1. Introduction

The consumption of natural resources in the construction industry has been growing in the last decades, as well as the production of demolition, construction and rehabilitation works waste. This process of “construction-demolition” has exerted great pressure on natural resources, especially the natural aggregates (NA), and generated high levels of the so-called construction and demolition waste (CDW), often ending up in landfills. Both these aspects have a negative impact on the environment. Because of the present economic and environmental crisis, the demands for a more sustainable development in the construction sector require a different approach to the concrete technology.

The use of recycled aggregates (RA) to produce new concrete seems to be a potential solution. It could solve the problems related with storage, transportation and dumping of CDW and contribute to the sustainability of the environment by adding value to this waste and consequently limiting the consumption of NA.

On the other hand, since the capacity to satisfy the clients’ needs and the relationship performance-quality-cost are the main distinctive factors of a healthy competition in the construction sector, the study of self-compacting concrete (SCC) with RA must contribute to an approach between the technological development activities and the needs of both the construction industry and its final clients.

The presence of adhered mortar in RA is one of the main reasons for their loss of quality. Consequently, RA have lower density, greater water absorption and lower mechanical strength than the NA. These properties are the ones that most influence the performance of the SCC in which they are incorporated [

1].

It is very important to evaluate the SCC fresh-state properties, since it must have specific characteristics to be considered self-compacting, i.e., it must have the capacity to flow and compact under its own weight only, fill the moulds with all the reinforcement bars, piping, negatives, etc., maintaining its homogeneity, and without the need of any on site vibration means [

2].

Table 1 presents a summary of all studies analyzing the influence of the incorporation of RA (at an incorporation ratio of 100%) on the SCC fresh-state properties.

The fluidity of SCC was evaluated through the slumpflow diameter. In the studies analyzed, this parameter decreases for high coarse recycled aggregates (CRA) incorporation ratios, since they absorb more water than the coarse natural aggregates (CNA) [

3,

4]. Safiuddin et al. [

5], Tuyan et al. [

6] and Modani and Mohitkar [

7] found that the slump-flow diameter increases for limited CRA incorporation ratios (less than 20% to 60%).

The viscosity of SCC is evaluated through the V-funnel flow time. It was found that it increases for high CRA incorporation ratios because of their rougher surface and more angular shape relative to CNA. Safiuddin et al. [

5] and Modani and Mohitkar [

7] found that the V-funnel flow time decreases for limited CRA incorporation ratios (less than 20% to 40%).

In terms of the SCC’s passing ability through confined spaces evaluated through the L-box passing ability index (PL), it was found that the PL values increase with the RA incorporation ratio. This was justified by the lower water absorption of the FRA in the beginning of the mixing [

8], a higher W/C ratio [

3] or an increase of the Superplasticizer (S

p) content [

6].

In terms of the SCC’s segregation resistance evaluated through the segregation ratio (SR), three different trends occur. Kou and Poon [

8] found that the SR increased with the FRA incorporation ratio because of their higher water absorption capacity. On the other hand, Grdic et al. [

3] found that the SR decreased as the CRA incorporation ratio grew due to the increase of water absorption. Finally, Safiuddin et al. [

5] found that the SR increased for small replacement ratios of NA with RA (30% and 40%), but decreased for high ratios (70% and 100%), because the fines fraction increases when the CRA are fractured during the mixing process.

In terms of the SCC’s passing ability through confined spaces evaluated through the J-ring slump flow diameter, it was found that the slump-flow diameter increases for small CRA incorporation ratios (30% and 40%). For higher ratios (70% and 100%), the J-ring slump flow diameter decreases, because of the fracture into smaller particles of the CRA during the mixing process, leading to greater water absorption of the RA.

In the hardened state, it was found that the SCC’s bulk density at 28 days decreased around 3% for 100% CRA incorporation [

4] and the ultrasonic pulse velocity (UPV) through SCC decreased around 6% for 60% CRA incorporation [

6]. The reduction in these two properties (bulk density and UPV) was justified by the lower density of the RA relative to the NA.

Based on the works analysed,

Table 2 presents a summary of the influence of the incorporation of RA (for 100% ratio) on the hardened-state SCC’s properties.

As seen in

Table 2, the compressive strength and the flexural tensile strength decrease in most of the studies as the RA incorporation ratio increases because of their lower mechanical strength relative to the NA.

The incorporation of CRA reduces the modulus of elasticity [

4]. The decrease is approximately 5% for 100% incorporation. This was justified by the lower stiffness of the CRA (relative to the CNA), given the presence of old mortar adhered to the original NA and the lower deformability of this mortar.

Shrinkage increases with the FRA incorporation ratio [

8]. This was explained by the greater porosity of the FRA and consequent lower density (because of the hardened mortar contained in the FRA), which decrease their stiffness and capacity to restrict deformation.

Table 3 presents a summary of the results of the studies analysed on the influence of the incorporation of RA (for a ratio of 100%) on the durability properties of SCC.

Modani and Mohitkar [

7] found that the SCC’s capillary water absorption increased with the W/C ratio and decreased as the CRA incorporation ratio grew, similarly to the water absorption by immersion [

3]. This was justified by the greater water absorption of the CRA.

On the other hand, Pereira-de-Oliveira et al. [

4] found that the capillary water absorption decreases as the replacement of CNA with CRA increased. This was justified by the high volume of cement paste that constitutes the SCC, involves the CRA and penetrates their pore structure.

The chloride migration decreases as the FRA content grows, which was explained by the greater pores filling effect caused by the FRA, since they have a higher content of small particles than river sand [

8]. On the other hand, the chloride migration increased with the CRA incorporation ratio [

6,

7]. This was justified by the greater porosity of the CRA relative to the CNA (because of the hardened mortar part of the RA).

2. Experimental Program

2.1. Materials

The following materials were used:

One type of cement complying with NP EN 197-1 [

9], cement type CEM I 42.5 R with a density of 3140 kg/m

3, whose chemical composition is provided in

Table 4;

In order to reduce the amount of cement in the mix, two mineral additions were used: fly ash (FA) complying with NP EN 450-1 [

10] and NP EN 450-2 [

11] with a density of 2300 kg/m

3, and limestone filler (LF) complying with specification LNEC-E466 [

12] with a density of 2720 kg/m

3, whose chemical composition is given in

Table 4;

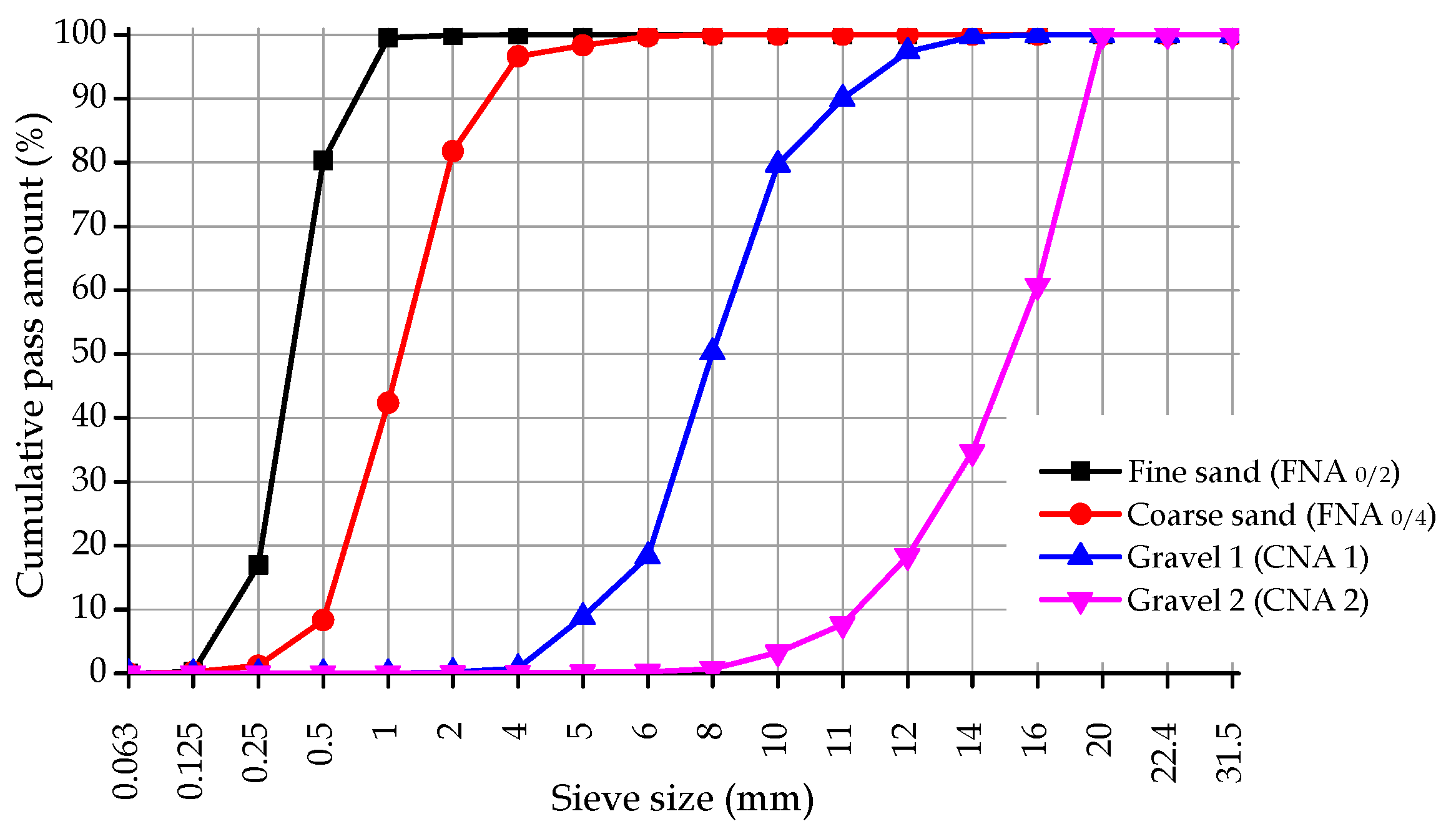

Two limestone coarse aggregates complying with NP EN 12620 [

13], gravel 1 with a density of 2640 kg/m

3, D

max of 11 mm and water absorption of 1.60%, and gravel 2 with a density of 2690 kg/m

3, D

max of 20 mm and water absorption of 0.80% (particle size distribution in

Figure 1);

Two siliceous sands complying with NP EN 12620 [

13], one coarse (0/4) with a density of 2670 kg/m

3 and water absorption of 0.40% and one fine (0/2) with a density of 2670 kg/m

3 and water absorption of 0.40% (particle size distribution in

Figure 1);

The RA came from crushed precast concrete elements of strength classes 45 and 65 MPa, designed to support very long beams: one coarse CRA 65 with a density of 2490 kg/m3 and 2.20% water absorption; one coarse CRA 45 with a density of 2600 kg/m3 and water absorption of 1.80%, one fine FRA 65 with a density of 2450 kg/m3 and water absorption of 7.50% and one fine FRA 45 with a density of 2560 kg/m3 and 5.00% water absorption;

A third-generation high-range/strong water-reducing admixture (Sp) complying with NP EN 934-1 [

14] and NP EN 934-2 [

15] (a modified polycarboxylic high-range water-reducing admixture in liquid form with a density of 1070 kg/m

3);

Tap water complying with NP EN 1008 [

16].

The RA were separated according to their size by mechanical sieving, and all fractions were used so the particle size distribution of the NA and RA was the same. Despite this, the grading curves of the NA and RA were different, and therefore, it was necessary to adjust the latter to match the former to achieve a similar fineness modulus. To accomplish this, it was necessary to separate the RA according to their different particle sizes. Although this type of procedure is difficult for practical application, it enables comparisons between mix compositions with the same particle size distribution, even though the replacement ratios differ.

2.2. Mix Proportions

To cover all the content alternatives used in the mixes and the corresponding analysis of the RA influence, 10 SCC mixes were produced according to NP EN 206-9 [

17]. The mix proportions and basic fresh-state properties of the SCC produced are shown in

Table 5.

A preliminary stage of mortar study was carried out, which allowed determining the composition of the various mixes by adjusting the W/C ratio and the superplasticizer content, before adding the coarse aggregate (natural and/or recycled) in order to evaluate, at this stage, the workability parameters.

A value for the ratio, in absolute volume, between the total amounts of fine material (cement and additions) and fine aggregates in the mixes (V

p/V

s) was set. According to the results obtained by Silva et al. [

18], the value V

p/V

s = 0.80 was considered.

The percentage of cement replacement by additions (fad) was determined taking the target strength into account. For 65 MPa mortars, the value of fad is necessarily lower than the one assumed for 45 MPa mortars, since mixes with higher strengths require higher percentage of cement in their formulation.

All studied mortar and concrete mixes contemplated the introduction of LF and FA in ternary mixes; for 45 MPa mortars, a 60% value of fad was considered, corresponding 50% to FA and 10% to LF, and 35% value of fad for 65 MPa mortars, corresponding 30% to FA and 5% to LF.

The V

w/V

p (ratio between the water and fine material contents, in absolute volume) and S

p/p% (percentage ratio between the superplasticizer and fine material contents, in weight) values vary according to the need of water and S

p of each mix. Since the objective was to maintain the workability constant while maintaining the volume of fine material in each family of self-compacting mortar (45 MPa and 65 MPa) constant, a starting pair of hypothetical values for V

w/V

p and S

p/p% was considered (V

w/V

p = 0.80 and S

p/p% = 0.65 for 65 MPa mortars and V

w/V

p = 0.85 and S

p/p% = 0.50 for 45 MPa mortars) and gradually adapted to the target workability parameters in an iterative process. These parameters were chosen while taking into account several works on SCC using the Nepomuceno et al. [

19] method, which presented satisfactory results [

2,

18,

20,

21,

22], and adjusted afterwards.

The adjustments were only made for the reference mortar (100% NA). Once the proper self-compacting mortar workability was reached, all the method parameters (V

p/V

s, f

ad, V

w/V

p and S

p/p%) remained constant, and only natural aggregate replacements were made (25%, 50% and 100%). This substitution was made in mass and for each particle size fraction, reproducing the reference curve obtained by Nepomuceno et al. [

19]. Adjustments were also made in the mixing water in order to take into account the effect of the water absorption, which is much higher in RA.

Knowing the absolute volume of all components, their densities and, in the case of fine materials, their unit percentages, the mortars’ composition was determined.

For the SCC formulation, it was necessary to set some additional parameters. The value of the void volume (V

v) was considered constant and equal to 0.03 m

3, according to the Nepomuceno et al. [

19] method. The “mix number” (MN) is defined as the product of V

p/V

s (already arbitrated) and V

m/V

g (ratio between the mortar and coarse aggregates contents in the mix, in absolute volume), and depends on the desired degree of self-compactability. This parameter was set at 1.82, according to the satisfactory results obtained by Silva and de Brito [

2]. Knowing the value of MN, the value of V

m/V

g was calculated, which is required to calculate the amounts of coarse aggregates (natural and/or recycled) in the mix and, along with the fixed parameters determined in the mortar phase, it was possible to calculate all mix contents.

2.3. Test Methods and Sample Preparation

The test procedure used in the determination of the density of hardened concrete is described in NP EN 12390-7 [

23]. This test was performed at 7, 28 and 91 days on the compressive strength cubes.

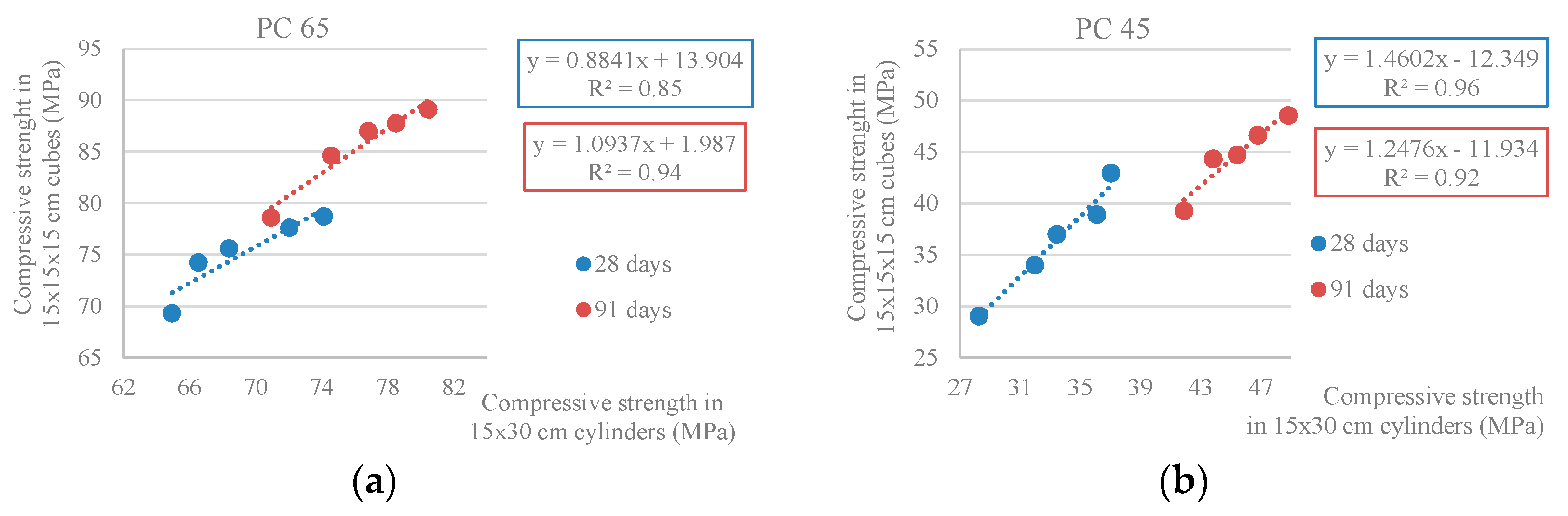

The test procedure used in the determination of the compressive strength is described in NP EN 12390-3 [

24]. This test was performed at 7, 28 and 91 days on 150 mm cubic moulds and at 28 and 91 days on 150 mm diameter × 300 mm high cylindrical moulds.

The test procedure used to determine the splitting tensile strength is described in NP EN 12390-6 [

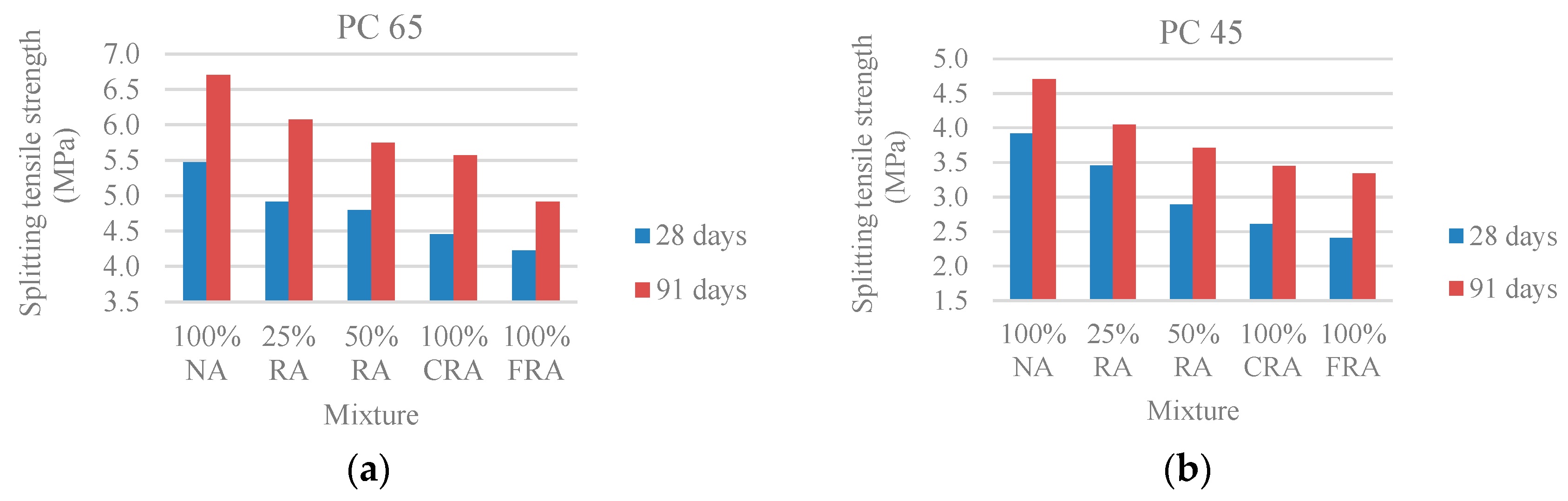

25]. This test was performed on 150 mm diameter × 300 mm high cylindrical moulds at 28 and 91 days.

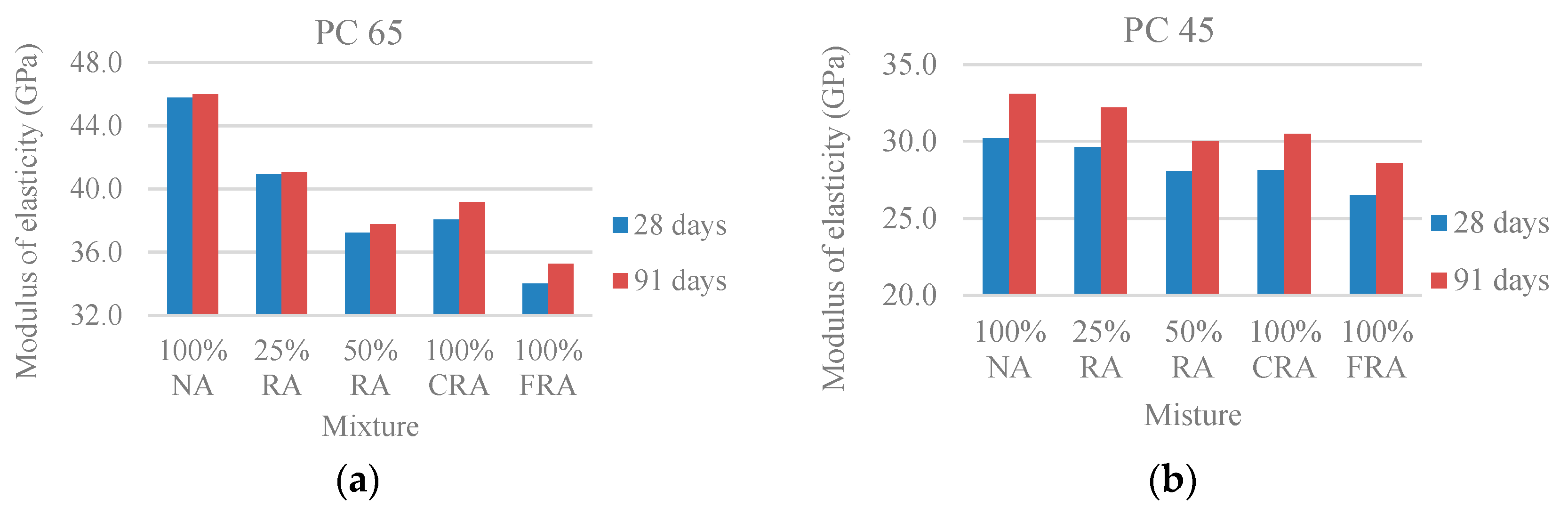

The test procedure used to determine the secant elastic modulus of elasticity (E

cm) is described in LNEC E 397 [

26]. This test was performed on 150 mm diameter × 300 mm high cylindrical moulds at 28 and 91 days.

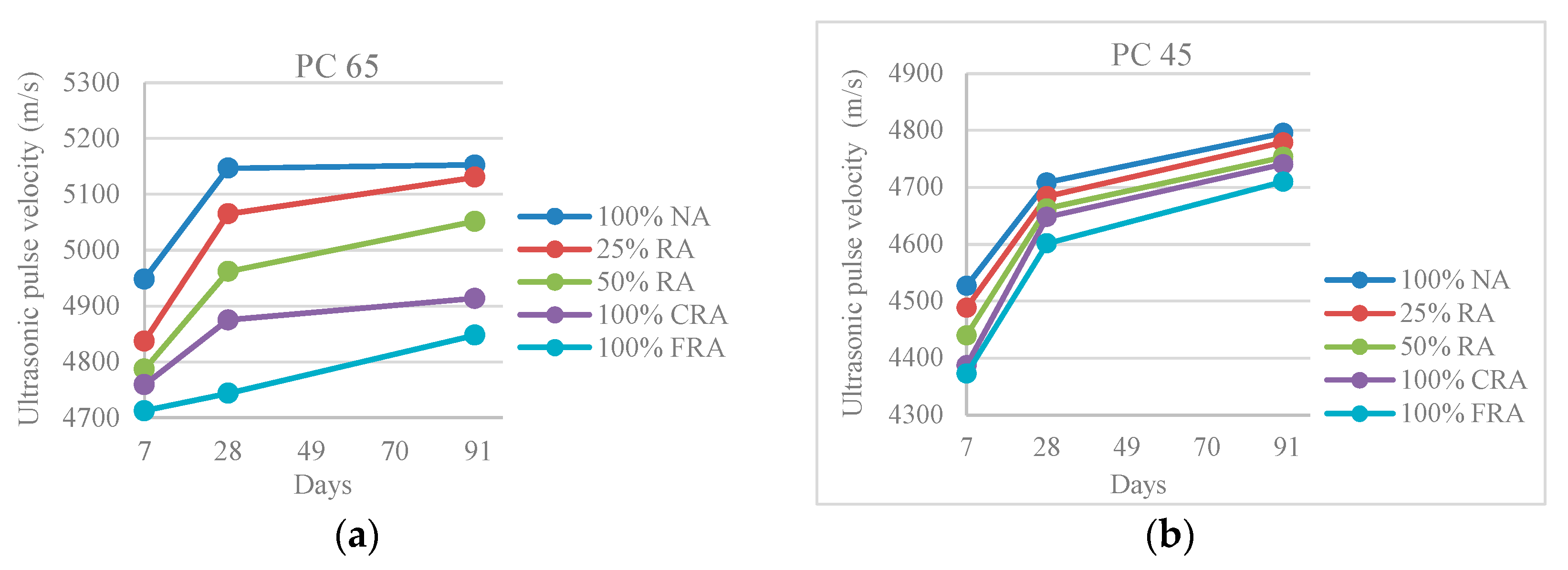

The test procedure used to determine the ultrasonic pulse velocity test is described in NP EN 12504-4 [

27]. The ultrasonic waves propagation time was evaluated in saturated 150 mm cubic specimens, later used to determine the compressive strength.

As for abrasion resistance, 71 × 71 × 40 mm prisms were tested, using a grinding wheel, according to DIN 52108 [

28].

4. Conclusions

The tests in the fresh state were performed in order to check the compliance of the SCC mixes with the fresh properties required by NP EN 206-9 [

17]. As such, the workability of concrete was a parameter fixed a priori through the compositions adjustment previously carried out in self-compacting mortars.

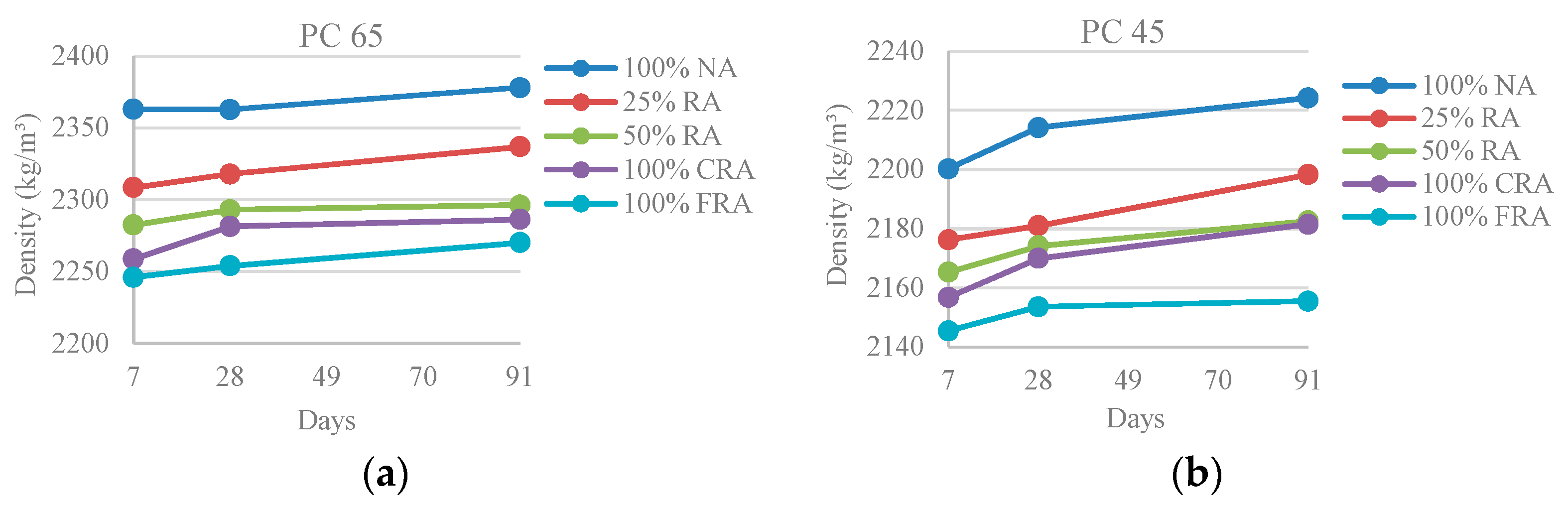

All mixes complied with the requirements demanded from a SCC: fluidity; flow speed, both in the absence and the presence of obstructions; filling capacity; flow capacity; passing ability; and segregation resistance. The concrete density did not significantly change with the incorporation of RA and its variation is closely related with the density of the RA used in each composition.

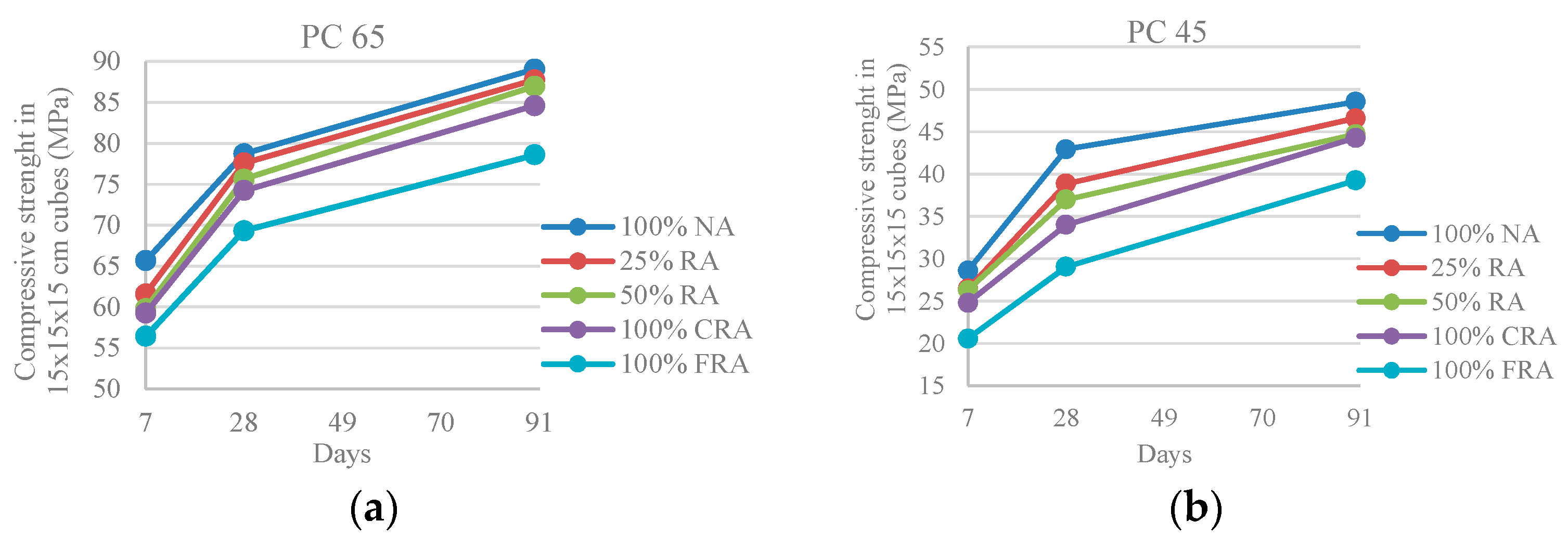

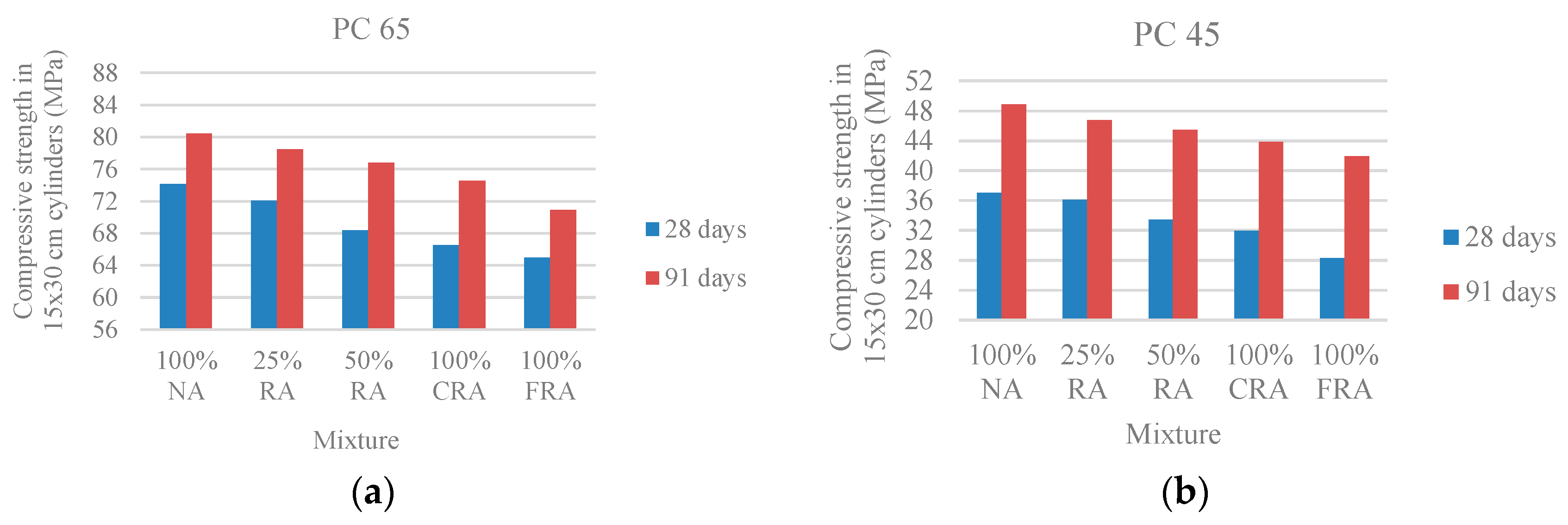

In terms of the SCC’s mechanical strength, in compression and tension, it is concluded that the replacement of NA with RA causes a performance loss, explained by the lower quality of RA compared to NA, due to the adhered mortar. The strength loss was greater in the PC 65 family, due to the worst quality of the RA, resulting from a lower strength source concrete. The objective of reproducing the strength of the RA’s source concrete was reached only in the PC 65 family. However, for the PC 45 family, all the mixes, except for the one with 100% FRA, belong to the C20/25 strength class or higher, and can thus be used as structural concrete. Besides the RA’s lower strength, the higher W/C ratio may have contributed to the poorer performance of the PC 45 family mixes.

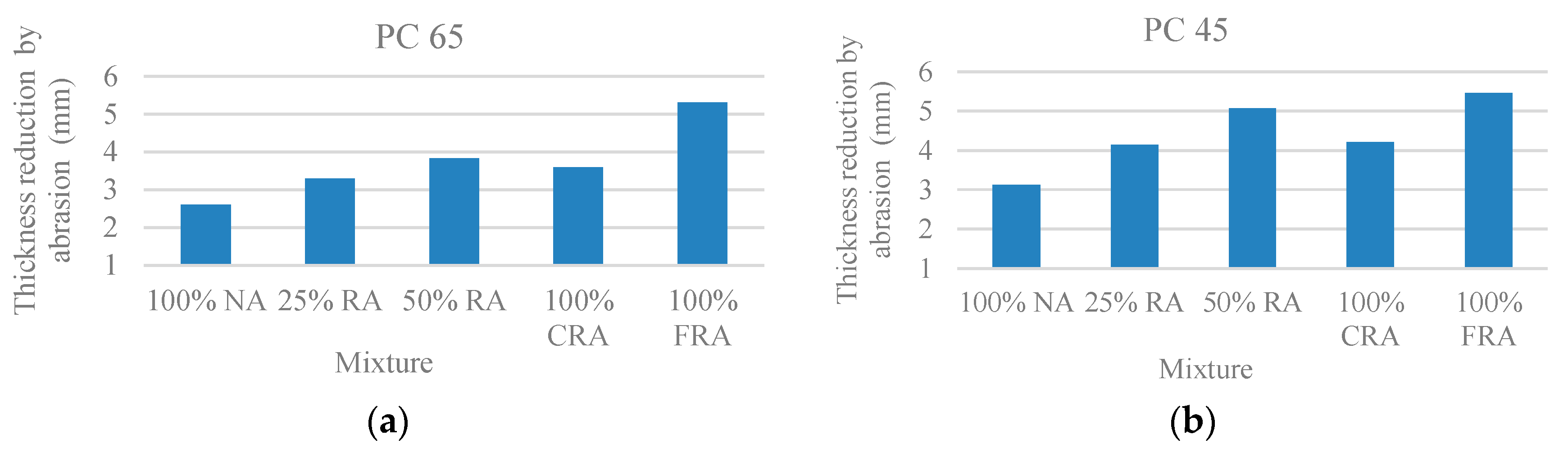

The modulus of elasticity suffered a reduction as the FRA incorporation increased, explained by the latter’s lower stiffness and the greater deformability of the adhered mortar. It was found that the mix with 100% CRA had a better performance than the one with 50% RA, meaning that this property was most influenced by the FRA content. The ultrasonic pulse velocity decreased with the RA incorporation ratio, even though this reduction is small, being caused by the increase in porosity of the RA, again linked with adhered mortar. The abrasion wear increased with the FRA replacement ratio, because of the latter’s greater porosity and consequent lower density, leading to a stiffness loss.

Finally the following general conclusions are presented, based on the results of the experimental work performed:

The aggregates used, coming from discarded elements from the concrete precasting industry, are of excellent quality, with a better performance in terms of all their properties than that reported in most of the research consulted;

For the majority of the mechanical properties, incorporation ratios of 25% RA, 50% RA and 100% CRA are viable;

Therefore, it is considered that an increase of the maximum incorporation ratios of this type of aggregates in existing codes could be contemplated, provided that their quality is demonstrated (as in the case of aggregates from precast concrete elements).