Thermo-Hydraulic Analysis of Heat Storage Filled with the Ceramic Bricks Dedicated to the Solar Air Heating System

Abstract

:1. Introduction

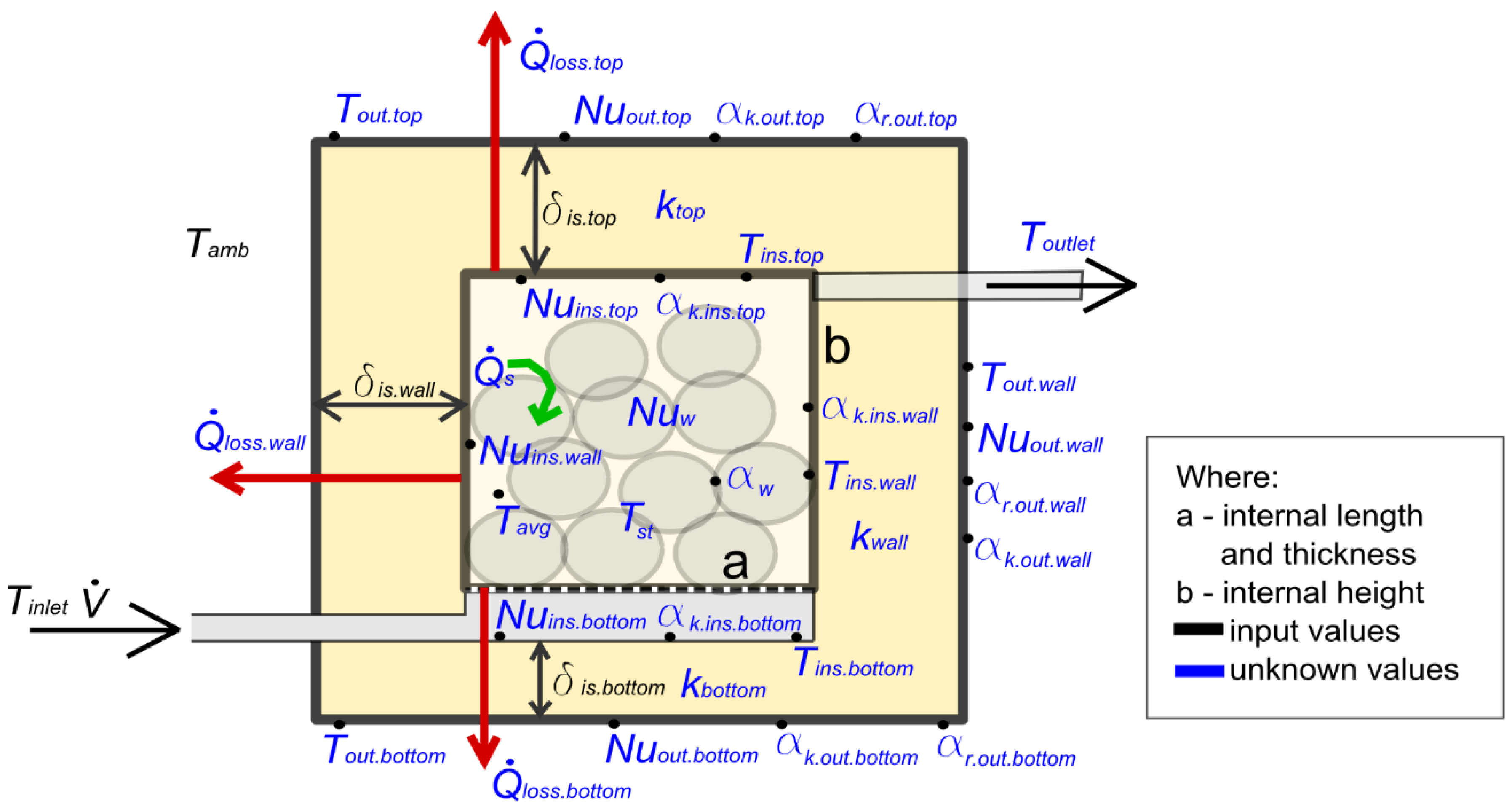

2. Thermo-Hydraulic Efficiency

3. Mathematical Model

- < 10−3, C = 0.5, n = 0

- 10−3 < , C = 1.18, n = 1/8

- , C = 0.54, n = 1/4

- , C = 0.135, n = 1/3.

- temperatures: Toutlet, Tst, Tavg, Tins.wall, Tout.wall, Tins.bottom, Tout.bottom, Tins.top, and Tout.top;

- heat fluxes: s, loss.wall, loss.botttom, and loss.top;

- the Nu numbers: Nuw, Nuout.wall, Nuins.wall, Nuins.bottom, Nuout.bottom, Nuins.top, and Nuout.top;

- heat-transfer coefficients: αw, αk.out.wall, αk.ins.wall, αr.out.wall, αk.ins.bottom, αk.out.bottom, αr.out.bottom, αk.ins.top, αk.out.top, and αr.out.top; and

- overall heat transfer coefficients: kwall, kbottom, and ktop.

The Nusselt Number

4. Experimental Set-Up

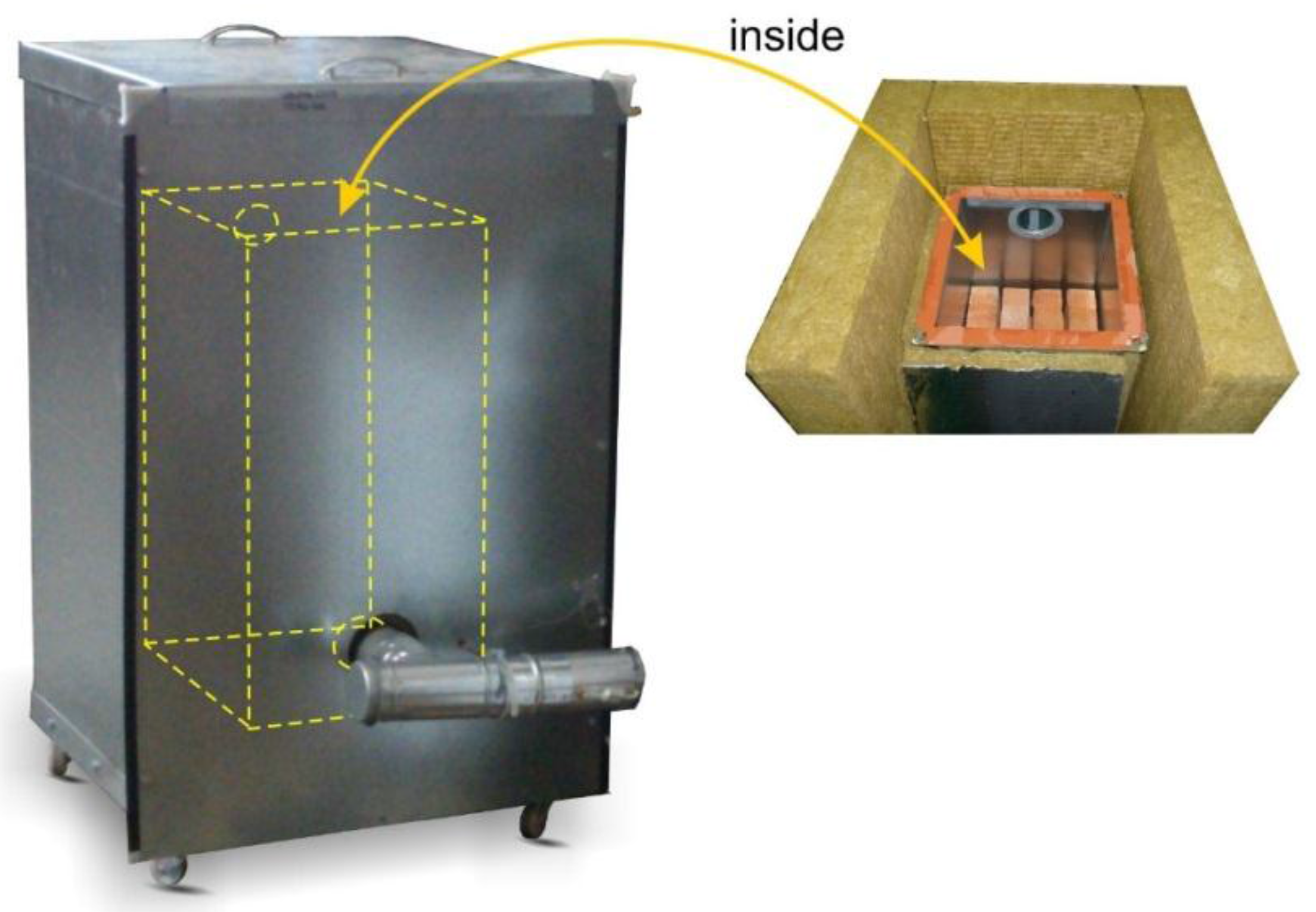

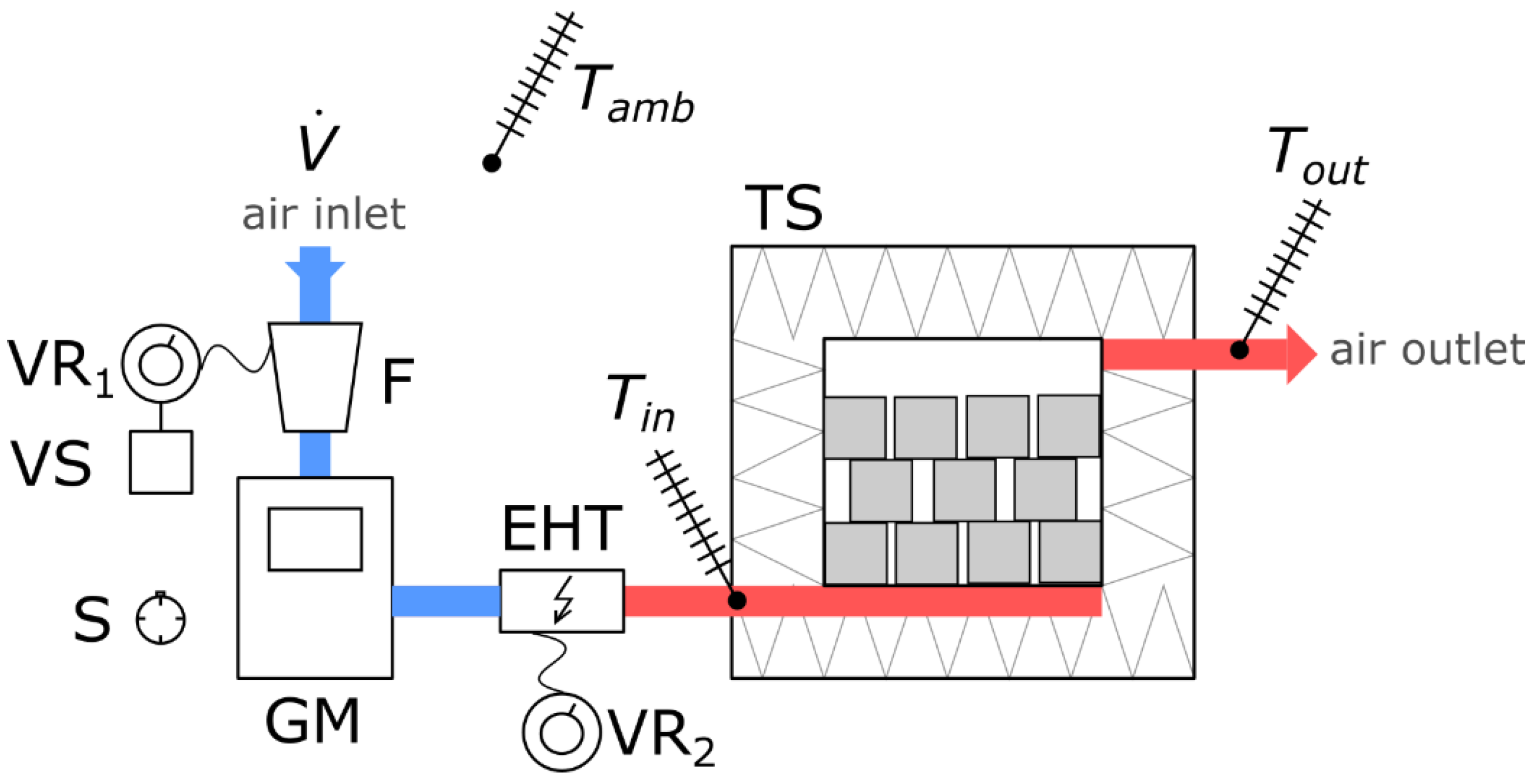

4.1. The Operating Principle and the Measuring Apparatus

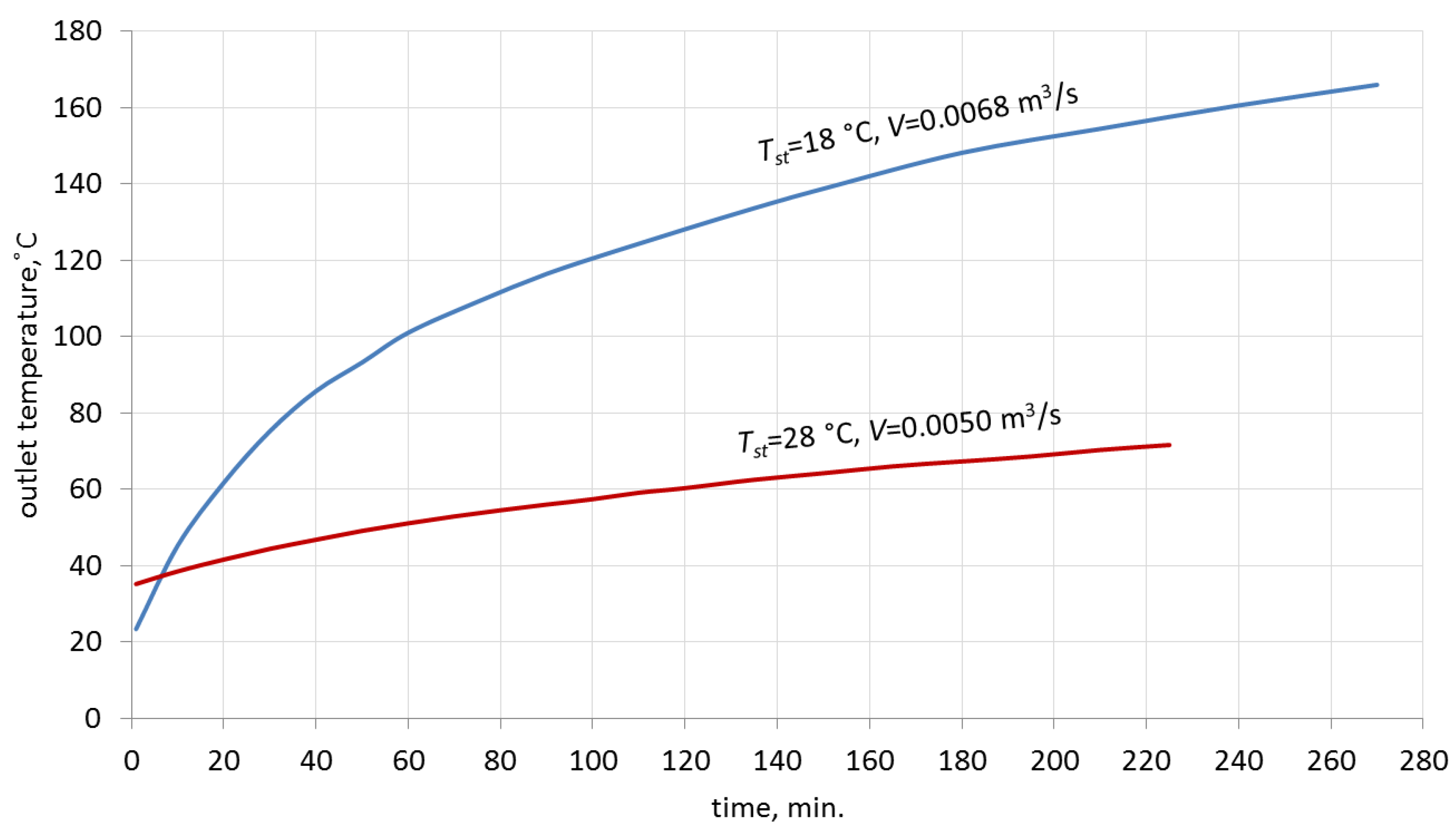

4.2. Experimental Tests and Uncertainty Analysis

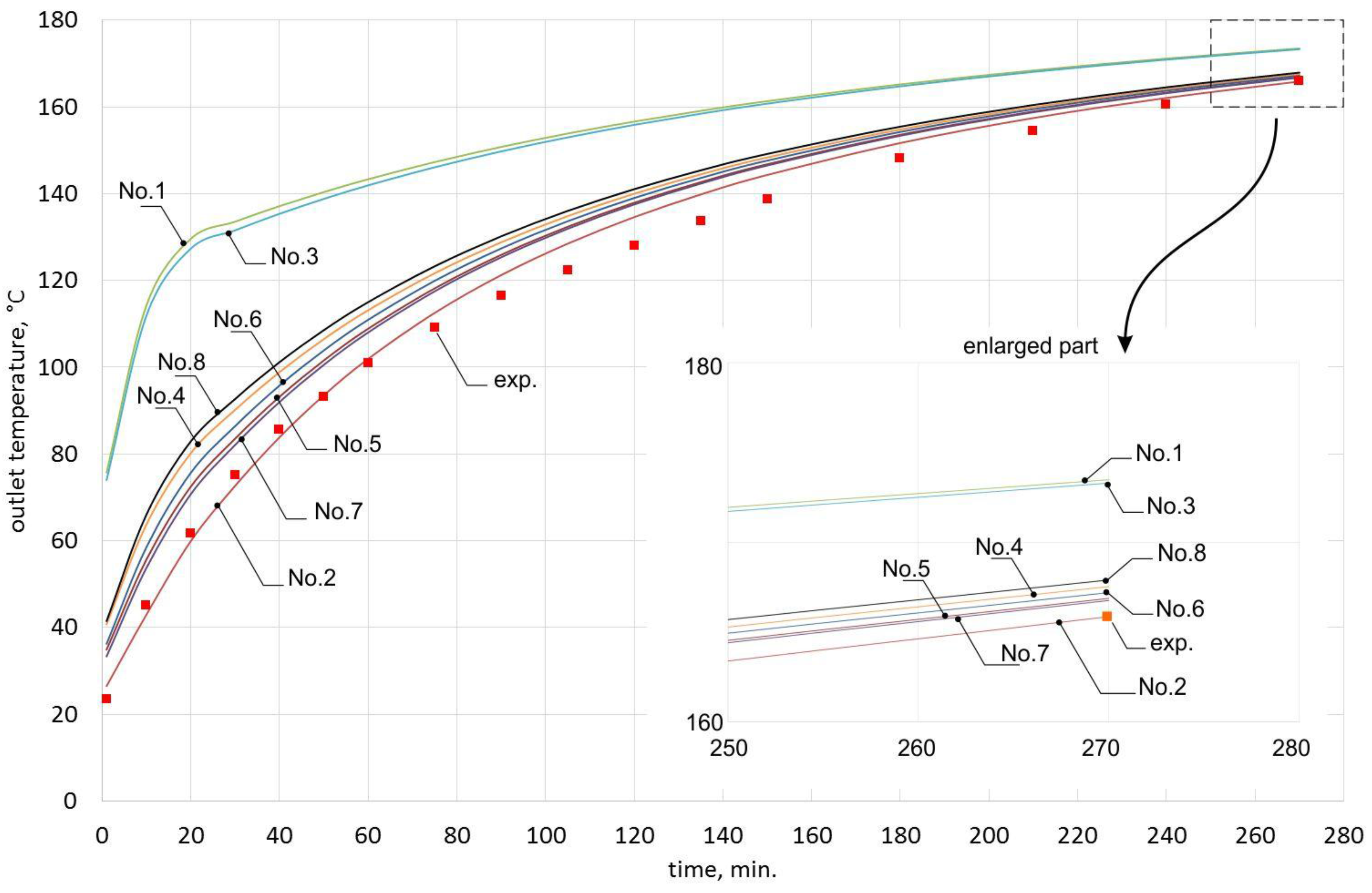

5. Model Validation

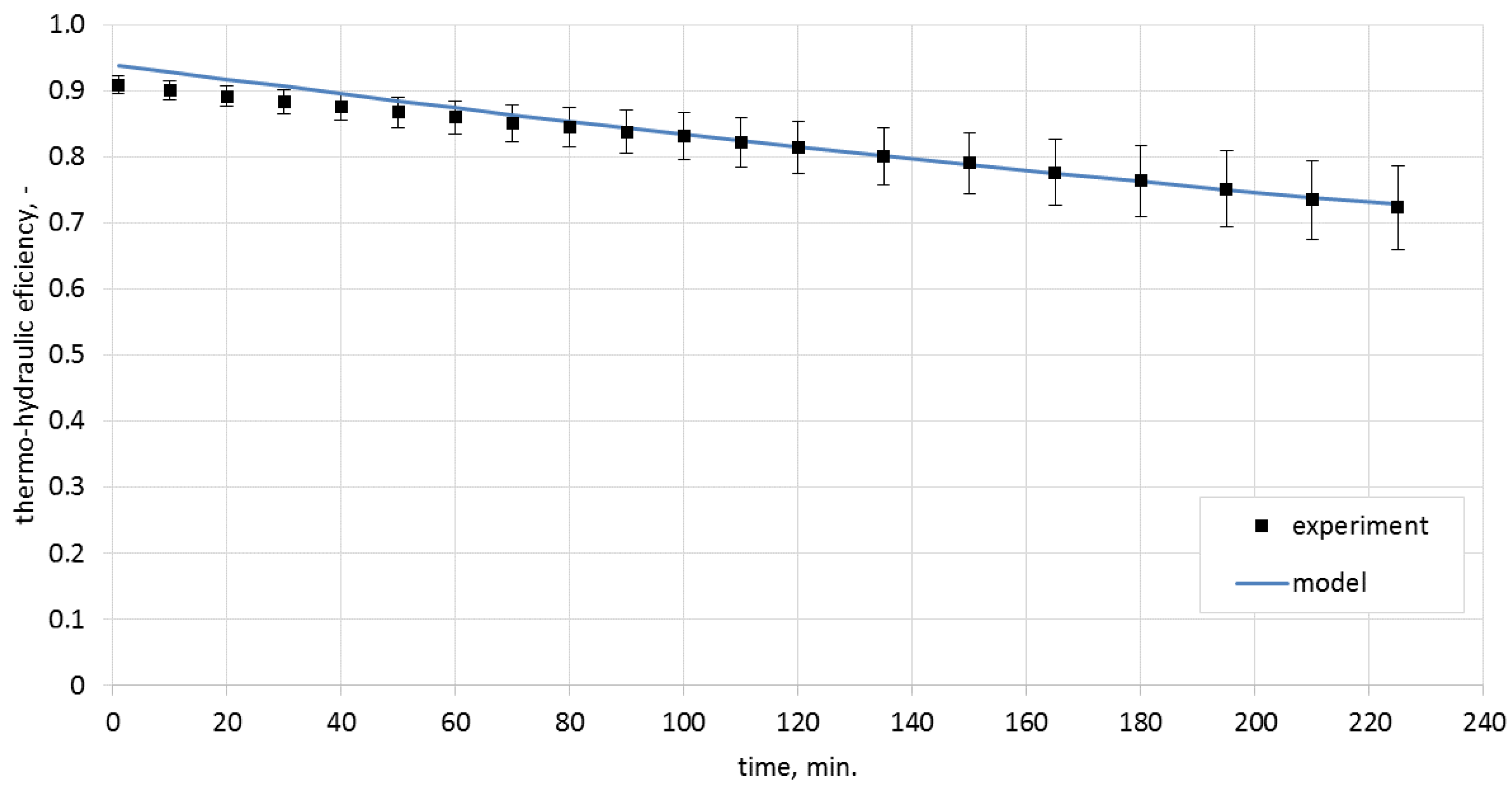

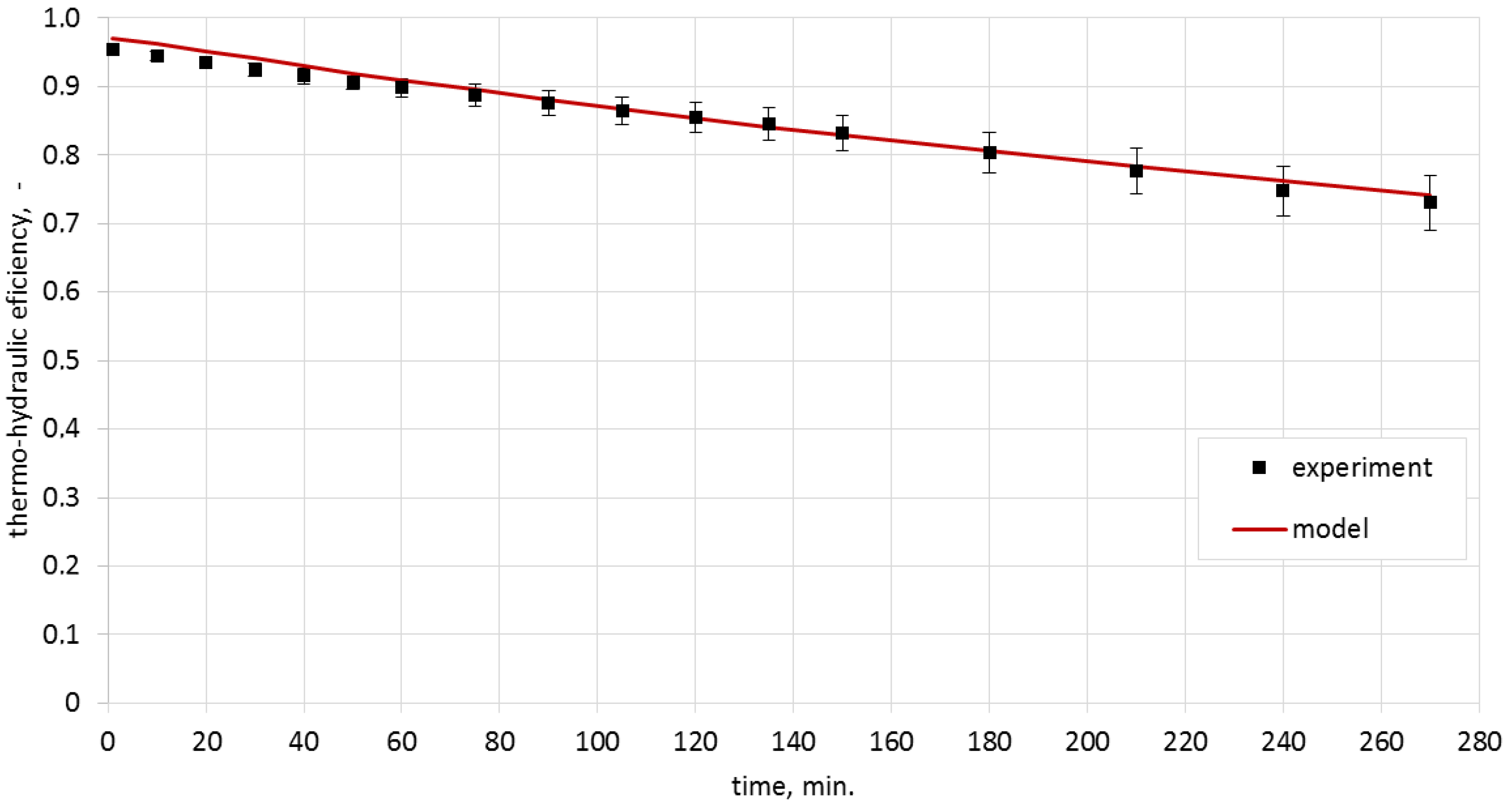

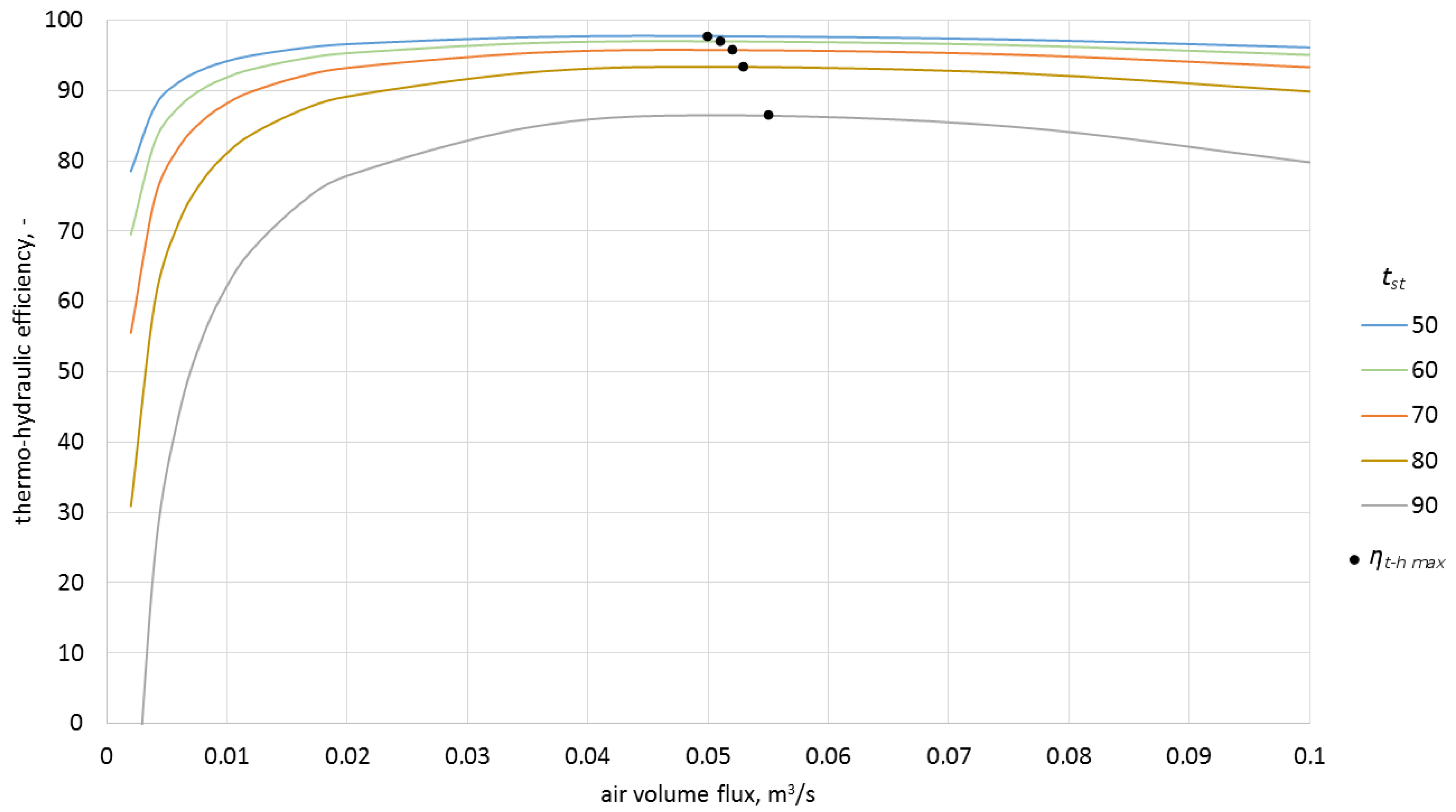

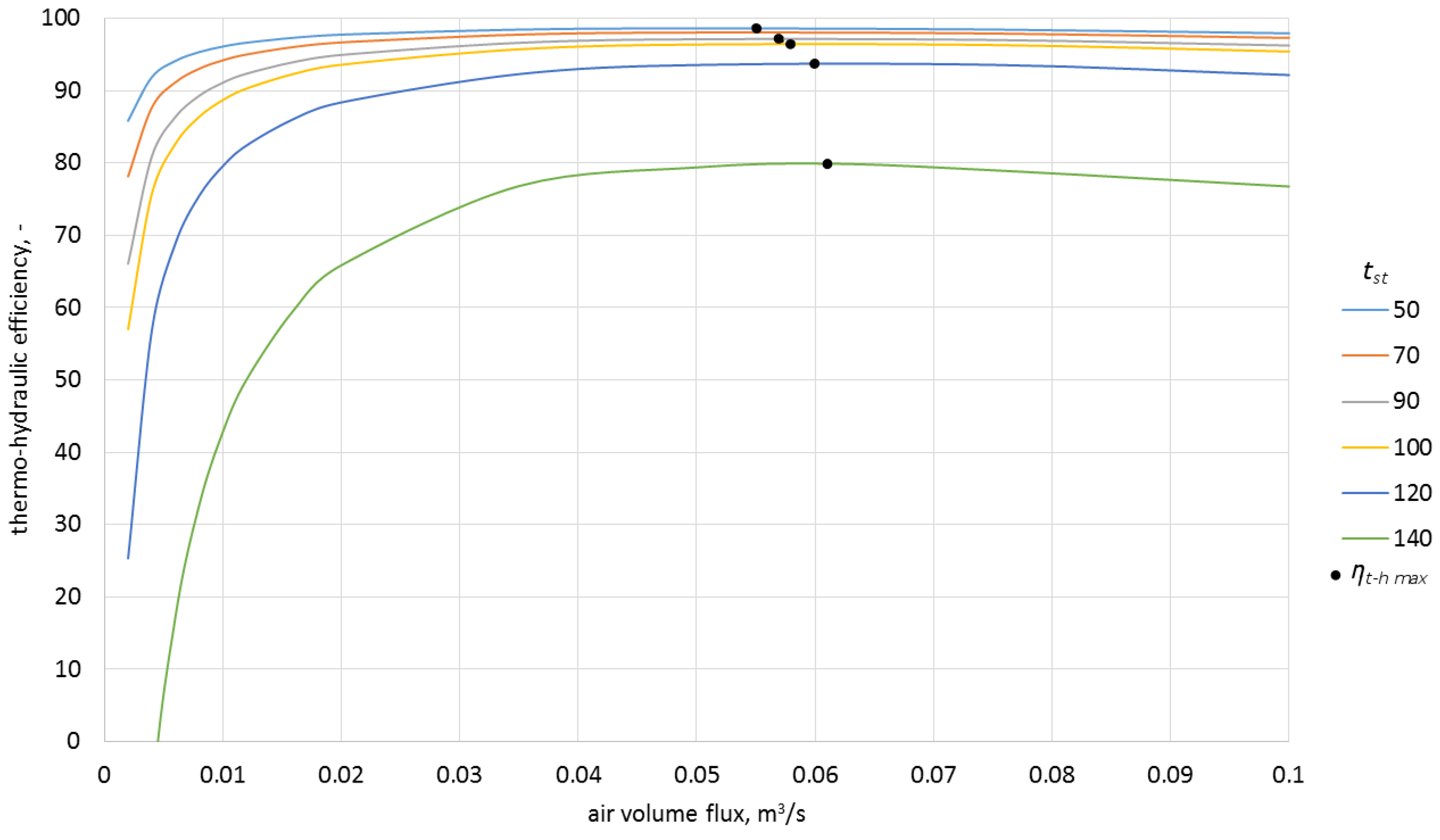

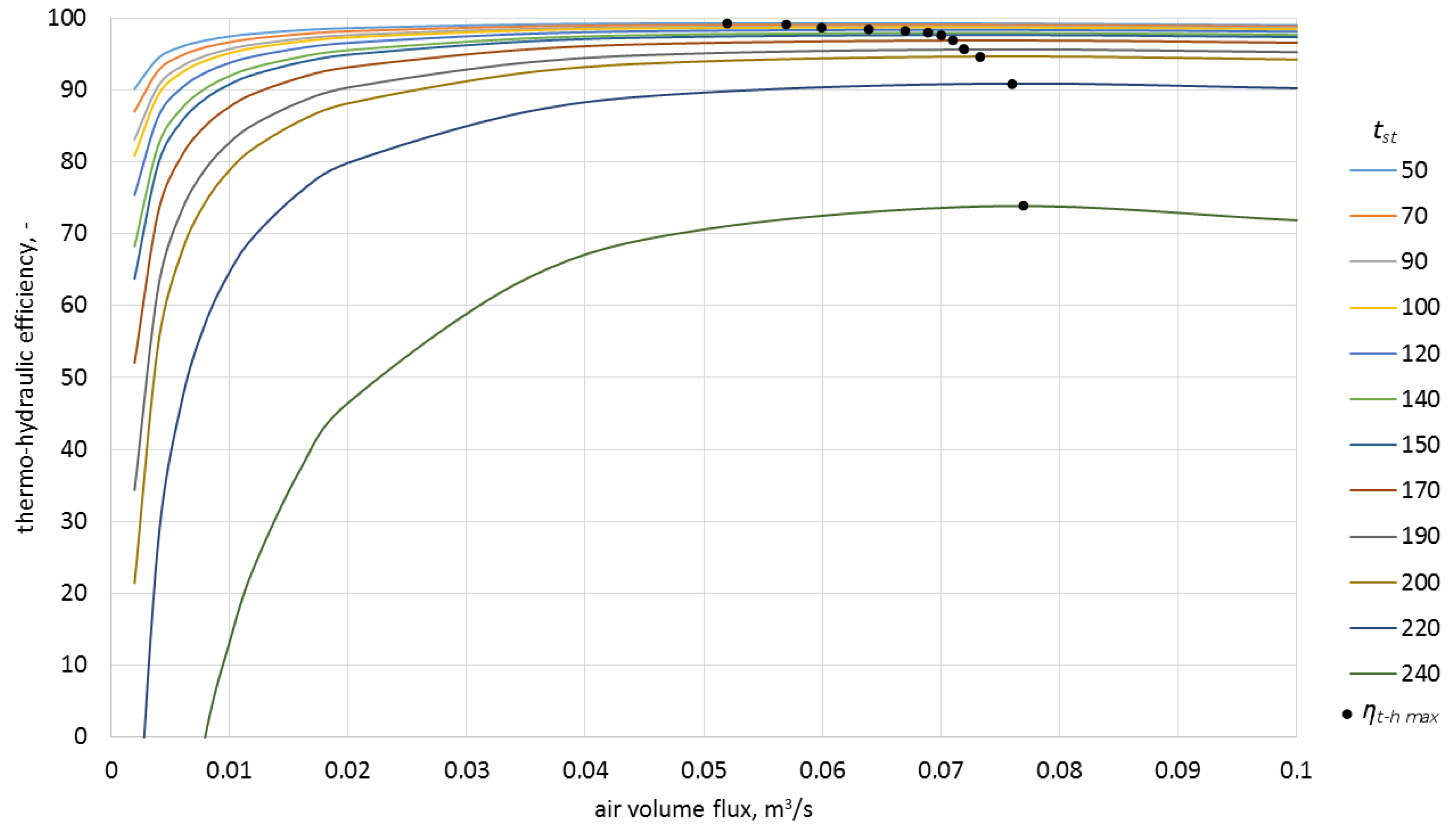

Analysis of the Thermo-Hydraulic Efficiency for the Heat Storage Process in Ceramic Bricks

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Starr, C.H. Global energy and electrical futures. Energy 1993, 18, 33–39. [Google Scholar] [CrossRef]

- Cabeza, L.F. Surplus Heat Management Using Advanced TES for CO2 Mitigation; Final report, Annex 25; Energy Conservation through Energy Storage (ECES IA): Paris, France, 2011. [Google Scholar]

- Mehling, H.; Cabeza, L.F. Heat and Cold Storage with PCM; Springer: Berlin, Germany, 2008. [Google Scholar]

- Chandra, P.; Willits, D.H. Pressure drop and heat transfer characteristics of air-rockbed thermal storage systems. Sol. Energy 1981, 27, 547–553. [Google Scholar] [CrossRef]

- Sagara, K.; Nakahara, N. Thermal performance and pressure drop of rock beds with large storage materials. Sol. Energy 1991, 47, 157–163. [Google Scholar] [CrossRef]

- Meier, A.; Winkler, C.; Wuillemin, D. Experiment for modeling high temperature rock bed storage. Sol. Energy Mater. 1991, 24, 255–264. [Google Scholar] [CrossRef]

- Garg, H.P.; Bandyopadhyay, B.; Sharma, V.K. Investigation of rock bed solar collector cum storage system. Energy Convers. Manag. 1981, 21, 275–282. [Google Scholar] [CrossRef]

- Allen, K.G.; Von Backstrom, T.W.; Kroger, D.G.; Kisters, A.F.M. Rock bed storage for solar thermal power plants: Rock characteristics, suitability, and availability. Sol. Energy Mater. Sol. Cells 2014, 126, 170–183. [Google Scholar] [CrossRef]

- Zanganeh, G.; Pedretti, A.; Zavattoni, S.; Barbato, M.; Steinfeld, A. Packed-bed thermal storage for concentrated solar power—Pilot-scale demonstration and industrial-scale design. Sol. Energy 2012, 86, 3084–3098. [Google Scholar] [CrossRef]

- Kurklu, A.; Bilgin, S.; Ozkan, B. A study on the solar energy storing rock-bed to heat a polyethylene tunnel type greenhouse. Renew. Energy 2003, 28, 683–697. [Google Scholar] [CrossRef]

- Abbud, I.A.; Löf, G.O.G.; Hittle, D.C. Simulation of solar air heating at constant temperature. Sol. Energy 1995, 54, 75–83. [Google Scholar] [CrossRef]

- Cortes, A.; Piacentini, R. Improvement of the efficiency of a Bare Solar Collector by means of turbulence promoters. Appl. Energy 1990, 36, 253–261. [Google Scholar] [CrossRef]

- Mittal, V.; Kumar, T.S. First & Second Law Analysis of Solar Air Heater. J. Technol. Innov. Renew. Energy 2012, 1, 63–71. [Google Scholar] [CrossRef]

- El-Sebaii, A.A.; Aboul-Enein, S.; Ramadan, M.R.I.; El-Bialy, E. Year round performance of double pass solar air heater with packed bed. Energy Convers. Manag. 2007, 48, 990–1003. [Google Scholar] [CrossRef]

- Gupta, D.; Solanki, S.C.; Saini, J.S. Thermohydraulic performance of solar air heaters with roughened absorber plates. Sol. Energy 1997, 61, 33–42. [Google Scholar] [CrossRef]

- Singh, S.; Dhiman, P. Thermal and thermohydraulic efficiency of recyclic-type double pass solar air heaters with fins and baffles. Heat Transf. Eng. 2016, 37, 1302–1317. [Google Scholar] [CrossRef]

- Mittal, M.K.; Varshney, L. Optimal thermohydraulic performance of a wire mesh packed solar air heater. Sol. Energy 2006, 80, 1112–1120. [Google Scholar] [CrossRef]

- Wisniewski, S.; Wisniewski, T.S. Heat Transfer; WNT: Warsaw, Poland, 2012. [Google Scholar]

- Kostowski, E. A Collection of Tasks with Heat Flow; Silesian University of Technology: Gliwice, Poland, 2006. [Google Scholar]

- Kasperski, J.; Nemś, M. Investigation of thermo-hydraulic performance of concentrated solar air-heater with internal multiple-fin array. Appl. Therm. Eng. 2013, 58, 411–419. [Google Scholar] [CrossRef]

- Nemś, M.; Kasperski, J. Experimental investigation of concentrated solar air-heater with internal multiple-fin array. Renew. Energy 2016, 97, 722–730. [Google Scholar] [CrossRef]

- Fernández, A.I.; Martínez, M.; Segarra, M.; Martorell, I.; Cabeza, L.F. Selection of materials with potential in sensible thermal energy storage. Sol. Energy Mater. Solar Cells 2010, 94, 1723–1729. [Google Scholar] [CrossRef]

- Grabarczyk, C.Z. Flows in Closed Conduits. Calculation Methods; Envirotech: Poznan, Poland, 1997. [Google Scholar]

- Jezowiecka-Kabsch, K.; Szewczyk, H. Fluid Mechanics; Publishing House of Wroclaw University of Science and Technology: Wroclaw, Poland, 2001. [Google Scholar]

- Pelech, A. Fundamentals of Air Conditioning and Ventilation; Publishing House of Wroclaw University of Science and Technology: Wroclaw, Poland, 2013. [Google Scholar]

- Domanski, R. Storage of Heat Energy; PWN: Warsaw, Poland, 1990. [Google Scholar]

- Wakao, N.; Kaguei, S.; Funazkri, T. Effect of fluid dispersion coefficients on particle-to-fluid heat transfer coefficients in packed beds: Correlation of Nusselt numbers. Chem. Eng. Sci. 1979, 34, 325–336. [Google Scholar] [CrossRef]

- Nield, D.A.; Bejan, A. Convection in Porous Media, 3rd ed.; Springer International Publishing: Cham, Switzerland, 2006. [Google Scholar]

- Beasley, D.E.; Clark, J.A. Transient response of packed bed for thermal energy storage. Int. J. Heat Mass Transf. 1984, 27, 1659–1669. [Google Scholar] [CrossRef]

- Singh, R.; Saini, R.P.; Saini, J.S. Nusselt number and friction factor correlations for packed bed solar energy storage system having large sized elements of different shapes. Sol. Energy 2006, 80, 760–771. [Google Scholar] [CrossRef]

- Kline, S.; McClintock, F. Describing uncertainties in single-sample experiments. Mech. Eng. 1953, 75, 3–8. [Google Scholar]

| Rock bed | Internal height | 0.5 m |

| Internal thickness | 0.3 m | |

| Internal length | 0.3 m | |

| Storage material | Equivalent sphere diameter | 0.149 m |

| Specific heat | 880 J/kgK | |

| Density | 1800 kg/m3 | |

| Porosity | 0.4 | |

| Temperature in bed 1 | 18 °C | |

| Temperature in bed 2 | 28 °C | |

| Mass | 40.16 kg | |

| Air | Volumetric flow rate 1 | 0.0068 m3/s |

| Volumetric flow rate 2 | 0.0050 m3/s | |

| Temperature inlet 1 | 220 °C | |

| Temperature inlet 2 | 100 °C | |

| Specific heat | f(T) | |

| Density | f(T) | |

| Kinematic viscosity | f(T) | |

| Ambient temperature | 18 °C | |

| Insulation | Top insulation thickness | 0.20 m |

| Bottom insulation thickness | 0.15 m | |

| Side insulation thickness | 0.15 m | |

| Specific heat | 0.039 W/mK |

| No. | Dimensionless Equation | Notes | Reference | |

|---|---|---|---|---|

| 1 | (34) | 1 ≤ Re ≤ 70,000 0.6 ≤ Pr ≤ 400 | [19] | |

| 2 | (35) | 500 ≤ Re ≤ 50,000 | [19] | |

| 3 | (36) | - | [26] | |

| 4 | (37) | 100 ≤ Re Pr for typical gases and liquids | [26] | |

| 5 | (38) | 15 ≤ Re ≤ 8500 | [27] | |

| 6 | (39) | Re ≤ 2400 | [28] | |

| 7 | (40) | 60 ≤ Re | [29] | |

| 8 | (41) | [30] | ||

| Experiment | Models | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | No. 6 | No. 7 | No. 8 | |||

| No. | t | Tout | Tout | Tout | Tout | Tout | Tout | Tout | Tout | Tout |

| min | °C | °C | °C | °C | °C | °C | °C | °C | °C | |

| 1 | 1 | 35.2 | 60.6 | 34.3 | 59.8 | 40.6 | 38.1 | 39.8 | 37.7 | 42.4 |

| 2 | 10 | 38.5 | 61.8 | 37.1 | 61.0 | 43.2 | 41.0 | 42.7 | 40.6 | 45.1 |

| 3 | 20 | 41.6 | 63.0 | 40.4 | 62.2 | 46.4 | 44.1 | 45.7 | 43.8 | 47.9 |

| 4 | 30 | 44.4 | 64.2 | 43.6 | 63.5 | 49.1 | 47.0 | 48.5 | 46.7 | 50.5 |

| 5 | 40 | 46.8 | 65.2 | 46.6 | 64.6 | 51.5 | 49.7 | 51.0 | 49.4 | 52.8 |

| 6 | 50 | 49.1 | 66.2 | 49.3 | 65.7 | 53.7 | 52.1 | 53.3 | 51.9 | 54.9 |

| 7 | 60 | 51.1 | 67.1 | 51.8 | 66.5 | 55.5 | 54.3 | 55.3 | 54.0 | 56.8 |

| 8 | 70 | 52.9 | 68.0 | 54.0 | 67.5 | 57.6 | 56.2 | 57.2 | 56.0 | 58.5 |

| 9 | 80 | 54.5 | 68.8 | 56.0 | 68.4 | 59.2 | 58.0 | 58.9 | 57.8 | 60.1 |

| 10 | 90 | 56.0 | 69.5 | 57.8 | 69.1 | 60.7 | 59.6 | 60.4 | 59.3 | 61.5 |

| 11 | 100 | 57.4 | 70.2 | 59.4 | 69.9 | 62.1 | 61.1 | 61.8 | 61.0 | 62.8 |

| 12 | 110 | 59.1 | 70.9 | 60.9 | 70.6 | 63.4 | 62.5 | 63.1 | 62.3 | 64.0 |

| 13 | 120 | 60.3 | 71.5 | 62.3 | 71.2 | 64.5 | 63.7 | 64.3 | 63.6 | 65.2 |

| 14 | 135 | 62.5 | 72.4 | 64.2 | 72.1 | 66.1 | 65.4 | 65.9 | 65.3 | 66.7 |

| 15 | 150 | 64.2 | 73.2 | 65.8 | 73.0 | 67.5 | 66.9 | 67.4 | 66.8 | 68.0 |

| 16 | 165 | 66.0 | 74.0 | 67.3 | 73.8 | 68.8 | 68.3 | 68.7 | 68.2 | 69.3 |

| 17 | 180 | 67.3 | 74.7 | 68.6 | 74.5 | 70.0 | 69.5 | 69.9 | 69.4 | 70.4 |

| 18 | 195 | 68.6 | 75.4 | 69.8 | 75.2 | 71.1 | 70.6 | 71.0 | 70.5 | 71.4 |

| 19 | 210 | 70.3 | 76.0 | 70.9 | 75.9 | 72.0 | 71.6 | 71.9 | 71.6 | 72.4 |

| 20 | 225 | 71.6 | 76.6 | 71.9 | 76.4 | 72.9 | 72.6 | 72.9 | 72.5 | 73.3 |

| Experiment | Models | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | No. 6 | No. 7 | No. 8 | |||

| No. | t | Tout | δTout | δTout | δTout | δTout | δTout | δTout | δTout | δTout |

| min | °C | % | % | % | % | % | % | % | % | |

| 1 | 1 | 35.2 | 72.2 | 2.6 | 69.9 | 15.3 | 8.2 | 13.1 | 7.1 | 20.5 |

| 2 | 10 | 38.5 | 60.5 | 3.6 | 58.4 | 12.2 | 6.5 | 10.9 | 5.5 | 17.1 |

| 3 | 20 | 41.6 | 51.4 | 2.9 | 49.5 | 11.5 | 6.0 | 9.9 | 5.3 | 15.1 |

| 4 | 30 | 44.4 | 44.6 | 1.8 | 43.0 | 10.6 | 5.9 | 9.2 | 5.2 | 13.7 |

| 5 | 40 | 46.8 | 39.3 | 0.4 | 38.0 | 10.0 | 6.2 | 9.0 | 5.6 | 12.8 |

| 6 | 50 | 49.1 | 34.8 | 0.4 | 33.8 | 9.4 | 6.1 | 8.6 | 5.7 | 11.8 |

| 7 | 60 | 51.1 | 31.3 | 1.4 | 30.1 | 8.6 | 6.3 | 8.2 | 5.7 | 11.2 |

| 8 | 70 | 52.9 | 28.5 | 2.1 | 27.6 | 8.9 | 6.2 | 8.1 | 5.9 | 10.6 |

| 9 | 80 | 54.5 | 26.2 | 2.8 | 25.5 | 8.6 | 6.4 | 8.1 | 6.1 | 10.3 |

| 10 | 90 | 56.0 | 24.1 | 3.2 | 23.4 | 8.4 | 6.4 | 7.9 | 5.9 | 9.8 |

| 11 | 100 | 57.4 | 22.3 | 3.5 | 21.8 | 8.2 | 6.4 | 7.7 | 6.3 | 9.4 |

| 12 | 110 | 59.1 | 20.0 | 3.0 | 19.5 | 7.3 | 5.8 | 6.8 | 5.4 | 8.3 |

| 13 | 120 | 60.3 | 18.6 | 3.3 | 18.1 | 7.0 | 5.6 | 6.6 | 5.5 | 8.1 |

| 14 | 135 | 62.5 | 15.8 | 2.7 | 15.4 | 5.8 | 4.6 | 5.4 | 4.5 | 6.7 |

| 15 | 150 | 64.2 | 14.0 | 2.5 | 13.7 | 5.1 | 4.2 | 5.0 | 4.0 | 5.9 |

| 16 | 165 | 66.0 | 12.1 | 2.0 | 11.8 | 4.2 | 3.5 | 4.1 | 3.3 | 5.0 |

| 17 | 180 | 67.3 | 11.0 | 1.9 | 10.7 | 4.0 | 3.3 | 3.9 | 3.1 | 4.6 |

| 18 | 195 | 68.6 | 9.9 | 1.7 | 9.6 | 3.6 | 2.9 | 3.5 | 2.8 | 4.1 |

| 19 | 210 | 70.3 | 8.1 | 0.9 | 8.0 | 2.4 | 1.8 | 2.3 | 1.8 | 3.0 |

| 20 | 225 | 71.6 | 7.0 | 0.4 | 6.7 | 1.8 | 1.4 | 1.8 | 1.3 | 2.4 |

| deviation % | avg. | 27.6 | 2.2 | 26.7 | 7.7 | 5.2 | 7.0 | 4.8 | 9.5 | |

| max. | 72.2 | 3.6 | 69.9 | 15.3 | 8.2 | 13.1 | 7.1 | 20.5 | ||

| min. | 7.0 | 0.4 | 6.7 | 1.8 | 1.4 | 1.8 | 1.3 | 2.4 | ||

| Experiment | Models | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | No. 6 | No. 7 | No. 8 | |||

| No. | t | Tout | Tout | Tout | Tout | Tout | Tout | Tout | Tout | Tout |

| min | °C | °C | °C | °C | °C | °C | °C | °C | °C | |

| 1 | 1 | 23.4 | 75.7 | 26.5 | 74.0 | 40.7 | 34.9 | 36.2 | 33.4 | 41.5 |

| 2 | 10 | 45.2 | 114.3 | 43.0 | 111.9 | 63.8 | 55.7 | 58.6 | 53.8 | 66.1 |

| 3 | 20 | 61.7 | 129.6 | 59.9 | 127.3 | 80.2 | 72.5 | 75.7 | 70.8 | 82.9 |

| 4 | 30 | 75.2 | 133.6 | 72.7 | 131.6 | 90.2 | 83.6 | 86.5 | 82.1 | 92.7 |

| 5 | 40 | 85.7 | 137.1 | 83.9 | 135.4 | 98.9 | 93.2 | 95.8 | 92.0 | 101.2 |

| 6 | 50 | 93.2 | 140.4 | 93.5 | 138.8 | 106.5 | 101.6 | 103.9 | 100.6 | 108.6 |

| 7 | 60 | 101.0 | 143.3 | 101.9 | 141.9 | 113.1 | 108.9 | 110.9 | 108.0 | 115.0 |

| 8 | 75 | 109.1 | 147.3 | 112.5 | 146.1 | 121.7 | 118.2 | 119.9 | 117.5 | 123.3 |

| 9 | 90 | 116.4 | 150.8 | 121.2 | 149.8 | 128.8 | 125.9 | 127.4 | 125.3 | 130.2 |

| 10 | 105 | 122.4 | 153.9 | 128.5 | 153.0 | 134.8 | 132.4 | 133.7 | 131.9 | 136.0 |

| 11 | 120 | 128.1 | 156.6 | 134.6 | 155.9 | 140.0 | 137.9 | 139.0 | 137.5 | 141.1 |

| 12 | 135 | 133.6 | 159.1 | 139.8 | 158.4 | 144.5 | 142.7 | 143.6 | 142.3 | 145.4 |

| 13 | 150 | 138.7 | 161.3 | 144.3 | 160.8 | 148.4 | 146.8 | 147.6 | 146.5 | 149.2 |

| 14 | 180 | 148.1 | 165.2 | 151.7 | 164.8 | 154.8 | 153.6 | 154.2 | 153.4 | 155.4 |

| 15 | 210 | 154.4 | 168.4 | 157.4 | 168.1 | 159.9 | 159.0 | 159.5 | 158.8 | 160.5 |

| 16 | 240 | 160.5 | 171.1 | 162.1 | 170.9 | 164.1 | 163.3 | 163.7 | 163.2 | 164.5 |

| 17 | 270 | 165.9 | 173.5 | 165.9 | 173.3 | 167.5 | 166.9 | 167.2 | 166.8 | 167.9 |

| Experiment | Models | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | No. 6 | No. 7 | No. 8 | |||

| No. | t | Tout | δTout | δTout | δTout | δTout | δTout | δTout | δTout | δTout |

| min | °C | % | % | % | % | % | % | % | % | |

| 1 | 1 | 23.4 | 223.7 | 13.2 | 216.2 | 74.1 | 49.2 | 54.9 | 42.6 | 77.3 |

| 2 | 10 | 45.2 | 152.8 | 4.9 | 147.6 | 41.1 | 23.3 | 29.6 | 19.0 | 46.2 |

| 3 | 20 | 61.7 | 110.0 | 2.8 | 106.4 | 30.0 | 17.5 | 22.6 | 14.7 | 34.4 |

| 4 | 30 | 75.2 | 77.6 | 3.3 | 74.9 | 19.9 | 11.1 | 15.0 | 9.2 | 23.3 |

| 5 | 40 | 85.7 | 60.0 | 2.1 | 58.0 | 15.4 | 8.8 | 11.8 | 7.3 | 18.1 |

| 6 | 50 | 93.2 | 50.6 | 0.4 | 48.9 | 14.3 | 9.0 | 11.5 | 7.9 | 16.5 |

| 7 | 60 | 101.0 | 41.9 | 0.9 | 40.5 | 12.0 | 7.8 | 9.8 | 7.0 | 13.9 |

| 8 | 75 | 109.1 | 35.0 | 3.2 | 33.9 | 11.5 | 8.3 | 9.9 | 7.7 | 13.0 |

| 9 | 90 | 116.4 | 29.5 | 4.2 | 28.7 | 10.7 | 8.2 | 9.4 | 7.7 | 11.8 |

| 10 | 105 | 122.4 | 25.7 | 5.0 | 25.0 | 10.2 | 8.2 | 9.2 | 7.8 | 11.1 |

| 11 | 120 | 128.1 | 22.3 | 5.1 | 21.7 | 9.3 | 7.7 | 8.5 | 7.4 | 10.1 |

| 12 | 135 | 133.6 | 19.1 | 4.7 | 18.6 | 8.1 | 6.8 | 7.5 | 6.5 | 8.8 |

| 13 | 150 | 138.7 | 16.3 | 4.1 | 15.9 | 7.0 | 5.8 | 6.4 | 5.6 | 7.5 |

| 14 | 180 | 148.1 | 11.5 | 2.4 | 11.2 | 4.5 | 3.7 | 4.1 | 3.6 | 5.0 |

| 15 | 210 | 154.4 | 9.1 | 2.0 | 8.9 | 3.6 | 2.9 | 3.3 | 2.8 | 3.9 |

| 16 | 240 | 160.5 | 6.6 | 1.0 | 6.5 | 2.2 | 1.7 | 2.0 | 1.7 | 2.5 |

| 17 | 270 | 165.9 | 4.6 | 0.0 | 4.5 | 1.0 | 0.6 | 0.8 | 0.5 | 1.2 |

| deviation % | avg. | 52.7 | 3.5 | 51.0 | 16.2 | 10.6 | 12.7 | 9.3 | 17.9 | |

| max. | 223.7 | 13.2 | 216.2 | 74.1 | 49.2 | 54.9 | 42.6 | 77.3 | ||

| min. | 4.6 | 0.0 | 4.5 | 1.0 | 0.6 | 0.8 | 0.5 | 1.2 | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nemś, M.; Nemś, A.; Kasperski, J.; Pomorski, M. Thermo-Hydraulic Analysis of Heat Storage Filled with the Ceramic Bricks Dedicated to the Solar Air Heating System. Materials 2017, 10, 940. https://doi.org/10.3390/ma10080940

Nemś M, Nemś A, Kasperski J, Pomorski M. Thermo-Hydraulic Analysis of Heat Storage Filled with the Ceramic Bricks Dedicated to the Solar Air Heating System. Materials. 2017; 10(8):940. https://doi.org/10.3390/ma10080940

Chicago/Turabian StyleNemś, Magdalena, Artur Nemś, Jacek Kasperski, and Michał Pomorski. 2017. "Thermo-Hydraulic Analysis of Heat Storage Filled with the Ceramic Bricks Dedicated to the Solar Air Heating System" Materials 10, no. 8: 940. https://doi.org/10.3390/ma10080940