The Dry Sliding Wear Properties of Nano-Sized TiCp/Al-Cu Composites at Elevated Temperatures

Abstract

:1. Introduction

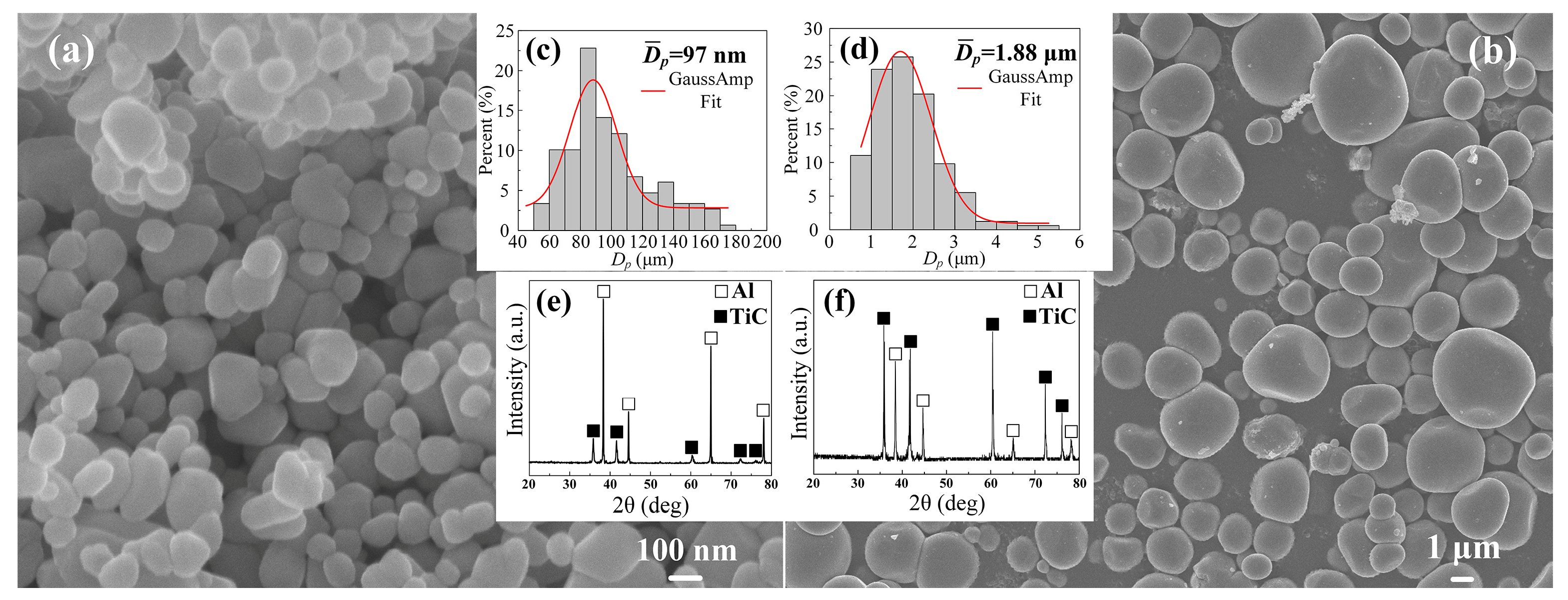

2. Experimental Procedures

3. Results and Discussion

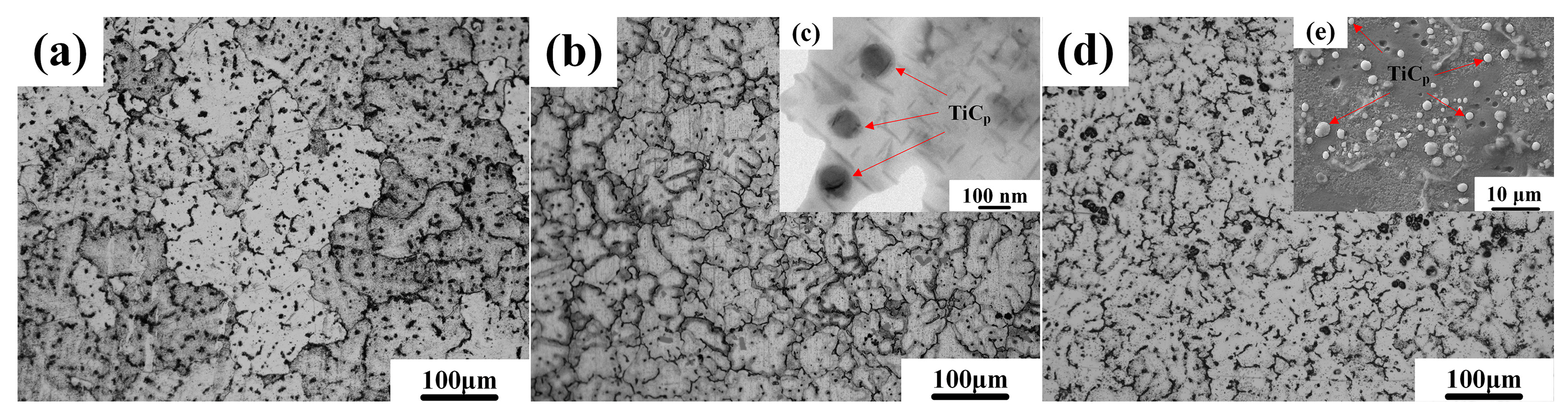

3.1. Microstructure

3.2. Dry Sliding Wear Behavior of the Nano-sized TiCp/Al-Cu Composite

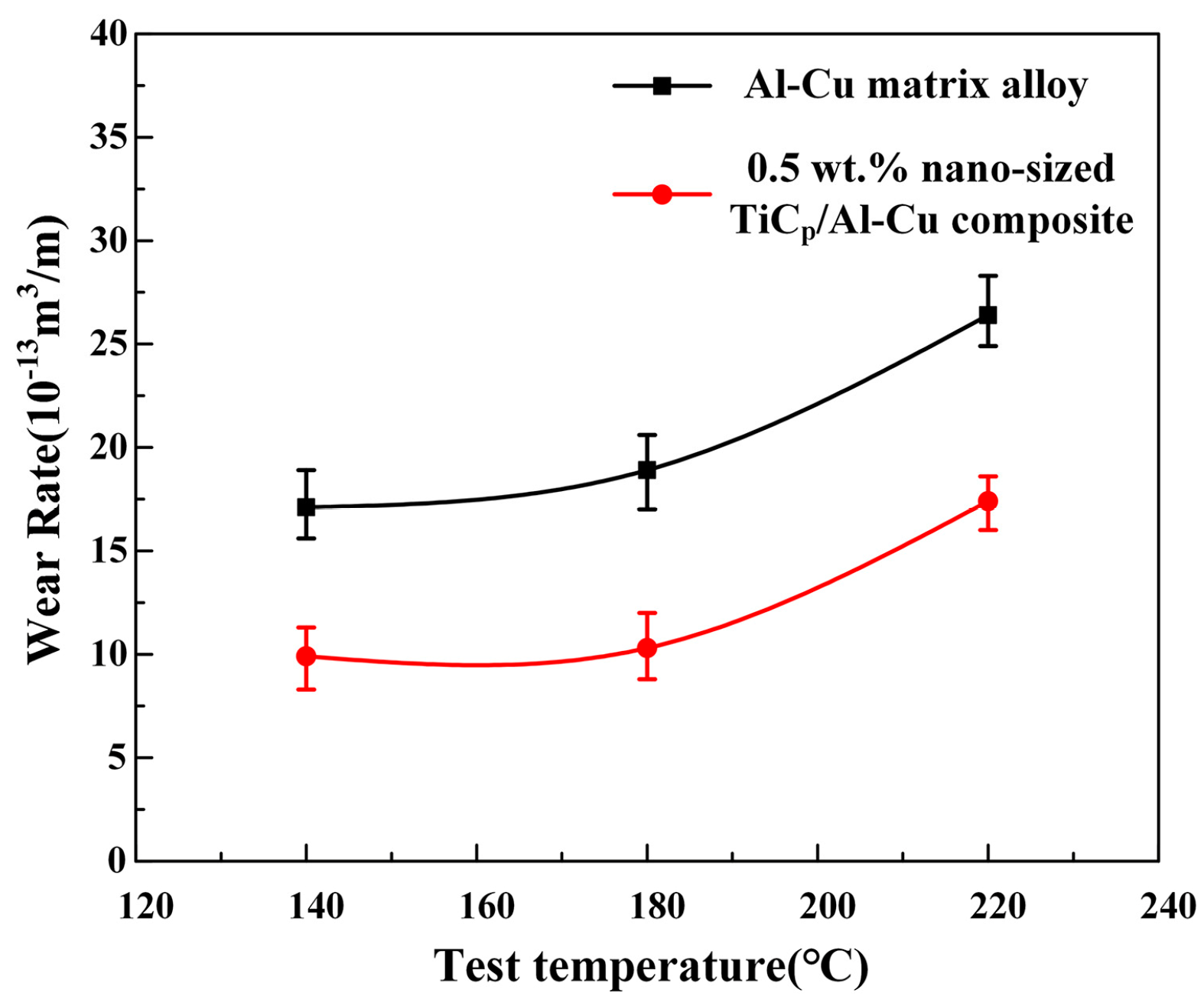

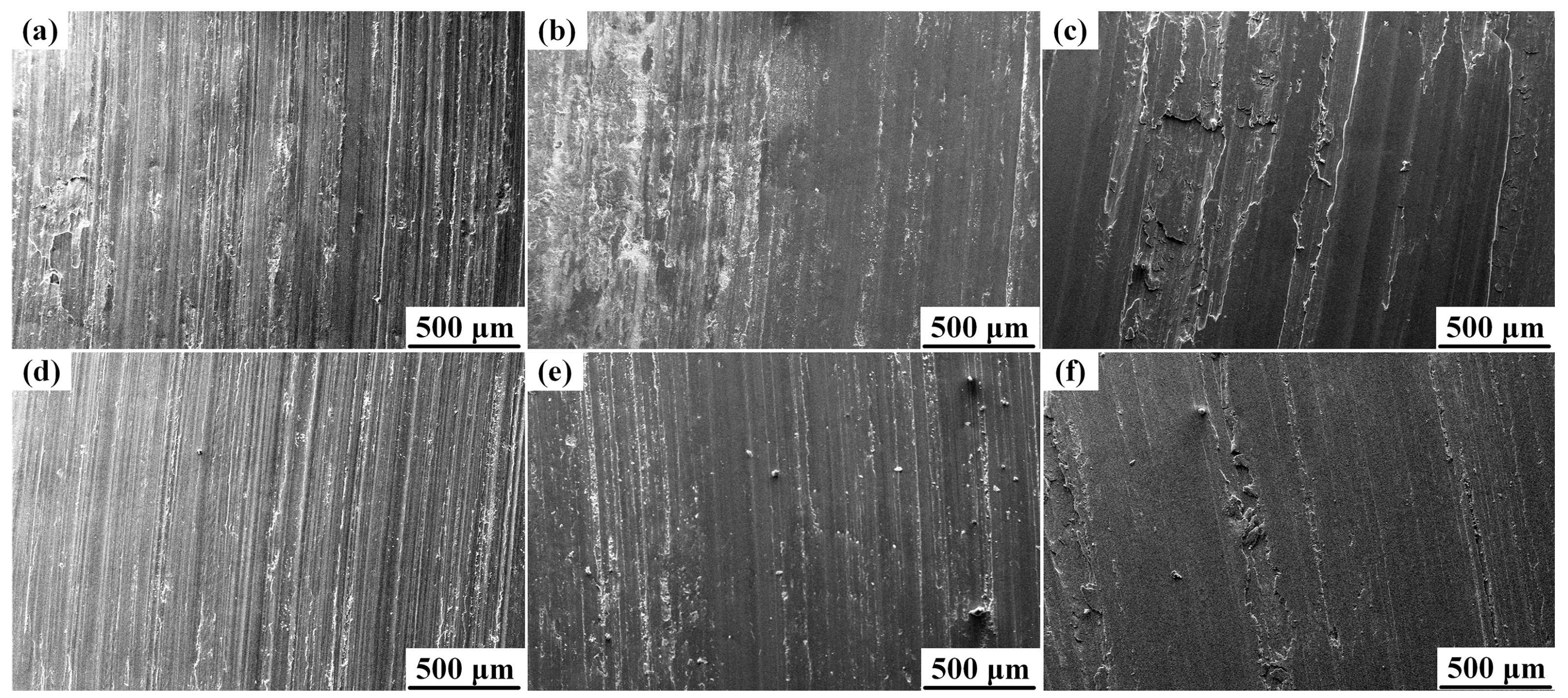

3.2.1. Effect of Temperature

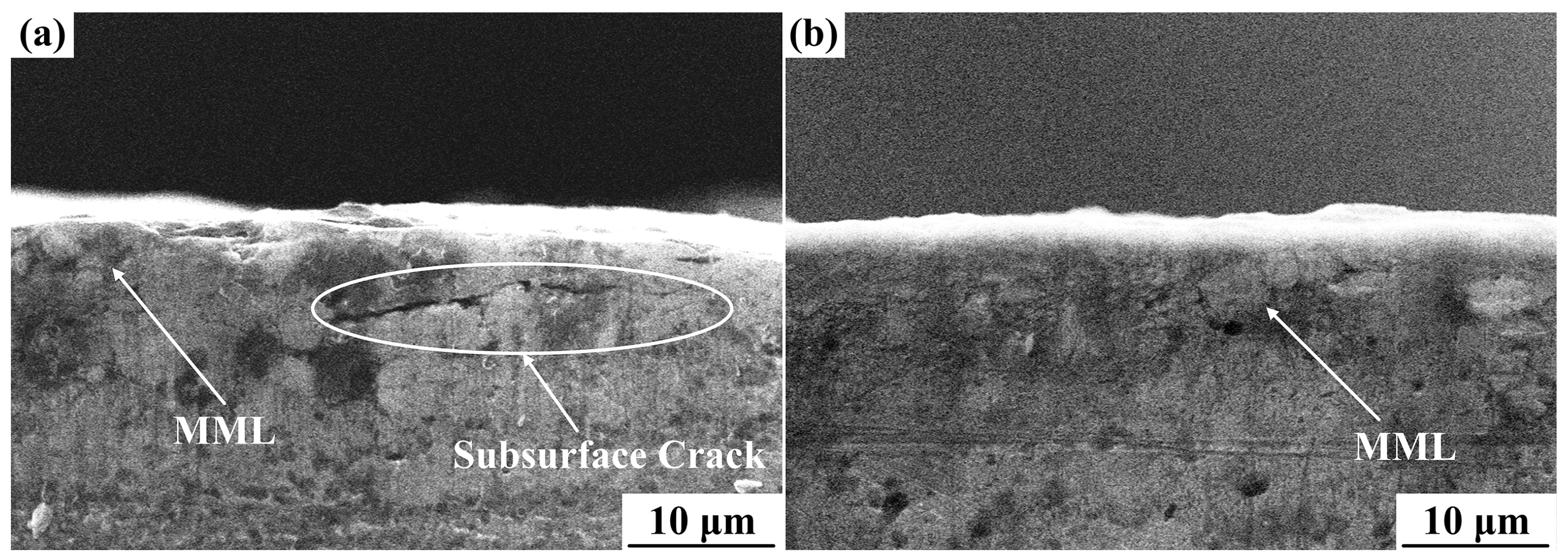

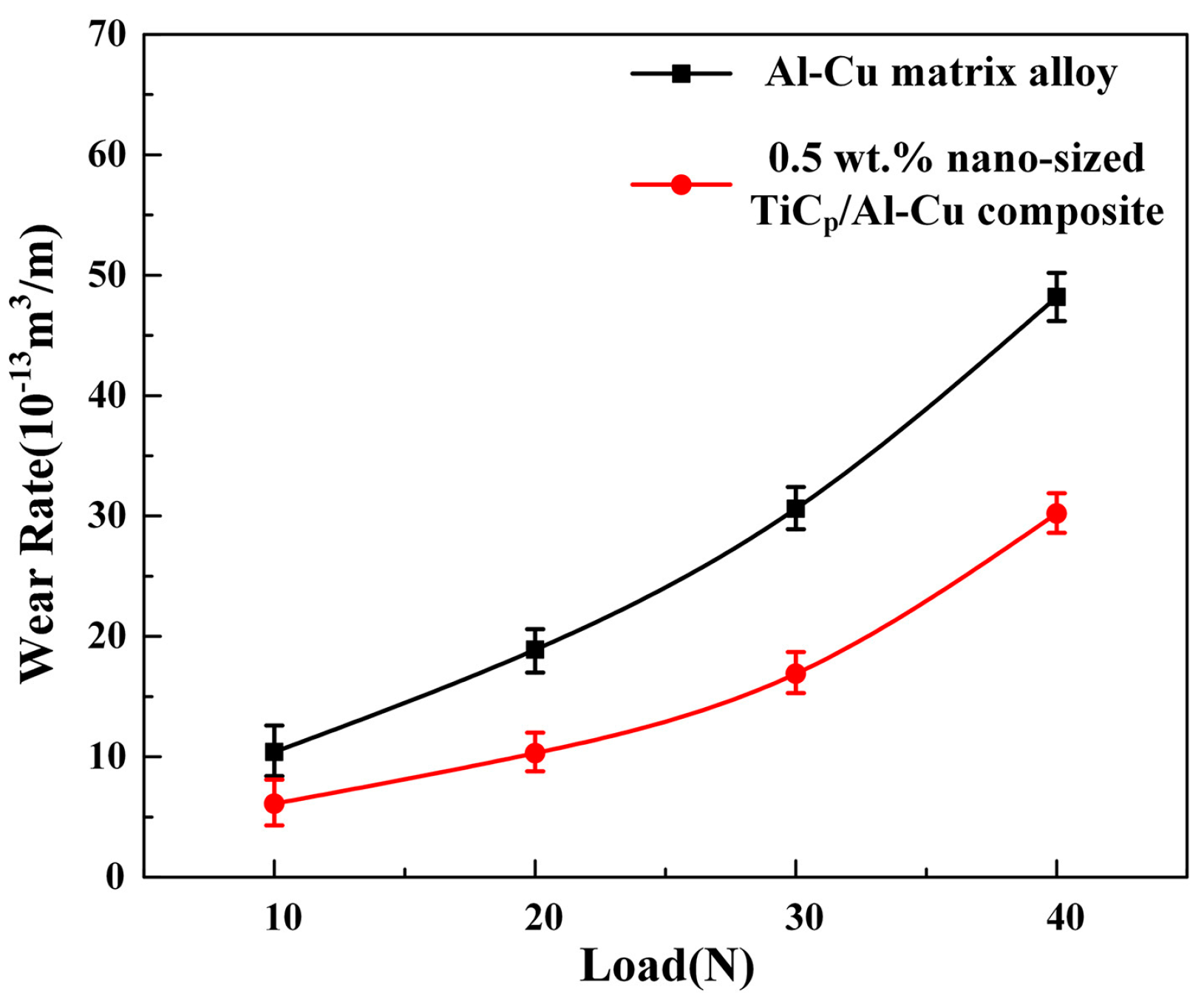

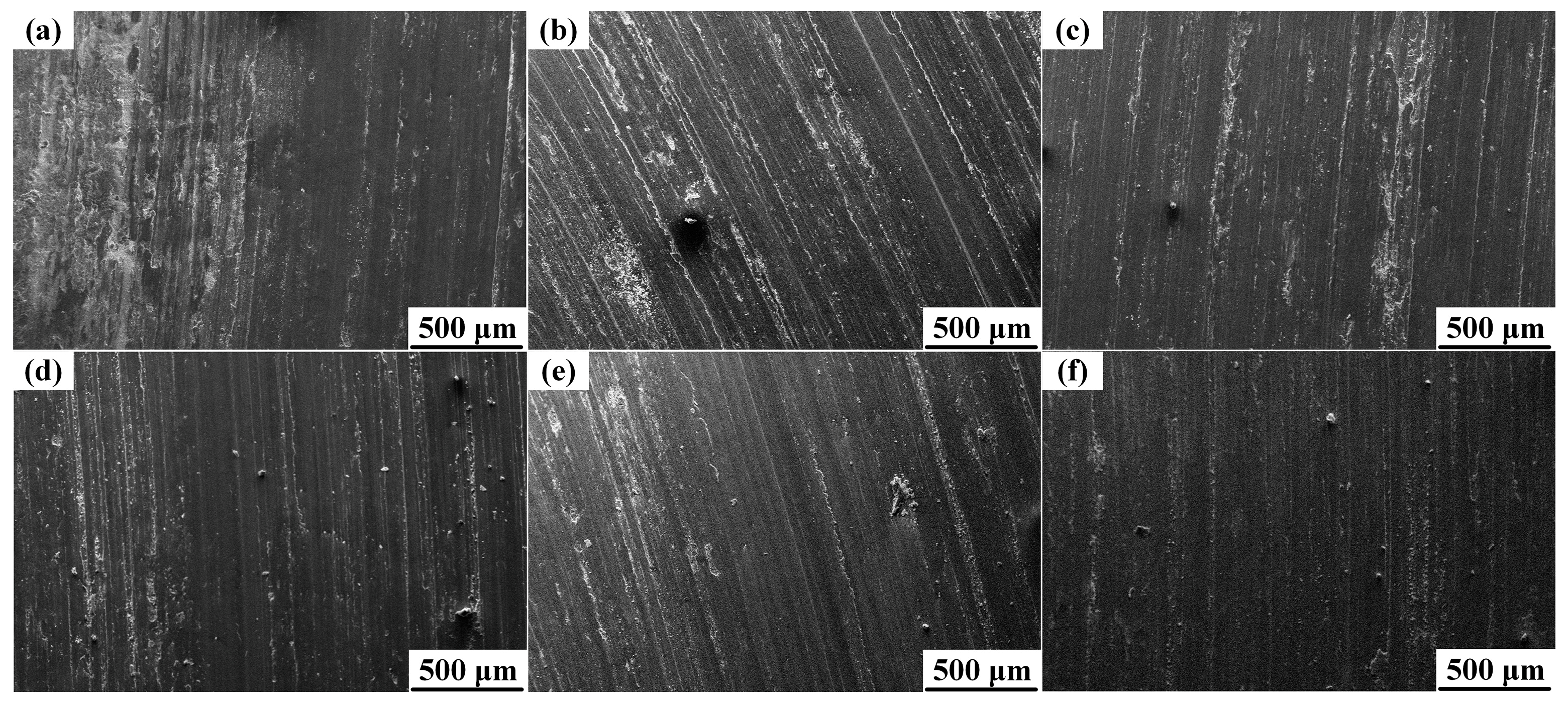

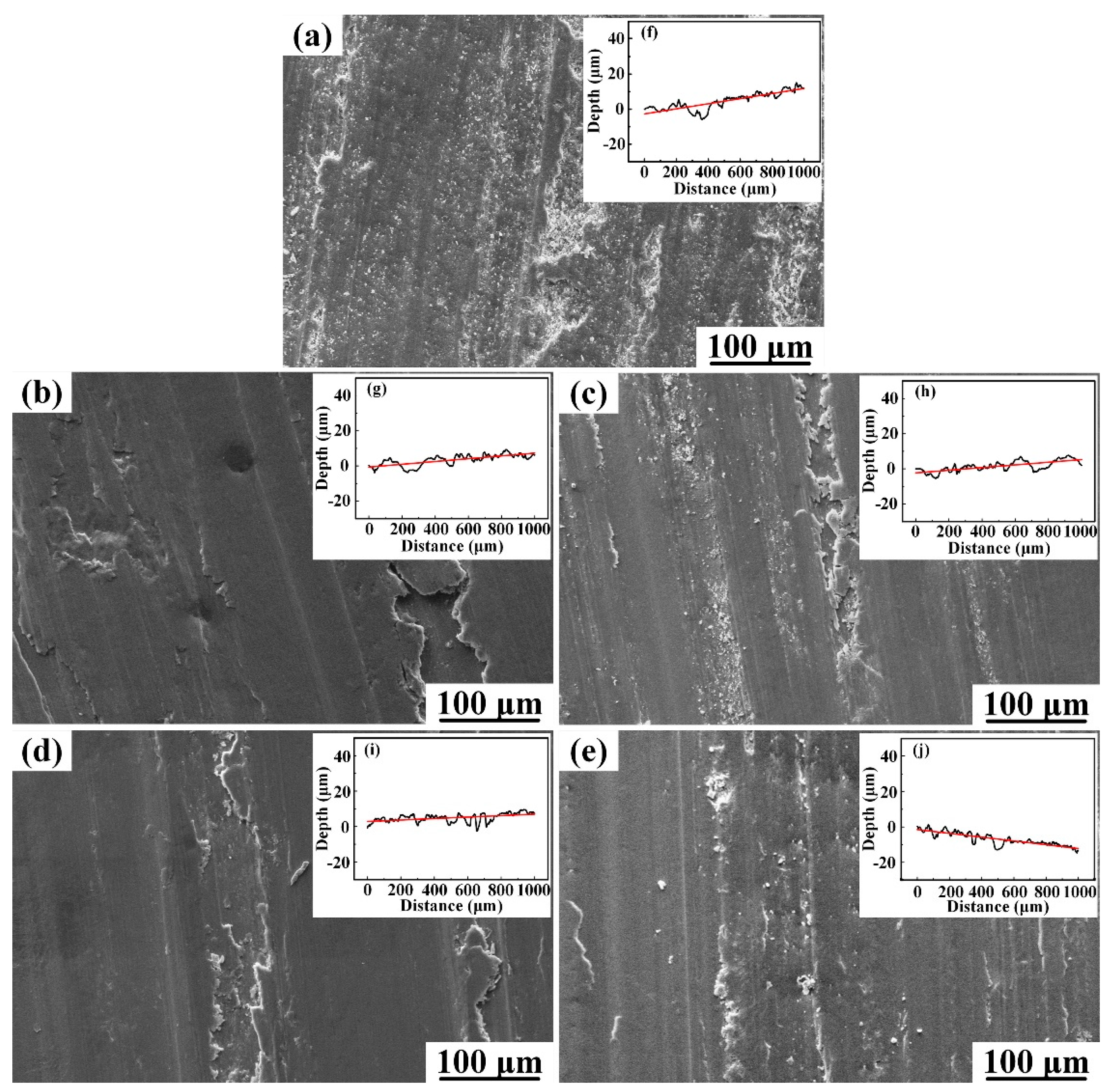

3.2.2. Effect of Applied Load

3.2.3. Effect of TiCp Contents

3.3. Comparing with the Micro-Sized TiCp/Al-Cu Composite

4. Conclusions

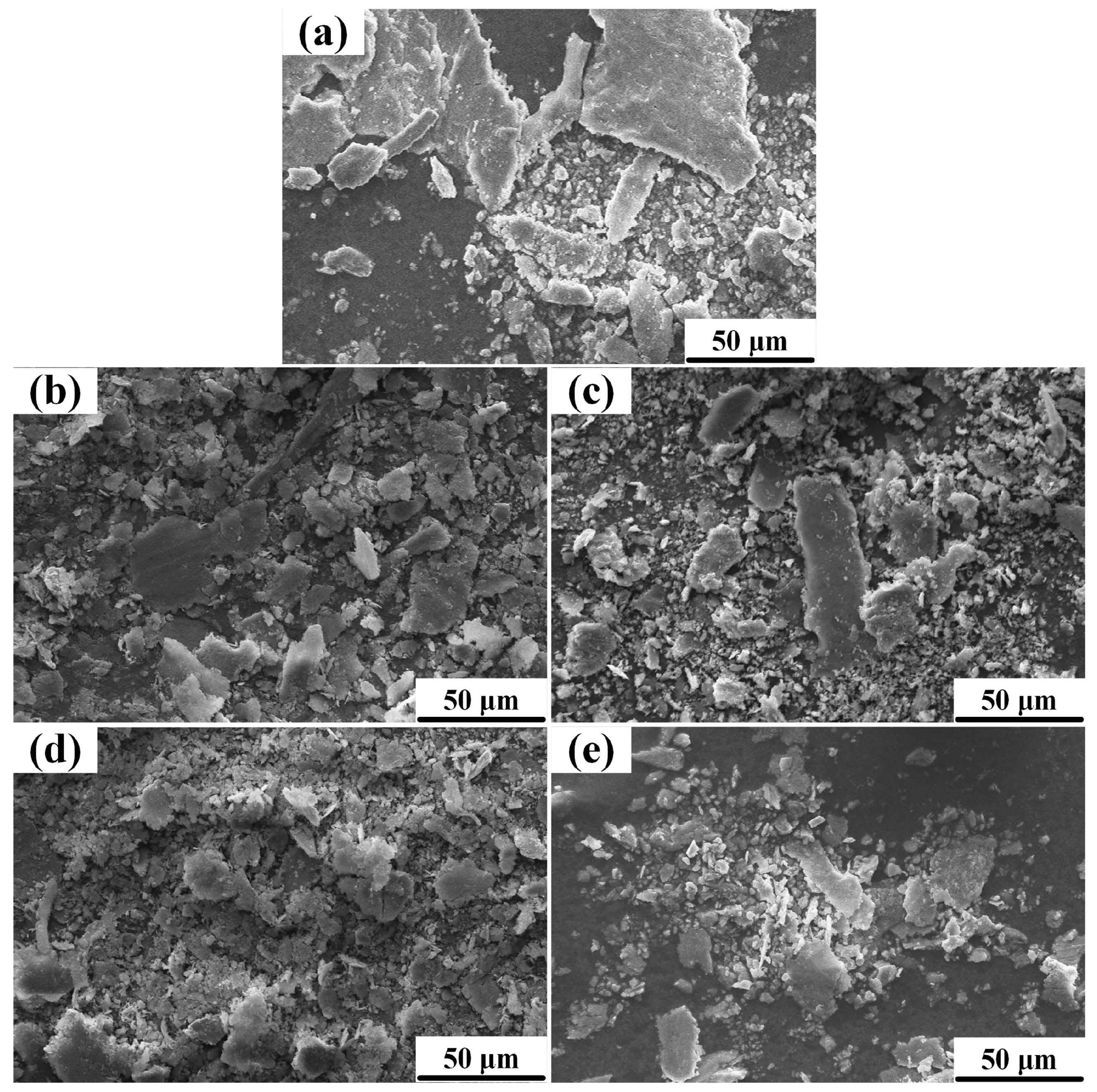

- The relative wear resistance of the 0.5 wt.% nano-sized TiCp/Al-Cu composite was 72.7%, 83.5% and 51.7% higher than that of the Al-Cu matrix alloy at 140 °C, 180 °C and 220 °C under 20 N load, respectively. The wear rate of the nanocomposite increased with the increase in temperature, but it was still lower than that of the Al-Cu matrix alloy at the same temperature. The worn surfaces indicated that the dominant wear mode for the nanocomposite was ploughing at 140 °C and 180 °C, and a combination of ploughing and delamination at 220 °C, while for the matrix alloy a combination of ploughing and delamination was dominant at all sliding temperatures studied.

- The nanocomposite exhibited superior wear resistance in the load range of 10 N–40 N at 180 °C, of which the relative wear resistance was improved by 59.6–83.5%, compared with the Al-Cu matrix alloy. The wear rate of the nanocomposite increased with the increase in the load, similarly to the Al-Cu matrix alloy, while it was lower than that of the matrix alloy under the same load. The worn surfaces indicated that the onset load of obvious delamination of the nanocomposite (40 N) was higher than that of the Al-Cu matrix alloy (20 N). Besides, with the increase in the content of nano-sized TiCp, the relative wear resistance tended to increase.

- The 0.5 wt.% nano-sized TiCp/Al-Cu composite exhibited superior high-temperature dry sliding wear resistance to the 5 wt.% micro-sized TiCp/Al-Cu composite at 180 °C under a constant load of 20 N, of which the relative wear resistance was 16.5% higher, attributed to the pronounced Orowan strengthening effect of nanoparticles in the nanocomposite.

Acknowledgments

Author Contributions

References

- Jerome, S.; Ravisankar, B.; Kumar Mahato, P.; Natarajan, S. Synthesis and evaluation of mechanical and high temperature tribological properties of in-situ Al–TiC composites. Tribol. Int. 2010, 43, 2029–2036. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Hamim, S.U.; Karbalaei Akbari, M.; Fakhrhoseini, S.M.; Khayyam, H.; Pakseresht, A.H.; Ghasali, E.; Zabet, M.; Munir, K.S.; Jia, S.; et al. Carbon fiber reinforced metal matrix composites: Fabrication processes and properties. Compos. Part A Appl. Sci. Manuf. 2017, 92, 70–96. [Google Scholar] [CrossRef]

- Nemati, N.; Khosroshahi, R.; Emamy, M.; Zolriasatein, A. Investigation of microstructure, hardness and wear properties of Al–4.5 wt.% Cu-TiC nanocomposites produced by mechanical milling. Mater. Des. 2011, 32, 3718–3729. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Khayyam, H.; Abdizadeh, H.; Karbalaei Akbari, M.; Pakseresht, A.H.; Abdi, F.; Abbasi, A.; Naebe, M. Effect of B4C, TiB2 and ZrSiO4 ceramic particles on mechanical properties of aluminium matrix composites: Experimental investigation and predictive modelling. Ceram. Int. 2015, 42, 6206–6220. [Google Scholar] [CrossRef]

- Kumar, S.; Subramanya Sarma, V.; Murty, B.S. High temperature wear behavior of Al-4Cu-TiB2 in situ composites. Wear 2010, 268, 1266–1274. [Google Scholar] [CrossRef]

- Shu, S.L.; Yang, H.Y.; Tong, C.Z.; Qiu, F. Fabrication of TiCx-TiB2/Al composites for application as a heat sink. Materials 2016, 9. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N.; Gautam, G.; Gautam, R.K.; Mohan, A.; Mohan, S. Wear, friction and profilometer studies of insitu AA5052/ZrB2 composites. Tribol. Int. 2016, 97, 313–326. [Google Scholar] [CrossRef]

- Harichandran, R.; Selvakumar, N. Effect of nano/micro B4C particles on the mechanical properties of aluminium metal matrix composites fabricated by ultrasonic cavitation-assisted solidification process. Arch. Civ. Mech. Eng. 2016, 16, 147–158. [Google Scholar] [CrossRef]

- Moazami-Goudarzi, M.; Akhlaghi, F. Wear behavior of Al 5252 alloy reinforced with micrometric and nanometric SiC particles. Tribol. Int. 2016, 102, 28–37. [Google Scholar] [CrossRef]

- Hekner, B.; Myalski, J.; Pawlik, T.; Sopicka-Lizer, M. Effect of carbon in fabrication Al-SiC nanocomposites for tribological application. Materials 2017, 10, 679. [Google Scholar] [CrossRef] [PubMed]

- Natarajan, S.; Narayanasamy, R.; Kumaresh Babu, S.P.; Dinesh, G.; Anil Kumar, B.; Sivaprasad, K. Sliding wear behaviour of Al 6063/TiB2 in situ composites at elevated temperatures. Mater. Des. 2009, 30, 2521–2531. [Google Scholar] [CrossRef]

- Michael Rajan, H.B.; Ramabalan, S.; Dinaharan, I.; Vijay, S.J. Effect of TiB2 content and temperature on sliding wear behavior of AA7075/TiB2 in situ aluminum cast composites. Arch. Civ. Mech. Eng. 2014, 14, 72–79. [Google Scholar] [CrossRef]

- Mahdavi, S.; Akhlaghi, F. Effect of the SiC particle size on the dry sliding wear behavior of SiC and SiC-Gr-reinforced Al6061 composites. J. Mater. Sci. 2011, 46, 7883–7894. [Google Scholar] [CrossRef]

- Zhu, H.G.; Dong, K.; Wang, H.; Huang, J.W.; Li, J.L.; Xie, Z.H. Reaction mechanisms of the TiC/Fe composite fabricated by exothermic dispersion from Fe-Ti-C element system. Powder Technol. 2013, 246, 456–461. [Google Scholar] [CrossRef]

- Li, P.J.; Kandalova, E.G.; Nikitin, V.I.; Makarenko, A.G.; Luts, A.R.; Zhang, Y.F. Preparation of Al-TiC composites by self-propagating high-temperature synthesis. Scr. Mater. 2003, 49, 699–703. [Google Scholar] [CrossRef]

- Zhou, D.S.; Qiu, F.; Jiang, Q.C. The nano-sized TiC particle reinforced Al–Cu matrix composite with superior tensile ductility. Mater. Sci. Eng. A 2015, 622, 189–193. [Google Scholar] [CrossRef]

- Tian, W.S.; Zhou, D.S.; Qiu, F.; Jiang, Q.C. Superior tensile properties of in situ nano-sized TiCp/Al-Cu composites fabricated by reaction in melt method. Mater. Sci. Eng. A 2016, 658, 409–414. [Google Scholar] [CrossRef]

- Jin, S.B.; Shen, P.; Zhou, D.S.; Jiang, Q.C. Self-propagating high-temperature synthesis of nano-TiCx particles with different shapes by using carbon nano-tube as C source. Nanoscale Res. Lett. 2011, 6, 515. [Google Scholar] [CrossRef] [PubMed]

- Jin, S.B.; Shen, P.; Zou, B.L.; Jiang, Q.C. Morphology Evolution of TiCx Grains During SHS in an Al–Ti–C System. Cryst. Growth Des. 2009, 9, 646–649. [Google Scholar] [CrossRef]

- Yao, D.M.; Xia, Y.M.; Qiu, F.; Jiang, Q.C. Effects of La addition on the elevated temperature properties of the casting Al–Cu alloy. Mater. Sci. Eng. A 2011, 528, 1463–1466. [Google Scholar] [CrossRef]

- Kumar, S.; Subramanya Sarma, V.; Murty, B.S. Effect of temperature on the wear behavior of Al-7Si-TiB2 in-situ composites. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009, 40, 223–231. [Google Scholar] [CrossRef]

- Hosseini, N.; Karimzadeh, F.; Abbasi, M.H.; Enayati, M.H. Tribological properties of Al6061–Al2O3 nanocomposite prepared by milling and hot pressing. Mater. Des. 2010, 31, 4777–4785. [Google Scholar] [CrossRef]

- Alidokht, S.A.; Abdollah-zadeh, A.; Assadi, H. Effect of applied load on the dry sliding wear behaviour and the subsurface deformation on hybrid metal matrix composite. Wear 2013, 305, 291–298. [Google Scholar] [CrossRef]

- Alizadeh, A.; Taheri-Nassaj, E. Mechanical properties and wear behavior of Al–2wt.% Cu alloy composites reinforced by B4C nanoparticles and fabricated by mechanical milling and hot extrusion. Mater. Charact. 2012, 67, 119–128. [Google Scholar] [CrossRef]

- Ramesh, C.S.; Ahamed, A. Friction and wear behaviour of cast Al 6063 based in situ metal matrix composites. Wear 2011, 271, 1928–1939. [Google Scholar] [CrossRef]

- Attar, H.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Manufacture by selective laser melting and mechanical behavior of commercially pure titanium. Mater. Sci. Eng. A 2014, 593, 170–177. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Prashanth, K.G.; Attar, H.; Chaubey, A.K.; Cao, G.H.; Zhang, L.C. Evaluation of mechanical and wear properties of Ti-xNb-7Fe alloys designed for biomedical applications. Mater. Des. 2016, 111, 592–599. [Google Scholar] [CrossRef]

- Gadelmawla, E.S.; Koura, M.M.; Maksoud, T.M.A.; Elewa, I.M.; Soliman, H.H. Roughness parameters. J. Mater. Process. Technol. 2002, 123, 133–145. [Google Scholar] [CrossRef]

- Koraman, E.; Baydoğan, M.; Sayılgan, S.; Kalkanlı, A. Dry sliding wear behaviour of Al–Fe–Si–V alloys at elevated temperatures. Wear 2015, 322–323. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D.L. Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength. Scr. Mater. 2006, 54, 1321–1326. [Google Scholar] [CrossRef]

- Zhao, Q.L.; Holmedal, B.; Li, Y.J. Influence of dispersoids on microstructure evolution and work hardening of aluminium alloys during tension and cold rolling. Philos. Mag. 2013, 93, 2995–3011. [Google Scholar] [CrossRef]

- McLellan, R.B.; Ishikawa, T. The elastic properties of aluminum at high temperatures. J. Phys. Chem. Solids 1987, 48, 603–606. [Google Scholar] [CrossRef]

- Nardone, V.C.; Prewo, K.M. On the strength of discontinuous silicon carbide reinforced aluminum composites. Scr. Metall. 1986, 20, 43–48. [Google Scholar] [CrossRef]

- Prasada Rao, A.K.; Das, K.; Murty, B.S.; Chakraborty, M. Effect of grain refinement on wear properties of Al and Al-7Si alloy. Wear 2004, 257, 148–153. [Google Scholar] [CrossRef]

- Karbalaei Akbari, M.; Rajabi, S.; Shirvanimoghaddam, K.; Baharvandi, H. Wear and friction behavior of nanosized TiB2 and TiO2 particle-reinforced casting A356 aluminum nanocomposites: A comparative study focusing on particle capture in matrix. J. Compos. Mater. 2015, 49, 3665–3681. [Google Scholar] [CrossRef]

| Samples (wt.%) | Wear Rate (10−13 m3/m) | Relative Wear Resistance | Surface Roughness Ra (μm) | ΔσOro + ΔσLoad (MPa) |

|---|---|---|---|---|

| Al-Cu alloy (M) | 1.000 | 1.918 | 0.0 | |

| M+1.0 micro-TiCp | 1.340 | 1.812 | 2.5 + 0.6 | |

| M+3.0 micro-TiCp | 1.421 | 1.706 | 4.7 + 1.8 | |

| M+5.0 micro-TiCp | 1.575 | 1.640 | 6.4 + 3.1 | |

| M+0.5 nano-TiCp | 1.835 | 1.501 | 21.8 + 0.3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, W.-S.; Zhao, Q.-L.; Zhao, C.-J.; Qiu, F.; Jiang, Q.-C. The Dry Sliding Wear Properties of Nano-Sized TiCp/Al-Cu Composites at Elevated Temperatures. Materials 2017, 10, 939. https://doi.org/10.3390/ma10080939

Tian W-S, Zhao Q-L, Zhao C-J, Qiu F, Jiang Q-C. The Dry Sliding Wear Properties of Nano-Sized TiCp/Al-Cu Composites at Elevated Temperatures. Materials. 2017; 10(8):939. https://doi.org/10.3390/ma10080939

Chicago/Turabian StyleTian, Wei-Si, Qing-Long Zhao, Chuan-Jiang Zhao, Feng Qiu, and Qi-Chuan Jiang. 2017. "The Dry Sliding Wear Properties of Nano-Sized TiCp/Al-Cu Composites at Elevated Temperatures" Materials 10, no. 8: 939. https://doi.org/10.3390/ma10080939