The Effect of Temperature on Moisture Transport in Concrete

Abstract

:1. Introduction

2. Theoretical Background

2.1. Moisture Transport under the Isothermal Condition

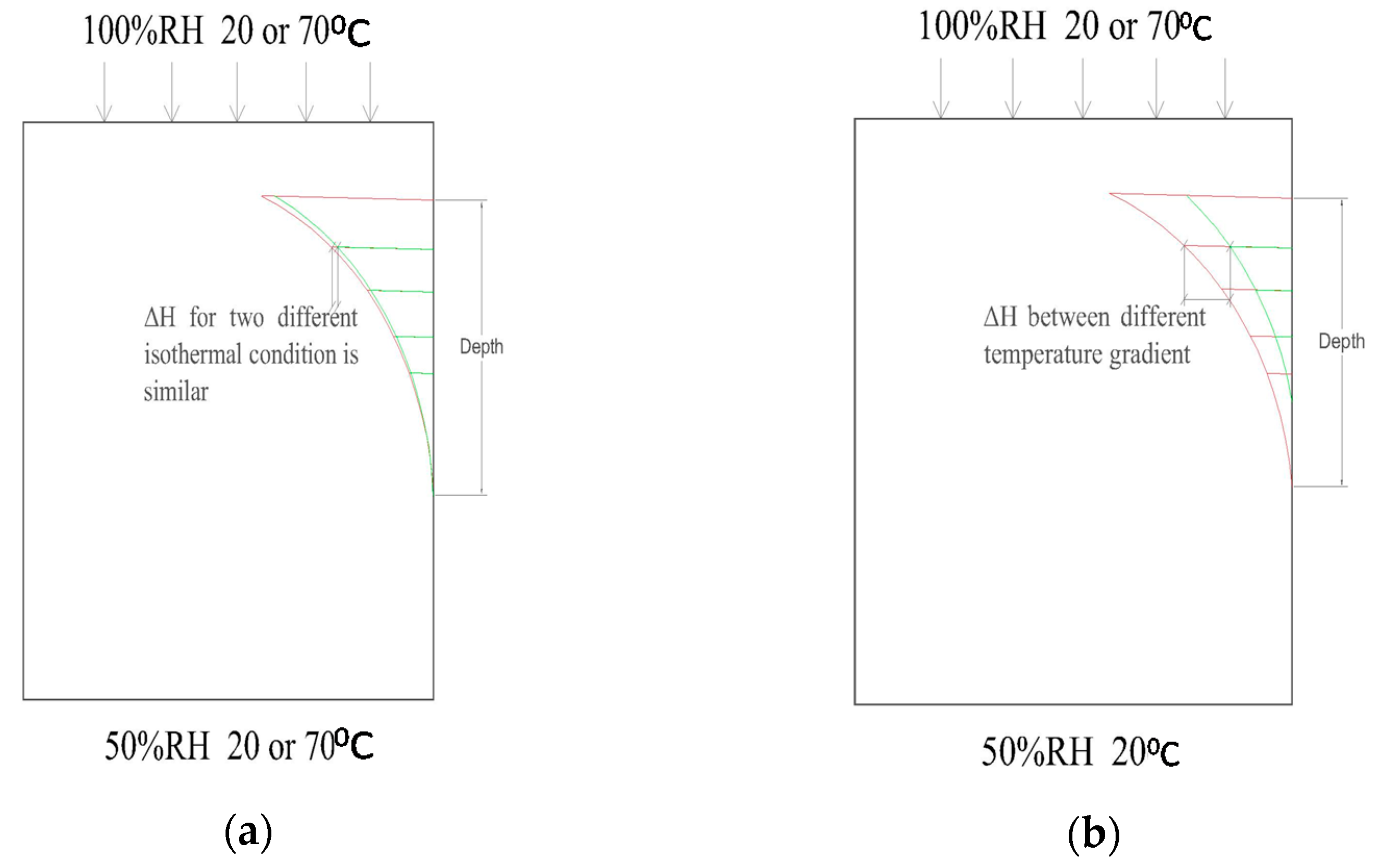

2.2. Moisture Transport under the Non-Isothermal Condition

3. Experimental Procedures

3.1. Materials and Specimen Preparation

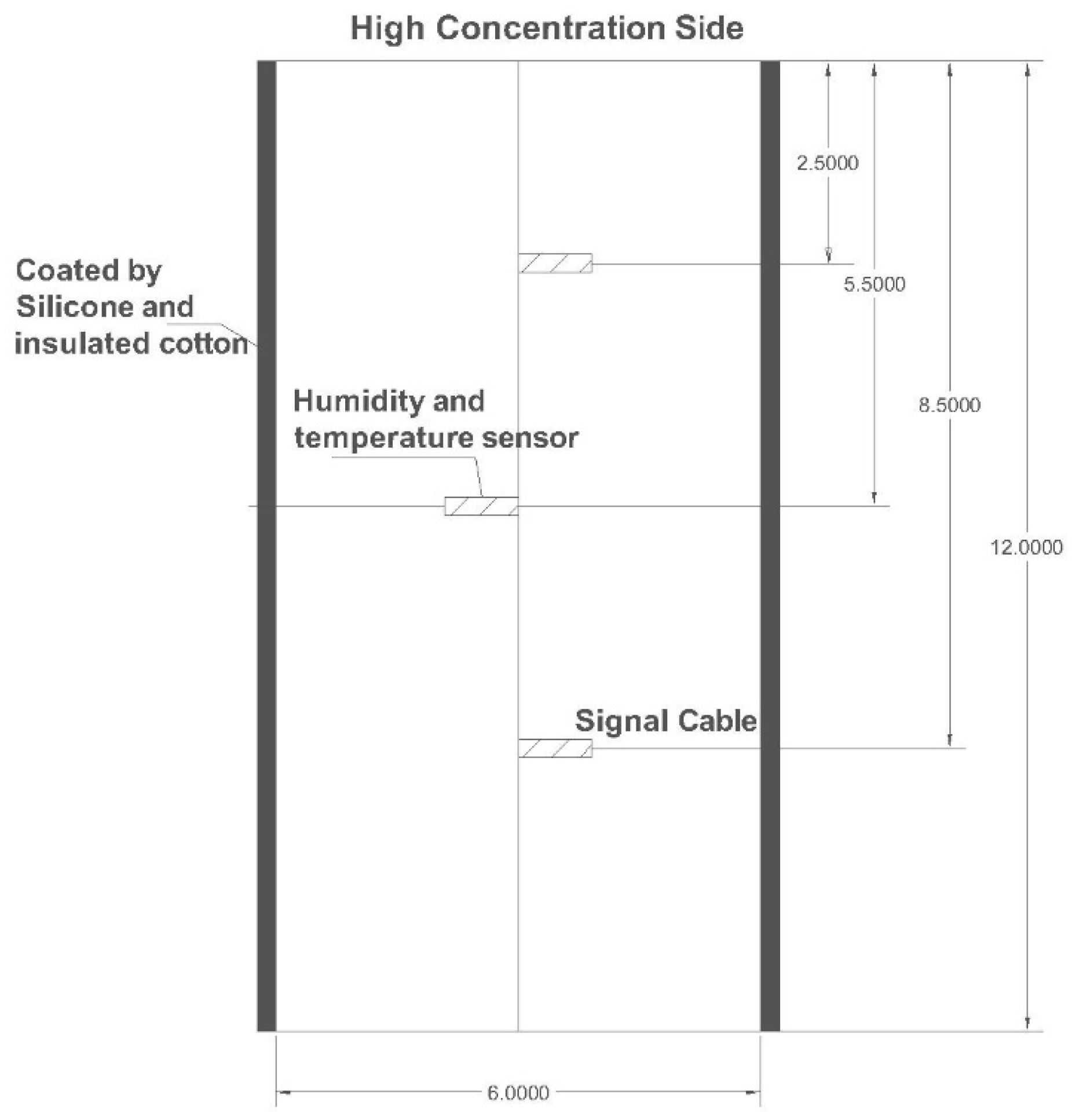

3.2. Approach to Measure the Internal Relative Humidity and Temperature

3.3. Experimental Conditions

4. Experimental Results and Discussions

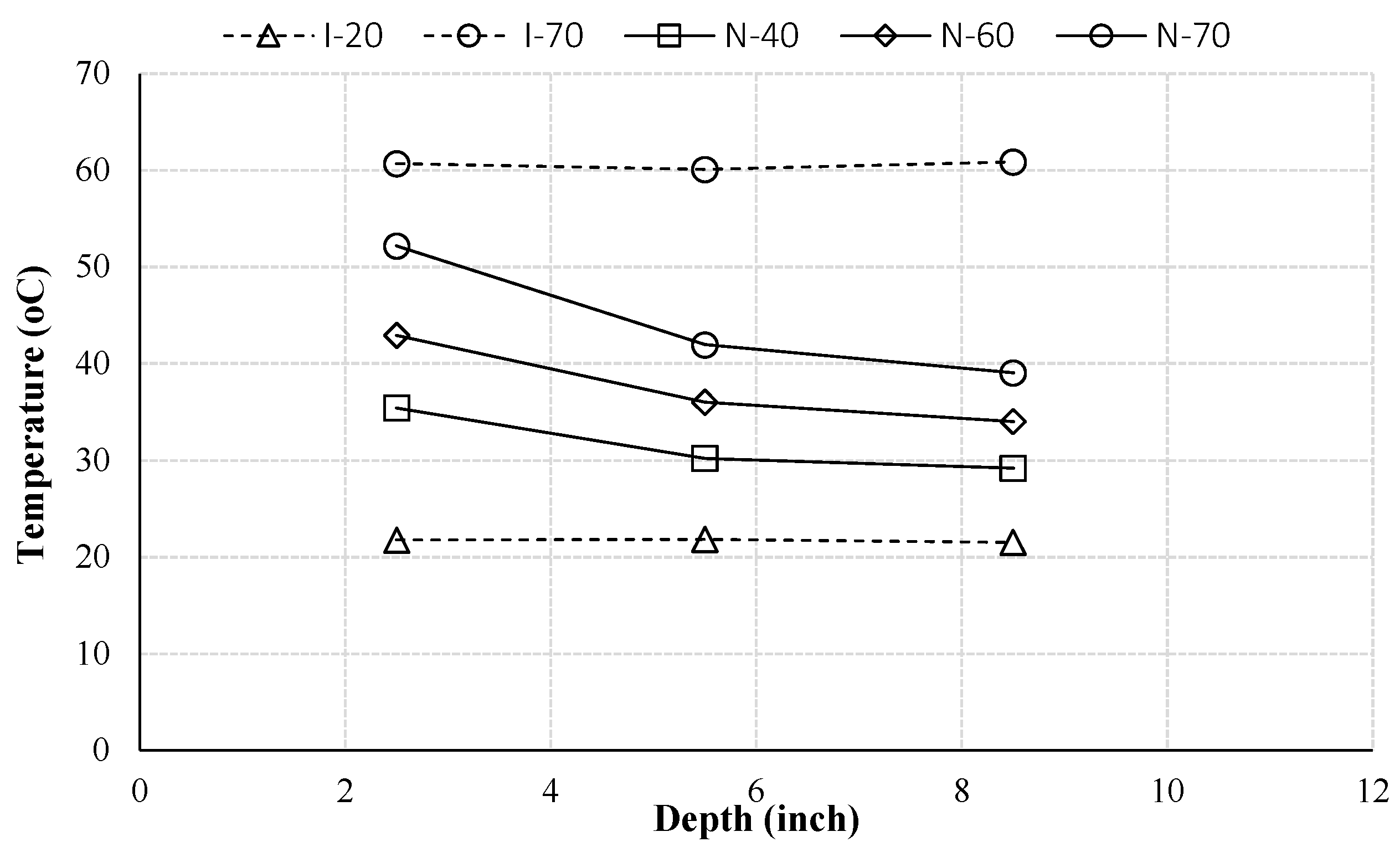

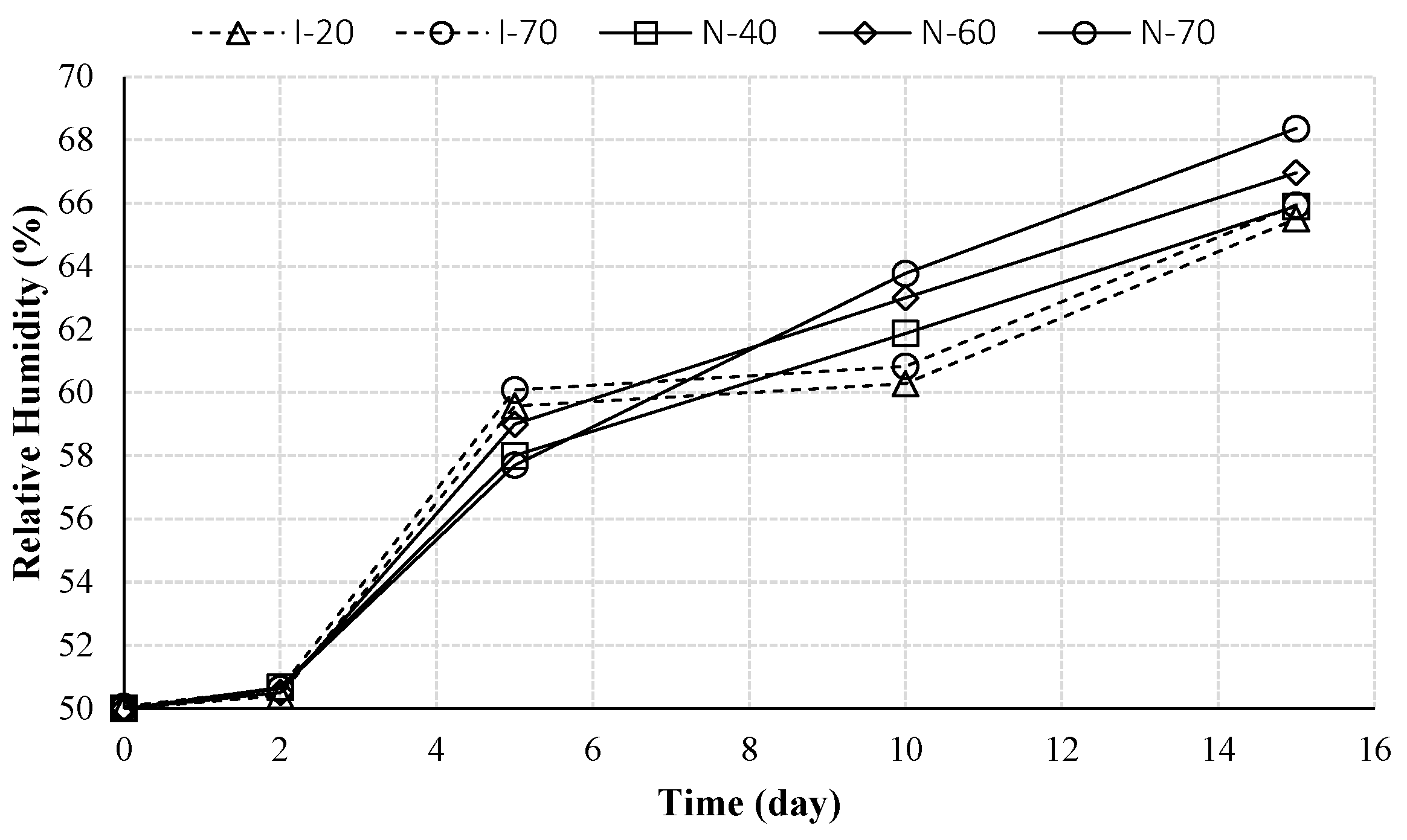

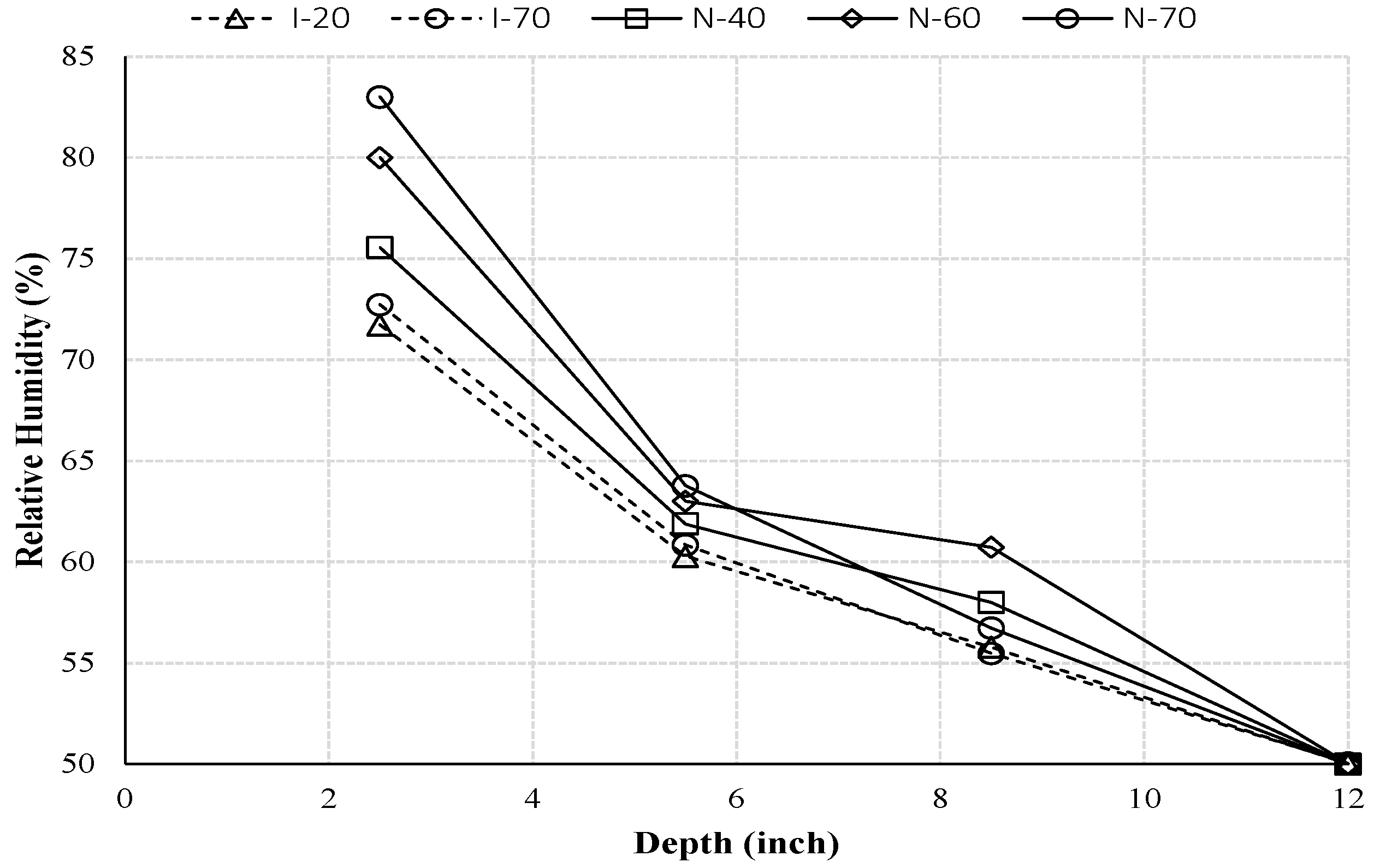

4.1. Experimental Results

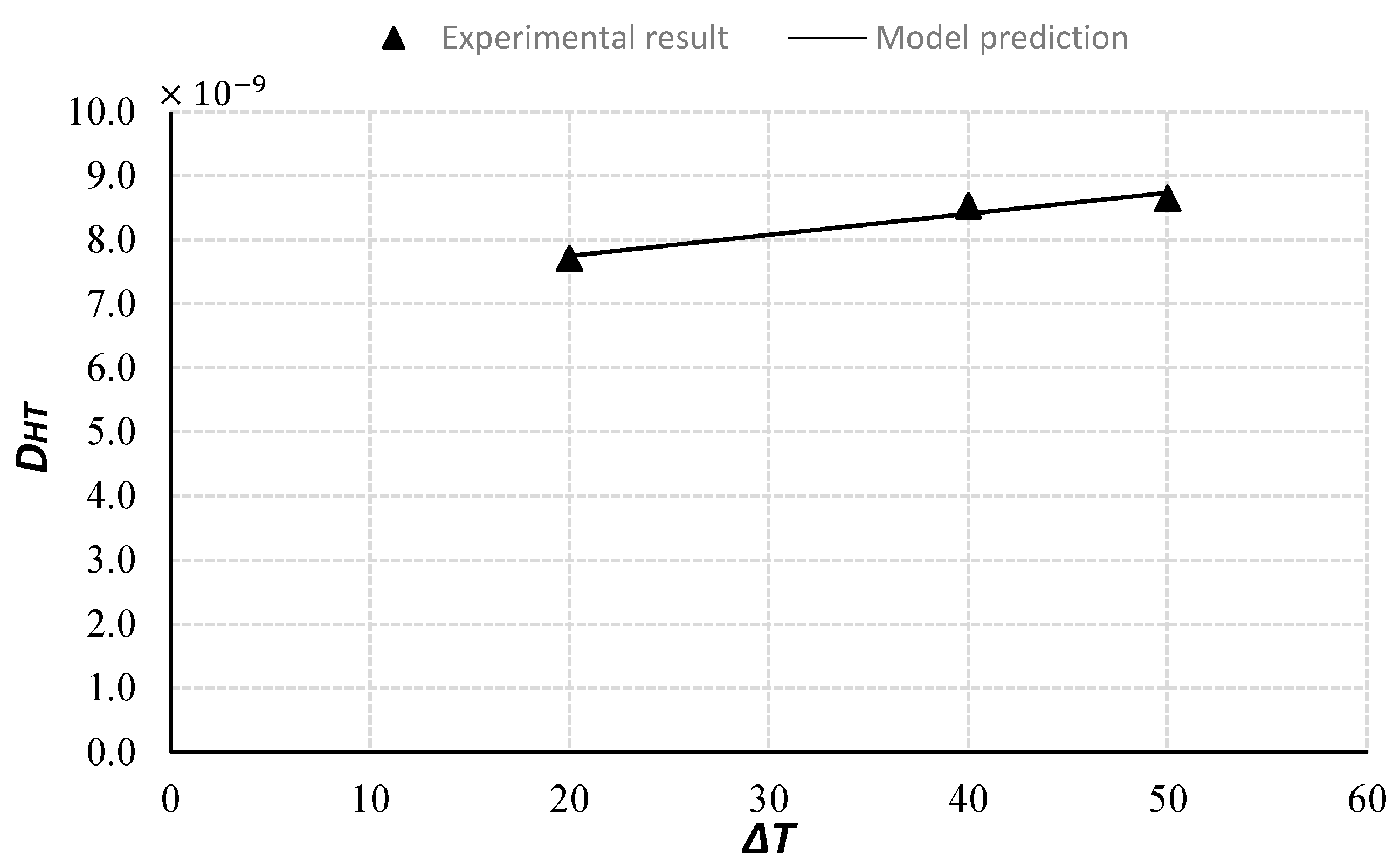

4.2. Evaluation of the Coupling Parameter DHT

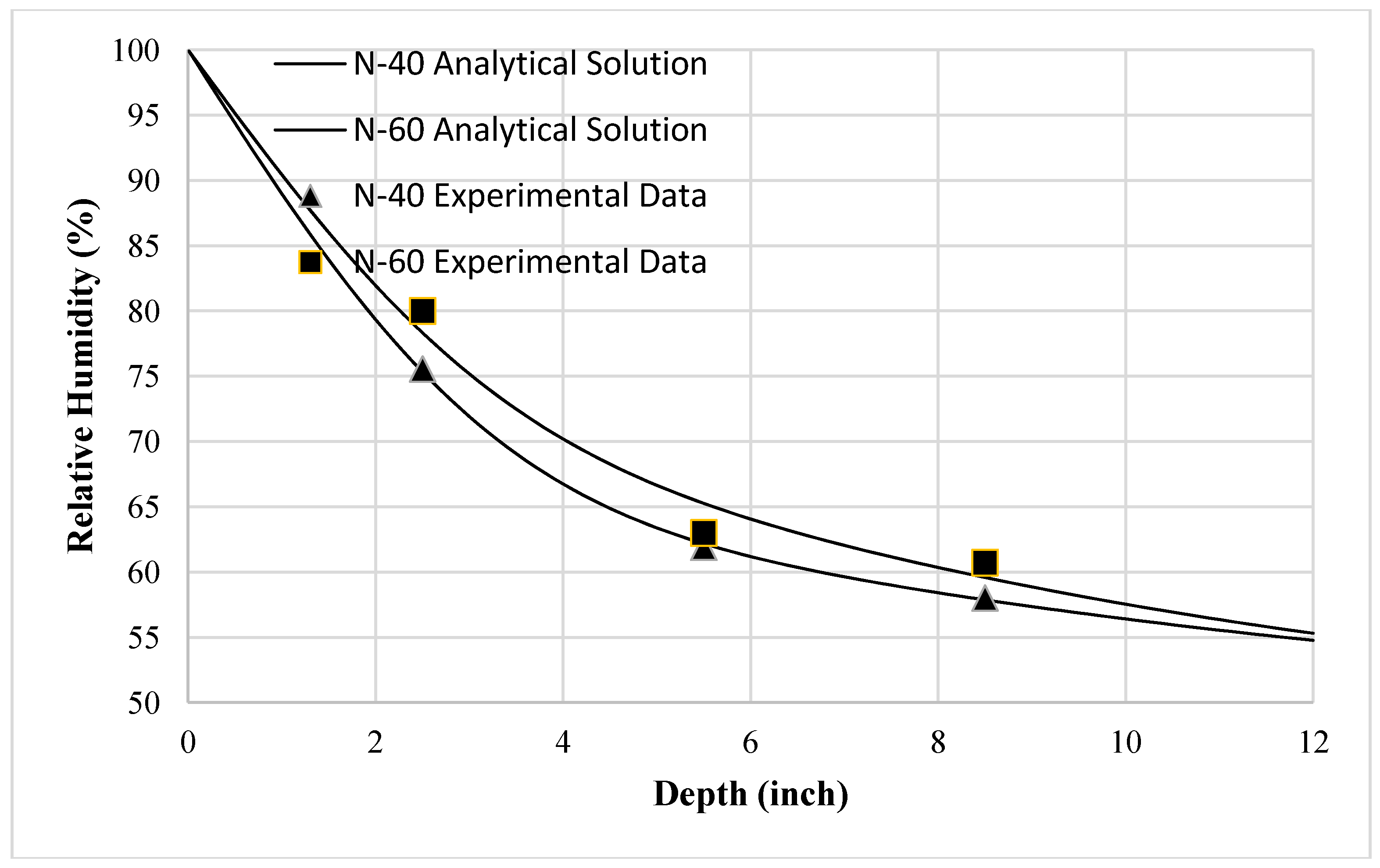

4.3. Model Verification

5. Conclusions

- (1)

- A literature review was performed to examine the effect of heat transfer on moisture transfer, the so-called Soret effect. Although the effect was recognized long time ago and studied for different materials, there has been no systematic study for concrete.

- (2)

- An experimental technique was developed for studying the temperature effect on moisture transfer in concrete. The technique was used with four different temperature conditions to study the effect of temperature on moisture transfer in concrete and the test data can be used to obtain the value of the related material parameter.

- (3)

- The experimental data indicates that the elevated temperature without a temperature gradient (an isothermal condition) does not have a significant effect on moisture transfer in concrete. On the other hand, the effect of the temperature gradient under a non-isothermal condition is significant and becomes more significant as the temperature gradient increases.

- (4)

- The effect of the temperature gradient on moisture transfer can be modelled by using an additional term of the temperature gradient in the moisture flux equation. The coefficient of the temperature gradient is called the coupling parameter DHT (i.e., the coefficient of Soret effect in moisture flux equation).

- (5)

- An analytic approach was developed based on the governing equations for the coupled moisture and heat transfer to calculate the coupling parameter DHT based on the present test dada. The results show that DHT is not a constant but increases linearly with temperature variation. In addition, the parameter DHT depends on the mix design parameters of concrete, such as the water-cement ratio, the aggregate volume fraction, and the ratio of cement-replacement.

- (6)

- An available analytical solution of the coupled moisture and heat transfer equations was used to verify the material parameters obtained in the present study. The predicted moisture distributions under the influence of the temperature gradient were compared with the experimental results. They agreed reasonably well.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zuber, B.; Marchand, J. Predicting the volume instability if hydrated cement systems upon freezing using poro-mechanics and local phase equilibria. Mater. Struct. 2004, 37, 257–270. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Chern, J.C.; Rosenberg, A.M.; Gaidis, J.M. Mathematical model for freeze-thaw durability of concrete. J. Am. Ceram. Soc. 1998, 71, 776–783. [Google Scholar] [CrossRef]

- Tsongas, G. Case studies of moisture problems in residences. In Proceedings of the 2nd Annual Conference on Durability and Disaster Mitigation in Wood-Frame Housing, Madison, Wisconsin, 6–8 November 2000. [Google Scholar]

- Ganjian, E.; Pouya, H.S. The effect of Persian Gulf tidal zone exposure on durability of mixes containing silica fume and blast furnace slag. Constr. Build. Mater. 2009, 23, 644–652. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Impedance spectroscopy study of the effect of environmental conditions in the microstructure development of OPC and slag cement mortars. Arch. Civ. Mech. Eng. 2015, 15, 569–583. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Influence of different curing conditions on the pore structure and the early age properties of mortars with fly ash and blast-furnace slag. Mater. Constr. 2012, 63, 219–234. [Google Scholar]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Durability related transport properties of OPC and slag cement mortars hardened under different environmental conditions. Constr. Build. Mater. 2012, 27, 176–183. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Antón, C.; De Vera, G.; Climent, M.A. Influence of environment on durability of fly ash cement mortars. ACI Mater. J. 2012, 109, 647–656. [Google Scholar]

- Çakir, Ö.; Aköz, F. Effect of curing conditions on the mortars with and without GGBFS. Constr. Build. Mater. 2008, 22, 308–314. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Malhotra, V.M. Effect of curing on the compressive strength, resistance to chloride-ion penetration and porosity of concretes incorporating slag, fly ash or silica fume. Cem. Concr. Compos. 1995, 17, 125–133. [Google Scholar] [CrossRef]

- Barnett, S.J.; Soutsos, M.N.; Millard, S.G.; Bungey, J.H. Strength development of mortars containing ground granulated blast-furnace slag: effect of curing temperature and determination of apparent activation energies. Cem. Concr. Res. 2006, 36, 434–440. [Google Scholar] [CrossRef]

- Geiseler, J.; Kollo, H.; Lang, E. Influence of blast furnace cements on durability of concrete structures. ACI Mater. J. 1995, 92, 252–257. [Google Scholar]

- Chalee, W.; Ausapanit, P.; Jaturapitakkul, C. Utilization of fly ash concrete in marine environment for long term design life analysis. Mater. Des. 2010, 31, 1242–1249. [Google Scholar] [CrossRef]

- Thomas, M.D.; Matthews, J. Performance of pfa concrete in a marine environment—10 year results. Cem. Concr. Compos. 2004, 26, 5–20. [Google Scholar] [CrossRef]

- Thomas, M.D.; Scott, A.; Bremner, T.; Bilodeau, A.; Day, D. Performance of slag concrete in marine environment. ACI Mater. J. 2008, 105, 628–634. [Google Scholar]

- Detwiler, J.; Kjellsen, K.O.; Gjorv, O.E. Resistance to Chloride Intrusion of Concrete Cured at Different Temperatures. ACI Mater. J. 1991, 88, 19–24. [Google Scholar]

- Costa, A.; Appleton, J. Chloride penetration into concrete in marine environment—Part I: Main parameters affecting chloride penetration. Mater. Struct. 1999, 32, 252–259. [Google Scholar] [CrossRef]

- Sedlbauer, K.; Krus, M.; Zillig, W.; Kunzel, H.M. Mold Growth Prediction by Computational Simulation. In Proceedings of the ASHRAE Conference, San Francisco, CA, USA, November 2001. [Google Scholar]

- Bertolini, L.; Elsener, B.; Pedeferri, P.; Plder, R. Corrosion of Steel in Concrete; Wiley-VCH Verlag Gmbh & Co., KGaA: Weinheim, Germany, 2013. [Google Scholar]

- Anold, J.R.; Garrabrants, A.C.; Samson, E.; Flach, G.P.; Langton, C.A. Moisture Transport Review; CBP-TR-2009-002 Cementitous Barriers Partnership: Phoenix, AZ, USA, 2009. [Google Scholar]

- Bazant, Z.P.; Chern, J.; Thonguthai, W. Finite element program for moisture and heat transfer in heated concrete. Nucl. Eng. Des. 1982, 68, 61–70. [Google Scholar] [CrossRef]

- Szekeres, A. Cross-coupled heat and moisture transport. J. Therm. Stresses 2012, 35, 248–268. [Google Scholar] [CrossRef]

- Zhang, W.; Min, H.; Gu, X. Temperature response and moisture transport in damaged concrete under an atmospheric environment. Constr. Build. Mater. 2016, 123, 290–299. [Google Scholar] [CrossRef]

- Platten, J.K. The Soret effect: A review of recent experimental results. J. Appl. Mech. 2005, 73, 5–15. [Google Scholar] [CrossRef]

- Haupl, J.; Fechner, H. Coupled heat air and moisture transfer in building structures. Int. J. Heat Mass Transf. 1997, 40, 1633–1642. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Thonguthai, W. Pore pressure in heated concrete walls: theoretical prediction. Mag. Concr. Res. 1979, 31, 67–76. [Google Scholar] [CrossRef]

- Eastman, E.D. Theory of the Soret effect. J. Am. Chem. Soc. 1928, 50, 283–291. [Google Scholar] [CrossRef]

- Xi, Y.; Jennings, H. Shrinkage of cement paste and concrete modelled by a multiscale effective homogeneous theory. Mater. Struct. 1997, 30, 329–339. [Google Scholar] [CrossRef]

- Trabelsi, A.; Belarbi, R.; Abahri, K.; Qin, M. Assessment of temperature gradient effects on moisture transfer through thermogradient coefficient. Build. Simul. 2012, 5, 107–115. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Najjar, L.J. Nonlinear water diffusion of nonsaturated concrete. Mater. Struct. 1972, 5, 3–20. [Google Scholar]

- Harstad, K. Modeling the Soret effect in dense media mixtures. Ind. Eng. Chem. Res. 2009, 48, 6907–6915. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Ceram. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Xi, Y.; Bazant, Z.P.; Molina, L.; Jennings, H.M. Moisture diffusion in cementitious materials: Adsorption Isotherm. Adv. Cem. Based Mater. 1994, 1, 248–257. [Google Scholar] [CrossRef]

- Xi, Y.; Bazant, Z.P.; Molina, L.; Jennings, H.M. Moisture diffusion in cementitious materials: Moisture Capactiy and Diffusivity. Adv. Cem. Based Mater. 1994, 1, 258–266. [Google Scholar] [CrossRef]

- Brunauer, S.; Skalny, J.; Bodor, E.E. Adsorption on nonporous solids. J. Coll. Inter. Sci. 1969, 30, 546–552. [Google Scholar] [CrossRef]

- Homan, L.; Ababneh, A.; Xi, Y. The effect of moisture transport on chloride penetration in concrete. Constr. Build. Mater. 2016, 125, 1189–1195. [Google Scholar] [CrossRef]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids; Oxford at the Clarendon Press: Oxford, UK, 1965. [Google Scholar]

- Murray, R.S. Theory and Problems of Laplace Transforms; McGraw-Hill. Inc.: New York, NY, USA, 1965. [Google Scholar]

- Bai, Y.; Wang, Y.; Xi, Y. An Analytical Solution for the Effect of Thermal Gradient on Moisture Transfer in Concrete. Comput. Concr. 2017. submitted. [Google Scholar]

| Water–Cement Ratio | Sand-Cement Ratio | Gravel-Cement Ratio |

|---|---|---|

| 0.6 | 2.4 | 2.9 |

| Specimen | Top Side | Bottom Side | ||

|---|---|---|---|---|

| RH | T (°C) | RH | T (°C) | |

| I-20 | 100% | 20 | 50% | 20 |

| I-70 | 100% | 70 | 50% | 70 |

| N-40 | 100% | 40 | 50% | 20 |

| N-60 | 100% | 60 | 50% | 20 |

| N-70 | 100% | 70 | 50% | 20 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Xi, Y. The Effect of Temperature on Moisture Transport in Concrete. Materials 2017, 10, 926. https://doi.org/10.3390/ma10080926

Wang Y, Xi Y. The Effect of Temperature on Moisture Transport in Concrete. Materials. 2017; 10(8):926. https://doi.org/10.3390/ma10080926

Chicago/Turabian StyleWang, Yao, and Yunping Xi. 2017. "The Effect of Temperature on Moisture Transport in Concrete" Materials 10, no. 8: 926. https://doi.org/10.3390/ma10080926