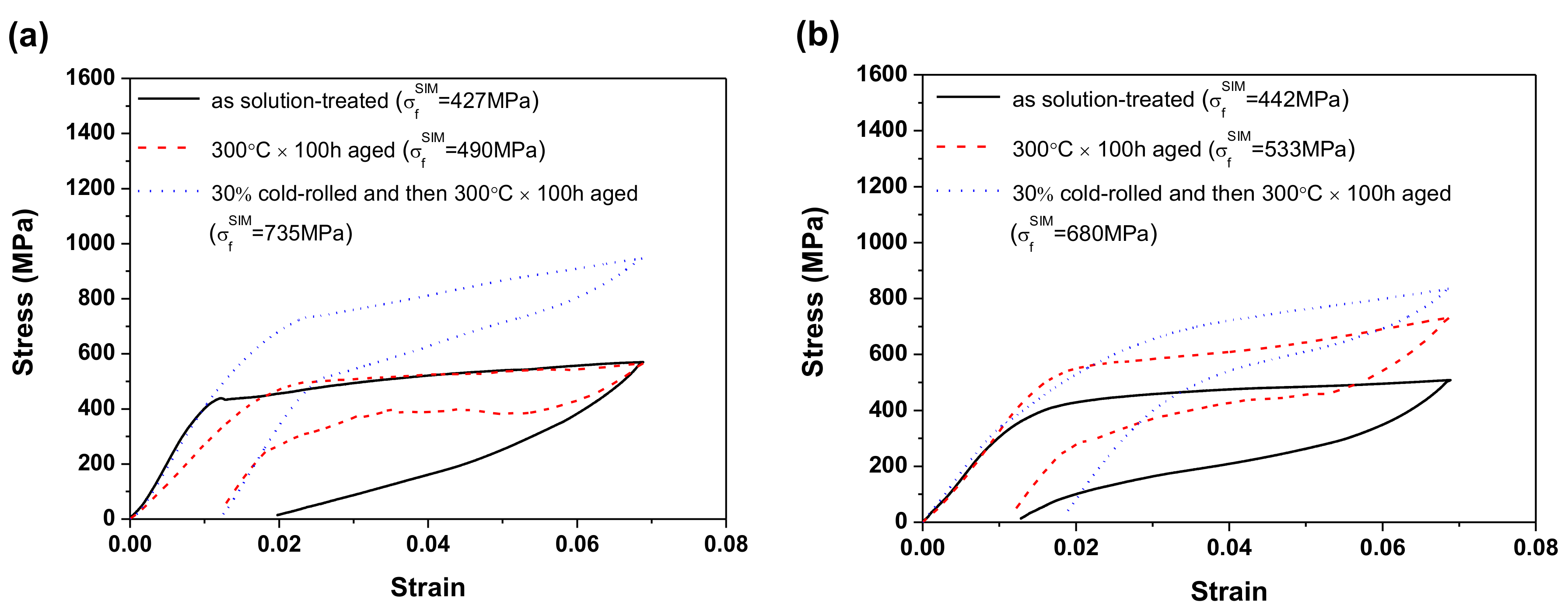

2.3. Superelasticity Measurements

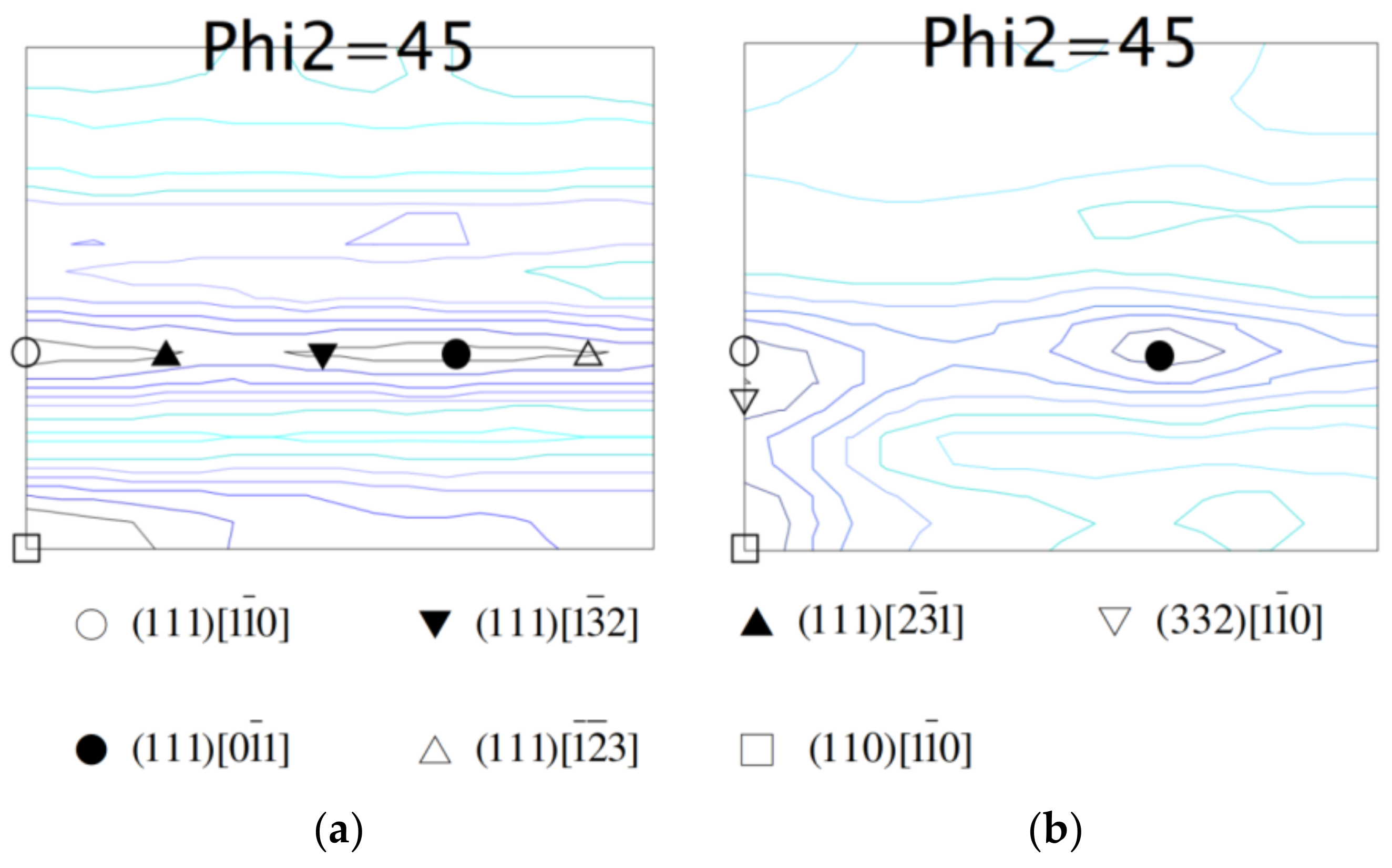

2.4. Orientation Distribution Functions (ODF) Calculations

3. Discussion

4. Experimental Procedures

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Alam, M.S.; Youssef, M.A.; Nehdi, M. Utilizing shape memory alloys to enhance the performance and safety of civil infrastructure: A review. Can. J. Civ. Eng. 2007, 34, 1075–1086. [Google Scholar] [CrossRef]

- Lin, H.C.; Wu, S.K. The tensile behavior of a cold-rolled and reverse-transformed equiatomic TiNi alloy. Acta Metall. 1994, 42, 1623–1630. [Google Scholar] [CrossRef]

- Kockar, B.; Karaman, I.; Kim, J.I.; Chumlyakov, Y.I.; Sharp, J.; Yu, C.J. Thermomechanical cyclic response of an ultrafine-grained NiTi shape memory alloy. Acta Mater. 2008, 56, 3630–3646. [Google Scholar] [CrossRef]

- Kim, J.I.; Miyazaki, S. Effect of nano-scaled precipitates on shape memory behavior of Ti-50.9 at.%Ni alloy. Acta Mater. 2005, 53, 4545–4554. [Google Scholar] [CrossRef]

- Miyazaki, S.; Kimura, S.; Otsuka, K.; Suzuki, Y. The habit plane and transformation strains associated with the martensitic transformation in Ti–Ni single crystals. Scr. Metall. 1984, 18, 883–888. [Google Scholar] [CrossRef]

- Shu, Y.C.; Bhattacharya, K. The influence of texture on the shape-memory effect in polycrystals. Acta Mater. 1998, 46, 5457–5473. [Google Scholar] [CrossRef]

- Inoue, H.; Miwa, N.; Inakazu, N. Texture and shape memory strain in TiNi alloy sheets. Acta Mater. 1996, 44, 4825–4834. [Google Scholar] [CrossRef]

- Ye, B.; Majumdar, B.S.; Dutta, I. Texture development and strain hysteresis in a NiTi shape-memory alloy during thermal cycling under load. Acta Mater. 2009, 57, 2403–2417. [Google Scholar] [CrossRef]

- Laplanche, G.; Kazuch, A.; Eggeler, G. Processing of NiTi shape memory sheets—Microstructural heterogeneity and evolution of texture. J. Alloys Compd. 2015, 651, 333–339. [Google Scholar] [CrossRef]

- Laplanche, G.; Birk, T.; Schneider, S.; Frenzel, J.; Eggeler, G. Effect of temperature and texture on the reorientation of martensite variants in NiTi shape memory alloys. Acta Mater. 2017, 127, 143–152. [Google Scholar] [CrossRef]

- Gall, K.; Juntunen, K.; Maier, H.J.; Sehitoglu, H.; Chumlyakov, Y.I. Instrumented micro-indentation of NiTi shape-memory alloys. Acta Mater. 2001, 49, 3205–3217. [Google Scholar] [CrossRef]

- Gall, K.; Sehitoglu, H.; Chumlyakov, Y.I.; Zuev, Y.L.; Karaman, I. The role of coherent precipitates in martensitic transformations in single crystal and polycrystalline Ti-50.8 at%Ni. Scr. Mater. 1998, 39, 699–705. [Google Scholar] [CrossRef]

- Gall, K.; Sehitoglu, H.; Chumlyakov, Y.I.; Kireeva, I.V. Pseudoelastic cyclic stress-strain response of over-aged single crystal Ti-50.8 at%Ni. Scr. Mater. 1999, 40, 7–12. [Google Scholar] [CrossRef]

- Gall, K.; Maier, H.J. Cyclic deformation mechanisms in precipitated NiTi shape memory alloys. Acta Mater. 2002, 50, 4643–4657. [Google Scholar] [CrossRef]

- Sehitoglu, H.; Karaman, I.; Anderson, R.; Zhang, X.; Gall, K.; Maier, H.J.; Chumlyakov, Y.I. Compressive response of NiTi single crystals. Acta Mater. 2000, 48, 3311–3326. [Google Scholar] [CrossRef]

- Sehitoglu, H.; Jun, J.; Zhang, X.; Karaman, I.; Chumlyakov, Y.I.; Maier, H.J.; Gall, K. Shape memory and pseudoelastic behavior of 51.5% Ni–Ti single crystals in solutionized and overaged state. Acta Mater. 2001, 49, 3609–3620. [Google Scholar] [CrossRef]

- Wu, S.K.; Lin, H.C. The effect of precipitation hardening on the Ms temperature in a Ti49.2Ni50.8 alloy. Scr. Metall. 1991, 25, 1529–1532. [Google Scholar] [CrossRef]

- Nishida, M.; Wayman, C.M.; Chiba, A. Electron microscopy studies of the martensitic transformation in an aged Ti-51at%Ni shape memory alloy. Metallography 1988, 21, 275–291. [Google Scholar] [CrossRef]

- Honeycombe, R.W.K. The Plastic Deformation of Metals; Edward Arnold: Cambridge, UK, 1982; p. 335. [Google Scholar]

- Chang, S.H.; Wu, S.K. Textures in cold-rolled and annealed Ti50Ni50 shape memory alloy. Scr. Mater. 2004, 50, 937–941. [Google Scholar] [CrossRef]

- Bhattacharya, K. Microstructure of Martensite: Why It Forms and How It Gives Rise to the Shape-Memory Effect; Oxford University Press: Oxford, NY, USA, 2003. [Google Scholar]

- Bhattacharya, K.; Kohn, V. Symmetry, texture and the recoverable strain of shape-memory polycrystals. Acta Mater. 1996, 44, 529–542. [Google Scholar] [CrossRef]

- Shu, Y.C.; Yen, J.H. Pattern formation in martensitic thin films. Appl. Phys. Lett. 2007, 91, 021908. [Google Scholar] [CrossRef]

- Shu, Y.C.; Yen, J.H. Multivariant model of martensitic microstructure in thin films. Acta Mater. 2008, 56, 3969–3981. [Google Scholar] [CrossRef]

- Knowles, K.M.; Smith, D.A. The crystallography of the martensitic transformation in equiatomic nickel-titanium. Acta Metall. 1981, 29, 101–110. [Google Scholar] [CrossRef]

- Otsuka, K.; Sawamura, T.; Shimizu, K. Crystal structure and internal defects of equiatomic TiNi martensite. Phys. Status Solidi A 1971, 5, 457–470. [Google Scholar] [CrossRef]

- Miyazaki, S.; Otsuka, K.; Wayman, C.M. The shape memory mechanism associated with the martensitic transformation in Ti-Ni alloys—I. Self-accommodation. Acta Metall. 1989, 37, 1873–1884. [Google Scholar] [CrossRef]

| Specimen | Texture | RD | TD | Theoretical Recoverable Strain | εMtotal | ||

|---|---|---|---|---|---|---|---|

| RD | TD | RD | TD | ||||

| Solution-treated Ti49.3Ni50.7 SMA | 9.10% | 8.09% | 5.4% | 3.1% | |||

| 300 °C × 100 h aged Ti49.3Ni50.7 SMA | 9.10% | 8.09% | 8.7% | 8.8% | |||

| 30% cold-rolled and then 300 °C × 100 h aged Ti49.3Ni50.7 SMA | 8.23% | 7.34% | 6.5% | 5.5% | |||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, S.-H.; Lin, K.-H.; Wu, S.-K. Effects of Cold-Rolling/Aging Treatments on the Shape Memory Properties of Ti49.3Ni50.7 Shape Memory Alloy. Materials 2017, 10, 704. https://doi.org/10.3390/ma10070704

Chang S-H, Lin K-H, Wu S-K. Effects of Cold-Rolling/Aging Treatments on the Shape Memory Properties of Ti49.3Ni50.7 Shape Memory Alloy. Materials. 2017; 10(7):704. https://doi.org/10.3390/ma10070704

Chicago/Turabian StyleChang, Shih-Hang, Keng-Hua Lin, and Shyi-Kaan Wu. 2017. "Effects of Cold-Rolling/Aging Treatments on the Shape Memory Properties of Ti49.3Ni50.7 Shape Memory Alloy" Materials 10, no. 7: 704. https://doi.org/10.3390/ma10070704