Impact Load Behavior between Different Charge and Lifter in a Laboratory-Scale Mill

Abstract

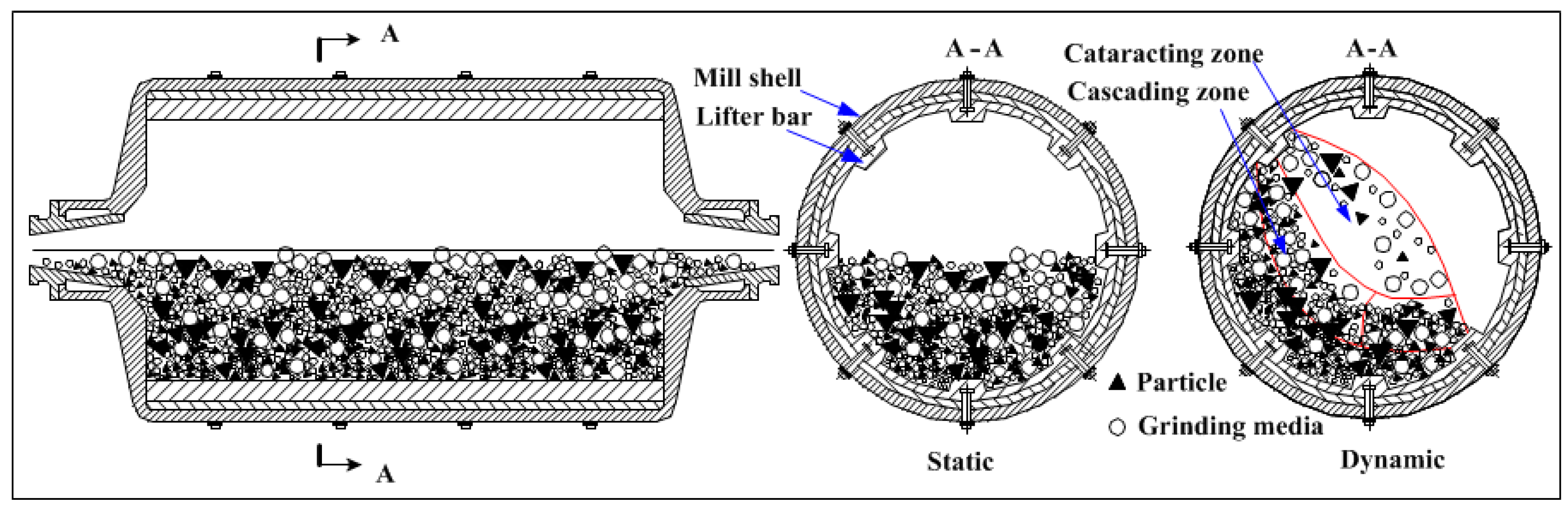

:1. Introduction

2. Power Draw Model of Discrete Element Method

3. Materials and Methods

3.1. Experimental Setup

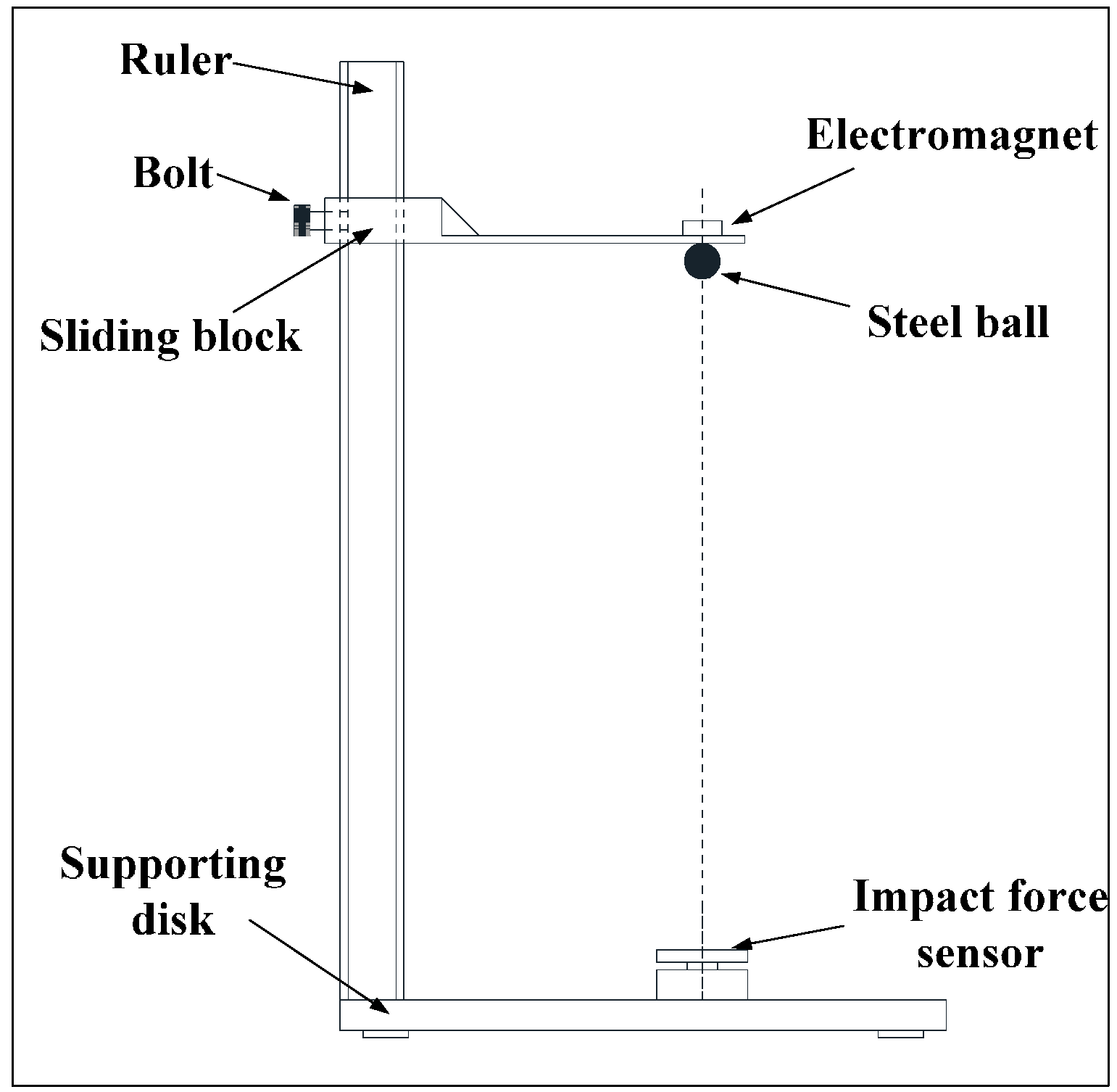

3.1.1. Drop Ball Experiments

3.1.2. Impact Breakage Experiments

3.2. Materials

4. Results and Discussion

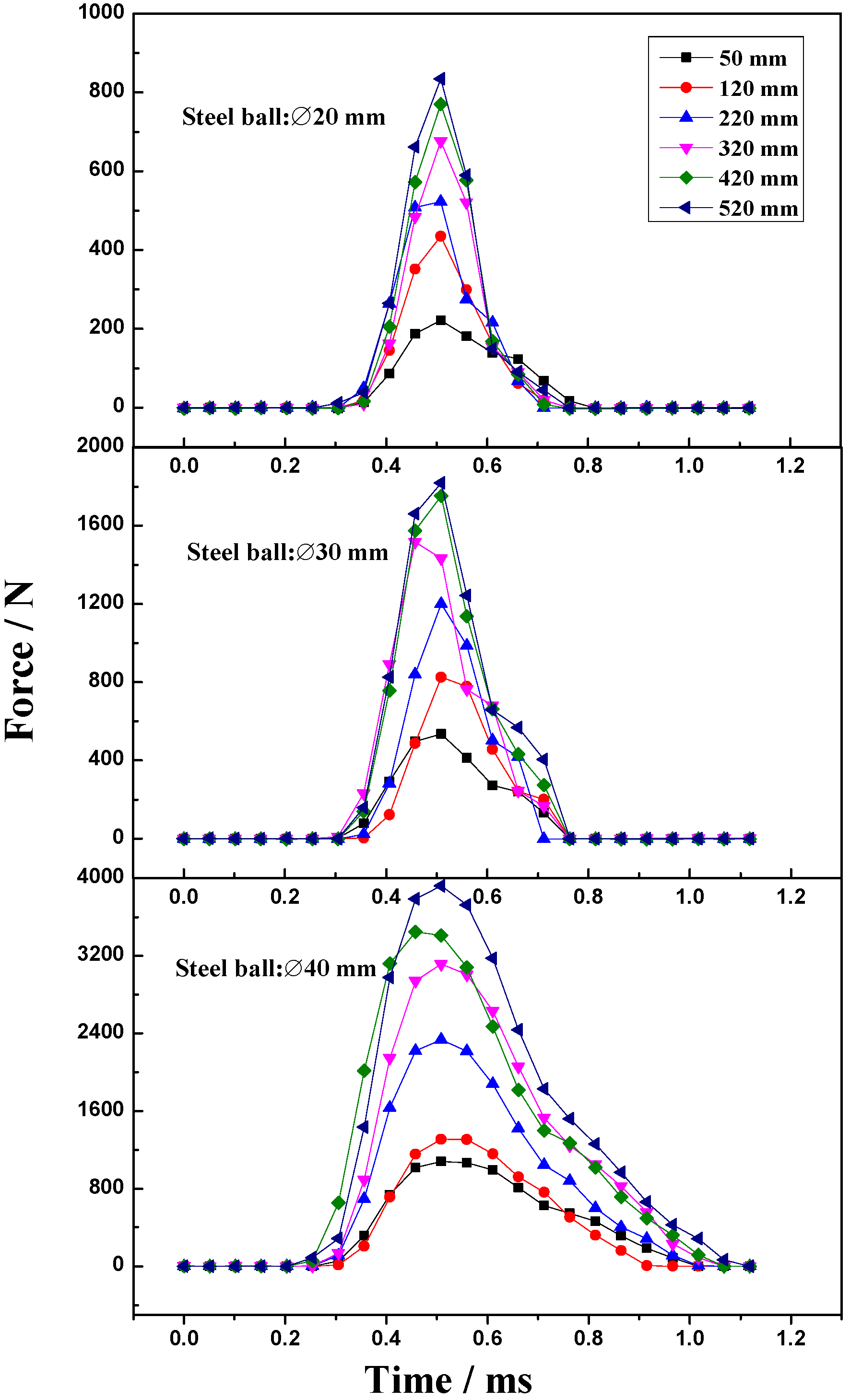

4.1. Effect of Steel Ball Size and Drop Height on Impact Force

4.2. Effect of Mill Speed on Impact Load Behavior

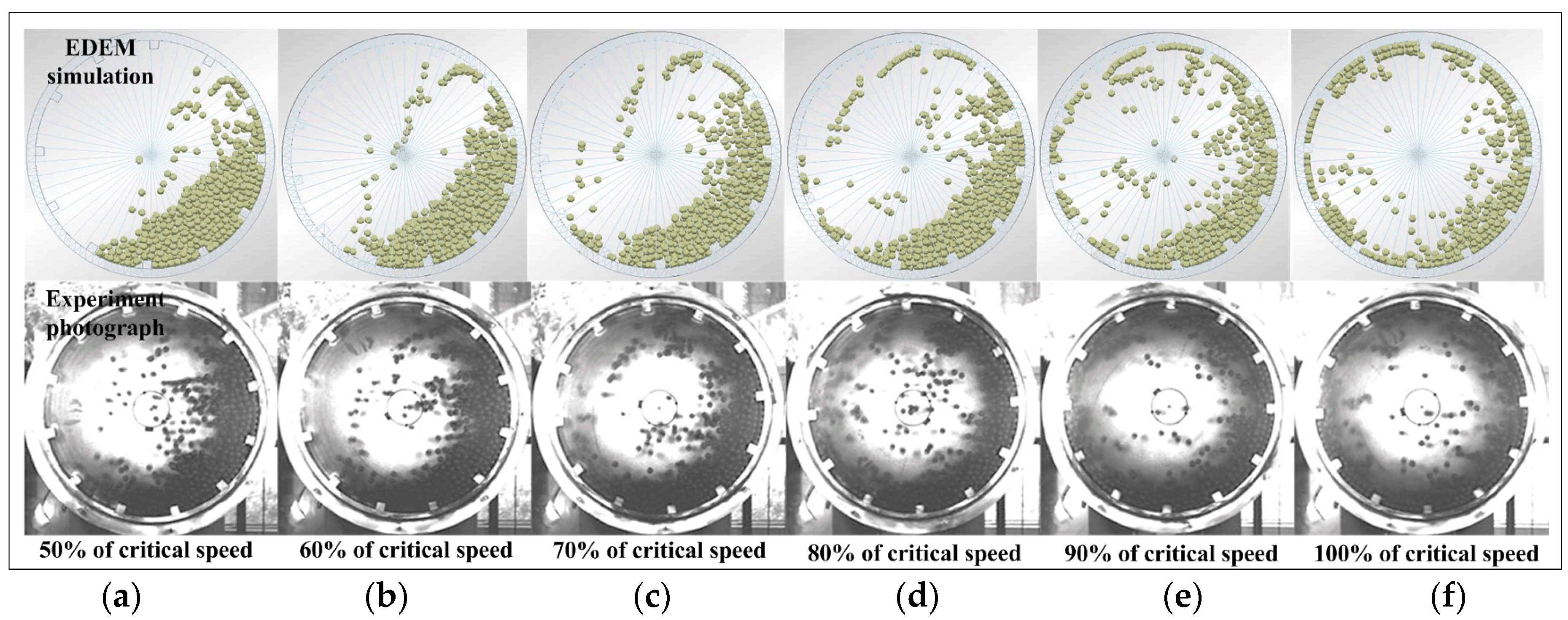

4.2.1. Steel Ball Trajectories of DEM Simulations and Experiments

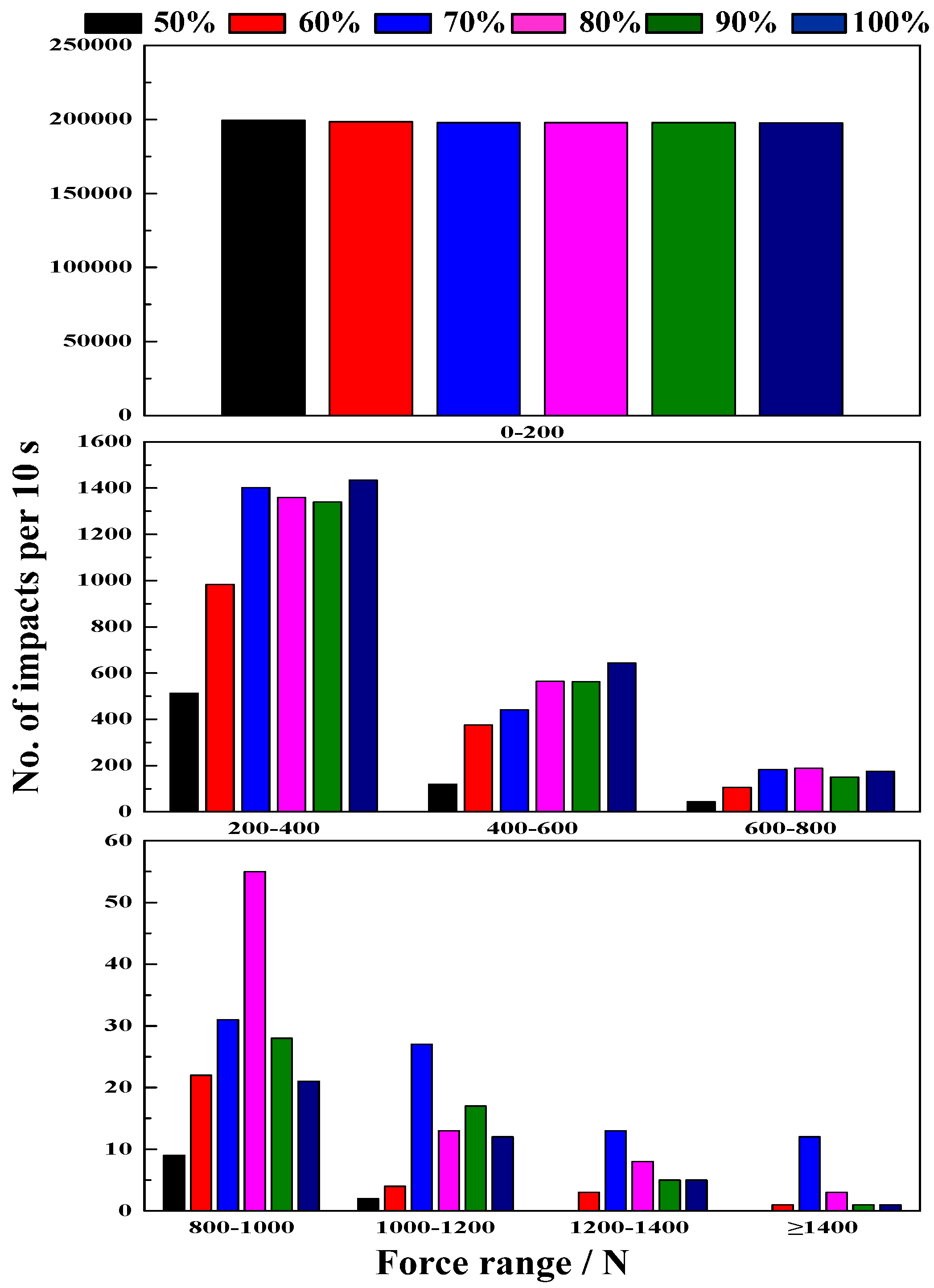

4.2.2. Effect of Mill Speed on Impact Force

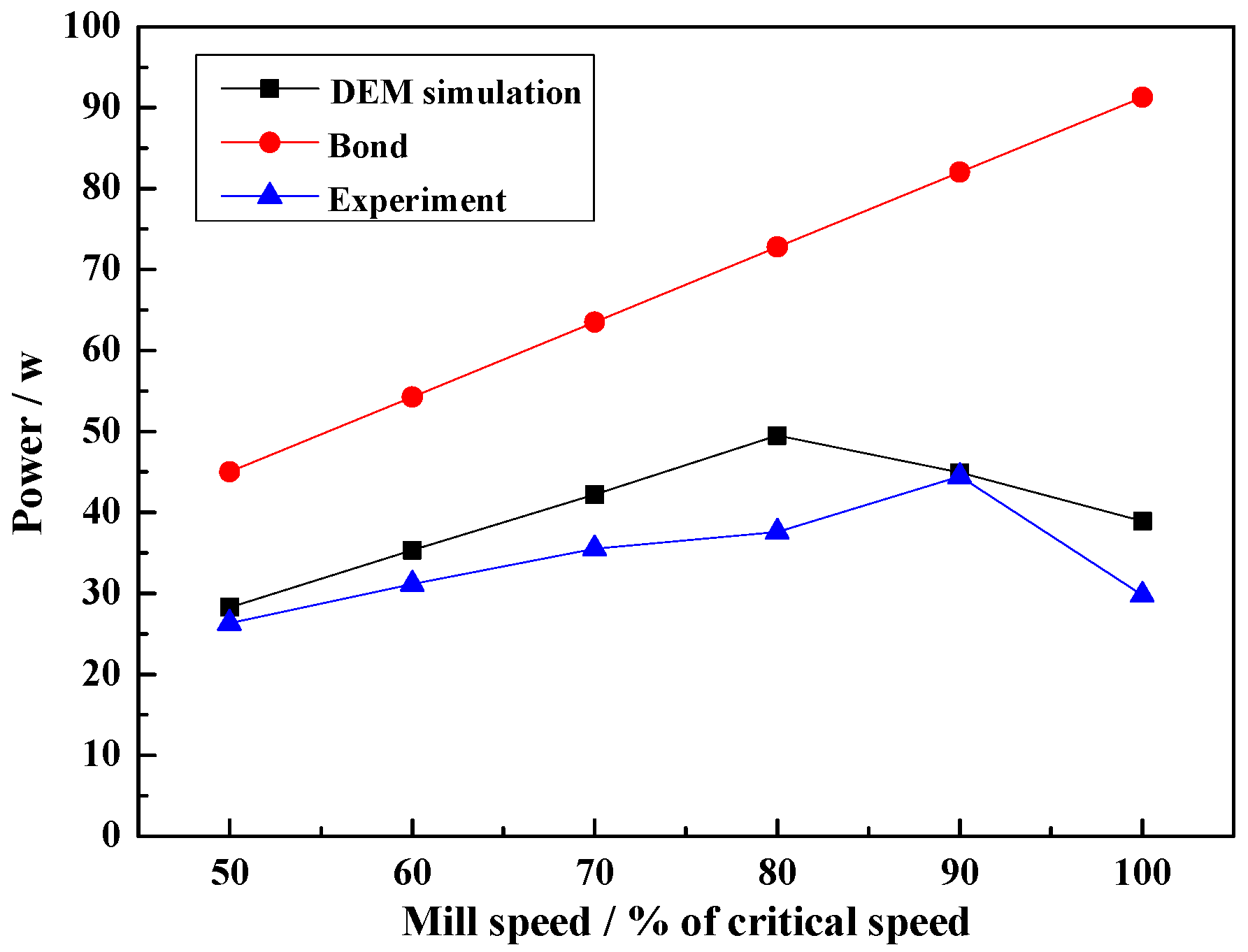

4.2.3. Effect of Mill Speed on Power Draw

4.3. Effect of Grinding Media Filling on Impact Load Behavior

4.3.1. Steel Ball Trajectories of DEM Simulation

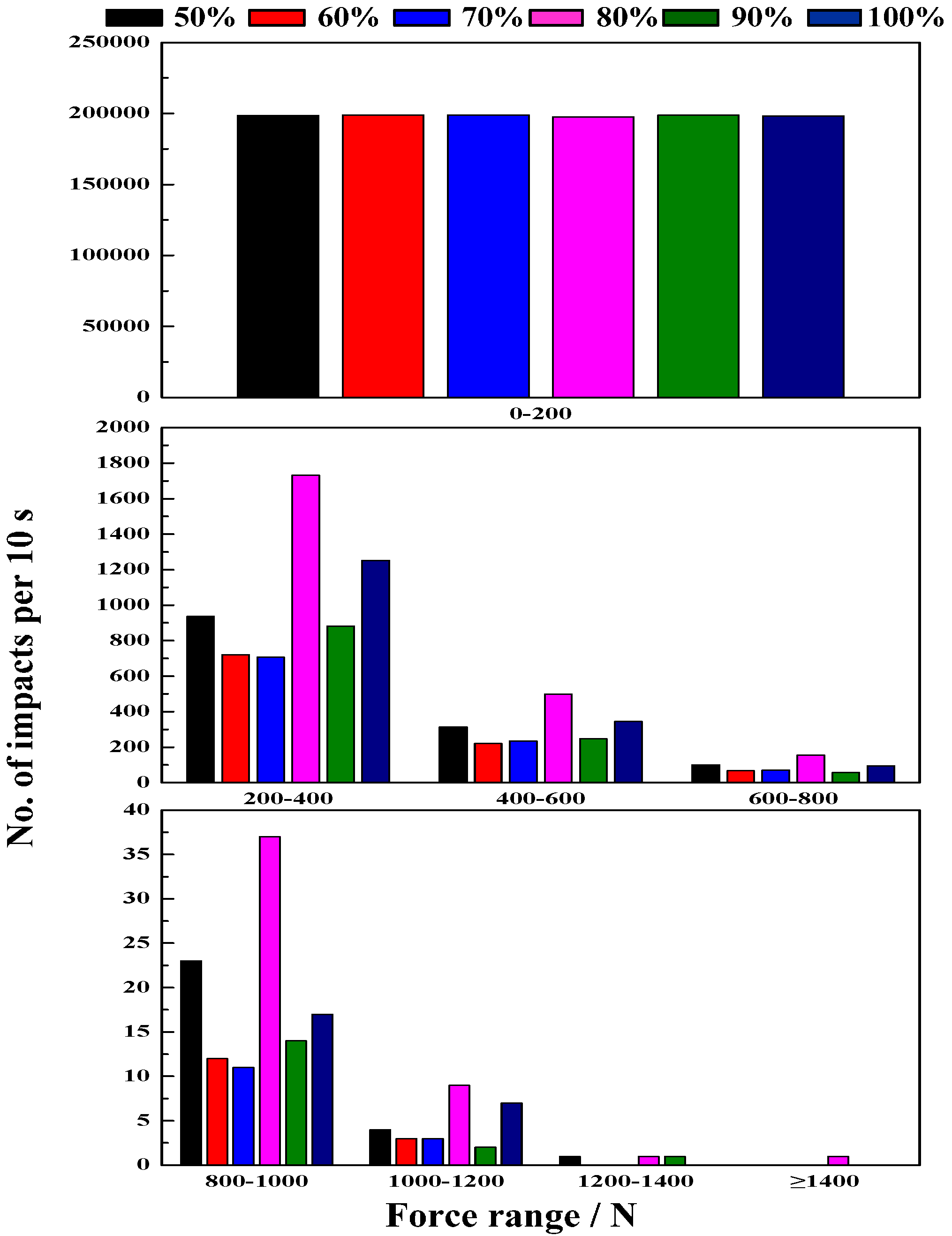

4.3.2. Effect of Grinding Media Filling on Impact Force

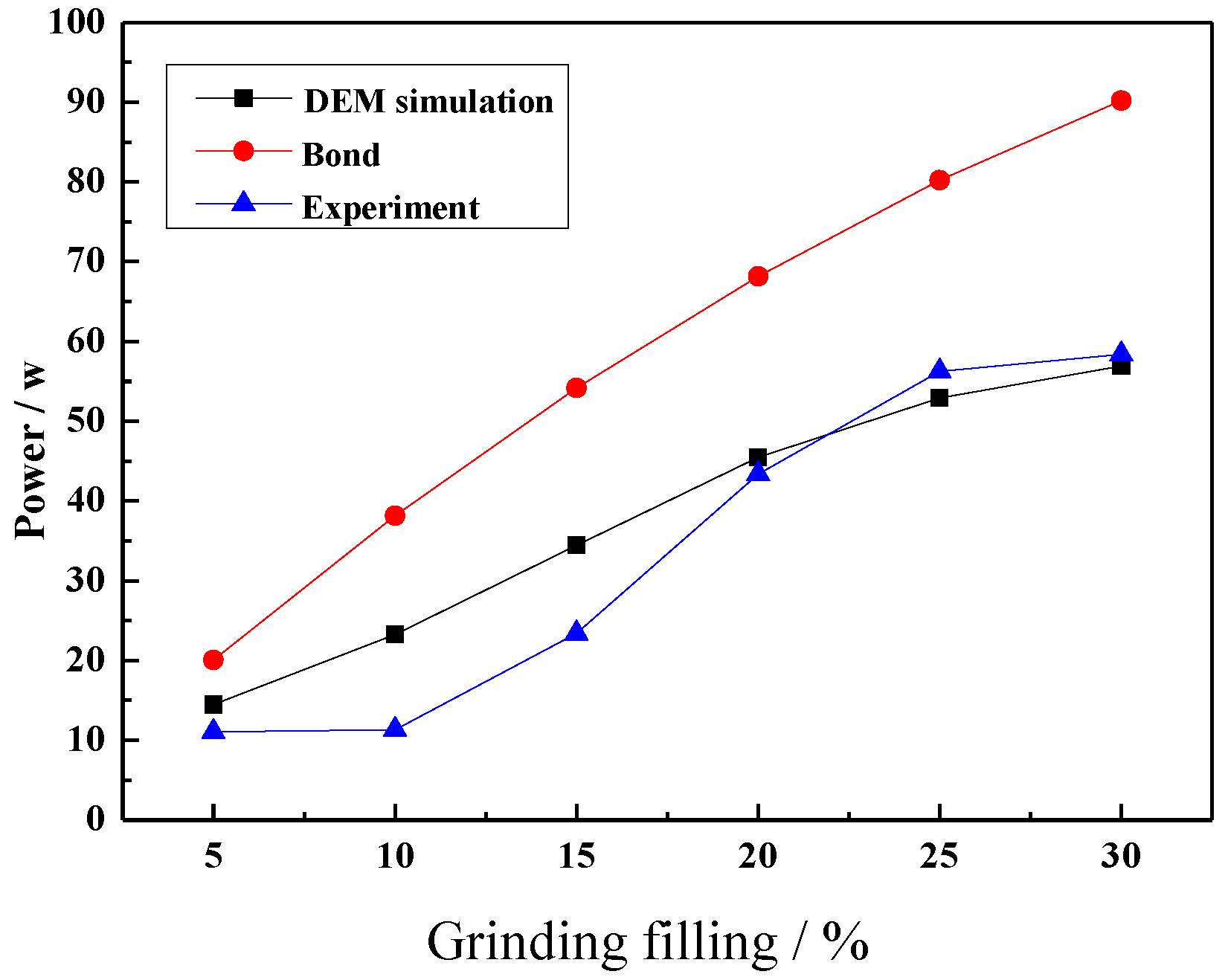

4.3.3. Effect of Grinding Media Filling on Power Draw

4.4. Effect of Lifter Height on Impact Load Behavior

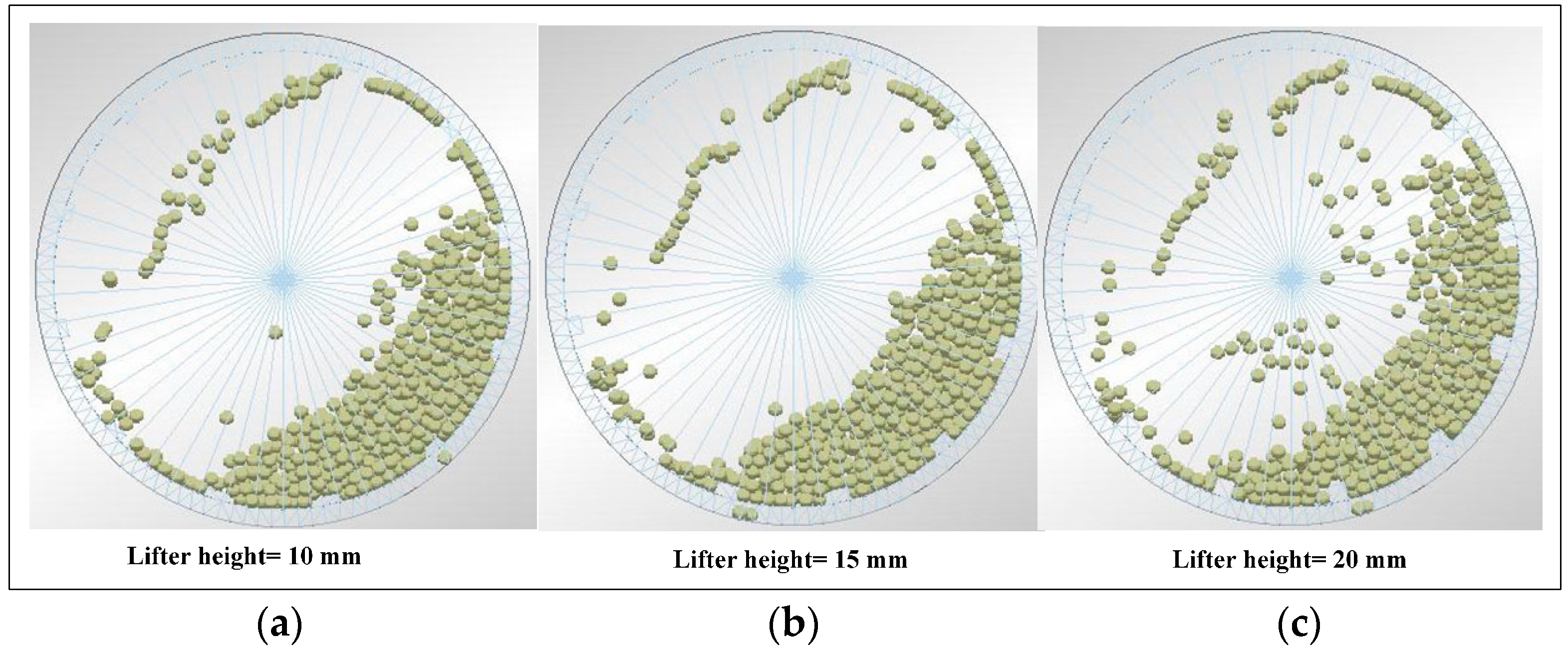

4.4.1. Steel Ball Trajectories of DEM Simulation

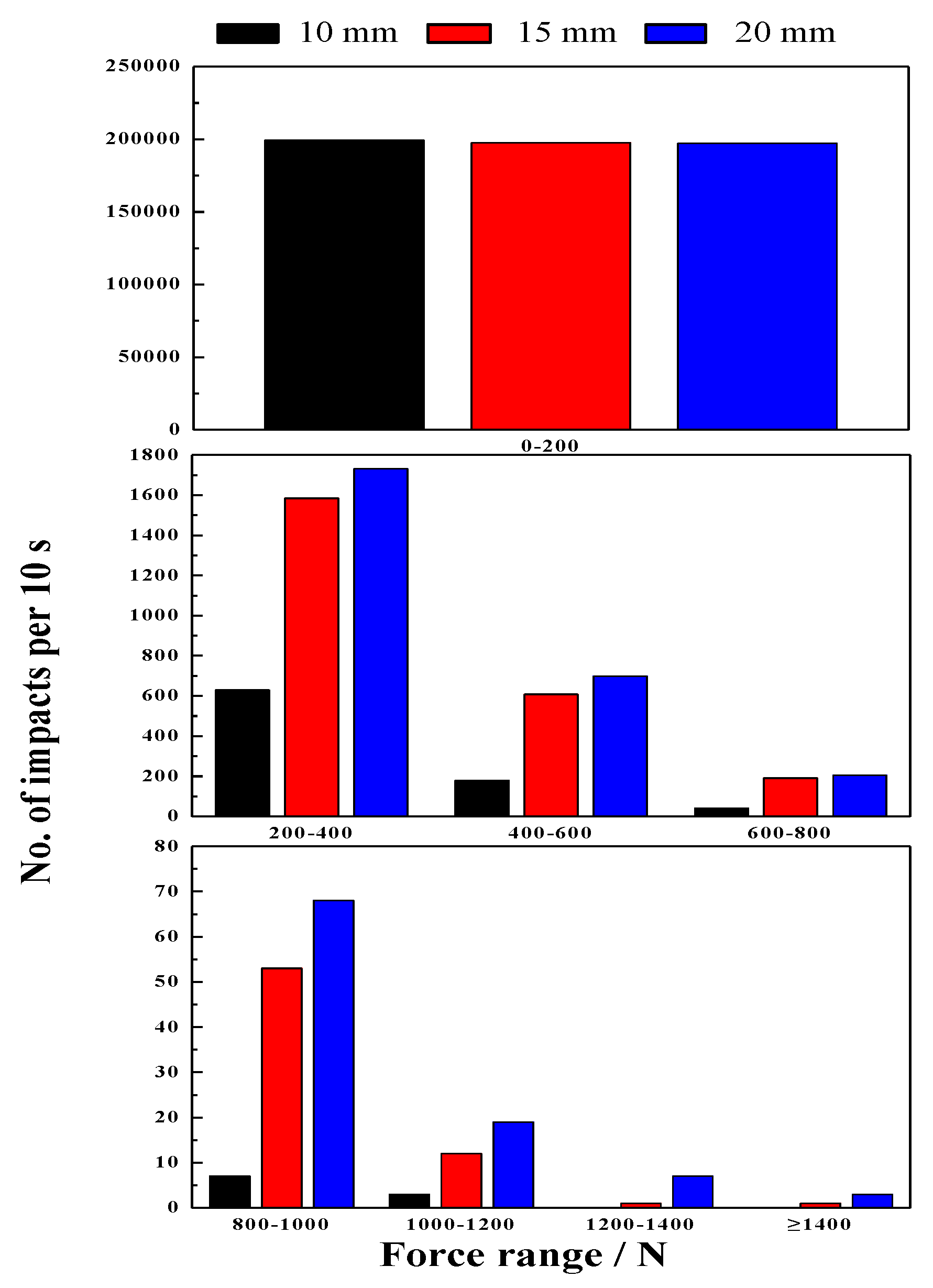

4.4.2. Effect of Lifter Height on Impact Force

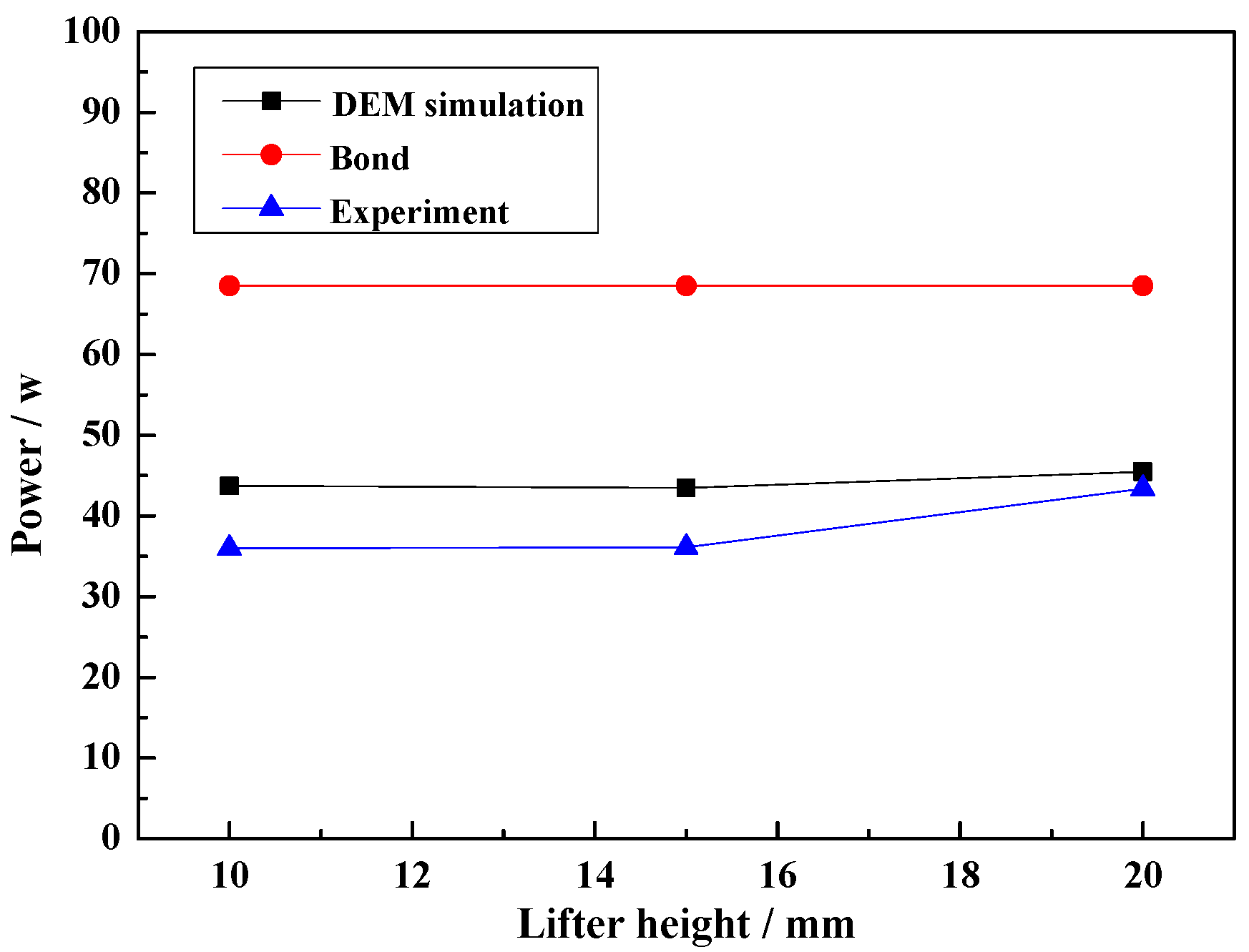

4.4.3. Effect of Lifter Height on Power Draw

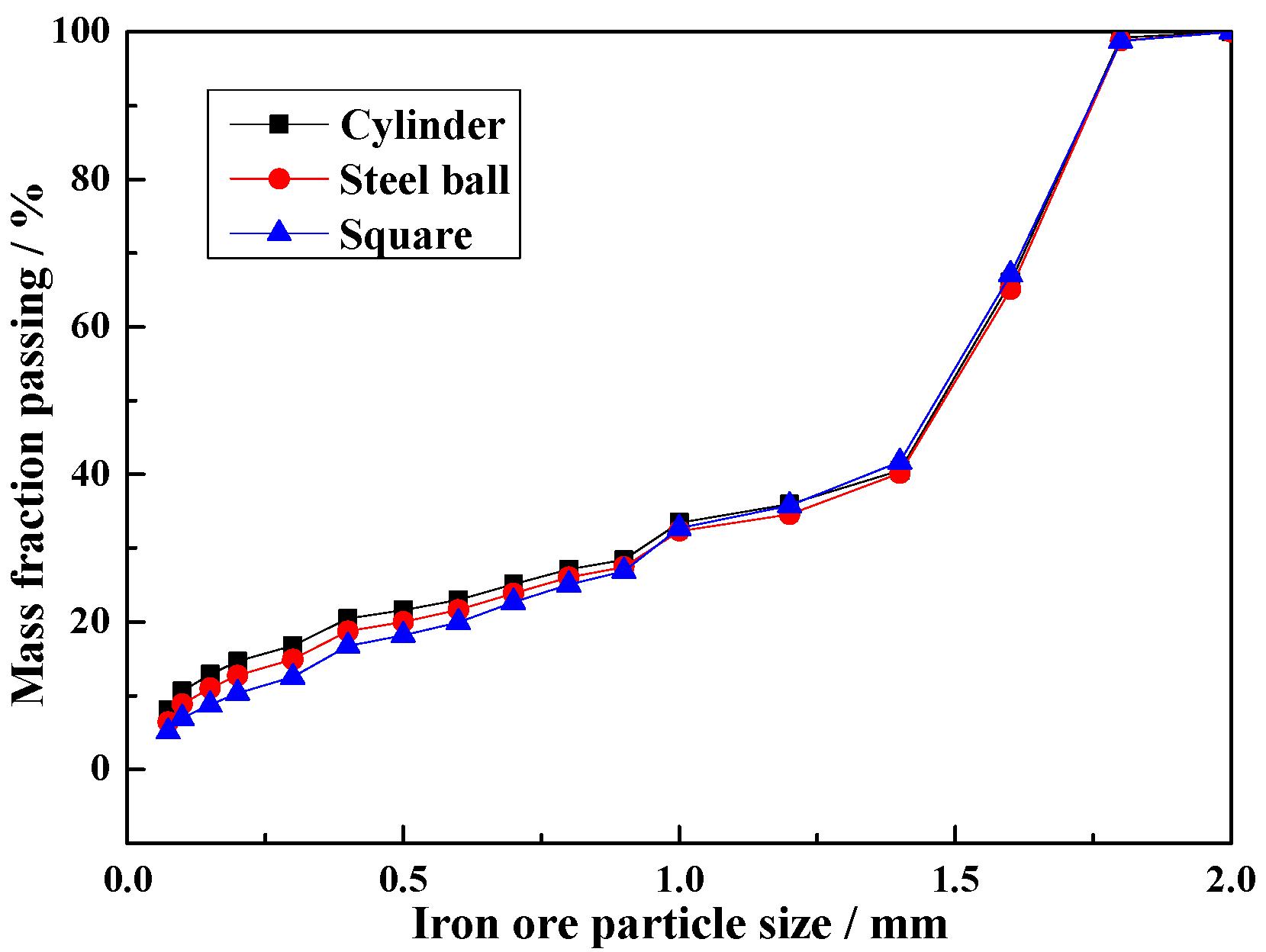

4.5. Effect of Media-Shape on Impact Load Behavior

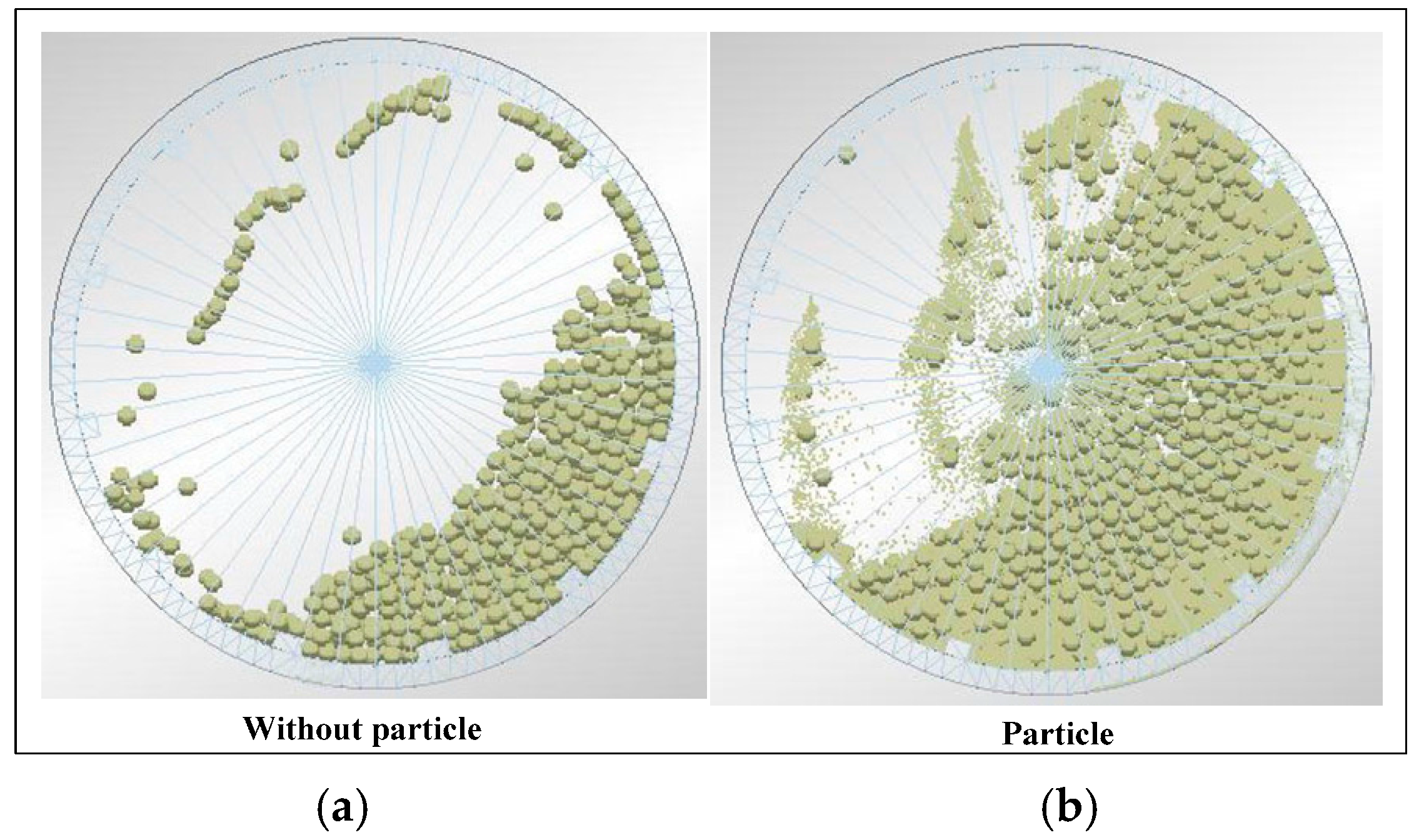

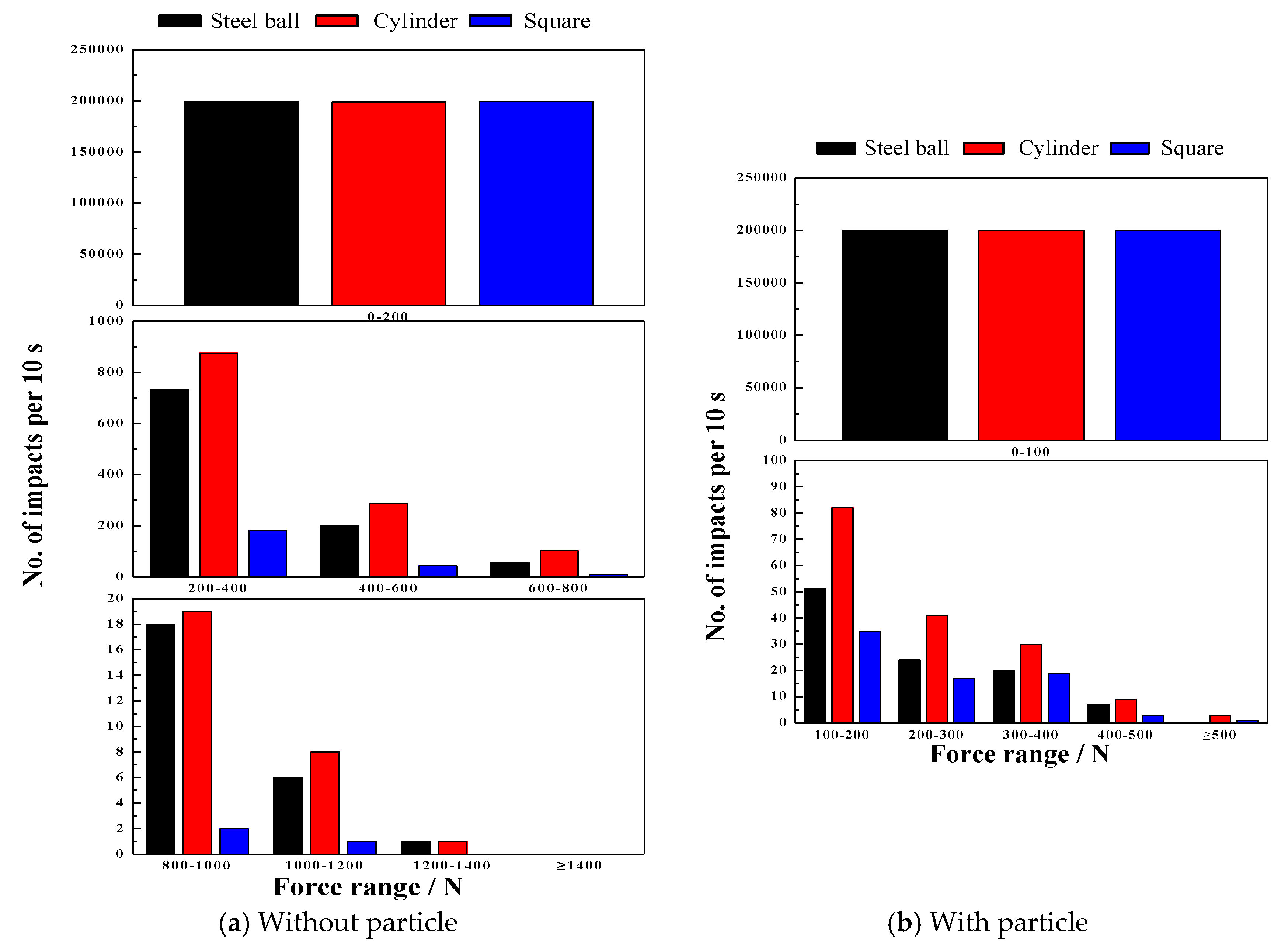

4.5.1. Effect of Particle on Load Behavior

4.5.2. Effect of Particle on Impact Force

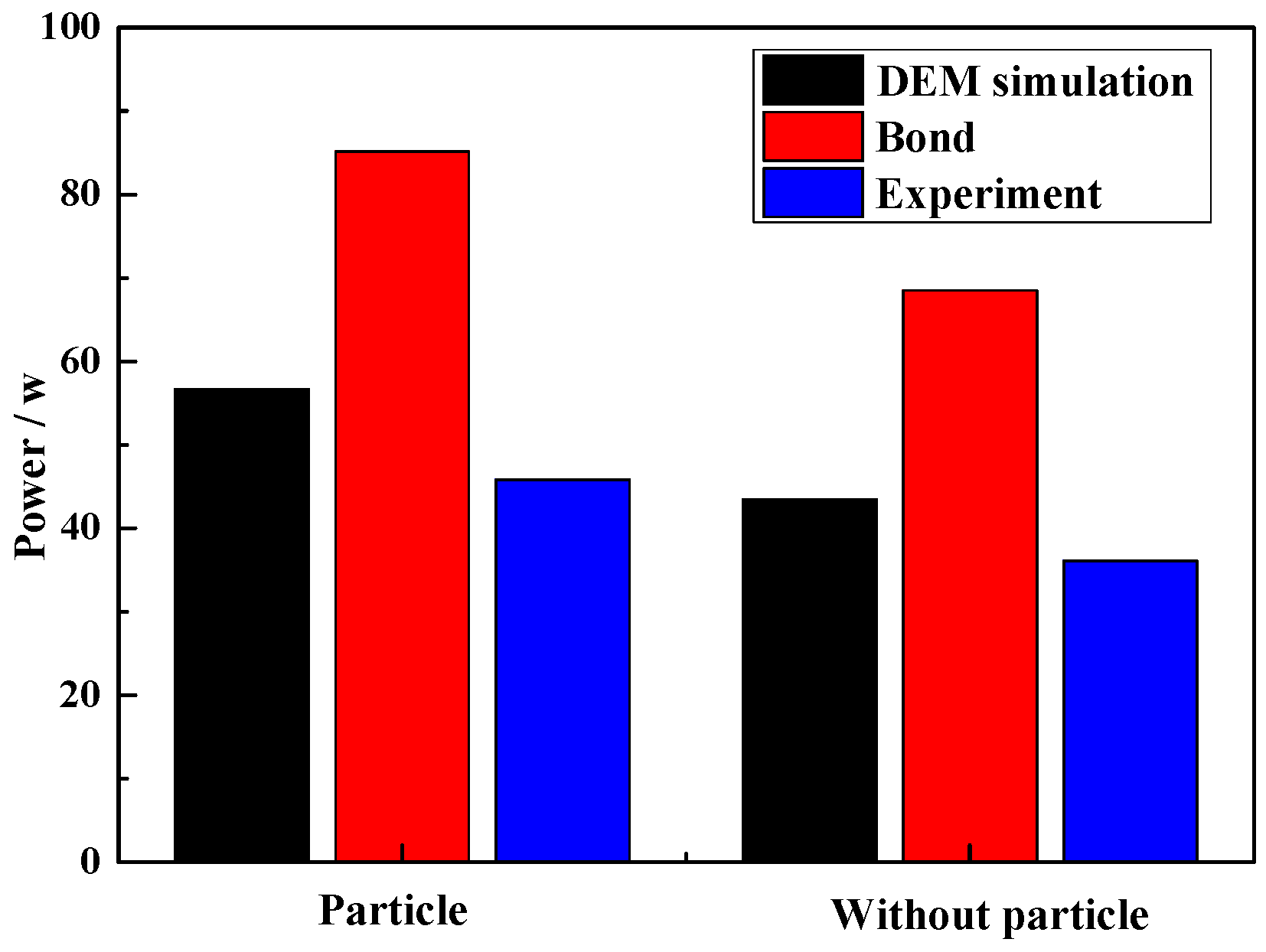

4.5.3. Effect of Particle on Power Draw

5. Conclusions

- The magnitude of impact force has strong sensitive to ball size and drop height. The impact force increases with the increase of ball size and drop height.

- Mill speed has profound effect on the ball trajectories, impact force and power draw. The mill can reach the best performance at the mill speed ranging from 70% to 80% of critical speed, and correspondingly the maximum percent of the impact force between 600 and 1400 N is obtained. For the 80% of critical speed, the measured power draw has a maximum value.

- Commonly, increasing the grinding media filling not only increases the fraction flying in the cataracting zone but also increases the rate of ball on ball contact per unit. In this research, it is interesting to find that increasing the grinding media filling does not the number of ball on ball contact. The impact force can be only above 1400 N at the grinding media filling of 20%, and the maximum percent of impact force between 200 and 1400 N is obtained at the grinding media filling of 20%. Besides, increasing the grinding media filling increases the power draw.

- Lifter height has a significantly influence on the load behavior. Increasing the lifter height increases the shoulder position and lifts the steel balls to the higher position,. The percent of impact force ranging from 0 to 200 N decreases with the increase of lifter height. However, this perfect will increase above 200 N. In general, increasing the lifter height does not lead to any variation in power draw.

- The impact force will decrease and the power draw will increase when the iron ore particles are added. The mass fraction passing of cylinder is greater than that of ball and square. The percent of −0.074 mm particle is 8.08% (cylinder), 6.42% (ball) and 5.14% (square), respectively.

- The semi-empirical power draw of Bond model in this paper does not apply very satisfactorily for the ball mills, while the power draw determined by DEM simulation show a good approximation for the measured power draw.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Huang, P.; Jia, M.P.; Zhong, B.L. Study on the method for Collecting vibration signals from mill shell based on measuring the fill level of ball mill. Math. Probl. Eng. 2014, 11, 1–10. [Google Scholar] [CrossRef]

- Si, G.Q.; Cao, H.; Zhang, Y.B.; Li, J. Experimental investigation of load behaviour of an industrial scale tumbling mill using noise and vibration signature techniques. Miner. Eng. 2009, 22, 1289–1298. [Google Scholar] [CrossRef]

- Delaney, G.W.; Cleary, P.W.; Morrison, R.D.; Cummins, S.; Loveday, B. Predicting breakage and the evolution of rock size and shape distributions in AG and SAG mills using DEM. Miner. Eng. 2013, 50, 132–139. [Google Scholar] [CrossRef]

- Li, T.Q.; Peng, Y.X.; Zhu, Z.C.; Zou, S.Y.; Liu, S.Y.; Yin, Z.X.; Ni, X.; Chang, X.D. Multi-layer kinematics and collision energy in a large-scale grinding mill-the largest semi-autogenous grinding mill in china. Adv. Mech. Eng. 2016, 8, 1–10. [Google Scholar] [CrossRef]

- Chen, B.C. Grinding Theory; Metall. Ind. Press: Beijing, China, 1989. [Google Scholar]

- Tian, Q.J. Study on the Working Performances of Large Tumbling Ball Mill Based on the Discrete Element Method. Master’s Thesis, Jilin University, Jilin, China, 2011. [Google Scholar]

- Powell, M.S.; Nurick, G.N. A study of charge motion in rotary mills part 2-experimental work. Miner. Eng. 1996, 9, 343–350. [Google Scholar] [CrossRef]

- Zeng, Y.G.; Forssberg, E. Effects of operating parameters on vibration signal under laboratory scale grinding conditions. Int. J. Miner. Process. 1992, 35, 273–290. [Google Scholar] [CrossRef]

- Behera, B.; Mishra, B.K.; Murty, C.V.R. Experimental analysis of charge dynamics in tumbling mills by vibration signature technique. Miner. Eng. 2007, 20, 84–91. [Google Scholar] [CrossRef]

- Tang, J.; Zhao, L.J.; Yue, H.; Yu, W.; Chai, T.Y. Vibration analysis based on empirical mode decomposition and partial least square. Procedia Eng. 2011, 16, 646–652. [Google Scholar] [CrossRef]

- Pax, R.A. Non-Contact Acoustic Measurement of in-Mill Variables of SAG Mills. In Proceedings of the International Conference on Autogenous and Semi-Autogenous Grinding Technology; University of British Columbia: Vancouver, BC, Canada, 2001. [Google Scholar]

- Tano, K.T.; Pålsson, B.I.; Sellgren, A. Online lifter deflection measurements showing flow resistance effects in grinding mills. Miner. Eng. 2005, 18, 1077–1085. [Google Scholar] [CrossRef]

- Moys, M.H.; Skorupa, J. Measurement of the radial and tangential forces exerted by the load on a liner in a ball mill as a function of load volume and mill speed. Int. J. Miner. Process. 1993, 37, 239–256. [Google Scholar] [CrossRef]

- Moys, M.H. The measurements of parameters describing the dynamic behaviour of the load in a grinding mill. Int. Conf. Miner. Sci. Technol. 1984, 1, 205–219. [Google Scholar]

- Kiangi, K.K.; Moys, M.H. Measurement of load behaviour in a dry pilot mill using an inductive proximity probe. Miner. Eng. 2006, 19, 1348–1356. [Google Scholar] [CrossRef]

- Deniz, V. The effects of ball filling and ball diameter on kinetic breakage parameters of barite powder. Adv. Powder Technol. 2012, 23, 640–646. [Google Scholar] [CrossRef]

- Kiangi, K.K.; Moys, M.H. Particle filling and size effects on the ball load behaviour and power in a dry pilot mill: Experimental study. Powder Technol. 2008, 187, 79–87. [Google Scholar] [CrossRef]

- Deniz, V.; Onur, T. Investigation of the breakage kinetics of pumice samples as dependent on powder filling in a ball mill. Int. J. Miner. Process. 2002, 67, 71–78. [Google Scholar] [CrossRef]

- Schnatz, R. Optimization of continuous ball mills used for finish-grinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time. Int. J. Miner. Process. 2004, 74, S55–S63. [Google Scholar] [CrossRef]

- Kiangi, K.K. Effect of Particle Filling and Size on the Behaviour of the Ball Load and Power in a Dry Mill. Ph.D. Thesis, Faculty of Engineering and the Built Environment, University of the Witwatersrand, Johannesburg, South Africa, 2011. [Google Scholar]

- Rezaeizadeh, M.; Fooladi, M.; Powell, M.S.; Mansouri, S.H. Experimental observations of lifter parameters and mill operation on power draw and liner impact loading. Miner. Eng. 2010, 23, 1182–1191. [Google Scholar] [CrossRef]

- Rajamani, R.; Delgadillo, J.; Duriseti, V. Online SAG Mill Pulse Measurement and Optimization Semi-Annual Technical Progress Report; The University Of Utah: Salt Lake City, UT, USA, 2006. [Google Scholar]

- Cleary, P.W. Charge behaviour and power consumption in ball mills: Sensitivity to mill operating conditions, liner geometry and charge composition. Int. J. Miner. Process. 2001, 63, 79–114. [Google Scholar] [CrossRef]

- Hlungwani, O.; Rikhotso, J.; Dong, H.; Moys, H. Further validation of DEM modeling of milling: Effects of liner profile and mill speed. Miner. Eng. 2003, 16, 993–998. [Google Scholar] [CrossRef]

- Djordjevic, N.; Shi, F.N.; Morrison, R. Determination of lifter design, speed and filling effects in AG mills by 3D DEM. Miner. Eng. 2004, 17, 1135–1142. [Google Scholar] [CrossRef]

- Moys, M.H.; Smit, I. The effect of discharge arrangement, load volume, slurry rheology and mill speed on power and slurry hold-up in rotary mills. Chem. Technol.-Bedfordview 1998, 27–31. [Google Scholar]

- Mulenga, F.K.; Moys, M.H. Effects of slurry filling and mill speed on the net power draw of a tumbling ball mill. Miner. Eng. 2014, 56, 45–56. [Google Scholar] [CrossRef]

- Owen, P.; Cleary, P.W. The relationship between charge shape characteristics and fill level and lifter height for a SAG mill. Miner. Eng. 2015, 83, 19–32. [Google Scholar] [CrossRef]

- Deniz, V. The effect of mill speed on kinetic breakage parameters of clinker and limestone. Cem. Concr. Res. 2004, 34, 1365–1371. [Google Scholar] [CrossRef]

- Deniz, V. Effects of mill speed on kinetic breakage parameters of four different particulate pumices. Part. Sci. Technol. 2013, 31, 101–108. [Google Scholar] [CrossRef]

- Huang, H.; Dallimore, M.P.; Pan, J.; McCormick, P.G. An investigation of the effect of powder on the impact characteristics between a ball and a plate using free falling experiments. Mater. Sci. Eng. A 1998, 241, 38–47. [Google Scholar] [CrossRef]

- Dong, H.; Moys, M.H. Measurement of impact behaviour between balls and walls in grinding mills. Miner. Eng. 2003, 16, 543–550. [Google Scholar] [CrossRef]

- Xu, G.H.; Liu, Y.J.; Shen, W.C. A method of measuring the impact stresses in ball mills. Phys. Exam. Test. 1995, 1, 23–26. [Google Scholar]

- Xu, G.H.; Shen, W.C.; Liu, Y.J. Measurement and calculation of impact stress of ball mill. J. Tsinghua Univ. (Sci. Tech.) 1996, 36, 87–92. [Google Scholar]

- Xu, G.H.; Liu, Y.J.; Shen, W.C.; Fang, H.S. Impact and breakage simulation experiment of ball mill. Min. Process. Equip. 1994, 2, 18–22. [Google Scholar]

- Wu, Q.; Bai, Y.; Zhang, J.G. Characteristic analysis on process of grinding ball impacting charge in ball mill. Min. Process. Equip. 2014, 42, 68–72. [Google Scholar]

- Katubilwa, F.M. Effects of Pool Volume on Wet Milling Efficiency. Ph.D. Dissertation, Faculty of Engineering and the Built Environment, University of the Witwatersrand, Johannesburg, South Africa, 2012. [Google Scholar]

- Mohsen, Y. Analysis of Liner Wear Impact on Charge Behaviour in AG and SAG Mills. Ph.D. Thesis, Faculty of Engineering, Shahid Bahonar University of Kerman, Kerman, Iran, 2010. [Google Scholar]

- Bond, F.C. Crushing and grinding calculations. Can. Min. Metall. Bull. 1961, 47, 466–472. [Google Scholar]

- Koleini, S.M.J.; Barani, K.; Rezaei, B. The effect of microwave treatment on dry grinding kinetics of iron ore. Miner. Process. Extr. Metall. Rev. 2012, 33, 159–169. [Google Scholar] [CrossRef]

| Test | Mill Speed/of Critical Speed | Filling Level | Lifter Height (mm) | Media-Shape | Particle |

|---|---|---|---|---|---|

| 4.2 | 50%, 60%, 70%, 80%, 90%, 100% | 20% | 20 | Steel ball | None |

| 4.3 | 75% | 5%, 10%, 15%, 20%, 25%, 30% | 20 | Steel ball | None |

| 4.4 | 75% | 20% | 10, 15, 20 | Steel ball | None |

| 4.5 | 75% | 20% | 15 | Steel ball, Square, Cylinder | None |

| 4.5 | 75% | 20% | 15 | Steel ball, Square, Cylinder | Yes |

| Materials | Size (L = Length; W = Width; H = Height) | ||

|---|---|---|---|

| Grinding media | Steel ball (∅15 mm) | Square (L: 12 × W: 12 × H: 12 mm) | Cylinder (∅12 × H: 16 mm) |

| Iron ore particle | 2–2.8 mm | ||

| Lifter | L: 40 × W: 20 × H: 10 mm | L: 40 × W: 20 × H: 15 mm | L: 40 × W: 20 × H: 20 mm |

| Material Parameters | Value |

|---|---|

| Iron ore particle density (kg/m3) | 3886 |

| Iron ore particle shear modulus (Pa) | 2.59 × 109 |

| Iron ore particle Poisson’s ratio | 0.28 |

| Shell density (kg/m3) | 7800 |

| Shell shear modulus (Pa) | 7 × 1010 |

| Shell Poisson’s ratio | 0.3 |

| Particle-shell restitution coefficient | 0.32 |

| Particle-shell static friction coefficient | 0.48 |

| Particle-shell rolling friction coefficient | 0.2 |

| Particle-Particle restitution coefficient | 0.49 |

| Particle-Particle static friction coefficient | 0.48 |

| Particle-Particle rolling friction coefficient | 0.16 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Z.; Peng, Y.; Zhu, Z.; Yu, Z.; Li, T. Impact Load Behavior between Different Charge and Lifter in a Laboratory-Scale Mill. Materials 2017, 10, 882. https://doi.org/10.3390/ma10080882

Yin Z, Peng Y, Zhu Z, Yu Z, Li T. Impact Load Behavior between Different Charge and Lifter in a Laboratory-Scale Mill. Materials. 2017; 10(8):882. https://doi.org/10.3390/ma10080882

Chicago/Turabian StyleYin, Zixin, Yuxing Peng, Zhencai Zhu, Zhangfa Yu, and Tongqing Li. 2017. "Impact Load Behavior between Different Charge and Lifter in a Laboratory-Scale Mill" Materials 10, no. 8: 882. https://doi.org/10.3390/ma10080882